Efficient laser decontamination system and method for radioactive metal surface

A metal surface and decontamination system technology, applied in the direction of radioactive purification, cleaning methods and appliances, chemical instruments and methods, etc., to achieve the effects of avoiding escape, improving radiation resistance, and avoiding deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

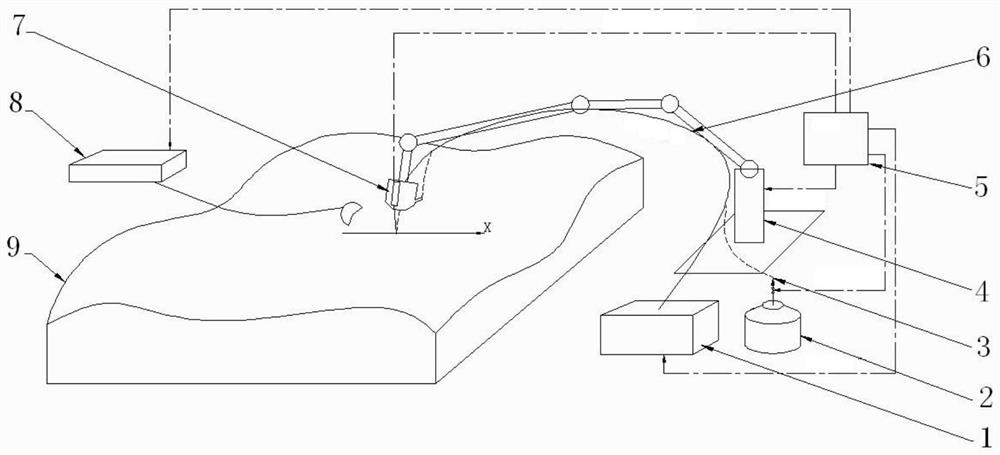

[0052] This embodiment provides a laser decontamination system for radioactive metal surfaces, including a laser head 7 and a motion mechanism 4. The motion mechanism 4 is a three-dimensional motion mechanism. Specifically, industrial robots, mechanical arms, multi-axis machine tools and other high-precision three-dimensional movement structure. The laser head 7 is installed on the operation end of the motion mechanism 4, and the motion mechanism 4 drives the laser head 7 to move in the operation area.

[0053] The outer wall of laser head 7 is also covered with shell cover, and the chamber between shell cover inner wall and laser head 7 outer walls is as cooling circuit 13; Cooling circuit 13 is also provided with air inlet 14, and the cooling air outlet in cooling circuit 13 Located at the output port of the output shaft. Also includes a negative pressure treatment device 8; after the cooling gas enters the cooling circuit 13 from the air inlet 14, it is discharged from the...

Embodiment 2

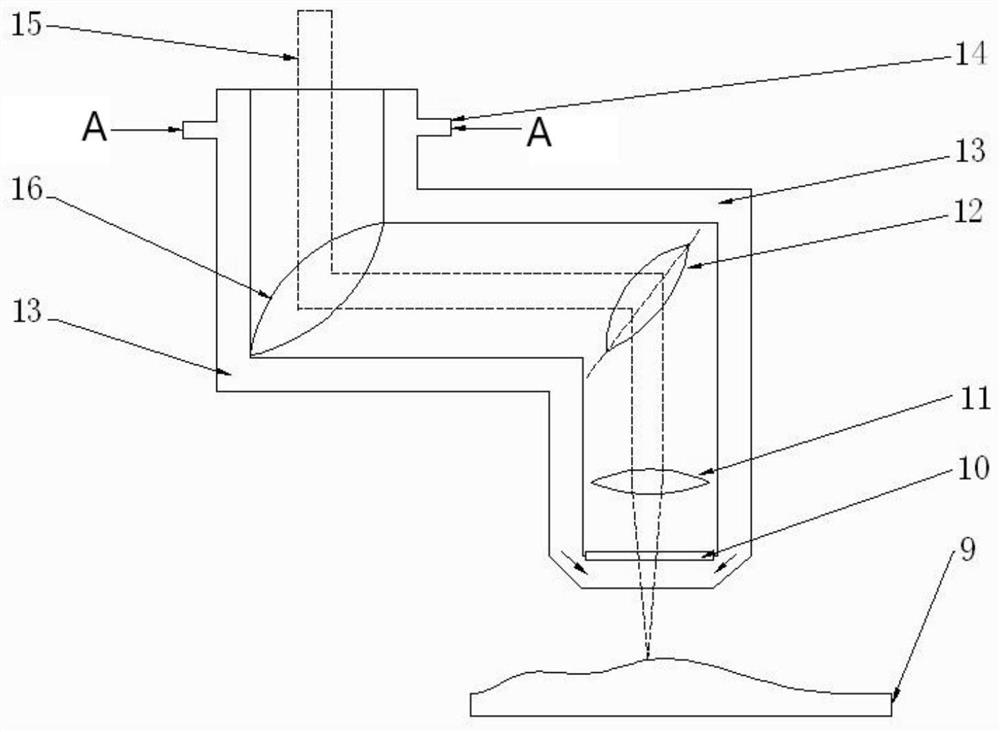

[0056] Further improvement on the basis of Embodiment 1, the laser head 7 is designed as a paraxial structure, specifically the laser head includes an input shaft and an output shaft, the output shaft is located next to the input shaft, and the axes of the output shaft and the input shaft are parallel; The input shaft and the output shaft are connected by the transmission shaft, and the axis of the transmission shaft is perpendicular to the axes of the input shaft and the output shaft; one axial end of the input shaft is used as the input port of the laser input laser head 7, and the other axial end of the input shaft is connected to the laser head 7. One end of the transmission shaft is connected, the other end of the transmission shaft is connected with one end of the output shaft, and the other end of the output shaft is used as the output port of the laser output laser head 7 . A deflection lens 16 is provided inside the connecting part of the input shaft and the transmissi...

Embodiment 3

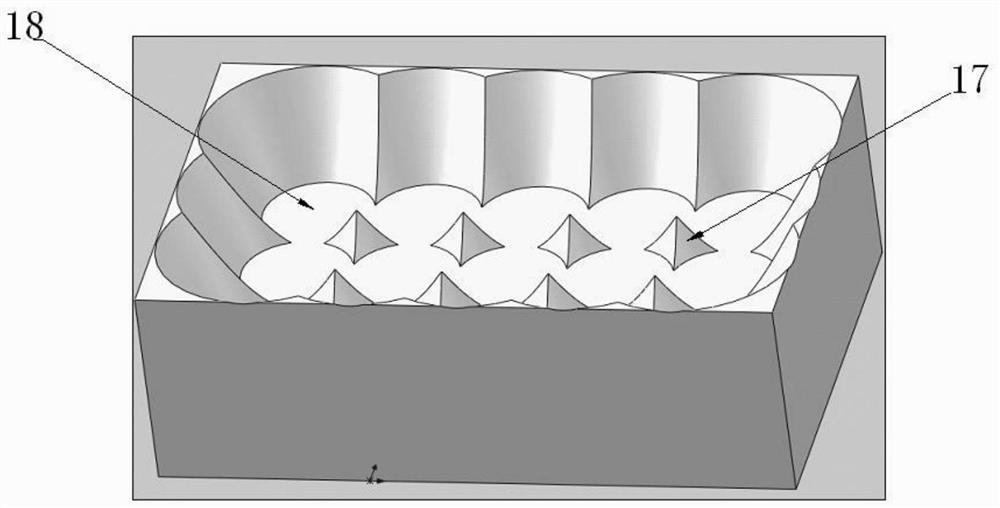

[0059] This embodiment provides a method for highly efficient laser decontamination of radioactive metal surfaces, using a laser decontamination system for radioactive metal surfaces provided in Embodiment 2; including the following steps: using the laser head 7 to perform point-by-point decontamination on the surface of the decontamination object 9 For scanning and decontamination, the optimal design adopts three laser heads 7 to operate simultaneously; the three laser heads 7 are arranged to operate in a character shape, and the circular light spots formed by the three laser heads 7 on the surface of the decontamination object 9 are circumscribed in pairs, each A circular light spot forms a decontamination cone 18 on the surface of the decontamination object 9 .

[0060] The process of laser decontamination using a laser decontamination system for radioactive metal surfaces provided in Embodiment 2 is as follows: The laser beam generated by the laser 1 is transmitted to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com