Method for treating sludge with cement kiln and cement kiln system for treating sludge with grate cooler

A cement kiln and grate cooler technology, applied in the cement kiln system field, can solve the problems of high energy consumption, sludge agglomeration and uneven distribution, and small disposal scale, and achieve large processing capacity, simplified transportation process, and sewage The effect of small amount of sludge disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

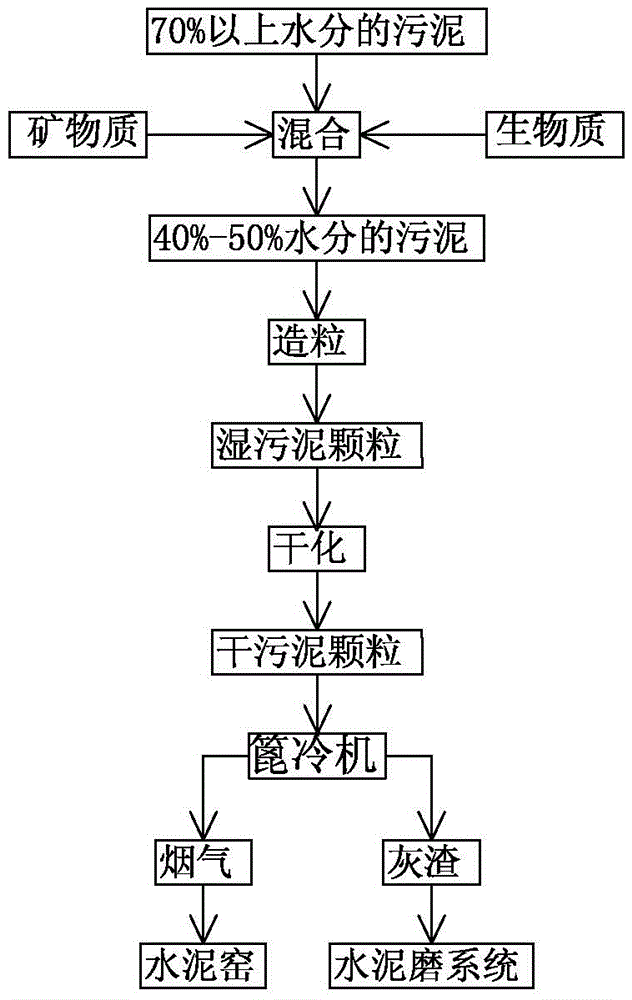

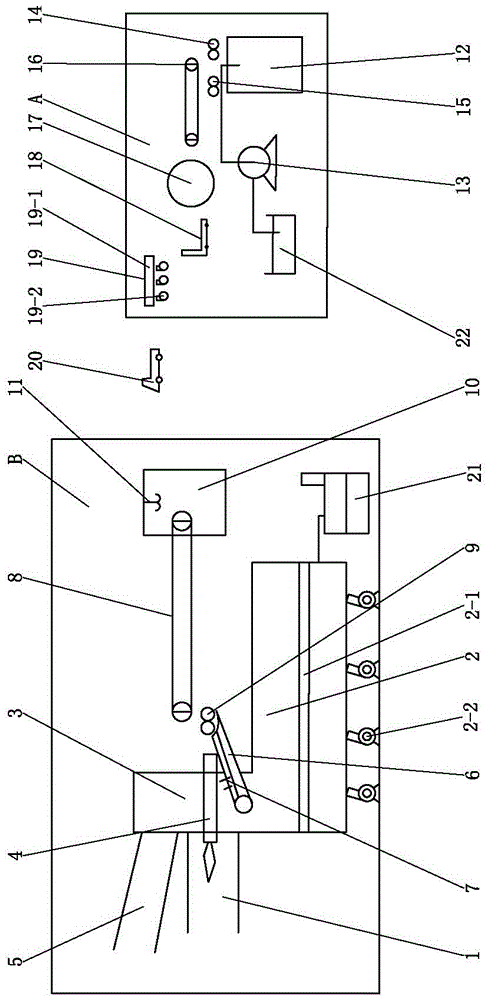

[0032] Such as Figure 1 to Figure 2 As shown, the method of using cement kiln to dispose of sludge in this embodiment is to first make wet sludge into dry sludge particles, then heat the dry sludge particles through high-temperature clinker calcined from cement kiln 1, and pass through The clinker is exposed to high-temperature air to burn the dry sludge particles. Finally, the flue gas is sent to the tertiary air system of the cement kiln, and the burned sludge particles and exothermic clinker are sent to the cement mill system.

[0033] In this embodiment, the wet sludge is first made into dry sludge particles, and then the dry sludge particles are sent to the grate cooler of the cement kiln, and then contacted with the discharged high-temperature air to burn the dry sludge particles, and finally , the technical means of sending the flue gas into the tertiary air system of the cement kiln, and sending the burned sludge particles and exothermic clinker into the cement mill s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com