Patents

Literature

50results about How to "Improve balance conversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

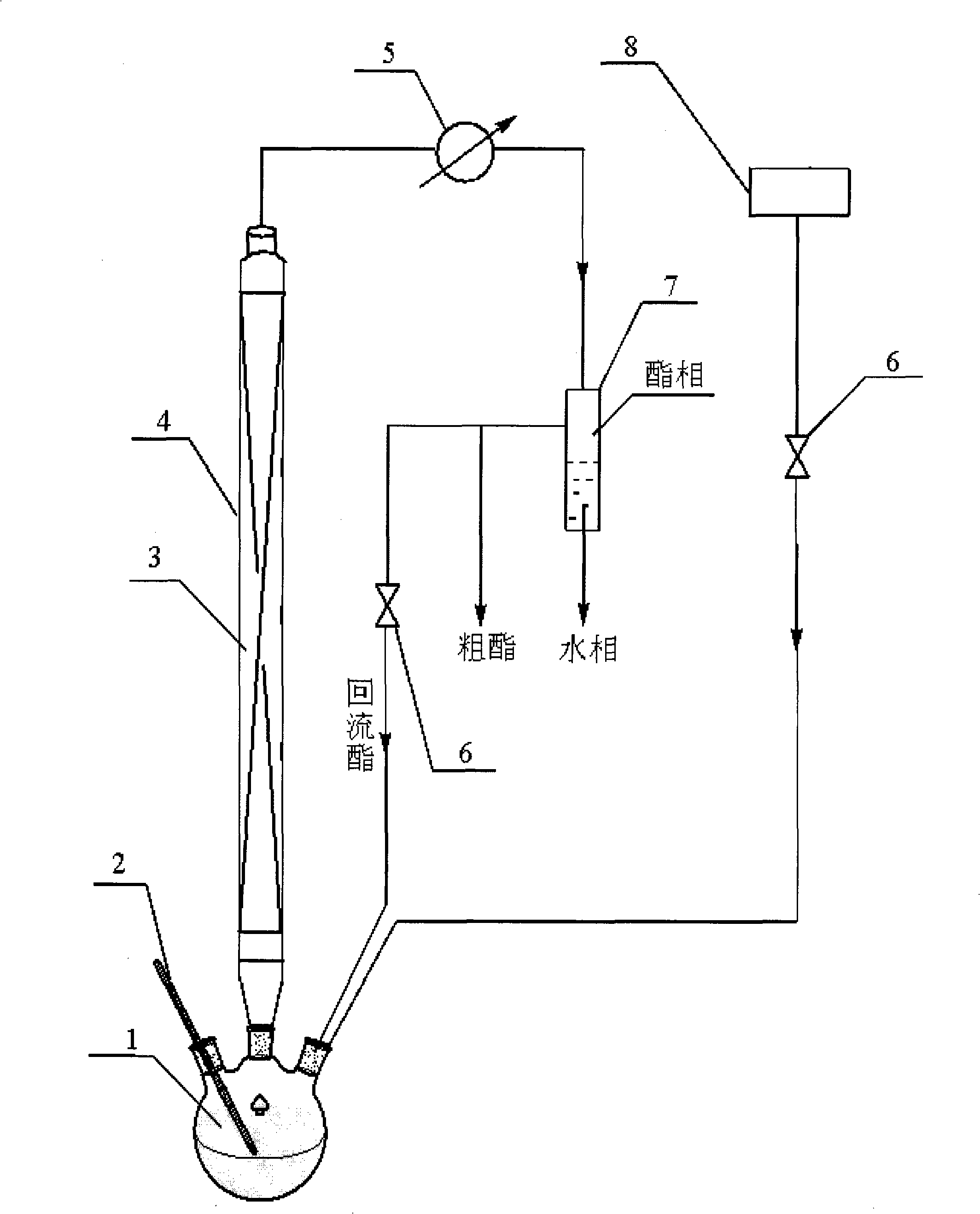

Method for synthesizing ethyl acetate by ionic liquid catalytic continuous esterification distillation

InactiveCN101255111AHigh Catalytic Esterification ActivityLess corrosiveOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDistillationEthyl acetate

The invention provides a method of ionic liquid catalyze, continuously esterifying and rectifying synthesized ethyl acetate, comprising adding a definite proportion of acetic acid, ethanol and ionic liquid catalytic agent that is alpha-pyrrolidone bisulphate at the bottom of rectification column, setting an upper heat-preserving temperature, a lower heat-preserving temperature, a reactor temperature and a reflux ratio, heating up to generate refluxing liquid at the top of the column, then holding total reflux for 15min, adding the mixed liquor of ethanol and acetic acid to the esterification reactor continuously from a high-level tank at a definite ratio of alcohol and acid and a certain feed flow speed, opening reflux ratio for preparing ethyl acetate by continuous reaction and rectification; for keeping the stability of the system, refluxing partial coarse ester at a definite refluxing speed to the bottom of the reactor, and bringing out superfluous product by azeotropy. The method uses a high catalytic activity, high selectivity, low corrosive, acidic ionic liquid to take place the traditional strong corrosivity concentrated sulphuric acid as a catalytic agent for catalyzing and rectifying continuously the synthesized ethyl acetate, the method has the advantage of low cost, high utilance for raw material, and high yield of product and purity.

Owner:GUANGDONG UNIV OF TECH

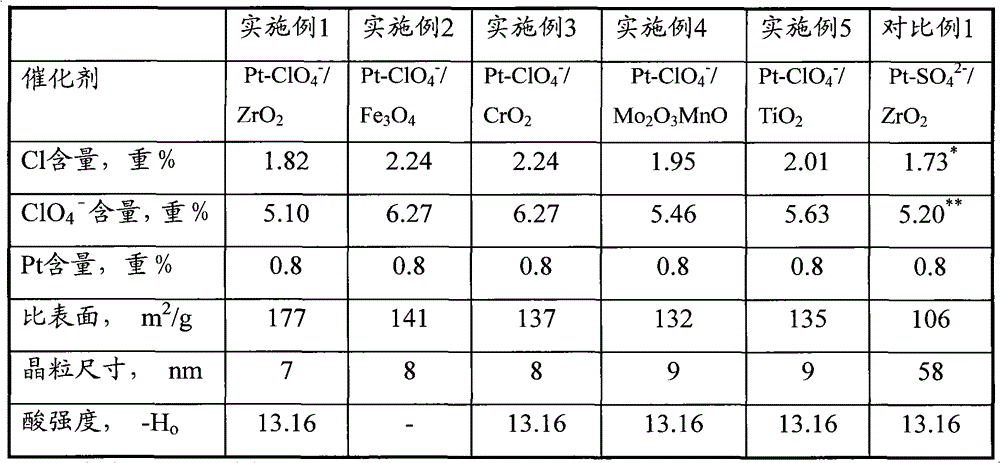

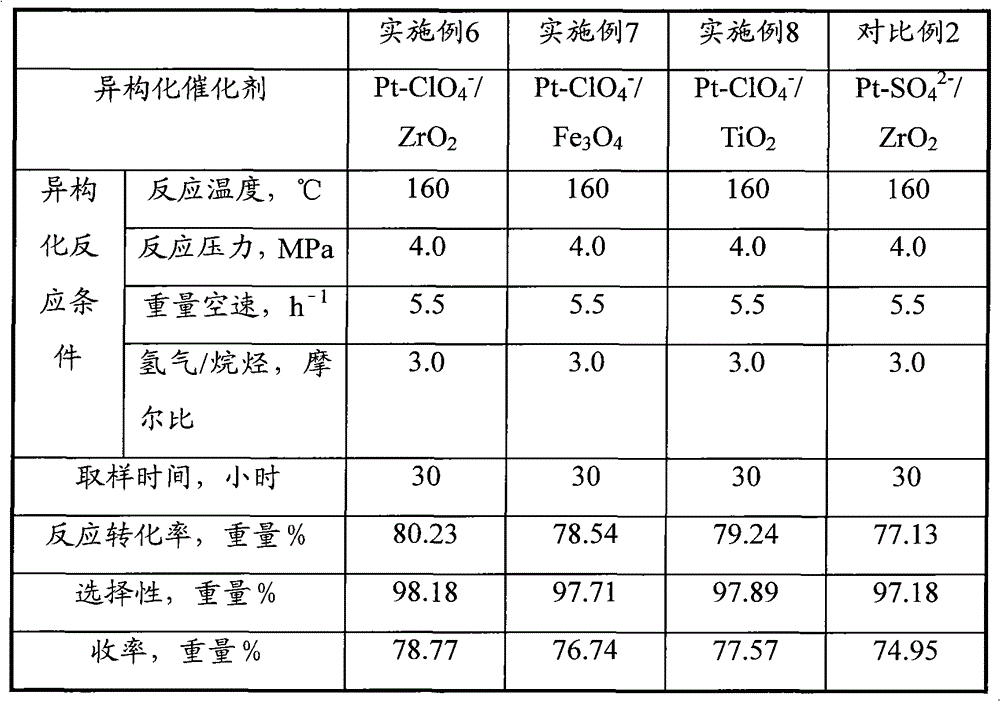

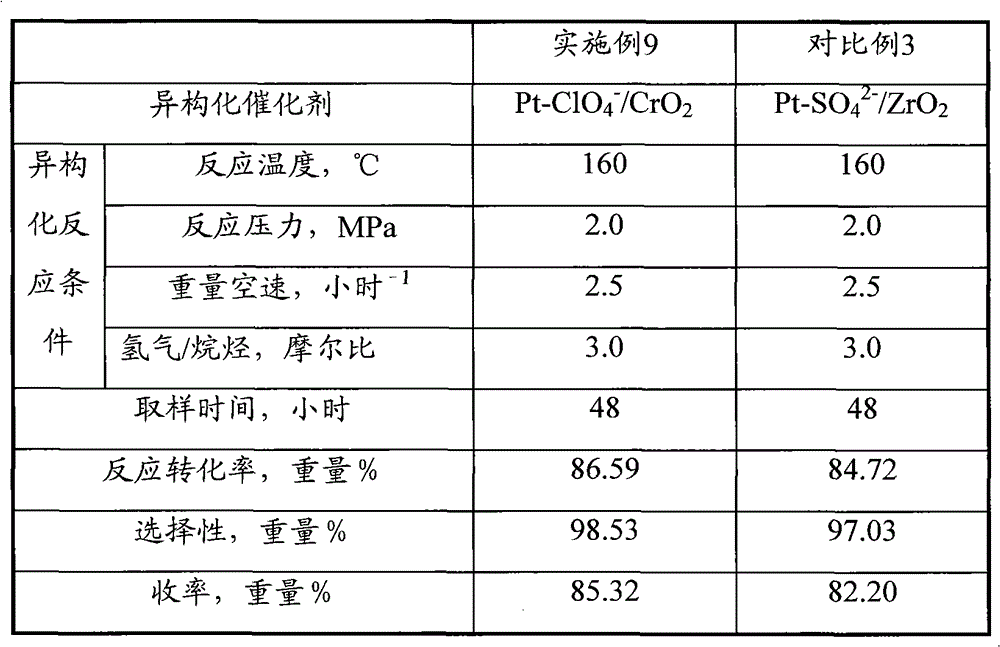

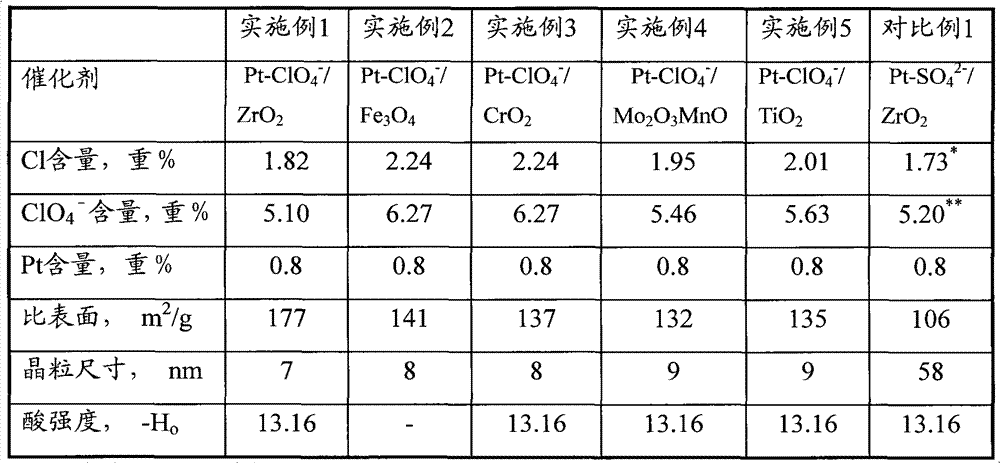

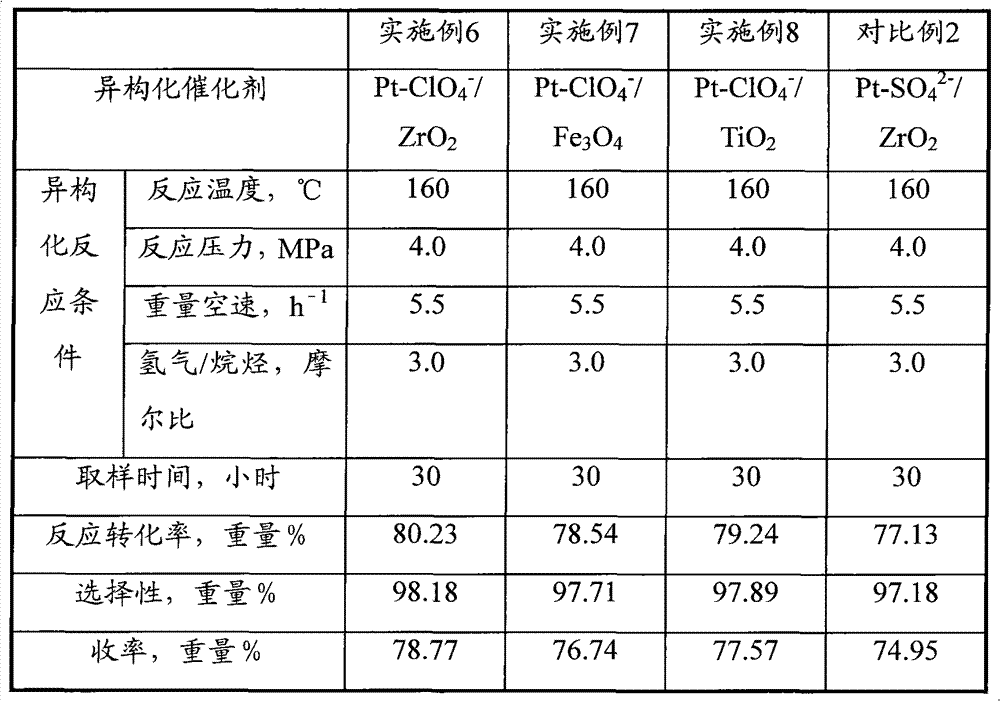

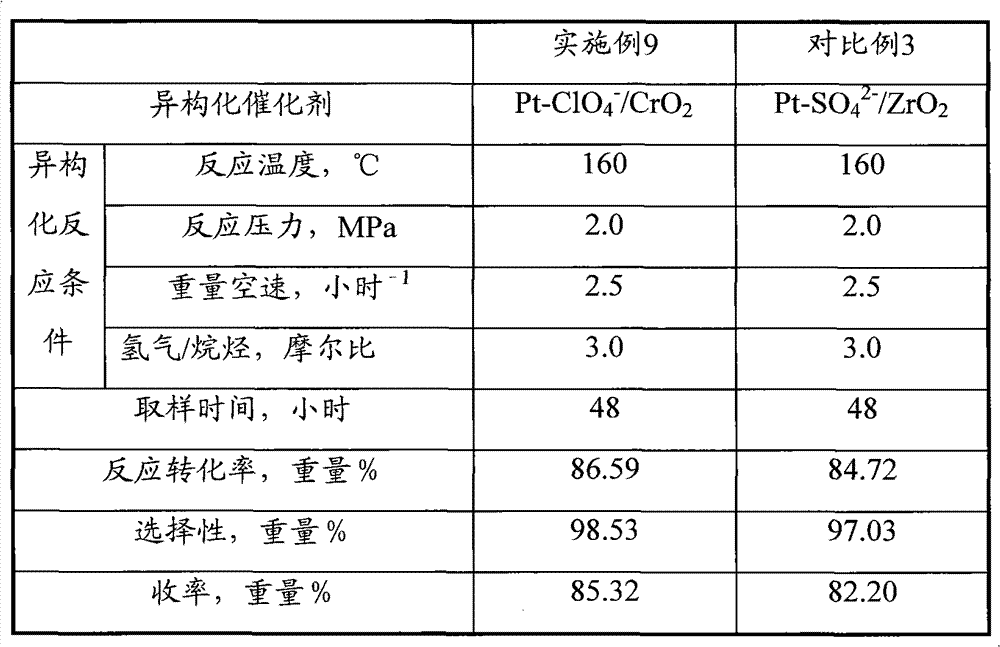

Solid superacid bifunctional catalyst and preparation method thereof

ActiveCN103055906AEasy to prepareHigh acid strengthHydrocarbon by isomerisationPhysical/chemical process catalystsAlkanePtru catalyst

A solid superacid bifunctional catalyst and a preparation method thereof. The catalyst is obtained by loading a hydrogenation / dehydrogenation metal component on metal oxide supported with ClO<4-> acid radicals; and the metal component is one or more selected from Pt, Pd and Ni. The preparation method is as follows: (1) evenly mixing a soluble chloride-containing metal salt water solution with a soluble alkali precipitator; subjecting the mixed solution to a hydro-thermal treatment under a closed condition to obtain a metal salt hydrogel; subjecting the hydrogel to aging and layering; drying and roasting precipitate at a lower layer to obtain a ClO<4-> / metal oxide; (2) impregnating the ClO<4-> / metal oxide in an ammonium perchlorate solution; then filtering, drying and roasting to obtain a metal oxide loaded with ClO<4-> radicals; and (3) impregnating the metal oxide loaded with ClO<4-> radicals in a water solution of a soluble hydrogen and dehydrogenation metal component compound; and then filtering, drying and roasting to obtain the solid superacid bifunctional catalyst. The catalyst provided by the invention can be used for catalysis of an isomerization reaction of straight-chain paraffin, and has the characteristics of low reaction temperature, high conversion rate and good selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

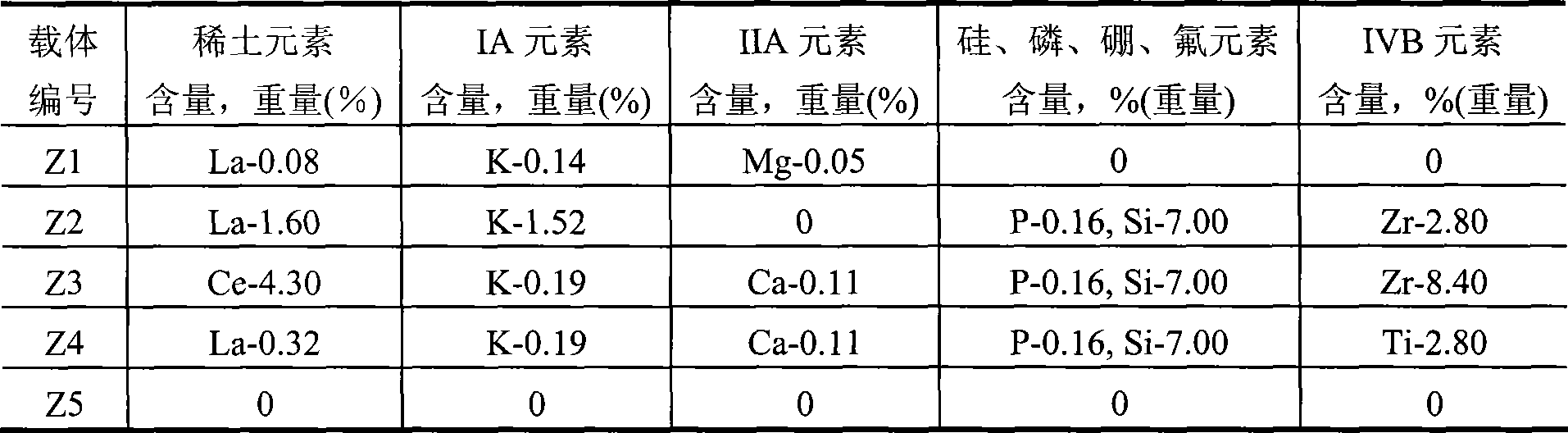

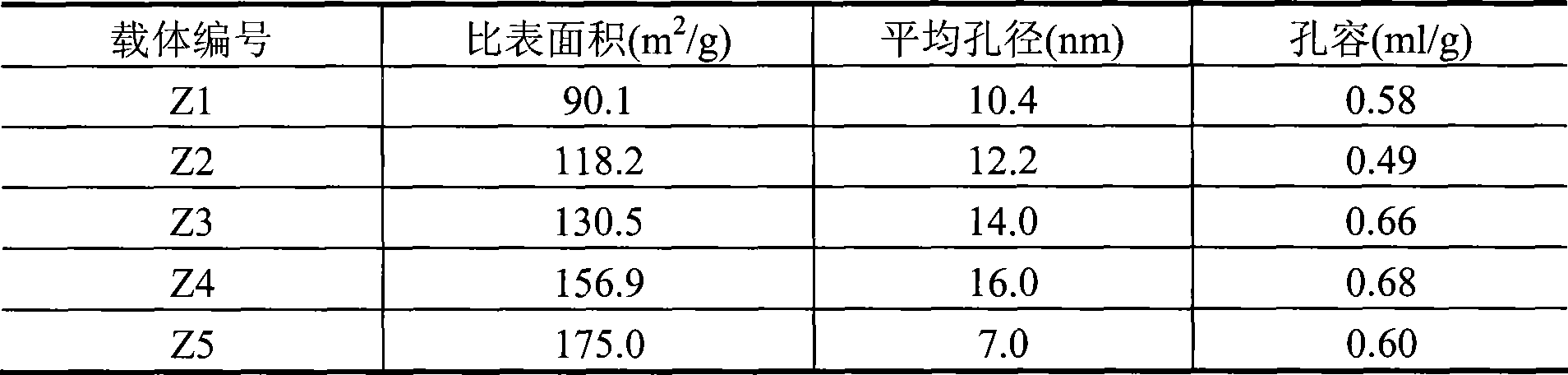

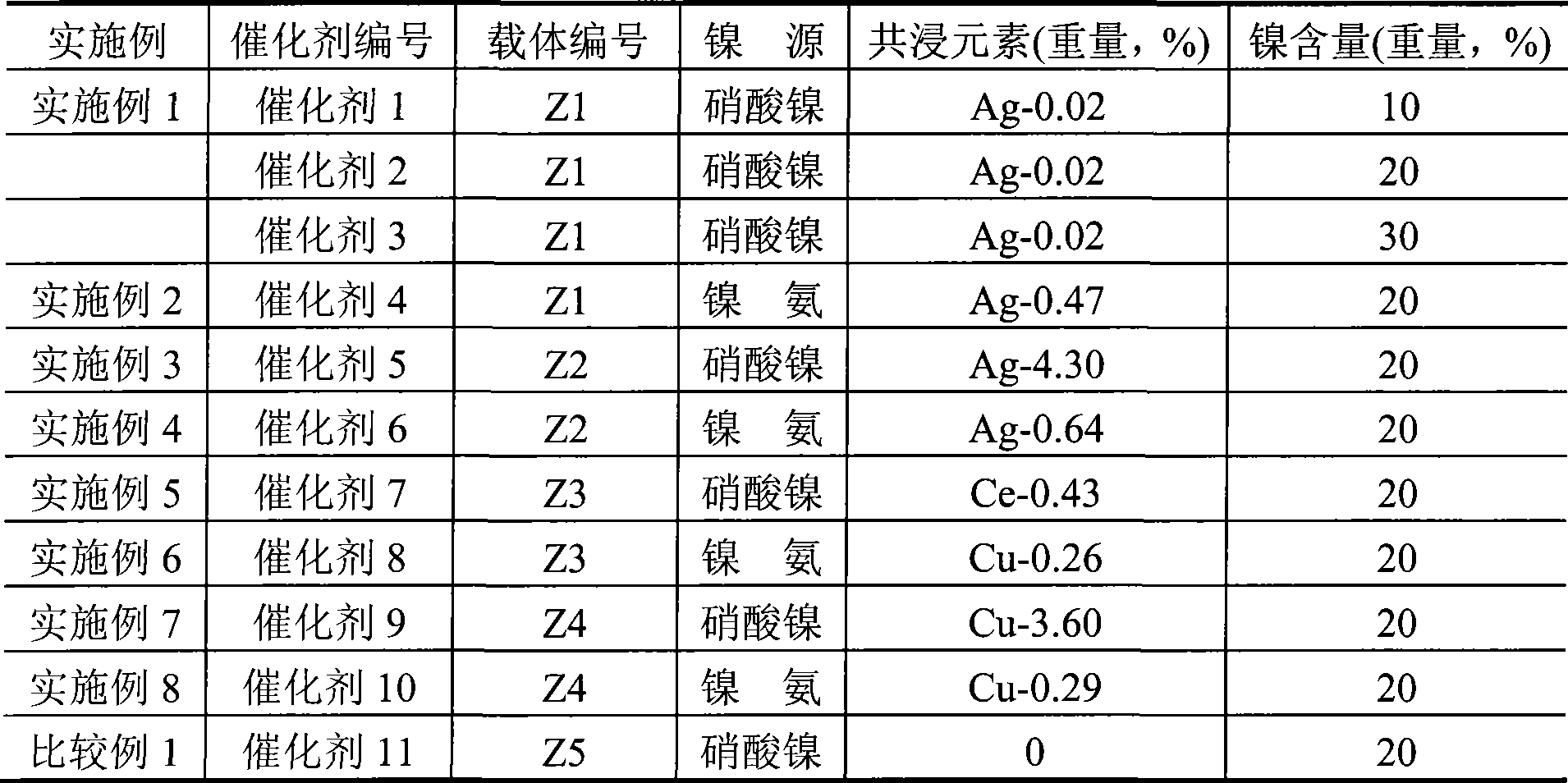

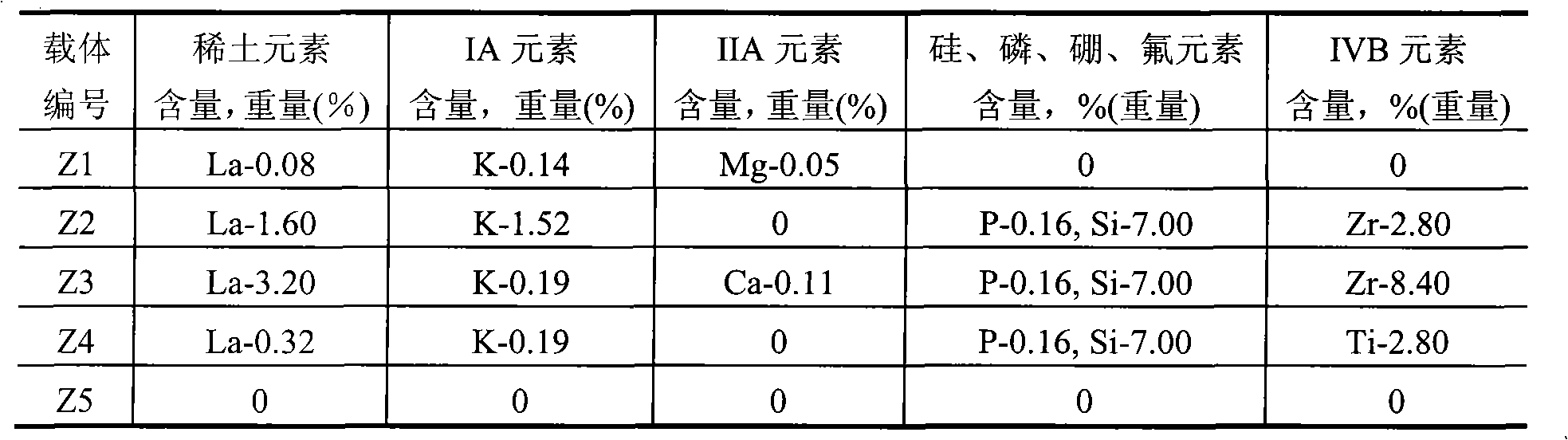

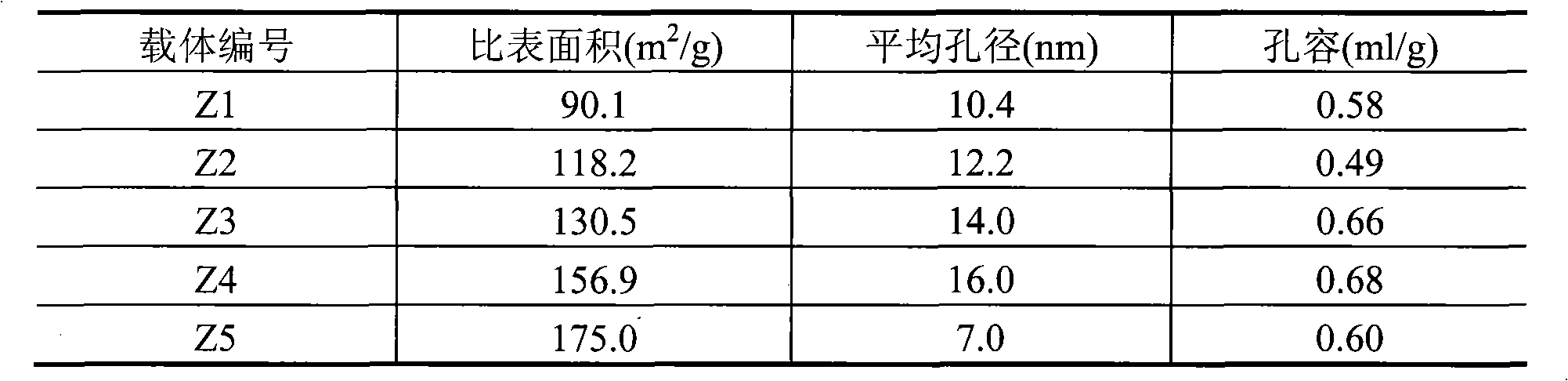

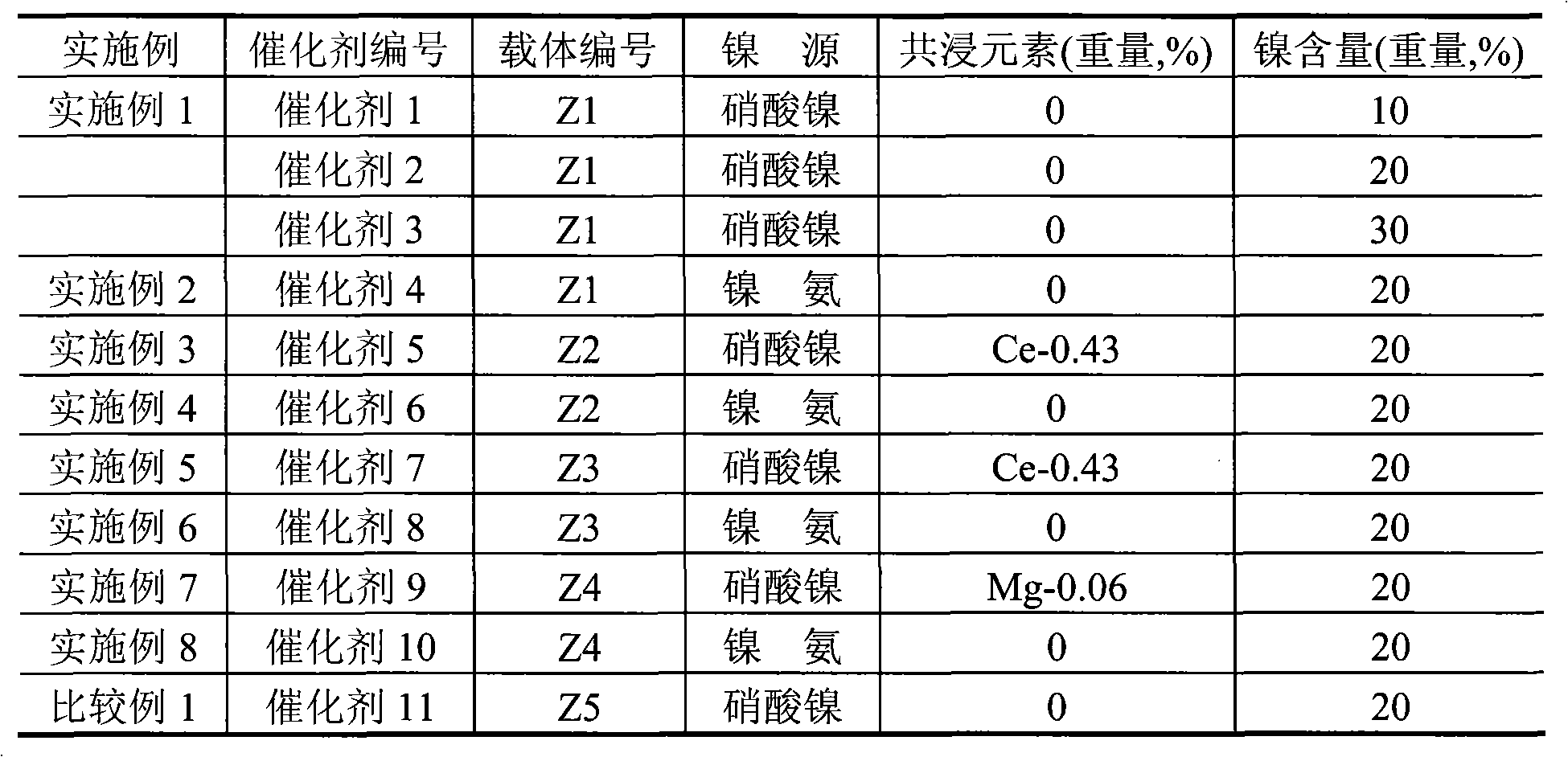

Nickel base catalyst for producing butylene-1 with butylenes-2 hydroisomerization containing a few butadiene

InactiveCN101428225AImproved pore size distributionHigh isomerization activityHydrocarbon by isomerisationMetal/metal-oxides/metal-hydroxide catalystsRare earthMetallic Nickel

The invention relates to a Ni-based catalyst for butene-1 synthesis via hydroisomerization of butene-2 containing a small amount of butadiene, and mainly solves the technical problems of low equilibrium conversion rate of butene-1 and high hydrogenation rate of alkenes in the prior art. In order to solve the problems, the technical scheme is as follows: the components in weight percentages of the Ni-based catalyst for butene-1 synthesis via hydroisomerization of butene-2 containing a small amount of butadiene are as follows: 5.0% to 40.0% of metal nickel or an oxide thereof, 0.01% to 6.0% of at least one element selected from Cu and Ag or an oxide thereof, 0.01% to 6.0% of at least one element selected from rare earths or an oxide thereof, 0.01% to 2.0% of at least one element selected from the group IA or the group IIA in the periodic table of elements or an oxide thereof, 0% to 12.0% of at least one element selected from Si, P, B and F or an oxide thereof, 0% to 10.0% of at least one element selected from the group IVB in the periodic table of elements or an oxide thereof, and aluminum oxide carrier in balance amount. The Ni-based catalyst is applied to the industrial production of butene-1 from butene-2 in pyrolysis or refinery C4 fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

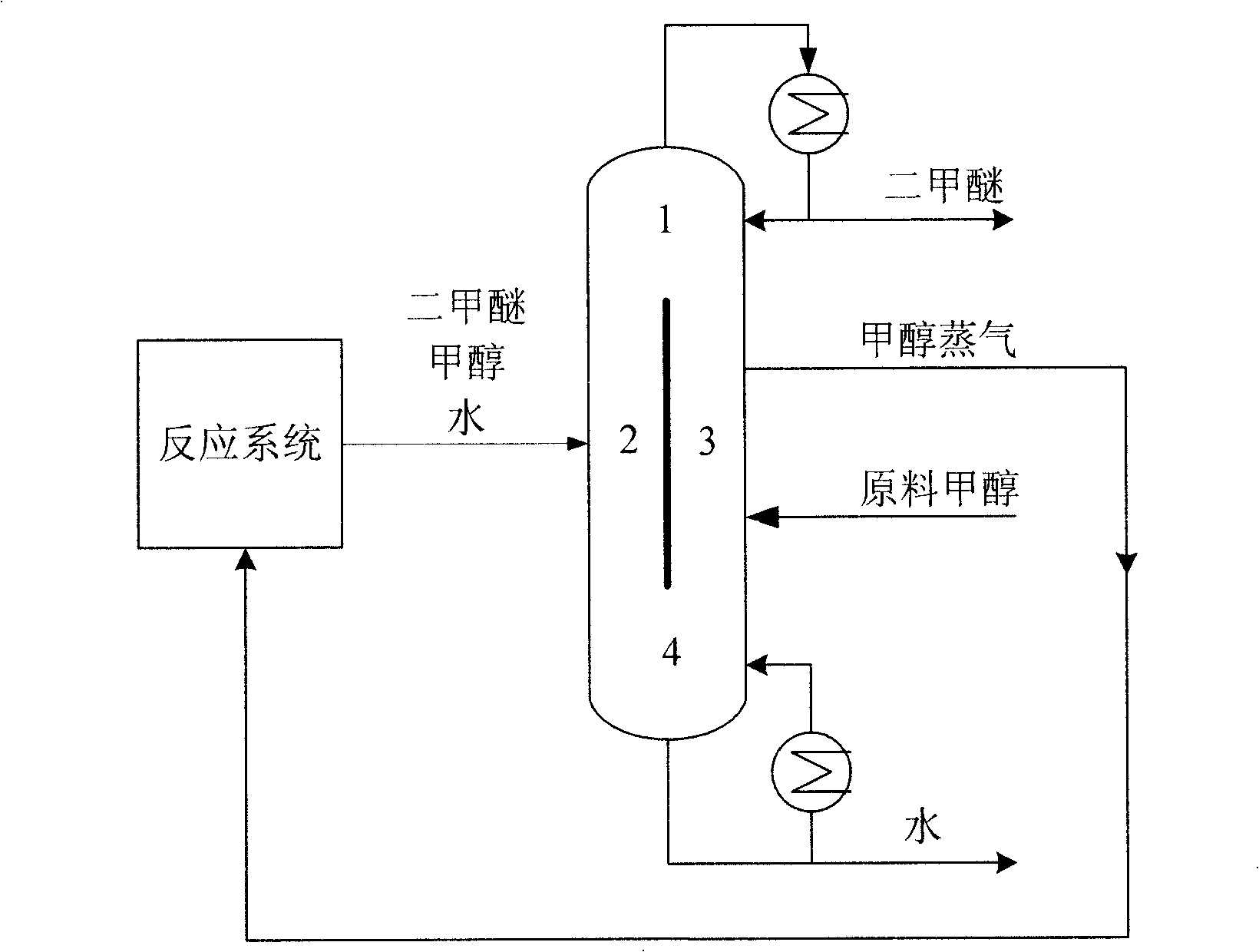

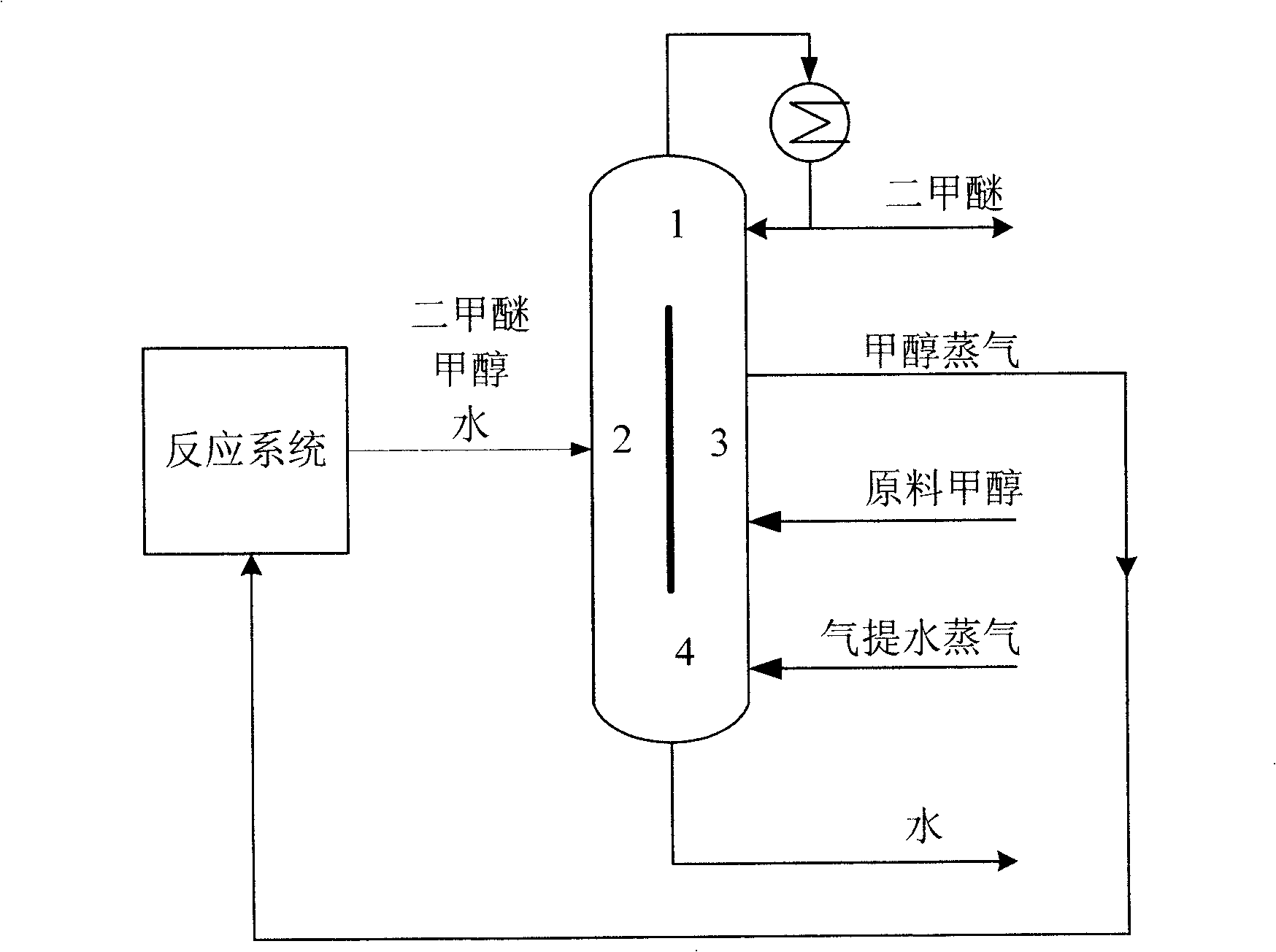

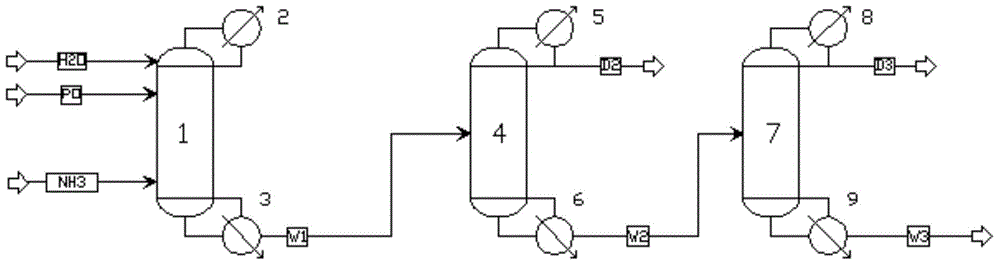

Energy-saving dimethyl ether production flow and apparatus thereof

InactiveCN101298412AImprove thermodynamic efficiencyLess reboiler duty and condenser dutyEther preparation by compound dehydrationChemistryDimethyl ether

The invention relates to a new energy-saving technique and a device for composing dimethyl ether by utilizing carbinol, which is characterized by integrating the separation of a reaction product and a substance not reacted as well as the gasification of the raw materials into a tower to be carried out simultaneously. The device of the invention consists of a reaction system and a dividing wall rectification column; the dividing wall rectification column is provided with a block of clapboard on the vertical direction in a normal rectification column; thereby dividing the inner cavity of the rectification column into four areas which are an upper area, a lower area, a left area and a right area; a dimethyl ether product is obtained from the top parts of the reaction product and the substance not reacted output from the reaction system after being separated by the dividing wall rectification column; a gas phase logistics taking carbinol as a main component is obtained from a side line as the incoming stock of the reaction system; while the water in the system is discharged from the bottom of the rectification column; simultaneously, the raw material, carbinol, containing unpurified water enters the rectification column from the right side of the dividing wall to obtain the carbinol and the water in gas phase. The invention can be used for various manufacture techniques and devices by using the carbinol in gas phase to catalyze and compose the dimethyl ether, can reduce device investment to a large extent, simplify the flows as well as reduce energy consumption and operation cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

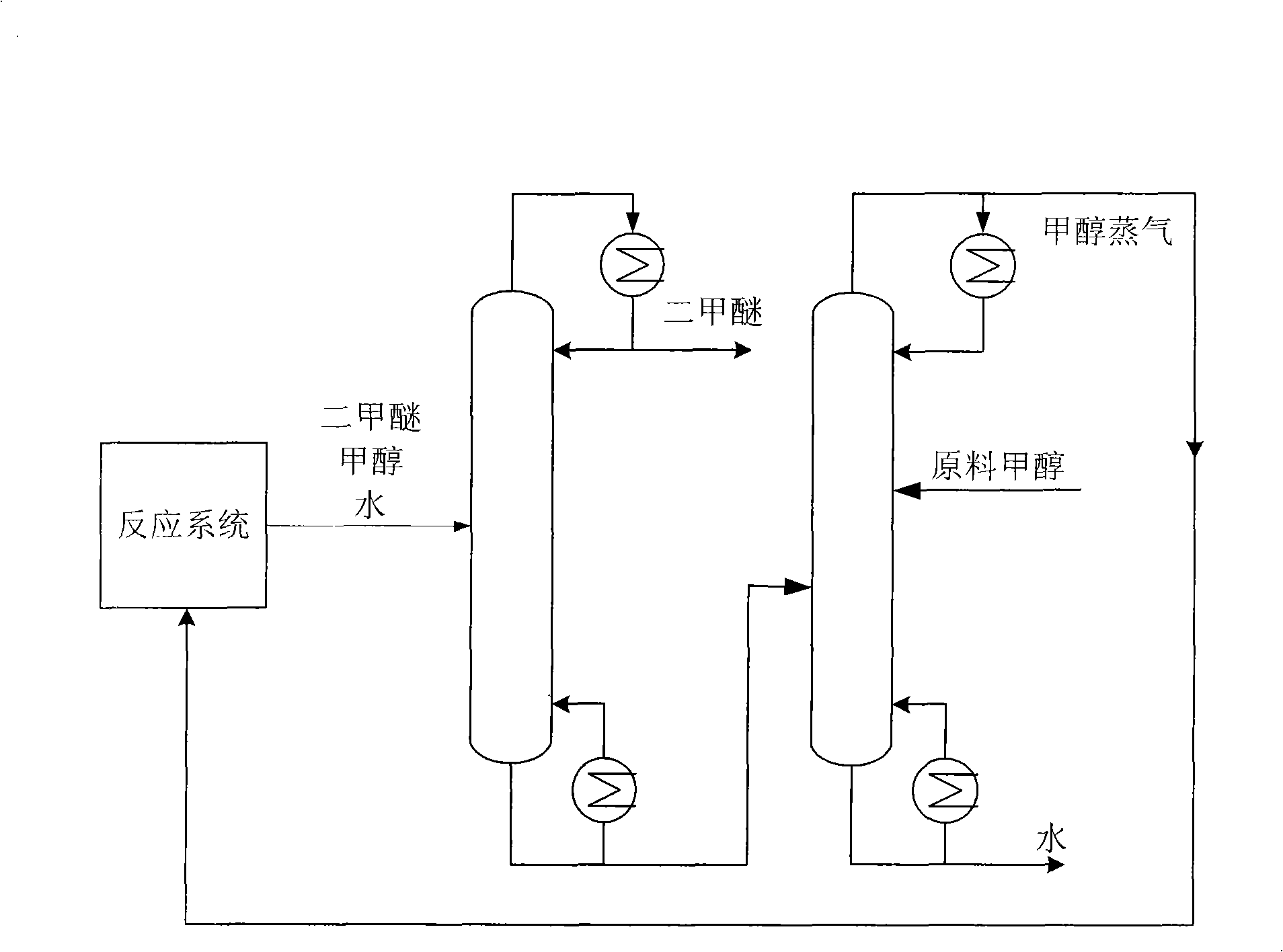

Method for producing dimethyl ether from methanol

ActiveCN1293029CReduce energy consumptionLess investmentEther preparation by compound dehydrationGas phaseVaporization

The method can be used for prodn. devices producing dimethyl ether by carbinol gas phase catalyzing. The characteristic is the special technology and structure of vaporization extracting-distilling tank and ingenious combination of vaporization extracting-distilling tank and dimethyl ether rectificating tank, the purpose of recovering carbinol can be realized without building carbinol recovering tank used for separating, purifying and recovering carbinol in mixed liquid in boiler of dimethyl ether rectificating tank. Another characteristic is that two different standard dimethyl ether (the one in them is high purity) can be produced simultaneously by the invention.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

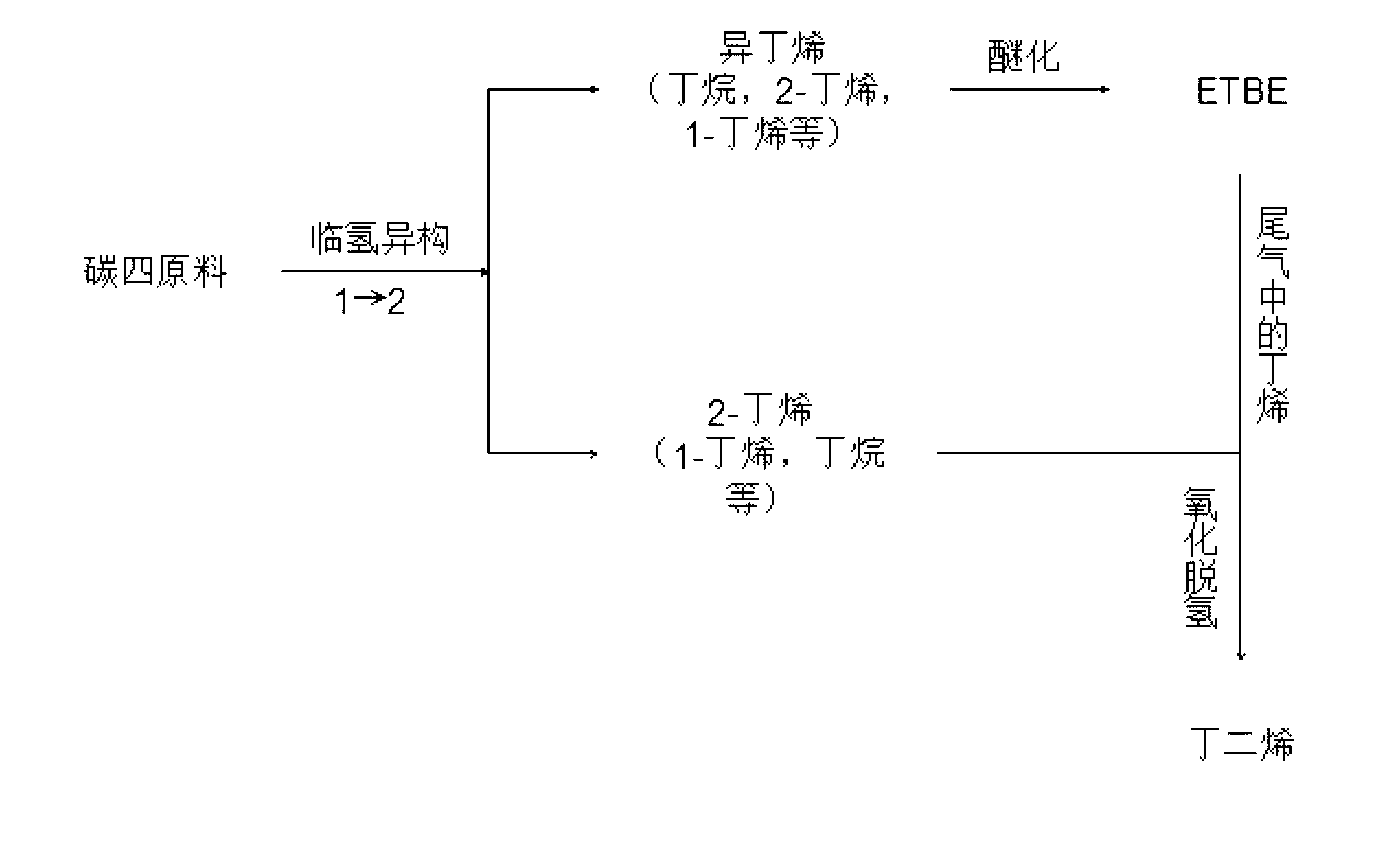

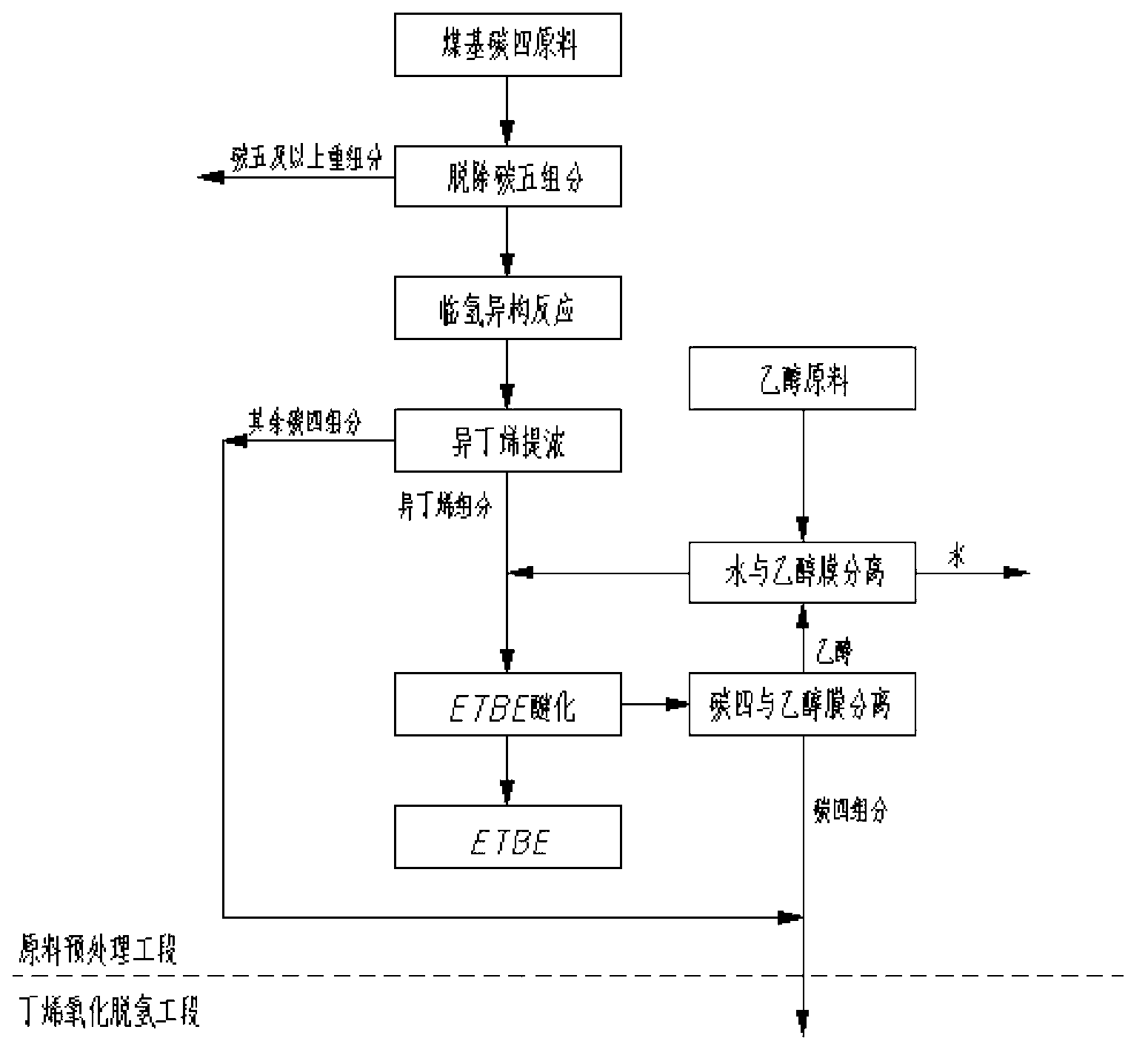

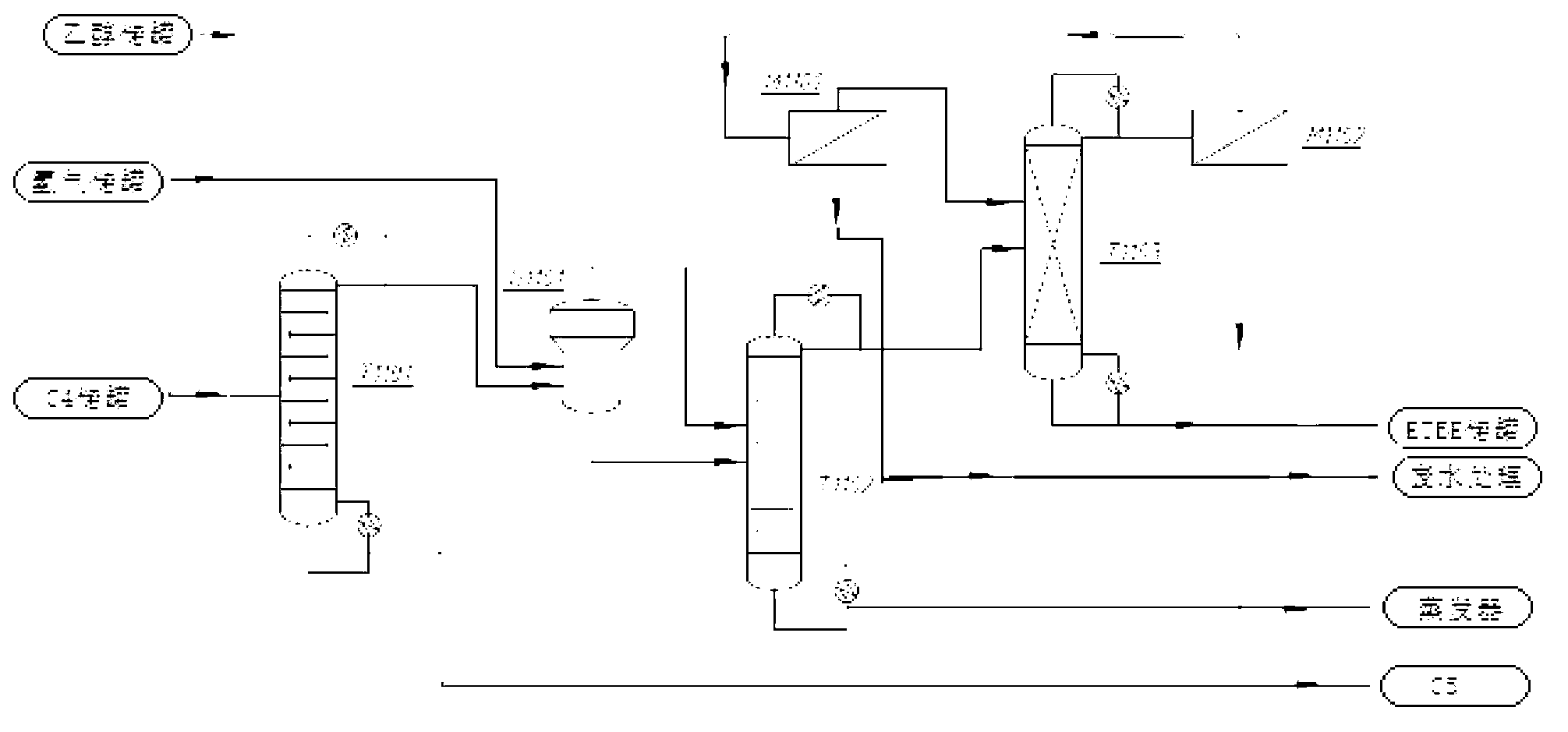

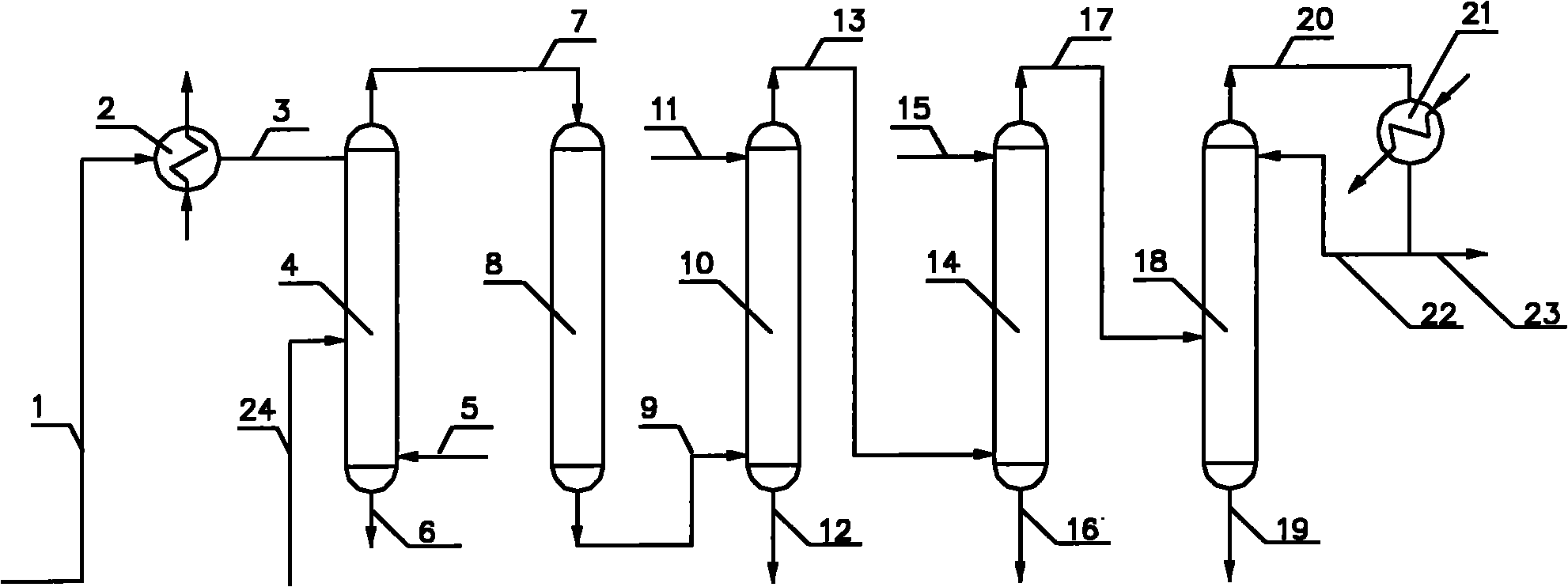

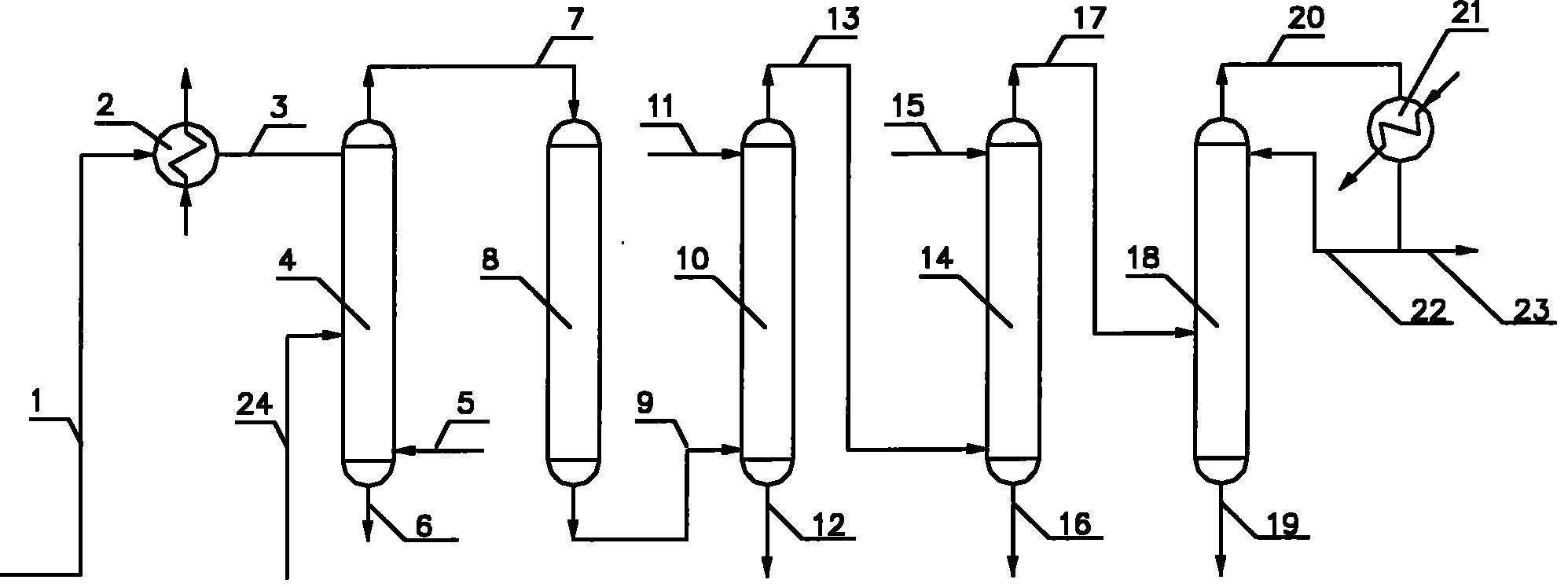

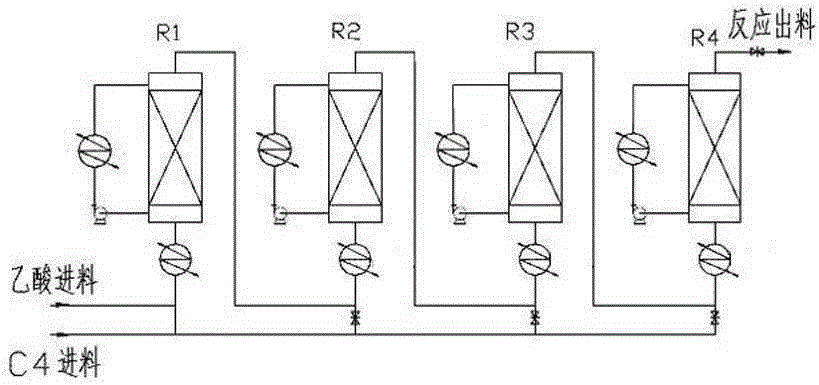

Device and method for coproduction of 1,3-butadiene and ethyl tert butyl ether from methanol to olefin (DMTO) byproduct coal-based mixing C4

InactiveCN103193581AImprove balance conversionReduce adverse effectsHydrocarbonsEther preparation by compound additionButeneButadiene Dioxide

The invention discloses a method for coproduction of 1,3-butadiene and ethyl tert butyl ether from methanol to olefin (DMTO) byproduct coal-based mixing C4. The method sequentially comprises the following three working sections: coal-based mixing C4 pretreatment and etherification working section, butene oxidative dehydrogenation working section and butadiene refining working section, wherein the coal-based mixing C4 pretreatment working section sequentially comprises the following steps: (1) removing a C5 component; (2) implementing hydroisomerization; and (3) condensing isobutene; and in the etherification step, isobutene obtained from the top of an isobutene condensation tower is pumped into an etherification tower together with ethanol for an etherification reaction. Furthermore, the invention discloses a combination device for coproduction of 1,3-butadiene and ethyl tert butyl ether from methanol to olefin (DMTO) byproduct coal-based mixing C4. The method can be used for realizing the effective and comprehensive utilization of 1-butene, isobutene, 2-butene and 1,3-butadiene in the coal-based mixing C4 as well as few C5 component, so that the comprehensive utilization rate is improved, and the method is a new trend of comprehensive utilization of the coal-based mixing C4.

Owner:EAST CHINA UNIV OF SCI & TECH

Ionic liquid as well as preparation method and its use in biological transesterification synthesis

InactiveCN101225073AAvoid pollutionAvoid security issuesOrganic chemistryFermentationDecompositionSilica gel

The invention discloses an ionic liquid with 1-isobutyl-3-methylimidazole structure and the preparation method and the application among biological transesterification reaction, belonging to technical field of organic compound preparation and application. The preparation method is characterized in that: equimolar methylimidazole and bromination isobutene are mixed directly and reacted for 18 hours at the temperature of 60 DEG C before heated slowly to 85 DEG C for continuous reaction until the reaction system is changed into sticky transparent liquid; double decomposition reaction is made for 1-isobutyl-3-methylimidazole bromide salt and equimolar inorganic salt containing different anions to get each kind of ion liquid crude product (the anion comprises PF6[-] and N(CF3)2)[-]. When the ion liquid crude product cannot be detected by bromine ion using super-pure water washing, acetone with five times of volume is used for dilution (the viscosity is close to water); active carbon and silica gel are respectively adopted for decoloration before vacuum distillation is made to remove acetone and non-reactant, thereby getting colorless products. The the preparation method for ionic liquid with 1-isobutyl-3-methylimidazole structure has the advantages of simple preparation technique, environmental protection, low cost, high purity for the ion, and thus can be applied in spectrum study and biocatalysis reaction.

Owner:JIANGNAN UNIV +1

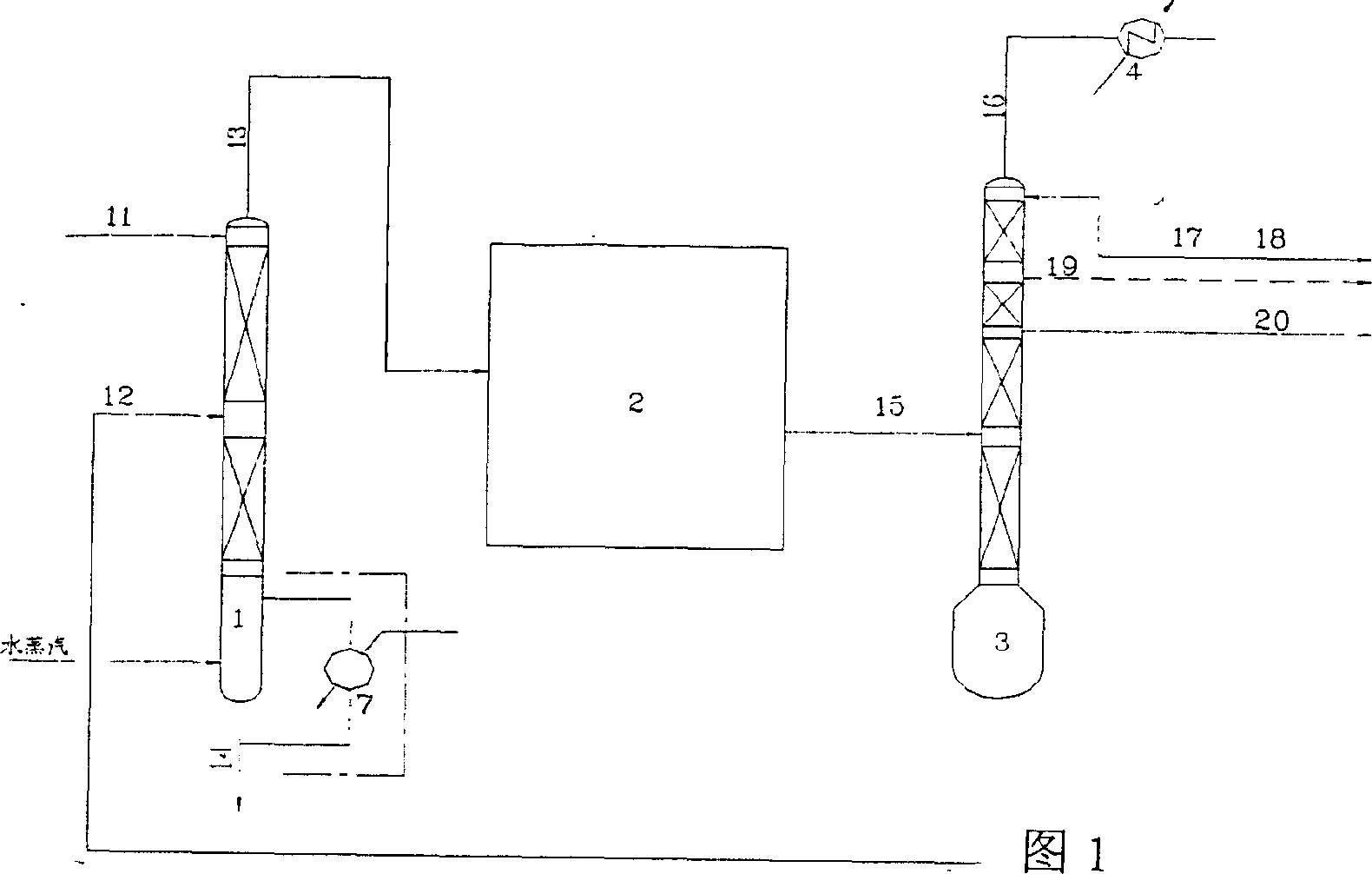

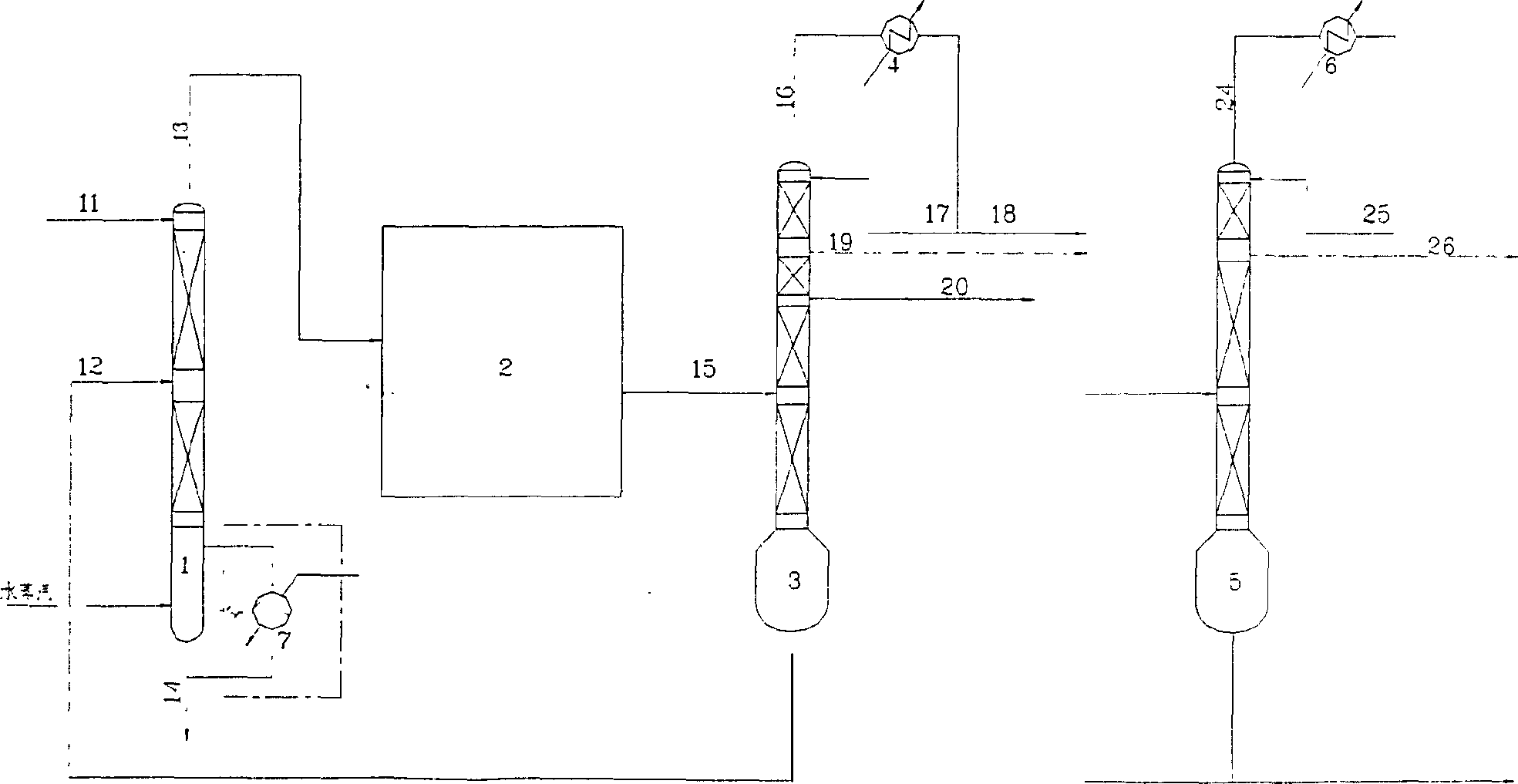

Method for preparing ethene by ethanol dehydration

ActiveCN102372564AReduce energy consumptionLess investmentHydrocarbon from oxygen organic compoundsChemical recyclingHigh energyWastewater

The invention relates to a method for preparing ethene by ethanol dehydration and mainly solves problems of large ethanol loss, high waste water COD value and high energy consumption apparatus in a production process flow of preparing ethene by ethanol dehydration of a prior art. According to the invention, fresh ethanol and recovered ethanol enter a gas stripping column to realize vaporization separation in the gas stripping column; kettle liquid in a column kettle of the gas stripping column is discharged out of a system continuously; ethanol steam is obtained at top of the gas stripping column and enters into the reaction system; dehydrated reaction products enter a washing and alkali washing system to remove impurities of ethanol, acetaldehyde and carbon dioxide, etc.; crude ethene obtained after the washing and alkali washing enters into an ethene rectifying tower; and ethene product is obtained at the top of the tower. The above technical scheme well solves the problems and can be applied to industrial production for preparing ethene by ethanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nickle base catalyst for producing butane-1 by hydro-isomerization of butane-2

ActiveCN101491760AImproved pore size distributionHigh isomerization activityHydrocarbon by isomerisationMetal/metal-oxides/metal-hydroxide catalystsIsomerizationRare earth

The invention relates to a nickel-based catalyst for preparing butane-1 by butane-2 hydroisomerization, and mainly solves the technical problems of low equilibrium conversion rate and high olefin hydrogenation rate of butane-2 hydroisomerization catalyst butane-1 in the prior art. By adopting the technical proposal that the nickel-based catalyst for preparing the butane-1 by the butane-2 hydroisomerization comprises the following components in percentage by weight: (a) 5.0 to 40.0 percent of metal nickel or oxides thereof, (b) 0.01 to 6.0 percent of at least one element or oxides thereof selected from rare earth, (c) 0.01 to 2.0 percent of at least one element or oxides thereof selected from IA or IIA in the periodic table of elements, (d) 0 to 12.0 percent of at least one element or oxides thereof selected from silicon, phosphorus, boron or fluorine, (e) 0 to 10.0 percent of at least one element or oxides thereof selected from IVB in the periodic table of elements, and (f) the balance being aluminum oxide carrier; and the nickel-based catalyst the solves the problems well, and can be used in the industrial production of the butane-1 prepared by cracking C4 or butane-2 component rich in refinery C4.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing monoisopropanolamine by virtue of reactive rectification

ActiveCN104961641AReduce energy consumptionCost savingsOrganic compound preparationChemical industryMonoisopropanolamineTriisopropanolamine

The invention provides a method for preparing monoisopropanolamine by virtue of reactive rectification. The method comprises the following steps: feeding liquid ammonia from the lower part of a reactive rectification tower by use of a pressure reducing valve, meanwhile, feeding propylene epoxide from the second tower plate at the upper part of the tower at 25 DEG C, and feeding catalyst water from the top of the tower at a temperature ranging from 15 to 40 DEG C, wherein the feeding molar ratio of the fed ammonia to the propylene epoxide is (0.8-2.0): 1, the feed quantity of the water is 10-50% of the mass percentage of the total feed quantity, and the total feed quantity is the mass sum of the water, liquid ammonia and propylene epoxide; the reactive rectification tower comprises 25-45 tower plates; the temperature at the top of the tower is controlled within the range of 31-50 DEG C, the temperature of the tower kettle is within the range of 165-310 DEG C, and the tower is under the pressure of 0.8MPa to 1.5MPa; the liquid ammonia feeding position is at the tower kettle of the reactive rectification tower or the first or second tower plate above the tower kettle. Compared with the traditional process, the method has the advantages that the content of monoisopropanolamine is increased by nearly 100%, and the content of triisopropanolamine is reduced by about 95% in comparison with the traditional process.

Owner:HEBEI UNIV OF TECH

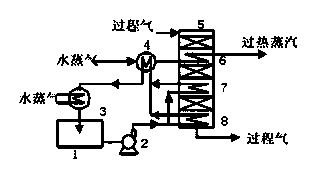

Hydrogen sulfide wet sulfuric acid preparation method with low emission

InactiveCN103803506AImprove balance conversionImprove the total conversion rate of SO2Sulfur compoundsEnergy inputSuperheaterInorganic Chemical

The invention belongs to the technical field of inorganic chemical industry sulfuric acid preparation, and discloses a hydrogen sulfide wet sulfuric acid preparation method with high conversion rate and low emission. According to the hydrogen sulfide wet sulfuric acid preparation method, interlayer hot air mixed cold shock is adopted, and a steam superheater is also combined for process gas cooling; O2 concentration of the process gas is increased, equilibrium conversion rate of SO2 catalytic oxidation is increased, and SO2 total conversion rate is increased further; and at the same time, a NWS series high-efficient wet conversion specially-used vanadium catalyst is used, so that the SO2 total conversion rate reaches 99.2%, and exhaust gas emission of a wet conversion sulfuric acid preparation apparatus is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

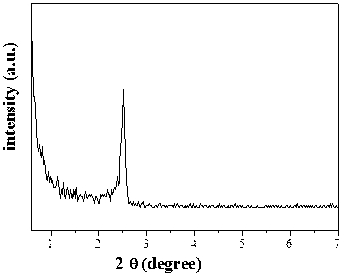

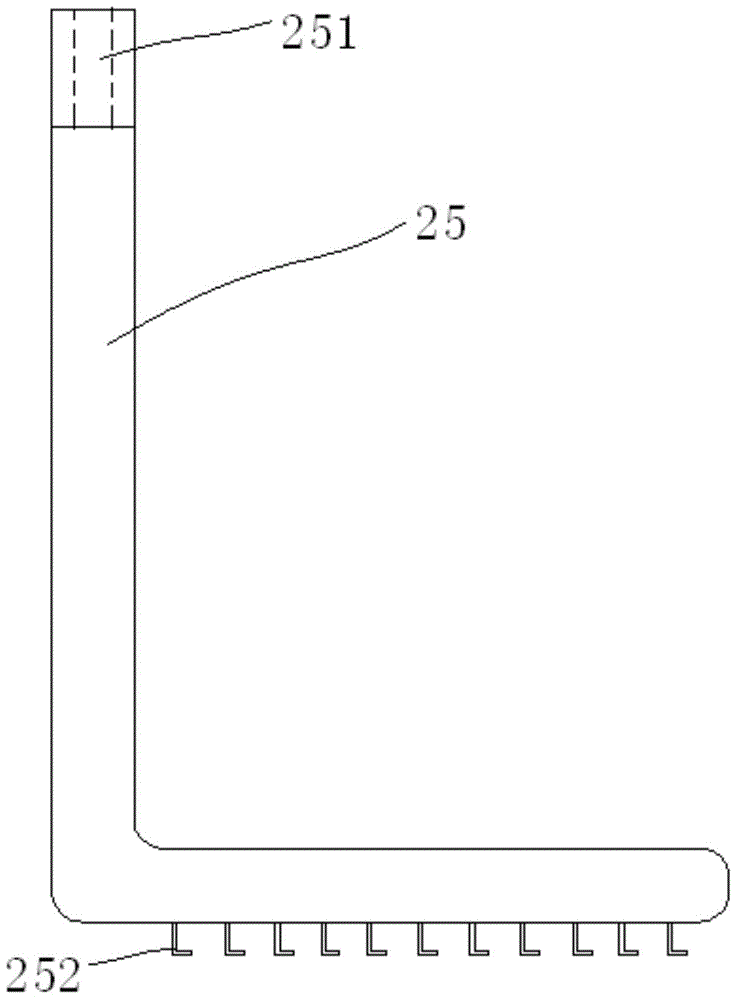

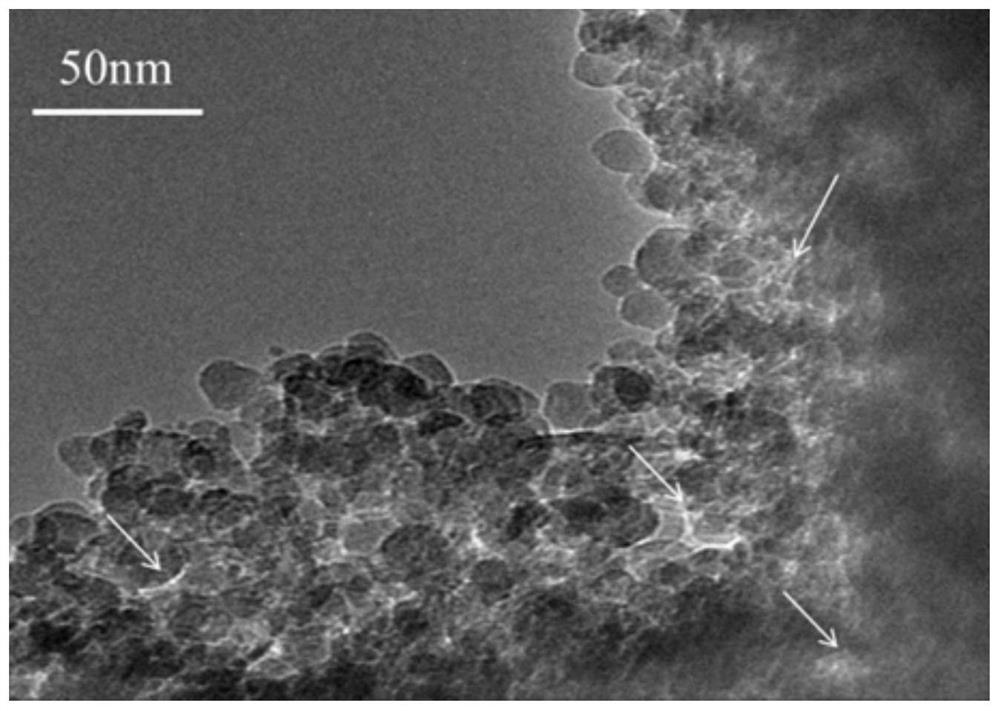

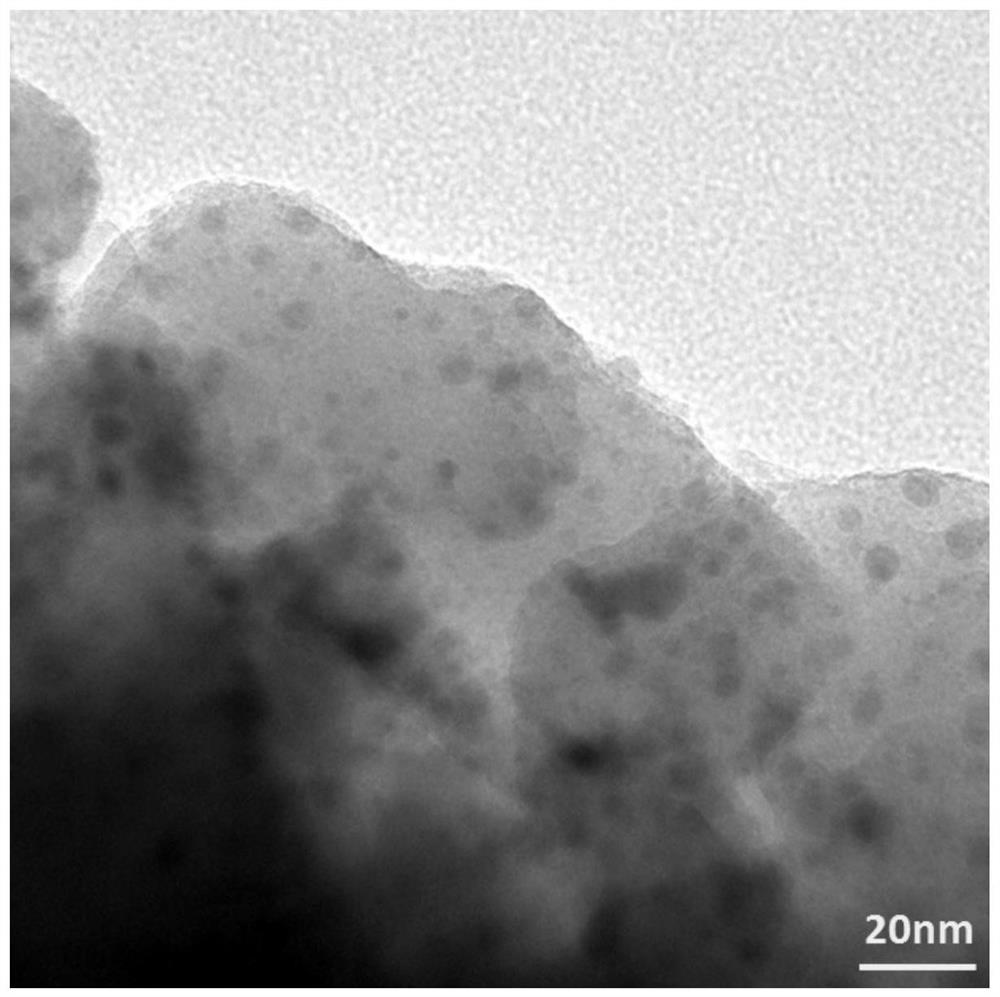

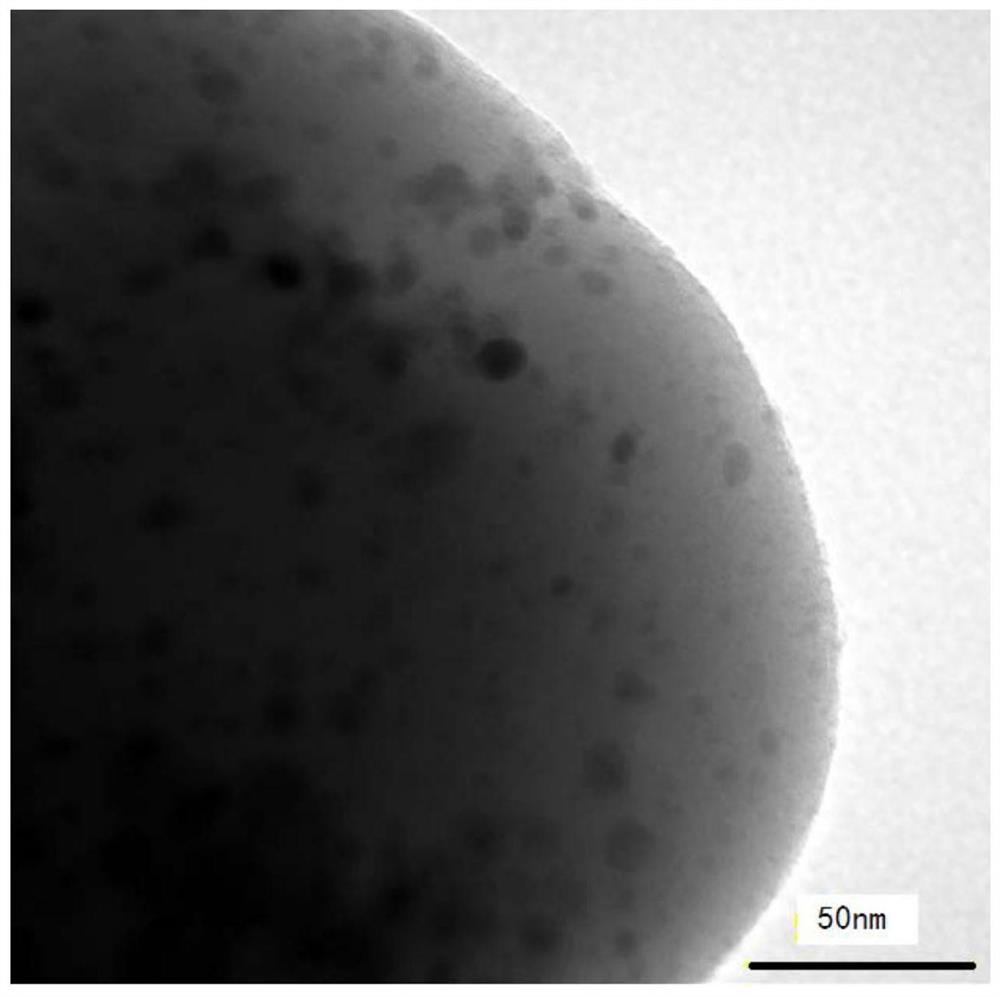

Supported micropore-mesopore composite molecular sieve membrane and preparation method thereof

InactiveCN107694600AHigh hydrothermal stabilityWith separation performanceMolecular sieve catalystsPreparation from organic carbonatesMolecular sievePhenol

The invention relates to a supported micropore-mesopore composite molecular sieve membrane and a preparation method thereof. The supported micropore-mesopore composite molecular sieve membrane is composed of a porous carrier and a layered compact Ti-HMS-1-micropore-mesopore composite molecular sieve membrane loaded on the porous carrier. The Ti-HMS-1-micropore-mesopore composite molecular sieve membrane is prepared by introducing a TS-1 micropore secondary structure unit into the pore walls of a pure silicon mesoporous molecular sieve HMS. The Ti-HMS-1-micropore-mesopore composite molecular sieve membrane can be applied to reactions with a low equilibrium conversion rate, such as exchange reactions between dimethyl carbonate and phenol ester to prepare diphenyl carbonate, as a catalytic separation membrane, so that catalytic reactions and separation are carried out at the same time during the reaction process. Through the separation effect of the catalytic membrane, products are removed out of the reaction system continuously, the thermodynamic equilibrium is broken down, and the yield is improved.

Owner:晋中市智诚科技服务中心

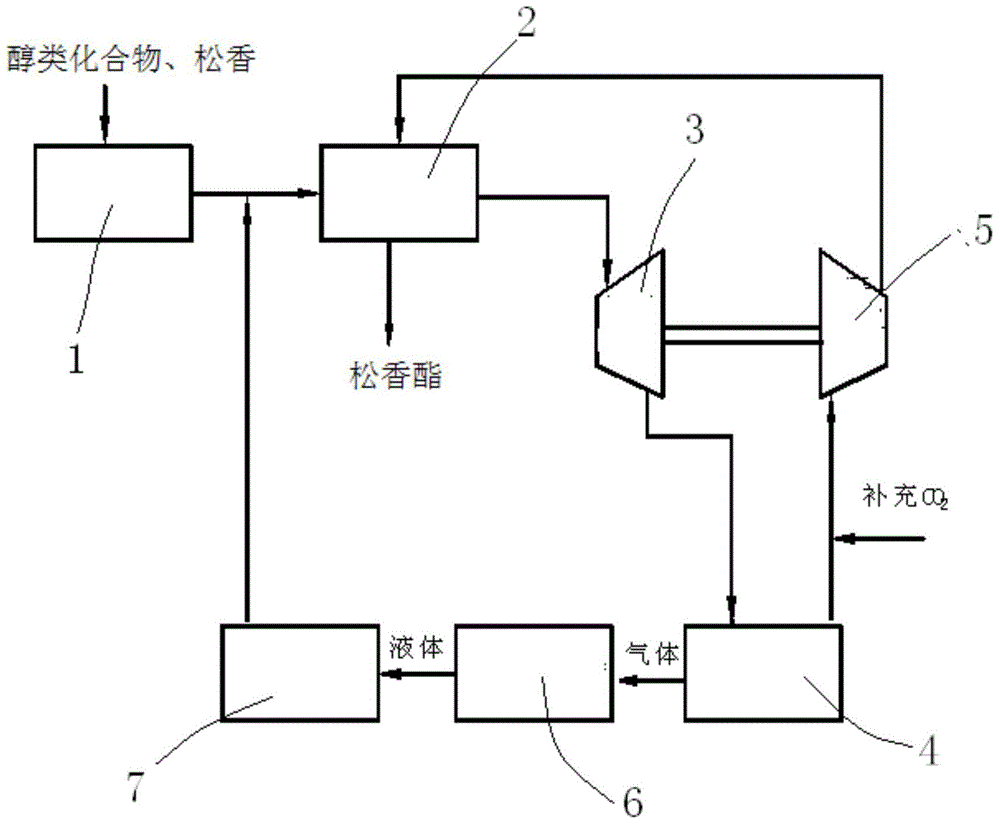

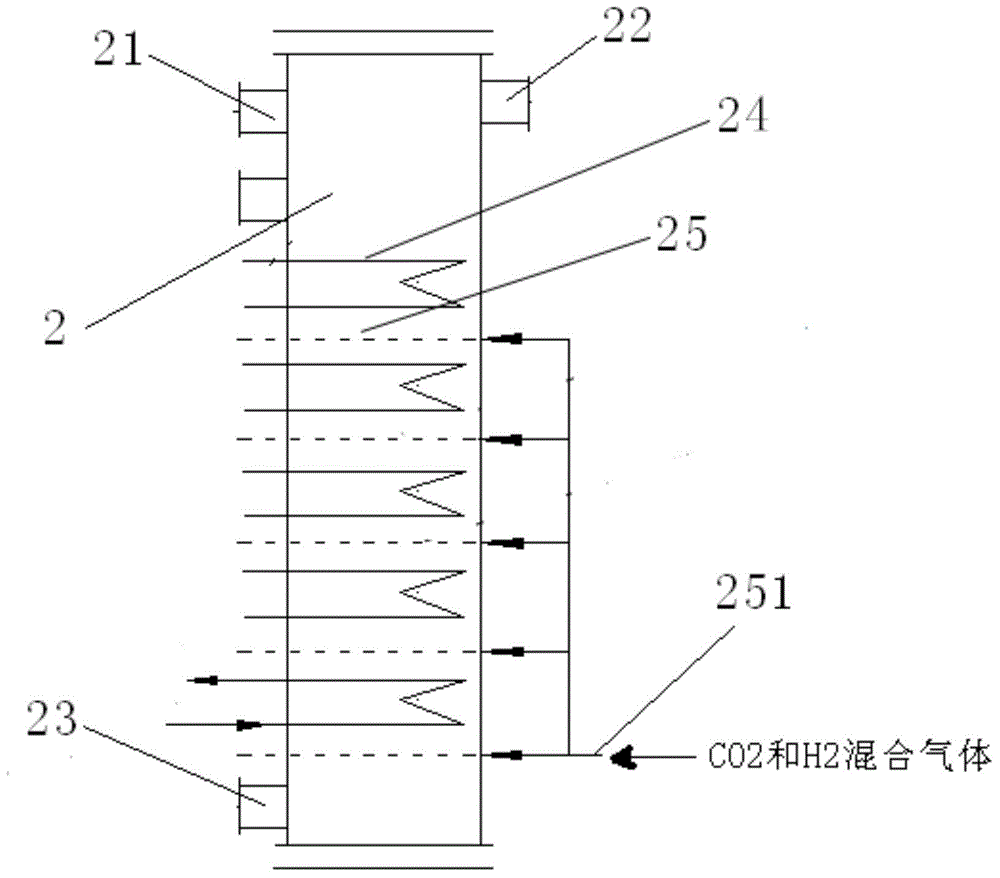

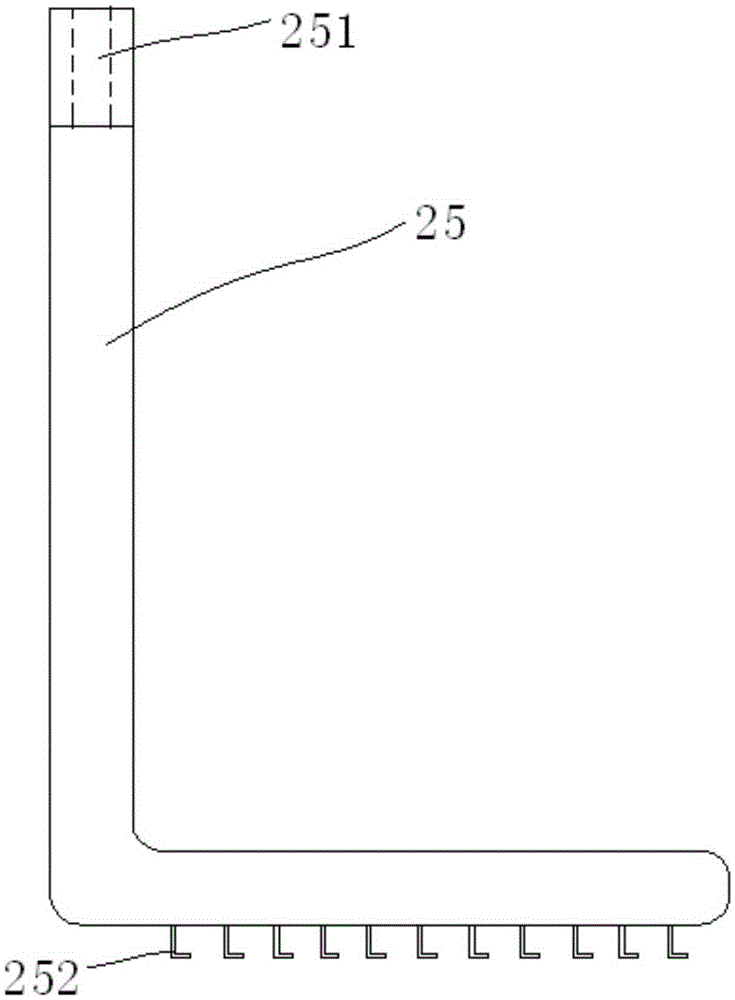

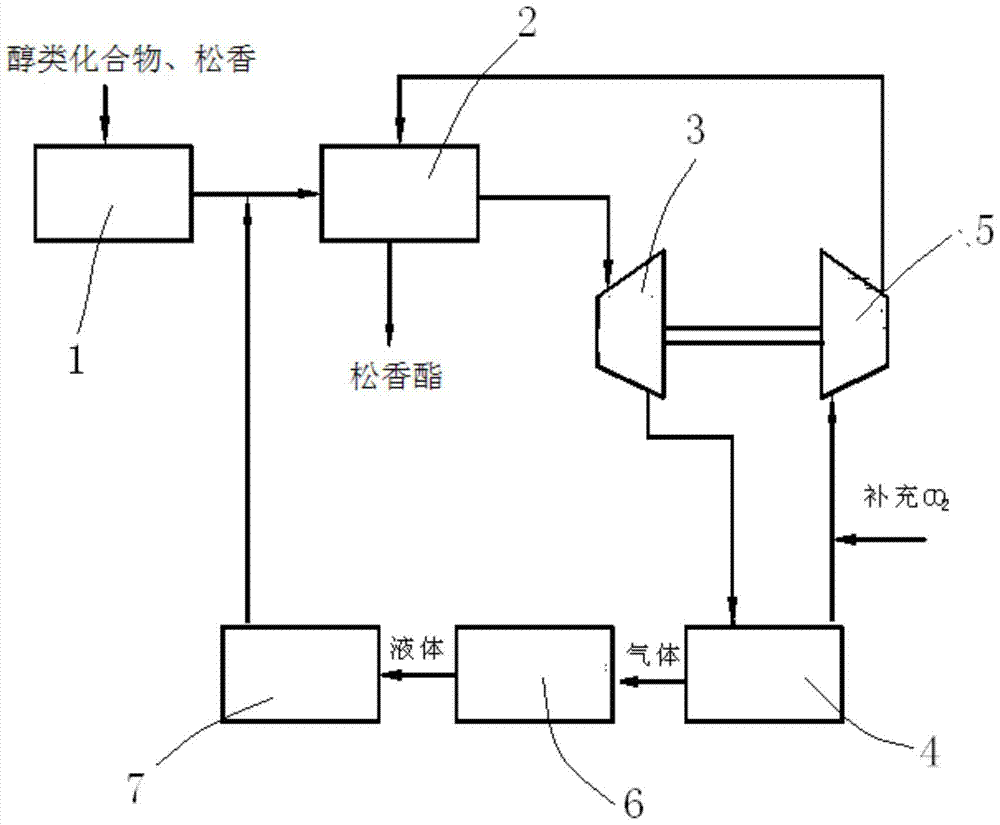

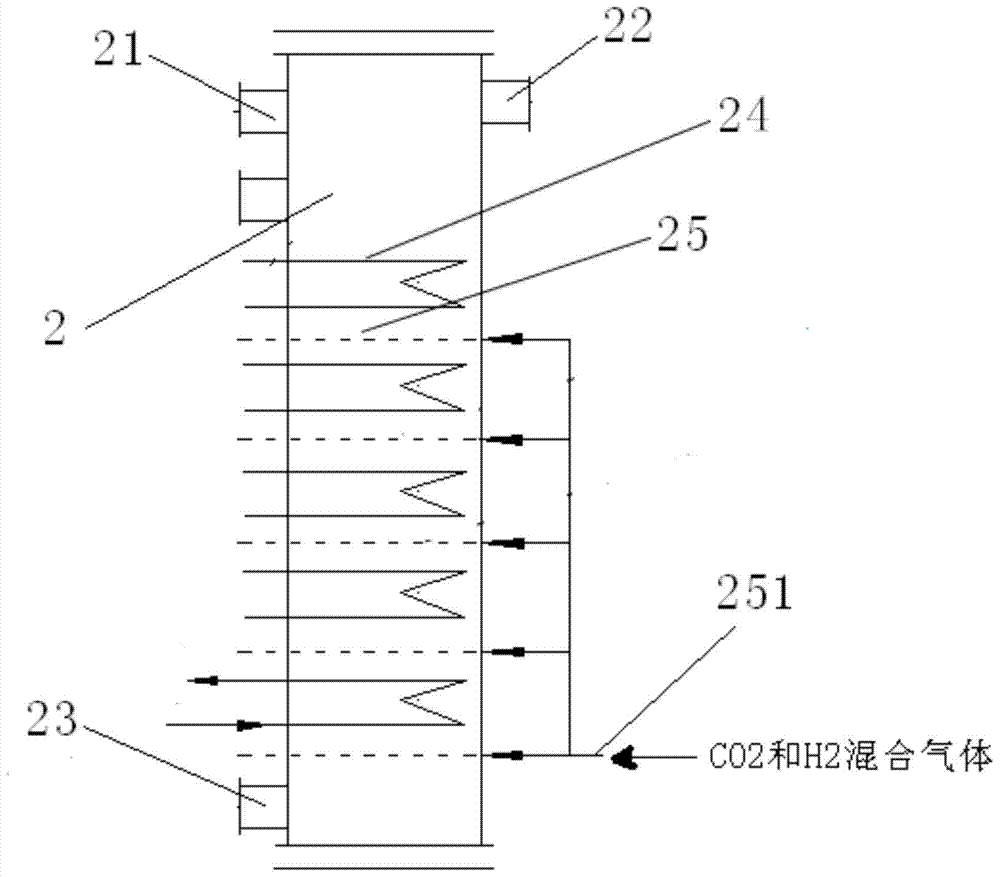

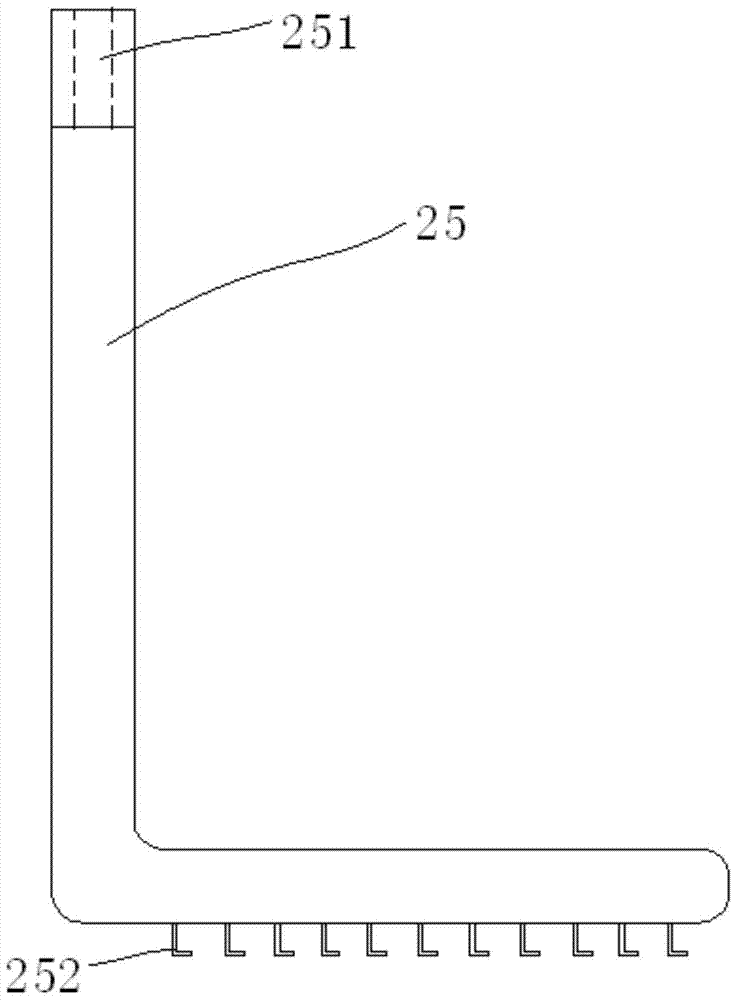

Method and device for preparing rosin ester by coupling catalytic esterification and separation

ActiveCN104694014AEliminate chemical balanceBreak chemical balanceChemical/physical/physico-chemical stationary reactorsNatural resin chemical modificationAlcoholVapor–liquid separator

The invention relates to a method for preparing rosin ester by coupling catalytic esterification and separation, which comprises the following operation steps: (1) mixing an alcohol compound, a rosin and a solvent, and dissolving; (2) putting the dissolved substance in the step (1) into an esterification reactor, and introducing 0.01-10.0-MPa CO2 to perform esterification reaction at 150-300 DEG C; (3) recovering the gas phase in the esterification reaction process, sending the gas phase into a gas-liquid separator through an expander, and returning the separated CO2 and newly supplemented CO2 into the esterification reactor through a turbine compressor; and (4) after reacting in the esterification reactor for 1.0-8.0 hours, relieving the pressure, and taking the obtained product out of the esterification reactor. The invention aims to provide a preparation method which has the advantages of lower cost and high rosin ester quality.

Owner:GUANGXI UNIV

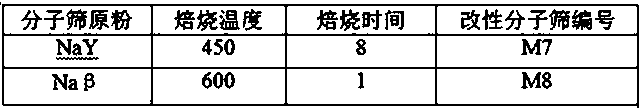

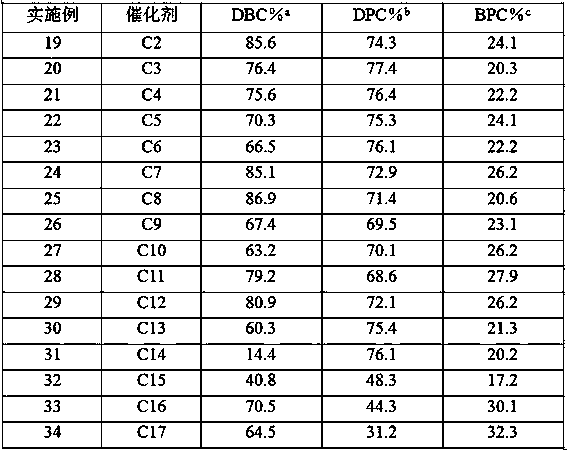

Catalyst for synthesizing diphenyl carbonate, preparation method thereof and process

ActiveCN111389452AImprove balance conversionImprove economyMolecular sieve catalystsOrganic compound preparationMolecular sievePtru catalyst

The invention discloses a catalyst for synthesizing diphenyl carbonate. The catalyst comprises a molecular sieve and a loaded active component, the molecular sieve is an alkali metal modified microporous molecular sieve, and the active component is binary mixed metal oxide AO / B<c>O<d>, wherein A is selected from Sn, Ga or Zn, B is selected from Zr, Cr or La, and a, b, c and d are stoichiometric numbers. Due to the addition of a lithium additive, the energy barrier in the side reaction process is remarkably improved, and the reaction speed of the side reaction is reduced. The tin oxide and other active components obviously lower the energy barrier in the main reaction process, and enhance the reaction speed of the main reaction. The catalyst provided by the invention has very high catalytic activity, effectively realizes diphenyl carbonate synthesis reaction, inhibits the occurrence of ether side reaction, and reduces the energy consumption of the production process.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of reactive distillation prepares the method for monoisopropanolamine

ActiveCN104961641BImprove separation efficiencyImprove balance conversionOrganic compound preparationChemical industryReactive distillationMonoisopropanolamine

Owner:HEBEI UNIV OF TECH

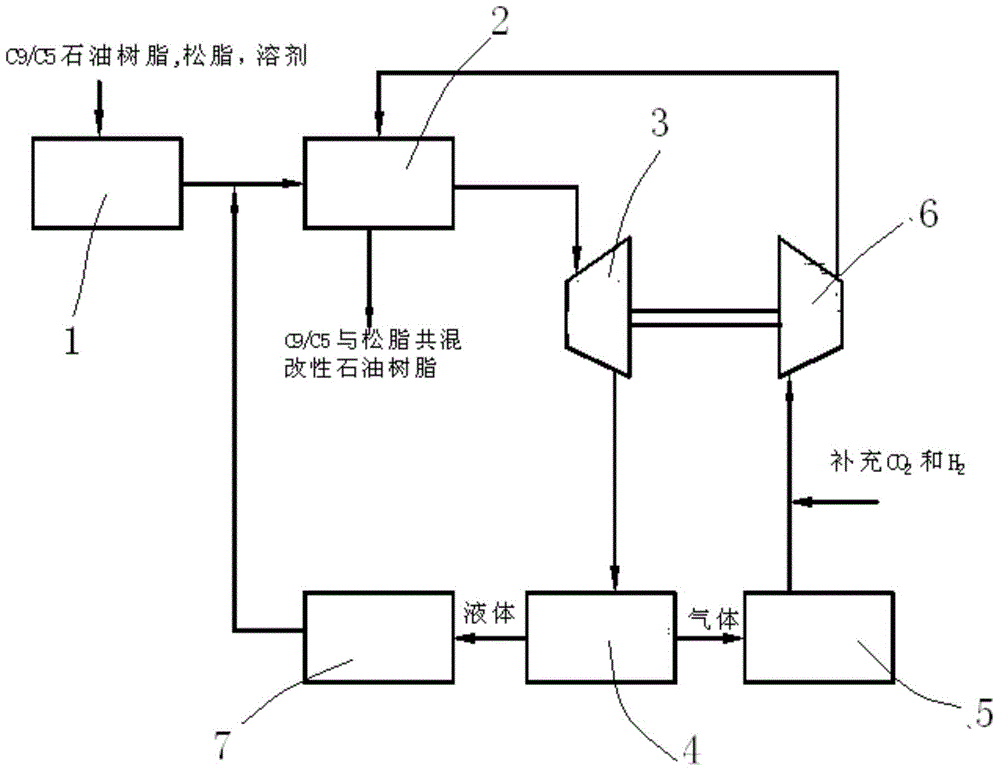

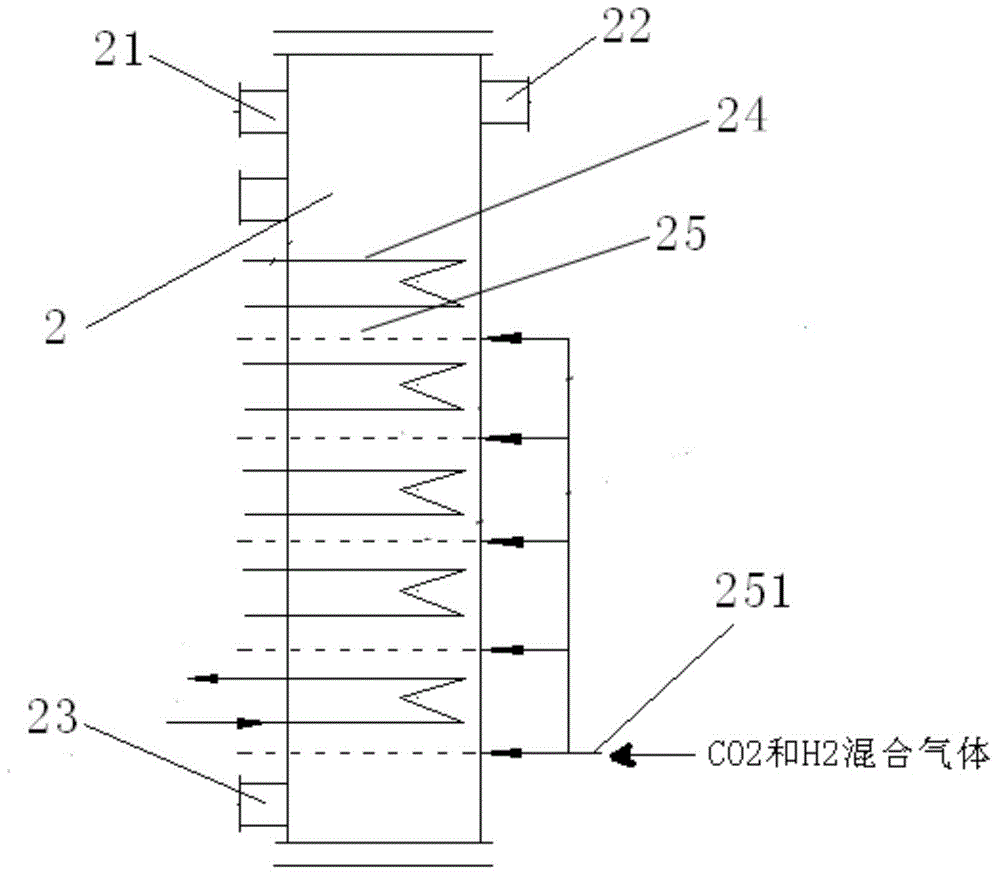

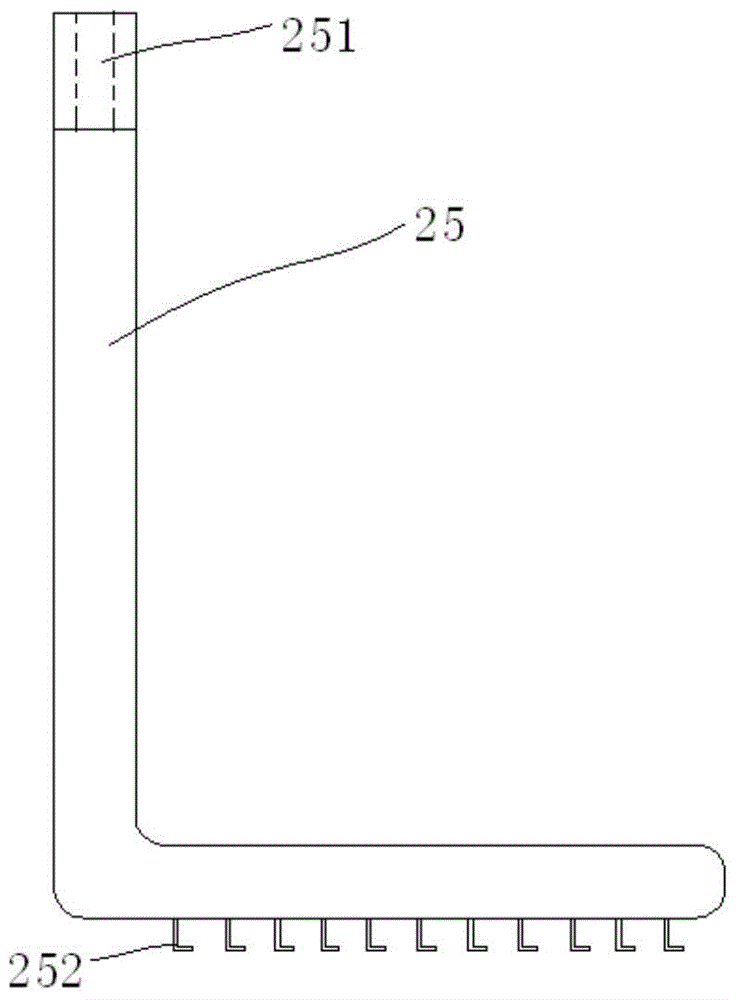

Turpentine-C9/C5 petroleum resin blend hydrogenation modification method and device

ActiveCN104693359AImprove heating efficiencyReduce heat conversion processNatural resin chemical modificationChemical/physical processesHydrogenation reactionTurpentine

The invention discloses a turpentine-C9 / C5 petroleum resin blend hydrogenation modification method which comprises the following steps: (1) raw material preparation: mixing raw materials turpentine and C9 / C5 petroleum resin with a solvent and a catalyst, and dissolving by heating; (2) hydrogenation reaction: putting the mixture prepared in the step (1) into a hydrogenation reactor, charging a gas mixture of H2 and CO2 in a mole ratio of 1:1-20:1, and carrying out hydrogenation reaction at 150-400 DEG C under the pressure of 3.0-35.0 MPa; (3) taking out the reacted gas mixture in the hydrogenation reactor, passing the gas through an expander which is connected with a turbine compressor, supplementing the CO2-H2 gas mixture into the turbine compressor, and introducing the gas mixture into the hydrogenation reactor; and (4) after carrying out hydrogenation-desulfurization reaction for 1-10 hours, relieving the pressure, and discharging the blend hydrogenation modified turpentine-C9 / C5 petroleum resin product out of the hydrogenation reactor. The method enhances the hydrogenation-desulfurization reaction speed and equilibrium conversion rate, and implements coupling of the hydrogenation reaction and desulfurization separation.

Owner:GUANGXI UNIV

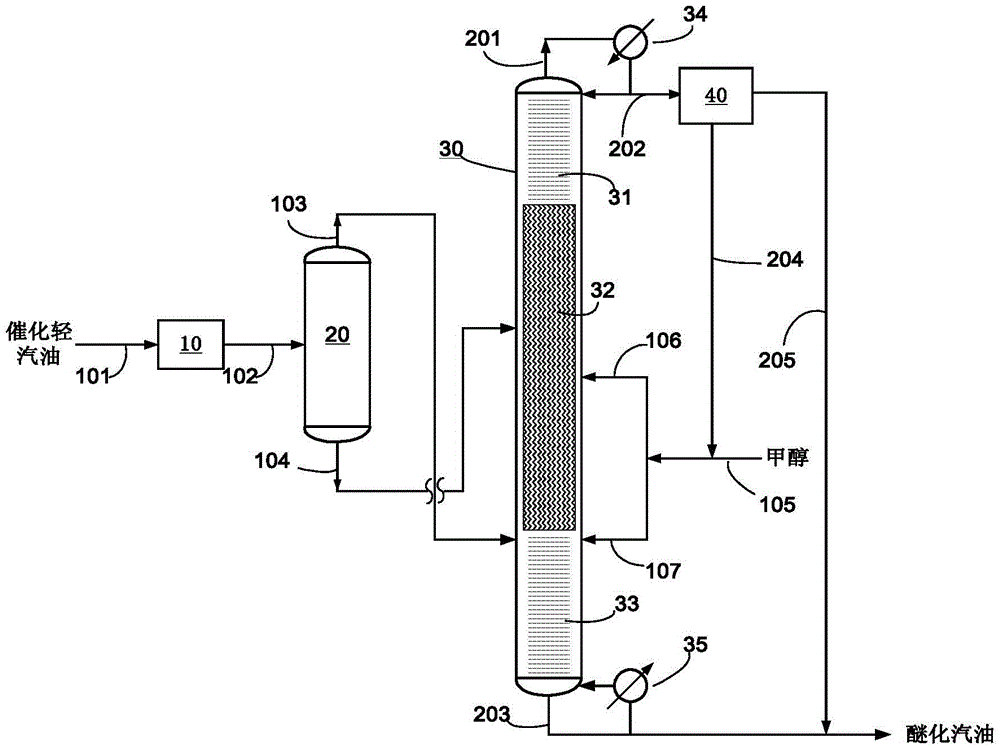

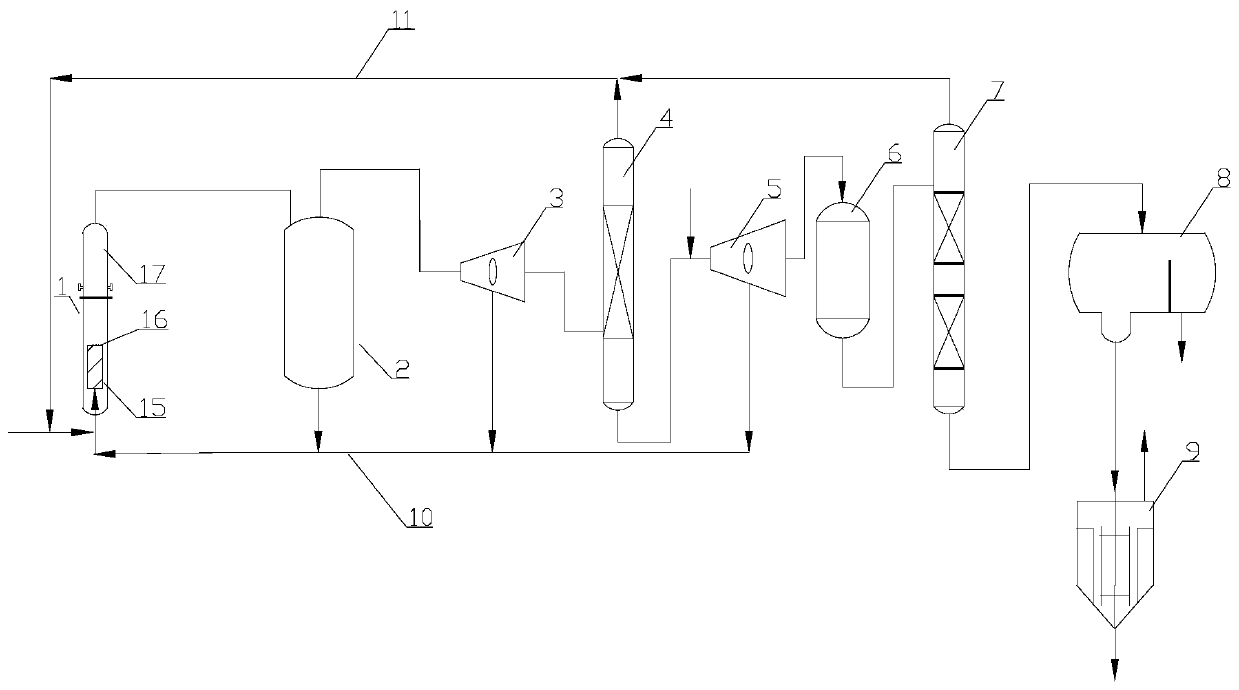

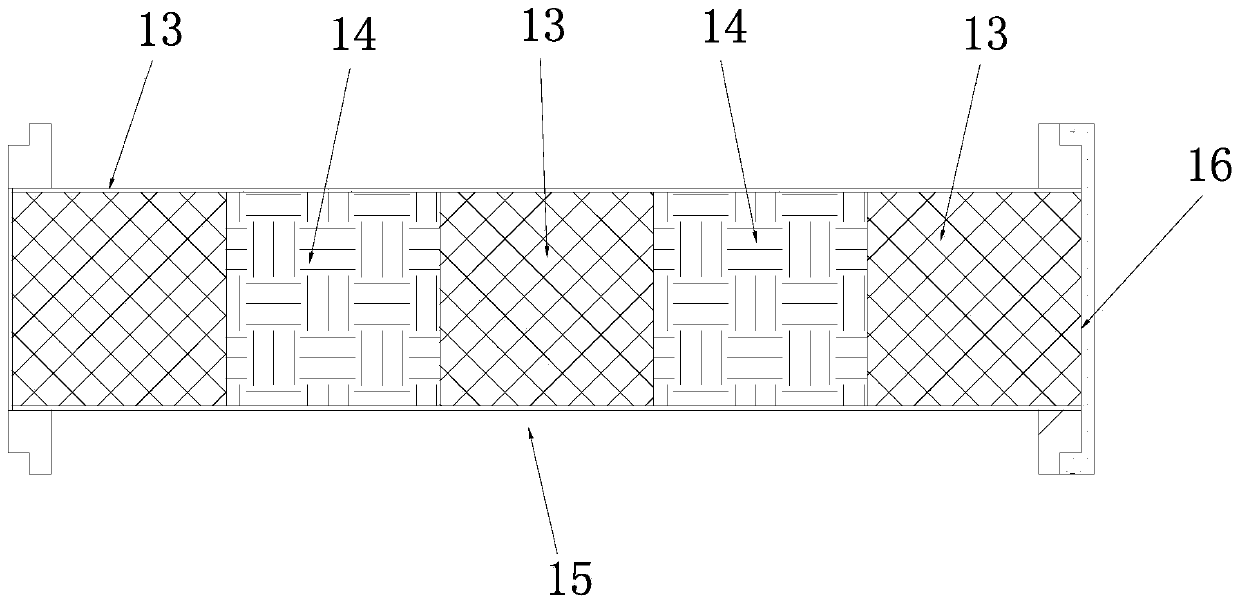

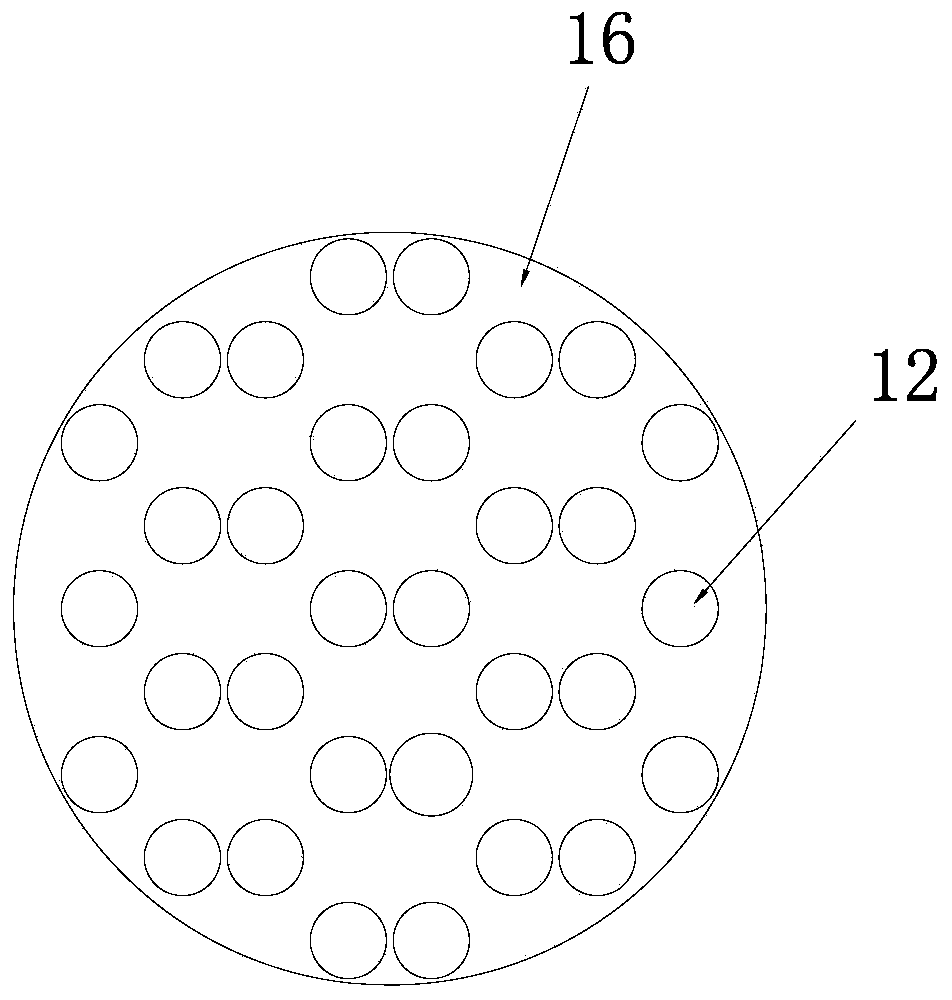

Light gasoline hydrocarbon recombination etherification catalytic rectification process and device thereof

ActiveCN106520187AReduce energy consumptionImprove balance conversionHydrocarbon oils treatmentCatalytic distillationMethanol

The invention provides a light gasoline hydrocarbon recombination etherification catalytic rectification process and a device thereof. With the light gasoline hydrocarbon recombination etherification catalytic rectification process provided by the invention, a method combining hydrocarbon recombination and catalytic rectification is adopted; C5 olefins and C6 olefins are introduced from positions with different heights in the reaction section of a catalytic rectification tower, thereby realizing contact with a catalyst in a same reaction section; meanwhile, methanol is introduced into the catalytic rectification tower from two positions with different heights in the reaction section. The invention also provides a light gasoline hydrocarbon recombination etherification catalytic rectification device used for realizing the above-mentioned process. The light gasoline hydrocarbon recombination etherification catalytic rectification process provided by the invention has the advantages of less investment, simple operation, low energy consumption and high olefin etherification conversion rate.

Owner:PETROCHINA CO LTD +1

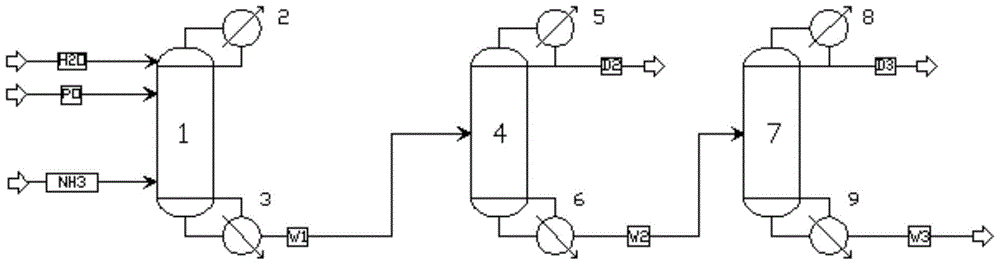

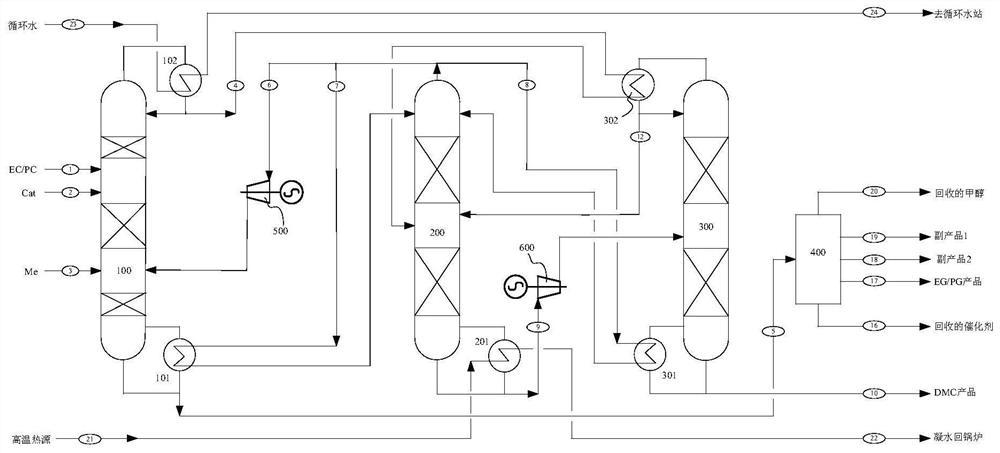

System and method for co-production of dimethyl carbonate and dihydric alcohol

PendingCN113769427AImprove balance conversionReduce evaporationOrganic compound preparationChemical industryPtru catalystAlcohol

The invention relates to a system and a method for co-production of dimethyl carbonate and dihydric alcohol. A methanol and dimethyl carbonate azeotrope material at the top of a reactive distillation column enters a first azeotropic distillation column, and a material extracted from the bottom of the reactive distillation column enters a methanol, dihydric alcohol and catalyst separation unit; a material at the bottom of the first azeotropic distillation column enters a second azeotropic distillation column, a first stream of steam material, a second stream of steam material and a third stream of steam material which are rich in methanol are extracted from the top of the first azeotropic distillation column, the first stream of steam material enters the reactive distillation column, the second stream of steam material enters a reboiler at the bottom of the reactive rectifying tower, and the third stream of steam material enters a reboiler at the bottom of the reactive distillation column; a third stream of steam material enters a reboiler at the bottom of the second azeotropic distillation column; and a DMC product is obtained at the tower bottom of the second azeotropic distillation column. Through the structural design, latent heat of high-pressure steam at the top of the first azeotropic distillation column is fully utilized, the energy efficiency is improved to the maximum extent, and the equipment investment is reduced.

Owner:SHANGHAI JIAO TONG UNIV

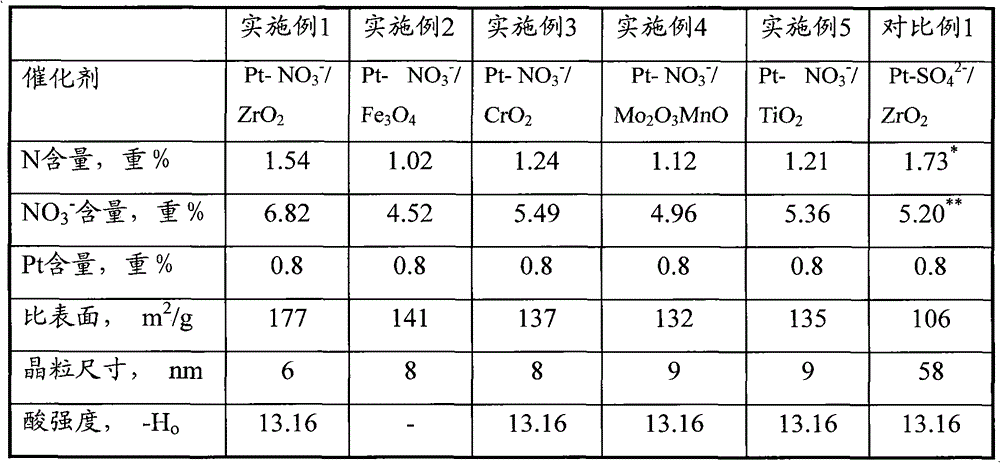

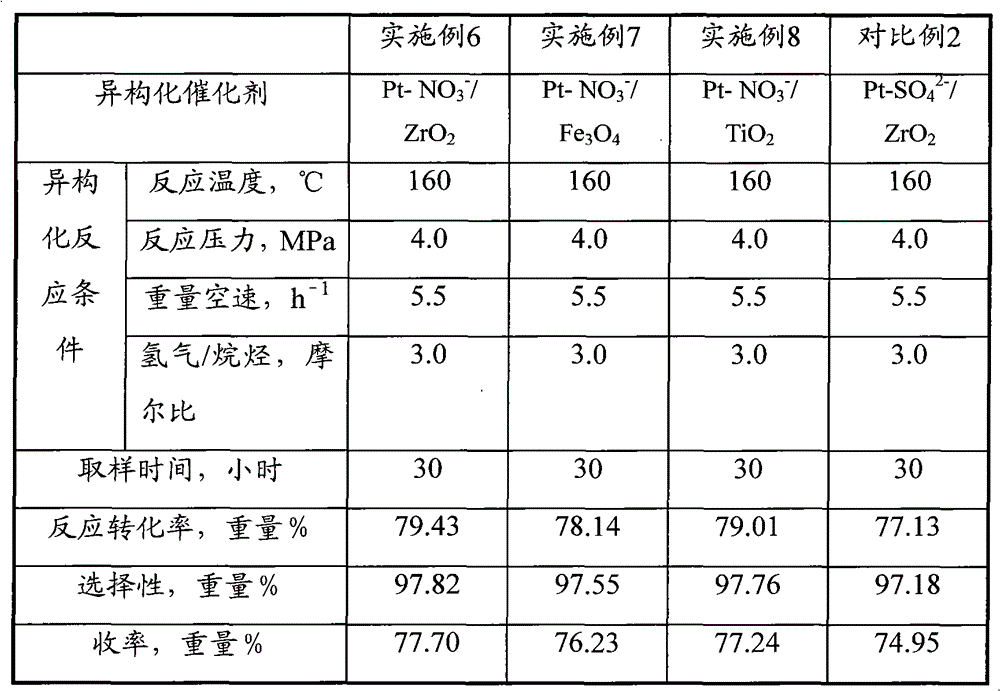

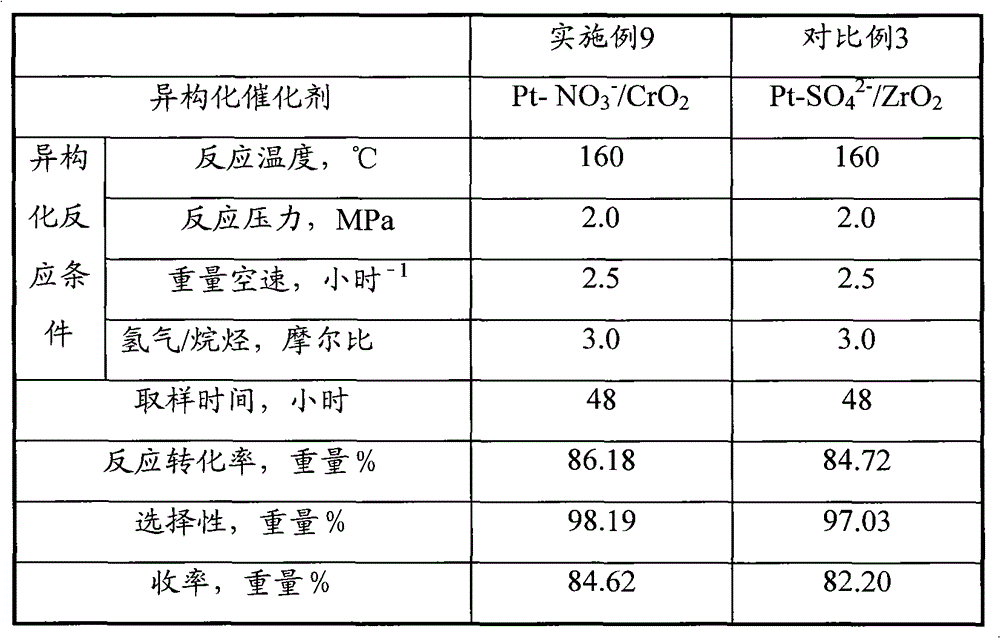

Solid superacid bifunctional catalyst and preparation method thereof

ActiveCN103055912AEasy to prepareHigh acid strengthHydrocarbon by isomerisationPhysical/chemical process catalystsIsomerizationDehydrogenation

A solid superacid bifunctional catalyst and a preparation method thereof. The catalyst is obtained by loading a hydrogenation / dehydrogenation metal component on metal oxide supported with NO<3-> acid radicals; and the metal component is one or more selected from Pt, Pd and Ni. The preparation method is as follows: (1) evenly mixing a water solution of a soluble chloride-containing metal salt with a soluble alkali precipitator; subjecting the mixed solution to a hydro-thermal treatment under a closed condition to obtain a metal salt hydrogel; subjecting the hydrogel to aging and layering; and drying and roasting the precipitate at a lower layer to obtain a NO<3-> / metal oxide; (2) impregnating the NO<3-> / metal oxide in an ammonium nitrate solution; and then filtering, drying and roasting to obtain a metal oxide loaded with NO<3-> radicals; and (3) impregnating the metal oxide loaded with NO<3-> radicals in a water solution of a soluble hydrogen and dehydrogenation metal component compound; and then filtering, drying and roasting to obtain the solid superacid bifunctional catalyst. The catalyst provided by the invention can be used for catalysis of an isomerization reaction of straight-chain paraffin, and has the characteristics of low reaction temperature, high conversion rate and good selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-production-efficiency polytetramethylene ether glycol preparation method

ActiveCN111574703AEfficient recyclingImprove conversion efficiencyFlow mixersOrganic-compounds/hydrides/coordination-complexes catalystsEthyl EthersDistillation

The invention relates to the field of chemical engineering, and discloses a high-production-efficiency polytetramethylene ether glycol preparation method which comprises the steps: 1) mixing tetrahydrofuran added with diethyl ether and a catalyst through an enhanced disperser, and carrying out a polymerization reaction at a temperature of 50-52 DEG C; 2) separating the catalyst from the reaction liquid through centrifugation; 3) distilling the residual reaction liquid to remove most tetrahydrofuran and all diethyl ether; mixing the concentrated solution with an extracting agent and then centrifuging; 4) adsorbing the residual mixed solution through an adsorption column, thoroughly removing the catalyst, and removing tetrahydrofuran through distillation; and 5) carrying out settling separation on the residual mixed solution at 38 DEG C, and treating by a refiner to obtain the polytetramethylene ether glycol. On one hand, a proper amount of diethyl ether is added into tetrahydrofuran, onthe other hand, the dispersity of the catalyst is improved through the reinforced disperser to increase the reaction speed, the reaction temperature is properly reduced through circulating heat exchange, the equilibrium conversion rate is increased, and thus the upper limit of the yield of polytetramethylene ether glycol is increased.

Owner:杭州三隆新材料有限公司

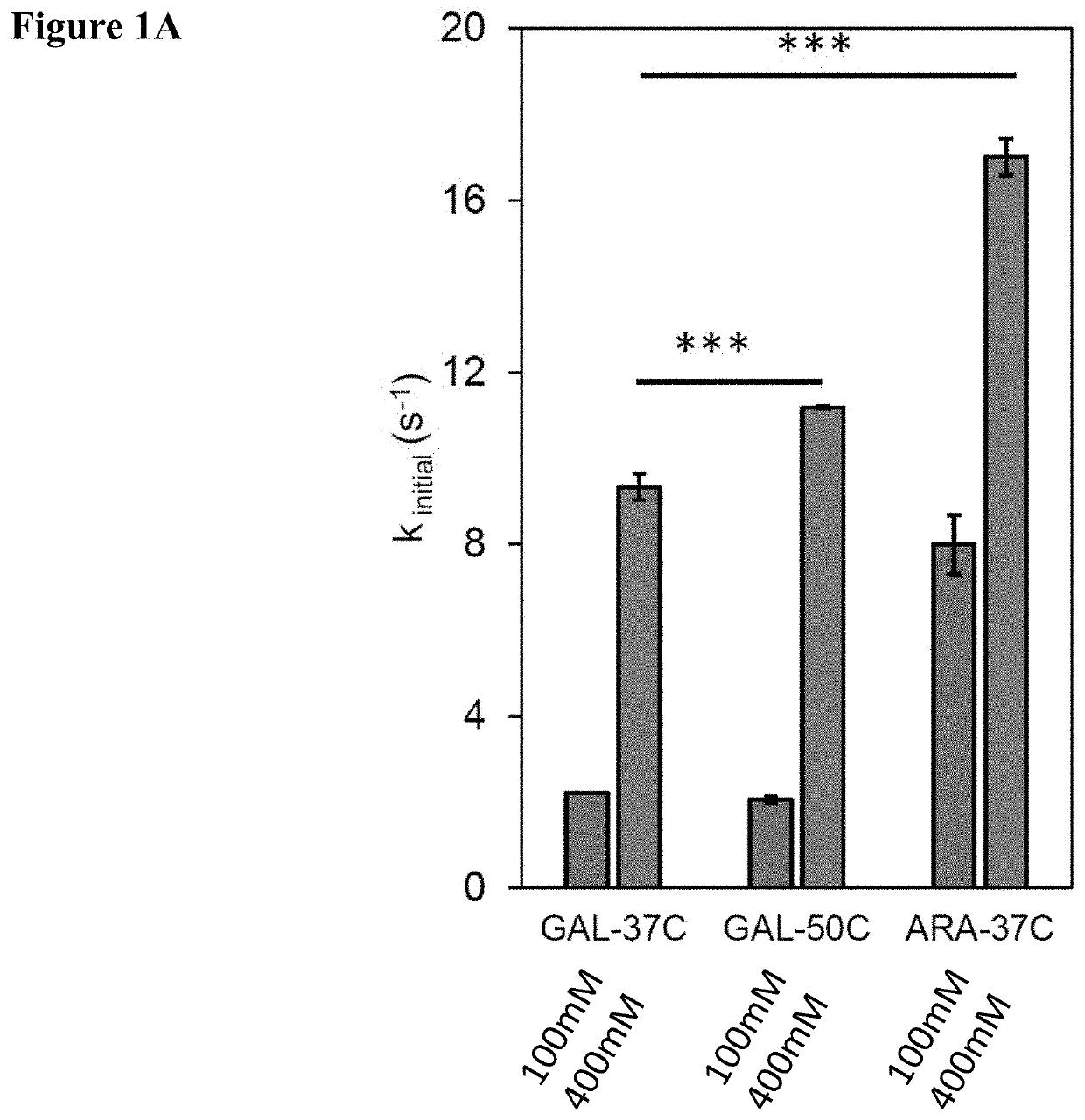

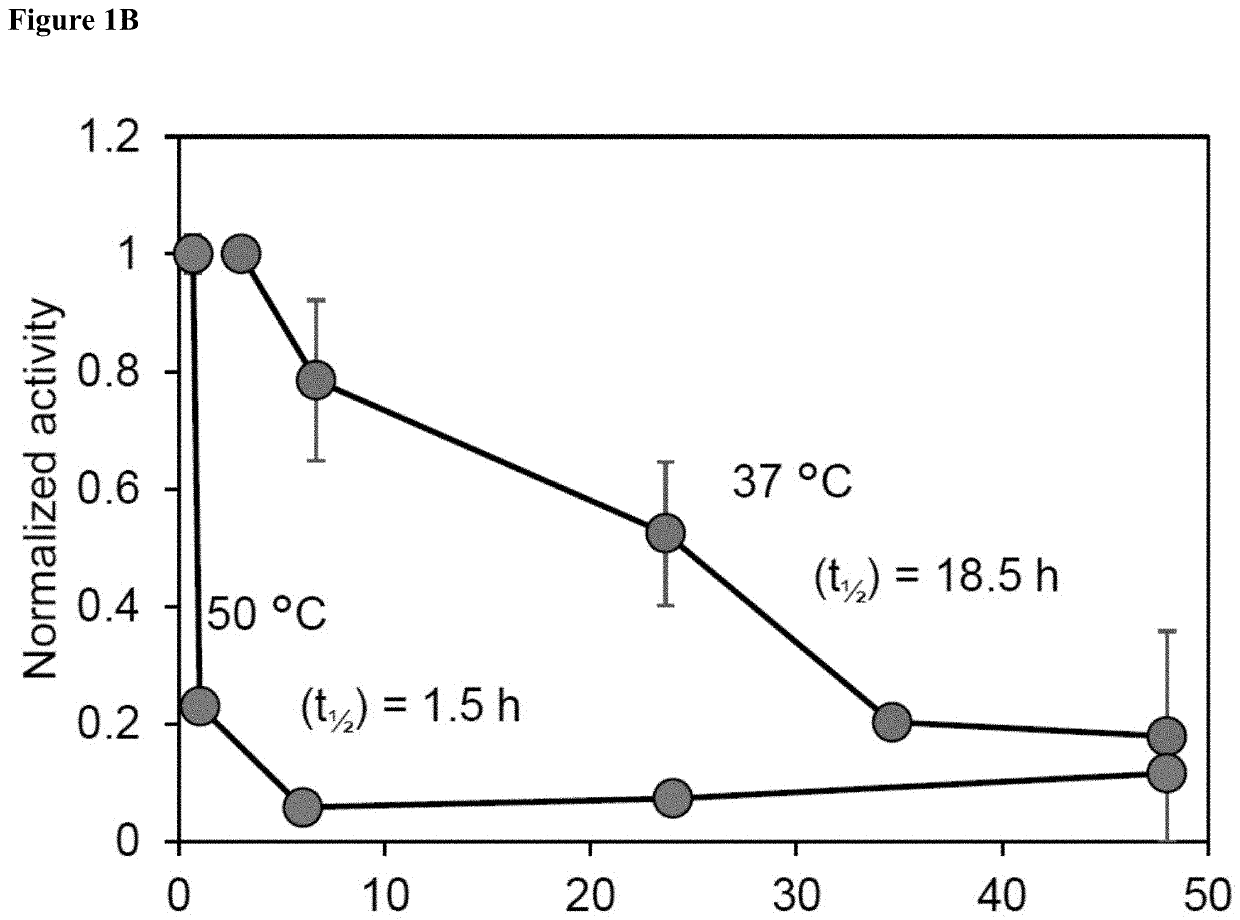

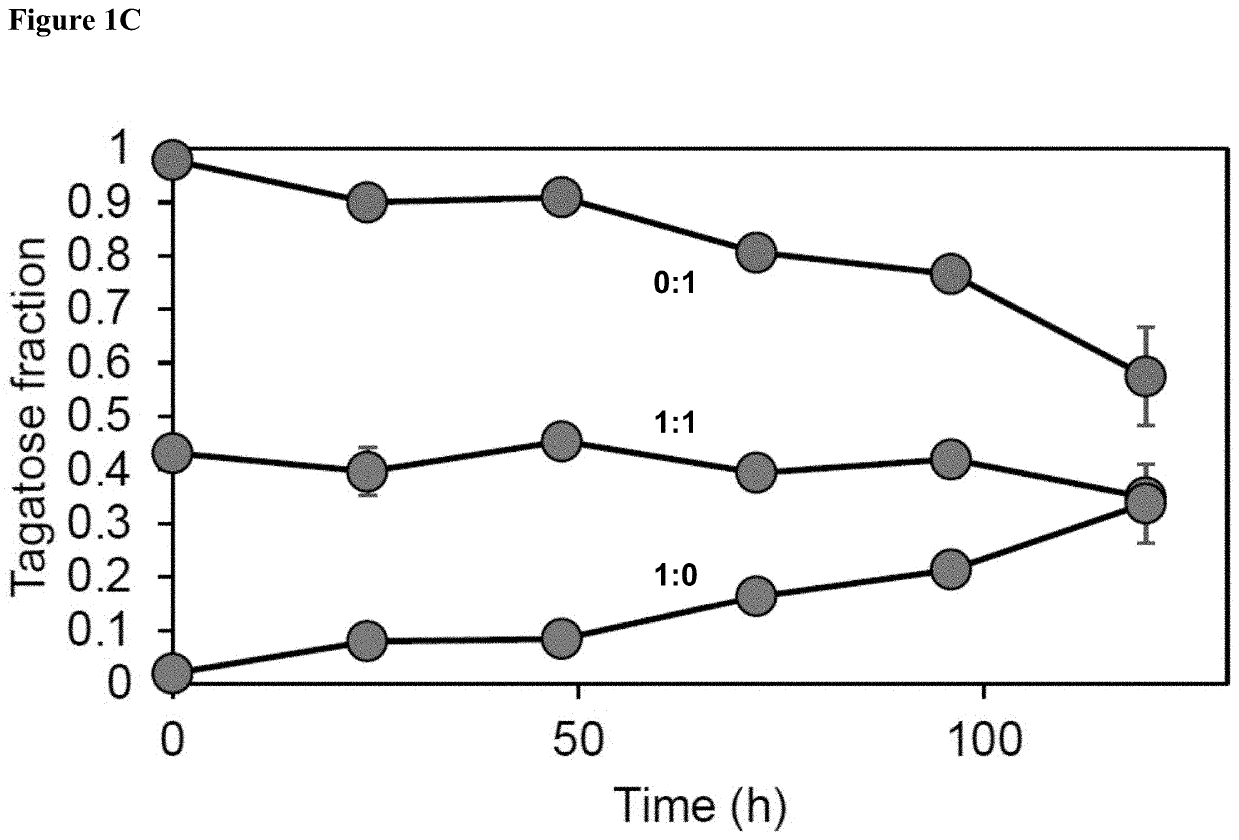

Galactose to tagatose isomerization at moderate temperatures with high conversion and productivity

PendingUS20210269839A1Improve balance conversionLoss of activityOxidoreductasesIsomerasesTagatoseMicroorganism

Disclosed are components and methods for preparing tagatose from galactose via isomerization reactions using engineered components. The engineered components include microbial cells and methods for preparing microbial cells that have been engineered to catalyze isomerization of galactose to tagatose, in which the microbial cells express cytoplasmically an exogenous L-arabinose isomerase enzyme. The disclosed microbial cells may further be modified for use in methods for preparing tagatose from galactose via isomerization reactions where the microbial cells are treated with reagents that permeabilize the cells. The disclosed methods enable isomerization reactions of galactose to tagatose at relatively high rates, high conversions, and elevated temperatures.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

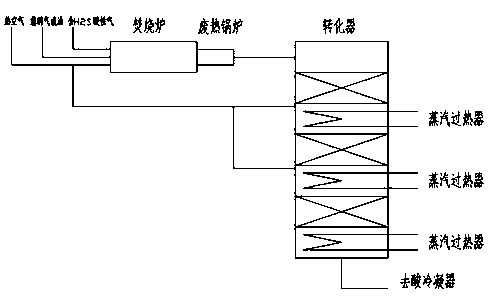

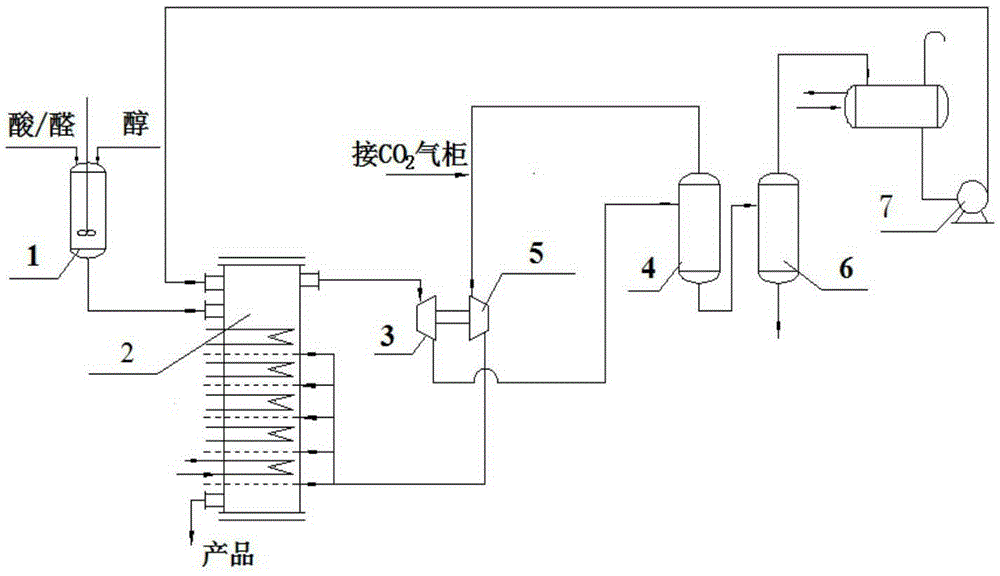

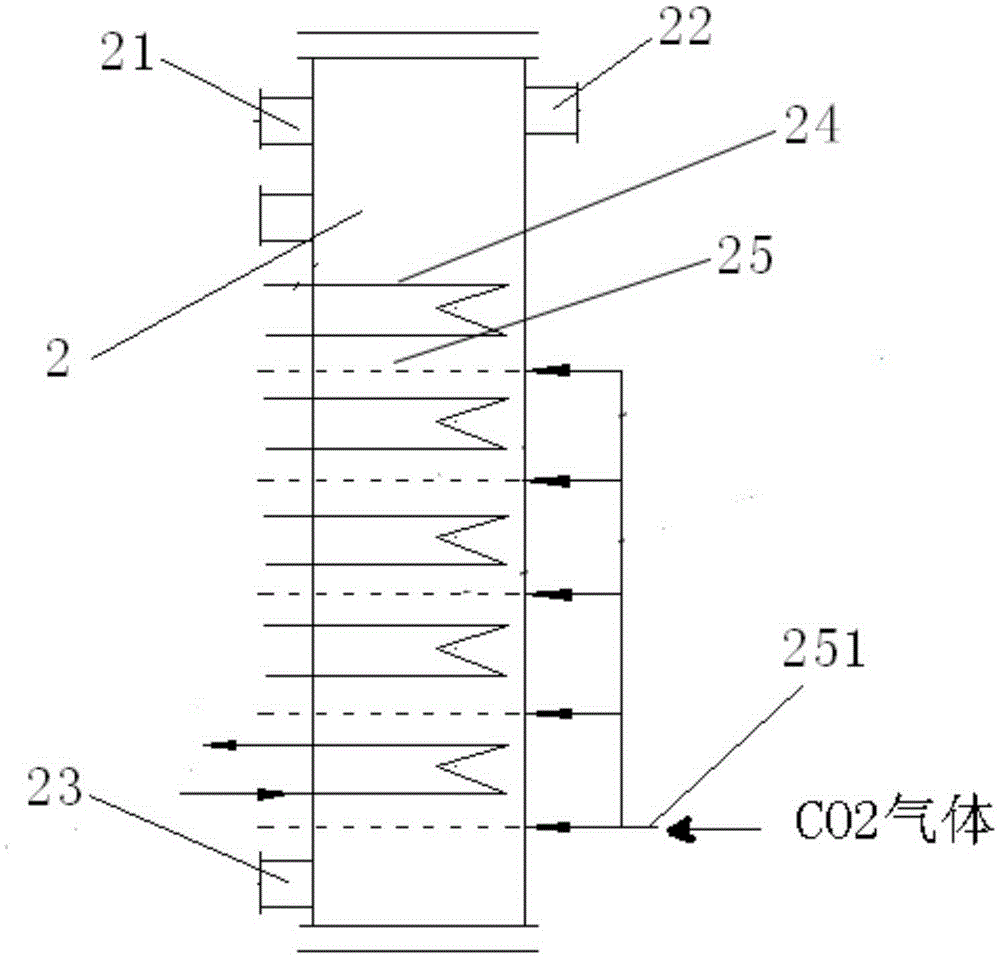

Transcritical CO2 catalytic esterification/condensation-separation coupling reaction method and equipment

ActiveCN105237318AAvoid pollutionImprove reaction speedOrganic compound preparationCarboxylic acid esters preparationVapor–liquid separatorAlcohol

The invention discloses a transcritical CO2 catalytic esterification / condensation-separation coupling reaction method. The method comprises the following steps: mixing alcohol compounds, acid / aldehyde compounds, and a solvent, dissolving, transferring the solution to a reactor, introducing CO2 into the reactor to carry out reactions; collecting the byproducts in gas phase, converting the gas phase by an expansion machine from a supercritical state into a subcritical state, then introducing the gas phase into a gas-liquid separator, pressurizing the separated CO2 and supplemented CO2 by a turbo-compressor, then introducing the pressurized CO2 into the reactor, carrying out reactions for 0.5 to 10 hours, reducing the pressure in the reactor, and taking out reaction products from the reactor. The equipment used by the provided method comprises an esterification / condensation reactor, which comprises a plurality of heating pipes and a gas distributor. The expansion machine and the turbo-compressor are integrated into one machine, and the turbo-compressor is driven by the recovered expansion work of the reaction system. The provided transcritical CO2 catalytic esterification / condensation-separation coupling reaction method and equipment have the advantages that the technology is convenient, the quality of esters / condensed carbonyl product is high, and the conversion rate is high.

Owner:GUANGXI UNIV

transcritical co 2 Catalytic esterification-separation coupling method and device for preparing rosin ester

ActiveCN104694014BAvoid pollutionImprove reaction speedChemical/physical/physico-chemical stationary reactorsNatural resin chemical modificationVapor–liquid separatorAlcohol

The invention relates to a method for preparing rosin ester by coupling catalytic esterification and separation, which comprises the following operation steps: (1) mixing an alcohol compound, a rosin and a solvent, and dissolving; (2) putting the dissolved substance in the step (1) into an esterification reactor, and introducing 0.01-10.0-MPa CO2 to perform esterification reaction at 150-300 DEG C; (3) recovering the gas phase in the esterification reaction process, sending the gas phase into a gas-liquid separator through an expander, and returning the separated CO2 and newly supplemented CO2 into the esterification reactor through a turbine compressor; and (4) after reacting in the esterification reactor for 1.0-8.0 hours, relieving the pressure, and taking the obtained product out of the esterification reactor. The invention aims to provide a preparation method which has the advantages of lower cost and high rosin ester quality.

Owner:GUANGXI UNIV

A kind of solid superacid bifunctional catalyst and preparation method thereof

ActiveCN103055906BEasy to prepareHigh acid strengthHydrocarbon by isomerisationPhysical/chemical process catalystsIsomerizationDehydrogenation

A solid superacid bifunctional catalyst and a preparation method thereof. The catalyst is obtained by loading a hydrogenation / dehydrogenation metal component on metal oxide supported with ClO<4-> acid radicals; and the metal component is one or more selected from Pt, Pd and Ni. The preparation method is as follows: (1) evenly mixing a soluble chloride-containing metal salt water solution with a soluble alkali precipitator; subjecting the mixed solution to a hydro-thermal treatment under a closed condition to obtain a metal salt hydrogel; subjecting the hydrogel to aging and layering; drying and roasting precipitate at a lower layer to obtain a ClO<4-> / metal oxide; (2) impregnating the ClO<4-> / metal oxide in an ammonium perchlorate solution; then filtering, drying and roasting to obtain a metal oxide loaded with ClO<4-> radicals; and (3) impregnating the metal oxide loaded with ClO<4-> radicals in a water solution of a soluble hydrogen and dehydrogenation metal component compound; and then filtering, drying and roasting to obtain the solid superacid bifunctional catalyst. The catalyst provided by the invention can be used for catalysis of an isomerization reaction of straight-chain paraffin, and has the characteristics of low reaction temperature, high conversion rate and good selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method for preparing sec-butyl acetate

ActiveCN104370741BHigh selectivityPrecise selectivityOrganic compound preparationCarboxylic acid esters preparationButeneLife stage

The invention discloses a method for preparing sec-butyl acetate, relates to the technical field of sec-butyl acetate, and aims at solving the technical problems in the existing method for preparing sec-butyl acetate through addition reaction between n-butene and acetic acid that the butene conversion rate is low and the selectivity of sec-butyl acetate product is poor. The method comprises the process of addition reaction between n-butene and acetic acid in the presence of a catalyst under the addition reaction condition and is characterized in that the n-butene raw material contains three isomers: 1-butene, cis-2-butene and trans-2-butenen, the catalyst is a strong acid cation exchange resin, the reaction pressure is 1.2MPa, the reaction temperature is controlled to gradually rise in the process of the addition reaction so that the three isomers gradually react, and the corresponding reaction temperature is approximately adjusted according to the life stage of the catalyst. Through the adoption of the method, the butene conversion rate and the selectivity of the sec-butyl acetate product can be effectively improved, so that the sec-butyl acetate is capable of being adapted to butene raw materials containing different ingredients and catalysts in different life stages.

Owner:HUIZHOU YUSSEN CHEM CO LTD

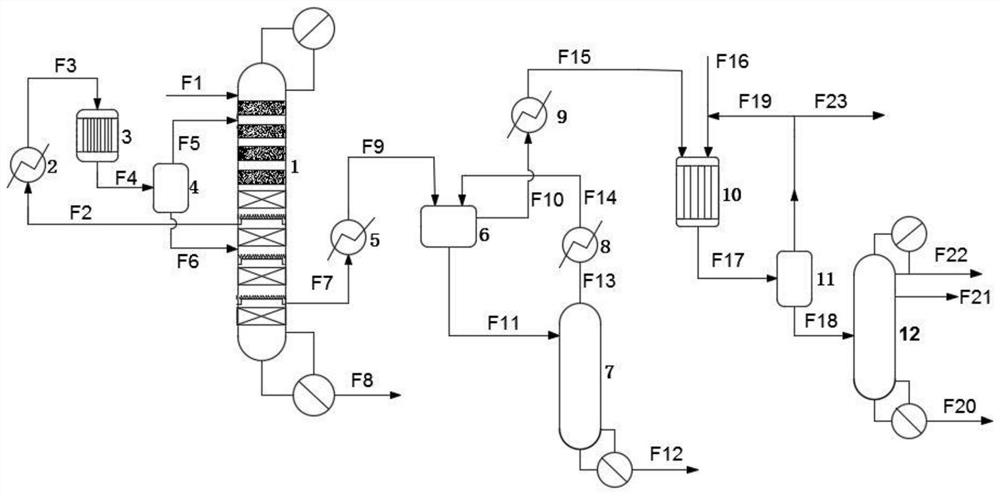

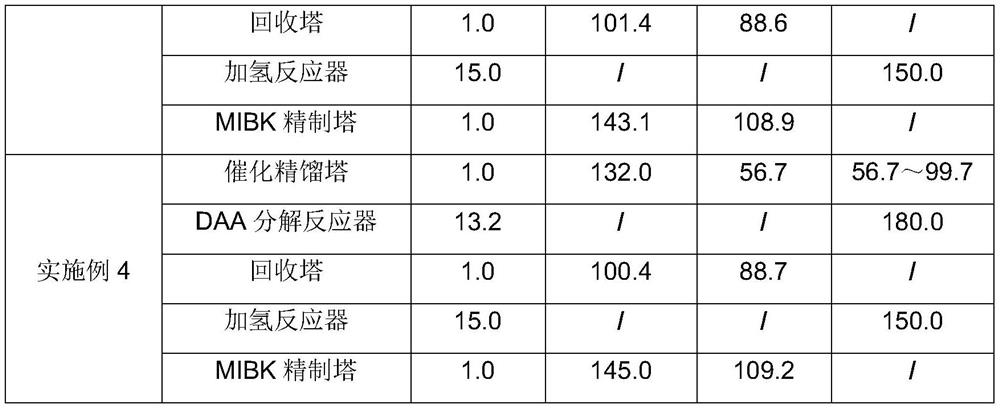

A kind of method and its equipment of synthesizing methyl isobutyl ketone by acetone two-step method

ActiveCN108002995BReduce the problem of high DAA contentReduce generationOrganic compound preparationEnergy inputMethyl isobutyl ketoneFluid phase

The invention discloses a method and equipment for synthesizing methyl isobutyl ketone by a two-step method from acetone. The method comprises: a. the raw material acetone is condensed and dehydrated in a catalytic rectification tower to generate DAA and MSO, and is fed to the side line of the catalytic rectification tower Extract products rich in MSO and water; b. The DAA-containing material is extracted from the side line of the catalytic rectification tower and enters the DAA decomposition reactor. The DAA in the material is converted into acetone and MSO, and the product is flash separated to obtain acetone-rich gas phase and The liquid phase containing MSO and water is recycled back to the tower respectively; c, the liquid phase product described in step a is cooled and phase-separated to obtain an organic phase rich in MSO and an aqueous phase containing a small amount of organic matter, and the aqueous phase enters the recovery tower to recover organic matter; d 1. The organic phase described in step c is hydrogenated to generate MIBK, and the hydrogen gas is recovered by flash evaporation and then enters the MIBK refining tower, and the MIBK product is extracted from the side line. The whole process conversion rate of acetone in the invention reaches 99.0%, and the purity of the product MIBK can reach 99.5%.

Owner:长成新能股份有限公司 +1

A dual-function catalyst for producing low-freezing-point biodiesel, its preparation method and application

ActiveCN109833906BWeak acidFacilitated DiffusionFatty acid hydrogenationMolecular sieve catalystsBiodieselVegetable oil

The present invention provides a kind of bifunctional catalyst for producing biodiesel with low freezing point and its preparation method and application. 2 P is a bimetallic active component, and the content of the active component is 0.05 to 5.05 wt% based on the weight of the carrier as 100%; the method for preparing biodiesel with low freezing point is to use vegetable oil hydrodeoxygenated oil as raw material , add the above-mentioned bifunctional catalyst, and carry out continuous reaction in the reactor, the reaction temperature is 250-370°C, the reaction pressure is 1.0-4.0MPa, and the mass space velocity of the vegetable oil hydrodeoxygenated oil is 1.0-4.0h ‑1 , the volume ratio of hydrogen to vegetable oil hydrodeoxygenated oil is 300-800:1. Catalyst of the present invention is carried Pd-Ni on the molecular sieve of hierarchical porous nanometer SAPO-31 2 The bifunctional catalyst prepared by the P bimetal has the advantages of less noble metal Pd consumption, high reactivity and isomerization selectivity, good stability, and high yield of biodiesel.

Owner:PETROCHINA CO LTD

Method for preparing methyl tertiary butyl ether (MTBE)

ActiveCN102351661BImprove balance conversionGuaranteed purityChemical industryEther preparation by compound additionFixed bedCatalytic distillation

The invention discloses a method for preparing methyl tertiary butyl ether (MTBE). The method is characterized in that: an external circular heat-removing fixed bed reactor is connected in series in front of an original mixed-phase fixed bed reactor. The method comprises the following steps of: (1) inputting mixed C4 serving as a raw material into the external circular heat-removing fixed bed reactor for reacting till the content of isobutene in the mixed C4 serving as the raw material is lowered below 30 percent by weight; (2) introducing the reacted material into the mixed-phase fixed bed reactor for reacting; and (3) introducing the reacted material discharged out of the mixed-phase fixed bed reactor into a catalytic distilling tower for performing deep etherification and separating. The method can adapt to the raw material change of an upstream device, so that the equilibrium conversion rate of the MTBE is increased, the temperature of the catalytic distilling tower is prevented from surpassing a temperature limit, the raw material purity of a downstream device is ensured, and an MTBE device does not to halt during replacement of a catalyst.

Owner:HUIZHOU YUSSEN CHEM CO LTD

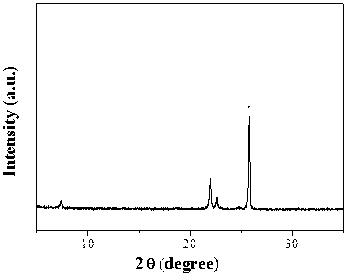

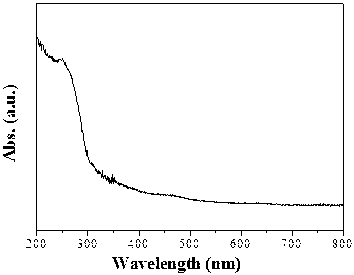

Microwave irradiation modification method of titanium dioxide sol

ActiveCN104495858AHeating evenlyAchieve densificationSilicon compoundsCrystallization temperatureEnergy consumption

The invention discloses a microwave irradiation modification method of titanium dioxide sol. The method comprises the following steps: adding titanium dioxide sol to a coiled pipe of a microwave irradiator, and carrying out microwave irradiation at 50-300 DEG C and 0.1-4MPa for 0.5-4 hours, so as to finish microwave irradiation modification of the titanium dioxide sol. The method is short in reaction time, low in cost, low in energy consumption, and suitable for industrialized production, and can be continuously prepared; and the modified titanium dioxide sol is low in crystallization temperature, small in sol particle size, narrow in distribution, and excellent in film-forming property.

Owner:XI AN JIAOTONG UNIV

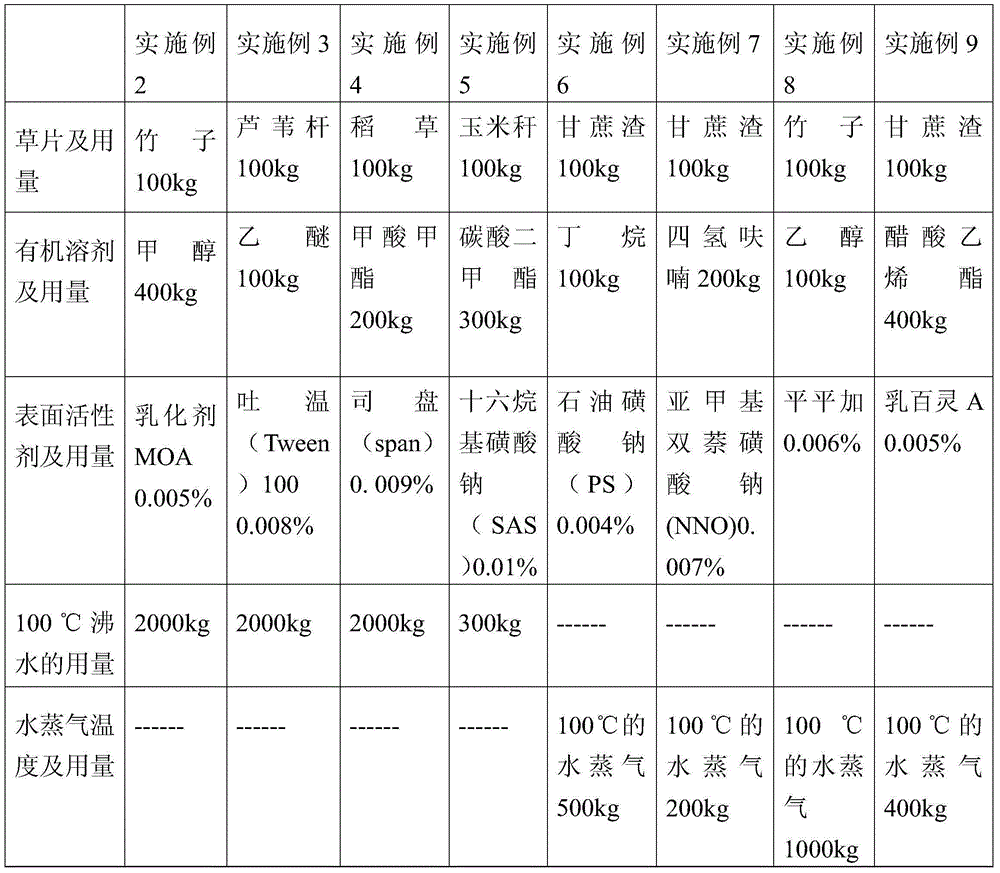

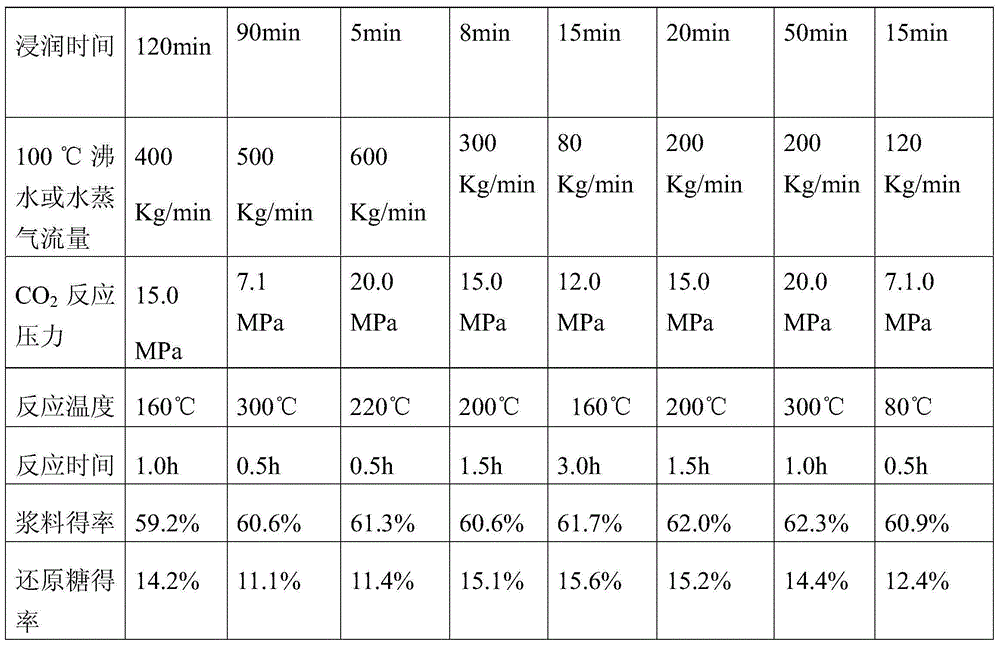

Method of producing pulp by instant vaporization expansion-infiltration in straw sheets

ActiveCN105200834AEliminate Feedback InhibitionIncreased reaction rate and equilibrium conversionPulping with organic solventsNon-woody plant/crop pulpBoiling pointCell membrane

The invention discloses a method of producing pulp by instant vaporization expansion-infiltration in straw sheets. The method includes the steps of adding straw sheets as a raw material into an organic solvent having a boiling point lower than 100 DEG C, according to a straw sheet to organic solvent weight ratio: 1:1 to 1:4 so as to infiltrate the straw sheets for 5-120 min, adding the straw sheets into 100 DEG C boiling water or vapor having a temperature higher than the boiling point of the organic solvent, according to a straw sheet to water weight ratio: 1:1 to 1:20, and producing pulp by boiling under supercritical CO2. cell membranes are caused to expand and break by instant vaporization of the organic solvent among fiber cells of the straw sheets, so that the speed of the removal of intercellular lignin from the straw sheets by boiling is increased by 1 to 5 times, and the usage of the organic solvent is decreased by 2 to 10 times.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com