Hot air barbed film tearing type glass recovery device

A recycling device and membrane technology, which is applied in the field of hot air barb tearing film glass recycling device, can solve the problem of lack of glass film opening device for tearing film, inability to remove colloid on the glass surface, lack of glass film and glass follow-up recycling processing device, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

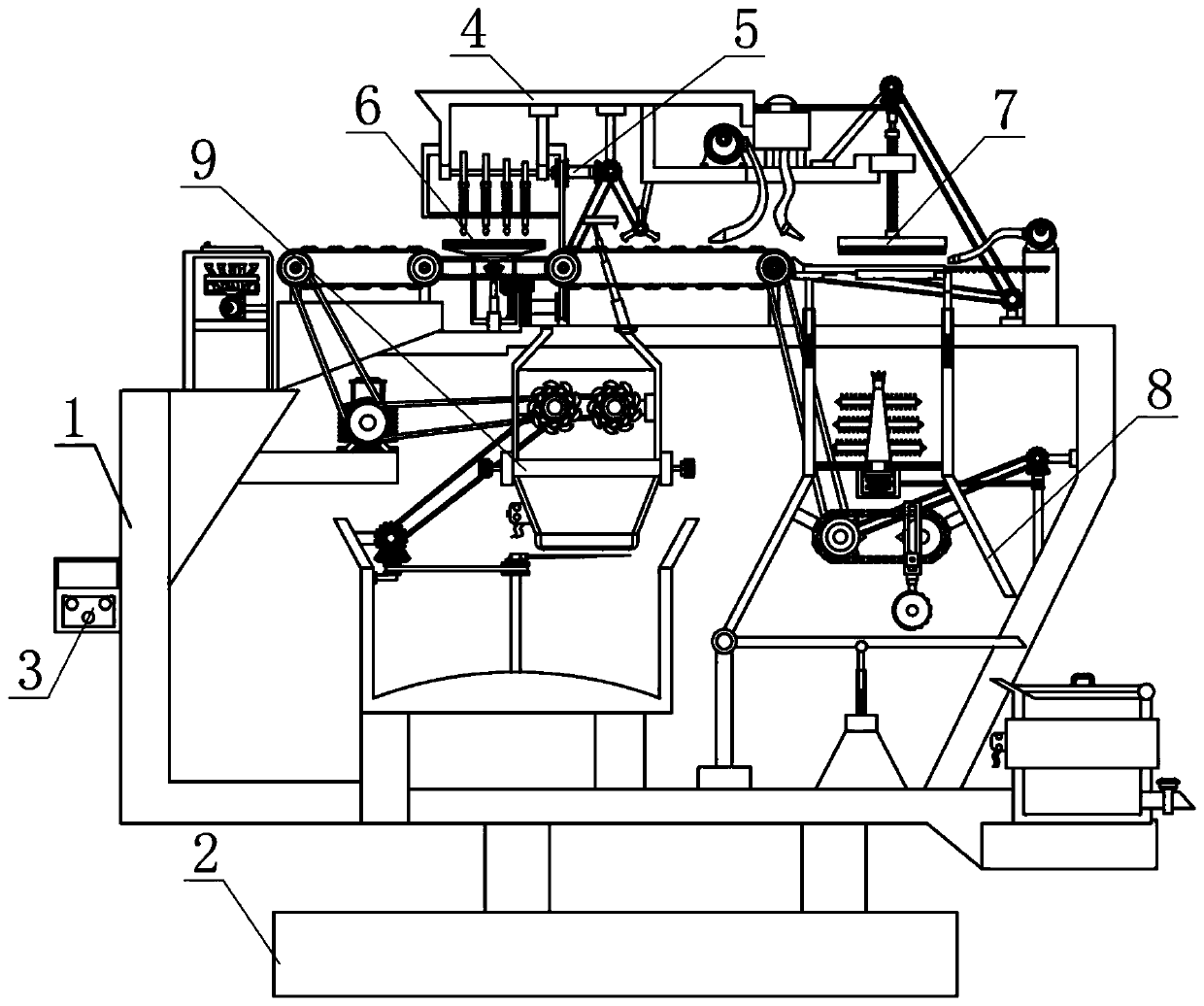

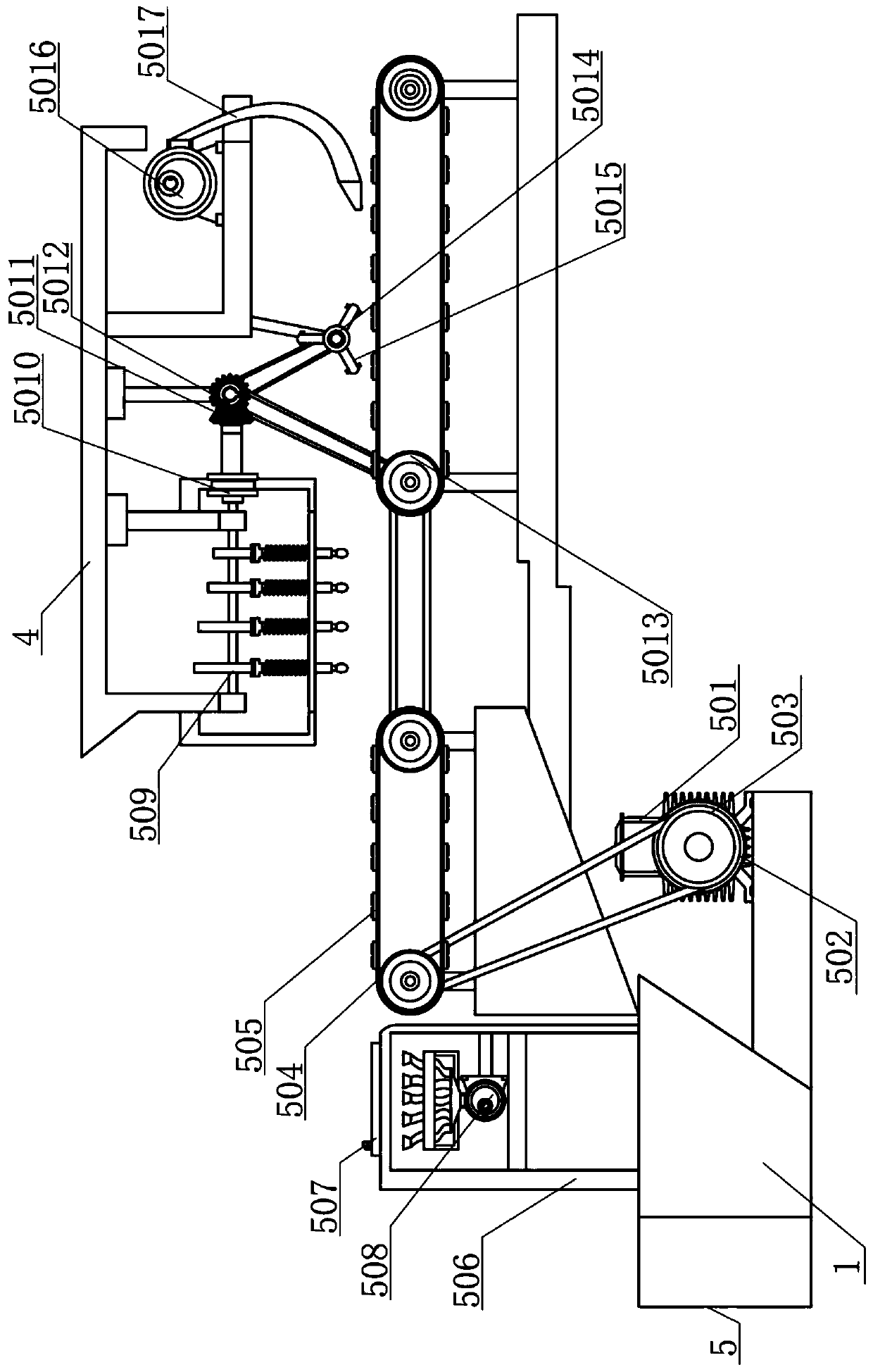

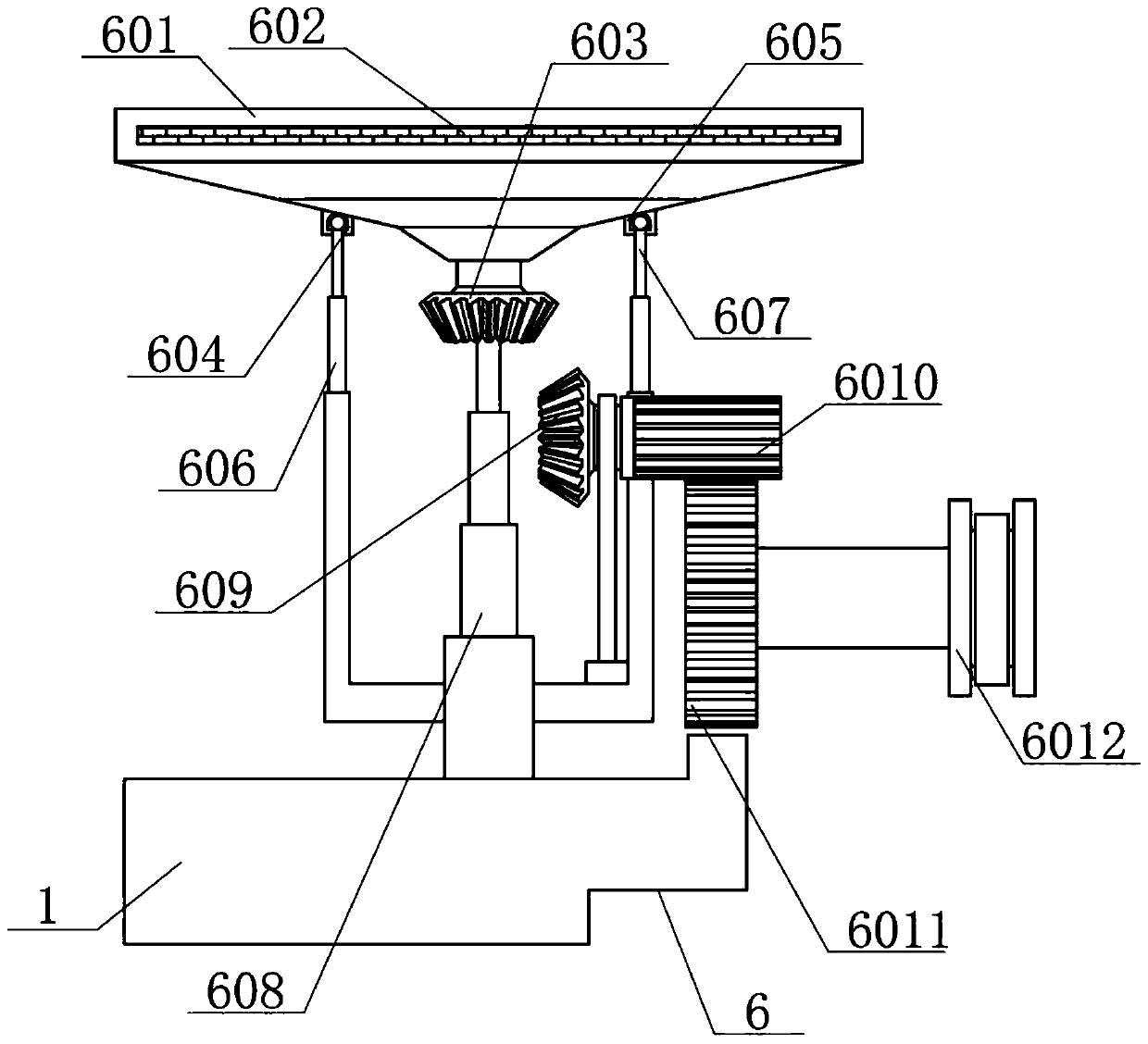

[0030] When using the hot-air barbed and tear-off glass recovery device, first fix it stably on the working surface, then add the necessary ammonia cleaning solution to the corresponding position inside the residual colloid processing mechanism 7, and then connect an external power source to turn on the control display 3. Start the motor 501 by controlling the display screen 3, the device starts to run, and then the glass to be processed runs in the crushing barb and tearing film mechanism 5, and the crushing fixed connection mechanism 6 completes the partial crushing and tearing of the glass and enters the next mechanism The residual colloid processing mechanism 7 removes the residual colloidal substances after tearing the film, so that the glass surface no longer contains impurities. After air drying, the glass enters the crushing powder processing mechanism 8 for pulverization, and forms a melt for secondary use, and the teared film Enter the glass film crushing and granulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com