Patents

Literature

54results about How to "Reduce disposal volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

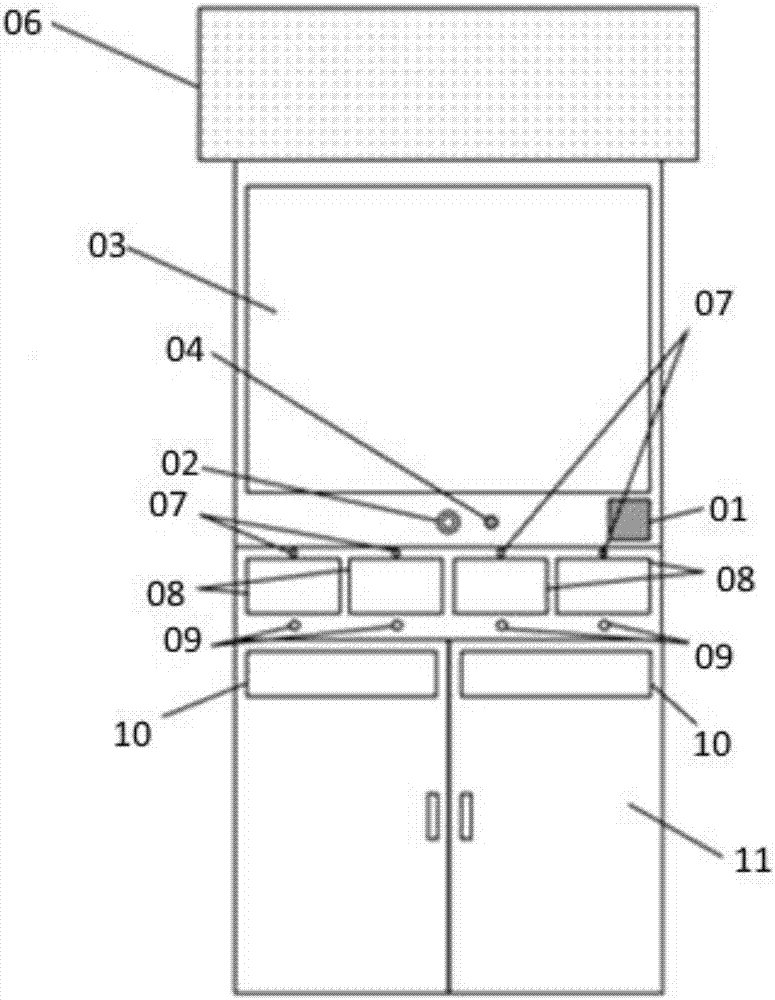

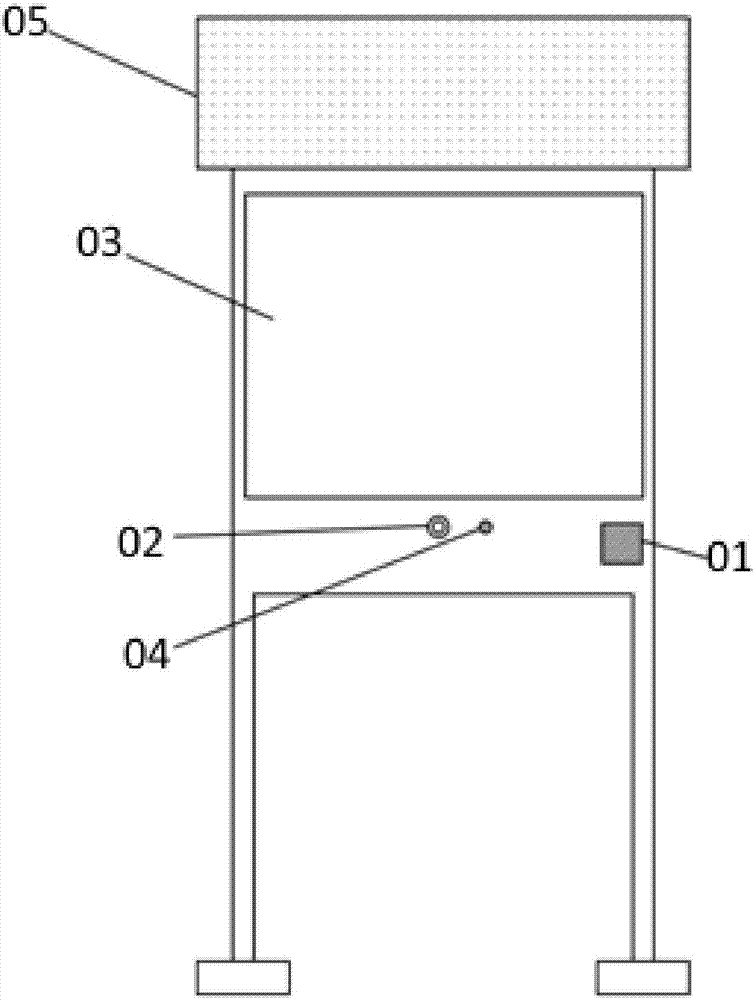

Garbage classification prompt garbage can and system based on image recognition

InactiveCN107054936AReduce workloadAchieve reuseWaste collection and transferRefuse receptaclesClassification resultImage based

The invention discloses a garbage classification prompt garbage can and system based on image recognition. The garbage classification prompt garbage can comprises a camera, an information processor, a garbage can shell, multiple internal garbage cans, an indicator lamp controller, multiple indicator lamps and a power supply module. The multiple internal garbage cans are located in the garbage can shell. The garbage can shell is provided with a distance sensing switch and multiple classification input ports. The camera is used for sending taken garbage pictures to the information processor. The information processor is used for classifying garbage according the garbage pictures and prestored standard templates in a standard template library, generating classification result information and sending lamp turning-on signals to the indicator lamp controller according to the classification result information so as enable the indicator lamp controller to control the corresponding indicator lamp to be turned on according to the turning-on signals. The garbage classification prompt garbage can has the advantages of rapidly recognizing garbage through the image recognition technology, helping people to rapidly classify garbage in daily life and reducing the workload of secondary garbage sorting.

Owner:GUANGDONG MATVIEW INTELLIGENT SCI & TECH CO LTD

Method for recycling titanium dioxide in waste SCR (Selective Catalytic Reduction) denitration catalyst

ActiveCN103130265AQuality assuranceAvoid overdoseTitanium dioxideChemical recyclingSolubilityPhosphorous acid

The invention relates to a method for recycling titanium dioxide in a waste SCR (Selective Catalytic Reduction) denitration catalyst. The method comprises the following steps of: firstly removing dust from the waste denitration catalyst, pulverizing, then adding concentrated sulfuric acid so as to carry out acid hydrolysis on the waste denitration catalyst to obtain a concentrated titanyl sulfate solution, and adding water for dilution; adding a non-ionic emulsifier serving as a flocculating agent and a sulfonate surface active agent or a polycarboxylate surface active agent as a coagulant aid, and adding water-solubility methyl silicone oil; pumping into a plate-and-frame filter press for filter pressing, carrying out vacuum concentration on filtrate, then heating to 90 DEG C to 98 DEG C, and maintaining for 5.5 hours so as to hydrolyze the filtrate; cooling a hydrolysis product to 40 DEG C, and carrying out vacuum filtration so as to sediment out metatitanic acid; rinsing with sand-filtered water and deionized water, and adding potassium carbonate or phosphorous acid to obtain metatitanic acid filter cakes; and drying the filter cakes, calcining at 500-800 DEG C, and then pulverizing to obtain a titanium dioxide finished product. The method has the advantages of being capable of reducing disposal amount of the waste denitration catalyst, recycling the waste denitration catalyst and reducing the production cost of the waste denitration catalyst.

Owner:江苏万德环保科技有限公司

Nanometer photocatalyst material supported embedded composite film and preparation method and application thereof

ActiveCN104084053AImprove hydrophilicityImprove throughputSemi-permeable membranesWater/sewage treatment by irradiationNano catalystComposite film

The invention discloses a method for preparing a nanometer photocatalyst material supported embedded composite film. The method comprises the following steps: dissolving an organic polymer base film material, a pore-forming agent and a nanometer catalyst in a solvent, stirring and standing to prepare a casting film solution; dispersing the nanometer photocatalyst in the solvent to obtain dispersion liquid, spreading the dispersion liquid on a plate to prepare a spreading solution, and drying the spreading solution to obtain a spreading film; and covering the spreading film with the casting film solution, scraping a liquid film by utilizing a film scraper, immersing the scraped liquid film in a constant temperature gel bath, and curing the liquid film to prepare the nanometer photocatalyst material supported embedded composite film. The invention also provides the nanometer photocatalyst material supported embedded composite film and application thereof. According to the method, a nanometer photocatalyst coating is uniformly, effectively, stably and firmly supported on the surface of the embedded composite film. Moreover, according to the composite film, the removal rate of pollutants is effectively improved, and film pollution is reduced.

Owner:SHANGHAI JIAO TONG UNIV

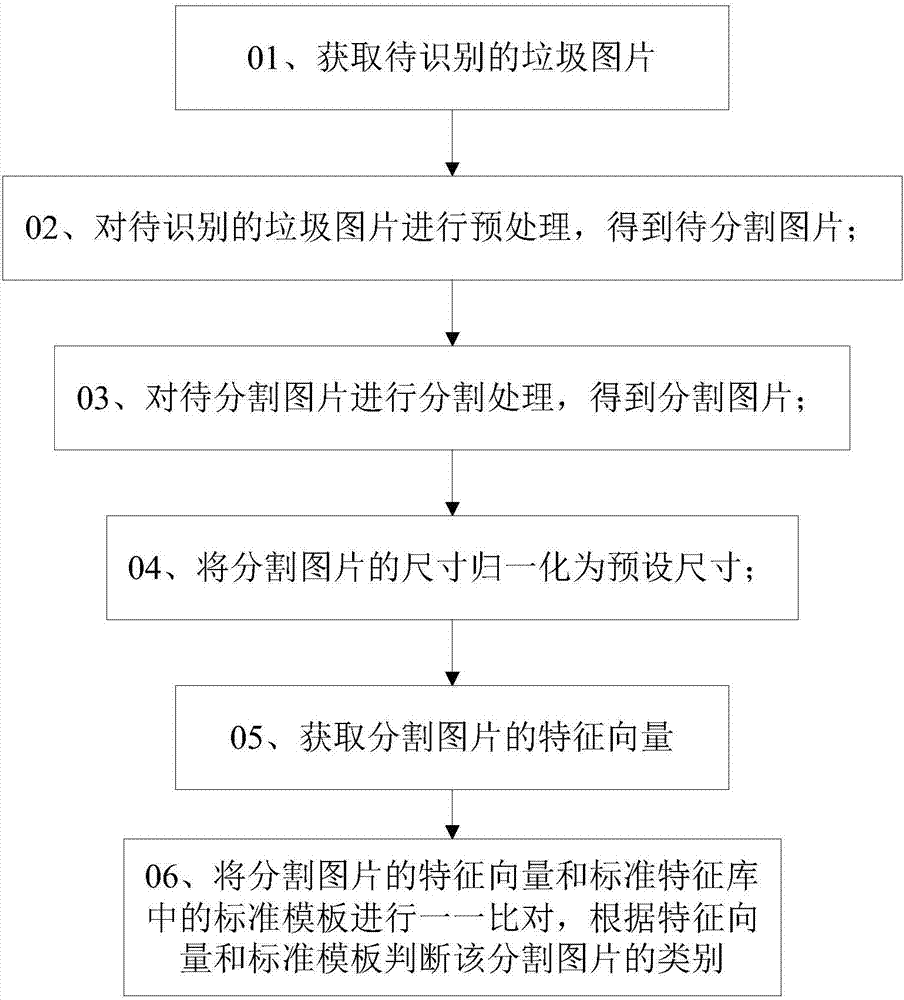

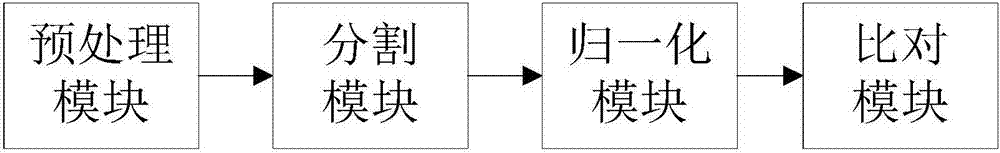

Garbage classification method, device and system based on image identification

ActiveCN107092914AEasy to classifyReduce workloadImage analysisCharacter and pattern recognitionFeature vectorClassification methods

The invention discloses a garbage classification method, device and system based on image identification. The method includes the steps of S1, pre-processing a garbage picture to be identified to obtain a picture to be segmented; S21, segmenting the picture to be segmented to obtain a plurality of sub pictures; S22, acquiring feature information of each sub picture, judging whether the feature information belongs to a preset threshold range, if so, judging the corresponding sub picture as a segmented picture, and if not, performing S23; S23, further segmenting the segmented picture for each sub picture; S3, normalizing the size of each segmented picture into a preset size; and S4, acquiring feature vectors of the segmented pictures, and judging the category of the segmented pictures according to the feature vectors and standard templates in a standard template library. The invention is advantageous in that garbage identification can be quickly performed through the image identification technique, people are assisted in quick garbage classification in daily life, and the workload for secondary garbage sorting is reduced.

Owner:GUANGDONG MATVIEW INTELLIGENT SCI & TECH CO LTD

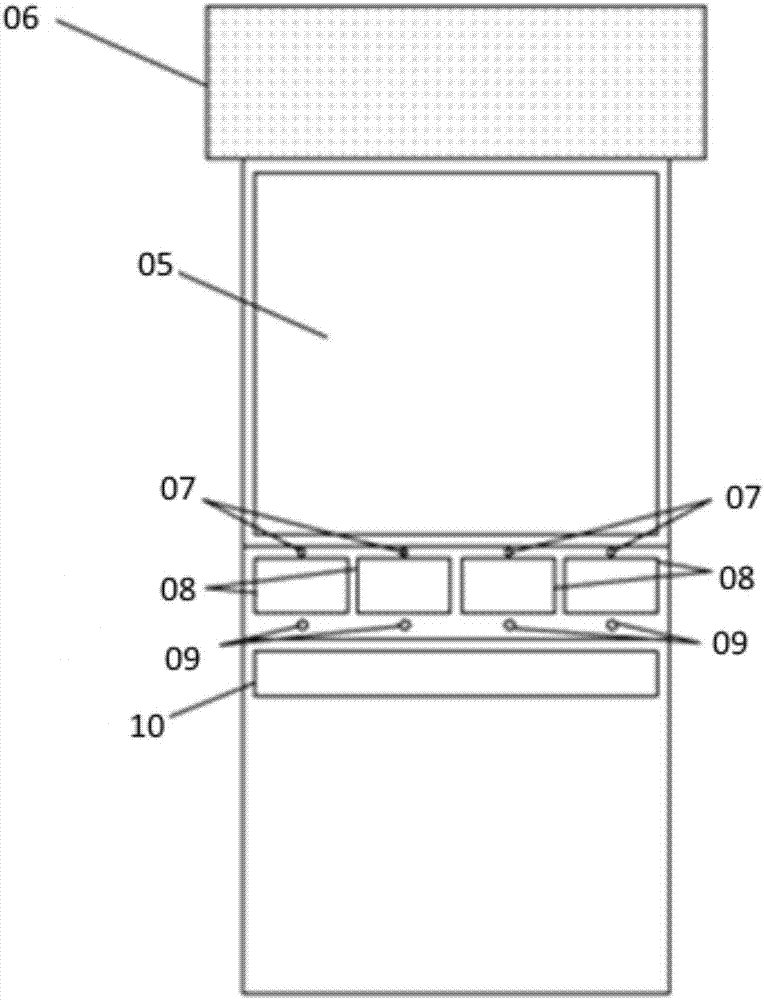

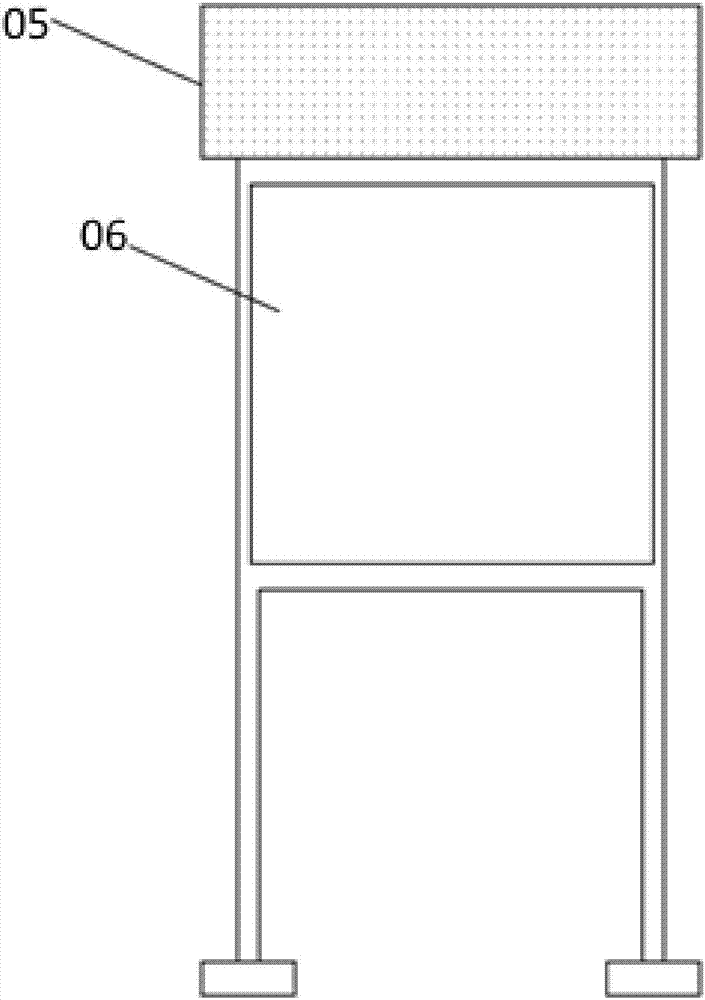

Garbage classification prompting device and system based on image recognition

The invention discloses a garbage classification prompting device and system based on image recognition. The device comprises a garbage classification prompting screen which comprises a camera, an information processor, a display module and a power supply module. The camera is used for sending taken garbage pictures to the information processor. The information processor is used for classifying garbage according the garbage pictures and prestored standard templates in a standard template library, generating classification result information and sending the classification result information to the display module to be displayed. The power supply module is used for supplying power to the camera, the information processor and the display module. The garbage classification prompting device has the advantages of rapidly recognizing garbage through the image recognition technology, helping people to rapidly classify garbage in daily life and reducing the workload of secondary garbage sorting.

Owner:GUANGDONG MATVIEW INTELLIGENT SCI & TECH CO LTD

Apparatus and methods for control of waste treatment processes

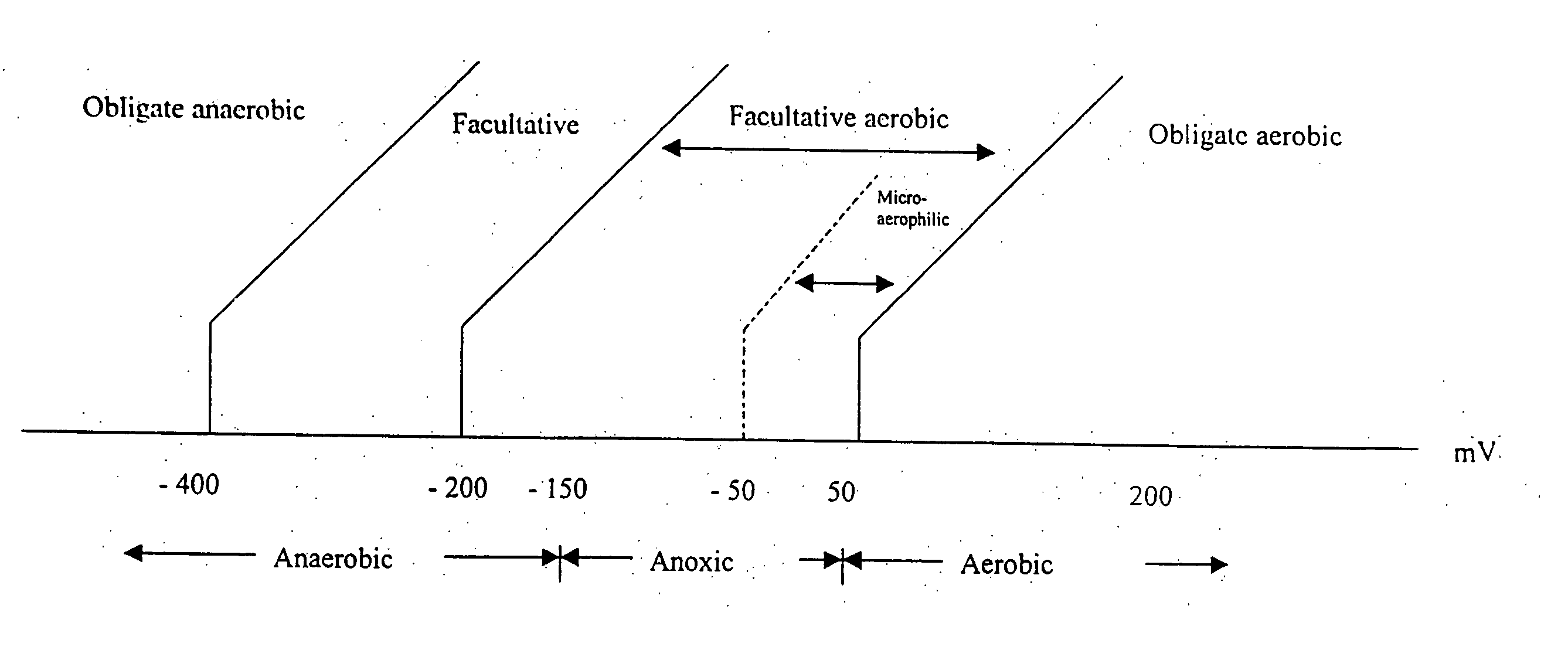

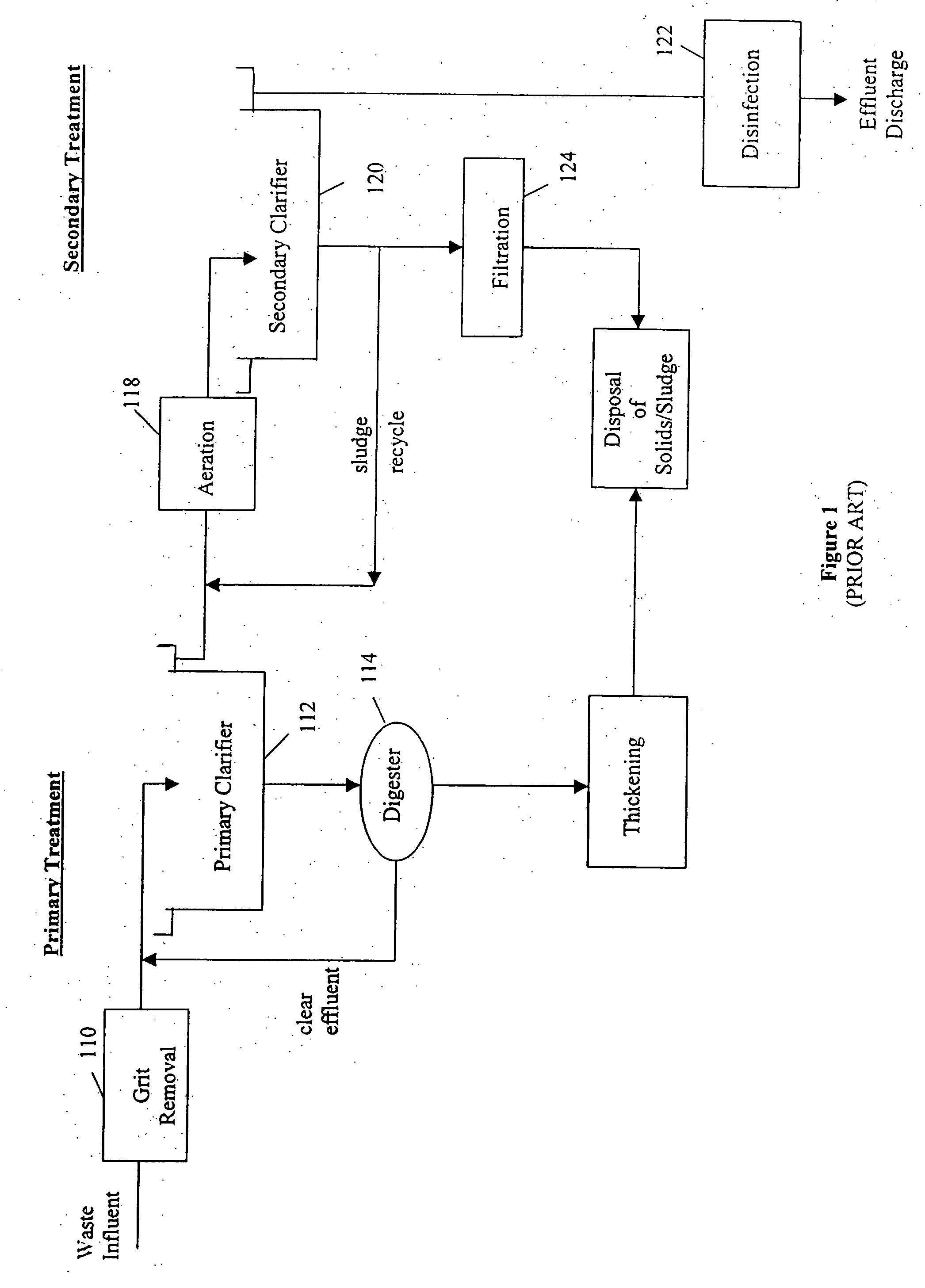

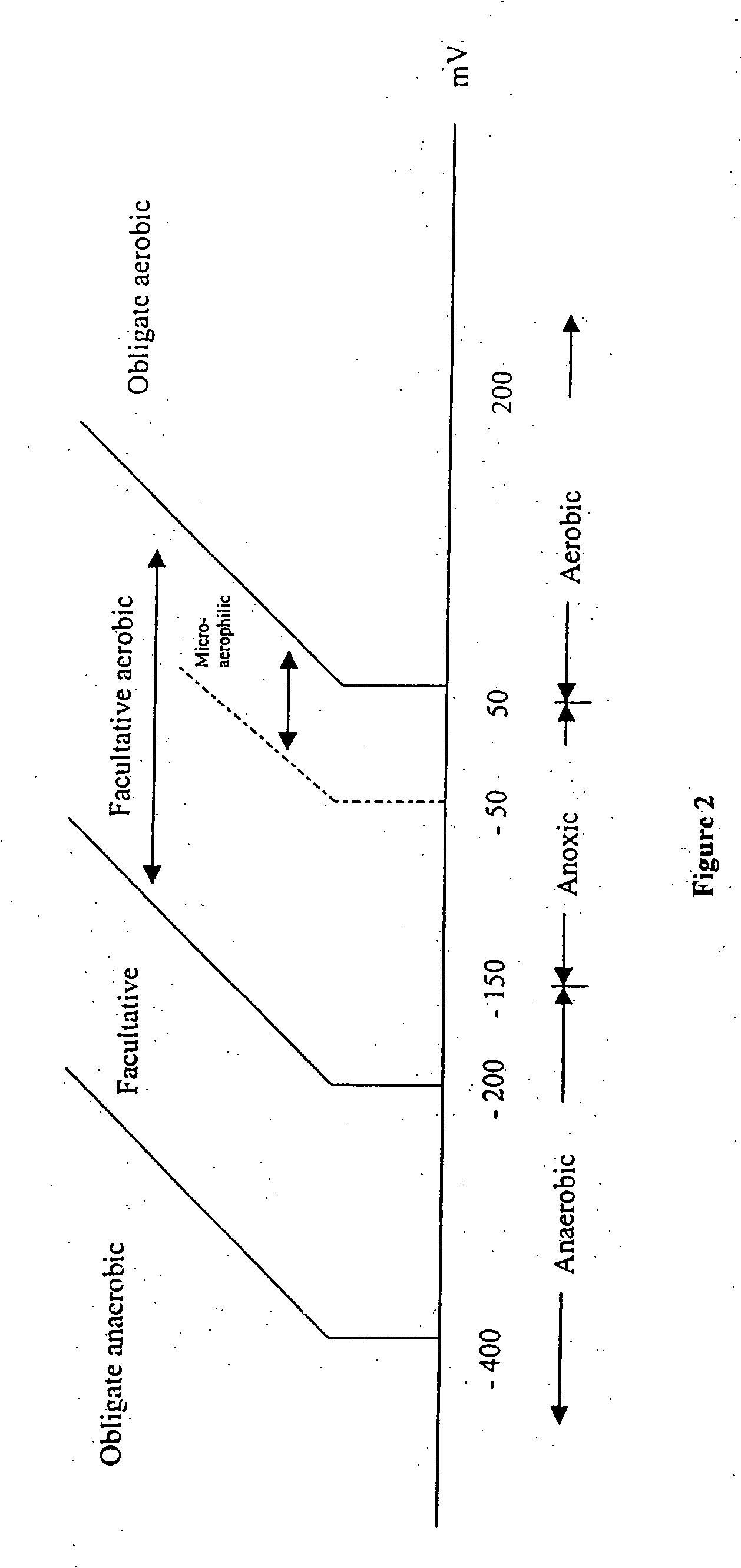

InactiveUS20060000769A1Reduce disposal volumeLow costWater treatment parameter controlTreatment using aerobic processesActivated sludgeParticulates

Waste-treatment processes are enhanced through generation and introduction of specific biological populations customized to perform or favor specific tasks either during the main process, for the formation or precipitation of certain biological nutrients, or to accomplish solids formation reduction in a post-treatment process. These bacteria may be grown from specialized mixes of activated sludge and waste influent by exposing these materials to controlled environments (e.g., in an off-line treatment area). They may then be returned to the main process to perform certain tasks such as converting particulate cBOD into soluble cBOD for utilization, to reduce high solids yield organisms by supplementing the population characteristics with low yield organism characteristics, to provide biological nutrients or oxygenation assistance, to improve nitrification / denitrification efficiency, or to disfavor filamentous biology such as Norcardia sp.

Owner:ADVANCED TREATMENT SCI

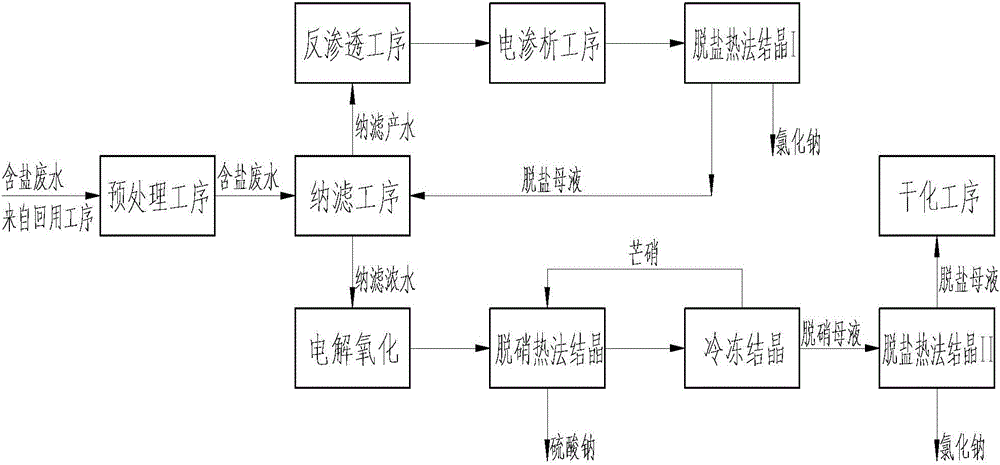

Method for extracting high-purity sodium sulfate and sodium chloride products from high-salt content wastewater in coal chemical industry

InactiveCN106116002AAchieve recyclingRealize separation and purificationWater treatment parameter controlGeneral water supply conservationElectrolysisSodium sulfate

The invention provides a method for extracting high-purity sodium sulfate and sodium chloride products from high-salt content wastewater in the coal chemical industry. The method comprises the following steps: firstly, pretreating the high-salt content wastewater in the coal chemical industry to reduce the hardness thereof and primarily concentrate the wastewater till the TDS content is about 30000mg / L, and primarily separating sodium sulfate and sodium chloride from the high-salt content wastewater in the coal chemical industry by a nanofiltration process to obtain nanofiltration concentrated water with the sodium sulfate as a main component and a nanofiltration produced water with the sodium chloride as a main component; secondly, removing a part of organic matters from the nanofiltration concentrated water to reduce the COD by an electrolytic oxidizing technology, and performing a hot crystallization technology and a freezing crystallizing technology to obtain a pure sodium sulfate product and a small amount of sodium chloride product; treating the nanofiltration produced water by a membrane concentration technology and a hot crystallizing technology to obtain a pure sodium chloride product. In the whole technical process, on the basis of achieving zero discharge of the wastewater, reuse of all water and maximized recycle of the salts in the wastewater are achieved, so that the economic efficiency is improved and the environment pollution is avoided.

Owner:EAST CHINA ENG SCI & TECH

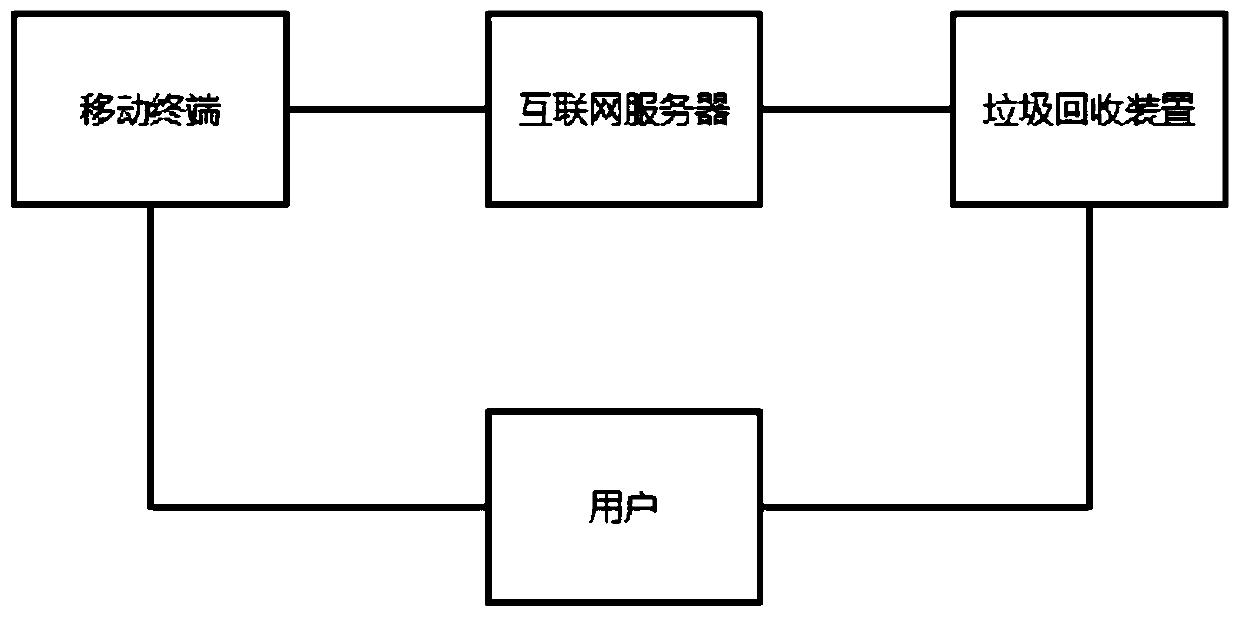

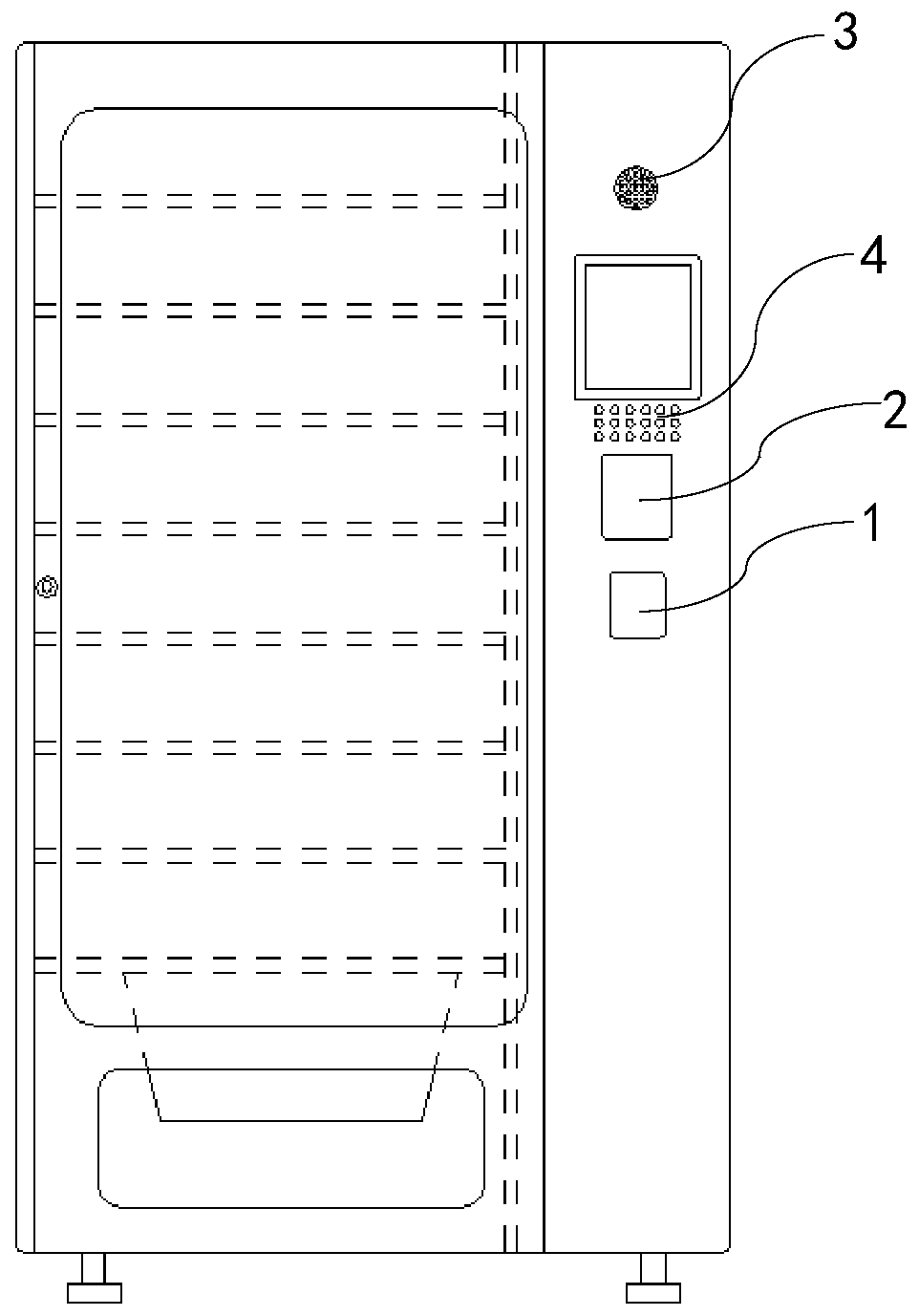

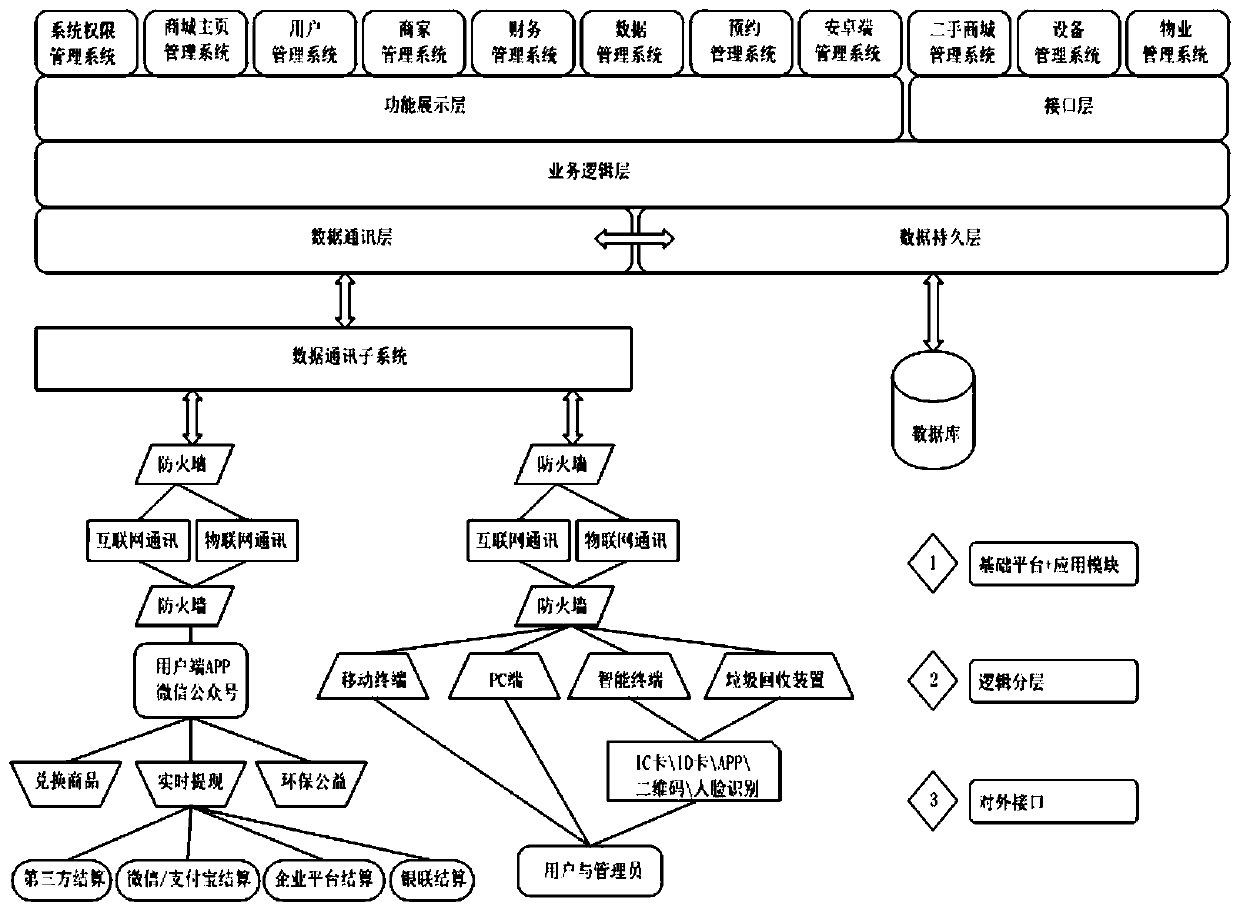

Smart garbage sorting and recycling mode

InactiveCN110021109ARealize the utilization of waste resourcesReduce waste disposalDiscounts/incentivesReturnable containers actuationThe InternetWaste sorting

The invention discloses a smart garbage sorting and recycling mode, which comprises the following steps: S1, when a user delivers garbage, the user logs in to an account in a garbage recycling device,and the corresponding garbage is delivered according to a fine garbage sorting guide; S2, after the user delivers the garbage, the garbage recycling device performs weighing and records the information to the Internet server, the Internet server records the delivery information of the user and performs related point conversion, and the Internet server establishes user garbage delivery big data and a credit information mechanism; S3, the information related to user garbage delivery is fed back to a client terminal through the Internet server, and a client can query related information; S4, theuser can use the earned integral for related exchange and amount exchange; and S5, when a garbage can is fully loaded, a corresponding warning light is on, the delivery port can not be opened, and early warning information is sent to workers. Garbage dumping service is provided for the user, a resident is helped with the garbage dumping problem, and garbage sorting and recycling can be realized at the same time.

Owner:广东沫益清环保科技有限公司

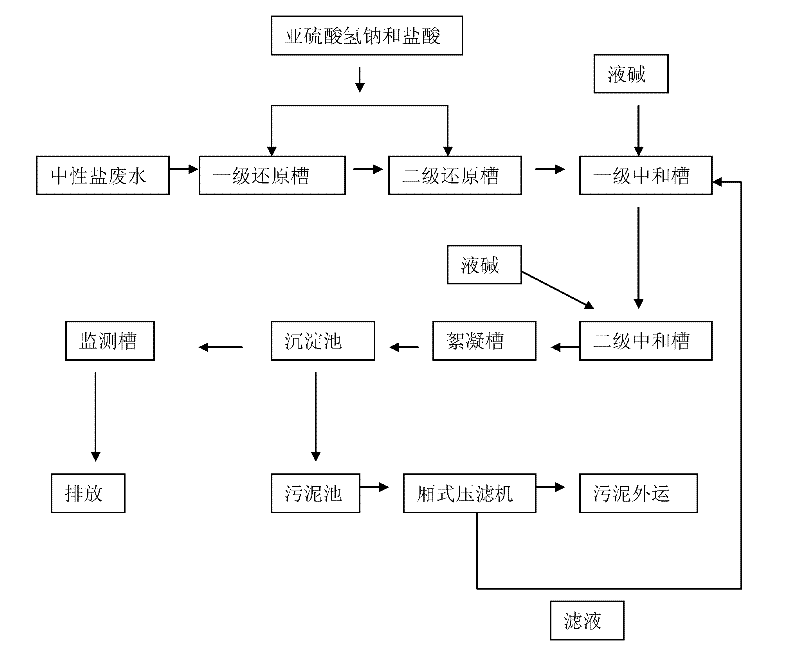

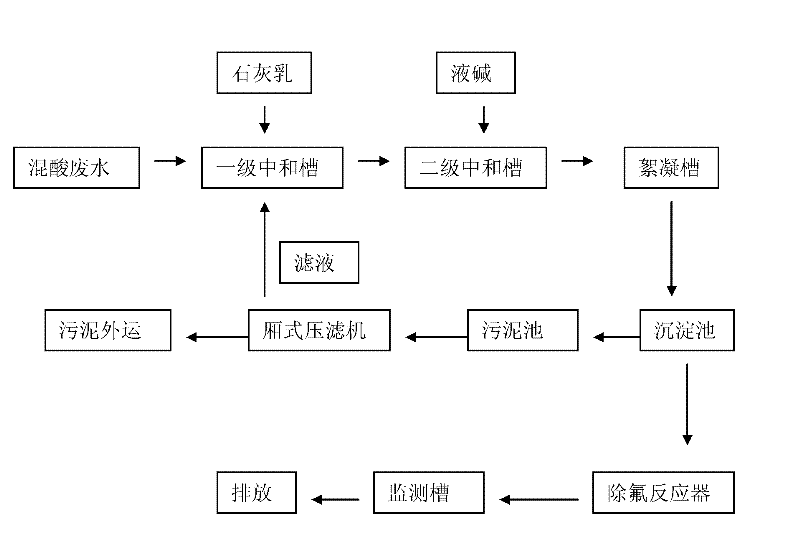

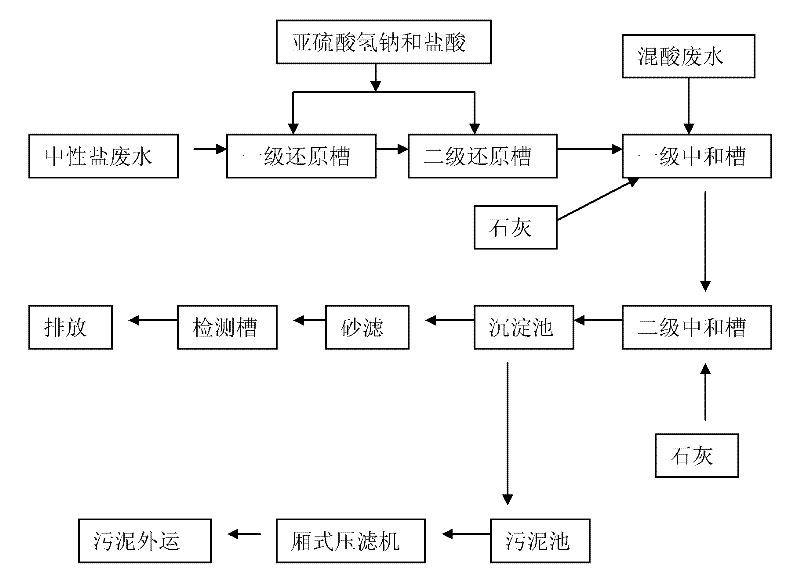

Method for sludge reduction for cold rolling pickling wastewater in steel industry

ActiveCN102211828AReduce productionReduce processingSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processSludgePolyacrylamide

The invention belongs to the technical field of sludge reduction for cold rolling pickling wastewater in the steel industry, and discloses a method for sludge reduction for the cold rolling pickling wastewater in the steel industry. In the method disclosed by the invention, neutral salt wastewater and wastewater mixed with acid are completely and separately treated to obtain sludge containing hazardous wastes and general sludge respectively, and the sludge output of each unit is reduced by accurately adding chemical agents at each unit; in the technology for treating the neutral salt wastewater, caustic soda liquid is respectively added in a first stage neutralizing tank and a second stage neutralizing tank; in the technology for treating the wastewater mixed with acid, the treatment is performed by using a lime and austic soda liquid combination method; and in the treatment of a neutralizing tank, the pH value is controlled between 1.5 and 3.0, and the pH value during neutralization reaction is controlled between 8.2 and 8.7; and a flocculation process is adopted after the neutralization reaction, polyaluminum chloride, polyacrylamide and other flocculants are added for reacting and are mixed so as to enlarge pollutant particles. By use of the method, the output water can stably reach the standard, and the water treatment cost per ton is reduced.

Owner:SHANGHAI MEIJIA WATER TREATMENT TECH

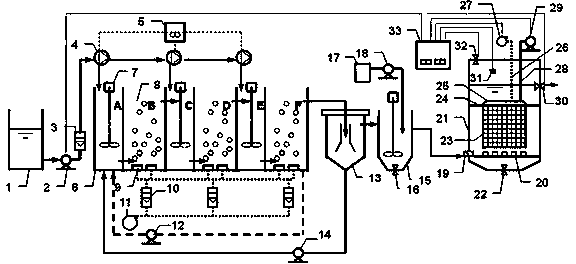

Nitrogen and phosphorus removal method coupling A/O step-feed MBBR (moving bed biofilm reactor) process with cloth filter

The invention relates to a nitrogen and phosphorus removal method coupling an A / O step-feed MBBR (moving bed biofilm reactor) process with a cloth filter. Suspended filler is added into a reaction tank of the A / O step-feed stage, and the pollutants are effectively removed by a biofilm formed on the suspended filler. Meanwhile, by adopting a chemical phosphorus removal process and coupling with the cloth filter, the sewage after nitrogen and phosphorus removal is further treated to realize deep nitrogen and phosphorus removal and further purify the water quality. The method provided by the invention has the advantages that the utilization rate of the carbon source is effectively increased, the energy consumption is reduced, phosphorus can be removed more stably and the impact resistance is improved. Meanwhile, by adopting the cloth filter process, the effluent quality is better.

Owner:JIANGSU YULONG ENVIRONMENTAL PROTECTION

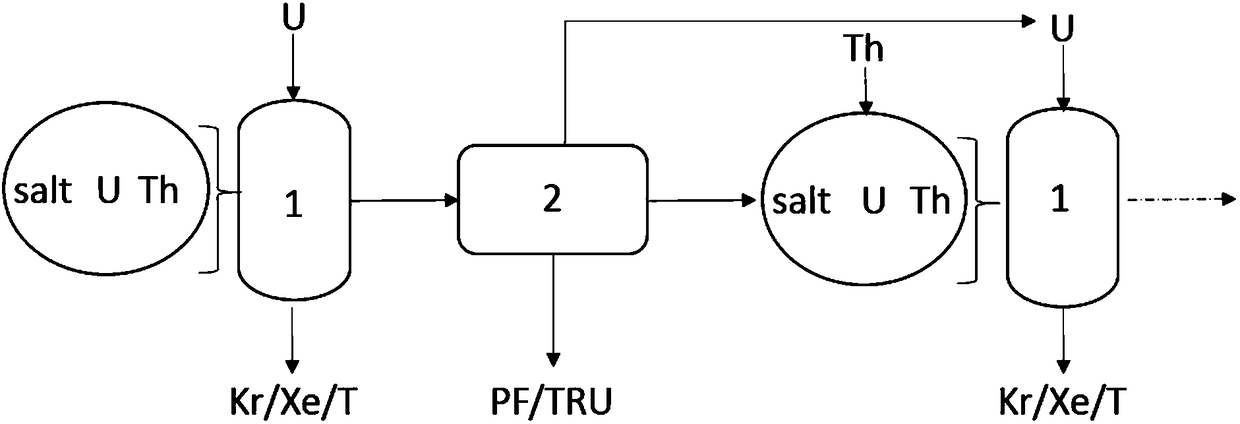

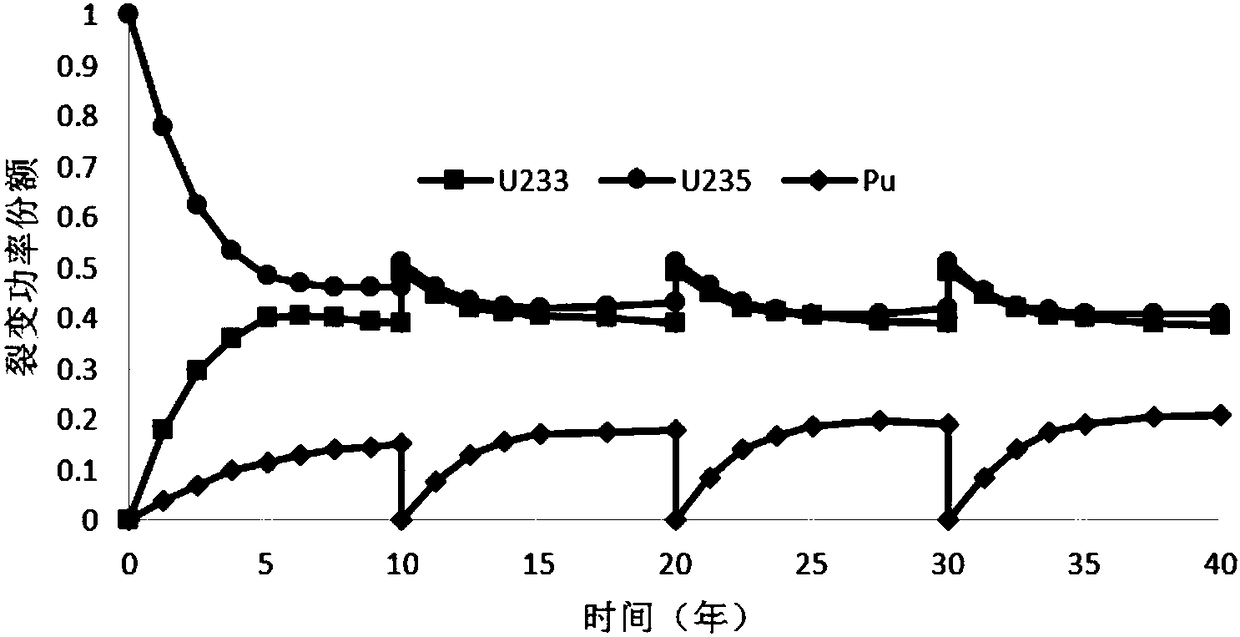

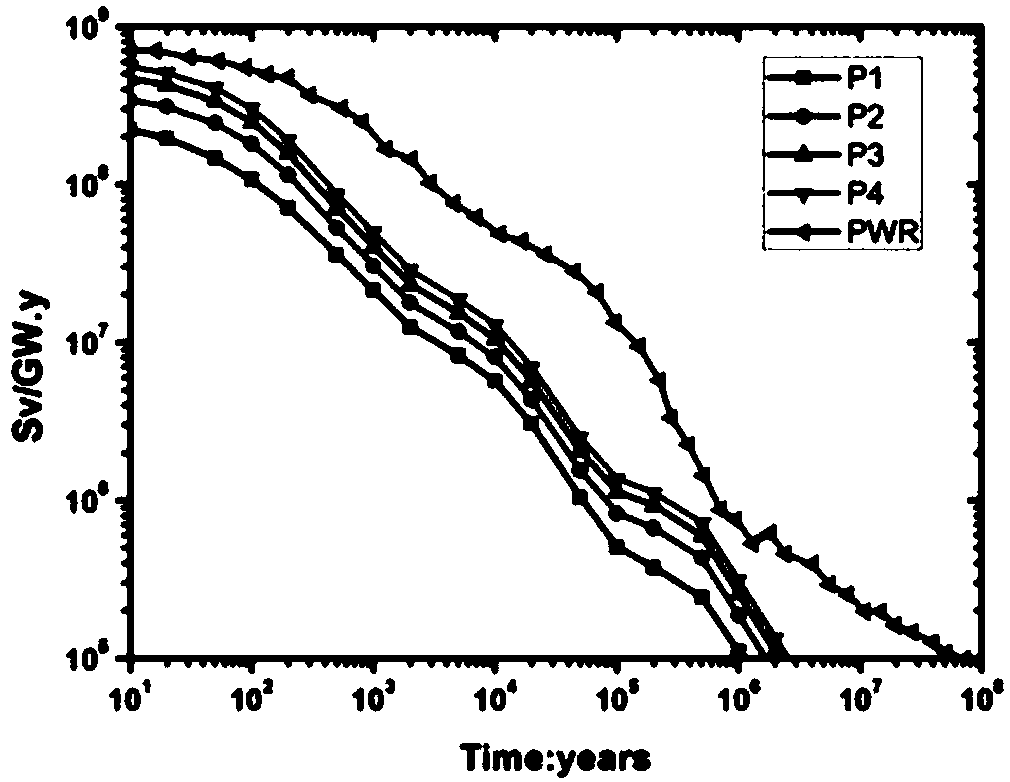

Molten salt reactor thorium fuel cyclic utilization method

InactiveCN108389634AIncrease profitLow radioactivityNuclear energy generationReactor fuel susbtancesEngineeringGraphite

The invention discloses a molten salt reactor thorium fuel cyclic utilization method. A reactor core comprises a graphite assembly and fuel molten salt, wherein the fuel molten salt is filled in a passage formed by the graphite assembly; the fuel molten salt comprises fuel salt and base salt; during operation, the on-line feeding is used; fission gas is cleared in a on-line way; reactor stopping off-line operation is performed, spent fuel is treated; recovered uranium, base salt and thorium are proportioned again and are then loaded into the reactor core for cyclic utilization, wherein the volume ratio of the fuel molten salt to the reactor core is 5 percent to 15 percent; the fuel salt is a mixture of ThF4 and UF4, wherein the U enrichment degree is 15 to 20 percent; the initial mole percentage of the fuel salt in the fuel molten salt is 6 percent to 8 percent; the initial mole percentage of ThF4 in the fuel salt is greater than 80 percent. The method has the advantages that under thecondition without depending an on-line treatment technology, the fission contribution of thorium fuel in the molten salt reactor is improved, so that the utilization rate of U-235 is improved; the radioactivity and the disposal quantity of the spent fuel are reduced.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

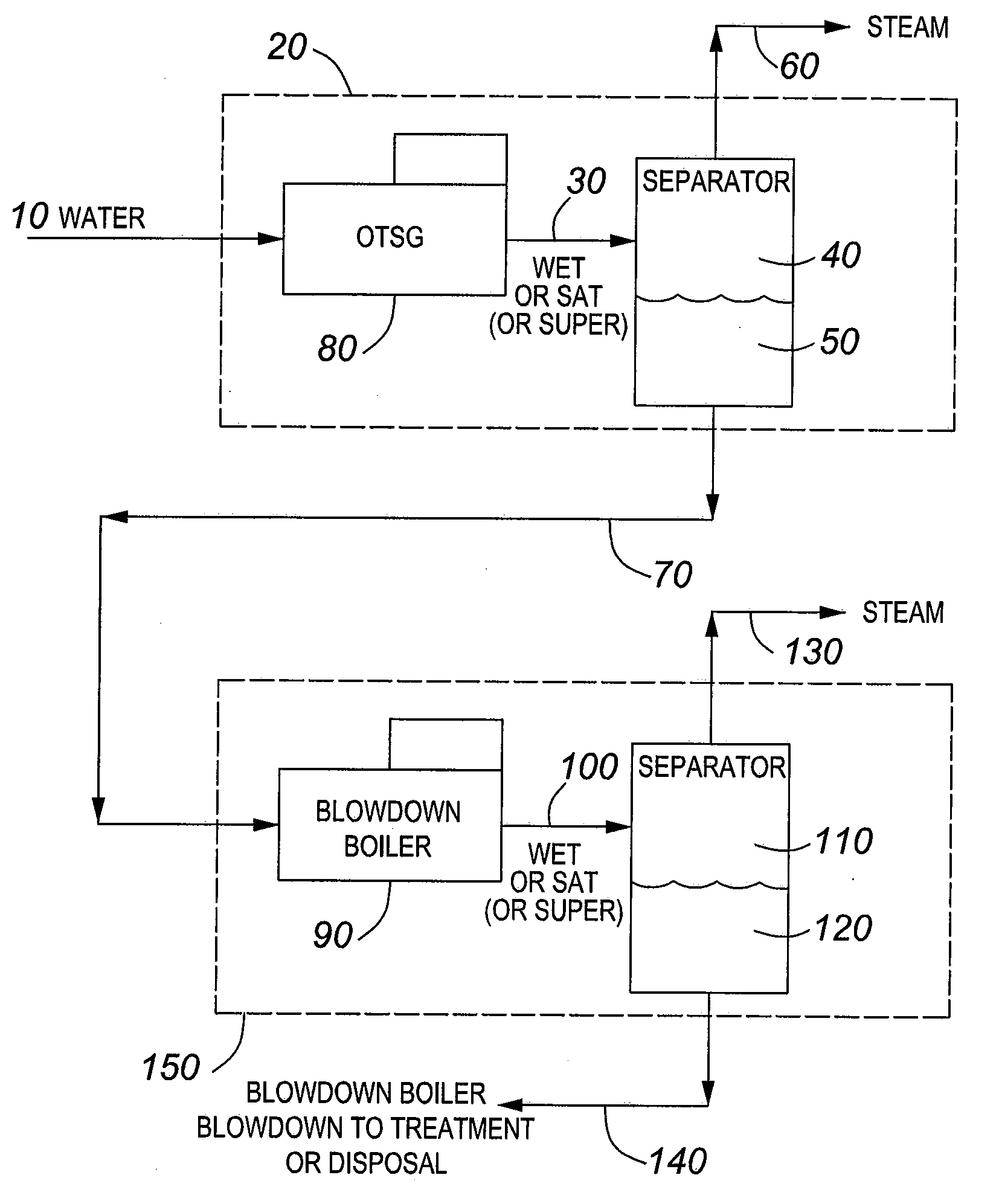

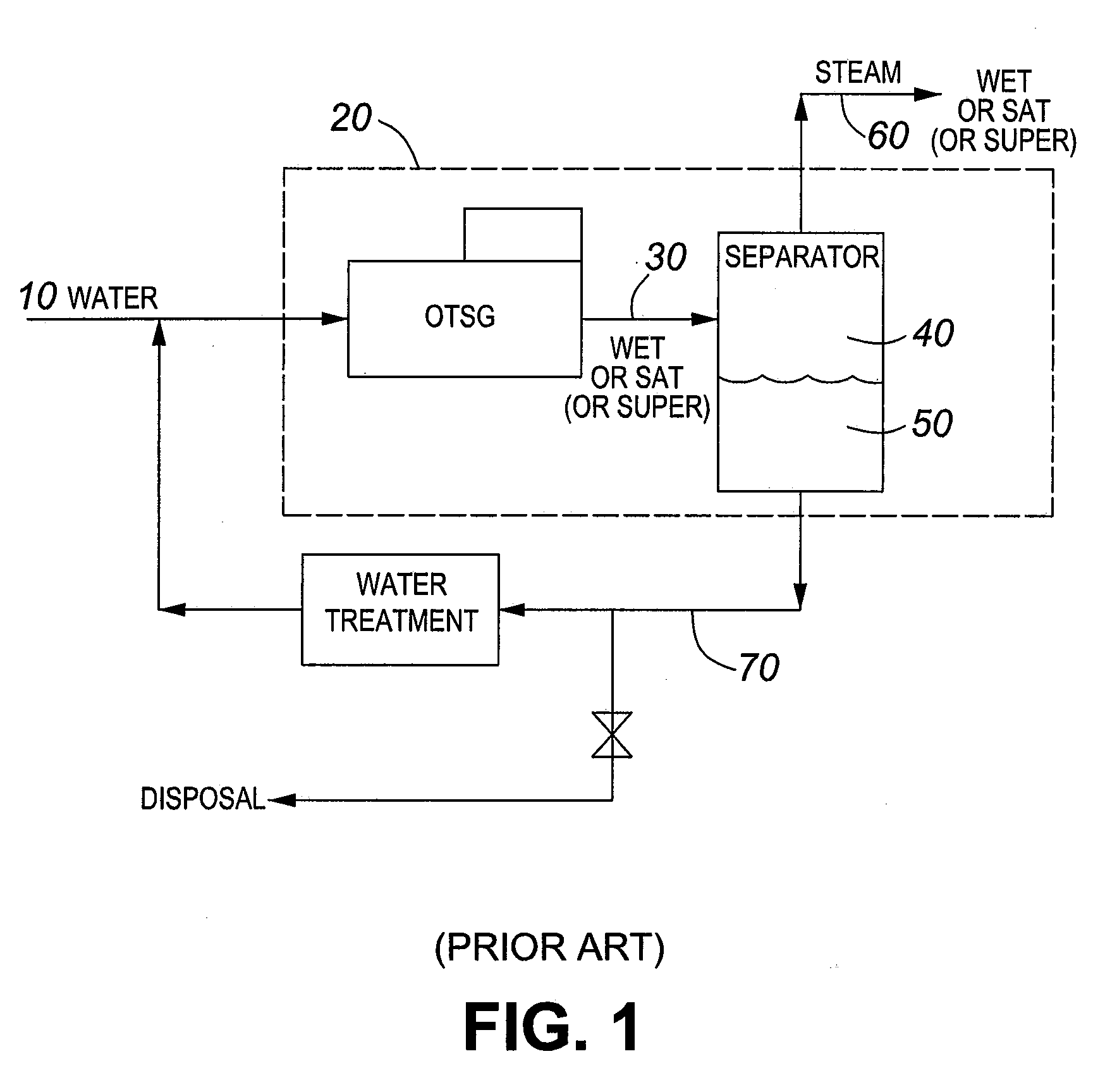

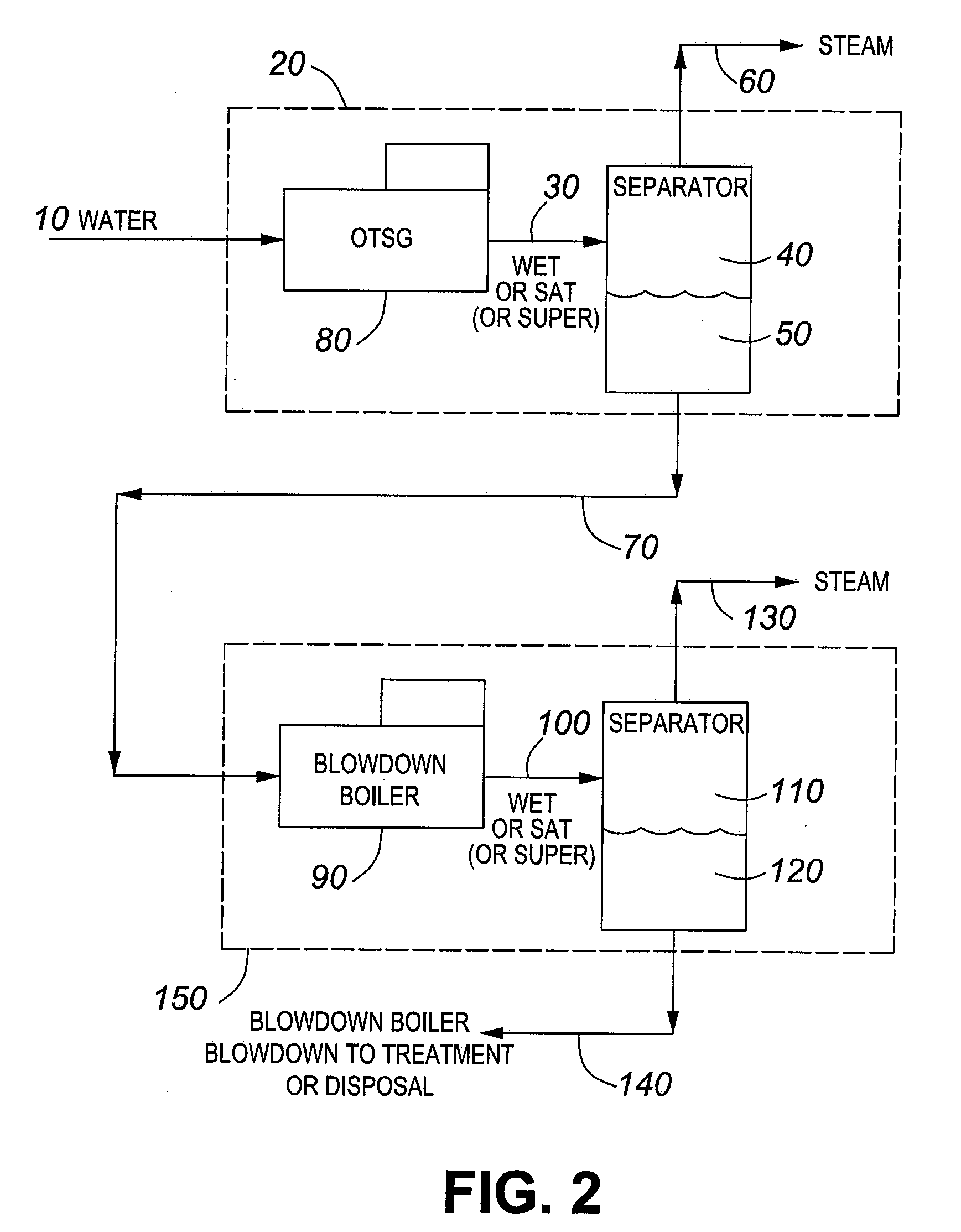

Method and apparatus for steam generation

ActiveUS20090133643A1Reduce in quantityIncrease volumeWater circulationSteam separation arrangementsBoiler blowdownHardness

A method, apparatus, and system and operation of surface equipment to generate steam while reducing the quantity of boiler blowdown and thereby increasing the amount of feedwater that is re-used or re-cycled in generating said steam. The present invention teaches that, on a sustained basis, the blowdown stream at the outlet of a once-through steam generator can be routed to the inlet of a second once-through steam generator that is in series with the first, that blowdown stream can be used to generate additional steam in the second once-through steam generator and further reduce the amount of blowdown, and that this can be accomplished without need of any treatment that reduces hardness or silica levels of the blowdown stream prior to its entering or during its entry into the inlet of the second once-through steam generator. The output of this second steam generator is a substantially dry saturated steam vapor stream and, complementarily, a blowdown stream whose mass rate has been reduced substantially from that of the blowdown stream exiting the first steam generator.

Owner:FCCL PARTNERSHIP

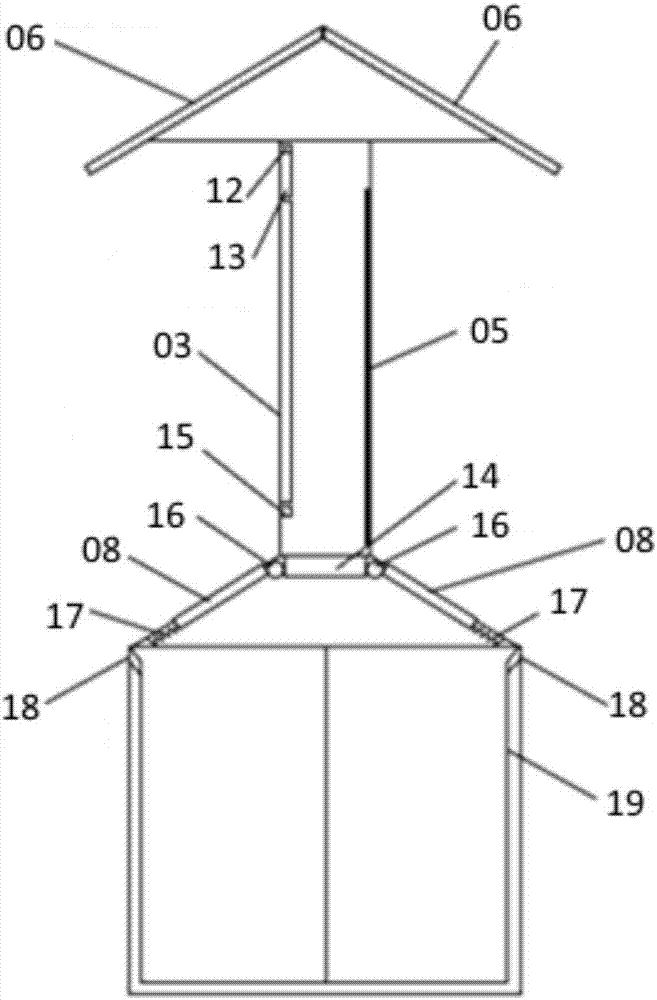

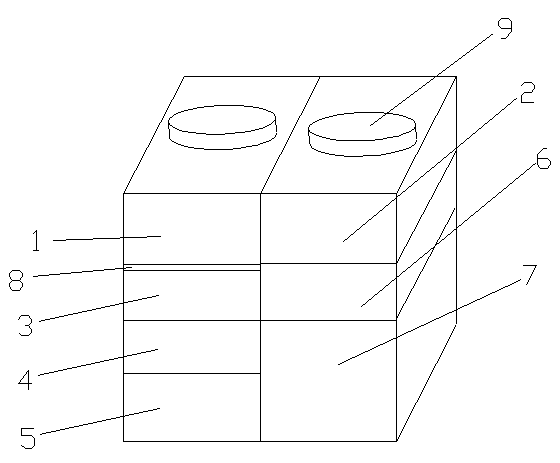

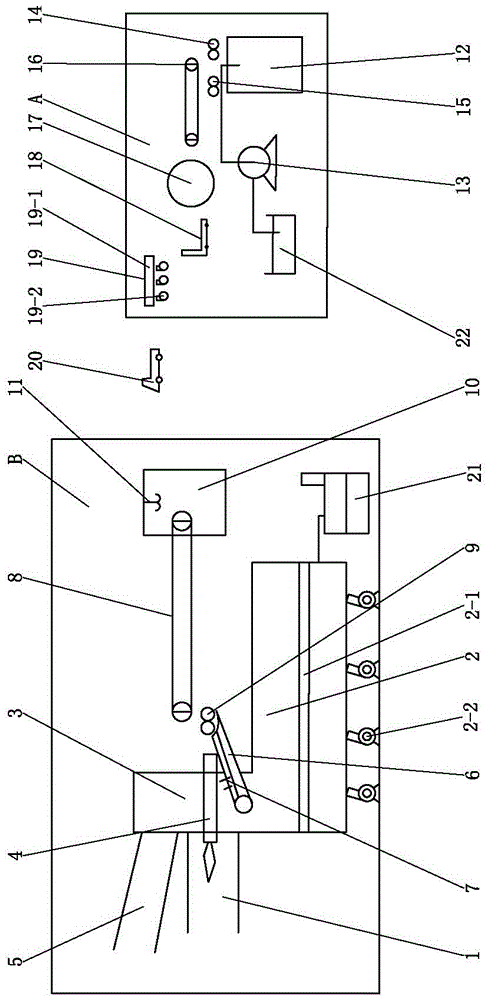

Novel garbage sorting, grinding and collecting device

InactiveCN103253474ARealize resource utilizationReduce disposal volumeWaste collection and transferRefuse receptaclesFertilizerPulverizer

The invention discloses a novel garbage sorting, grinding and collecting device which comprises a first sorting opening, a second sorting opening, a first garbage grinder, a first garbage compressor and a second garbage compressor. The second sorting opening is arranged on one side of the first sorting opening, the first garbage grinder is arranged at the bottom of the first sorting opening, the first garbage compressor is arranged at the bottom of the first garbage grinder, a first storage area is arranged at the bottom of the first garbage compressor, the second garbage compressor is arranged at the bottom of the second sorting opening, and a second storage area is arranged at the bottom of the second garbage compressor. The novel garbage sorting, grinding and collecting device has the advantages that garbage can be divided into a garbage part capable of being ground and another garbage part, the garbage part capable of being ground is manufactured into finished fertilizers, the other garbage part is directly compressed to save space and then is conveyed to a garbage recycling station, accordingly, garbage resources are utilized to the greatest extent, the garbage disposal quantity is reduced, the quality of a living environment is improved, and the novel garbage sorting, grinding and collecting device is environment-friendly.

Owner:SUZHOU GREEN BUILDING TECH RES CENT

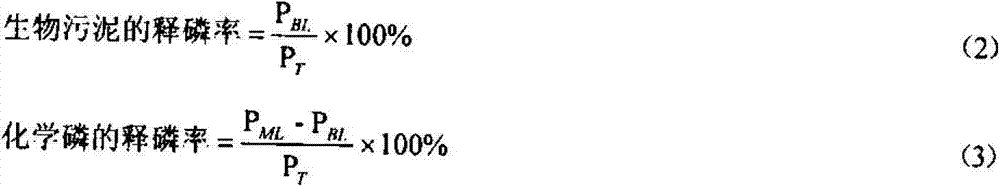

Method for extracting phosphorus in phosphorus containing chemical-biological mixed sludge

ActiveCN103204613AHigh recovery rateRealize resource utilizationBiological sludge treatmentSolubilityPhosphoric acid

The invention relates to a method for extracting phosphorus in phosphorus containing chemical-biological mixed sludge. The method for extracting phosphorus in phosphorus containing chemical-biological mixed sludge comprises the following steps of: placing phosphorus containing chemical-biological mixed sludge in a reactor, standing and precipitating for 24 hours at room temperature, and discharging supernate to obtain excess sludge; and adjusting and maintaining pH value of the excess sludge to be 2-8, closing the reactor, and carrying out anaerobic digestion for 7 days at the temperature of 30-50 DEG C, so that both biological phosphorus and chemical phosphorus in the phosphorus containing chemical-biological mixed sludge are released. Compared with the prior art, for the mixed sludge containing aluminium phosphate or iron phosphate, 60-80% of phosphorus in the mixed sludge can be released while the pH value is maintained to be 2-8, and 10-30% more phosphorus is released compared with the condition that the pH value is not adjusted; the digestion rate of an organic matter (in soluble organic carbon) can be 25-60 higher compared with the condition that the pH value is not adjusted; and the method for extracting phosphorus in phosphorus containing chemical-biological mixed sludge can improve phosphorus release rate in anaerobic digestion of the chemical-biological mixed sludge, is beneficial to release of organic matter and reduction of sludge and has significance on sludge recycling and reduction.

Owner:TONGJI UNIV

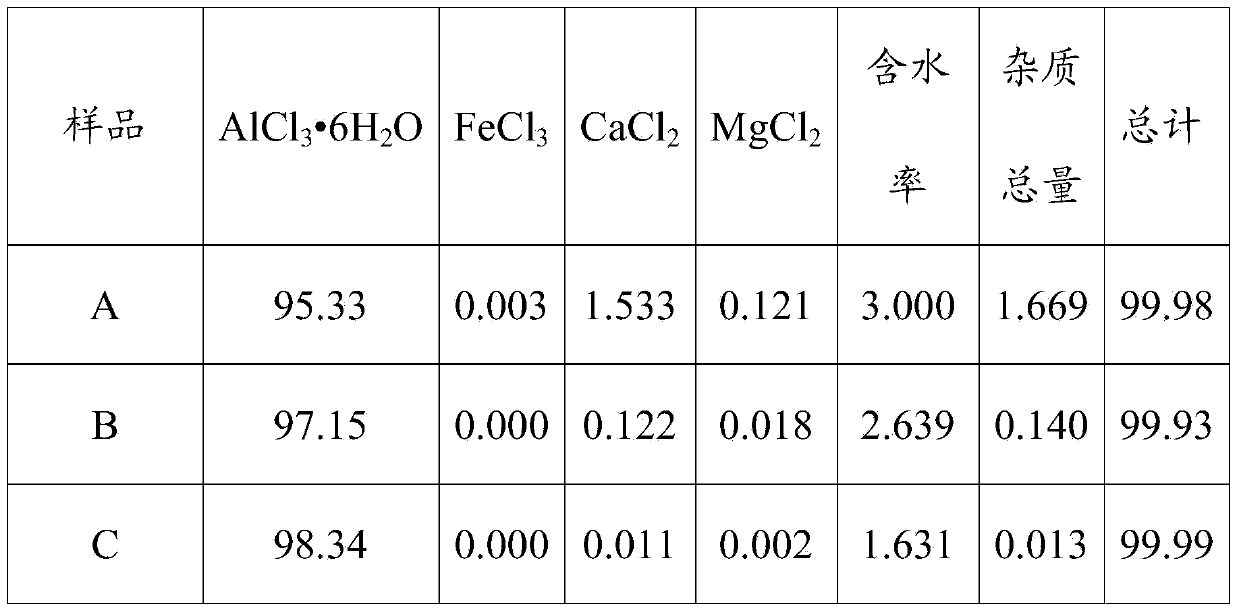

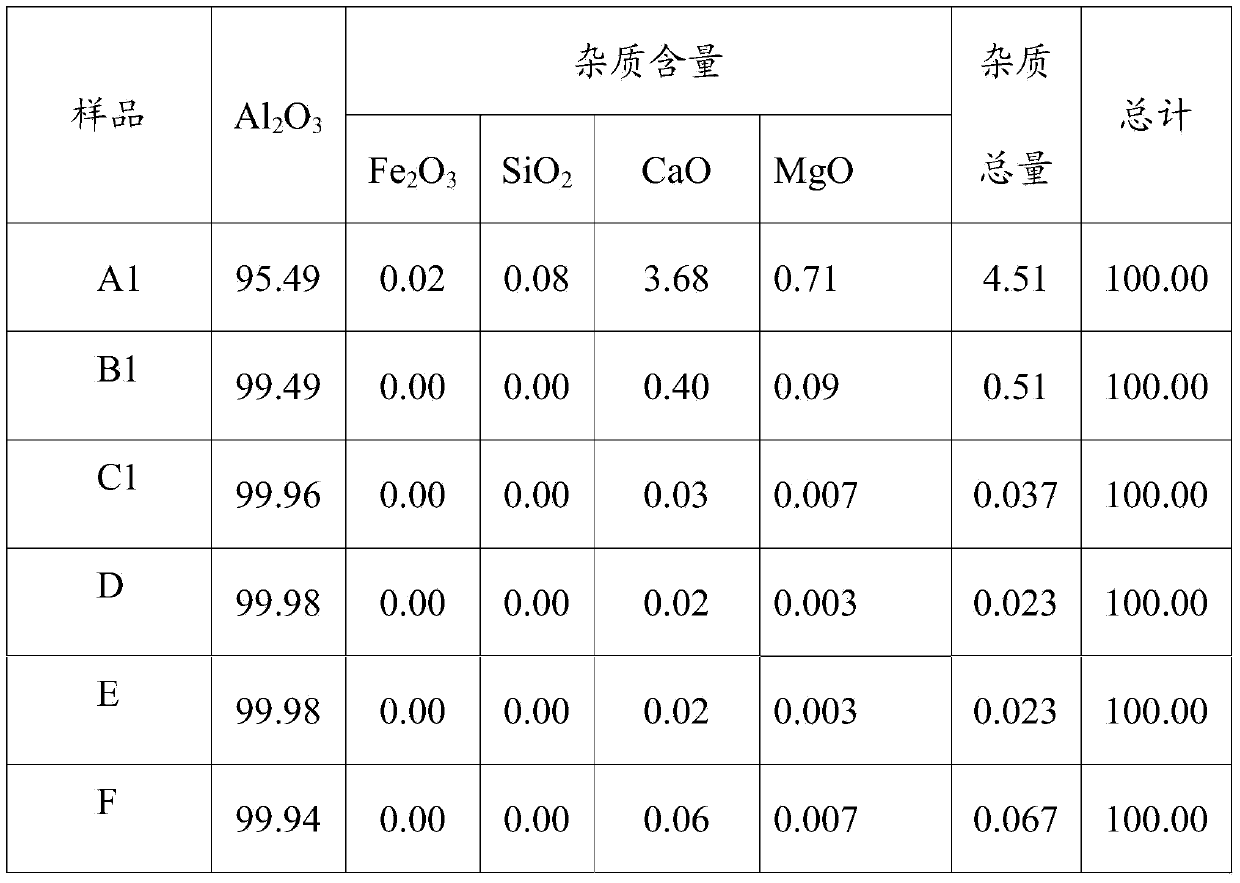

Method for making aluminum oxide by utilizing crystalline aluminum chloride

ActiveCN103738990ALow costImprove separation efficiencyAluminium oxide/hydroxide preparationAluminium chlorideChloride

The invention discloses a method for making high-purity aluminum oxide by utilizing crystalline aluminum chloride. The crystalline aluminum chloride is the crystalline aluminum chloride in the production process of the aluminum oxide by a fly ash acid method. The method comprises the following steps: utilizing part of the crystalline aluminum chloride to prepare an HCl solution of saturated AlCl3, performing purification on part of the crystalline aluminum chloride to obtain primary purification aluminum chloride crystals, then utilizing concentrated hydrochloric acid to perform secondary purification on the primary purification aluminum chloride crystals, and then calcining and crushing the obtained aluminum chloride to obtain the aluminum oxide. According to the method disclosed by the invention, a small part of the aluminum chloride to be purified is consumed and a large part of the aluminum chloride is purified, so that the cost is saved; furthermore, the solution after purification can be recycled; and in addition, impurity removal is performed on the crystals in the two purification processes, the purity of the aluminum chloride crystals is improved, the crystals are of large particles, the sand-like aluminum oxide is obtained after calcination, and the product purity is more than 99.9%.

Owner:CHINA SHENHUA ENERGY CO LTD +1

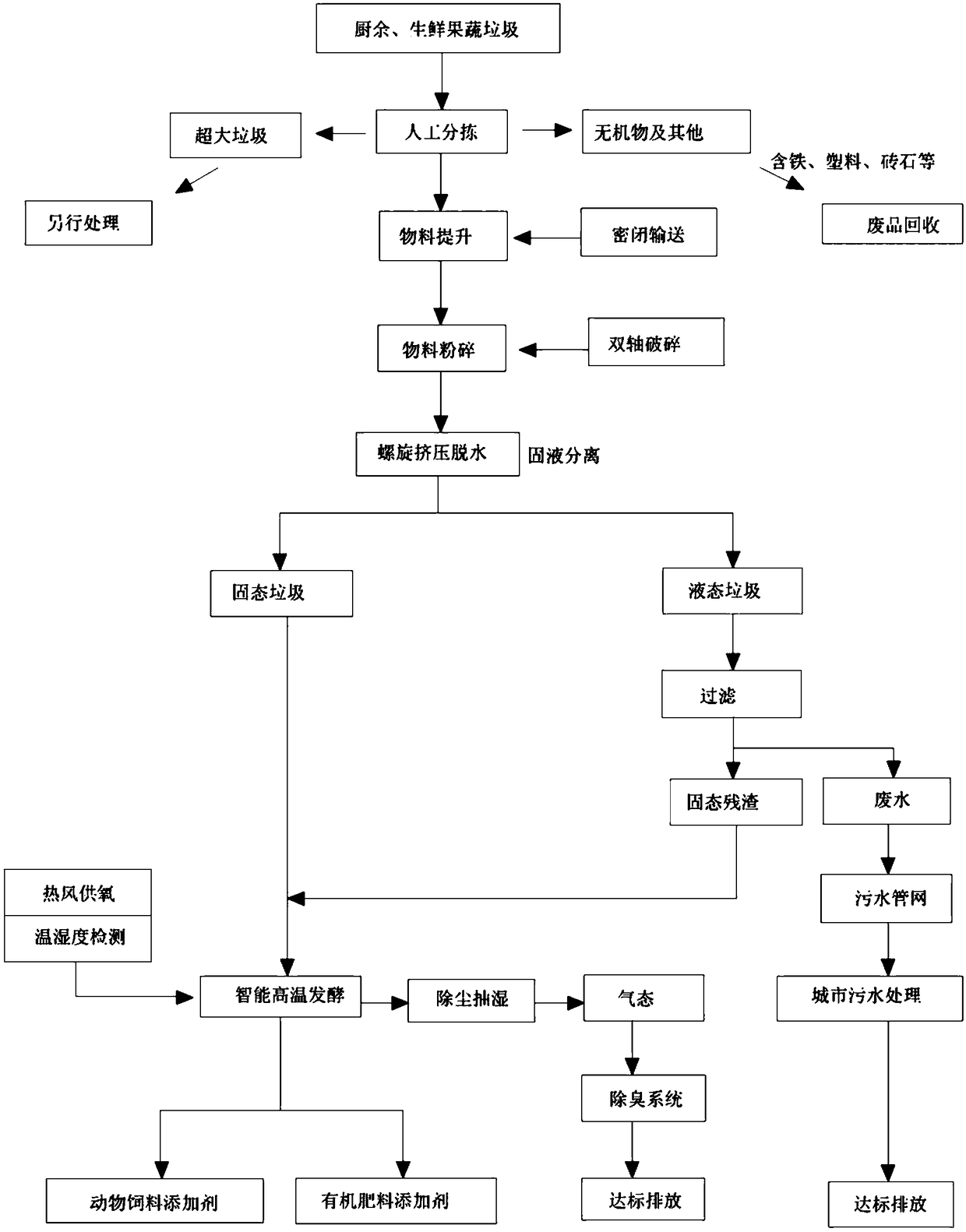

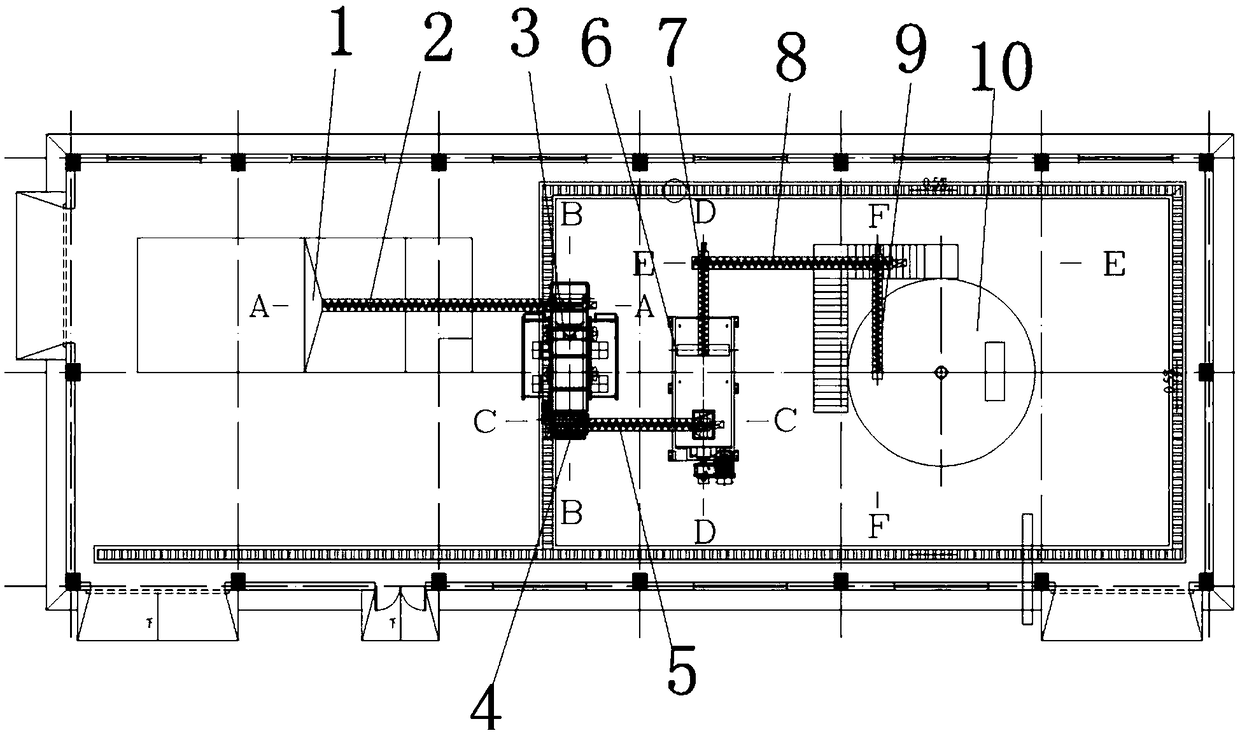

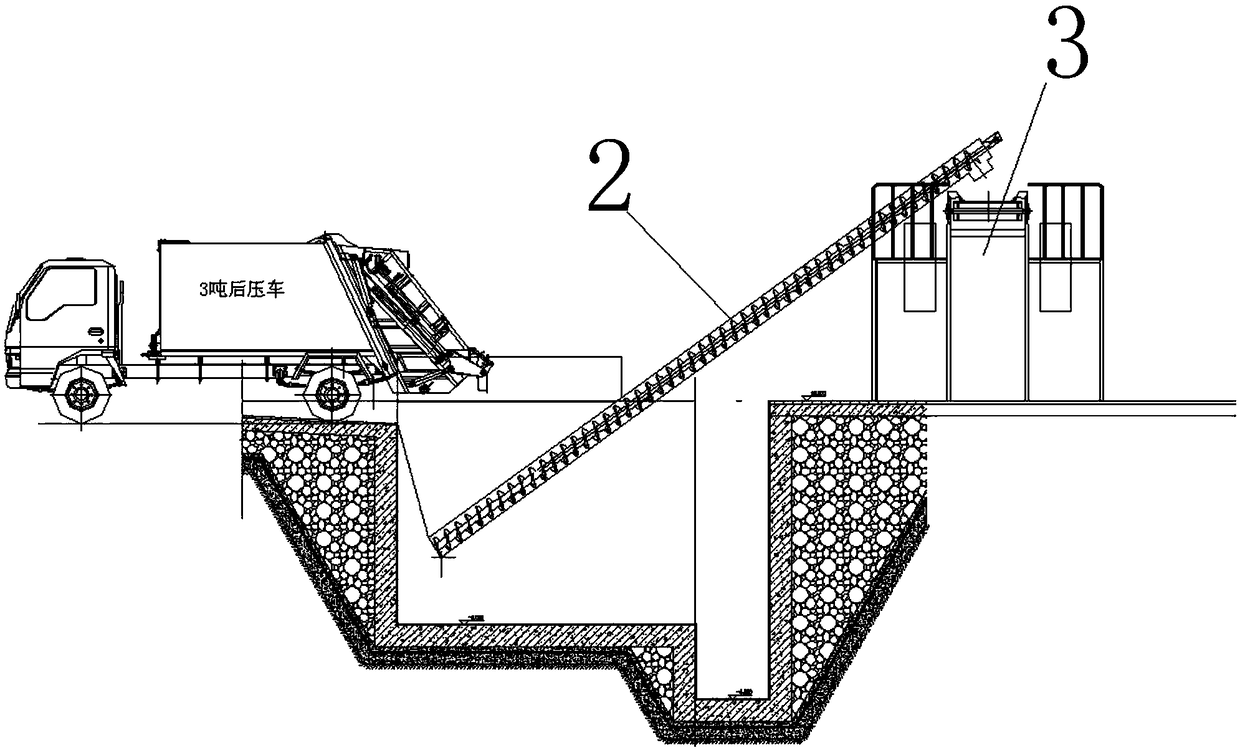

Wet garbage disposal device and technology

PendingCN109317501ARealize resource utilizationReduce disposal volumeSolid waste disposalTransportation and packagingResource utilizationLitter

The invention discloses a wet garbage disposal device and technology. The wet garbage disposal device comprises a material storage device, a feeding conveyor, a sorting conveyor, a crusher, a crushingconveyor, a dewatering machine, a dewatering conveyor, a filter residue conveyor, a fermentation conveyor and an intelligent fermentation tower; the feeding conveyor is obliquely arranged between thematerial storage device and the sorting conveyor, and the sorting conveyor is located above the material storage device; an input port of the crusher is located below an output port of the sorting conveyor; the crushing conveyor is obliquely arranged between an output port of the crusher and the dewatering machine; the dewatering conveyor is obliquely arranged at an output port of the dewateringmachine; the output end of the dewatering conveyor is connected to the input end of the filter residue conveyor; the output end of the filter residue conveyor is connected to the input end of the fermentation conveyor; and the output end of the fermentation conveyor is connected to the intelligent fermentation tower. The technology which is beneficial to the disposal of the device can be referredto the specification. According to the wet garbage disposal device and technology, garbage resource utilization can be realized, the garbage disposal amount can be decreased, and the quality of the living environment can be improved.

Owner:上海程胜环保科技有限公司

Method for recycling titanium dioxide in waste SCR (Selective Catalytic Reduction) denitration catalyst

ActiveCN103130265BReduce disposal volumeReduce manufacturing costTitanium dioxideChemical recyclingPhosphorous acidSolubility

The invention relates to a method for recycling titanium dioxide in a waste SCR (Selective Catalytic Reduction) denitration catalyst. The method comprises the following steps of: firstly removing dust from the waste denitration catalyst, pulverizing, then adding concentrated sulfuric acid so as to carry out acid hydrolysis on the waste denitration catalyst to obtain a concentrated titanyl sulfate solution, and adding water for dilution; adding a non-ionic emulsifier serving as a flocculating agent and a sulfonate surface active agent or a polycarboxylate surface active agent as a coagulant aid, and adding water-solubility methyl silicone oil; pumping into a plate-and-frame filter press for filter pressing, carrying out vacuum concentration on filtrate, then heating to 90 DEG C to 98 DEG C, and maintaining for 5.5 hours so as to hydrolyze the filtrate; cooling a hydrolysis product to 40 DEG C, and carrying out vacuum filtration so as to sediment out metatitanic acid; rinsing with sand-filtered water and deionized water, and adding potassium carbonate or phosphorous acid to obtain metatitanic acid filter cakes; and drying the filter cakes, calcining at 500-800 DEG C, and then pulverizing to obtain a titanium dioxide finished product. The method has the advantages of being capable of reducing disposal amount of the waste denitration catalyst, recycling the waste denitration catalyst and reducing the production cost of the waste denitration catalyst.

Owner:江苏万德环保科技有限公司

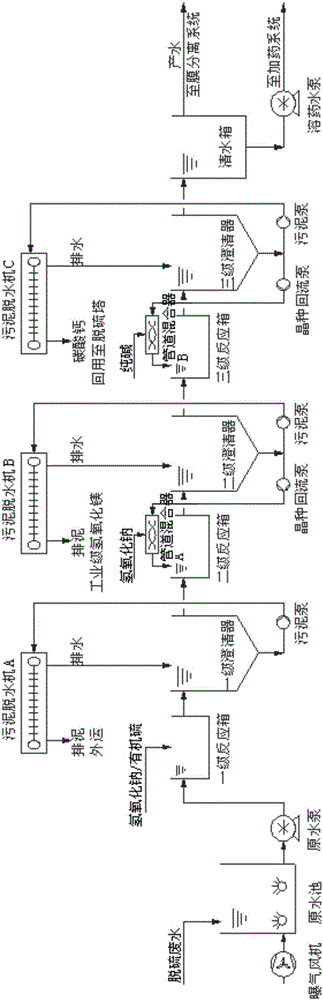

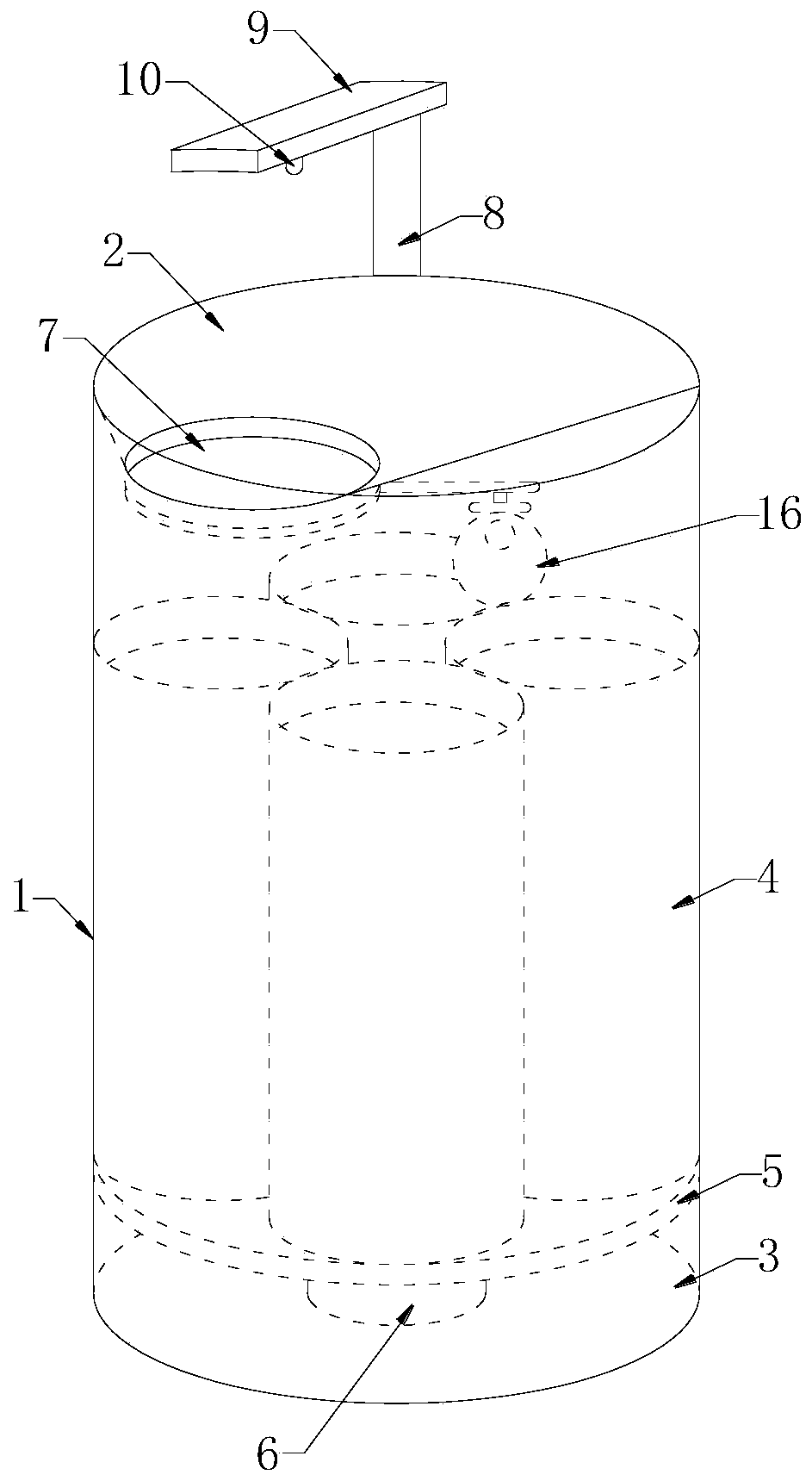

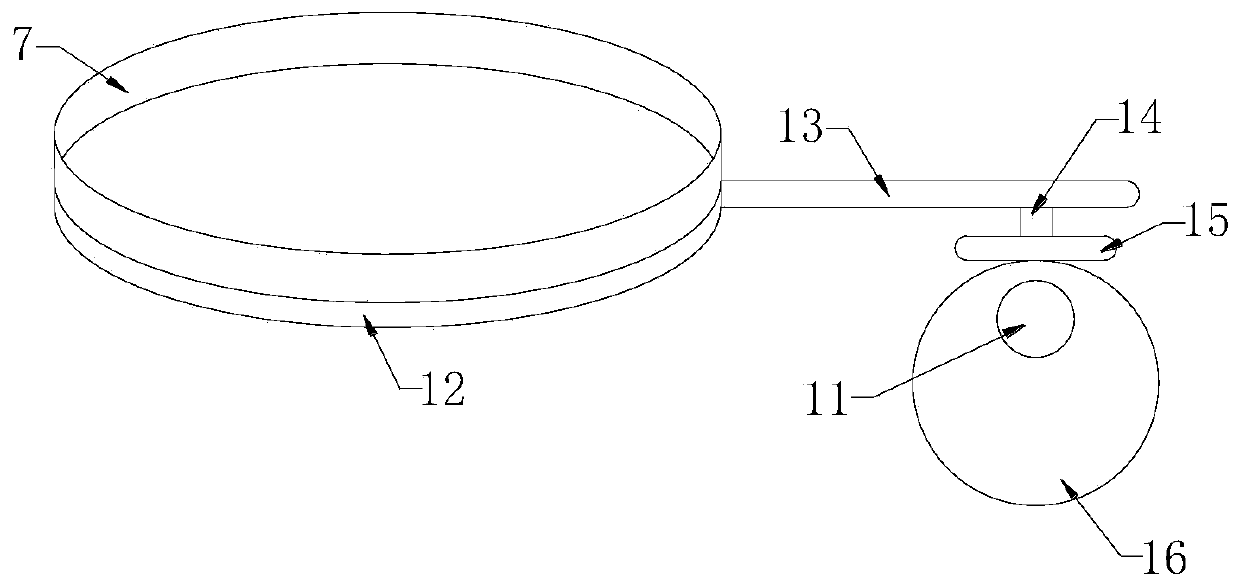

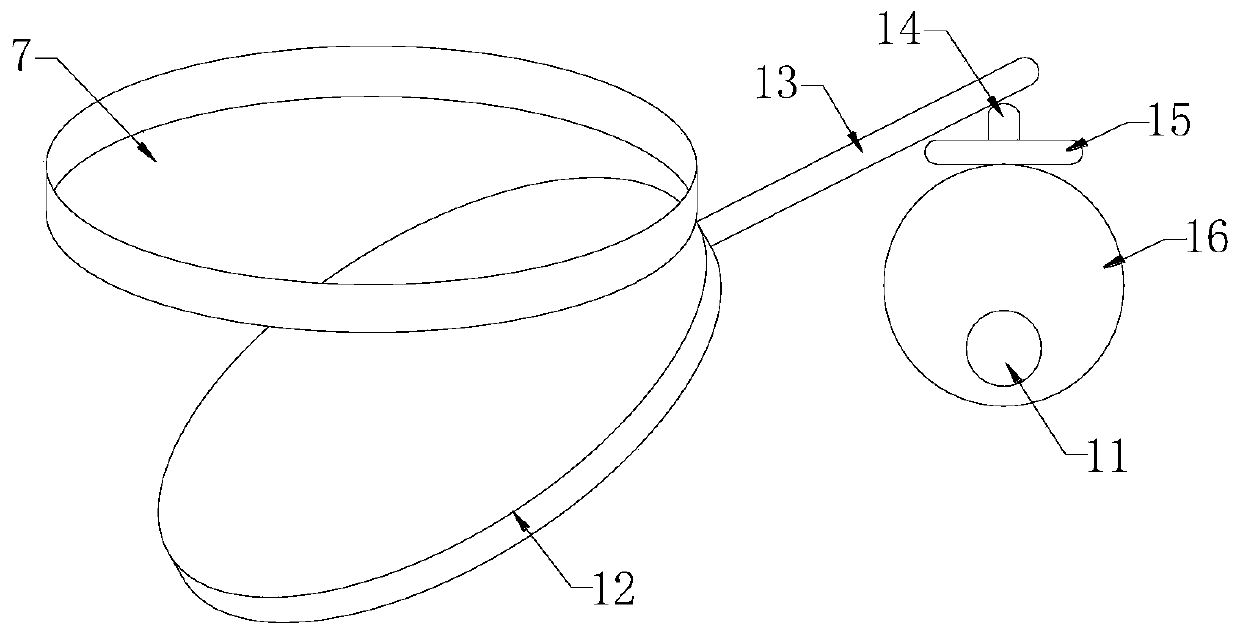

Desulfurization waste water sludge separation and salt separation zero-emission pretreatment system and process

ActiveCN105967389AEmission reductionReduce disposal volumeSludge treatment by de-watering/drying/thickeningWaste water treatment from gaseous effluentsThree levelSludge

The invention discloses a desulfurization waste water sludge separation and salt separation zero-emission pretreatment system and process. The system comprises a raw water pond, a primary reaction clarification system, a secondary reaction clarification system, a tertiary reaction clarification system and a clean water tank, all of which are sequentially connected. The reaction clarification systems each comprise a reaction tank and a clarifier. According to the pretreatment process, desulfurization waste water enters the raw water pond, an aeration fan introduces compressed air into the raw water pond, then the desulfurization waste water is lifted to primary reaction clarification through a raw water pump, through three levels of softening, the clarified desulfurization waste water enters the clean water pond, one part of the water in the clean water pond is supplied to a membrane treatment process system, and the other part of the water in the clean water pond is supplied to an agent adding system. The three-level clarification process is adopted, impurity sludge and industrial grade magnesium hydrate and calcium carbonate are output, sediment is classified, the disposal amount of hazardous waste is reduced, the operating cost of the system is reduced, part of the sediment has additional value, resource comprehensive utilization and waste recycling are achieved, and obvious environmental benefits are achieved.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

Intelligent garbage can

PendingCN111547408AReduce workloadReduce disposal volumeWaste collection and transferRefuse receptaclesGarbage collectionDrive motor

The invention belongs to the technical field of garbage collection, and particularly discloses an intelligent garbage can. The intelligent garbage can comprises a can body, the can body is divided into an upper garbage guide part, a middle garbage classified collection part and a lower equipment installation part, wherein the garbage guide part is suspended above the garbage classified collectionpart, a certain distance is reserved between the garbage guide part and the garbage classified collection part, and a cover door control assembly is mounted in the can body at the distance; and a plurality of garbage containing liners are arranged in the garbage classified collection part and located on a rotating disc, a control assembly and a driving motor are mounted in the equipment installation part, an output end shaft of the driving motor is connected with the rotating disc, the driving motor is electrically connected with the control assembly, and regular rotating movement of the rotating disc is achieved. Compared with the prior art, the garbage can has the advantages that garbage thrown into the garbage can by people can be automatically classified and collected, and the workloadof secondary garbage sorting is reduced.

Owner:ANHUI SCI & TECH UNIV

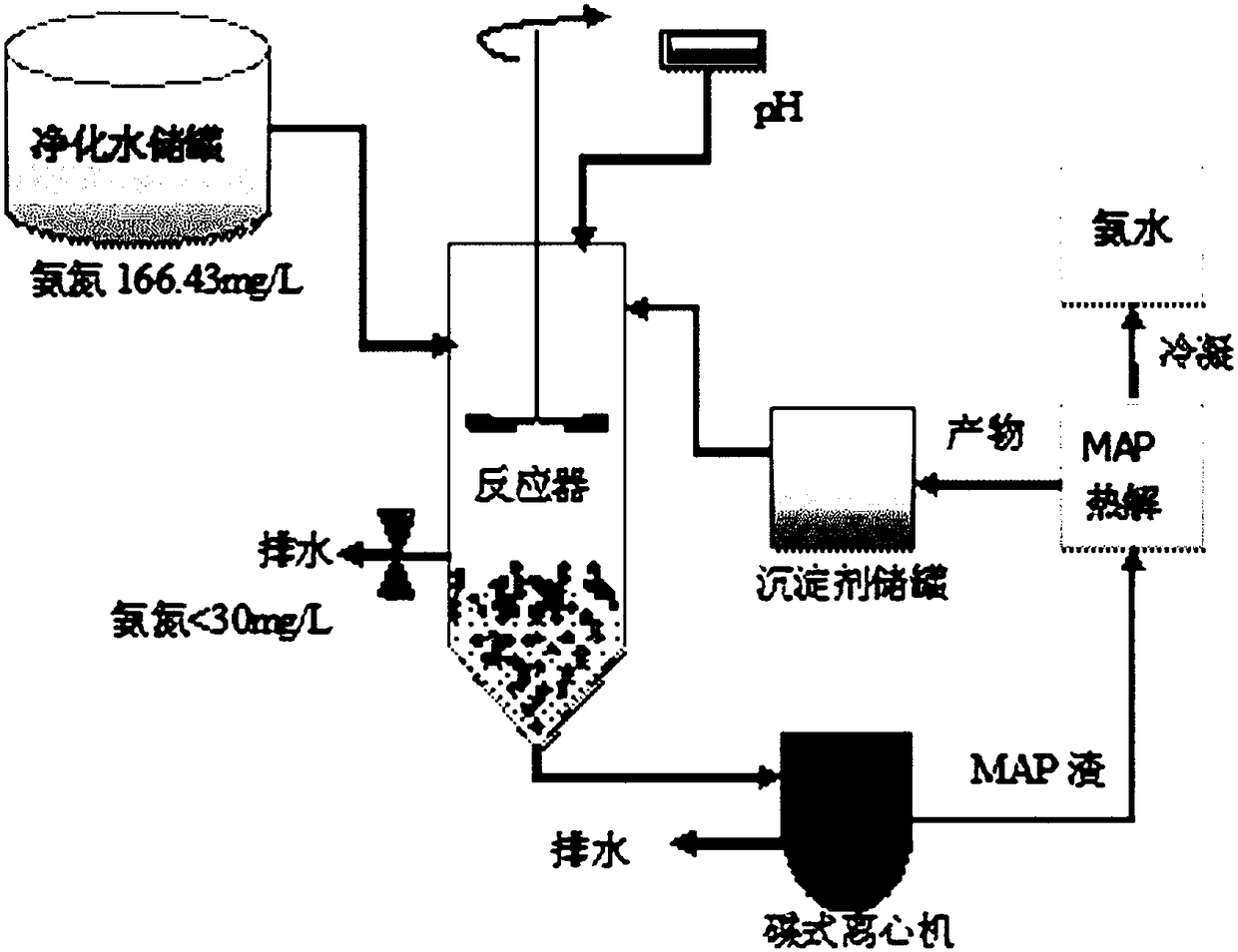

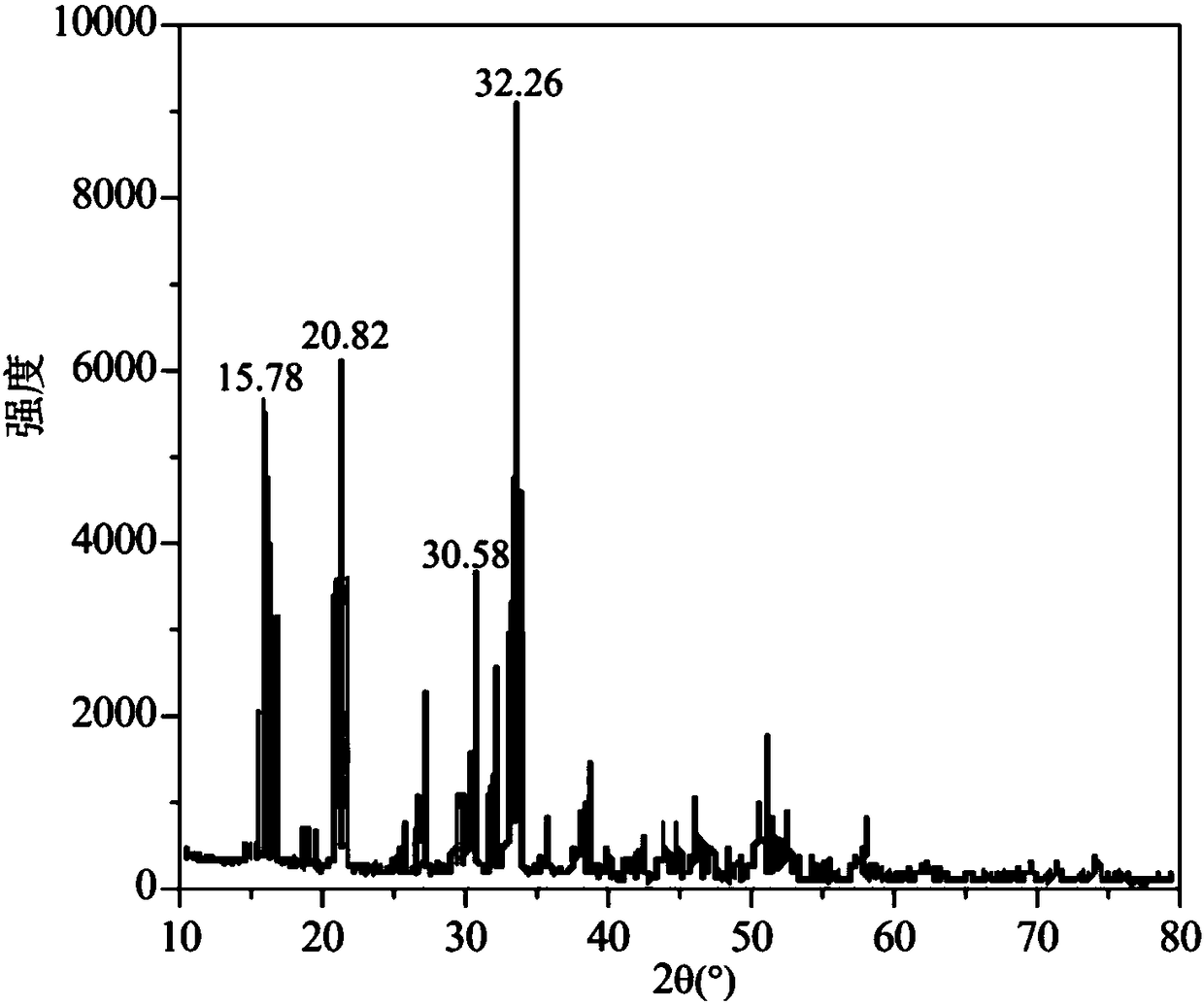

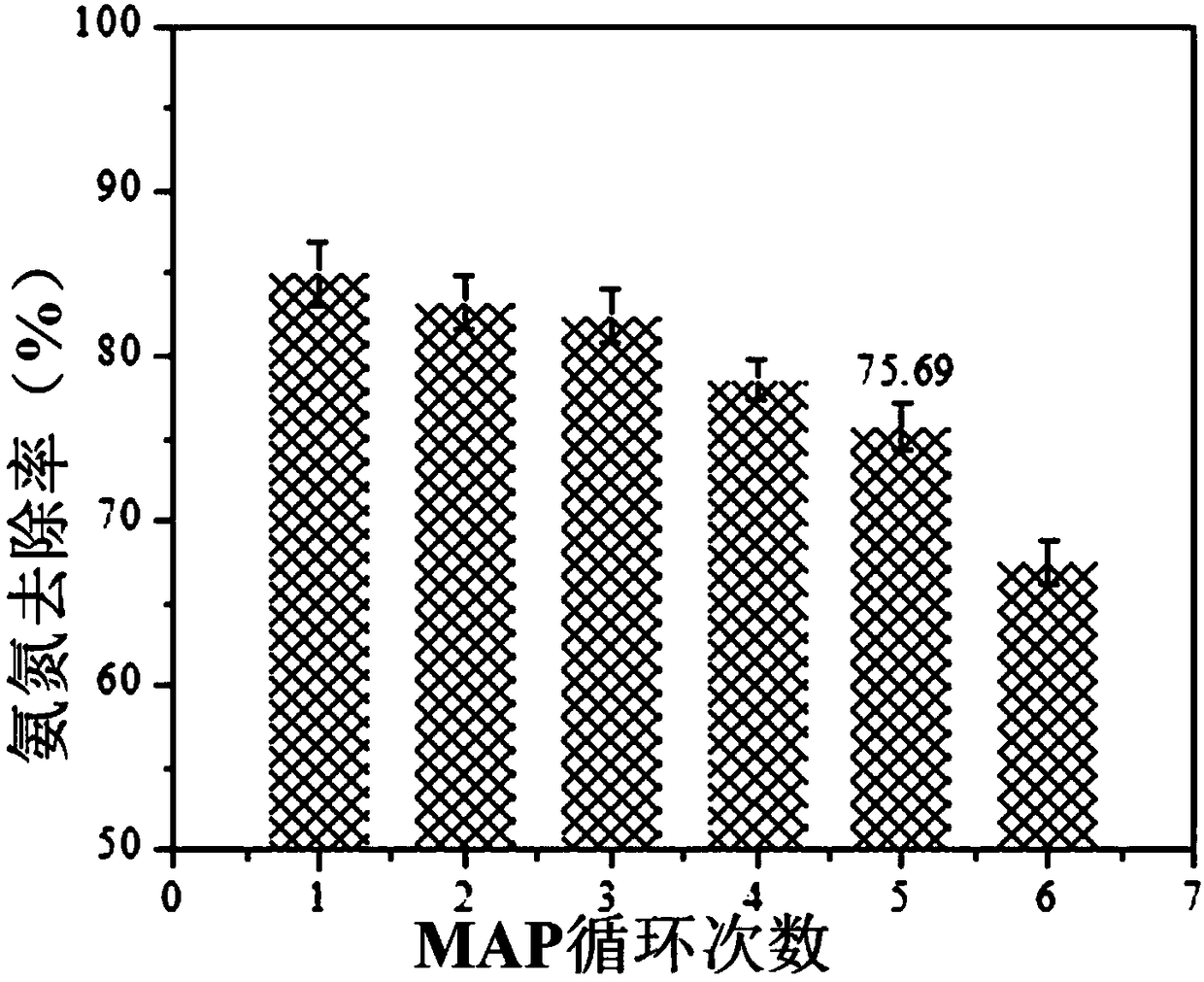

Method for cyclically using magnesium ammonium phosphate to treat ammonia nitrogen pollutants

InactiveCN108191115ASimple processThe effect of sinking ammonia is obviousWater/sewage treatment by centrifugal separationWater contaminantsReduction treatmentMagnesium ammonium phosphate

The invention provides a method for cyclically using magnesium ammonium phosphate to treat ammonia nitrogen pollutants. The method comprises the steps that the pH of water to be treated is regulated to be 8 to 8.5; magnesium chloride and disodium hydrogen phosphate are added; stirring is performed at 20 DEG C to 40 DEG C; centrifugation is performed to obtain magnesium ammonium phosphate precipitates and ammonia nitrogen removed liquid, so that the ammonia nitrogen pollutants in the water to be treated are removed; the ammonia nitrogen removed liquid is centrifuged; the obtained magnesium ammonium phosphate solids are heated and dried; a sodium hydroxide solution is added; pyrolytic reaction is performed to obtain ammonia gas, magnesium chloride and sodium dihydrogen phosphate; ammonia gasis condensed into ammonia water; the magnesium chloride and the sodium dihydrogen phosphate are repeatedly subjected to operations in the first step; the method for cyclically using magnesium ammonium phosphate to treat ammonia nitrogen pollutants is completed. The method for cyclically using the magnesium ammonium phosphate to treat the ammonia nitrogen pollutants has the advantages that the cost is low; the process is simple; the ammonia setting effect is obvious; the method is suitable for the emission reduction treatment on nitrogen pollutants of point source high-ammonia nitrogen steam stripping purified water of refinery enterprises from the source head.

Owner:PETROCHINA CO LTD +1

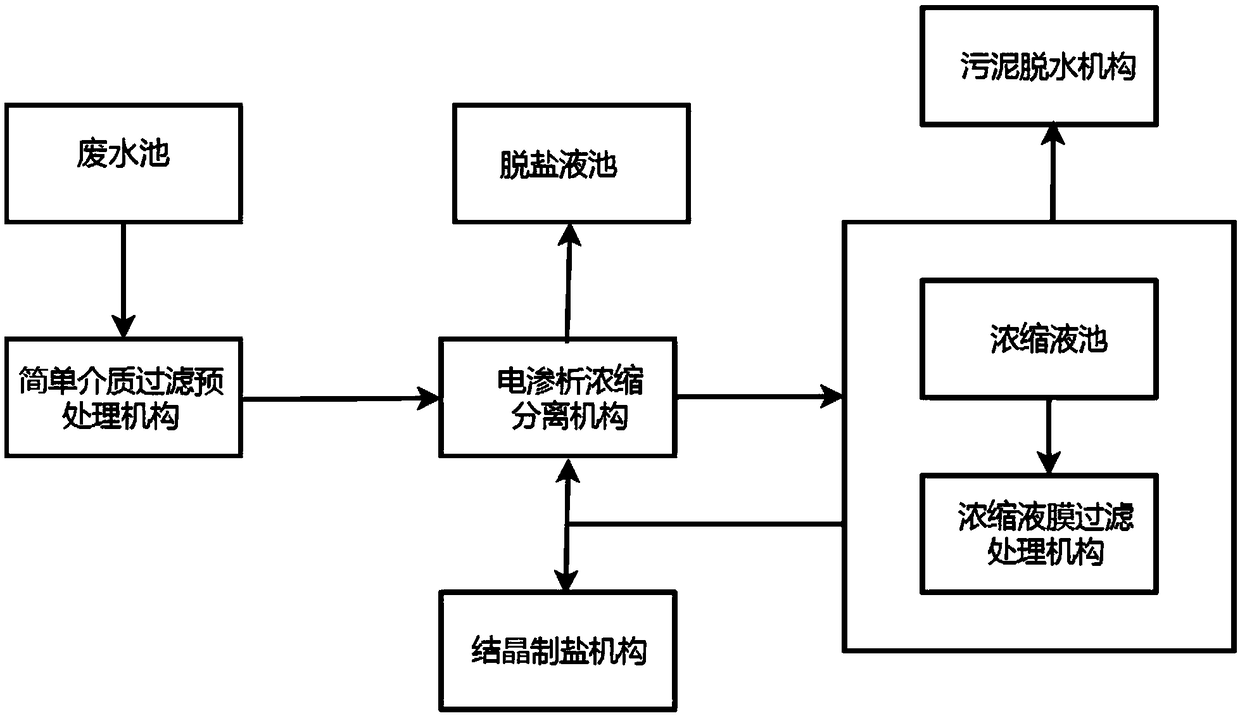

System and method for electrodialysis concentration of high-salt industrial wastewater without adding of chemicals for softening pretreatment

InactiveCN109205866AShort processReduce disposal volumeTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisWater trapIon

The invention discloses a system and method for electrodialysis concentration of high-salt industrial wastewater without adding of chemicals for softening pretreatment, and the system comprises a wastewater tank, a simple medium filtration pretreatment mechanism, an electrodialysis concentration separation mechanism, a desalting liquid pool, a concentrate liquid pool, a concentrated liquid membrane filtration treatment mechanism, a sludge dewatering mechanism, and a crystallization salt making mechanism, wherein the concentrated liquid membrane filtration treatment mechanism is provided with asubmerged membrane filtration device, a produced water first outlet of the submerged membrane filtration device is in connection with the electrodialysis concentration separation mechanism to form acirculation, a produced water second outlet is connected to the crystal salt making mechanism, and an outlet of concentrated water trapped by the submerged membrane filtration device is connected to the sludge dewatering mechanism. The whole process shortens the process, and does not need to add the chemicals for softening and removing hardness ions such as calcium and magnesium before the high-salt industrial wastewater enters the electrodialysis concentration separation mechanism, reduces the production amount and the discharge amount of inorganic precipitated sludge, and reduces investmentand operating cost of the whole system.

Owner:杭州匠容道环境科技有限公司

Precipitation water treatment method

InactiveCN106745594APromote growthNot brokenSettling tanks feed/dischargeCentrifugal force sediment separationWater sourceSludge

The invention discloses a precipitation water treatment method. The method involves a folded plate eddy current synergistic flocculation unit, an inclined pipe precipitation unit, a sludge backflow and discharge unit and a dredge pipe backwash unit, wherein the folded plate eddy current synergistic flocculation unit is composed of four folded plate eddy current reaction chambers, raw water enters an water inlet pipe, passes through a pipeline mixer, and orderly passes through the four folded plate eddy current reaction chambers via a pipe mixer, and then enters the inclined pipe precipitation unit after passing through a transition area; same-wave folded plates, opposite folded plates and eddy current reactors in different models are arranged in the four folded plate eddy current reaction chambers, and a sludge backflow, discharge and backwash device unit is arranged at the bottom of each of the four folded plate eddy current reaction chambers. By use of the method disclosed by the invention, the efficiency of the flocculation reaction is improved, the effects of improving the water purification amount and the water quality are obvious, and the clarifying efficiency and the precipitation effect are guaranteed at the same time, water sources and the coagulation reagent quantity are effectively saved, and the high social and beneficial benefit are realized.

Owner:EAST CHINA JIAOTONG UNIVERSITY

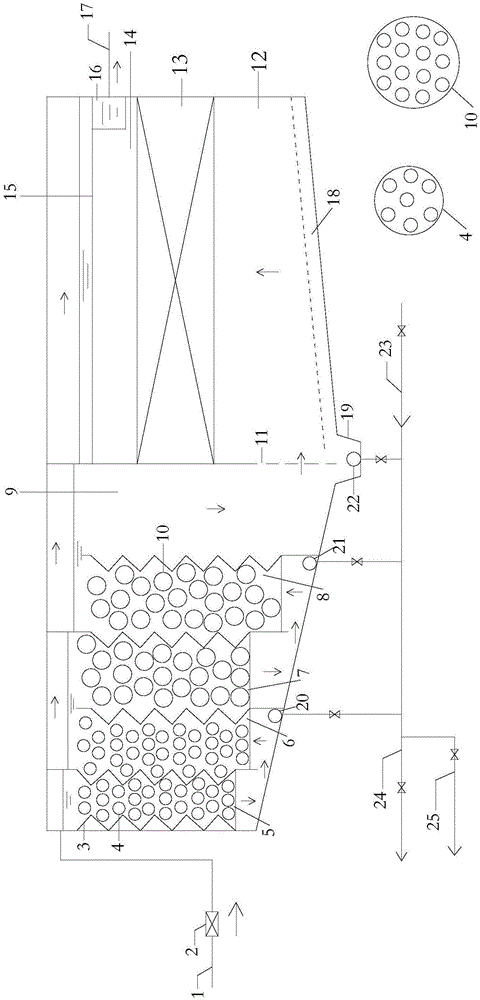

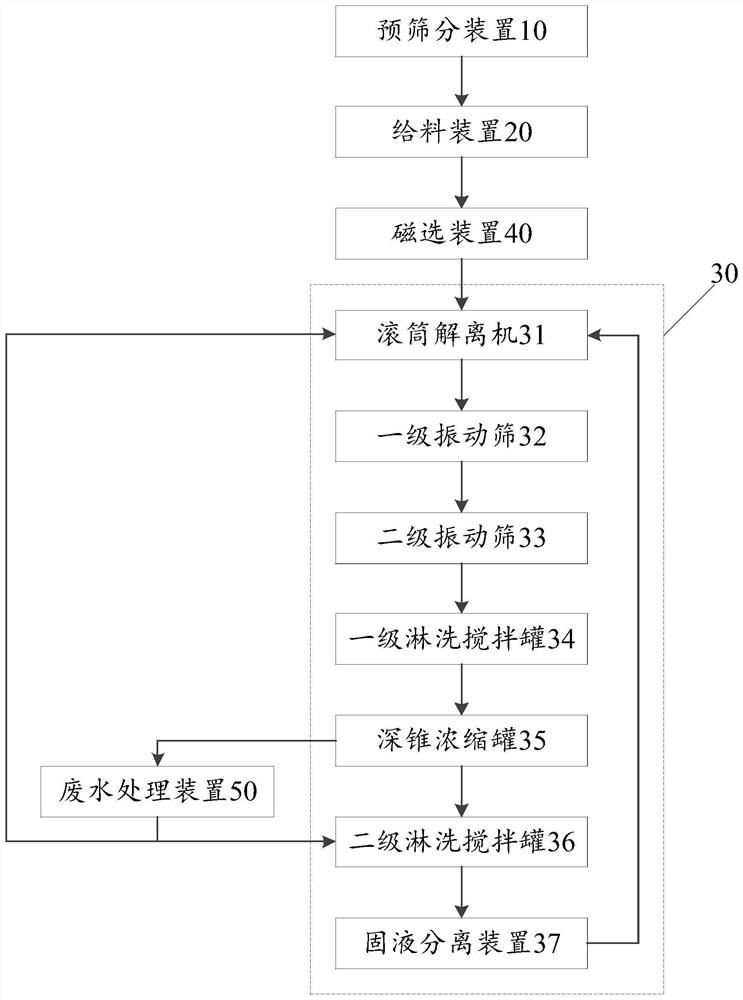

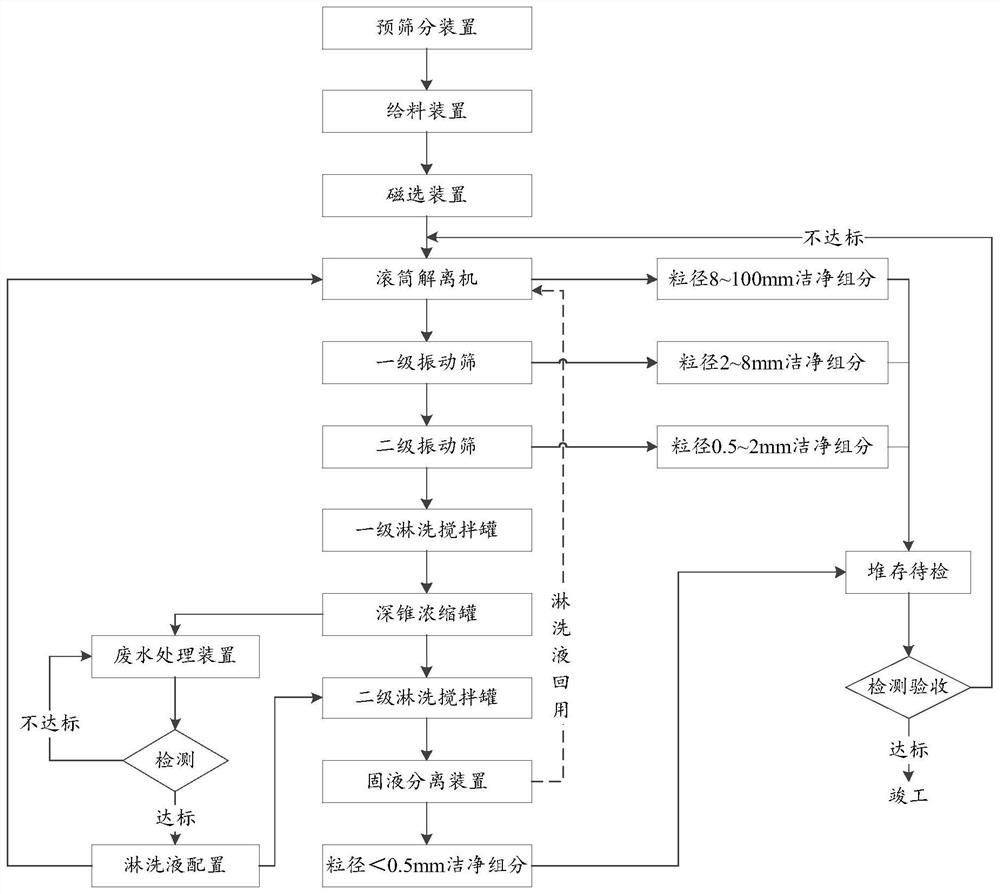

Contaminated soil leaching treatment system and method

InactiveCN112317524AReduce disposal volumeAchieve recyclingSievingGas current separationSolid componentSoil science

The invention discloses a contaminated soil leaching treatment system and method, wherein the system comprises a pre-screening device, a feeding device and leaching main body equipment; the pre-screening device is used for carrying out pre-screening treatment of contaminated soil, and screening out large-particle-size components; the feeding device is used for feeding the pre-screened contaminatedsoil into the leaching main body equipment; the leaching main body equipment is used for carrying out multi-stage leaching and screening on the contaminated soil, screened multi-stage clean solid components are piled up to be detected, and the screened small-particle-size components are subjected to primary leaching and primary solid-liquid separation; an upper-layer liquid subjected to primary separation is sent into a wastewater treatment device, and lower-layer slurry is subjected to secondary leaching and secondary solid-liquid separation; the liquid subjected to secondary separation returns to a multi-stage leaching and screening system, and the separated small-particle-size clean solid components are stacked for detection. While the solid-to-liquid ratio is guaranteed, most of waterin the equipment can be recycled, and the water consumption and the wastewater disposal amount are reduced; the system can realize parallel multistage treatment, reduce the residence time of pollutedsoil in single equipment, and improve the treatment efficiency of the system.

Owner:BEIJING GEOENVIRON ENG & TECH +1

Reduction treatment device and method for epoxy resin wastewater evaporative desalination mother liquor

InactiveCN105712580AAvoid secondary pollutionEmission reductionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationEpoxy

The invention provides a reduction treatment device for epoxy resin wastewater evaporative desalination mother liquor. The treatment device is composed of a pretreatment device, a high-salinity yeast treatment device and a high-salinity biochemical treatment device. The invention further discloses a treatment device. The epoxy resin wastewater evaporative desalination mother liquor is firstly subjected to pH, water quality and water amount adjustment through the pretreatment device, and the biochemistry of the mother liquor is improved; then high-concentration organic matter is subjected to efficient biodegradation through the yeast treatment device; then the organic matter is further degraded through the high-salinity biochemical treatment device. By means of the device and method, the COD reduction rate of the epoxy resin wastewater evaporative desalination mother liquor can reach 90% or above, and the treated mother liquor can be subjected to evaporative crystallization desalination again, so that the epoxy resin wastewater evaporative desalination mother liquor is greatly reduced, and a large amount of treatment and disposal cost of the desalination mother liquor is reduced for enterprises.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

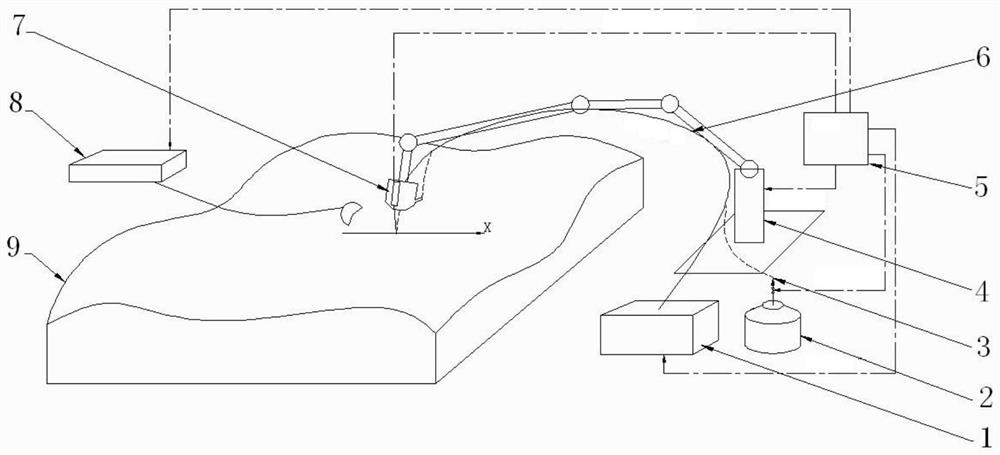

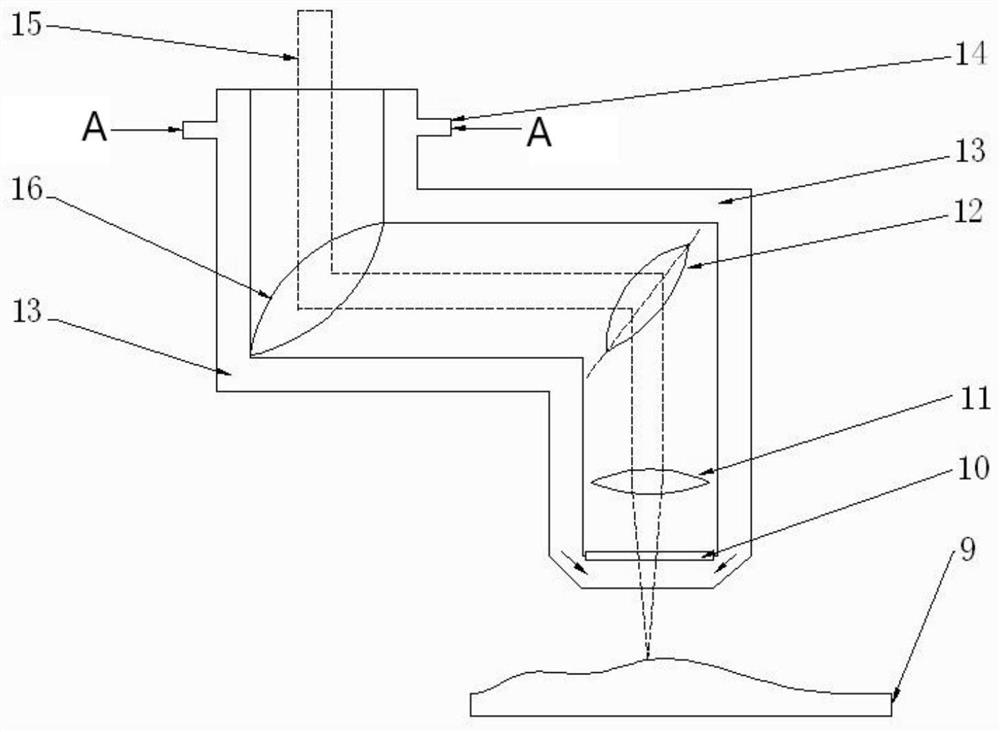

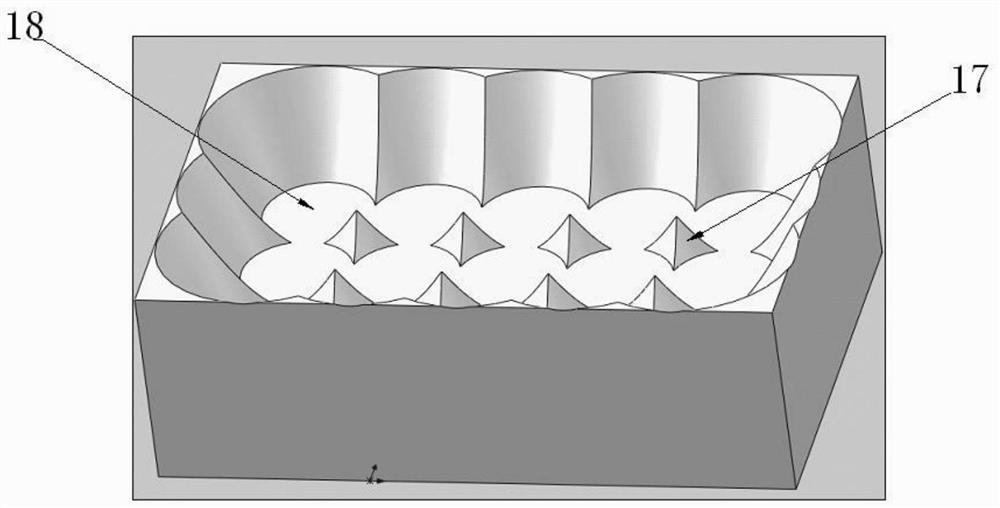

Efficient laser decontamination system and method for radioactive metal surface

ActiveCN112536292ASolve difficultyAvoid depositionNuclear energy generationRadioactive decontaminationNuclear engineeringRadiation resistance

The invention discloses an efficient laser decontamination system and method for a radioactive metal surface. The efficient laser decontamination system comprises a laser head and a movement mechanism. The laser head is installed at the operation end of the movement mechanism, and the movement mechanism drives the laser head to do three-dimensional movement in an operation area. The outer wall ofthe laser head is further wrapped with a shell cover, a cooling loop is arranged in the shell cover, or a cavity between the inner wall of the shell cover and the outer wall of the laser head serves as the cooling loop. The cooling loop is further provided with a gas inlet, and a cooling gas outlet in the cooling loop is located on an output port of an output shaft. After entering the cooling loopfrom the gas inlet, cooling gas is discharged from the cooling gas outlet and sprayed to the surface of a decontamination object, and a gas pressure flow field is formed by the cooling gas and a negative pressure treatment device; and the cooling gas flow carries removed secondary waste to enter the negative pressure treatment device. By means of the efficient laser decontamination system and method, loose contamination, oxide layer and metal base material shallow surface layer stripping of the radioactive metal surface can be achieved at the same time, and the radiation resistance of the laser decontamination head is high.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

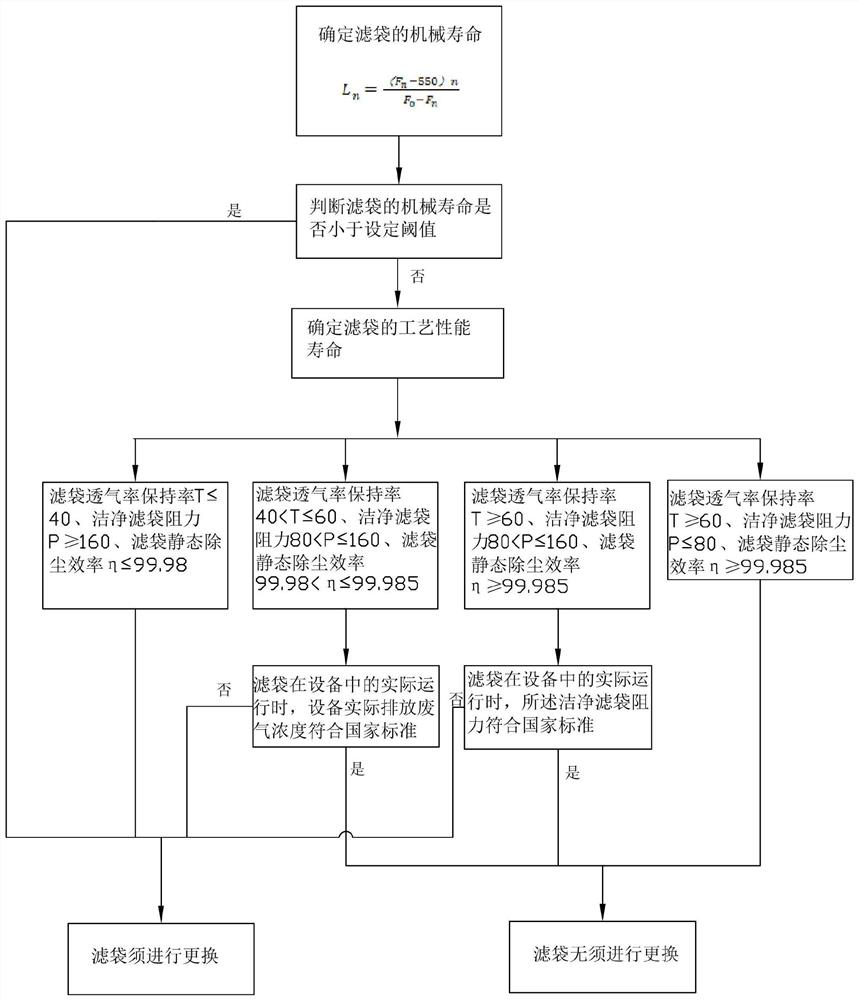

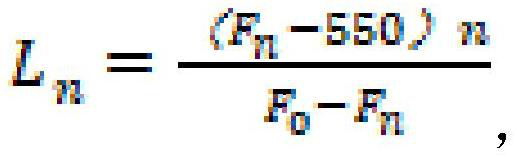

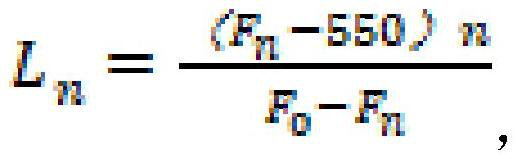

Method for evaluating comprehensive life of filter bag

PendingCN114705601AExtend your lifeControl consumptionMachine part testingPermeability/surface area analysisDust controlProcess engineering

The invention relates to a method for evaluating the comprehensive life of a filter bag, which comprises the following steps of: 1, determining the mechanical life of the filter bag, judging whether the mechanical life of the filter bag is less than a set threshold value or not, judging that the filter bag needs to be replaced if the mechanical life is less than the set threshold value, and carrying out a second step if the mechanical life is not less than the set threshold value; and 2, determining the processing property service life of the filter bag, and judging whether the filter bag needs to be replaced or not from the three aspects of filter bag air permeability retention rate, filter bag cleaning resistance and filter bag static dust removal efficiency. According to the filter bag comprehensive life evaluation method provided in the technical scheme, the mechanical life of the filter bag is evaluated firstly, if the residual mechanical life of the filter bag does not meet the requirement, filter bag processing property life evaluation does not need to be carried out, and the detection steps, time and cost are reduced; the service life of the process performance of the filter bag is judged from the three aspects of the air permeability retention rate of the filter bag, the clean filter bag resistance and the static dust removal efficiency of the filter bag, so that the performance of the filter bag is more comprehensively and effectively ensured to meet the design requirement of smoke control.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

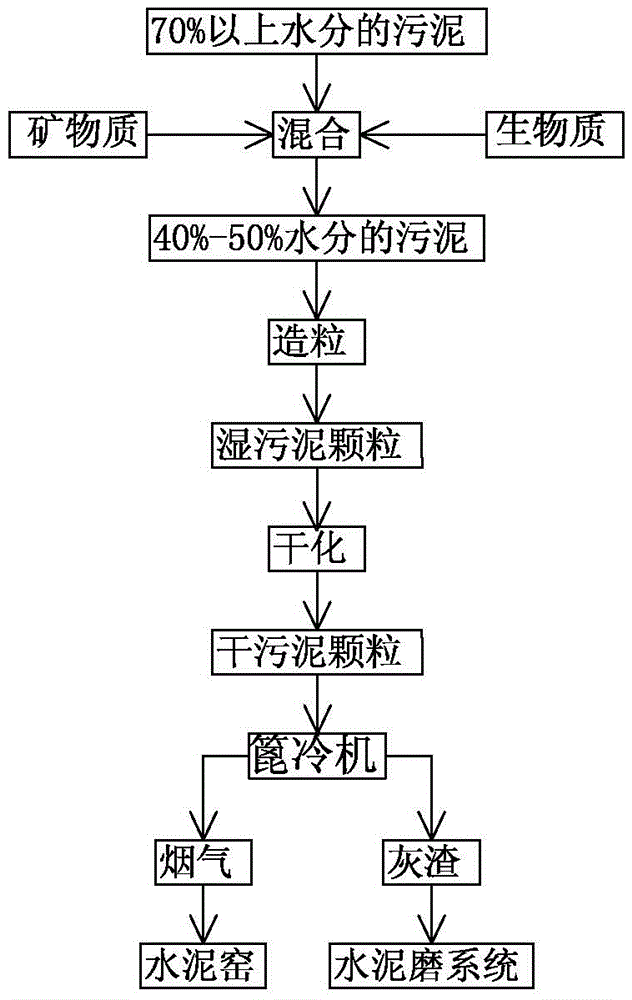

Method for treating sludge with cement kiln and cement kiln system for treating sludge with grate cooler

ActiveCN104478243BLarge amount of disposalSize DisposalCement productionIncinerator apparatusCombustionSludge

The invention discloses a method for treating sludge by a cement kiln and a cement kiln system for treating sludge by a grate cooler. The method comprises the steps: preparing dry sludge particles through wet sludge; heating the dry sludge particles through high temperature clinkers discharged from the cement kiln to prompt the combustion of the dry sludge particles; then feeding smoke into a third air system of the cement kiln; and feeding the combusted sludge particles and heated clinker into a cement grinding mill system. The cement kiln system comprises the cement kiln, and the grate cooler which communicates with the cement kiln through a head cover; the head cover communicates with the cement kiln through a third air pipeline; and a sludge feeding opening is formed in the head cover and communicates with a dry sludge particle storage through a dry sludge particle conveying device. With the adoption of the method and cement kiln system, the sludge can be treated massively, and the daily treatment capacity reaches 200t / d.

Owner:BBMG CORP +2

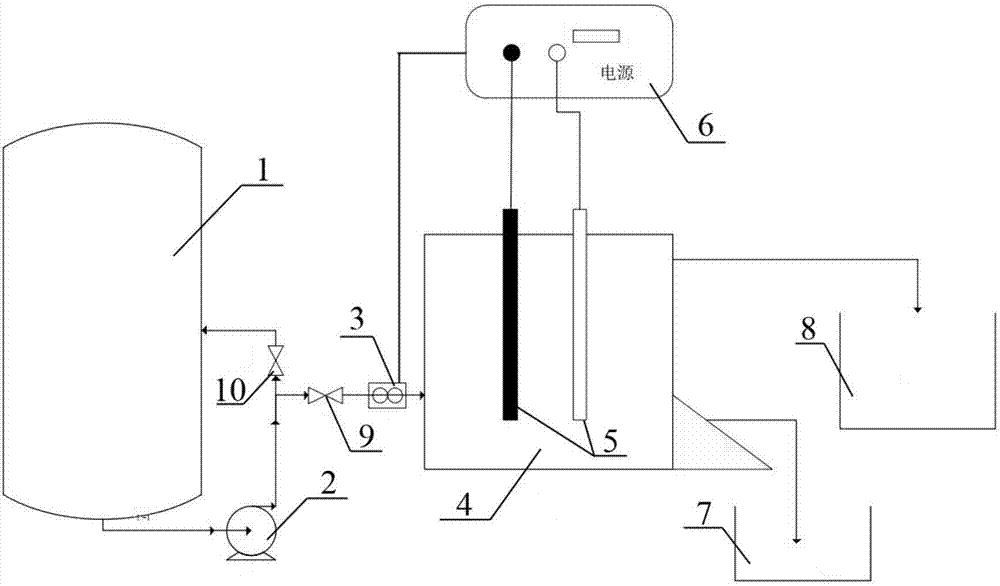

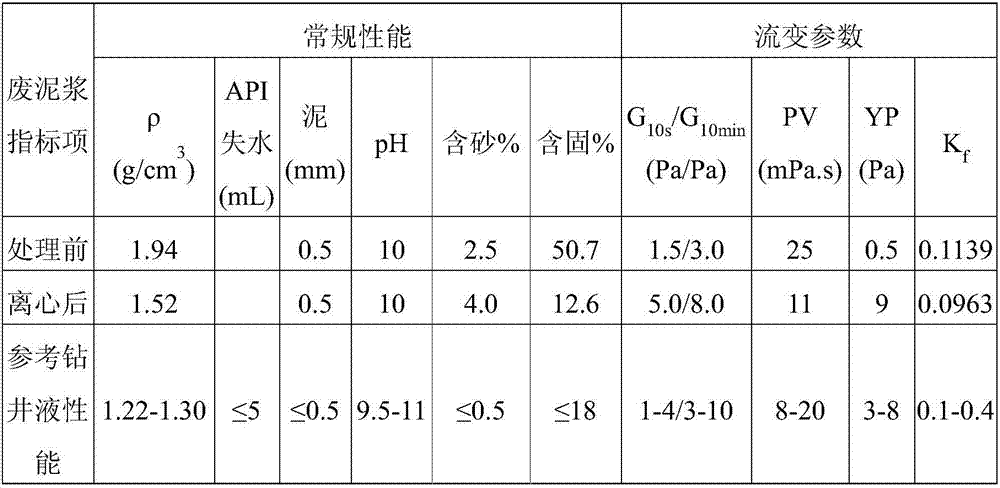

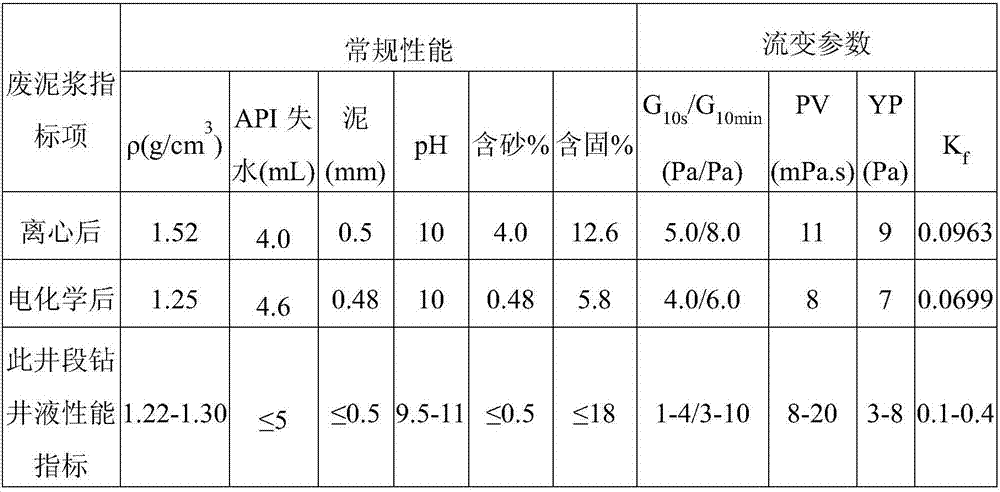

Electrochemical adsorption treatment device and process for water-based waste drilling fluid

ActiveCN107445258AAchieve removalImprove performanceWaste water treatment from quariesDispersed particle separationChemical treatmentWater based

The invention provides an electrochemical adsorption treatment device and process for water-based waste drilling fluid. The electrochemical adsorption treatment device for the water-based waste drilling fluid comprises a mud tank, a mud pump, a flow meter, an electrolytic bath, an electrode and an automatic control system, wherein the mud tank is circularly communicated with the mud pump; the mud pump is communicated with the flow meter; the mud tank is communicated with the flow meter; the flow meter is communicated with the electrolytic bath; the electrode comprise an anode and a cathode; the electrode is arranged in the electrolytic bath; the automatic control system is electrically connected with the electrode; the automatic control system is electrically connected with the flow meter. According to the electrochemical adsorption treatment device and process for the water-based waste drilling fluid, which are provided by the invention, a chemical treating agent is not added; an effective component in drilling fluid is not destroyed; inferior solid phases of a superfine micro-particle and the like in waste drilling fluid can be effectively removed; thus, main performance indexes of the density, the silt content, the solid content and the like of the waste drilling fluid are decreased; the rheological characteristic of the waste drilling fluid is improved, and the recycling performance index requirement of waste-based drilling fluid is met.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

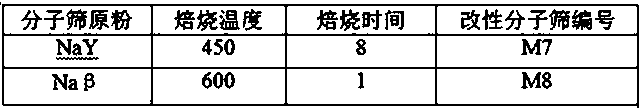

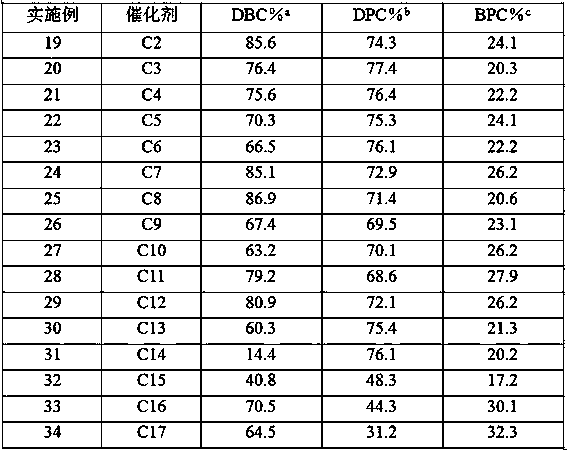

Catalyst for synthesizing diphenyl carbonate, preparation method thereof and process

ActiveCN111389452AImprove balance conversionImprove economyMolecular sieve catalystsOrganic compound preparationMolecular sievePtru catalyst

The invention discloses a catalyst for synthesizing diphenyl carbonate. The catalyst comprises a molecular sieve and a loaded active component, the molecular sieve is an alkali metal modified microporous molecular sieve, and the active component is binary mixed metal oxide AO / B<c>O<d>, wherein A is selected from Sn, Ga or Zn, B is selected from Zr, Cr or La, and a, b, c and d are stoichiometric numbers. Due to the addition of a lithium additive, the energy barrier in the side reaction process is remarkably improved, and the reaction speed of the side reaction is reduced. The tin oxide and other active components obviously lower the energy barrier in the main reaction process, and enhance the reaction speed of the main reaction. The catalyst provided by the invention has very high catalytic activity, effectively realizes diphenyl carbonate synthesis reaction, inhibits the occurrence of ether side reaction, and reduces the energy consumption of the production process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of butynedioic acid

ActiveCN111377812ANo apparent environmental hazardReduce disposal volumePreparation from carboxylic acid saltsOrganic compound preparationPtru catalystPhysical chemistry

The invention discloses a preparation method of butynedioic acid. The method comprises the following steps of: (1) firstly, carrying out water-free and oxygen-free treatment on a closed reaction kettle; (2) putting calcium carbide, a solvent, a catalyst and an auxiliary agent into the reaction kettle, introducing carbon dioxide into the reaction kettle, and heating and pressurizing for reaction; (3) separating the reacted mixture obtained in the step (2) to obtain a liquid mixture, and adding a KOH solution into the liquid mixture; stirring to separate out a white precipitate; and dissolving the white precipitate in hot water, acidifying with concentrated sulfuric acid, cooling, separating out the white precipitate, and filtering to obtain the product. The synthesis method disclosed by theinvention is relatively environment-friendly and low in production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com