Waste glass slag reutilization method and obtained glass

A waste glass slag and glass technology, which is applied in the field of waste glass slag reuse, can solve the problems of addition, composition complexity, adverse effects of surrounding environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take the waste borosilicate glass slag deposited in the flue when the flame kiln produces borosilicate glass, first grind the waste borosilicate glass slag (referred to as waste glass slag, the same below), pass through a 16-mesh sieve, and separate the block Grind the large waste glass slag, then add the waste glass slag to 2.5 times the mass of water and soak for 40-50 hours, stir once every 12 hours during the soaking process, filter the soaked waste glass slag, and dry at 80-120 °C to obtain Pretreated waste glass slag.

[0030] Put the pretreated waste glass slag directly into the refractory container or high-temperature furnace, heat it at 1150°C for 1-2.5 hours to obtain molten glass, cast the molten glass to form annealed glass plate, or quench the molten glass into glass powder.

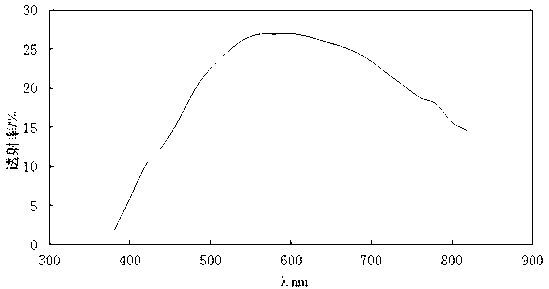

[0031] The resulting glass plate has a density ρ of 2.400 g / cm 3 , its transmittance spectrum curve is as follows figure 1 shown, from figure 1 It can be seen that the glass plate ...

Embodiment 2

[0033] Waste glass slag is directly made into glass plate or glass powder according to the method of Example 1, the difference is: in the soaking process, 1.6 times the water of its mass is added to waste glass slag, soaked for 80-96h, the performance of the gained glass plate is the same as Example 1 is close.

Embodiment 3

[0035] The stability of the glass made directly from the pretreated glass slag is not very good, so it can only be used as glass with low quality requirements such as ink bottles and paste bottles. To further increase the performance of the glass, waste glass slag can be mixed with other ingredients to make glass with improved chemical stability. The steps are: take the waste borosilicate glass slag deposited in the flue when the flame kiln produces borosilicate glass, first crush and grind the waste borosilicate glass slag (referred to as waste glass slag, the same below), and pass through 16 mesh Sieve, grind the larger blocky waste glass slag, then add the waste glass slag to 2 times the mass of water and soak for 60-70h, stir once every 12h during the soaking process, filter the soaked waste glass slag, 80 Dry at ~120°C to obtain pretreated waste glass slag.

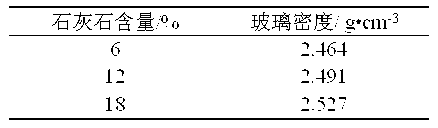

[0036] Add 6~18% limestone to the pretreated waste glass slag, mix the two thoroughly, put them into a refractory...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density ρ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com