Hydrogenation catalyst and preparation method and application thereof

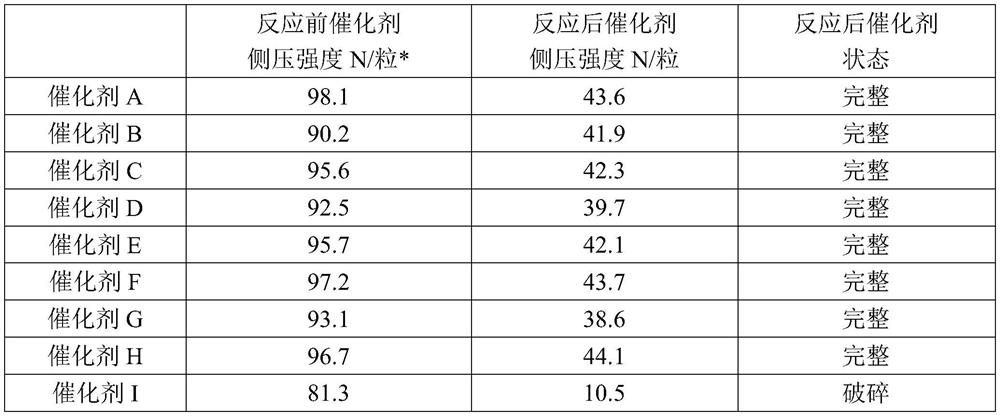

A hydrogenation catalyst and catalyst technology, applied in the field of catalysis, can solve the problems of easy pulverization of the catalyst, poor selectivity, and low product quality, and achieve the effects of smooth catalyst pores, high mechanical stability, and strong conversion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] (1) Add 300g water, 3.0g dimethyl dodecyl [3-(trimethoxysilyl) propyl group] ammonium chloride and 9g hydroxymethyl cellulose in the reaction kettle and stir evenly to obtain dispersion liquid I .

[0080] (2) 273.4g copper nitrate (Cu(NO 3 ) 2 ·3H 2 O, 242), 167.1g zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O, 298) and 163.4g aluminum nitrate (Al(NO 3 ) 3 9H 2 (2,375) was dissolved in 1471g water to prepare mixed salt solution, and preparation concentration was 15wt% sodium carbonate aqueous solution, and above-mentioned two kinds of solutions were heated to 60 ℃ respectively and then co-flow was added dropwise in the aforementioned reactor, and the time of dropping was 40min. The temperature of the precipitation process was controlled at 60°C, and the pH value of the precipitation process was 7.0 (wherein, according to the pH value of the precipitation process, the amount of sodium carbonate aqueous solution was controlled to be 105% of the theoretically required amount ...

Embodiment 2

[0090] (1) Add 300g of water, 2g of dimethyltetradecyl[3-(trimethoxysilyl)propyl]ammonium chloride and 6g of hydroxyethyl methylcellulose into the reaction kettle and stir evenly to obtain a dispersion I.

[0091] (2) 303.7g copper nitrate (Cu(NO 3 ) 2 ·3H 2 O, 242), 87.4g zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O, 298) and 348.8g aluminum nitrate (Al(NO 3 ) 3 9H 2 (2, 375) was dissolved in 1661.5g water to prepare a mixed salt solution, and the preparation concentration was an aqueous sodium carbonate solution of 15wt%, and the above two solutions were heated to 65° C. and then added dropwise to the aforementioned reaction kettle in parallel, and the dropping time was 50 minutes. , control the temperature of the precipitation process at 65°C, and the pH value of the precipitation process is 7.0 (wherein, according to the pH value of the precipitation process, the amount of sodium carbonate aqueous solution is controlled to be 105% of the theoretically required amount for the ...

Embodiment 3

[0098] (1) Add 300g of water, 1g of dimethylhexadecyl[3-(trimethoxysilyl)propyl]ammonium chloride and 3g of hydroxyethyl methylcellulose into the reaction kettle and stir evenly to obtain a dispersion I.

[0099] (2) 334.1g copper nitrate (Cu(NO 3 ) 2 ·3H 2 O, 242), 107.8g zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O, 298) and 161.9g aluminum nitrate (Al(NO 3 ) 3 9H 2 (2, 375) was dissolved in 1661.5g water to prepare mixed salt solution, and the preparation concentration was 15wt% sodium carbonate aqueous solution, the above two solutions were heated to 65°C respectively and then added dropwise to the aforementioned reaction kettle in parallel, and the dropping time was 60min , control the temperature of the precipitation process to 65°C, and the pH value of the precipitation process to be 7.0 (wherein, according to the pH value of the precipitation process, the amount of sodium carbonate aqueous solution is controlled to be 105% of the theoretically required amount to completel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com