A kind of method for modification of extruded titanium-silicon molecular sieve

A technology of titanium-silicon molecular sieve and extrusion molding, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of limited diffusion of macromolecules and low titanium content in the outer surface skeleton, and avoid large Molecular diffusion limitation, enhanced catalytic activity, enhanced activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

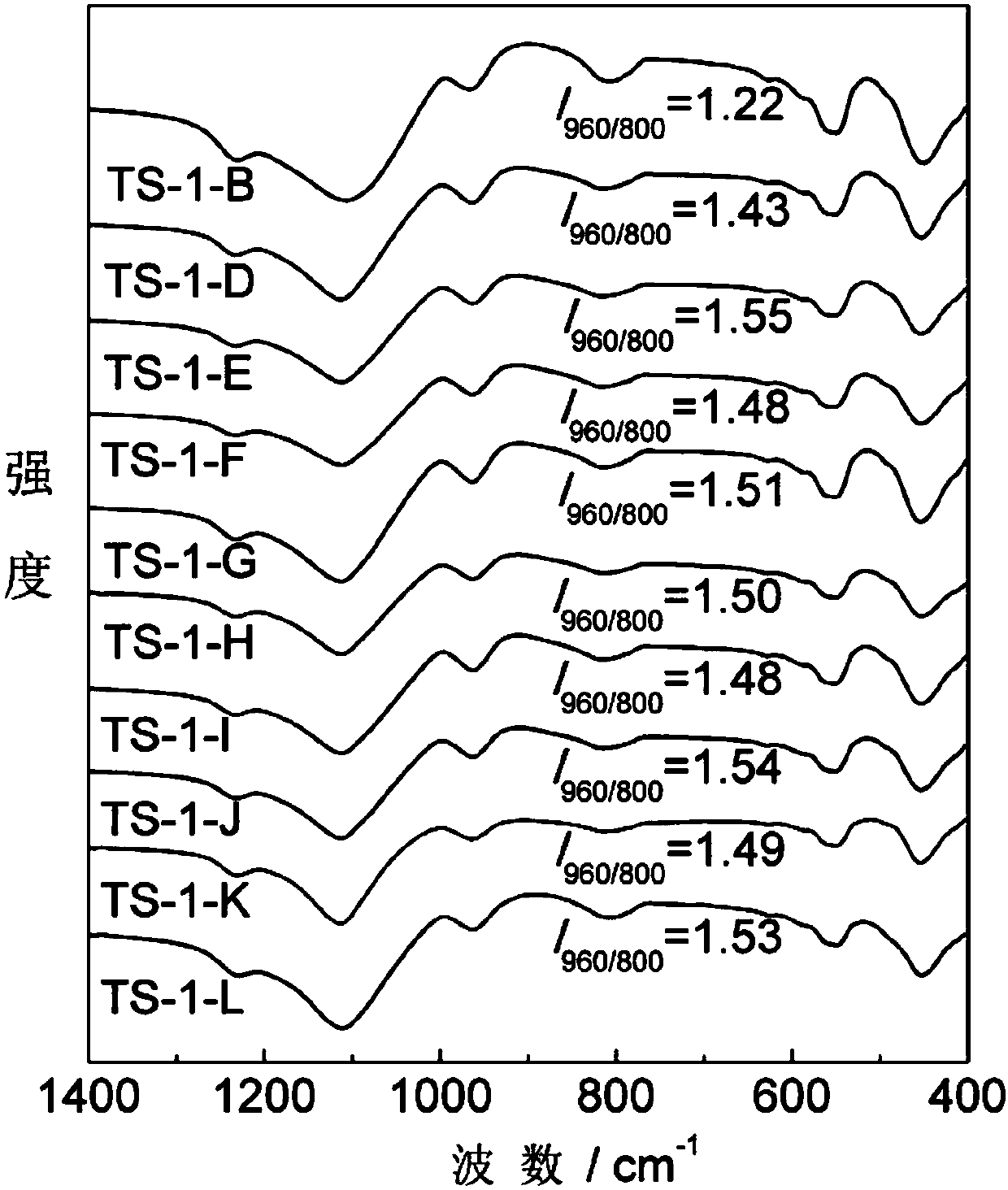

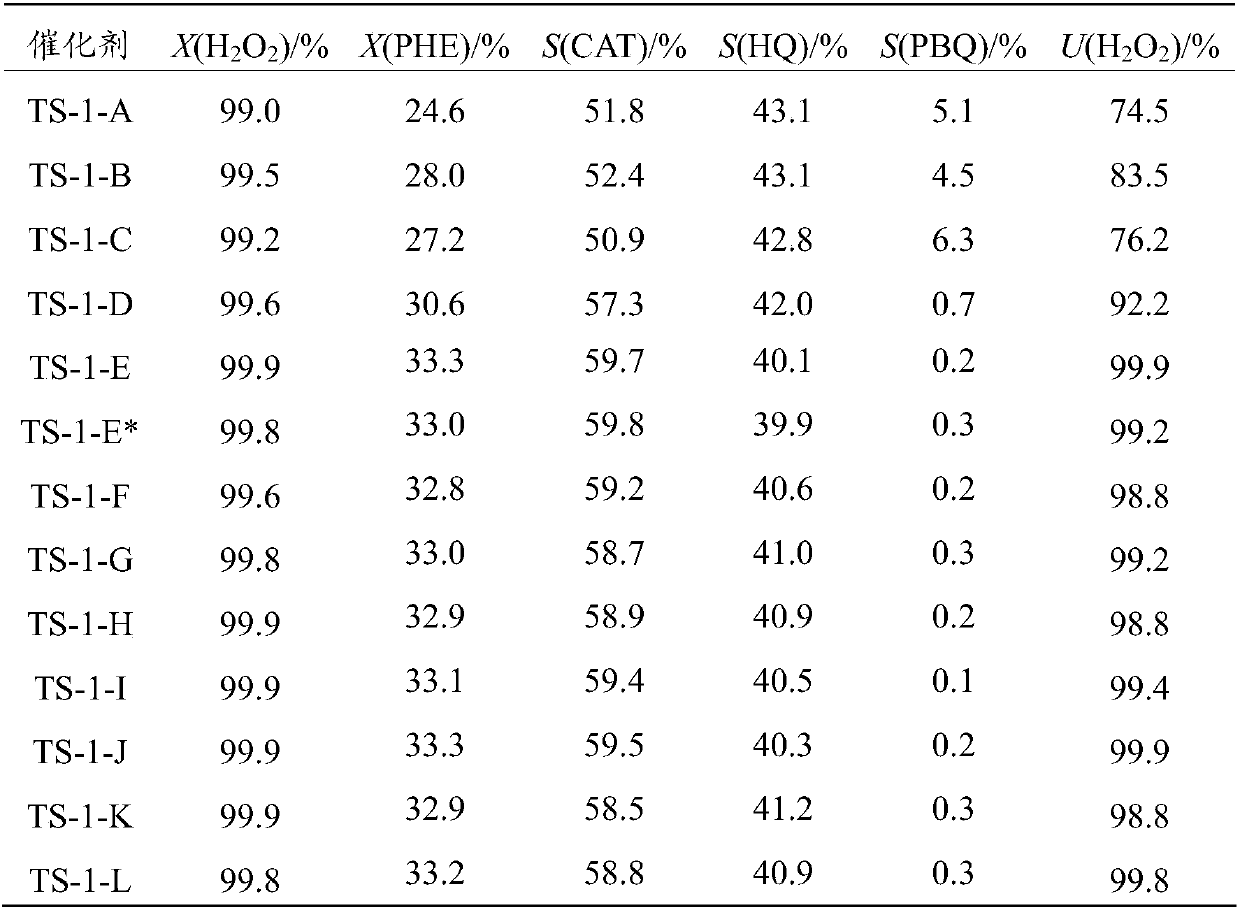

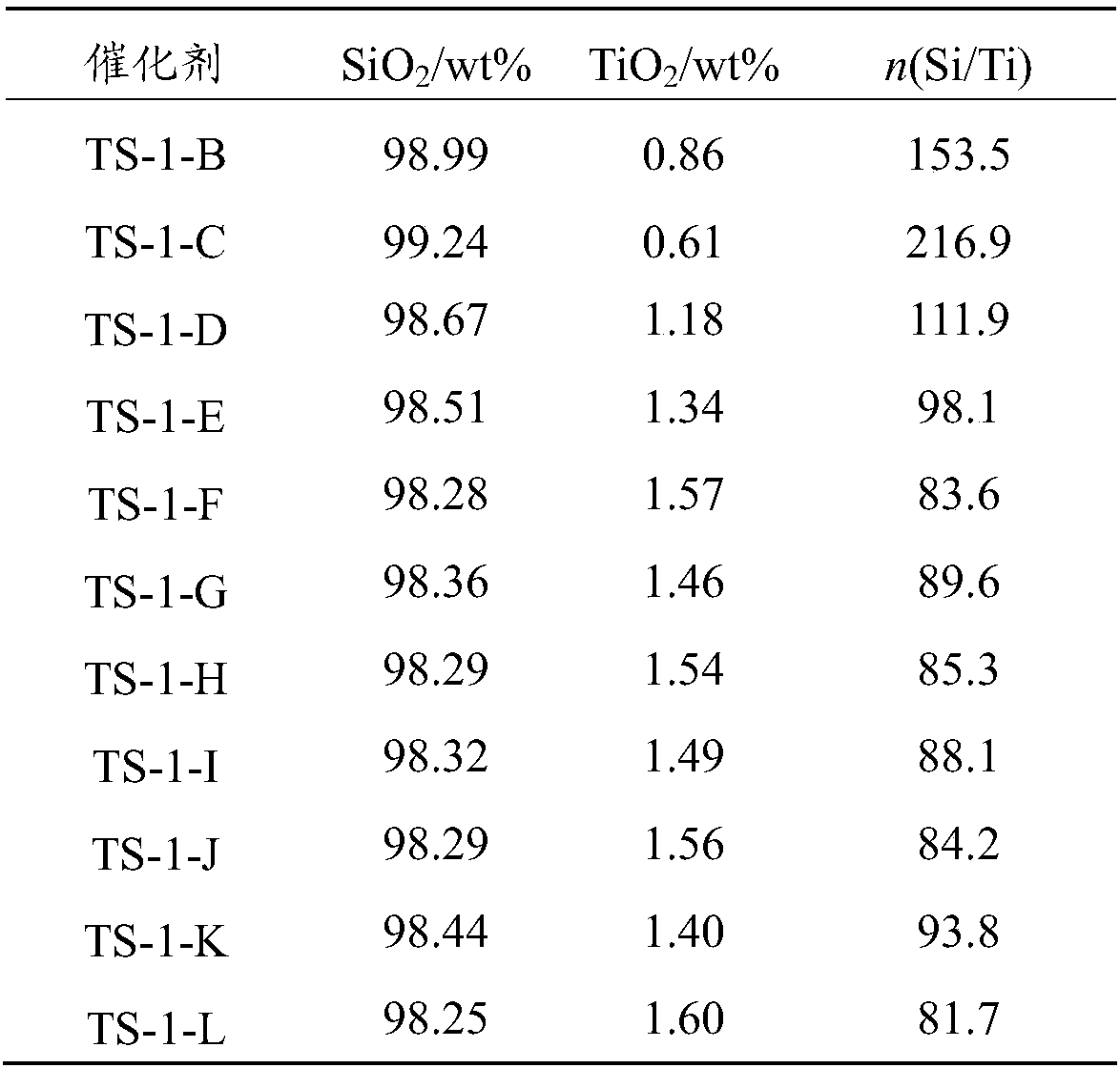

[0040] Mix 20g of titanium-silicon molecular sieve TS-1 powder prepared according to Comparative Example 1 of the present invention and 1.0g of starch evenly, add 10g of 25wt% silica sol, stir evenly, and quickly put it into -18°C for 10h in a sealed freezer, take out the freezer The product was thawed at 25°C, put into an extruder to extrude, and then dried and roasted to obtain a strip-shaped titanium-silicon molecular sieve. Add 8.0mL tetrabutyl titanate dropwise into 20mL isopropanol, react at 25°C for 40min, add 5mL 1.2mol / L tetrapropylammonium hydroxide, 67mL water and 7.7g Tween 40 to the solution successively, React at 25°C for 40 minutes to obtain titanium source hydrolyzate; mix 8g of strip-shaped titanium-silicon molecular sieve TS-1 with 70mL of titanium source hydrolyzate, put it in a crystallization kettle, and treat it at 170°C for 48h to separate the solid. Washed, dried, and baked at 550°C for 6h, the obtained sample was designated as TS-1-E.

Embodiment 2

[0042] Mix 20g of titanium-silicon molecular sieve TS-1 powder prepared according to Comparative Example 1 of the present invention and 1.5g of polymethylacrylate evenly, add 20g of 25wt% silica sol, stir evenly, and quickly put it into -18°C for 5h in a sealed freezer , take out the frozen product and thaw it at 30°C, put it into an extruder and extrude it, and then dry and roast it to obtain a strip-shaped titanium-silicon molecular sieve. Add 6.6mL of tetrabutyl titanate dropwise into 20mL of isopropanol, react at 25°C for 30min, add 5.2mL of 1.2mol / L tetrapropylammonium hydroxide, 68mL of water and 10.8g of Tween 20 to the solution successively, React at 25°C for 30 minutes to obtain titanium source hydrolyzate; mix 8g strip-shaped titanium-silicon molecular sieve TS-1 with 60mL titanium source hydrolyzate, put it in a crystallization kettle, treat at 170°C for 60h, separate the solid, and The solid was washed, dried, and calcined at 550°C for 6 hours, and the obtained sam...

Embodiment 3

[0044] Mix 20g of titanium-silicon molecular sieve TS-1 powder prepared according to Comparative Example 1 of the present invention and 2.0g of polyacrylic acid evenly, add 16g of 25wt% silica sol, stir evenly, quickly put it into -4°C and seal and freeze for 24h, take out The frozen product was thawed at 30°C, put into an extruder to extrude into a rod, and then dried and roasted to obtain a strip-shaped titanium-silicon molecular sieve. Add 6.0mL of titanium tetrachloride dropwise into 16mL of isopropanol, react at 25°C for 10min, add 2.2mL of 1.2mol / L tetrapropylammonium hydroxide, 58mL of water and 2.0g of Tween 60 to the solution successively. React at 20°C for 20 minutes to obtain a titanium source hydrolyzate; mix 8g of strip-shaped titanium-silicon molecular sieve TS-1 with 50mL of titanium source hydrolyzate, put it in a crystallization kettle, and treat it at 170°C for 48h to separate the solid. Washed, dried, and baked at 540°C for 5h, the obtained sample was design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com