Electric intelligentized sand-stone separator

A sand and gravel separator and a separator technology are applied in the field of sand and gravel separators, which can solve the problems of inability to meet the production requirements of a ready-mixed mortar production base, a small amount of treatment, and a low level of automation, and achieve the ability to handle large amounts, strong, Guarantee the quality of aggregate and the effect of large amount of disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

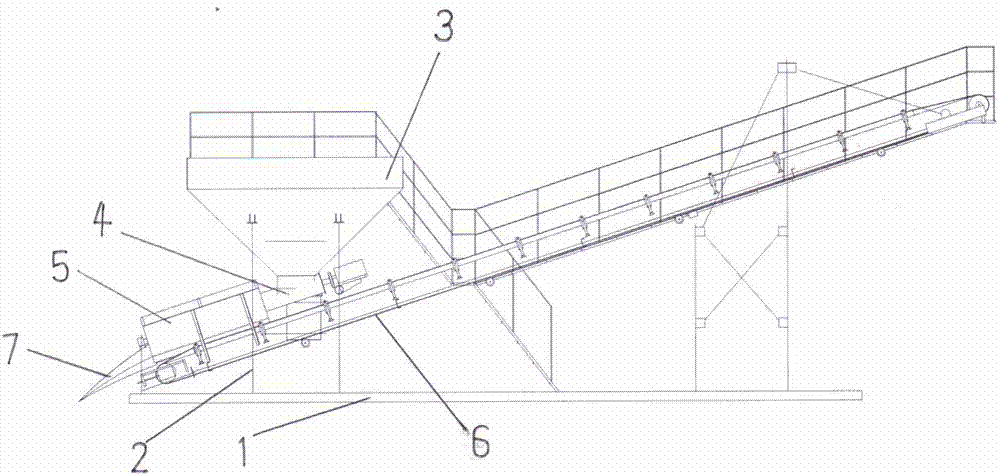

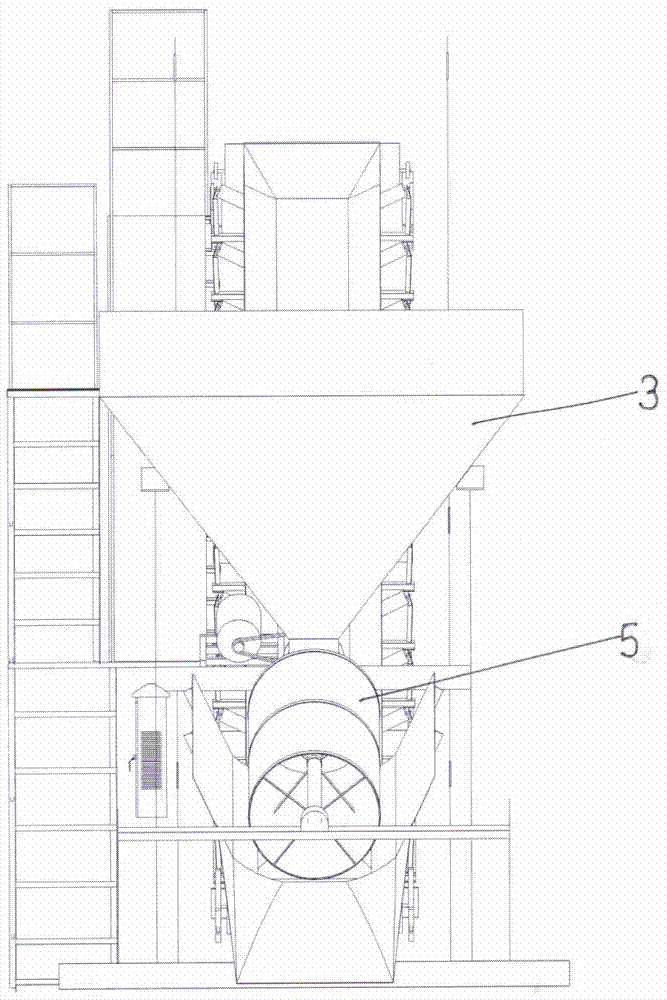

[0016] An electric intelligent sand and gravel separator, including a movable base 1, a bracket 2 mounted on the movable base, an aggregate collection bin 3 mounted on the bracket, the outlet of the aggregate collection bin communicates with the inlet of the aggregate separator 4 below , the aggregate separator is in the form of using spiral blades to stir and propel the materials. The outlet of the aggregate separator is connected to the barrel filter 5, and the conveyor belt 6 is set under the filter of the barrel filter, and the rear end of the barrel filter is Set the discharge plate 7;

[0017] A backhoe excavator or a belt conveyor is used to transport the aggregates to the aggregate collection bin. The lower part of the aggregate collection bin is an aggregate separator. The spiral blades are fully stirred to increase the void ratio of the aggregate. After the aggregate is stirred, the aggregate is evenly spread on the barrel filter of the aggregate separator; the barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com