Preparation method of titanium-containing nano-mordenite molecular sieve

A technology of mordenite and molecular sieve, which is applied in the field of synthesis of titanium (Ti) mordenite molecular sieve, to achieve the effect of shortening crystallization time and reducing titanium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 10.48 g NaOH to 190 ml of deionized water, stir until the solution is clear, add 1.6 g of sodium metaaluminate to the above solution, continue stirring at room temperature until the solids are completely dissolved, and then add 200 ml of deionized water to it, Add 27.52 g of fumed silica gel to the above mixed solution, continue to stir strongly for 1 hour, then add 2.76 g of mordenite as a seed crystal into the reaction system, and continue to stir for 0.5 hours after the addition to form system (1);

[0024] 2.980 g triethanolamine (TEAH 3 ) was mixed with 3.400 g butyl titanate to form system (2);

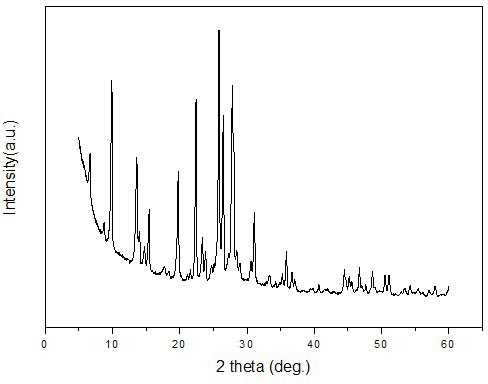

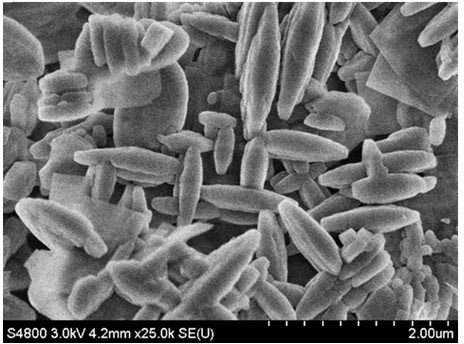

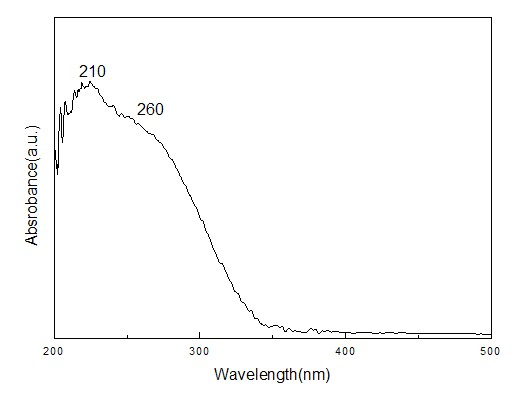

[0025] Add system (2) to system (1) quickly, stir for 0.5h, and finally put the mixture into a polytetrafluoroethylene-lined stainless steel crystallization kettle, seal it and crystallize it in an oven at 170°C for 24 hours, After filtering, washing and drying, a solid product was obtained. The molar composition of the initial sol of the mixture is: SiO 2 :Al 2 ...

Embodiment 2

[0028] Except that Qingdao silica gel was used instead of the fumed silica gel in Example 1 as the silicon source, other preparation conditions were the same as in Example 1.

[0029] The solid product is characterized by X-rays, SEM images, and UV-Vis images to be titanium-containing mordenite.

Embodiment 3

[0031] Except that triethanolamine in Example 1 was replaced with methylamine as the small organic molecule, other preparation conditions were the same as in Example 1.

[0032] The solid product is characterized by X-rays, SEM images, and UV-Vis images to be titanium-containing mordenite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com