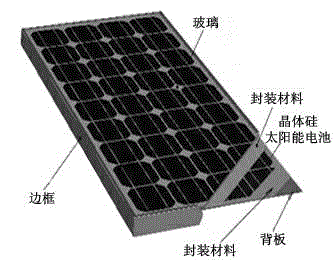

Waste crystalline silicon solar cell panel disassembling and recovering method

A solar panel, recycling technology, applied in waste treatment, electronic waste recycling, recycling technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

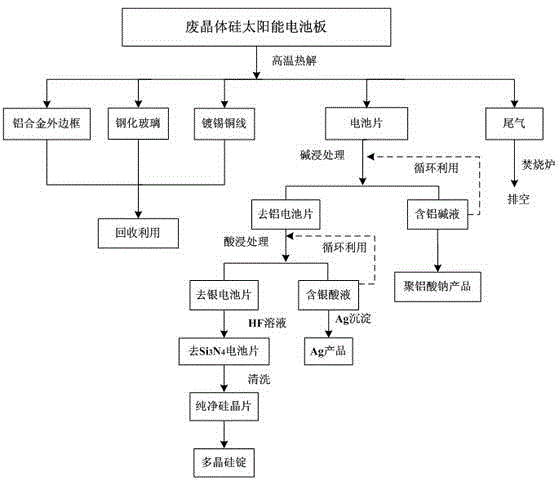

[0033] A method for dismantling and recycling waste crystalline silicon solar panels, the method for dismantling and recycling comprising the following steps:

[0034] a. First, put the waste crystalline silicon solar panel into a closed heating device for heating. Heating at high temperature can completely separate the aluminum alloy frame, copper wire, battery sheet and tempered glass. After being incinerated in the incinerator, it is emptied; after the heating equipment is cooled, the aluminum alloy frame, copper wire and tempered glass are sorted out for recycling;

[0035] b. The battery sheet after the heat treatment in the above step a is soaked in lye at room temperature, and after the lye reacts completely with the aluminum paste on the surface of the battery sheet, a dealuminized battery sheet is obtained, and the dealuminized battery sheet is taken out to obtain an aluminum-containing battery sheet. lye;

[0036] c. The aluminum-removed battery sheet after the alka...

Embodiment 2

[0044] This example is an optimized solution based on Example 1, and provides a method for dismantling and recycling waste crystalline silicon solar panels. For the parts in this embodiment that are the same as those in Embodiment 1, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be regarded as the content of this embodiment, and will not be described repeatedly here.

[0045] The dismantling and recycling processing method comprises the following steps:

[0046] a. First put the waste crystalline silicon solar panel into the airtight heating equipment (RX3 series - 18KW box-type tempering resistance furnace) for heating. It can be completely separated from the tempered glass, and the plastic parts such as the back panel are turned into ashes through heat treatment, and the exhaust gas is incinerated in the incinerator and then emptied. After the heating equipment cools down, aluminum alloy frames...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com