A dual-function catalyst for producing low-freezing-point biodiesel, its preparation method and application

A dual-function catalyst and biodiesel technology, applied in the preparation of catalysts and catalyst fields, can solve the problems of easy deactivation and low selectivity, and achieve the effects of mild acidity, high selectivity and high liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

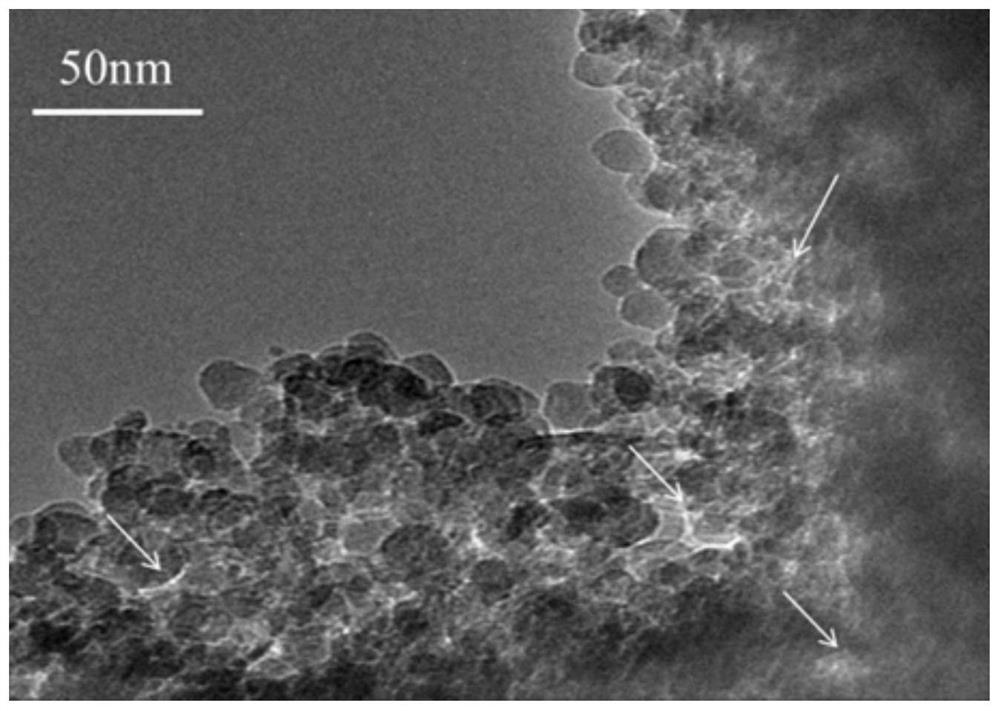

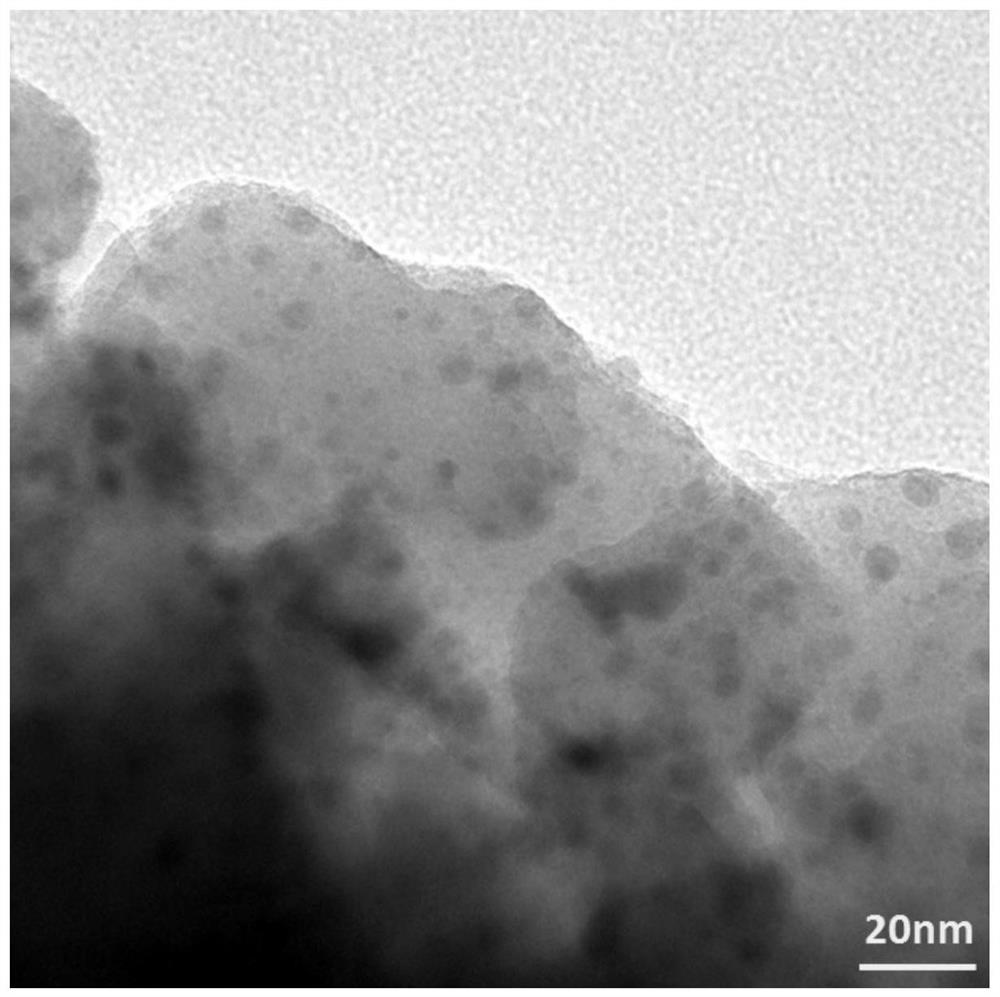

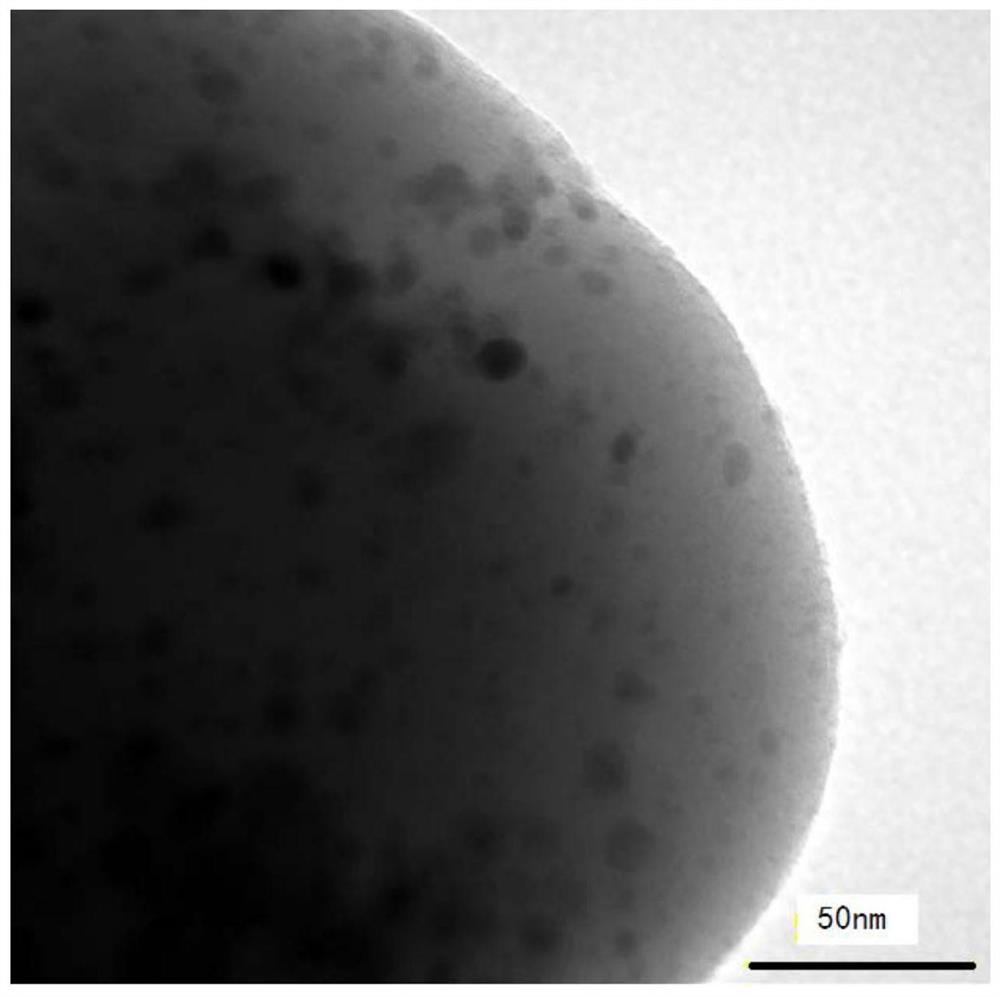

Image

Examples

Embodiment 1

[0040] A kind of Pd-Ni of this embodiment 2 P / SAPO-31 molecular sieve catalyzed a method for producing biodiesel with high selectivity by hydroisomerization of vegetable oil deoxygenated oil, the catalyst is 0.05%Pd+3%Ni 2 P / SAPO-31 molecular sieve bifunctional catalyst.

[0041] The experimental operation process of catalyst preparation is as follows:

[0042] Preparation of hierarchical porous nanometer SAPO-31 molecular sieve:

[0043] After the phosphoric acid of 5g 85%wt. is mixed with 15g deionized water, add 3g pseudo-boehmite (Al 2 o 3 The mass fraction is 71.13%wt.), 4g 95%wt. of di-n-butylamine, 3g silica sol (SiO 2 The mass fraction is 26.85%wt.) After the initial gel is made, it is transferred to a stainless steel crystallization kettle with a polytetrafluoroethylene liner, crystallized at a temperature of 185°C for 24h, and the crystallized product is cooled to room temperature, and then After centrifugation and washing, and dried at a temperature of 110°C fo...

Embodiment 2

[0050] A kind of Pd-Ni of this embodiment 2 P / SAPO-31 molecular sieve catalyzes the method for preparing biodiesel with high selectivity by hydroisomerization of vegetable oil deoxygenated oil, and the preparation method of the catalyst A is the same as that in Example 1.

[0051] Production of low freezing point biodiesel:

[0052] The above bifunctional catalyst A is first reduced to the reaction temperature in a fixed bed reactor at 400°C in a hydrogen atmosphere for 2 hours, and then the vegetable oil deoxygenated oil raw material solution is continuously injected into the fixed bed reactor with a metering pump, and the temperature is 340°C, The pressure is 2.0MPa, and the mass space velocity of vegetable oil deoxygenated oil is 1.67h -1 , the isomerization reaction was carried out under the condition that the volume ratio of hydrogen to vegetable oil deoxygenated oil was 500:1. The reaction time is 500h. The reaction conditions and product analysis results are shown in...

Embodiment 3

[0054] A kind of Pd-Ni of this embodiment 2P / SAPO-31 molecular sieve catalyzes the method for preparing biodiesel with high selectivity by hydroisomerization of vegetable oil deoxygenated oil, and the preparation method of the catalyst A is the same as that in Example 1.

[0055] Production of low freezing point biodiesel:

[0056] The above bifunctional catalyst A is first reduced to the reaction temperature in a fixed-bed reactor at 400°C for 2 hours in a hydrogen atmosphere, and then the raw material liquid of vegetable oil deoxygenated oil is continuously injected into the fixed-bed reactor with a metering pump, and is heated at a temperature of 350 ℃, the pressure is 2.0MPa, the mass space velocity of vegetable oil deoxygenated oil is 1.5h -1 , the isomerization reaction was carried out under the condition that the volume ratio of hydrogen to vegetable oil deoxygenated oil was 500:1. The reaction time is 500h. The reaction conditions and product analysis results are sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com