Patents

Literature

66results about How to "High titanium content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-nitrogen low-aluminum ferrotitanium, manufacturing method thereof and core-spun yarn

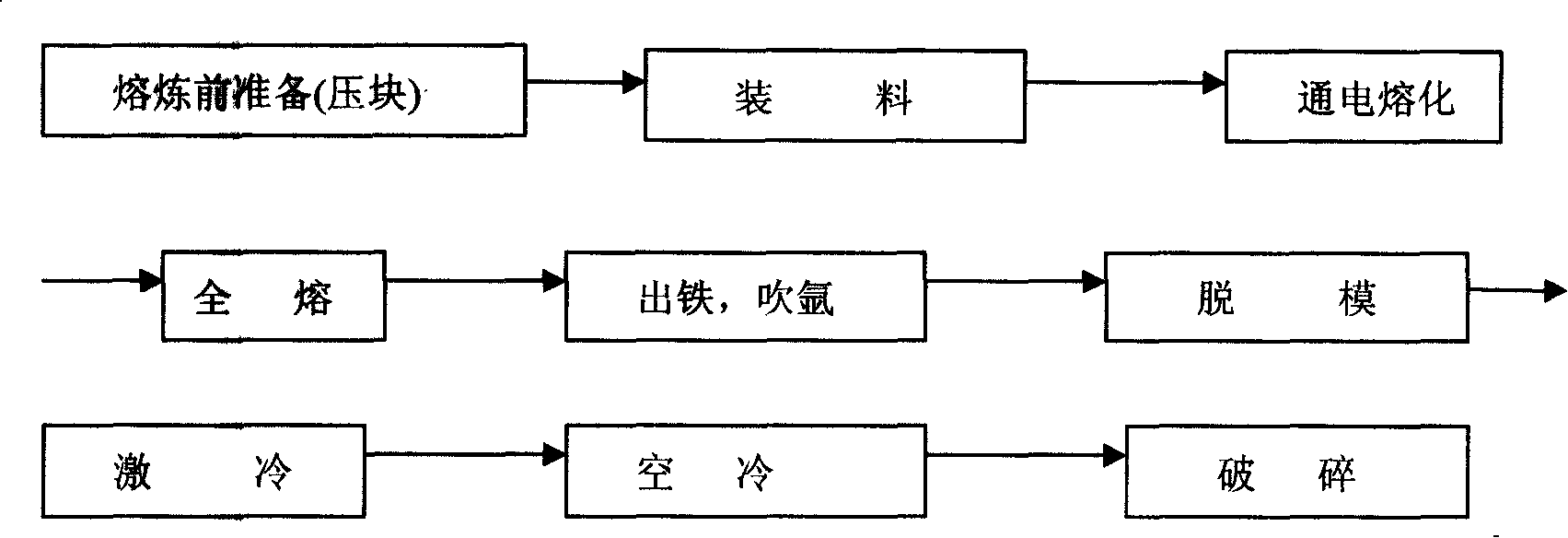

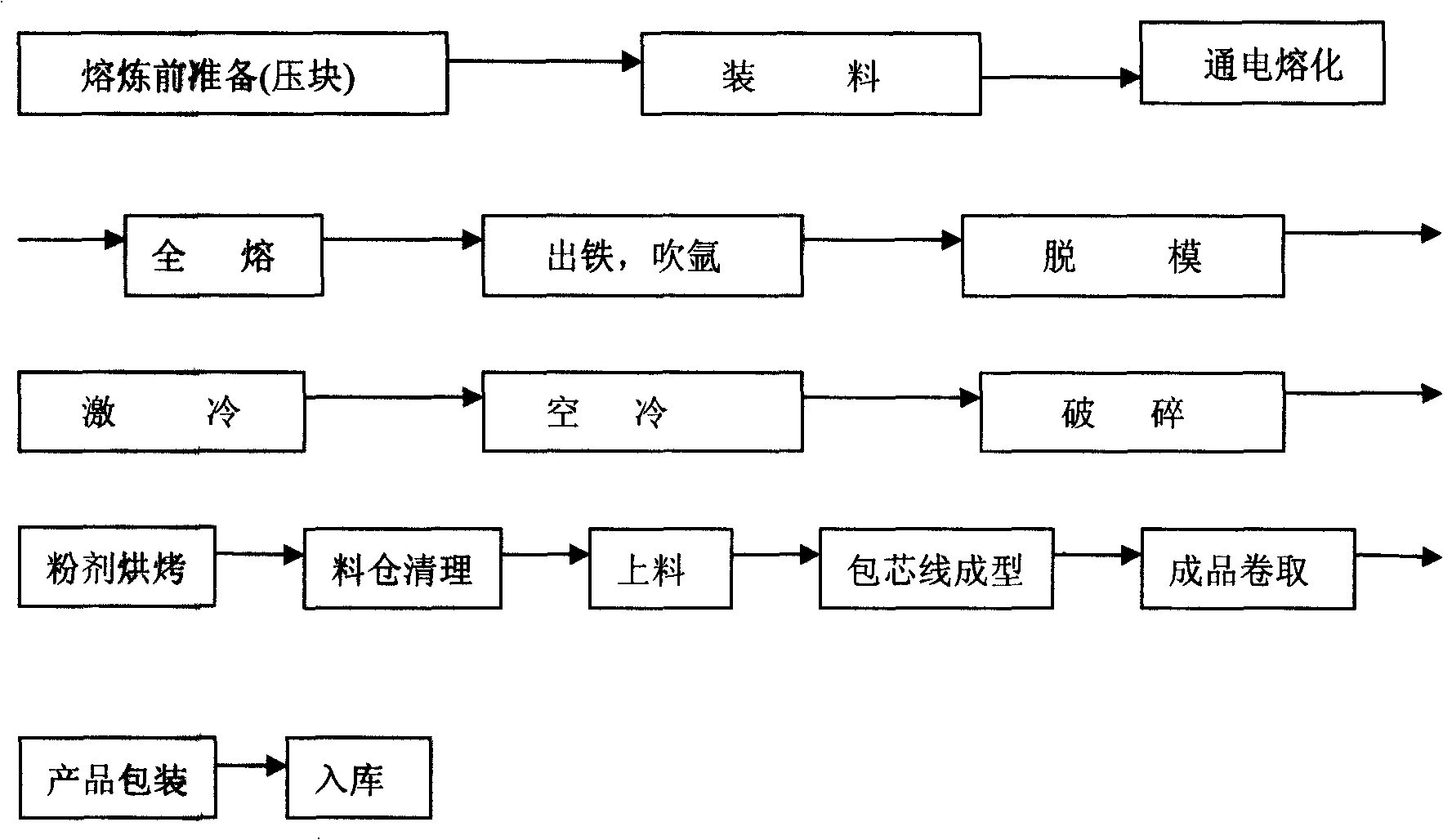

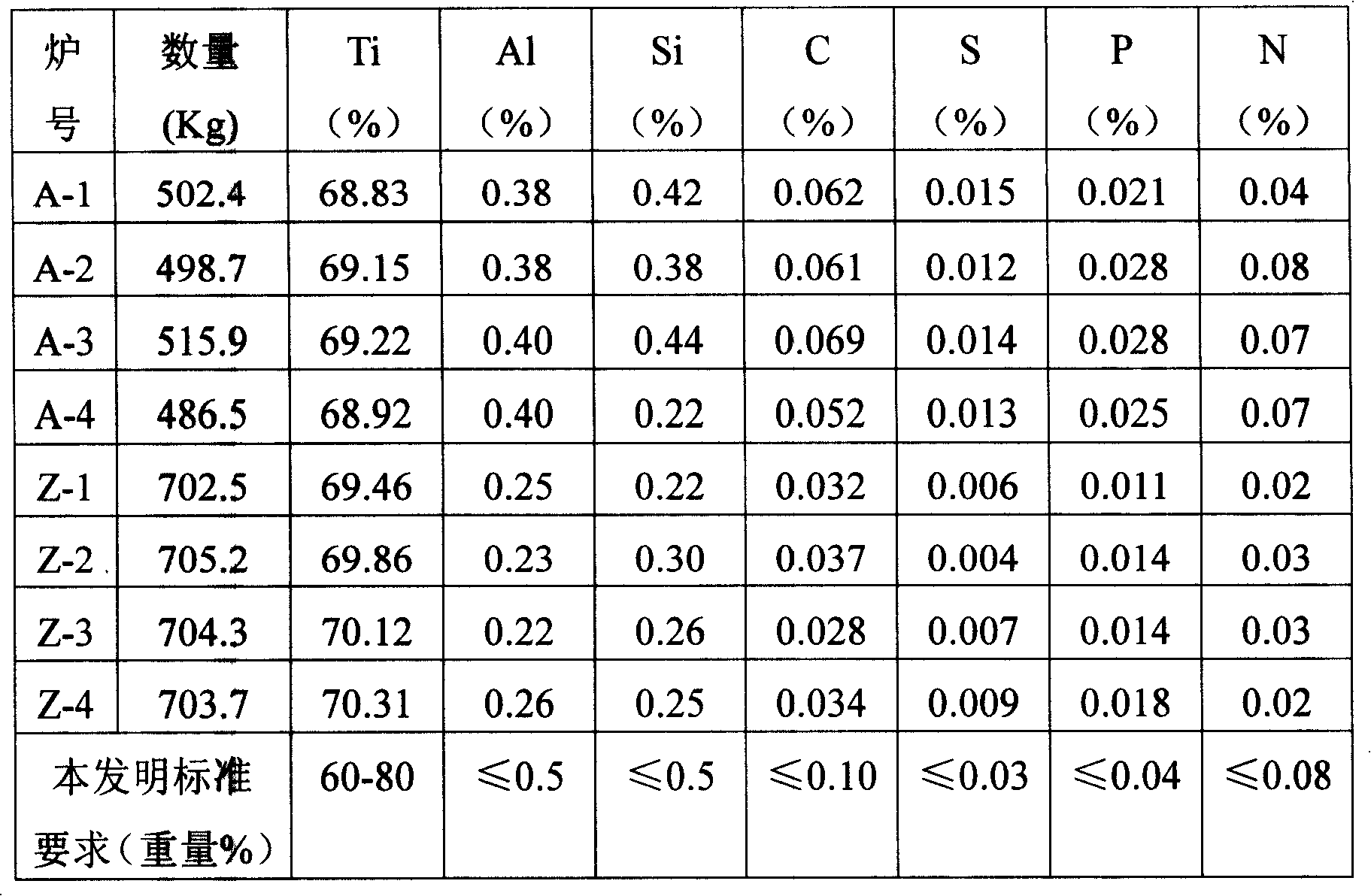

The invention relates to low nitrogen, low-aluminum ferrotitanium and a manufacture method and an alloy cored wire thereof. The low nitrogen and low-aluminum ferrotitanium is 70Fe-Ti alloy, comprising the impurity elements such as nitrogen, aluminum, silicon, carbon, phosphorus, and sulfur and so on, the content of nitrogen is less than or equal to 0.08 percent and the content of aluminum is less than or equal to 0.5 percent. The content of titanium is 60 percent to 80 percent, the content of silicon is less than or equal to 0.5 percent, the content of carbon is less than or equal to 0.1 percent, the content of phosphorus is less than or equal to 0.04 percent, and the content of sulfur is less than or equal to 0.03 percent, the rest is ferrum. The manufacture method is as follows: in a common smelting method, the industrial salt is used as slagging constituents during the smelting; the sponge titanium, waste titanium, high quality steel scraps or ferroferrite comprising the impurity elements, such as nitrogen, aluminum, silicon, carbon, phosphorus, and sulfur, etc. with low content are used as alloy raw materials, the raw materials are briquetted before smelting; the smelting is carried out in an argon smelting furnace or a consumable electrode vacuum furnace. The low nitrogen and low-aluminum ferrotitanium used as the alloy raw material is applied in manufacturing the high grade steel such as stainless steel, which requires titanium to be used as stabilization alloy element or alloy strengthening element to obtain good combination property in strength, plasticity, ductility, and inoxidability, etc. and which also requires low content of the impurity elements such as nitrogen, aluminum, silicon, carbon, phosphorus, sulfur, etc.

Owner:上海马腾新型材料厂

Preparation process of catalyst for ethylene polymerization

InactiveCN1861650AHigh titanium contentImprove particle size distributionPolymer scienceZiegler–Natta catalyst

A process for preparing a Ziegler-Natta catalyst used for the sludge polymerization of ethene features that in its preparing procedure the ultrasonic wave technique is used for increasing the content of Ti and improving the granularity distribution of polymer.

Owner:北京燕化高新催化剂有限公司

High-titanium and low-silicon titanium-silicon-iron alloy and preparation method thereof

The invention discloses a high-titanium and low-silicon titanium-silicon-iron alloy and a preparation method thereof, which belong to the technical fields of vanadium-titanium resource comprehensive utilization and iron alloy smelting. The titanium-silicon-iron alloy is characterized in that: the titanium content is higher than 40 percent by weight, and contains 40-70 percent by weight of Ti, 8-40 percent by weight of Si, 3-15 percent by weight of Fe and unavoidable impurities. In preparation method of the titanium-silicon-iron alloy, the high-titanium and low-silicon titanium-silicon-iron alloy is prepared by adding an admixture into high-titanium blast furnace slag and undergoing a melting thermal reduction reaction, wherein the weight proportion of the high-titanium blast furnace slag to the admixture is 1:(0.4-0.8); the admixture comprises 40-80 percent by weight of a reducing agent; and the major component of the reducing agent is metal aluminum. The titanium-silicon-iron alloy disclosed by the invention instead of titanium and iron can be taken as a titanium alloy agent, and the popularization and application of the titanium-silicon-iron alloy can be promoted; and according to the method disclosed by the invention, improvement on the environment is facilitated, and the resource utilization ratio is increased.

Owner:PANZHIHUA GANGCHENG GROUP

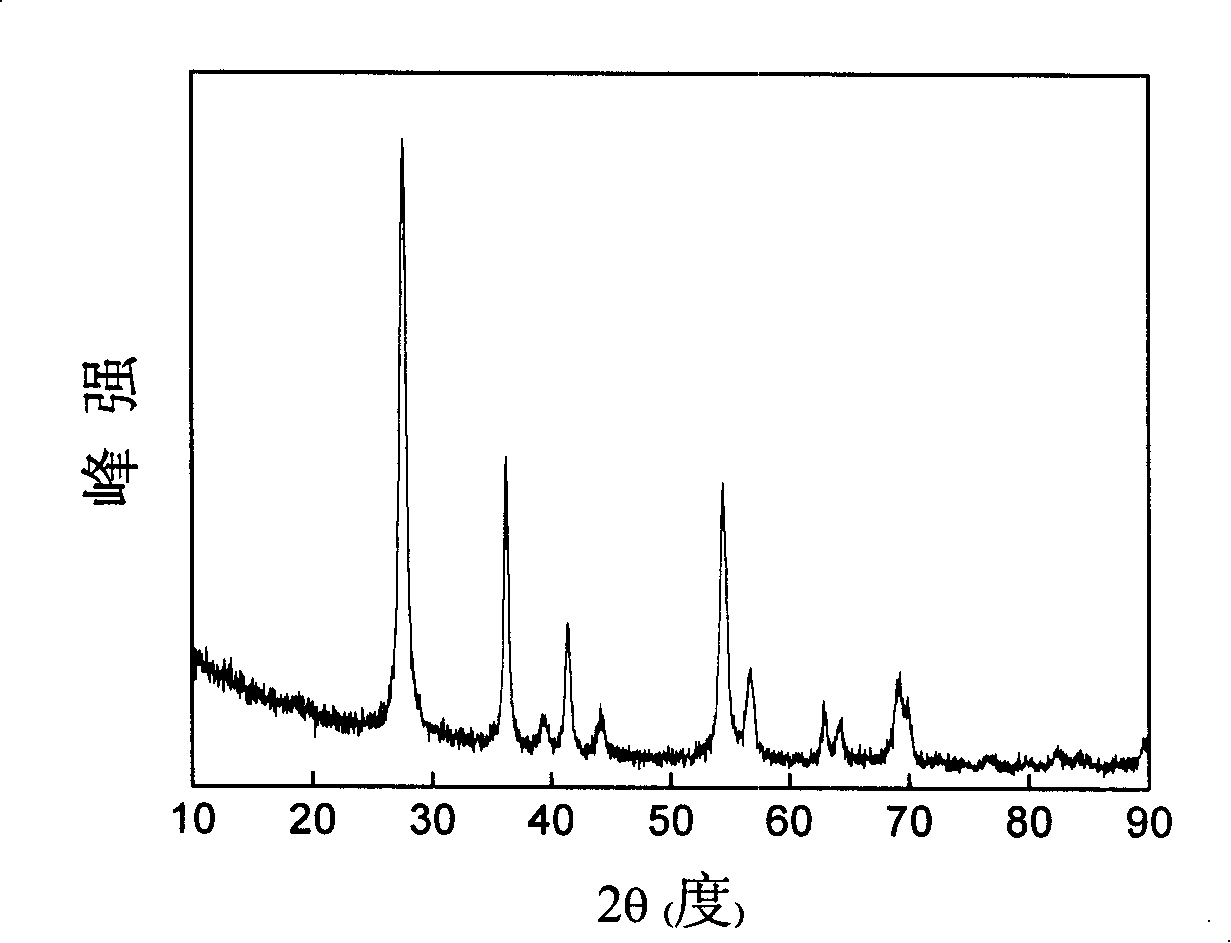

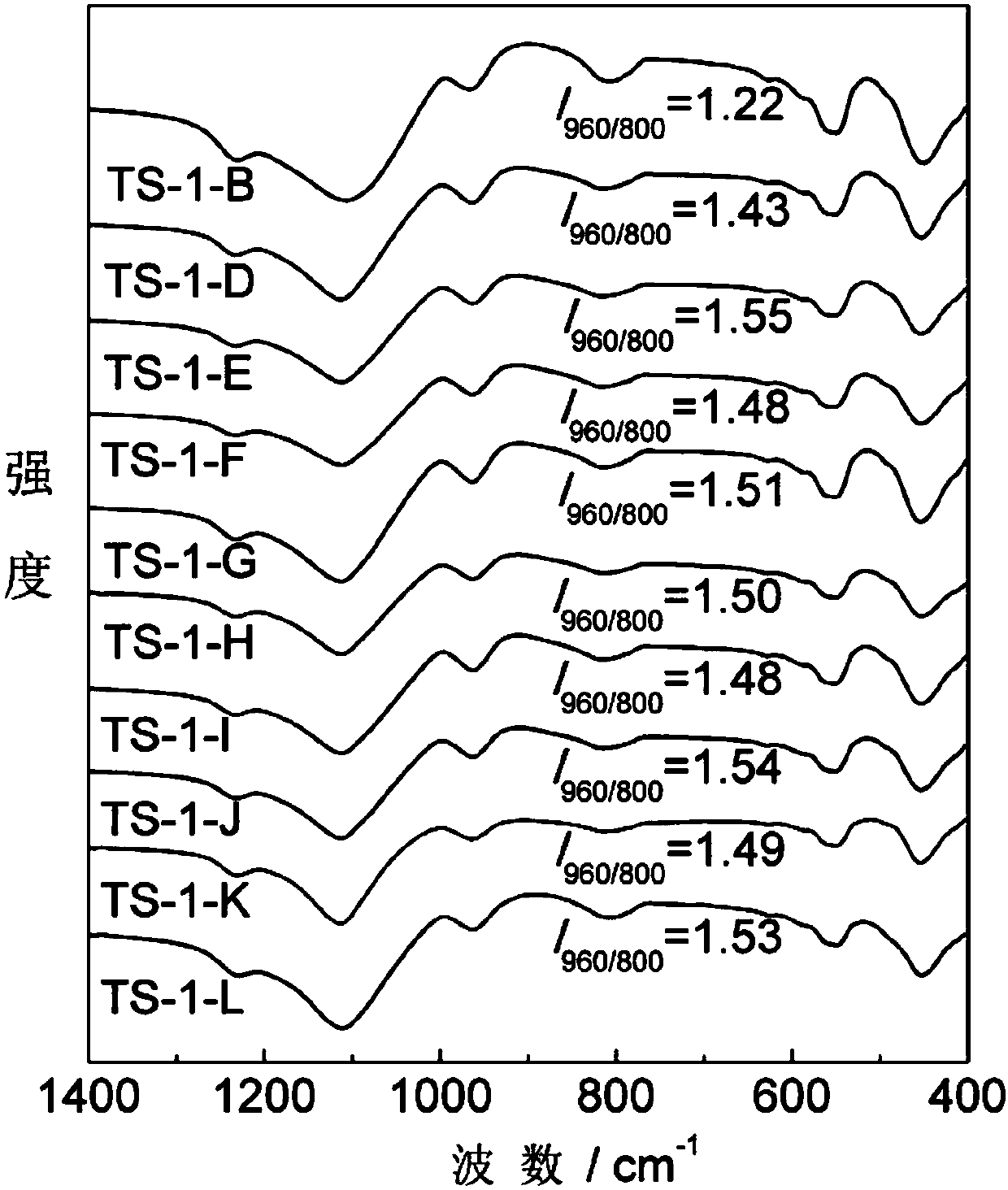

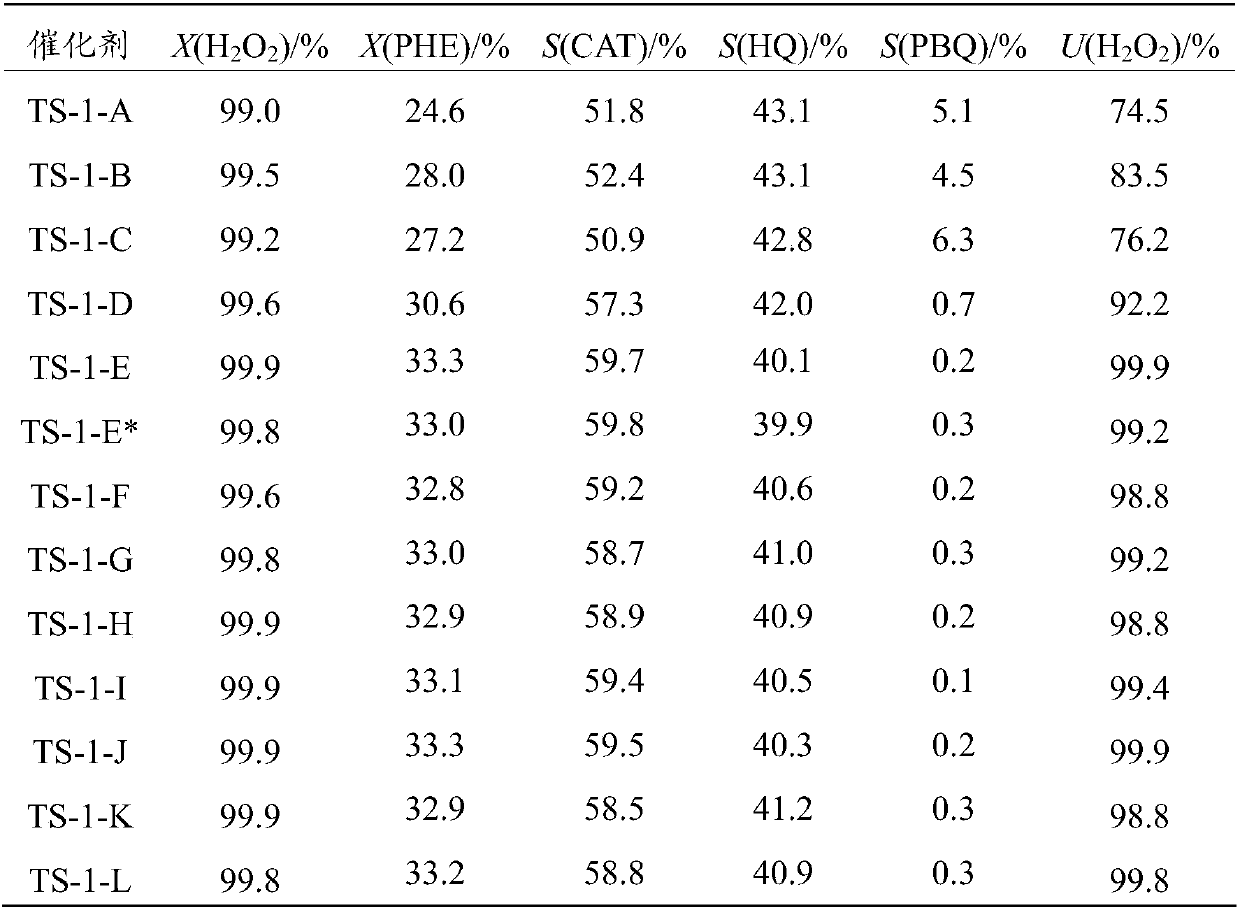

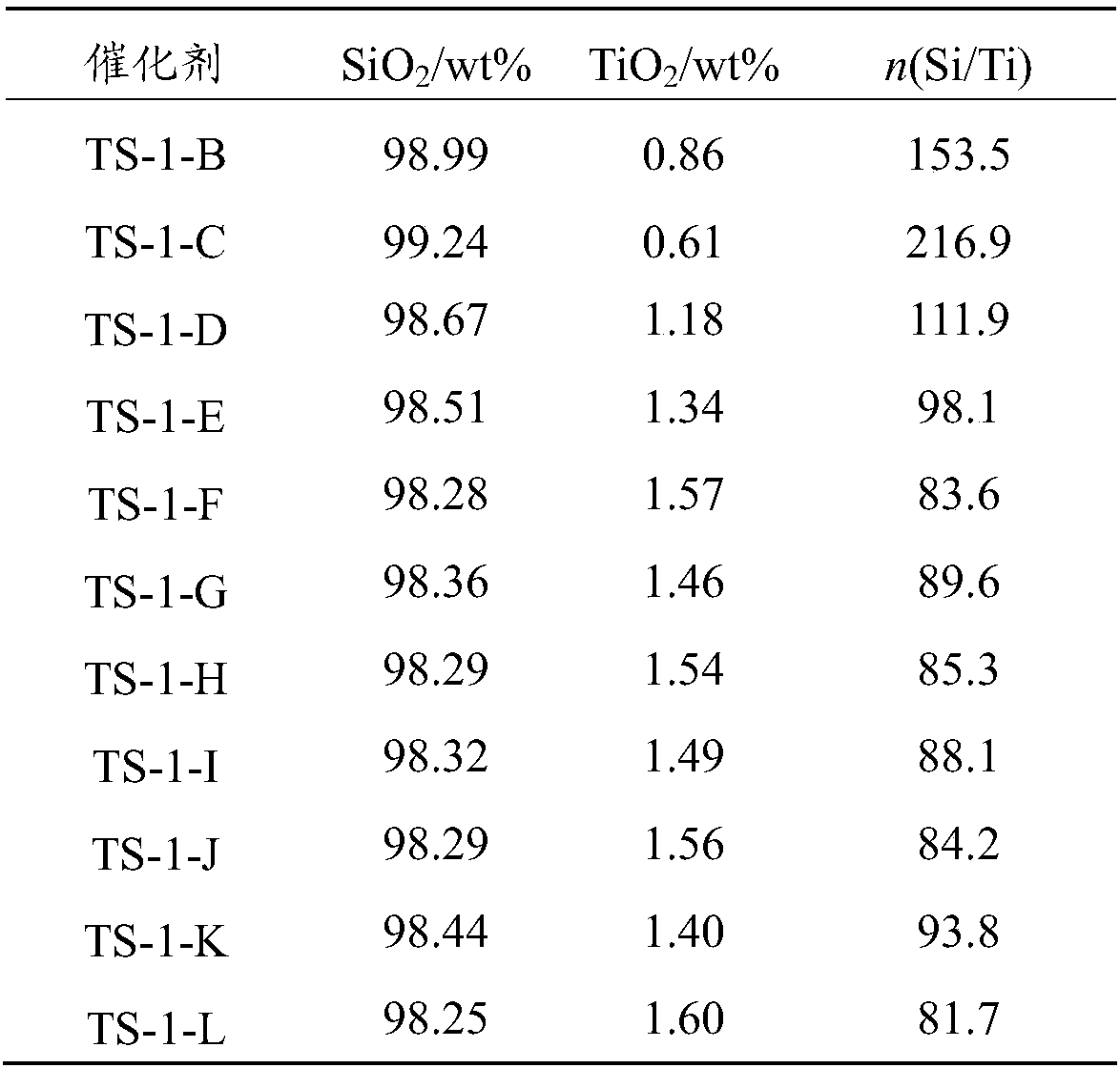

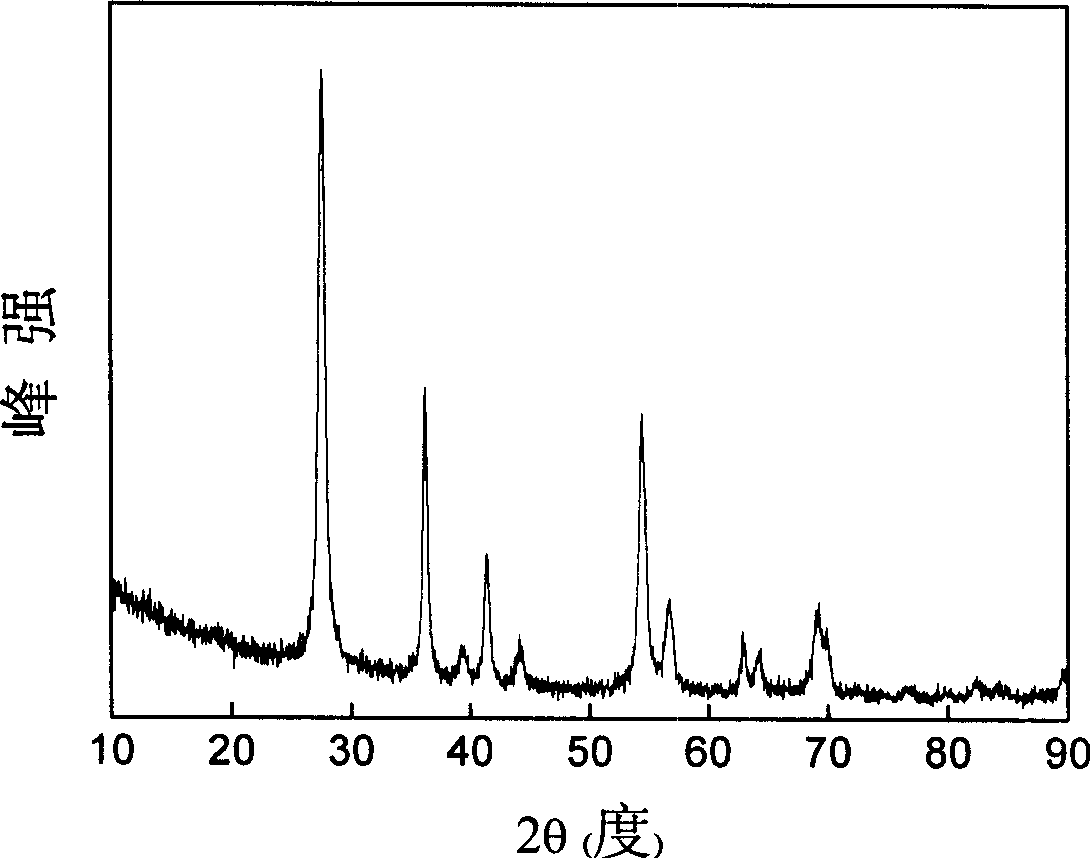

Hydro-thermal synthesis method for TS-1 molecular sieve and obtained product

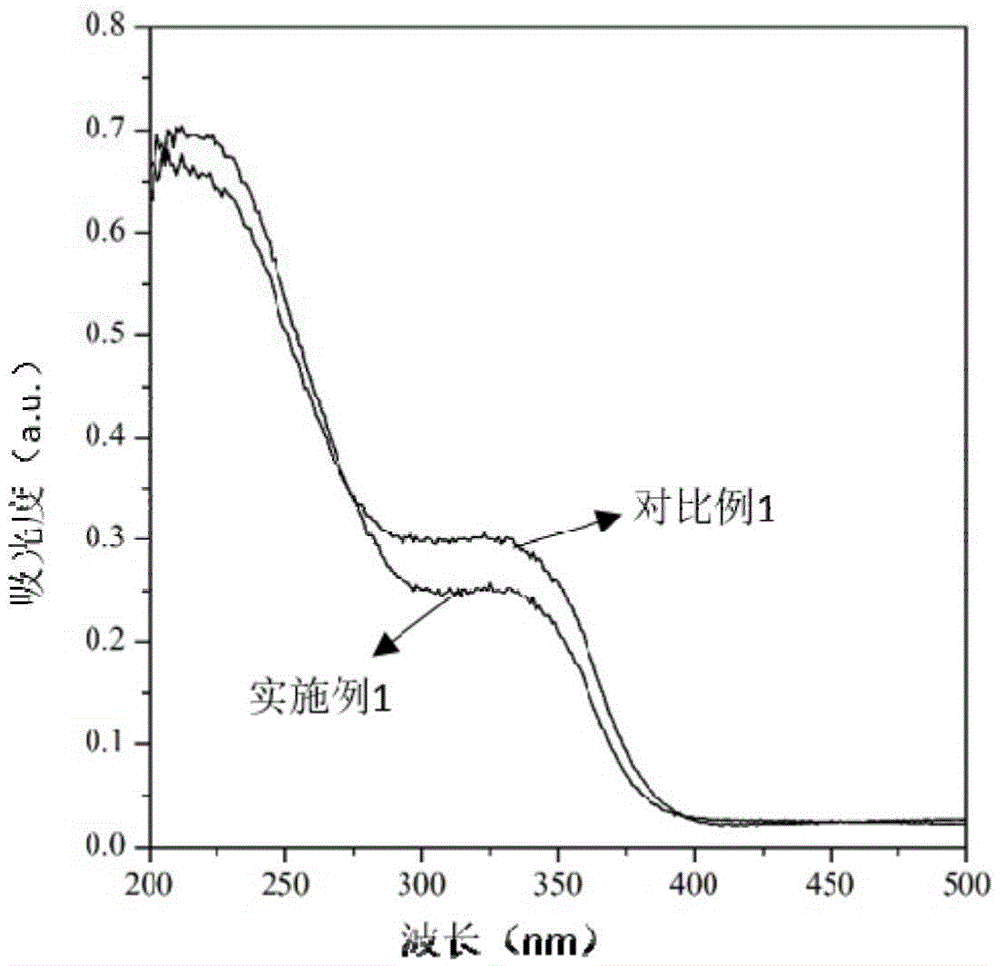

InactiveCN105597818AReduce formationHigh titanium contentMolecular sieve catalystsCatalyst activation/preparationMolecular sieveLevel structure

The invention provides a hydro-thermal synthesis method for a TS-1 molecular sieve. The hydro-thermal synthesis method includes the steps that 1, a silicon source and a template agent are mixed to obtain silicon source hydrolysate, a titanium source and polyhydric alcohol are mixed to be added into the silicon source hydrolysate, and then water is added; 2, a product obtained through step1 is subjected to pre-crystallization for 5-24 hours; 3, a silicon source is added again and heated to 60 DEG C-90 DEG C, and then polyhydric alcohol is removed; 4, a product obtained through step3 is crystallized, after the crystallization reaction, a reaction mixture is subjected to solid-liquid separation, and a solid is taken to be dried and calcined. In the hydro-thermal synthesis method, after the silicon source and the titanium source are gelatinized, alcohol is not removed, namely, crystallization is performed for 5-24 hours at 90 DEG C-100 DEG C under the presence of alcohol, in this way, forming of non-framework titanium can be effectively reduced, and the content of framework titanium can be increased. In the process of constructing a multi-level structure in the TS-1 molecular sieve, no mesporous template agent, organosilane and other organic additives are needed, in the whole synthesis process, operation is easy, the cost is low, an expected amplification effect is small, and large-scale industrial production and popularization are easy.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Process for preparing titanium dioxide-alumina compound oxide

InactiveCN101204671AHigh titanium contentLarge specific surface areaCatalyst carriersTitaniumComposite oxide

The invention provides a preparation method for composite oxide of titanium dioxide / aluminum oxide is provided by the invention. The method comprises the steps: metatitanic acid dissolves in acidic condition into titanium solution, which is A solution; an aluminum source, which is meta-aluminate or inorganic acid salt of aluminum, dissolves into aluminum solution, which is B solution; the A solution and the B solution are mixed to acquire a product C, which is regulated to be alkaline, dried and baked at the temperature of 300 DEG C-700 DEG C, thus acquiring the composite oxide of titanium dioxide / aluminum oxide; mole ratio of the added metatitanic acid and the added aluminum source is 1:0.1-10; product thus acquired has high titanium content and high specific surface area, and has the same mechanical strength with like products.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Clean method for preparing rutile-type titanium dioxide from high-titanium slag by hydrothermal method

InactiveCN101190802AProduced (processed) lessHigh titanium contentTitanium dioxideEconomic benefitsCleaning methods

The invention relates to a clean production method by high titanium slag hydrothermal method to prepare rutile titanium oxide. The method adopts high titanium slag as raw material and sodium hydroxide hydrothermal method to prepare the intermediate product of sodium titanate which is then separated from the solution and washed and hydrolyzed to obtain the rutile titanium oxide. The method of the invention adopts simple preparation technique to prepare the rutile TiO2, which spares high temperature calcination in the traditional technique; the conversion rate of titanium in the high titanium slag is of over 99.0 percent and the alkali circulation and the acid circulation are realized, which has good economic benefit and environmental benefit. Additionally, the sodium titanate which can be taken as the intermediate product for preparing titanium series obtained from the method is expected to have wide application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of trivalent titanium solution

The invention discloses a preparation method of a trivalent titanium solution, and belongs to the field of production of titanium dioxide. According to the preparation method disclosed by the invention, the production cost can be reduced. The preparation method of the trivalent titanium solution comprises the following steps: a) concentrating an alkaline bath washing solution in a process of producing TiO2 by a sulfuric acid method to prepare heavy paste with the TiO2 concentration of not less than 270g / L; b) mixing the heavy paste obtained by the step a) with sulfuric acid, and heating for realizing full reaction; and c) adding a reducing agent into materials after full reaction in the step b), and reducing quadrivalent titanium to trivalent titanium to obtain the trivalent titanium solution. According to the preparation method disclosed by the invention, the alkaline bath washing solution is utilized as a raw material, so that the production cost can be reduced; simultaneously, supernatant liquor obtained by concentration can be used for spraying calcination tail gas, so that the alkaline bath washing solution can be fully utilized; and furthermore, the prepared trivalent titanium solution can meet the production needs of rutile type titanium dioxide by the sulfuric acid method.

Owner:PANZHIHUA DONGFANG TITANIUM IND

Medical stone ceramic product and preparation method thereof

The invention discloses a medical stone ceramic product prepared from the following raw materials in percentage by weight: 41-45% of medical stone powder, 16-20% of potassium feldspar powder, 10-14% of soda feldspar powder, 8-10% of quartz powder and 12-17% of Laiyang soil. The preparation method comprises the following steps: weighing raw materials in percentage by weight, grinding and filtering the raw materials by a sieve with the granularity of 100-150 meshes, and uniformly mixing for later use; grinding the powder in a ball miller for 1-2 hours according to the condition that the ratio of the material to balls to water is 1:2:0.5, filtering mud through a sieve with the granularity of 32-35 meshes, and pugging to obtain a finished mud product; performing slip-casting, demoulding, correcting and grinding, and drying for 12-24 hours; sintering a dried mud blank in a furnace in steps and cooling to obtain the required product. The medical stone ceramic product is reasonable in material proportion and scientific in sintering method, so that the medical stone has improved performance, good air permeability and high plasticity, and the yield is up to 97%; the medical stone is free from toxicity and radiation, and has no change in original property and precipitated trace elements; the medical stone can be prepared into various beautiful new material tea sets, cups and other finished products.

Owner:马仁水

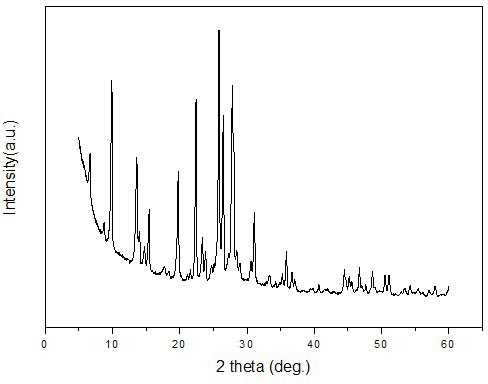

Preparation method of titanium-containing nano-mordenite molecular sieve

InactiveCN102674389AHigh titanium contentEasy to synthesizeNanotechnologyMordenite aluminosilicate zeoliteSynthesis methodsMordenite

The invention discloses a synthesis method of a titanium-containing nano-mordenite molecular sieve, comprising the following steps of: firstly, dissolving an aluminum source in sodium hydroxide solution, adding a silicon source, stirring by strong magnetic force at room temperature for evenly dispersing, mixing the evenly-dispersed silicon source and aluminum source solution to prepare glue at room temperature, adding the mordenite molecular sieve serving as a seed crystal, quickly adding Ti-containing micromolecule organic amine solution into the mixed solution, stirring by strong magnetic force at room temperature for evenly dispersing, transferring into a reaction crystallization kettle, carrying out crystallization reaction at 150-170DEG C for 0.5-3d, and carrying out conventional leaching, washing and drying operations to obtain a solid product. The synthesis method has the characteristic that the titanium atom is led into a micropore skeleton in the manner of quadridentate and high dispersion by using hydro-thermal synthesis, the micromolecule organic amine serving as the chelant of impurity metal titanium atom, and the one-step method is used, so that the obtained titanium-containing nano-mordenite molecular sieve is high in crystallinity and purity, controllable in particle size and shape and low in cost, and causes little environment pollution, thereby being convenient for the large-scale industrial production.

Owner:EAST CHINA NORMAL UNIV

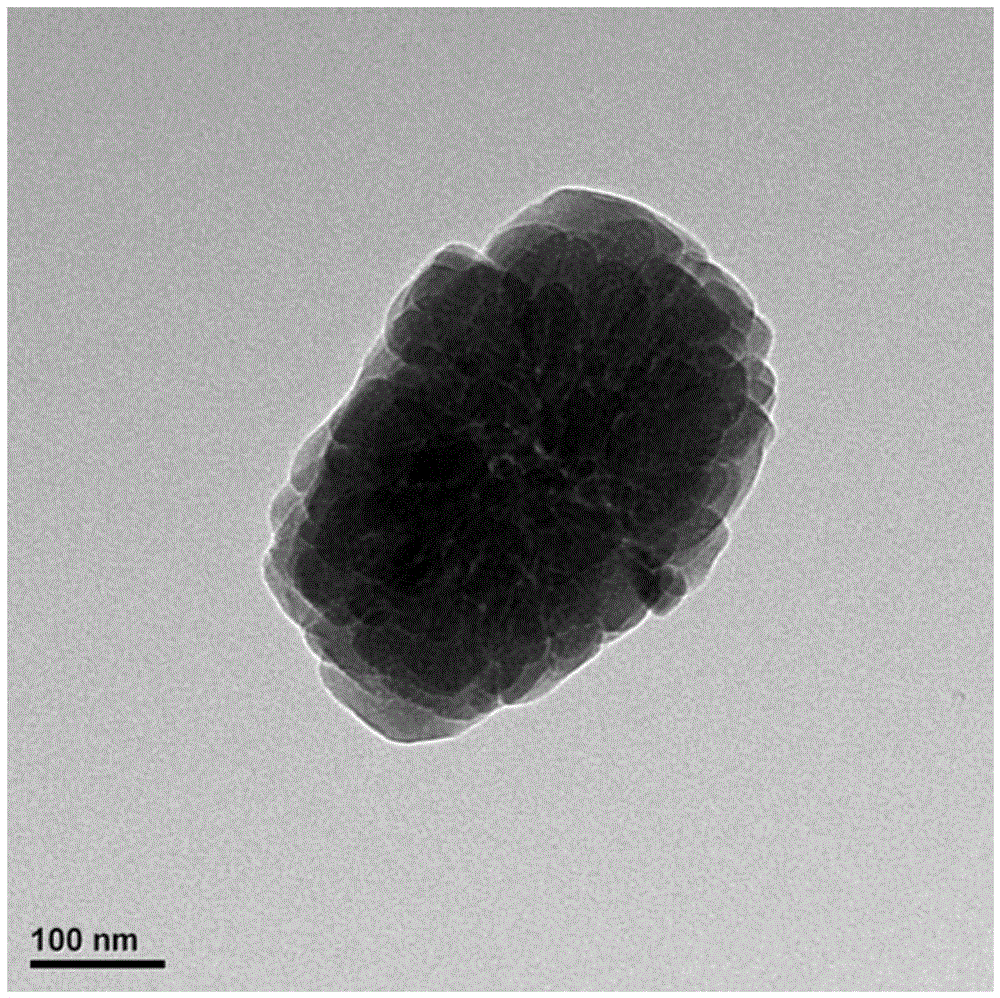

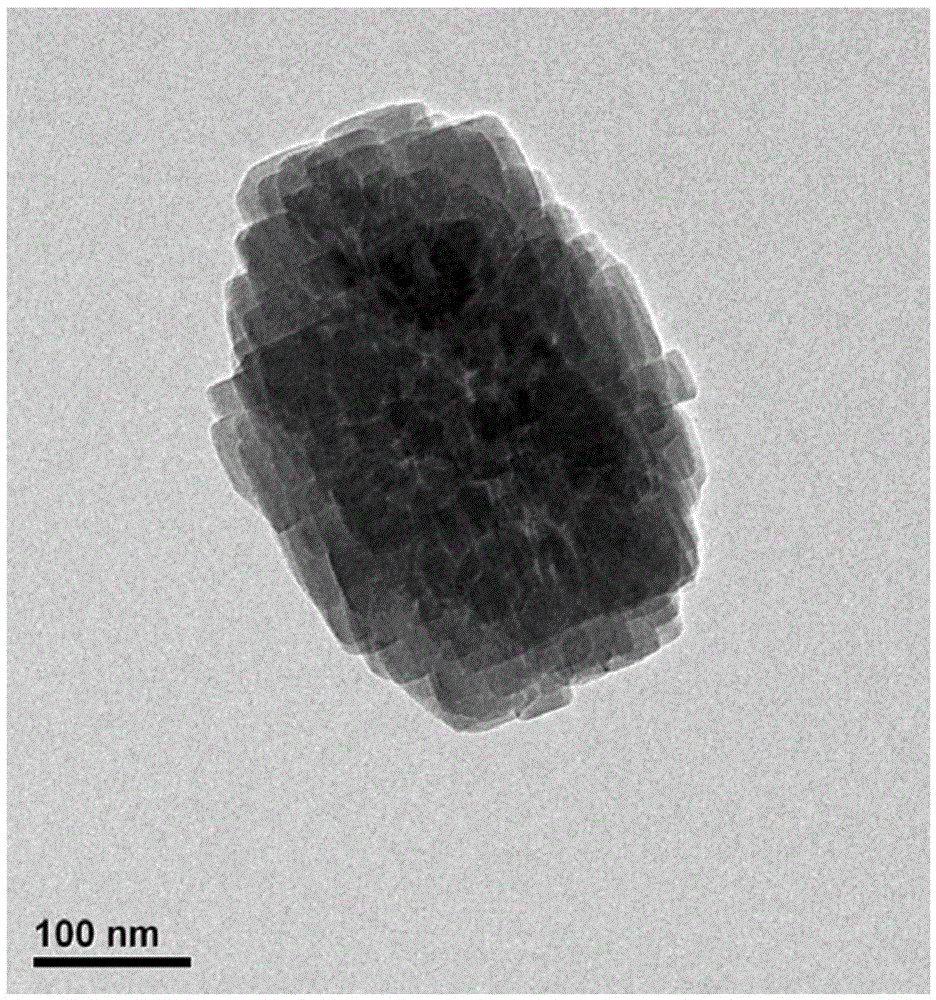

Component for olefinic polymerization loaded on nano carrier as well as its preparing method and application

A catalyst for the polymerization of olefin is a reaction product of magnesium compound, titanium compound and electronic donor compound, which are carried by a carrier whose average granularit is less than 100 nm. Its advantages are high polymerizing activity, uniform and controllable polymer granularity.

Owner:CHINA PETROLEUM & CHEM CORP +1

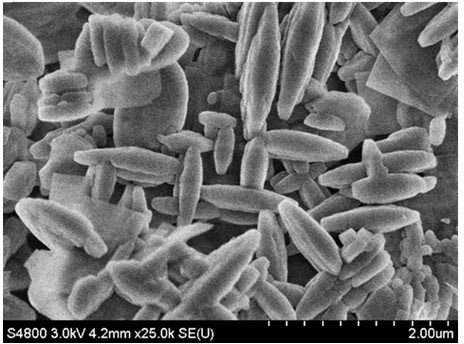

Method for preparing titanium silicon molecular sieve TS-1 with high framework titanium content

ActiveCN107032366AImprove bindingSpeed up entryMolecular-sieve silicatesCrystalline aluminosilicate zeolitesMolecular sieveAlcohol

The invention provides a method for preparing a titanium silicon molecular sieve TS-1 with high framework titanium content. The method particularly comprises the following steps: mixing a silicon source and a titanium source according to the proportion, and adding an aqueous solution of quaternary ammonium base to obtain mixed liquid; hydrolyzing the mixed liquid to remove alcohol, adding a starch solution and performing crystallization to obtain a crystallization product; and drying and roasting the crystallization product to obtain the titanium silicon molecular sieve TS-1 with high framework titanium content. According to the method, the starch solution is added in the synthesis process, the silicon source is in bridge connection with the titanium source by utilizing a large amount of hydroxyl groups in the starch, and the silicon source and the titanium source are easy to combine, so that more titanium can enter the TS-1 framework. The titanium silicon molecular sieve prepared with the method has high titanium content and hardly contains extra-framework titanium, and mother liquid can be recycled.

Owner:DALIAN UNIV OF TECH

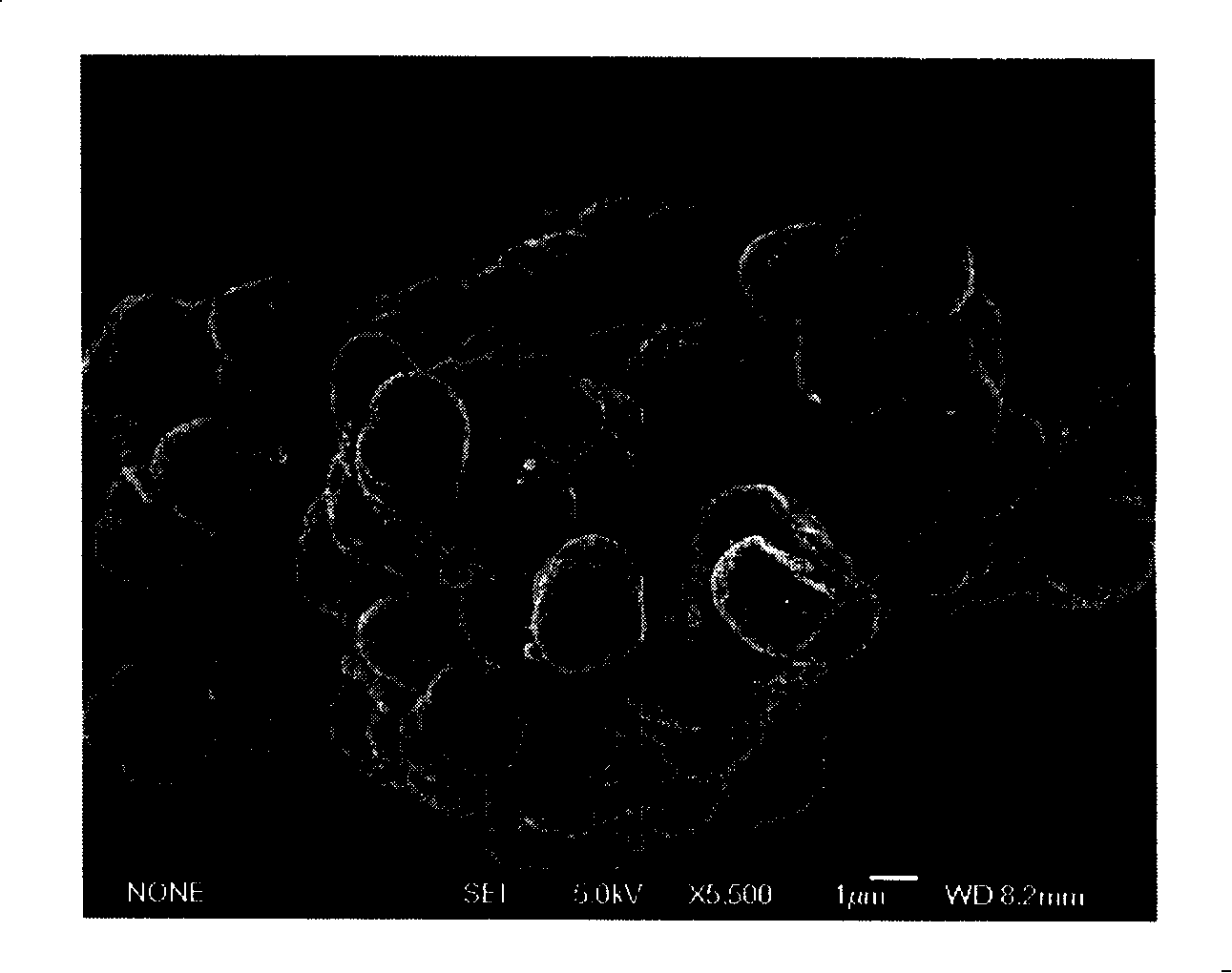

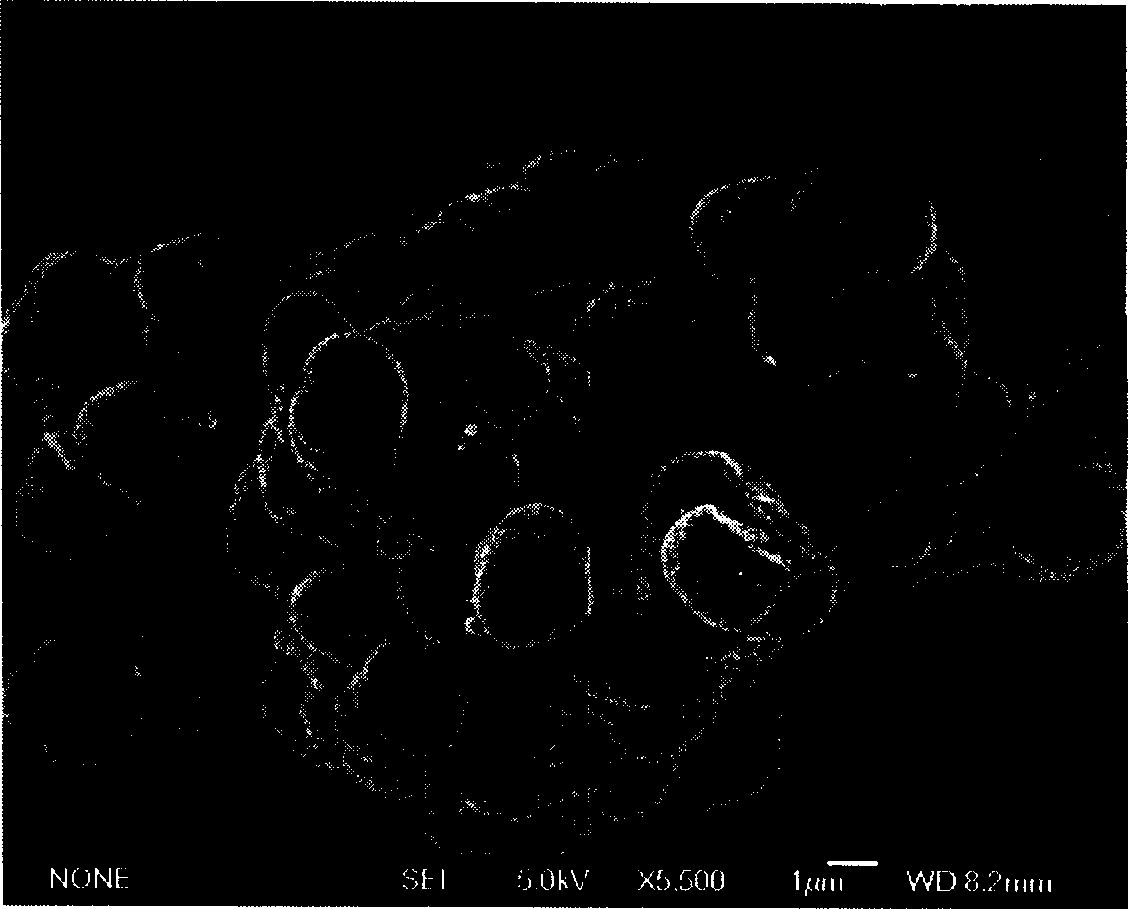

Process for producing titanium-silicon zeolite microcapsule

ActiveCN101428234AHigh titanium contentHigh crystallinityMolecular sieve catalystsSodium bicarbonatePotassium hydroxide

The invention relates to a method for preparing titanium silicalite microcapsules, and mainly solves the problems in the prior art, for example, the content of titanium in TS-1 molecular sieve is low, the TS-1 molecular sieve is not treated with alkali, and when the ZSM-5 molecular sieve is modified by alkali treatment, the crystallization degree is low and the microcapsule with more than 100 nm cavities and having a shell-like structure on the surface is not obtained. In order to overcome the problems, the technical scheme is as follows: the titanium silicalite microcapsules are obtained by treating TS-1 crude powders (the Si / Ti molar ratio (calculated as SiO2 / TiO2) ranges from 20 to 500 and the particle size ranges from 0.4 Mum to 20 Mum) with 0.4 mol / L to 5.0 mol / L of a solution of at least one alkali selected from sodium hydroxide, magnesium hydroxide, potassium hydroxide, calcium hydroxide, sodium carbonate and sodium bicarbonate, at a temperature ranging from 20 DEG C to 90 DEG C for a time period ranging from 1 hour to 48 hours; and the volume of cavities with a size in the range from 100nm to 160nm accounts for 20% to 70% of the total volume of cavities with a size more than 2 nm. The titanium silicalite microcapsules are applied to the industrial production of catalytic oxidationof macromolecules.

Owner:CHINA PETROLEUM & CHEM CORP +1

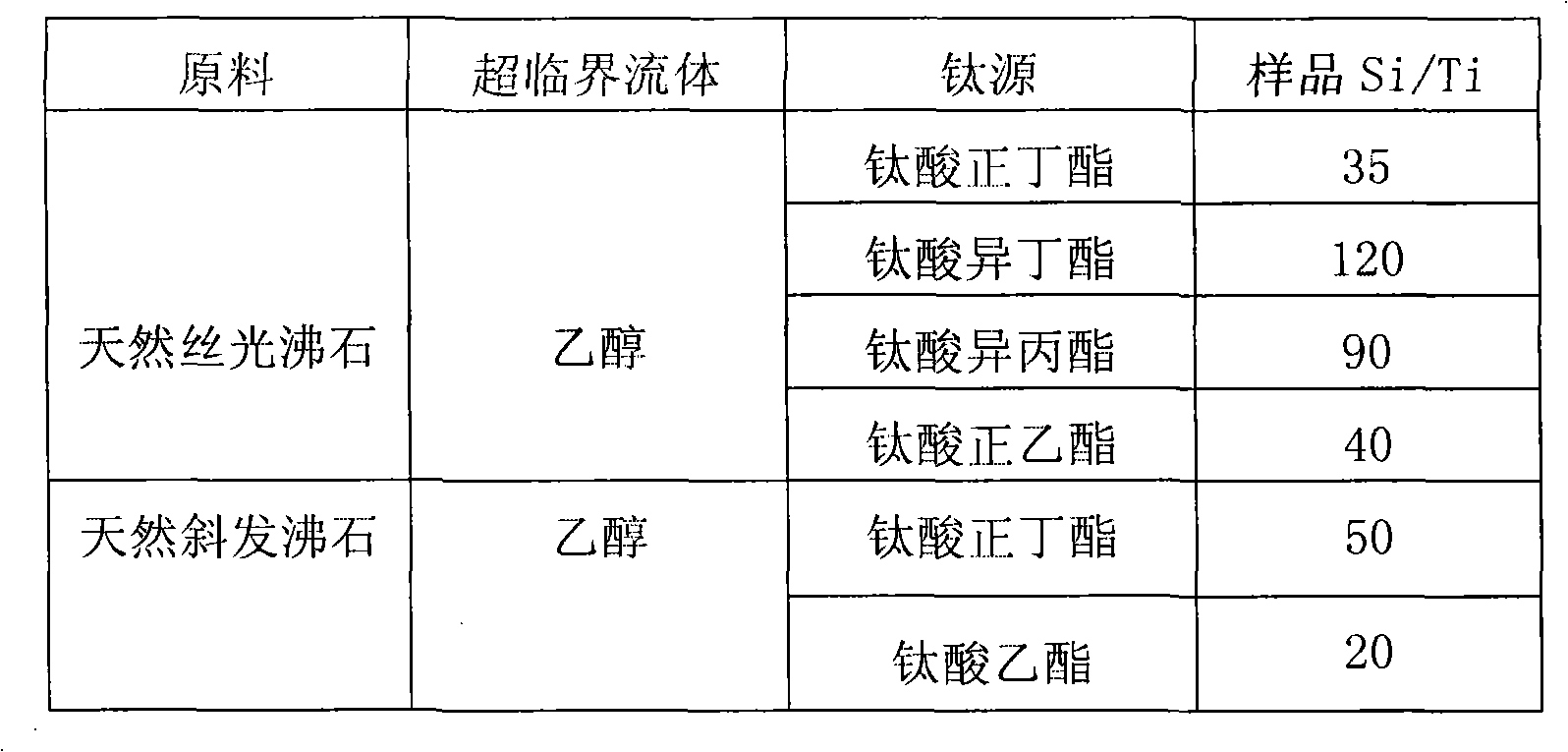

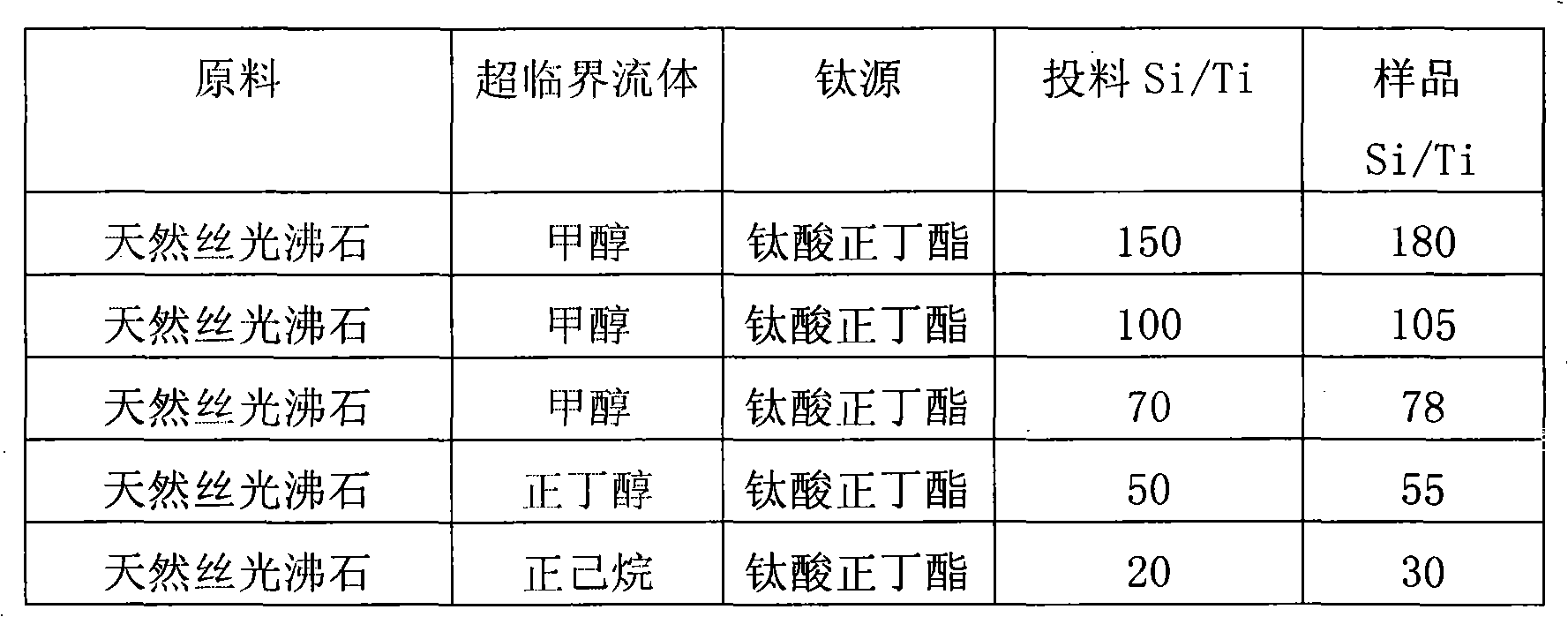

Method for preparing titanium-silicalite molecular sieve from natural zeolite through supercritical replacement and modification

InactiveCN102101679AEliminate mass transfer resistanceEvenly distributedCrystalline aluminosilicate zeolitesBulk chemical productionIon exchangeTemperature and pressure

The invention relates to natural zeolite material modification, and aims to provide a method for preparing a titanium-silicalite molecular sieve from natural zeolite through supercritical replacement and modification. The method comprises the following steps of: performing ion exchange treatment on the natural zeolite, treating by using a chemical dealumination method, and performing supercritical replacement reaction, putting the zeolite subjected to chemical dealumination treatment on the upper part of an autoclave, and ensuring that the zeolite is not directly contacted with carbon dioxide or an organic solvent; regulating the pressure and temperature until the pressure and the temperature are higher than critical parameters of the carbon dioxide or the organic solvent for reaction, and after the reaction is finished, washing a sample by using the carbon dioxide or the organic solvent and drying; and roasting in the air to obtain the titanium-silicalite molecular sieve. By the method, the mass transfer resistance of a titanium source in micropores of the molecular sieve is greatly reduced, the prepared sample has the characteristics of high titanium content, uniform titanium distribution and the like, and the method is a new method for improving the additional value of the natural zeolite product. The heteroatom molecular sieve prepared by the method is low in production cost and easy to operate, and has wide market prospect when used as an industrial catalyst and environmentally functional material.

Owner:ZHEJIANG UNIV

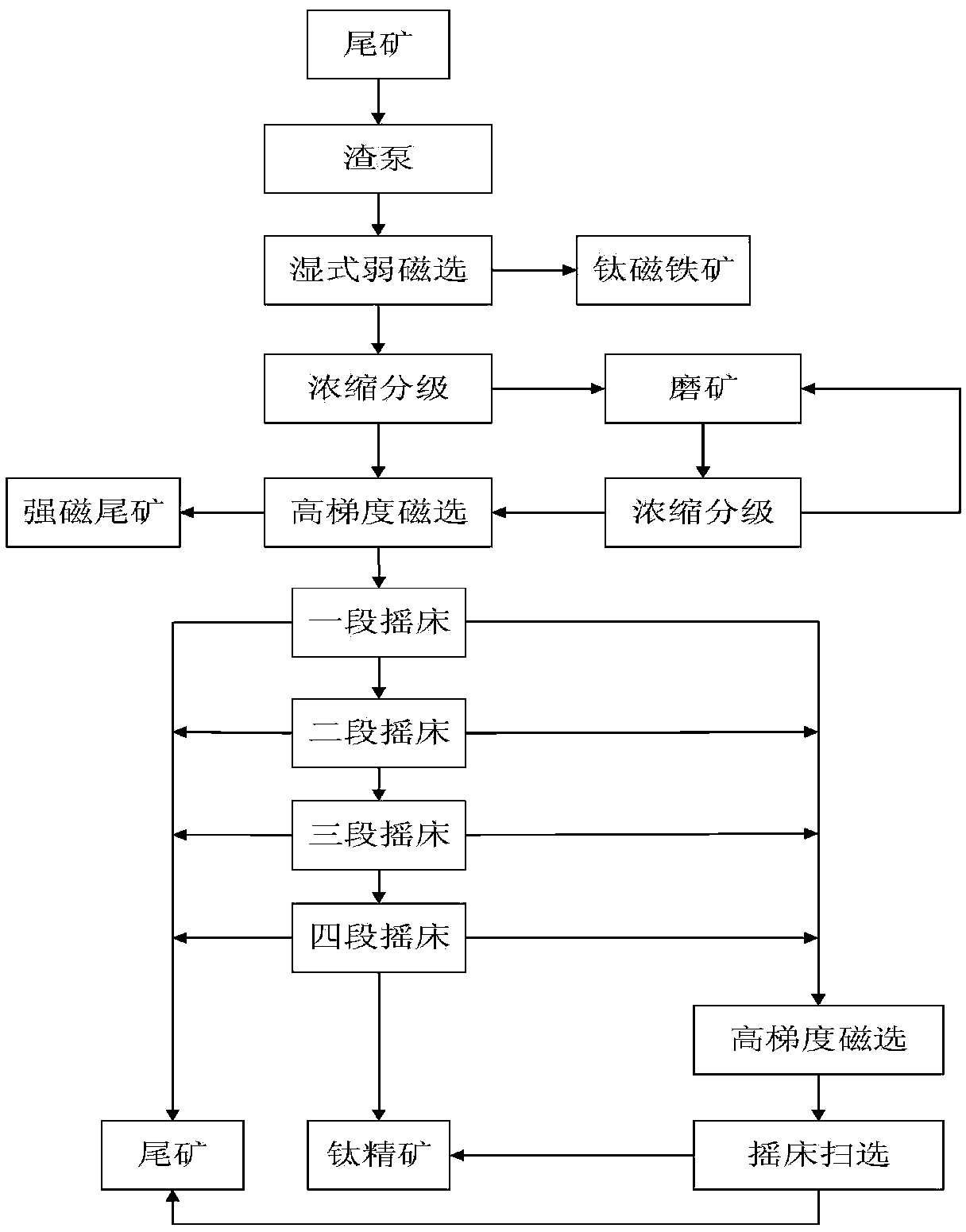

Environment-friendly method for titanium separation from iron tailings

ActiveCN109604050ALow costHigh titanium contentWet separationMechanical material recoveryMaterials scienceMineral processing

The invention discloses an environment-friendly method for titanium separation from iron tailings, and belongs to the technical field of mineral processing. The method solves the problems of an existing tailing mineral processing method that efficiency is low, the cost is high, and secondary pollution is liable to occur. The environment-friendly method for titanium separation from the iron tailings comprises the following steps that the iron tailings are adjusted to ore pulp with concentration of 30-50%, tailing pulp is obtained after weak-magnetism tailing discharging, the tailing pulp is concentrated until the ore pulp concentration is 40-60%, a ball milling product is obtained by ore grinding, the ball milling product is subjected to hydraulic classification to obtain an overflow material and a bed charge, the concentration of the overflow material is adjusted to 35-50%, high gradient strong-magnetic titanium extraction is conducted to obtain secondary coarse concentrate, the secondary coarse concentrate is separated by a four-stage shaking table to obtain titanium concentrate, titanium middlings and tailings, the titanium middlings are subjected to high gradient strong-magnetictitanium extraction and one-stage shaking table separation, and titanium concentrate and tailings are obtained. No chemical reagent is adopted in the whole process according to the method, secondarypollution does not occur, solid-liquid waste secondary resource recovery and utilization is achieved, and the ecological environment is protected.

Owner:PANZHIHUA UNIV

Method for preparing ferrovanadium alloy from titanium tetrachloride refined tailings

ActiveCN112981141ARealize resource utilizationHigh yield of vanadium smeltingProcess efficiency improvementTitanium chlorideRefining (metallurgy)

The invention relates to the technical field of metallurgy, and discloses a method for preparing a ferrovanadium alloy from titanium tetrachloride refined tailings. The method comprises the following steps of (1) crushing and levigating the titanium tetrachloride refined tailings, and oxidizing and roasting in a rotary kiln to obtain vanadium-containing roasted clinker; (2) uniformly mixing the vanadium-containing roasted clinker and vanadium oxide with iron particles, a reducing agent, a slag former and a heat generating agent to obtain a ferrovanadium smelting mixture, and then uniformly distributing the ferrovanadium smelting mixture in a smelting furnace for smelting; and (3) after finishing smelting and naturally cooling a furnace body, slag and gold, disassembling the furnace body, separating the slag and gold, and obtaining a ferrovanadium alloy cake and the smelting slag. According to the method, the titanium tetrachloride refined tailings are roasted to obtain the vanadium-containing roasted clinker, the vanadium-containing roasted clinker and vanadium oxide serve as mixed vanadium-containing raw materials, smelting is conducted according to the electrothermal reduction technology and the self-propagating smelting technology, a qualified ferrovanadium alloy product can be prepared, the vanadium smelting yield is high, and the generated smelting slag can be used as a titanium extraction raw material for further resource utilization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

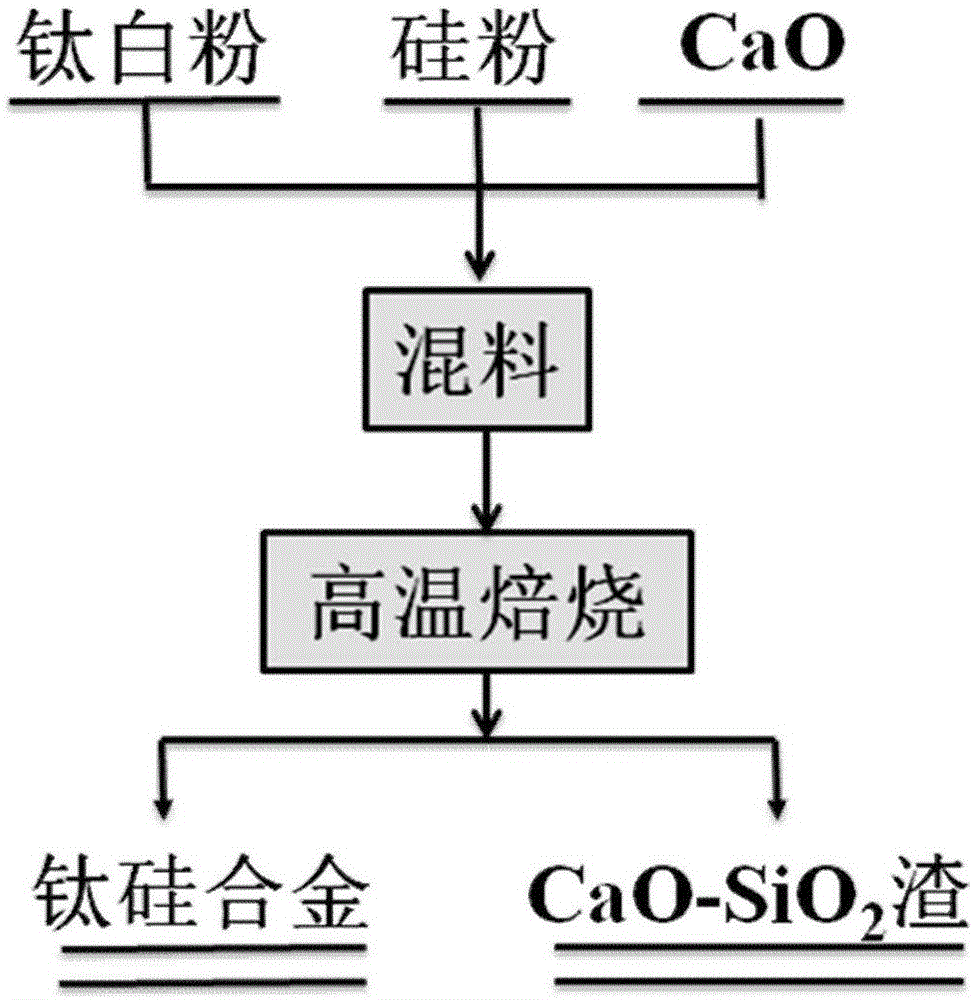

Titanium-silicon alloy material and preparation method thereof

The invention belongs to the technical field of metallurgy, and relates to a titanium alloy material and a preparation method thereof, in particular to a titanium-silicon alloy and a preparation method thereof. The titanium-silicon alloy material comprises, by weight, 37-60 parts of Ti and 40-63 parts of Si. The preparation method of the titanium-silicon alloy material comprises the following steps of a, preparing materials, b, mixing uniformly, c, roasting and d, cooling, wherein in the step a, 35.7-38.5 parts of titanium pigment, 26.9-32 parts of silicon powder and 25-34.6 parts of calcium oxide, by weight, are taken; in the step b, the materials prepared in the step a are mixed uniformly; in the step c, the raw materials mixed uniformly in the step b are roasted, the roasting temperature is 1450-1600 degrees and the roasting time is 10-30min; in the step d, the raw materials after the roasting in the step c are cooled, and effective separation between the titanium-silicon alloy and slag is realized. The titanium-silicon alloy is prepared through one-step synthesis by employing an electro-silicothermic process to reduce titanium pigment, the preparation method is simple in technology, the preparation of the titanium-silicon alloy is not required to be carried out in an inert gas or vacuum environment, the energy consumption is low, the titanium-silicon alloy can be produced and prepared in scale, and the titanium-silicon alloy and the preparation method have great application prospects.

Owner:广西亚龙铝业有限公司

Titanium microalloyed Q355B structural steel plate and recrystallization controlled rolling process method thereof

The invention belongs to the technical field of medium plate production, and particularly relates to a titanium microalloyed Q355B structural steel plate and a recrystallization controlled rolling process method thereof. The steel plate comprises the following chemical components in percentage by mass: 0.16 to 0.20 percent of C, 0.15 to 0.30 percent of Si, 0.70 to 0.90 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S, 0.015 to 0.045 percent of Als, 0.055 to 0.070 percent of Ti and the balance of Fe and inevitable impurities. The process method comprises the steps of blast furnace molten iron smelting, molten iron pre-desulfurization, converter smelting, deoxidation alloying, LF refining furnace refining, slab continuous casting, slab reheating, rolling mill rolling, laminar cooling, steel plate straightening, finished product sampling inspection and warehousing. The recrystallization controlled rolling process is adopted in the rolling stage, conventional two-stage controlled rolling is not adopted, temperature holding after first-stage rolling is avoided, and the production rhythm is high.

Owner:天津市新天钢钢铁集团有限公司

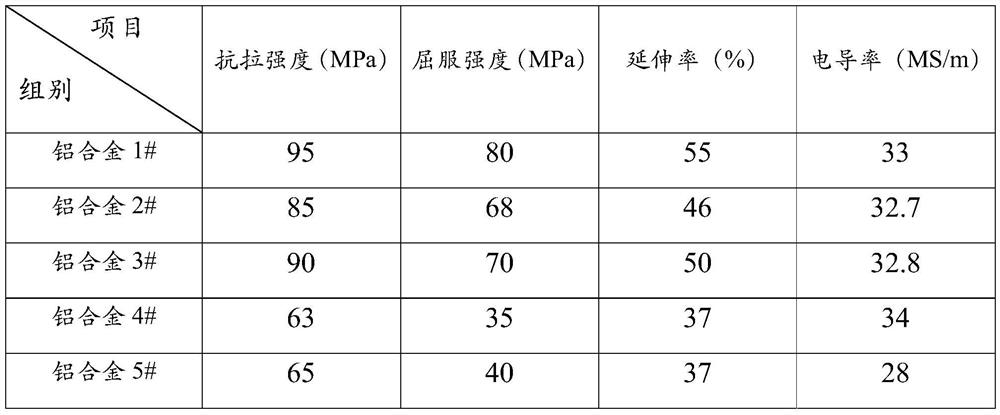

New energy automobile motor rotor casting aluminum alloy and preparation method thereof

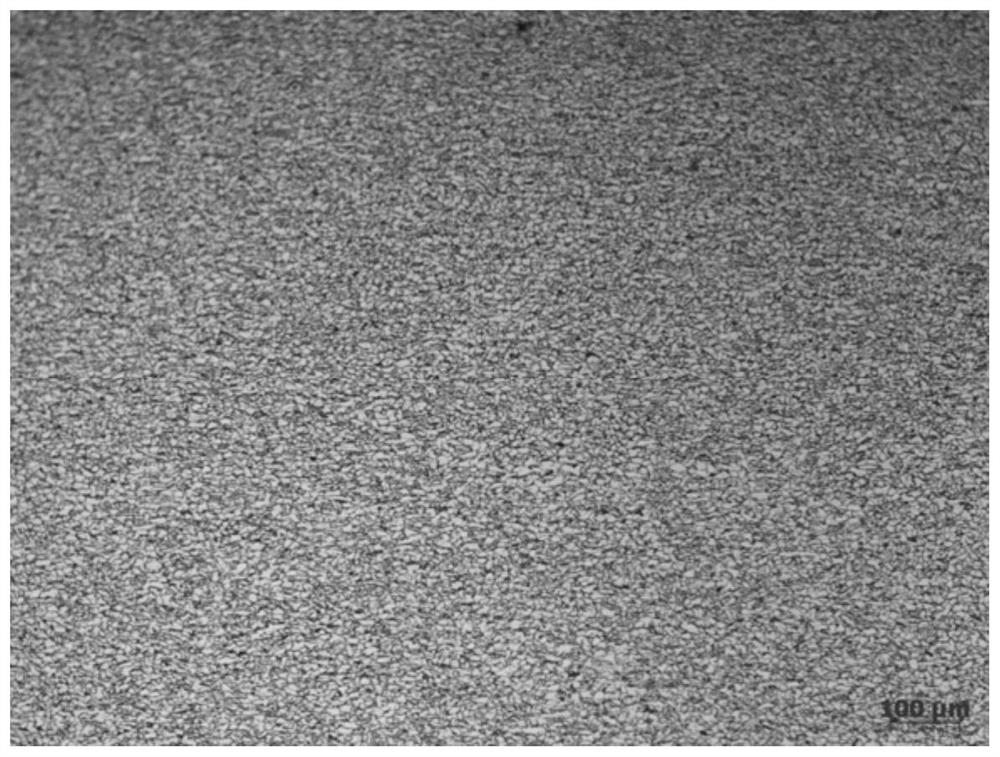

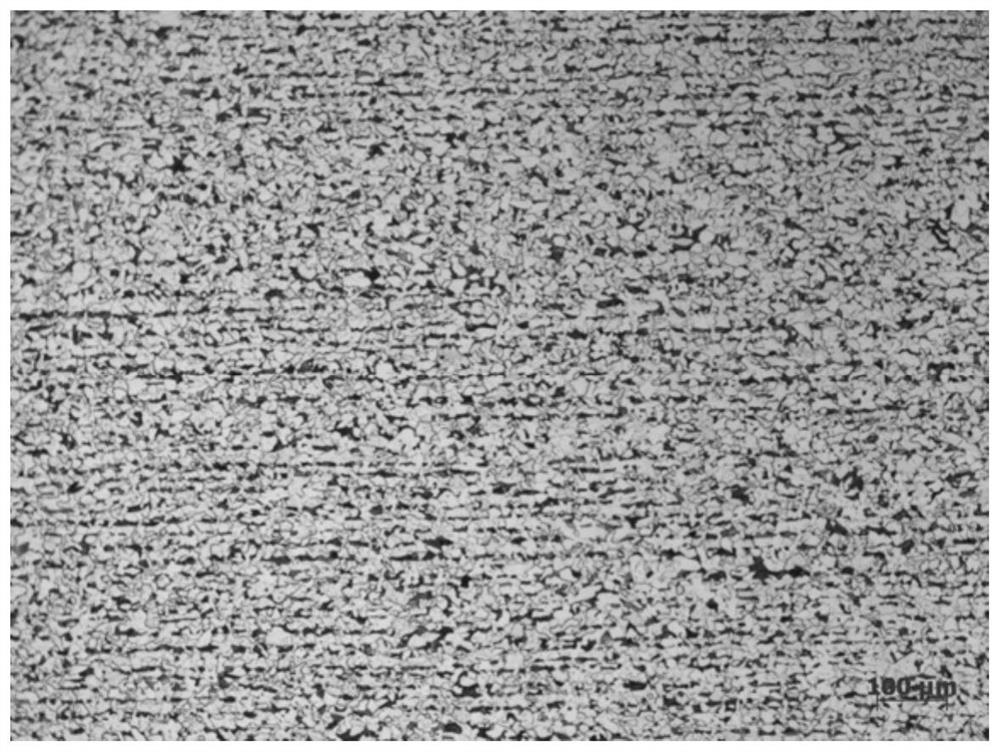

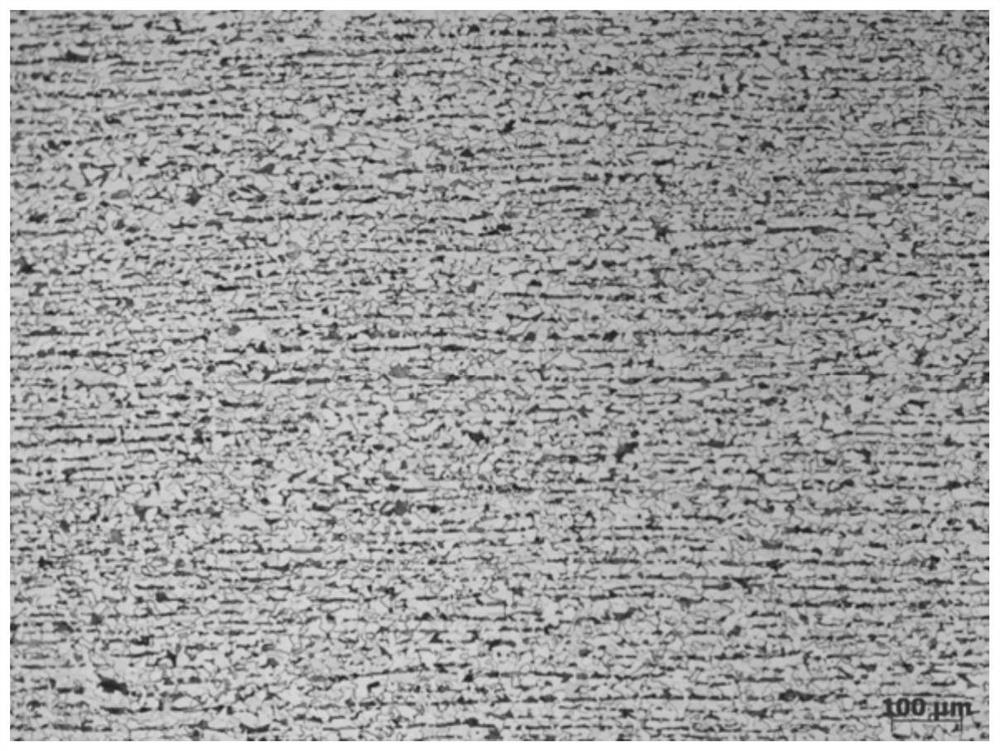

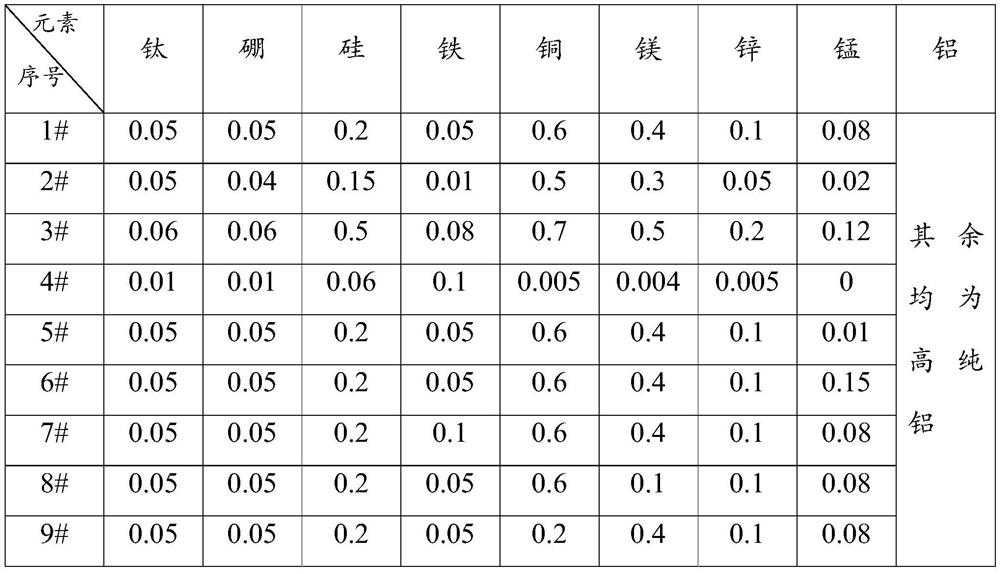

The invention discloses a new energy automobile motor rotor casting aluminum alloy and a preparation method thereof, and belongs to the technical field of new energy automobile motors, the new energy automobile motor rotor casting aluminum alloy comprises 0.05 wt%-0.06 wt% of titanium, 0.04 wt%-0.06 wt% of boron, 0.15 wt%-0.5 wt% of silicon, 0.01 wt%-0.08 wt% of iron, 0.5 wt%-0.7 wt% of copper, 0.3 wt%-0.5 wt% of magnesium, 0.01 wt%-0.2 wt% of zinc, 0.02 wt%-0.12 wt% of manganese, and the balance aluminum. By adding new elements and adjusting the proportion of all the elements, the strength of the cast aluminum alloy is improved, and meanwhile excellent conductivity can be kept.

Owner:SHANDONG BOYUAN PRECISION MASCH CO LTD

Ferrotitanium reducing material for maintaining blast furnace and preparation method thereof

InactiveCN101921885AHigh titanium contentGood effectBlast furnace detailsSodium BentoniteGranularity

The invention relates to a ferrotitanium reducing material for maintaining a blast furnace and a preparation method thereof. The ferrotitanium reducing material for maintaining the blast furnace comprises the following main components in percentage by weight: 75 to 90 percent of vanadium ilmenite powder, 5 to 20 percent of titanium oxide powder, 2 to 5 percent of sodium bentonite powder and 0.1 to 10 percent of carbon powder, wherein the granularity of each component is less than or equal to 0.074 mm. The preparation method comprises the following steps of: mixing the raw materials uniformly; palletizing in a mode of spraying water while rotating; roasting at the temperature of between 1,080 and 1,120 DEG C; firing at the temperature of between 1,220 and 1,300 DEG C; cooling to the normal temperature; pulverizing pellets until the granularity is less than or equal to 0.074 mm; and sealing for later use. In the method, the semi-metallized titanium pellet-containing reducing material is pulverized to be fine powder and the fine powder is added into the blast furnace from a tuyere or an iron notch, so the titanium content of liquid iron can be increased, a vanadium-titanium protection effect on the blast furnace is improved, the service life of a hearth of the blast furnace is prolonged, and the cost of the traditional vanadium-titanium furnace protection is reduced.

Owner:武钢集团有限公司

Low-radiation cover glass and use thereof

The invention relates to a low-radiation cover glass for radiation-sensitive sensors, with low intrinsic a-radiation, in particular for use with semiconductor technology. The glass includes a glass composition, selected from the following: aluminosilicate glass, aluminoborosilicate glass, borosilicate glass, in particular borosilicate glass that is devoid of alkali, with a TiO2 content of >0.1 - 10 % by weight, in particular 1 - 8 % by weight.

Owner:SCHOTT AG

Tailing processing technology and processing system

InactiveCN109692757AHigh titanium contentImprove practicalityWet separationTitaniumMaterials science

The invention discloses a tailing processing technology. The tailing processing technology comprises the titanium concentrate screening and titanium concentrate enriching. The titanium concentrate screening comprises the following steps that S1, tailings are collected; S2, the collected tailings are graded based on the grain size to obtain a first tailing group with the large grain size and a second tailing group with the small grain size; S3, the first tailing group is introduced into a physical screening device for magnetic separation; and S4, ore with high titanium content screened in the step 3 is subjected to flotation processing to obtain titanium concentrate. The titanium concentrate enriching comprises the following steps that S5, the titanium concentrate obtained in the step 4 issubjected to hydrochloric acid processing; S6, the ore processed in the step 5 is subjected to chloridization; and S7, the ore processed in the step 6 is subjected to magnesium thermal reaction to obtain finished titanium ore. According to the tailing processing technology, the tailings after primary separation can be screened to obtain the ore with high titanium content finally. Different end products can be obtained, and practicability is high.

Owner:攀枝花市兴鼎钛业有限公司

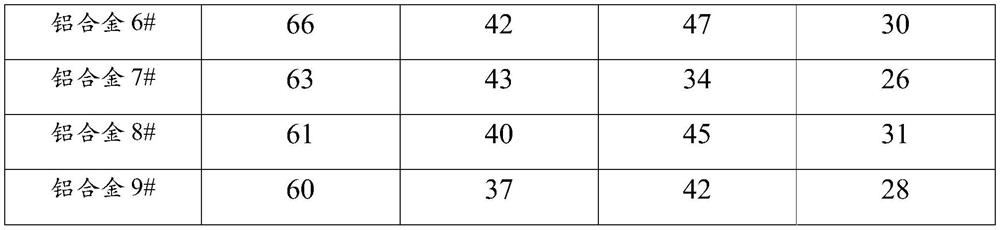

Titanium dioxide synthetic system

PendingCN110372033AHigh titanium contentShort processing cycleTitanium tetrachlorideTitanium dioxideTitanium tetrachlorideTitanium dioxide

The invention provides a titanium dioxide synthetic system. The titanium dioxide synthetic system comprises a titanic iron ore supply device, a reduction smelting unit, a chlorination unit and an oxidizing unit, the reduction smelting unit is provided with a feeding port and a high titanium slag discharging port, the feeding port communicates with the titanic iron ore supply device, the chlorination unit is provided with a high titanium slag inlet, a chlorine inlet and a titanium tetrachloride discharging port, the high titanium slag inlet communicates with the high titanium slag discharging port through a high titanium slag transport pipeline, the oxidizing reaction unit is provided with a titanium tetrachloride inlet and a titanium dioxide discharging port, and the titanium tetrachlorideinlet communicates with a titanium tetrachloride discharging port through a titanium tetrachloride transport pipeline. According to the titanium dioxide synthetic system, the environmental protectiveperformance of the technology can be greatly improved, and meanwhile the titanium dioxide synthetic system has the advantages that operation is easy, the preparation period is short, and the cost islow.

Owner:CHINA ENFI ENGINEERING CORPORATION

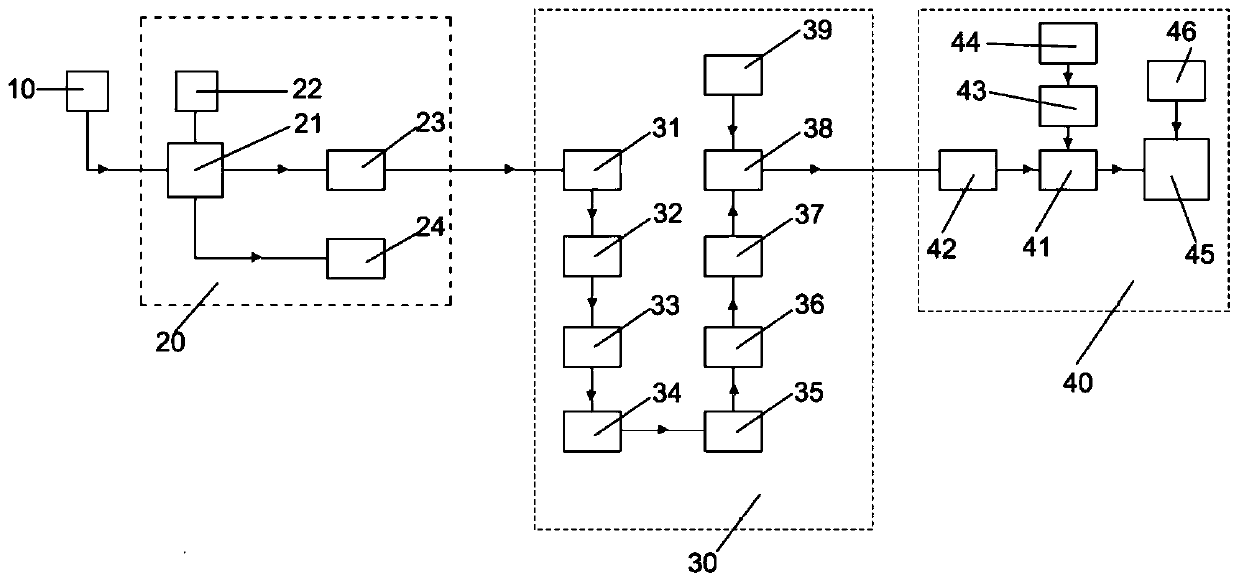

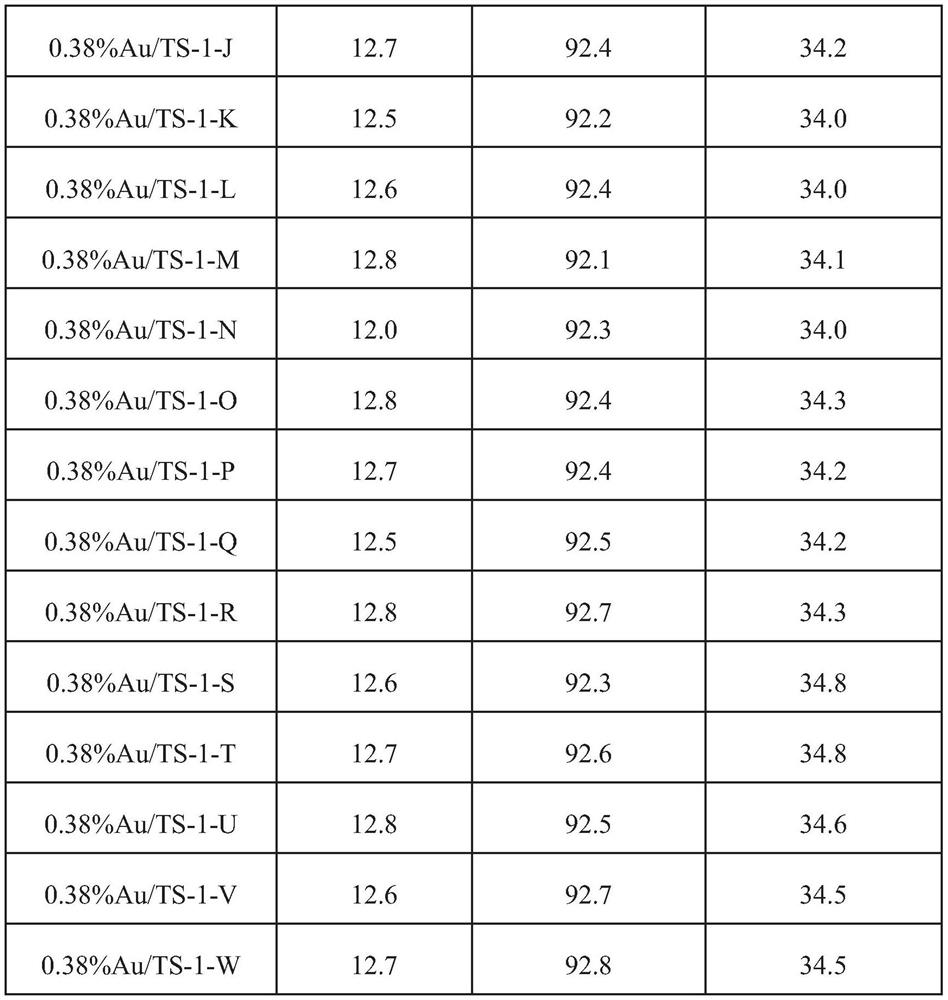

Preparation method of high-activity low-byproduct propylene gas-phase epoxidation catalyst

InactiveCN112871205AHigh titanium contentLower pHOrganic chemistryMolecular sieve catalystsPtru catalystHigh activity

The invention discloses a preparation method of a high-activity low-byproduct propylene gas phase epoxidation catalyst. In the preparation process of the catalyst, a defect site auxiliary agent and an S auxiliary agent are added, titanium-rich defect sites suitable for Au loading are obtained, amorphous species on the catalyst are stabilized by S, then the high-activity propylene gas phase epoxidation catalyst is obtained, and alkali metal ions introduced at the same time with the S auxiliary agent can reduce the production probability of by-products, so that the conversion rate of propylene, the selectivity of PO and the hydrogen efficiency are greatly improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of method for modification of extruded titanium-silicon molecular sieve

ActiveCN106238094BImprove solubilityPromote secondary crystallizationMolecular sieve catalystsMolecular sieveTitanium

The invention provides a method for modifying an extrusion moulding titanium silicalite molecular sieve. The method comprises the following specific steps: adding a titanium source into an alcohols solvent dropwise, sequentially adding a quaternary ammonium base, water and a protective agent, reacting for 10-60 minutes at the temperature of 20-30 DEG C to obtain a modified solution, mixing the modified solution and a strip titanium silicalite molecular sieve TS-1 obtained through extrusion moulding, putting the mixture in a crystallization kettle, processing for 12-48 hours at the temperature of 100-190 DEG C, separating a solid, washing the solid, and carrying out drying and roasting to obtain the strip titanium silicalite molecular sieve with high titanium content on the outer surface. The method solves the problems that the titanium content of a framework on the outer surface of the extrusion moulding titanium silicalite molecular sieve TS-1 is low and the large molecule is difficult to diffuse, the TS-1 with high titanium content of the framework on the outer surface is prepared, then the diffusion path of a reactant is shortened, the activity of the TS-1 in catalysis of a macromolecule reaction is improved, and the application of the TS-1 is further expanded.

Owner:DALIAN UNIV OF TECH

Clean method for preparing rutile-type titanium dioxide from high-titanium slag by hydrothermal method

InactiveCN101190802BProduced (processed) lessHigh titanium contentTitanium dioxideEconomic benefitsCleaning methods

The invention relates to a clean production method by high titanium slag hydrothermal method to prepare rutile titanium oxide. The method adopts high titanium slag as raw material and sodium hydroxide hydrothermal method to prepare the intermediate product of sodium titanate which is then separated from the solution and washed and hydrolyzed to obtain the rutile titanium oxide. The method of the invention adopts simple preparation technique to prepare the rutile TiO2, which spares high temperature calcination in the traditional technique; the conversion rate of titanium in the high titanium slag is of over 99.0 percent and the alkali circulation and the acid circulation are realized, which has good economic benefit and environmental benefit. Additionally, the sodium titanate which can be taken as the intermediate product for preparing titanium series obtained from the method is expected to have wide application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

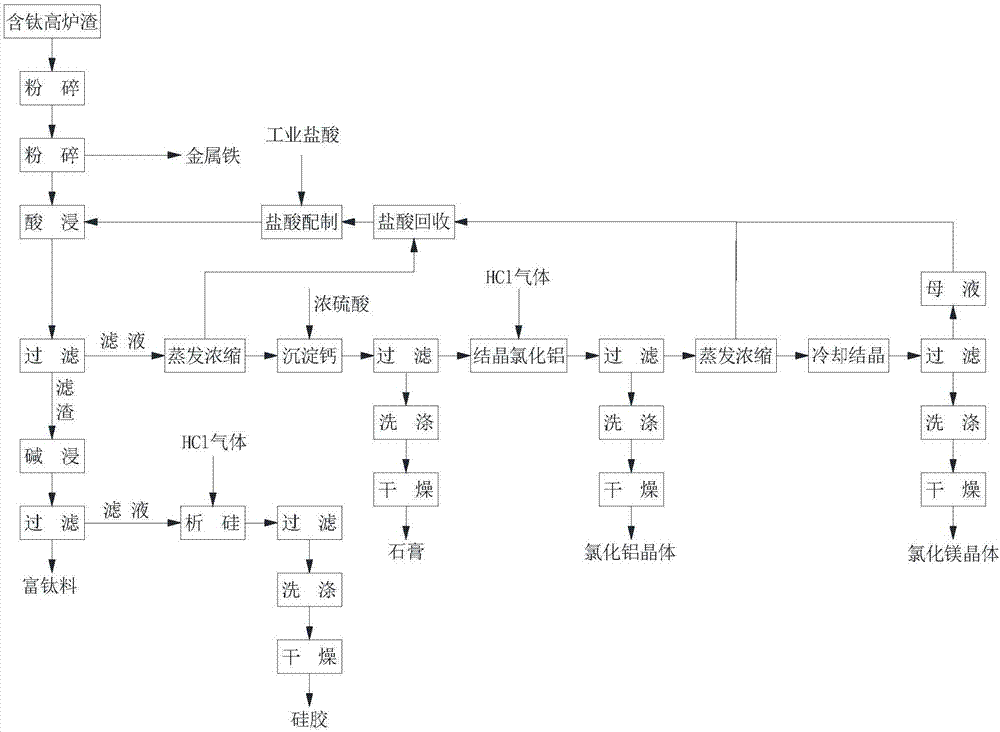

Resource treatment method of titanium-bearing blast furnace slag and rich-titanium material acquiring method

InactiveCN107354252AReduce acid consumptionReduce concentrationSilicaMagnesium chloridesMineral SourcesSlag

The invention discloses a method for gathering TiO2 in titanium-bearing blast furnace slag and a resource treatment method of the titanium-bearing blast furnace slag and belongs to the technical field of comprehensive utilization of mineral resources. The method is implemented specifically according to the following steps that the titanium-bearing blast furnace slag is smashed to be 150-250 [mu]m, magnetic separation is conducted to remove iron, and blast furnace slag powder is obtained; the blast furnace slag powder is added into a hydrochloric acid solution with the concentration being 18-22% according to the solid-liquid rate of 1:2.5-3.5, the mixture is leached for 3.5-4 hours at the temperature of 85-92 DEG C and then filtered, and filtrate and acid-leaching filter residues are obtained; and the acid-leaching filter residues are added into a NaOH solution according to the solid-liquid rate of 1:1.0-1.5, the mixture is subjected to a reaction for 2-3 hours at the heating temperature of 48-55 DEG C and then filtered, filter residues are separated out, and the filter residues are a rich-titanium material. According to the method, titanium in the titanium-bearing blast furnace slag is gathered through an acid and alkali combined technology with high efficiency, low pollution and small acid consumption, the rich-titanium material with the high titanium content is prepared, and meanwhile other products are prepared.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

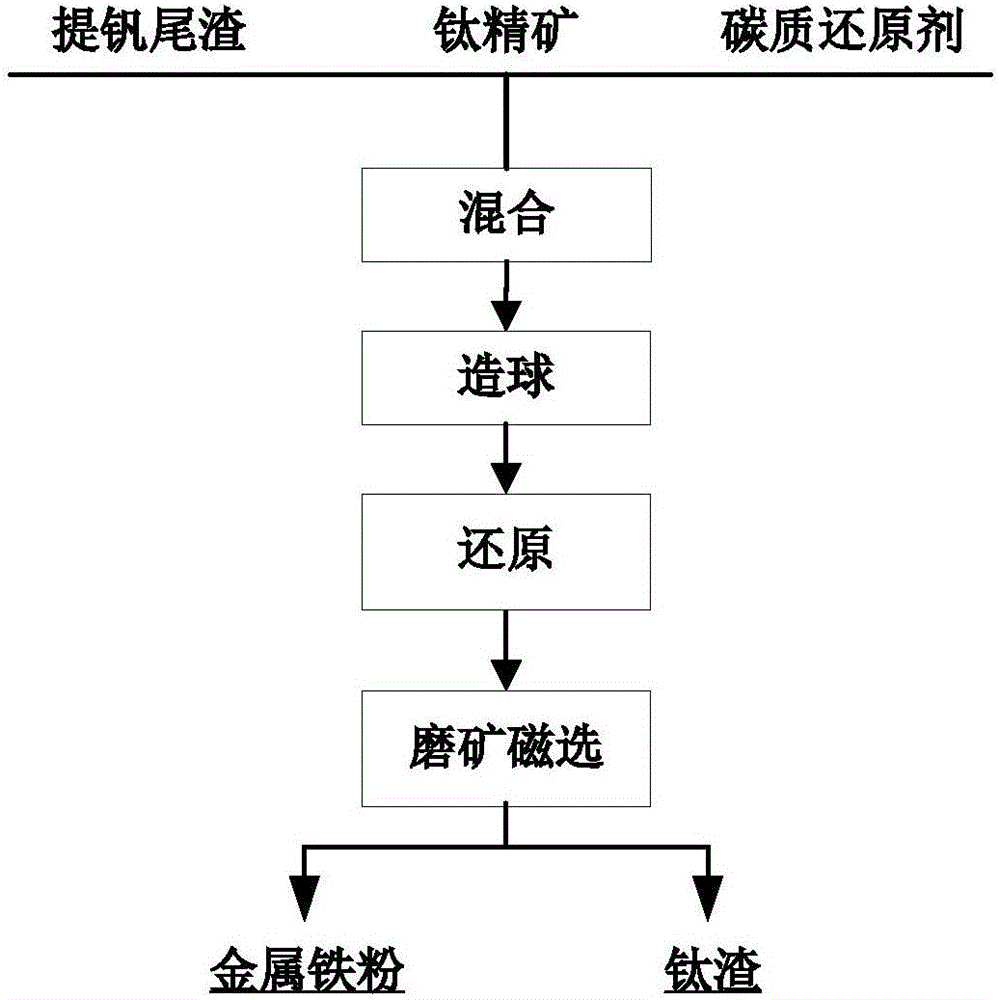

Treatment system and method for vanadium extraction tailings

PendingCN106636628ASolve the technical problem of low recovery rateHigh titanium contentProcess efficiency improvementIron powderReduction treatment

The invention relates to a treatment system and method for vanadium extraction tailings. The system comprises a blending device, a pelletizing device, a reduction device and an ore grinding and magnetic separation device which are sequentially connected. The method comprises the steps that the vanadium extraction tailings, titanium concentrate and a carbonaceous reducing agent are blended in the blending device, so that a blended material is obtained; the blended material is pelletized in the pelletizing device to obtain pellets; the pellets are subjected to reduction treatment in a reduction furnace, so that metalized pellets are obtained; and the metalized pellets are treated through the ore grinding and magnetic separation device, and metallic iron powder and titanium tailings are obtained. By adding the titanium concentrate, the technical problem that the titanium recovery rate of low-titanium-content vanadium extraction tailings is low is solved, the recovery rate can reach 98% or over, and the novel method for comprehensive recycling of the vanadium extraction tailings is provided.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

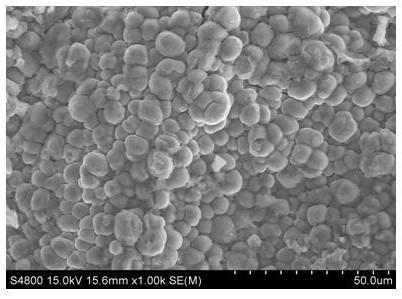

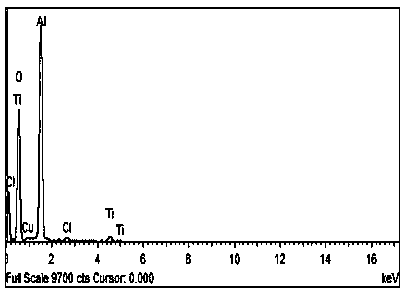

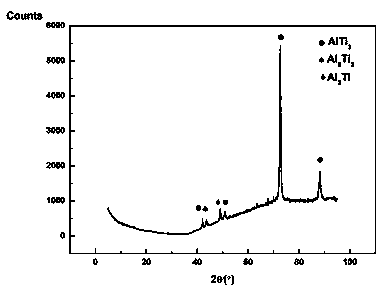

Method of preparing aluminum-titanium alloy plating through electrodeposition in organic solvent system at room temperature

The invention provides a method of preparing an aluminum-titanium alloy plating through electrodeposition in an organic solvent system at the room temperature, and relates to a method of preparing analloy plating. The method comprises the following preparing processes that plating solution is prepared, specifically, anhydrous aluminum chloride and lithium aluminium tetrahydride are weighed, anhydrous titanium tetrachloride is slowly added into the anhydrous aluminum chloride and the lithium aluminium tetrahydride, and in the process, the using ratio of benzene to tetrahydrofuran is (4:1)-(4:3); a copper matrix is treated, specifically, a copper sheet is polished smoothly through 400, 800 and 1200 meshes of abrasive paper in sequence, and then oil removing is conducted; and constant-current electrodeposition is conducted, specifically, graphite serves as an anode, the copper sheet serves as a cathode, the current density is controlled to be 6-38 milliampere / square centimeter, electrodeposition is conducted, thus a pure aluminum-titanium alloy with the uniform particle size can be obtained, and the electrodeposition time is controlled to be 3-5 hours. The method adopts the graphiteas the anode, titanium ions with a certain concentration are obtained by adding the anhydrous titanium tetrachloride, the method is low in cost, the generated aluminum-titanium alloy is pure and uniform in particle size, and the titanium content is high.

Owner:SHENYANG UNIV

Process for producing anhydrous formaldehyde by dehydrogenation of methanol

InactiveCN107162884AImprove synergyImprove dispersionMolecular sieve catalystsOrganic compound preparationChemical industryMolecular sieve

The invention belongs to the technical field of chemical industry, and in particular relates to a process for producing anhydrous formaldehyde by dehydrogenation of methanol, a soluble copper salt and an additive are homogeneously precipitated on the surface of a titanium silicon molecular sieve carrier, after cooling, an acid modifier is added for modification under microwave effect, and after the completion of the reaction, the anhydrous formaldehyde is obtained by drying and air roasting. The methanol is used as a raw material, and an inert gas is used as a carrier gas. The reaction is carried out in a fixed bed reactor. A copper based catalyst is filled in a reaction tube, and the reaction tube is sent to the reactor for reaction. Through the acid modification under the microwave effect, the synergistic effect of the Cu base and the titanium silicon molecular sieve can be effectively enhanced, the dispersion of the catalyst is significantly increased, the titanium content outside the framework of the molecular sieve is reduced, and the effective framework titanium content is increased.

Owner:册亨荣畅化工科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com