Desulfurization waste water sludge separation and salt separation zero-emission pretreatment system and process

A technology of desulfurization wastewater and zero discharge, which is applied in dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, gaseous effluent wastewater treatment, etc., to achieve waste resource utilization, system operation stability enhancement, The effect of reducing disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

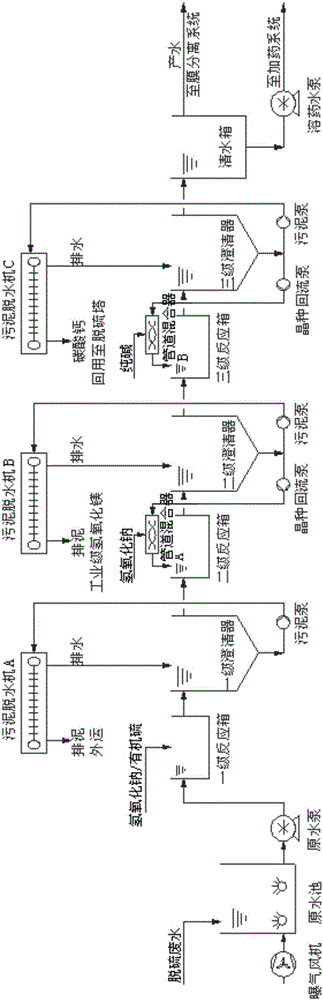

[0030] Such as figure 1 The desulfurization waste water sludge separation and salt zero discharge pretreatment system shown includes a raw water tank, a primary reaction clarification system, a secondary reaction clarification system, a tertiary reaction clarification system, and a clean water tank. The primary reaction clarification system It includes a primary reaction box and a primary clarifier, the secondary reaction clarification system includes a secondary reaction box and a secondary clarifier, and the tertiary reaction clarification system includes a tertiary reaction box and a tertiary clarifier; the original The pool is connected to the primary reaction tank through the raw water pump, the raw water pool is also connected to an aeration fan, the primary reaction tank is also connected to a primary clarifier, and the upper part of the primary clarifier is connected to a secondary reaction tank , the bottom of the first-stage clarifier is connected to a sludge dehydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com