Resource treatment method of titanium-bearing blast furnace slag and rich-titanium material acquiring method

A disposal method and blast furnace slag technology, applied in magnesium halide, aluminum halide, magnesium chloride and other directions, can solve the problems of high requirements for equipment and environmental measures, large acid consumption, low titanium leaching rate, etc. High levels, equipment and environmental measures require less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

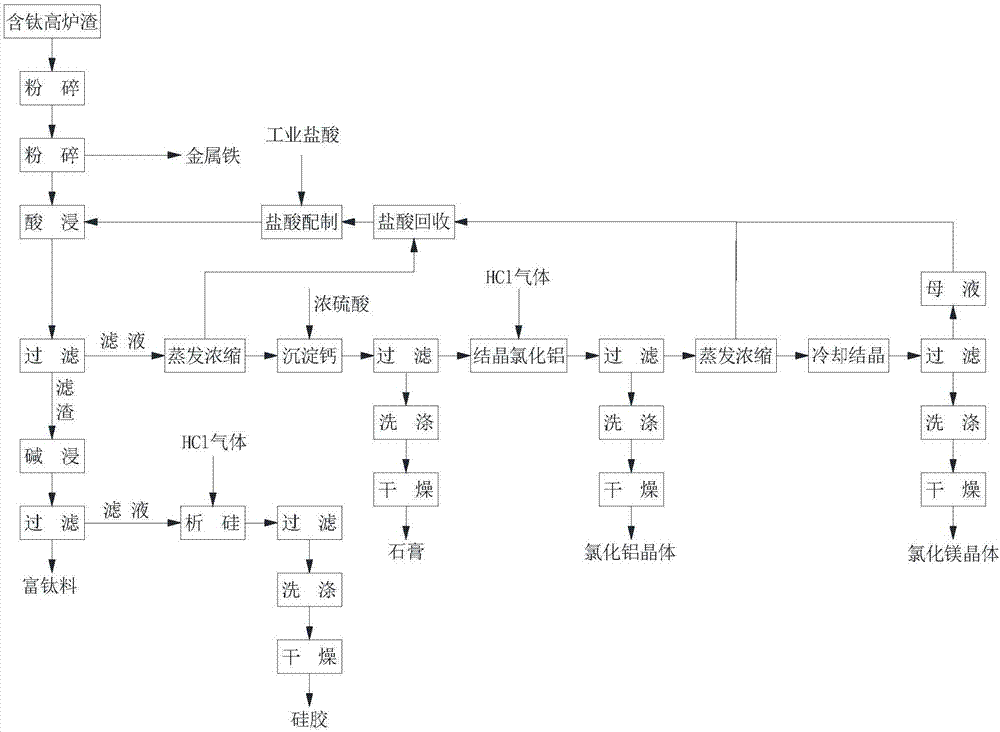

Image

Examples

Embodiment 1

[0037] In this embodiment, a method for enriching TiO in titanium-containing blast furnace slag 2 The method is implemented according to the following steps: crush titanium-containing blast furnace slag to 150-250 μm, remove iron by magnetic separation, and obtain blast furnace slag powder; Add 20% hydrochloric acid solution, filter at 90°C for 4 hours to obtain filtrate and acid leaching filter residue; the obtained acid leaching filter residue is according to the ratio of solid to liquid 1:1.2 (g / mL, the same below) Add it into 400g / L NaOH solution, react at a heating temperature of 50°C for 2 hours, then filter, and separate out the filter residue, which is titanium-rich material, the main components are perovskite and metatitanic acid, and a small amount that does not participate in the reaction residue.

Embodiment 2

[0039] In this embodiment, a method for enriching TiO in titanium-containing blast furnace slag 2 The method is implemented according to the following steps: crush the titanium-containing blast furnace slag to 150-250 μm, remove iron by magnetic separation, and obtain blast furnace slag powder; After leaching at 85°C for 4 hours, filter to obtain filtrate and acid leaching filter residue; add the obtained acid leaching filter residue to 380g / L NaOH solution according to the ratio of solid to liquid ratio of 1:1, and react at a heating temperature of 48°C After 2 hours, filter and separate the filter residue, which is titanium-rich material.

Embodiment 3

[0041] In this embodiment, a method for enriching TiO in titanium-containing blast furnace slag 2 The method is implemented according to the following steps: crush the titanium-containing blast furnace slag to 150-250 μm, remove iron by magnetic separation, and obtain the blast furnace slag powder; add the blast furnace slag powder into 22% hydrochloric acid solution according to the ratio of material to liquid 1:3.5, After leaching at 92°C for 3.5 hours, filter to obtain filtrate and acid leaching filter residue; add the obtained acid leaching filter residue to 350g / L NaOH solution according to the ratio of solid to liquid 1:1.5, and react at a heating temperature of 55°C After 3 hours, filter and separate the filter residue, which is titanium-rich material.

[0042] Based on the same inventive concept, the enrichment of TiO in titanium-containing blast furnace slag by acid-base combined process 2 At the same time, we can also further recycle other substances produced, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com