Patents

Literature

71results about How to "No change in physical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ecological type water-based synthetic leather

InactiveCN103361988ANo change in physical propertiesGuaranteed cleanlinessLamination ancillary operationsSynthetic resin layered productsLeather industryWater based

The invention relates to ecological type water-based synthetic leather which comprises a dry layer, a foaming layer, a bonding layer and a base material, and is characterized in that the dry layer, the foaming layer, the bonding layer and the base material are sequentially compounded in a layered way; and the dry layer, the foaming layer and the bonding layer are made from water-based resin. The product does not change the physical properties of solvent type synthetic leather, the whole leather layer structure adopts the non-toxic, harmless, safe and environment-friendly water-based material, and all the links of the whole production process are maintained to be clean and environment-friendly, so that the ecological type water-based synthetic leather is completely environment-friendly. The ecological type water-based synthetic leather saves a great deal of organic solvent, reduces the production cost of the synthetic leather, and is in accordance with the development tendency of synthetic leather industry, thus having a wide application prospect.

Owner:广东宏裕智汇创新科技有限公司

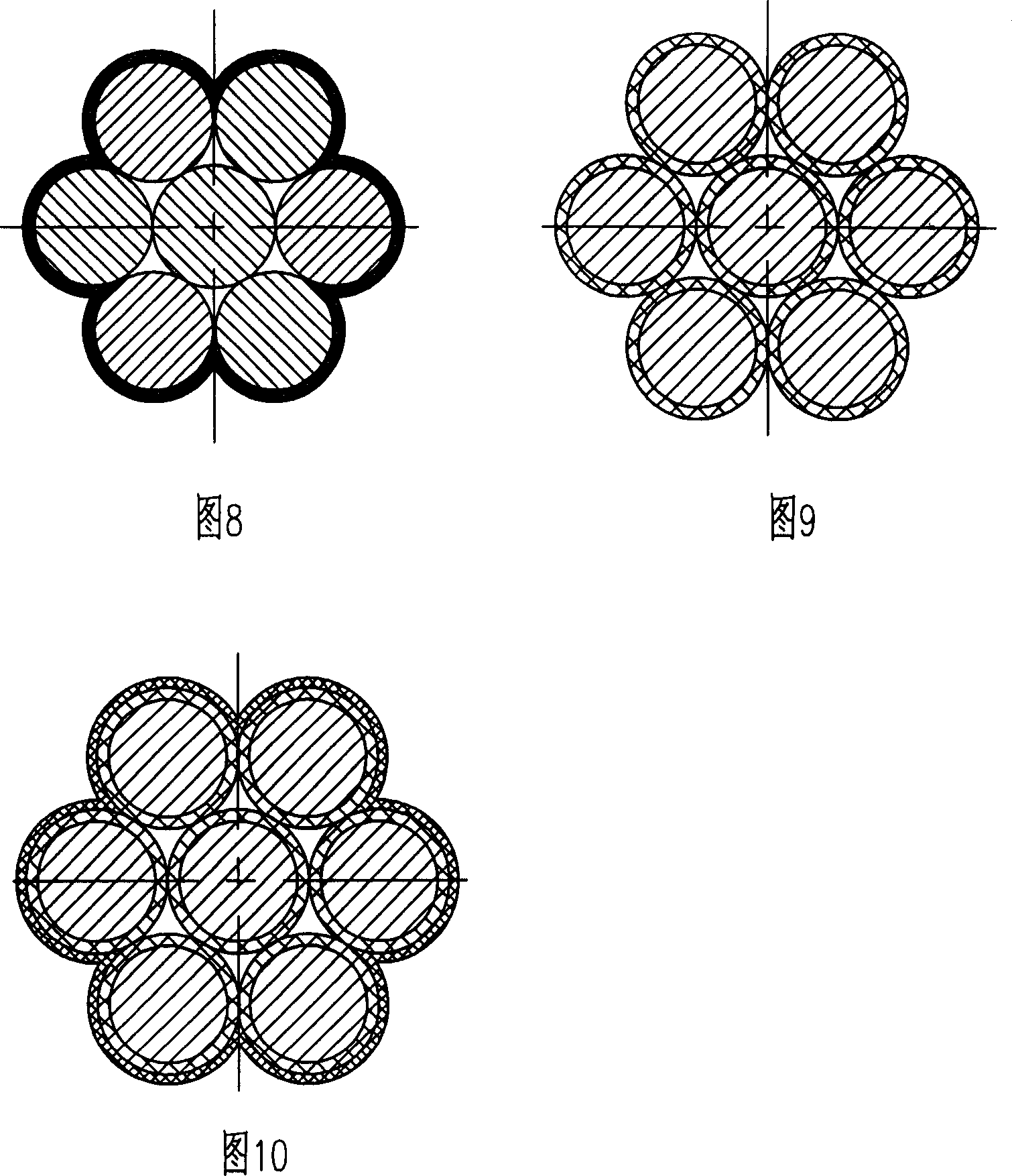

Nickel-copper composite metal textile and preparation method thereof

InactiveCN1558017AImprove conductivityLow conductivityFibre treatmentLiquid/solution decomposition chemical coatingCopperLow frequency

The fabric with compounded metal nickel and copper is prepared with dacron or nylon fabric, and through surface roughening, sensitizing, activating, chemically plating one layer of metal nickel, electroplating one intermediate copper layer, and finally electroplating one protecting nickel layer. The formed Ni-Cu-Ni layers have nickel amount o 5-20 g / sq m and Cu / Ni weight ratio of 1.5-3; and the metal fabric has excellent electromagnetic shielding effect on low frequency electromagnetic wave, and the shielding effect is 60-90 dB in the frequency range of 10 KHz-3 GHz, and 50-70 dB in the frequency below 10 KHz.

Owner:HUNAN CORUN NEW ENERGY CO LTD

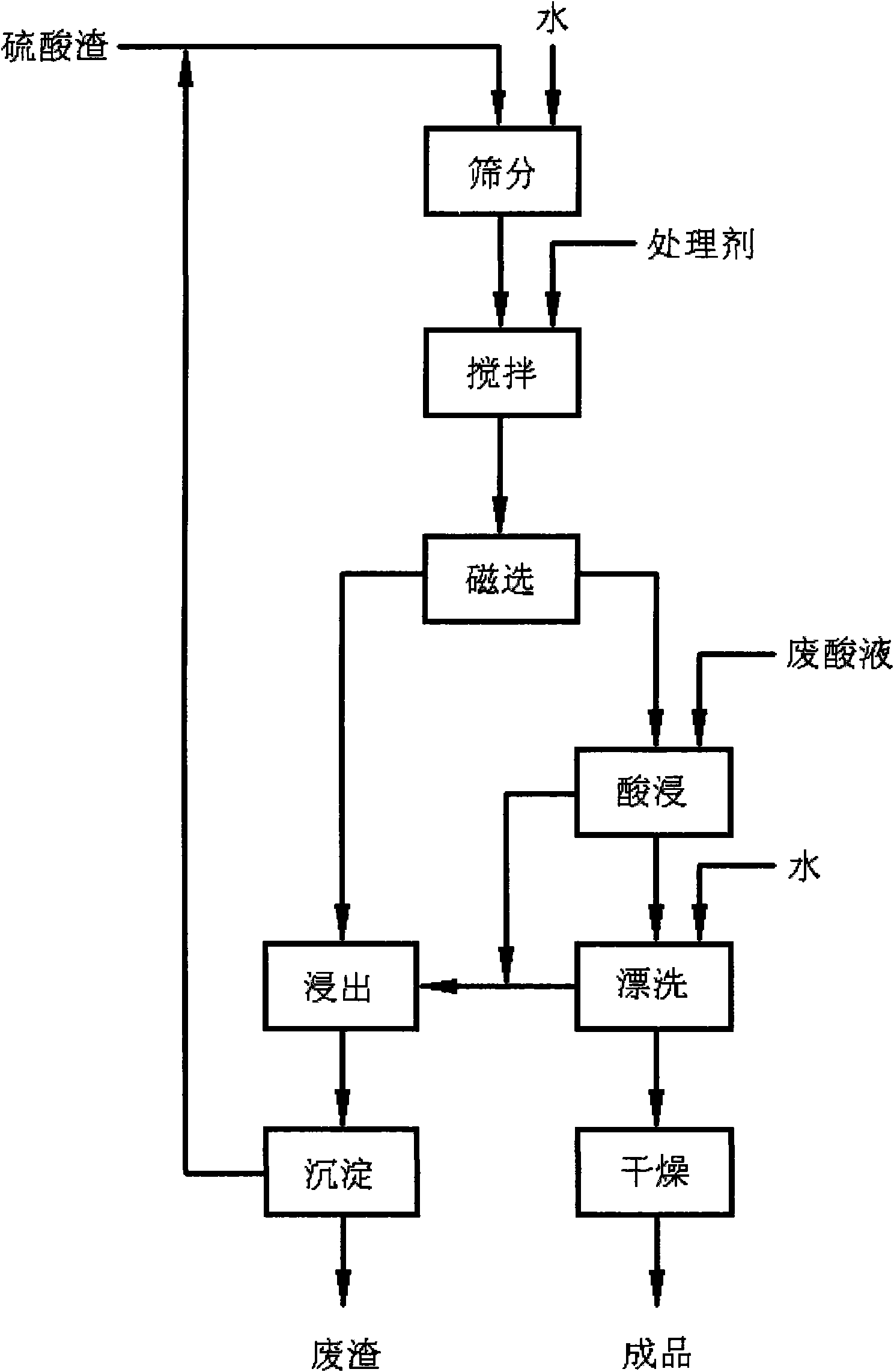

Method for recycling industrial waste sulfate slag

InactiveCN101554613ANo change in physical propertiesHigh recovery rateSolid waste disposalWet separationSocial benefitsSlag

The invention provides a method for recycling industrial waste sulfate slag, which comprises the steps of sieving, stirring, magnetic separation, acid dipping, rinsing and drying to obtain iron-bearing materials. The method not only reallocates the available resource of the sulfate slag which is difficult to be processed and has high pollution, but also reduces the severe contamination of the sulfate slag to the environment and simultaneously lowers the production cost greatly; the metal recovery rate is 50 to 82 percent, high quality iron concentrate with the grade of iron being larger than 60 percent, the grade of sulfur being smaller than 0.3 percent and the grade of arsenic being smaller than 0.1 percent is obtained; simultaneously the recovery processing capacity is large, the equipment is simple, the investment is small, the operation is convenient, the sulfate slag material is not limited, both the sulfate slag with high iron content and the sulfate slag with low iron content can be recycled, and the method has good social benefit and remarkable economic effect.

Owner:房志强 +1

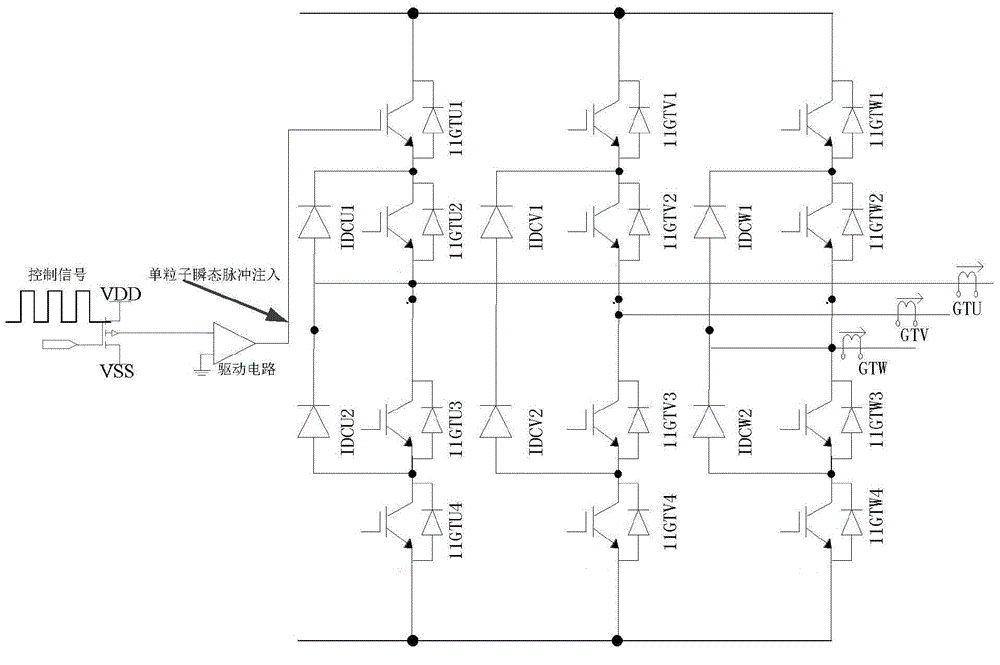

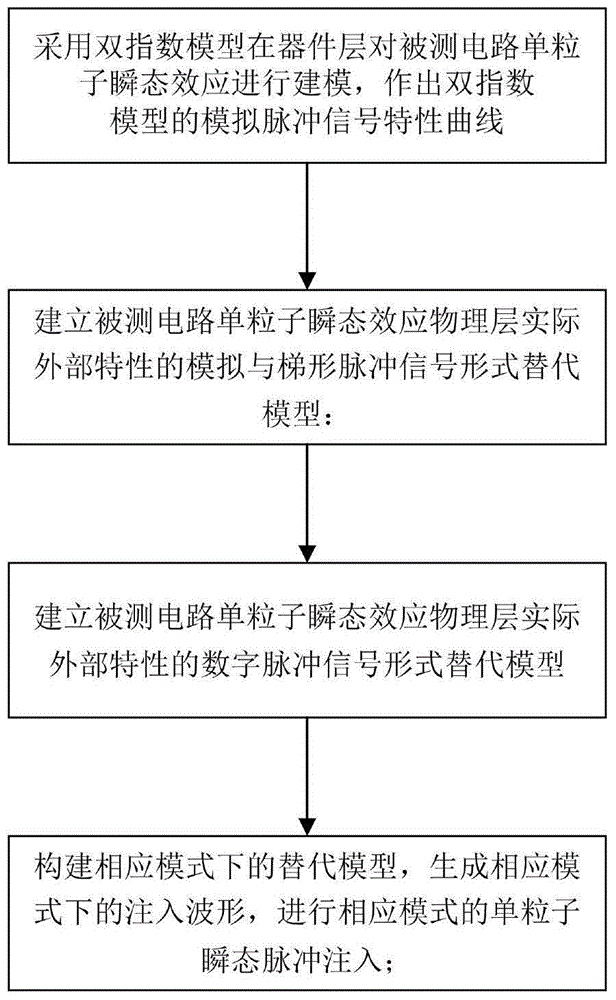

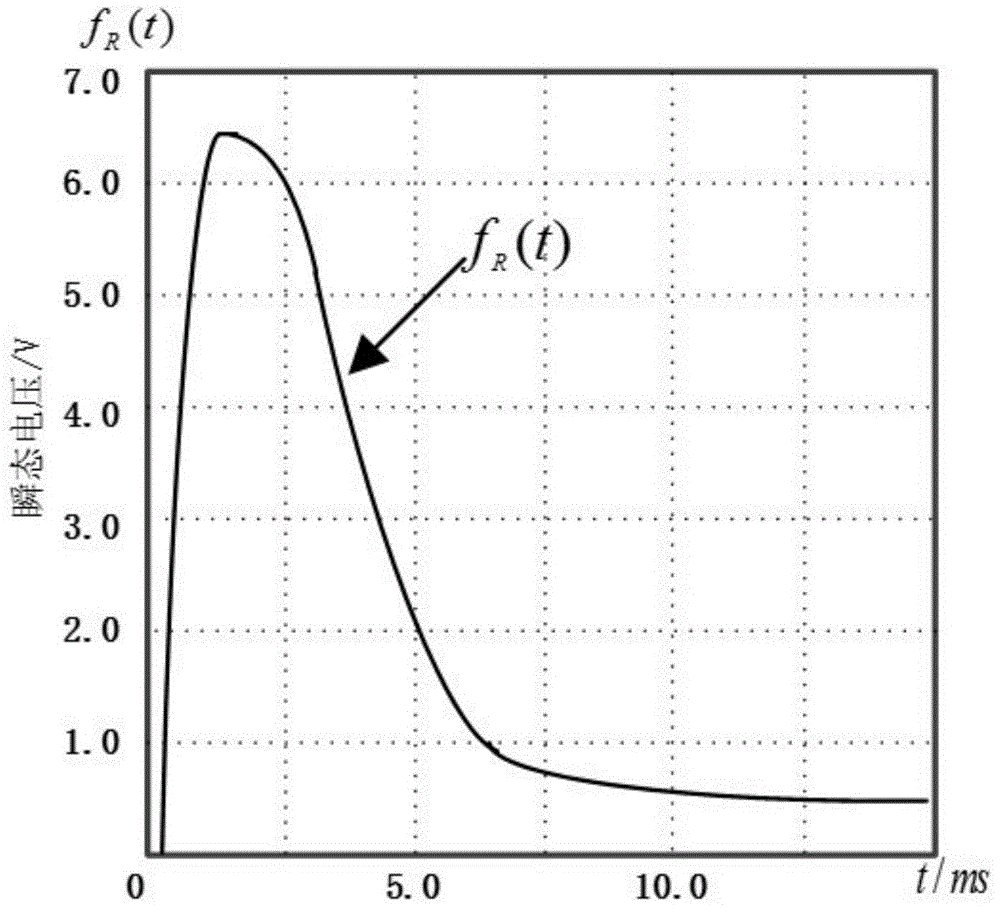

Single-particle transient effect injection method based on substitution model

ActiveCN105044500ANo change in physical propertiesReal and reliable fault simulation environmentElectronic circuit testingFault toleranceSubstitution model

The invention discloses a single-particle transient effect injection method based on a substitution model. The method includes modeling single-particle transient effect of a circuit to be detected on a device layer with a bi-index model, respectively establishing analog pulse signal formed, trapezoid pulse signal formed and digital pulse signal formed substitution models for actual external physical layer characteristics of single-particle transient effect of the circuit to be detected, constructing substitution models for actual external physical layer characteristics of single-particle transient effect of the circuit to be detected under corresponding models by setting analog, trapezoid or digital pulse signal injection models, generating injection waveforms under corresponding modes, and completing injection of single-particle transient pulse under different modes. No special device is needed, the physical characteristics of a device / circuit to be detected remain unchanged, and injection of different expression forms of single-particle transient effect for single device and circuit structure can be completed. A real and reliable fault simulating environment can be provided for researching circuit reinforcing technology, real-time fault diagnosis, and isolation and fault tolerance technology.

Owner:CENT SOUTH UNIV

Novel environment-friendly aqueous joint adhesive and preparation method thereof

InactiveCN103113838AGood effectNo toxicityNon-macromolecular adhesive additivesGraft polymer adhesivesEnvironmental resistanceSodium sulfate

The invention provides a novel environment-friendly aqueous joint adhesive which is mainly prepared by the reaction of butyl acrylate, methacrylic acid, a VAE (Vinyl Acetateethylene Emulsion), a PVAC (Polymer Vinyl Acetate) emulsion, lauryl sodium sulfate, rosin adhered resin, p-methylbenzene sulfonic acid, sodium polyacrylate protective colloid, ammonium persulfate, BL-100 organosilicone foam inhibitor, OP-10 dispersant and a magnesium chloride coupler. The invention further provides a preparation method of the aqueous joint adhesive. The aqueous joint adhesive is nontoxic, safe and environment-friendly and simple to operate, and can directly replace natural rubber joint adhesive without changing the device. Compared with natural rubber self-adhesive glue, the physical properties of the aqueous joint adhesive are substantially not changed, and the aqueous joint adhesive better carries forward the advantages of the original natural rubber self-adhesive glue. Compared with natural rubber self-adhesive glue, the cost of the aqueous joint adhesive is lowered to a greater extent, and the raw material source is easier and more convenient to get.

Owner:宿州鹏御源新材料科技有限公司

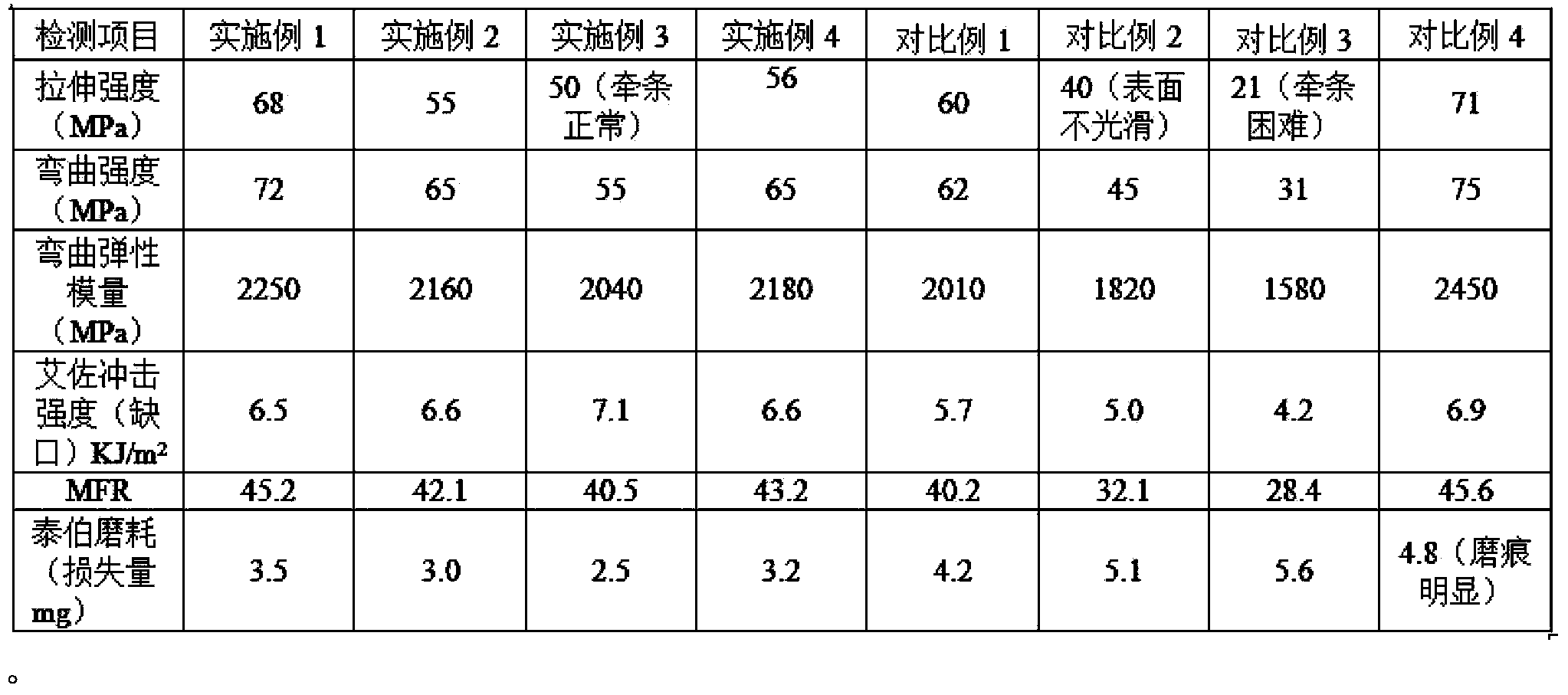

Ultrahigh-molecular weight polyethylene modified nylon 66 and preparation method thereof

The invention discloses ultrahigh-molecular weight polyethylene modified nylon 66 and a preparation method thereof. The ultrahigh-molecular weight polyethylene powder particle surface heterogeneous-grafting maleic anhydride is used as a nylon 66 wear-resistant modifier to reduce the abrasion of the nylon 66. The ultrahigh-molecular weight polyethylene modified nylon 66 consists of 10-30% of ultrahigh-molecular weight polyethylene, 68-88% of nylon 66, 0.1-0.3% of composite antioxidant and 0.5-1.7% of lubricant; the ultrahigh-molecular weight polyethylene is the heterogeneous maleic anhydride-grafting ultrahigh-molecular weight polyethylene; and the components are extruded and granulated by a parallel co-rotating twin screw extruder. The method disclosed by the invention is simple and easy to implement; and the intrinsic wear resistance of the ultrahigh-molecular weight polyethylene is maintained, and the ultrahigh-molecular weight polyethylene is 'riveted' with the nylon 66 to be conveniently added into the nylon 66, thereby remarkably improving the wear resistance of the nylon 66.

Owner:NANJING LIHAN CHEM CO LTD

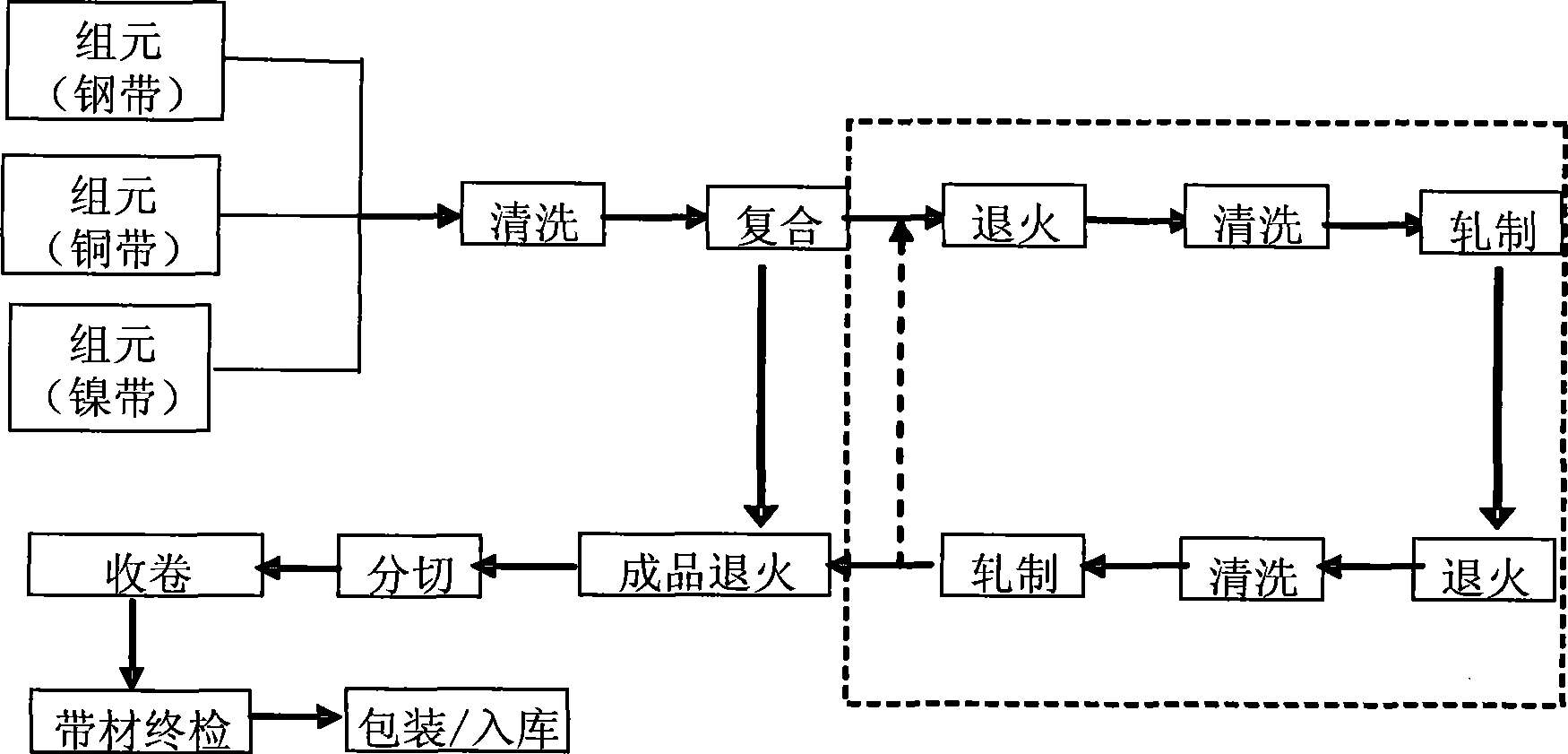

Battery lead wire and manufacturing method

InactiveCN101383406ASolve the scarcityGuaranteed Performance ConductivitySingle bars/rods/wires/strips conductorsWork treatment devicesMetallic NickelThermal conductivity

The invention relates to a battery lead-out line which is formed by overlapping the three materials of steel, nickel and copper in a strap-shape and then cold rolling. The manufacturing process for the battery lead-out line comprises the following steps: firstly, the three materials of the steel, the nickel and the copper are cold-rolled into strap-shapes according to the required thickness; secondly, surface treatment is respectively performed to all the strap-shaped materials; thirdly, the three strap-shaped materials are overlapped together in sequence, and then cold-rolled and pressed to reach the thickness required by the lead-out line; fourthly, annealing treatment is carried out; and fifthly, the lead-out line is cut into the required width. The invention fully utilizes the characteristics of all the materials, the differences between the materials of the battery lead-out line and the pure nickel strip material are not significant in the electrical conductivity, the thermal conductivity, the resistance and the welding performance among the lead-out line, the tab and the cover plate thereof, the materials of the battery lead-out line are superior to the copper strip or copper nickel composite material, and can replace the original pure nickel material, therefore, the production cost is reduced, and the problem of the scarcity of the nickel material is also solved. The manufacturing process is not required to change the original physical characteristics of the three materials, and the three materials are closely combined, thereby the service performance of the products is effectively ensured.

Owner:SHENZHEN BAK BATTERY CO LTD

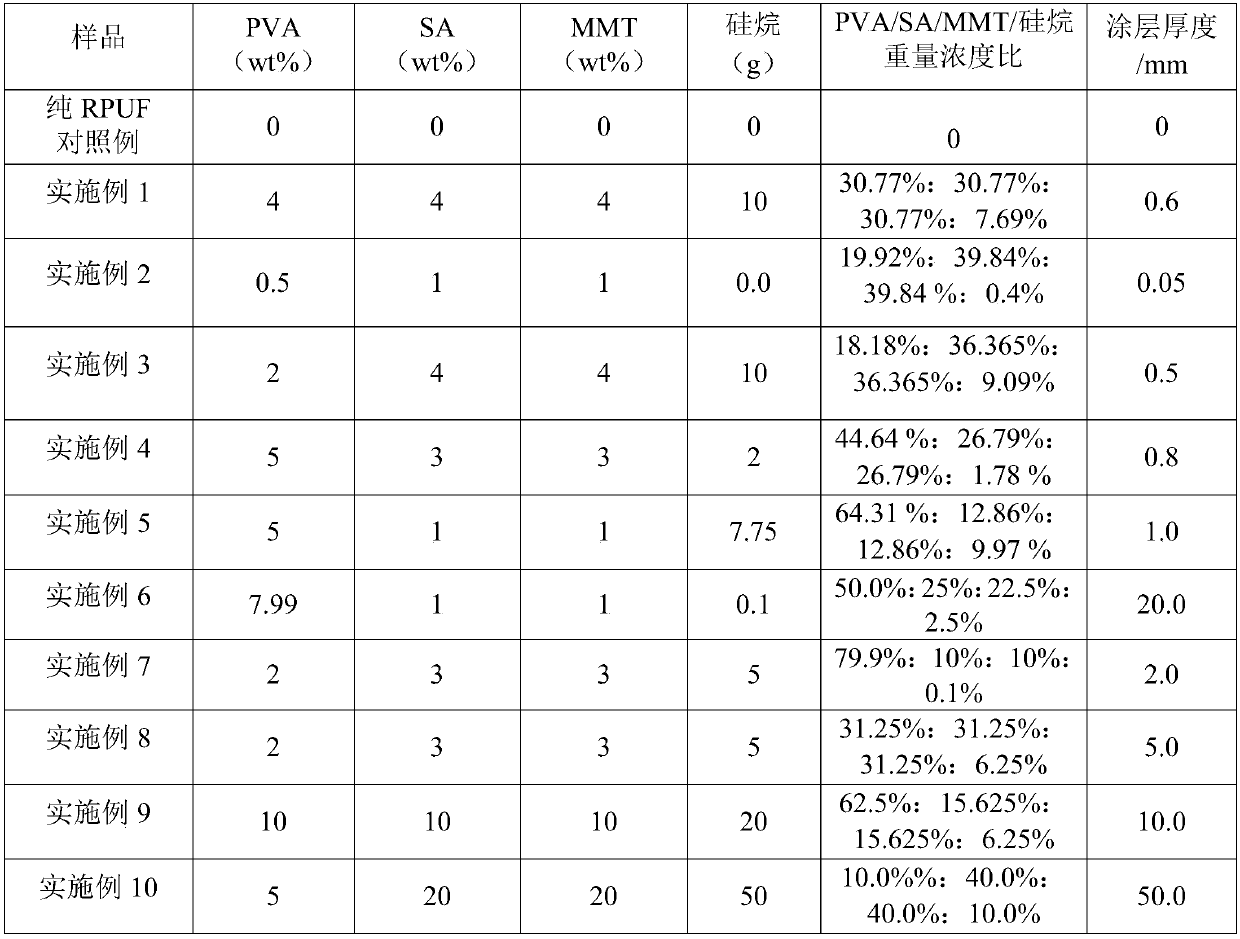

Flame-retarding polyvinyl alcohol-based composite crosslinked aerogel-coating rigid polyurethane foam material and preparation method thereof

InactiveCN109575355AGood smoke suppressionImprove flame retardant performanceFireproof paintsAlginic acid coatingsSilanesFreeze-drying

The invention discloses a flame-retarding polyvinyl alcohol-based composite crosslinked aerogel-coated rigid polyurethane foam material. A sol-gel process and silane hydrolyzing and crosslinking reactions are adopted to prepare composite polyvinyl alcohol / sodium alginate / montmorillonite crosslinked hydrogel for coating a surface of a rigid polyurethane foam material, and a freeze-drying process isadopted to prepare the flame-retarding polyvinyl alcohol-based composite crosslinked aerogel-coated rigid polyurethane foam material. The flame-retarding polyvinyl alcohol-based composite crosslinkedaerogel-coated rigid polyurethane foam material has the advantages of excellent flame-retarding performance, excellent smoke suppression capability, high limit oxygen index which reaches to 45.0% andsmall influences of a polyvinyl alcohol-based composite crosslinked aerogel coating on physical properties including foaming, heat insulating and the like of polyurethane, and thereby having an important application value in application fields of flame retarding and heat insulating.

Owner:QINGDAO UNIV OF SCI & TECH

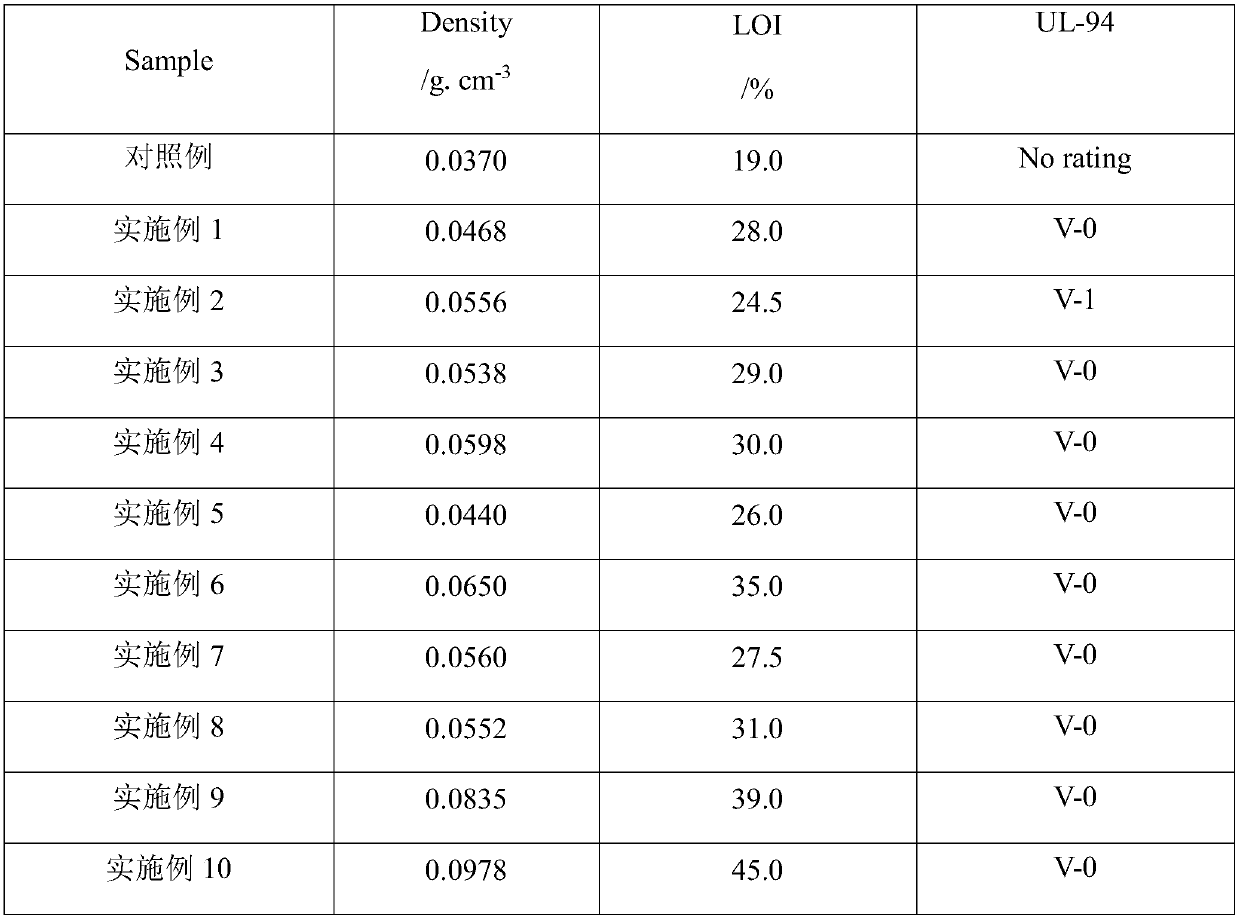

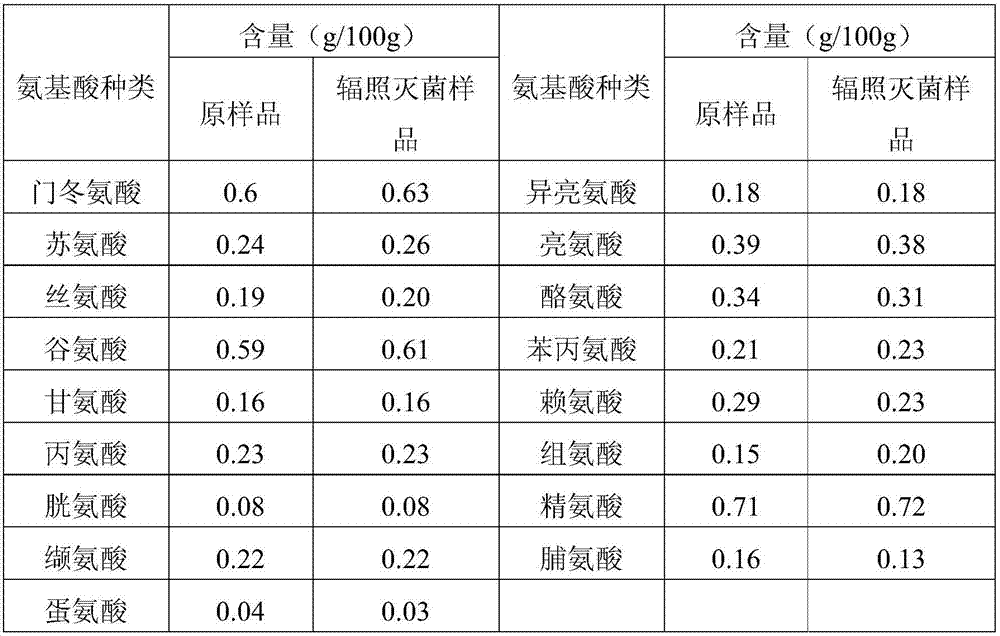

Sterilization method for traditional Chinese medicine ultramicro powder

InactiveCN107875410AAddress health and safety issuesAvoid lostRadiationActive componentRadioactive source

The invention discloses a sterilization method for traditional Chinese medicine ultramicro-powder which is pseudo-ginseng ultramicro-powder. The sterilization method includes steps of: performing pretreatment and bag-sealing package to a pseudo-ginseng ultramicro-powder raw material, and performing irradiation sterilization with Co-60-gamma radioactive source to prepare the sterilized pseudo-ginseng ultramicro-powder. The method is carried out at normal temperature and is free of heating and addition of any additives, has almost no influence on extracts of the pseudo-ginseng ultramicro-powder,content of notoginsenoside, components such as amino acids and minerals, and hemostasis function of the pseudo-ginseng ultramicro-powder. The method can completely sterilize the ultramicro-powder quickly, has simple operations, is convenient to carry out continuously at large scale, and completely solves problems of sanitary and safety of traditional Chinese medicine ultramicro-powders and avoidsloss of the active components during conventional sterilization process of the traditional Chinese medicine ultramicro-powder.

Owner:湖南省核农学与航天育种研究所

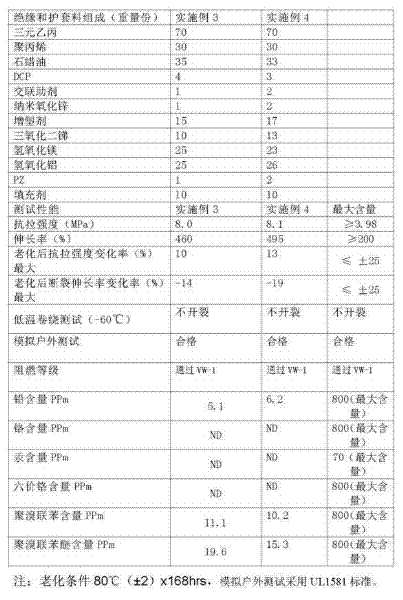

High flame retardant super low temperature resistant environmental flexible cable

ActiveCN102262936AImprove anti-agingGood heat and cold resistancePlastic/resin/waxes insulatorsInsulated cablesElectrical conductorPlasticizer

The invention relates to the technical field of novel material application, in particular to an environment-friendly flexible cable with high flame retardance and super low temperature resistance. The environment-friendly flexible cable with the high flame retardance and the super low temperature resistance comprises a flexible twisted conductor, an insulating layer and an outer protective layer, wherein the insulating layer is wrapped outside the flexible twisted conductor to form single insulated wires; the outer protective layer wraps at least two single insulated wires; the insulating layer and the outer protective layer are made from the same materials, take an ethylene-propylene-diene monomer as a disperse phase and take polypropylene as a continuous phase; the insulating layer contains a plasticizer which is cold-resistant, and also contains 30 to 40 parts of paraffin oil, 2 to 6 parts of cross linking agent and 50 to 70 parts of flame retardant; and the outer protective layer contains the plasticizer which is cold-resistant, and also contains 30 to 40 parts of paraffin oil, 2 to 6 parts of cross linking agent and 50 to 70 parts of flame retardant. Due to the adoption of the technical scheme, the environment-friendly flexible cable with the high flame retardance and the super low temperature resistance has high torsion resistance, the super low temperature resistance and flame retardance, is difficult to age and crack and environment-friendly, and can work stably in low temperature environments of below -60 DEG C.

Owner:GUANGDONG ZHONGDE CABLE

Cigarette

A cigarette features that an empty segemtn is arranged between tip filter and tobacco shreds segment for decreasing the consumption of tobacco, tar and nicotin, that is, decreasing the damage of cigarette to human body.

Owner:CHINA TOBACCO GUANGDONG IND

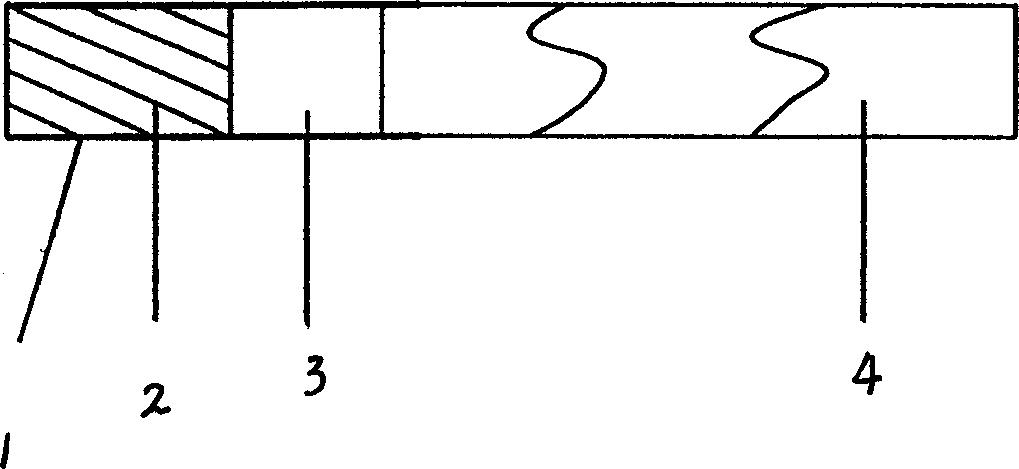

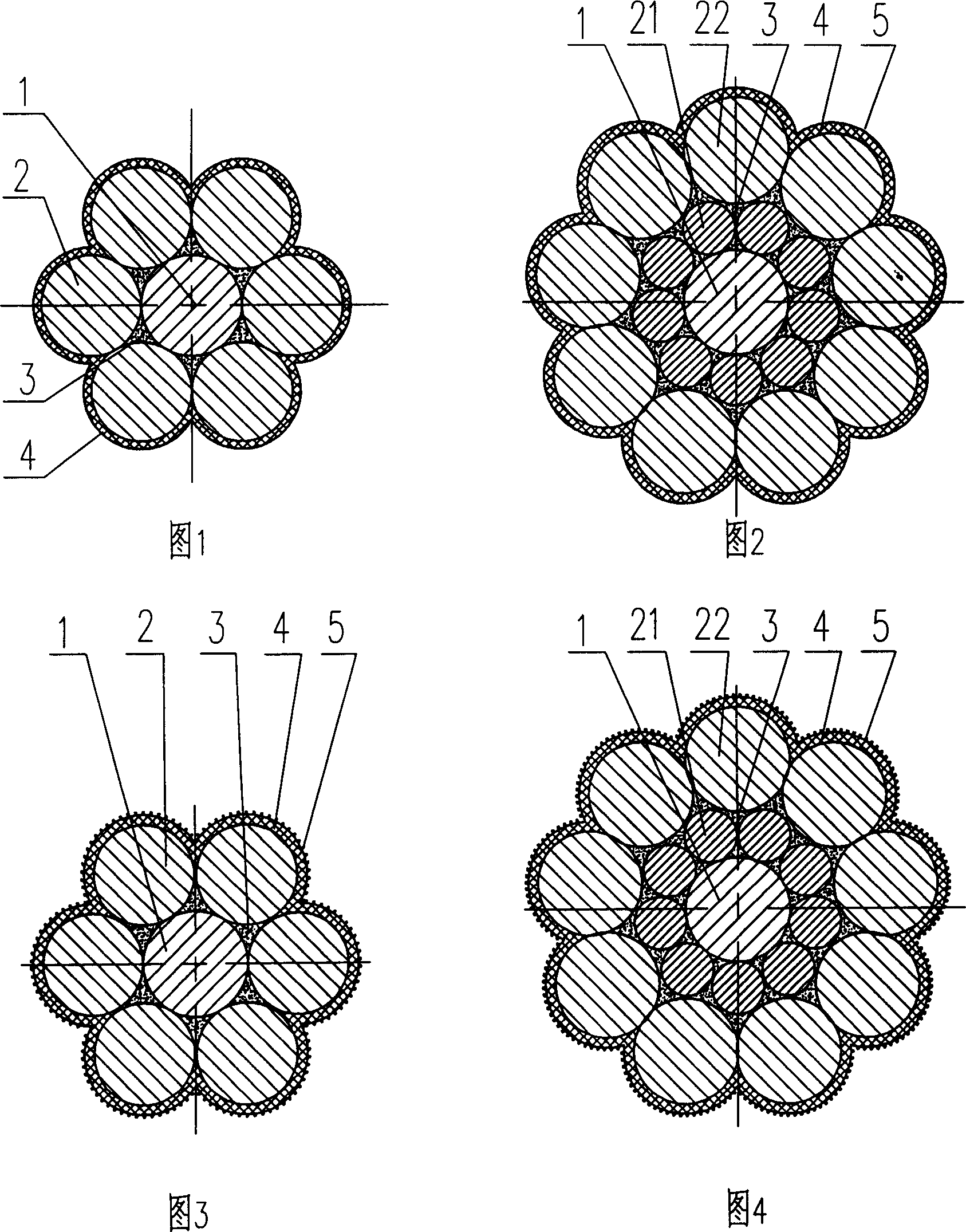

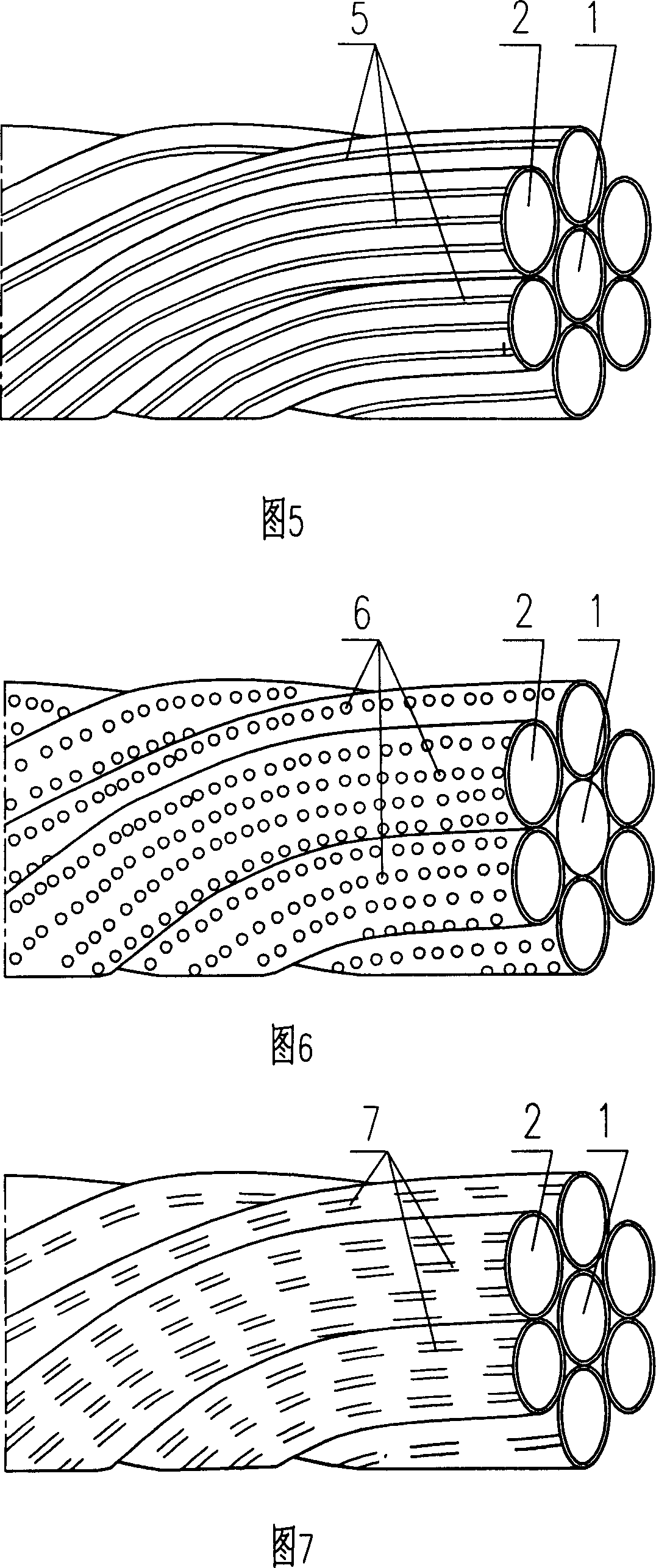

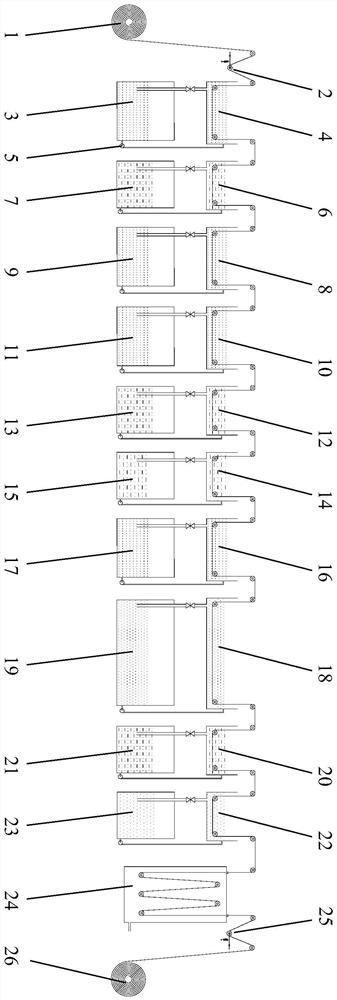

Anticorrosive steel strand and its production method

InactiveCN1995536AImprove anti-corrosion performanceExtended service lifeRope making machinesCoatingsEngineeringPlastics extrusion

The invention relates to an anti-corrosion steel strand, which is made of central line and edge wire by twisting. Anti-corrosion material, which is filled round the central line and edge wire and in the twisting gap and which is coated round the outset layer of edge wire to form anti-corrosion layer, is made of thermoplastic polymers. The anti-corrosion material round the central line and edge wire and in the twisting gap is melted with the anti-corrosion material round the outer layer of edge wire together. The outer anti-corrosion layer can be the anti-corrosion layer with anti-sliding structure. The manufacturing method of steel strand is that the steel strand is taken apart; the central line of steel strand and each edge wire are coated wit a layer of thermoplastic polymers by turbocharged plastic extrusion process so that the outset edge wire of steel strand is coated by a layer of thermoplastic polymer, which forms inner filling layer and outer coating layer, which are melted together, finally cooling is carried. The steel strand is provided with strong anti-corrosion ability, long service life, improved construction performance by outer anti-sliding structure and good effect for anchorage.

Owner:LIUZHOU OVM MASCH CO LTD

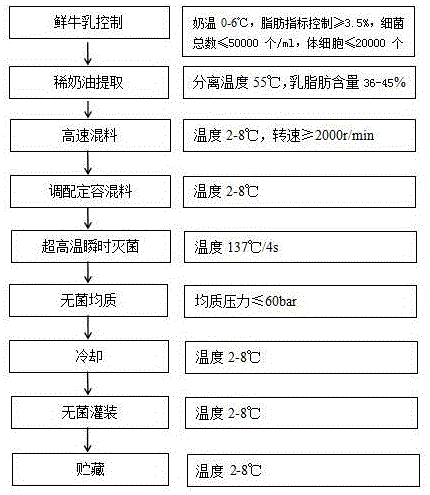

Low-temperature single cream and preparation method thereof

InactiveCN106260007AKeep the tasteFat agglomeration does not occurCream preparationAdditive ingredientMixed materials

The invention relates to low-temperature single cream and a preparation method thereof. The low-temperature single cream comprises fresh milk, single cream extracted from fresh milk and Iota-carrageenan. The preparation method comprises the following steps: controlling the quality of the fresh milk; extracting the single cream; mixing the materials at a high speed, wherein the fresh milk, the single cream extracted from the fresh milk and the Iota-carrageenan are mixed by taking the fresh milk as a colloid melting carrier, and the material mixing sequence is that the Iota-carrageenan and the fresh milk are mixed firstly and then the mixture and the single cream are mixed, and the mixed materials are sheared at a high speed and are stirred uniformly, so that colloid is dispersed quickly; performing mixing and volume metering on the mixed materials; performing ultrahigh-temperature instantaneous sterilization; performing sterile homogenization; cooling; performing sterile filling; performing storage. According to the invention, single Iota-carrageenan colloid is adopted and separated single cream is further processed to produce a low-temperature type single cream product subjected to ultrahigh-temperature treatment; the ingredient list of the product is extremely clear, the product has healthy and nutritional characteristics, the natural taste and mouthfeel of the product are maintained, the melting point and the crystallinity of milk fat are utilized, and the preparation method is applied to the technical field of food nutrition.

Owner:辽宁辉山生物科技研究有限公司

Filter material for self-antibacterial and self-disinfecting mask and manufacturing method thereof

PendingCN111841149ADoes not change filterabilityNo change in physical propertiesBiochemical fibre treatmentMembrane filtersFiberMicroorganism

The invention belongs to the technical field of daily protection products, in particular to a filter cloth material for a mask with self-antibacterial and self-disinfecting functions and a manufacturing method thereof. The specific implementation process comprises the steps of discharging, degreasing, washing, acid pickling, sensitizing, washing, activating, pre-silvering, silvering, washing, surface modifying, drying, collecting and the like, and proper nano-silver particles can be deposited on the fiber surface after a conventional mask filter material is treated by the method, so that the killing effect on microorganisms such as bacteria or viruses is realized. According to the technology, the defect that an existing mask filter material can only filter particulate matter or droplets but cannot exterminate bacteria or viruses can be overcome; meanwhile, the nano-silver particles and the filter material fibers are firmly combined and are only distributed on the surfaces of the filtermaterial fibers, and compared with other silver-containing filter materials, the nano-silver filter material has the advantages of continuous industrial production, high effective utilization rate ofsilver, strong binding force of the silver particles and the filter material fibers, low manufacturing cost and the like.

Owner:常州微度化工新材料科技有限公司

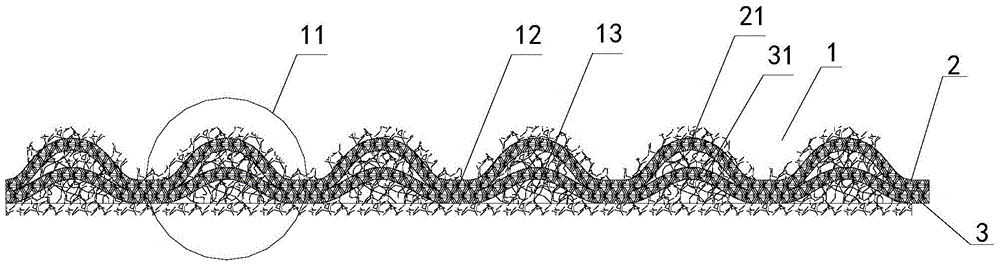

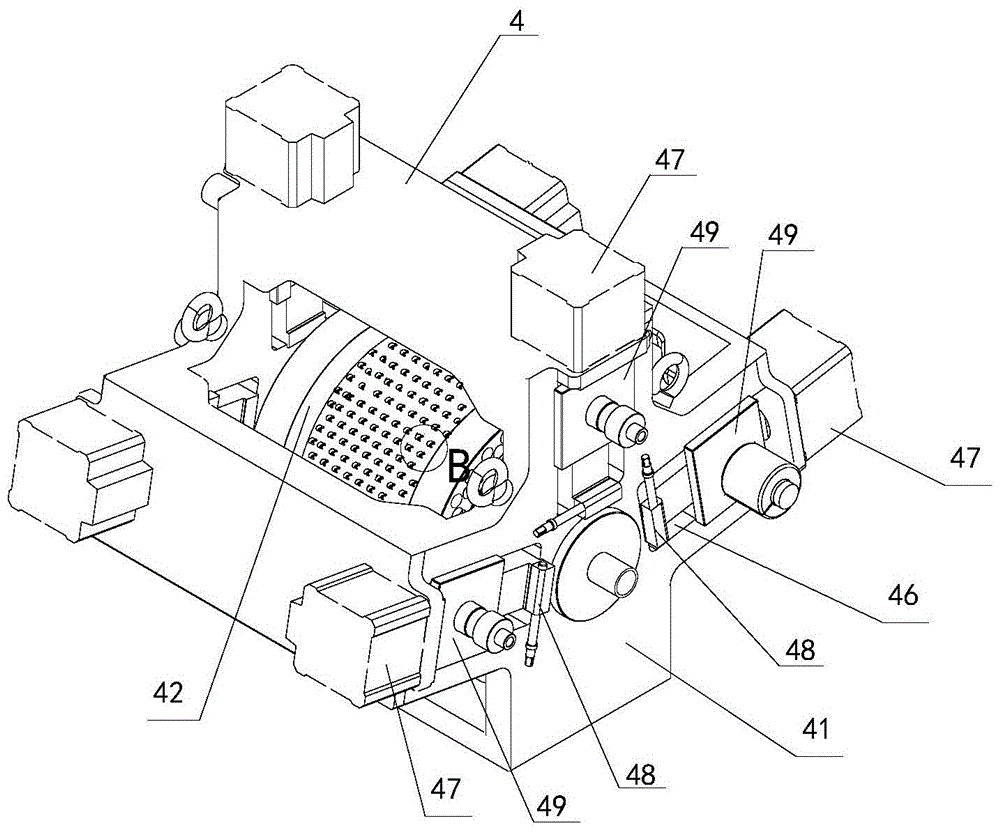

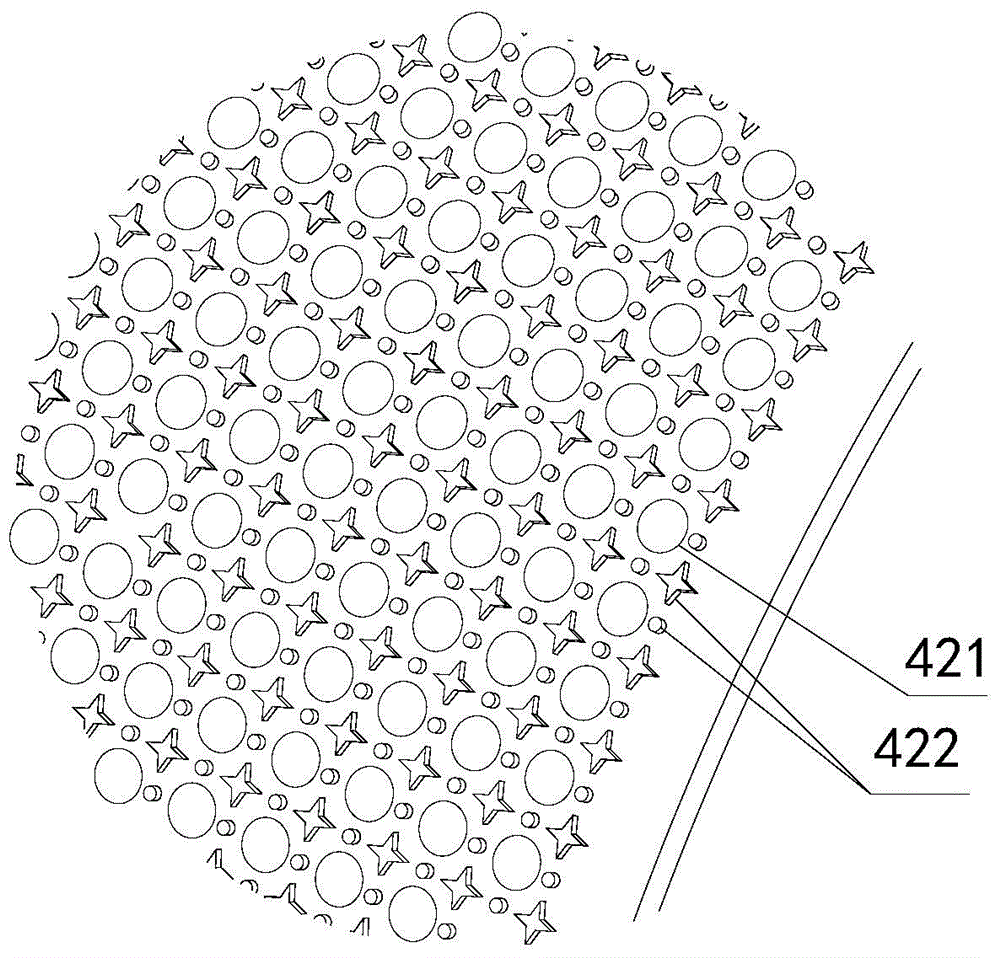

Composite nonwoven fabric and manufacturing device

ActiveCN105729898AClear textureProtruding three-dimensional plumpLamination ancillary operationsLaminationTouch SensesNonwoven fabric

The invention belongs to the field of mechanical manufacturing, and relates to composite nonwoven fabric.The composite nonwoven fabric comprises first fabric and second fabric, multiple first protrusions are arranged on the first fabric, multiple second protrusions are arranged on the second fabric, the first fabric is compounded to the second fabric, the second protrusions are located in cavities of the first protrusions to form fiber bags, rough selvedge fibers on the opposite faces of the first protrusions and the second protrusions make contact in a staggered mode, and protrusive patterns are arranged in gaps between the fiber bags.The composite nonwoven fabric has the advantages that the manufactured elastic fabric has clear texture, the protrusions are stereoscopic and full, the appearance effect is remarkably promoted, and as double layers of coincident protrusions are arranged, the composite nonwoven fabric has pliable and tough touch sense and can resist deformation such as toppling, depression and flattening.Due to the full and stable protrusions, the composite nonwoven fabric has good ventilating, dry and comfortable performance; by means of the fiber bags formed by the double layers of the coincident protrusions, the absorbing and drainage effects and absorption performance are promoted remarkably in comparison with common fabric with protrusions.

Owner:ANQING HENG CHANG MACHINERY

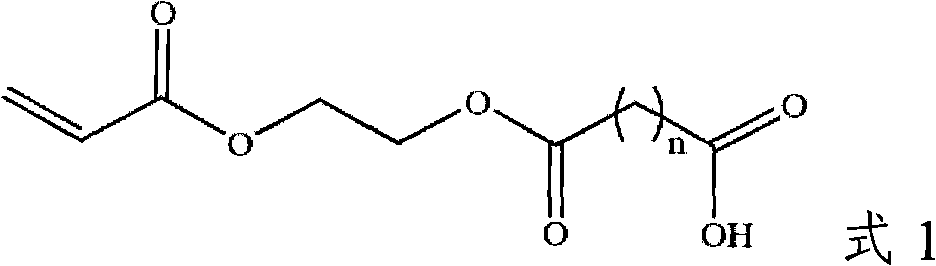

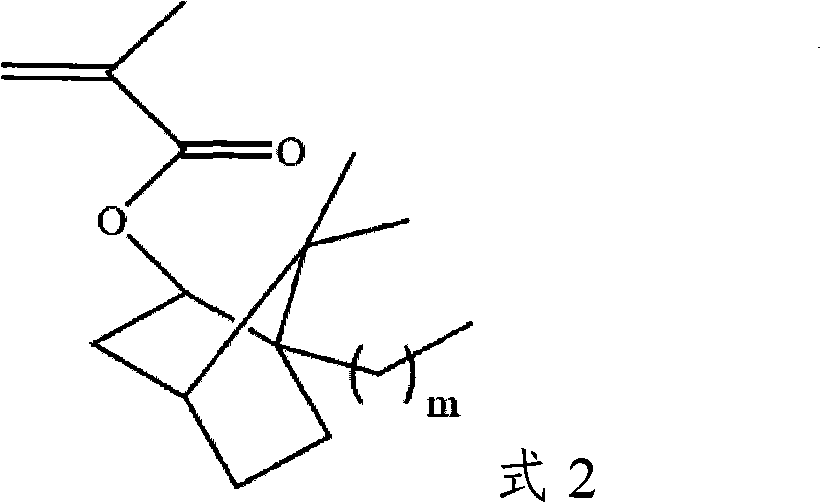

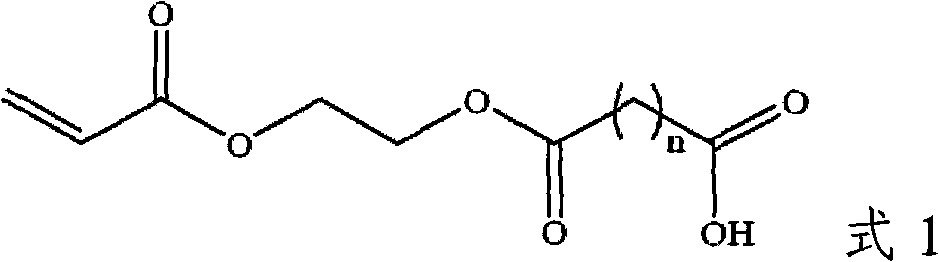

Black-colored photosensitive resin composition, black matrix prepared by using thereof and color filter comprising the black matrix

ActiveCN102213917ANo desensitizationUniform occlusionOptical filtersPhotosensitive materials for photomechanical apparatusOptical densityLight filter

The invention provide a black photosensitive resin composition, which comprises contains an alkali-developable resin (B) obtained by polymerizing a monomer including compounds marked with chemical formula 1. A black matrix (Black Matrix) manufactured by the black photosensitive resin and a color filter (Color Filter) including the black matrix are also provided. The black photosensitive resin composition is good in adhesion performance to substrates and storage stability. The bake processing thermal fluidity is reduced while the sensitivity thereof is maintained, so that the optical density difference between different positions during the formation of fine patterns is improved.

Owner:DONGWOO FINE CHEM CO LTD

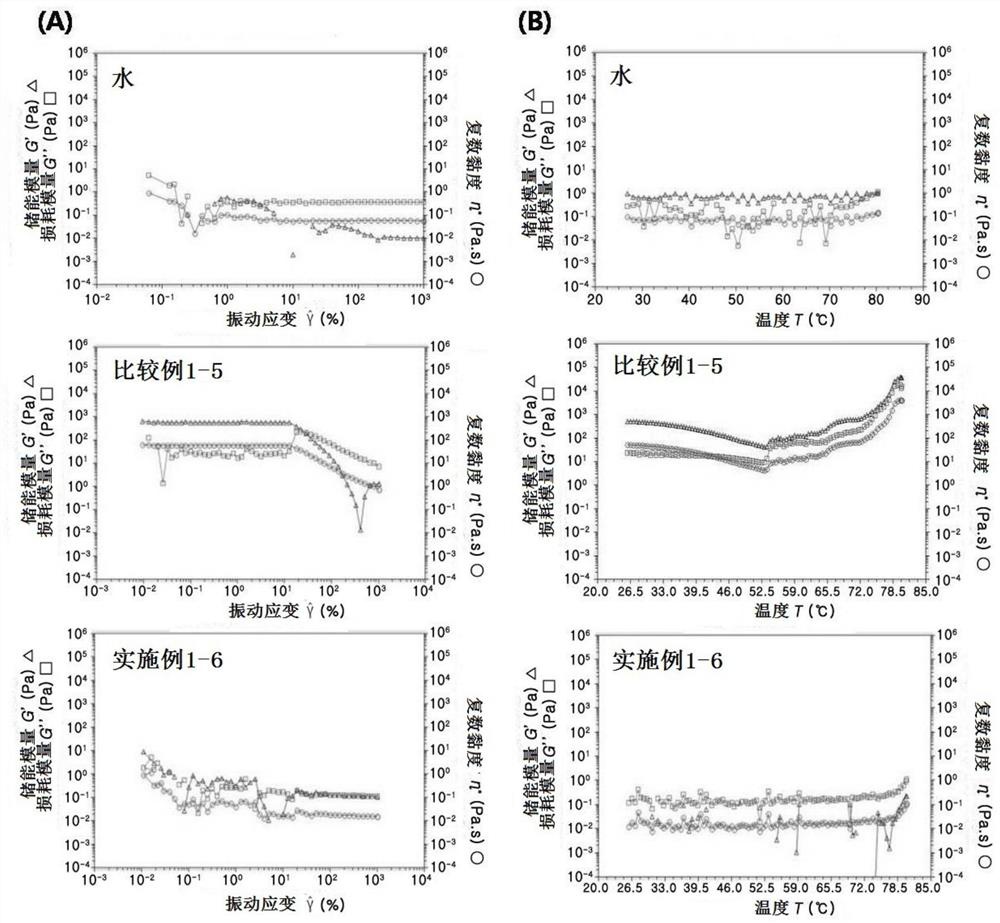

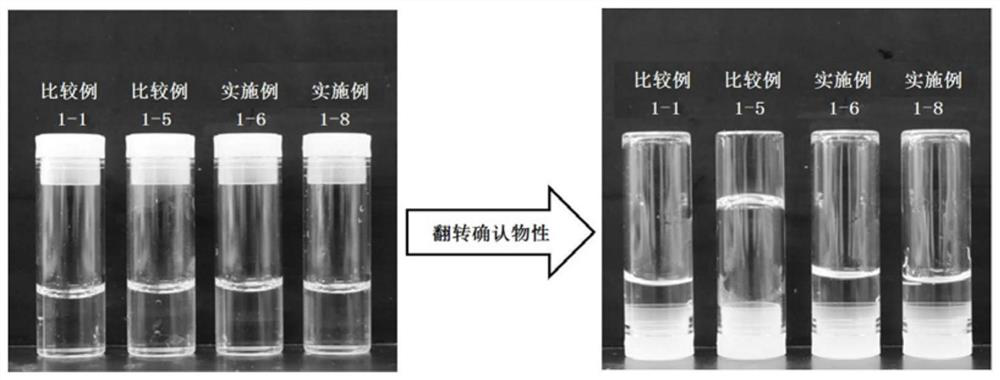

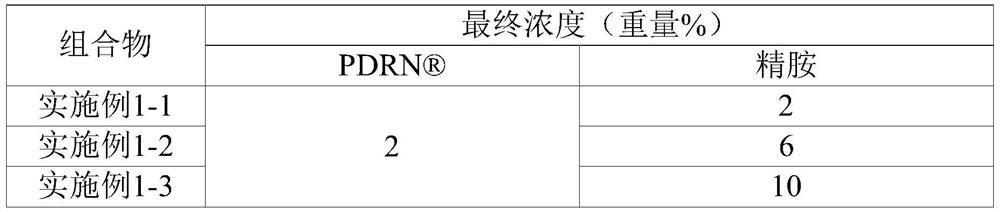

Liquid composition containing high concentration of DNA fragment mixture and having fluidity and preparation method therefor

ActiveCN111836617ANo change in physical propertiesImprove stabilityOrganic active ingredientsGenetic material ingredientsHigh concentrationA-DNA

The present invention relates to a liquid composition containing a high concentration of a DNA fragment mixture and a preparation method therefor. A liquid composition containing a high concentrationof a DNA fragment mixture and having fluidity was prepared. The liquid composition that contains a high concentration of a DNA fragment mixture and has fluidity was identified to maintain a pharmaceutical activity, have high stability even during long-term storage, and be effectively injectable to the human body, whereby a high concentration of a DNA fragment mixture having fluidity is expected tobe applicable to the development of various formulations such as injections, liquid agents, creams, and the like.

Owner:RES MEDICAL

Reutilization process of industrial solid waste

The invention discloses a reutilization process of industrial solid waste. The reutilization process comprises the steps that (1) the recycled industrial solid waste is crushed into fragments; (2) after being crushed, the industrial solid waste is divided into a material capable of being molten and a material which cannot be molten according to certain plastic melting temperature, and the materialcapable of being molten and the material which cannot be molten are mixed according to the proportion of 1:1 to obtain a pre-mixed material; (3) a mold is taken, a layer of Dacron non-woven fabric isput in the mold, heat conduction oil is contained in an inner cavity of the mold, low-pressure circulation electromagnetic heating is carried out, the mold is firstly heated to the plastic melting temperature in the step (2), the pre-mixed material is put into the mold to be pressed, and crude finished products are obtained; (4) trimming deflashing, cooling and temperature decrease are carried out, and cooling is carried out to room temperature; (5) the product quality is detected, and unqualified products are crushed again and re-machined; and (6) qualified products are packaged. According to the reutilization process, no poisonous gas is generated during machining, various special-shaped products are obtained through machining and can be used as environment-friendly novel material products to replace wooden products and plastic products, ageing resistance is high, toughness is good, waterproofness is achieved, and cyclic utilization can be achieved.

Owner:史为芬

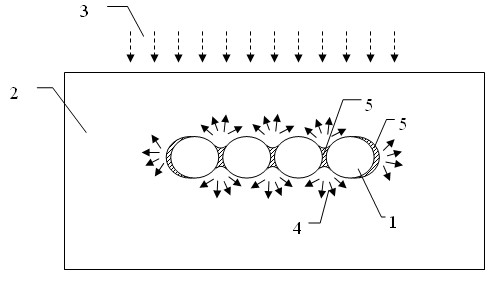

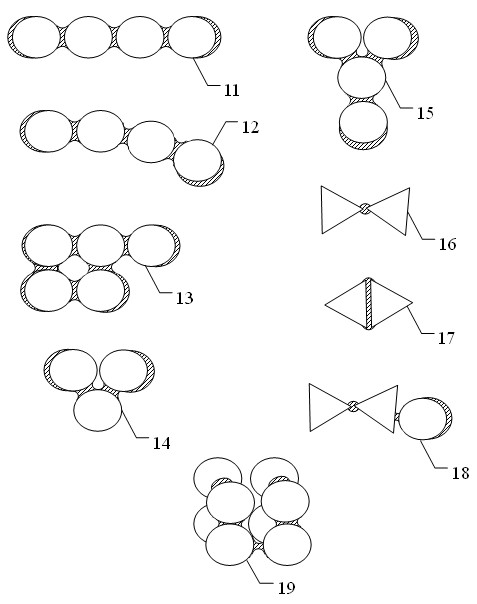

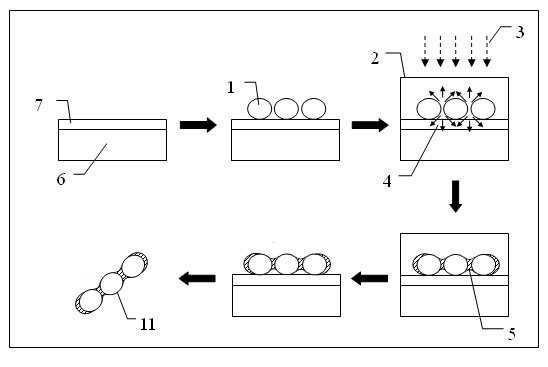

Nano-linking method based on photo-curing with nonlinear frequency shift effect

ActiveCN102556960APrecise position controlPrecisely control the areaNanostructure manufacturePhoto irradiationNanoparticle

A nano-linking method based on photo-curing with nonlinear frequency shift effect is disclosed, which specifically comprises the following steps of: step 1, placing nano-particles close to each other and with surface plasma resonance characteristic in an ultraviolet photosensitive polymer; step 2, irradiating the ultraviolet photosensitive polymer by a low-frequency visible light, and releasing ahigh-frequency light because the incident low-frequency visible light generates great light scattering reinforcement among the nano-particles close to each other and with surface plasma resonance characteristic, and generates remarkable nonlinear frequency shift effect; and step 3, absorbing a multi-frequency light and curing by the ultraviolet photosensitive polymer in an area among the nano-particles with surface plasma resonance characteristic to form a photo-cured polymer, and permanently connecting a plurality of nano-particles with surface plasma resonance characteristic together to obtain nano-microstructures with different shapes. The nano-linking method disclosed by the invention has an ultrahigh resolution which breaks through diffraction limit, and can realize selective linkagefor nano-materials according to design proposal.

Owner:SOUTHEAST UNIV

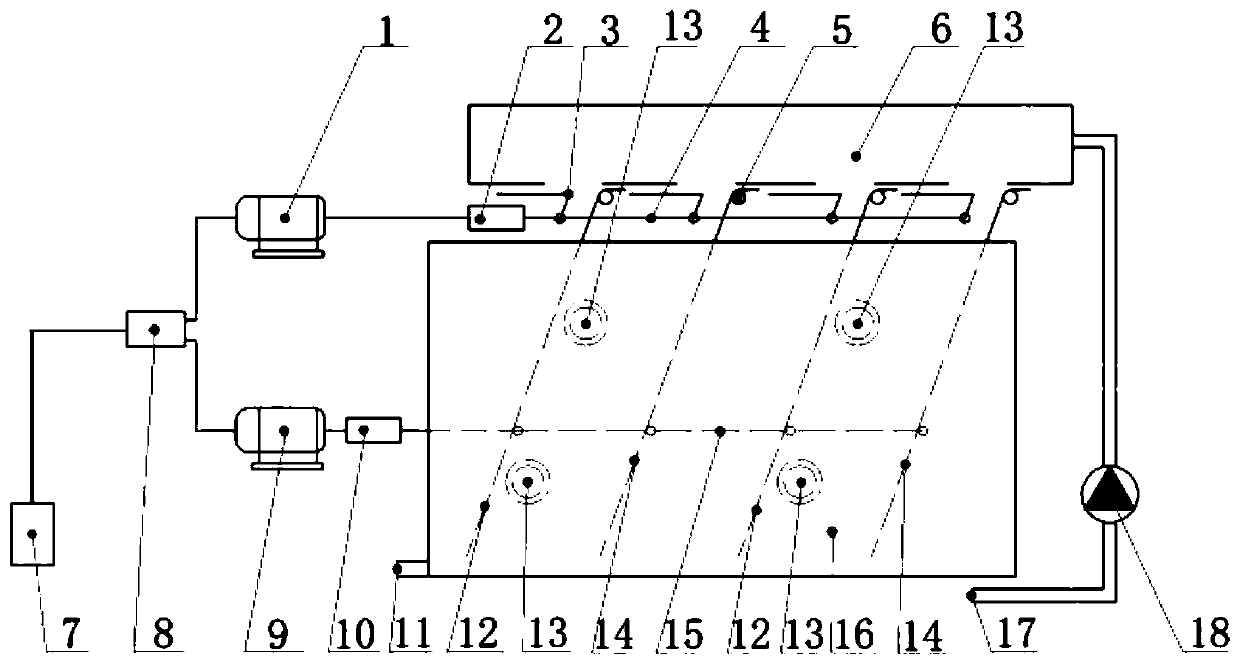

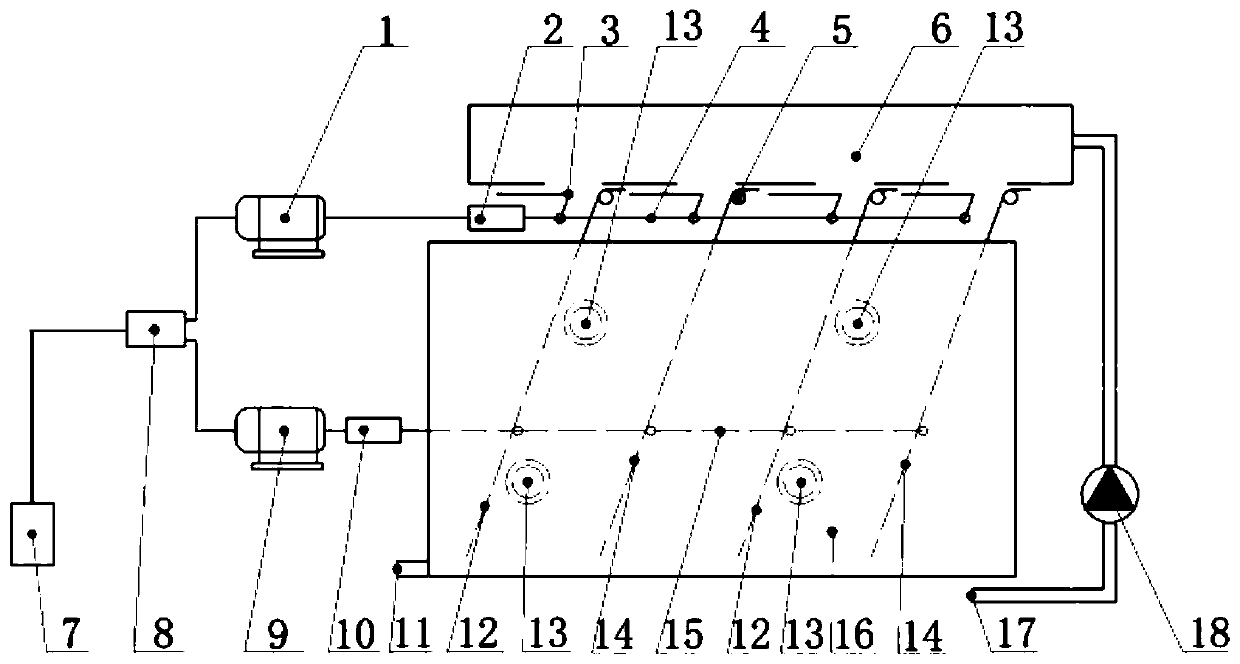

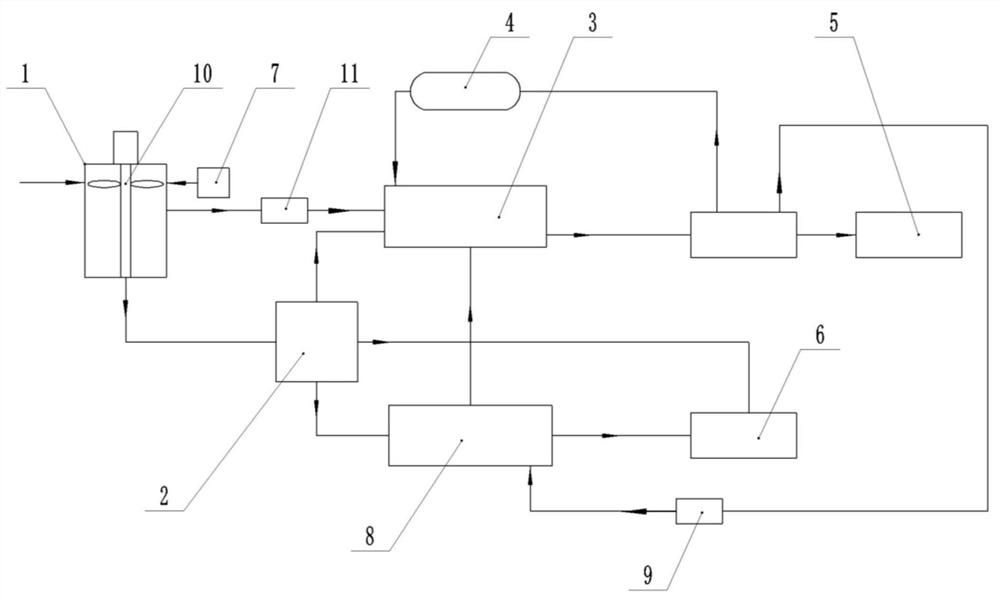

Emergency method and device for treating port ballast water through ultraviolet rays, photocatalysis and strong oxidation

ActiveCN109970140AEnergy savingImprove utilization efficiencyWater/sewage treatment by irradiationWater treatment compoundsPhotocatalysisWater quality

The invention provides an emergency device for treating port ballast water through ultraviolet rays, photocatalysis and strong oxidation. The device comprises a reaction box, slant quartz plates and common fixing plates are sequentially arranged in a box body, and a catalytic material is sprayed on the slant plates. By changing slant angles and the water film thickness of the slant plates, it canbe guaranteed that water films meet the discharging requirement of the ballast water in the process that the slant plates fall up and down through a synergistic effect between ultraviolet radiation and photocatalysis according to the actual volume and the water quality condition of the ballast water. Ultraviolet lamps are arranged on the back faces of the quartz plates, can simultaneously illuminate water flow on the quartz plates and non-transparent plates, and are efficiently used. The ultraviolet lamps are not in contact with the ballast water, the physical property of the water cannot be changed, dirt cannot be attached to the ultraviolet lamps, and the penetration rate of ultraviolet rays is guaranteed. According to the emergency device, the ultraviolet lamps can be maximally used, energy consumption is small, and aims of being environmentally friendly and capable of saving energy are achieved; the treating speed is high, and the emergency treating requirement is met; modularization can be achieved, and the emergency device meets the using requirements of various ballast capacities.

Owner:SHANGHAI MARITIME UNIVERSITY

Method for preparing super-hydrophobic surfaces

ActiveCN105648770ALong-lasting superhydrophobic effectStable super hydrophobic performanceUltrasonic/sonic fibre treatmentLiquid repellent fibresWeather resistanceMetallurgy

The invention discloses a method for preparing super-hydrophobic surfaces. The method includes steps of 1), pre-treating stock solution, to be more specific, injecting the stock solution into a pipeline and preheating the stock solution under the condition of the temperatures of 80-150 DEG C to vaporize the stock solution; 2), carrying out plasma treatment on the surfaces of base materials in the atmosphere of inert gas; 3), carrying out grafting treatment, to be more specific, uniformly spraying the stock solution on the surfaces of the base materials in a mist spray manner, and simultaneously carrying out plasma treatment on the surfaces of the base materials to form super-hydrophobic layers with nano-structures on the surfaces of the base materials. The method for preparing the super-hydrophobic surfaces has the advantages that the method is simple and is high in operability, and the super-hydrophobic surfaces prepared by the aid of the method are good in weather resistance, high in mechanical strength and long in service life.

Owner:GUANGZHOU BIOFIL AIR PURIFICATION MATERIAL CO LTD

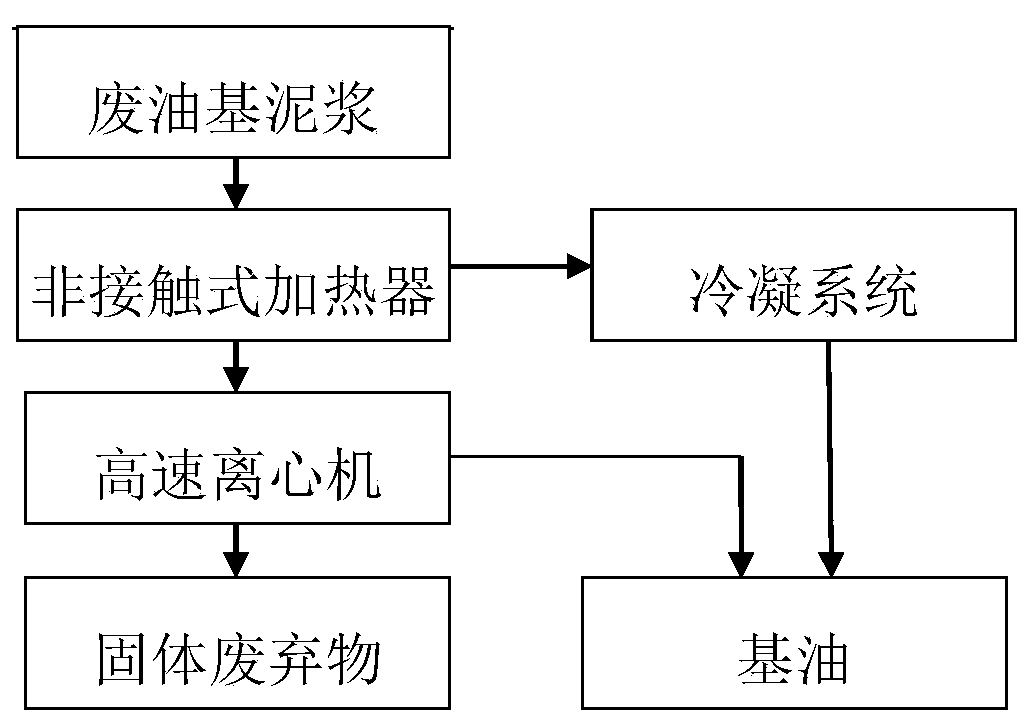

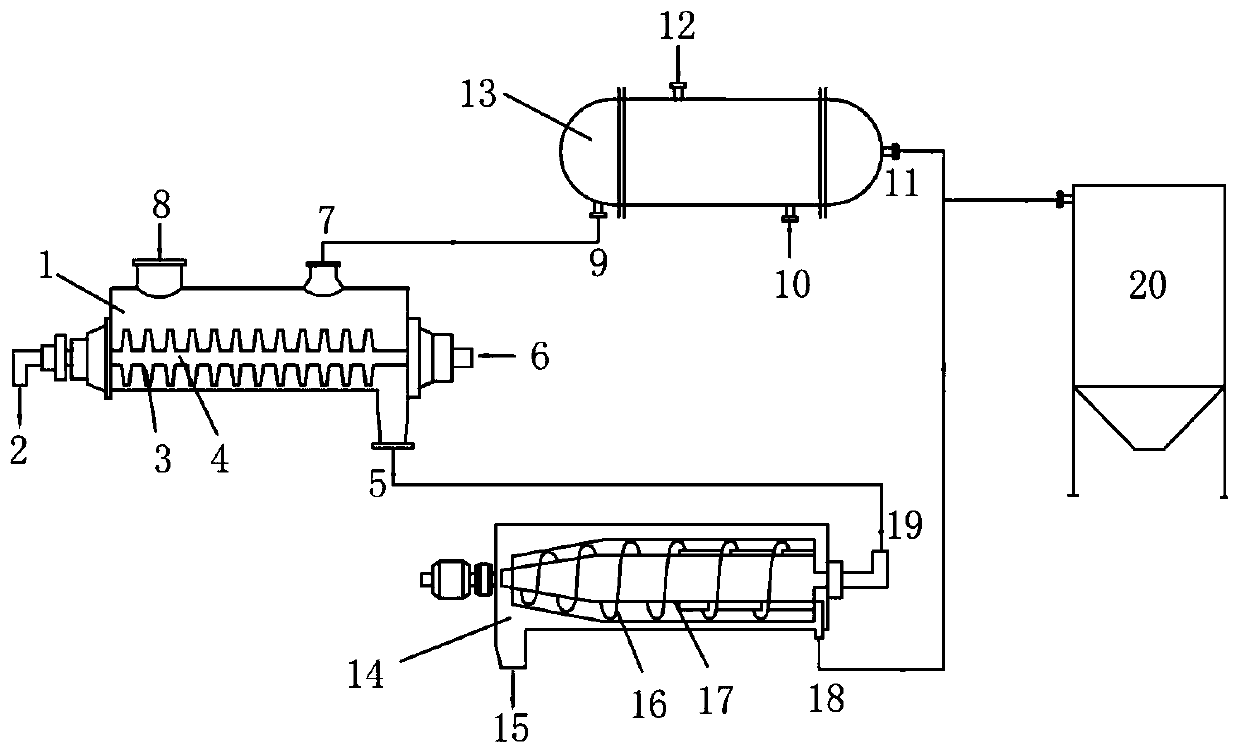

Process and device for recovering base oil in drilling-oil-based mud debris

The invention provides a process and device for recovering base oil in drilling-oil-based mud debris, and discloses a process and device for recovering the base oil in waste-oil-based drilling mud. The device is composed of a heater, a high-speed centrifuge, a condensing device and a base oil storing tank. The process comprises the steps: the waste-oil-based mud is fed into the heater and heated to 40-350 DEG C through heat transfer, the heated waste-oil-based mud enters the high-speed centrifuge, tiny solid particles of the waste-oil-based mud are centrifugally separated, oil-containing steam generated in the heating and centrifuging processes is cooled into cooling liquid through the condensing device, and the cooling liquid is recovered and guided into the centrifuged base oil completely. The solid particles and the base oil in the waste-oil-based mud are separated through low-temperature heating and centrifugal separation, the physical property of the base oil is not changed, the base oil can be used for preparing the oil-based drilling mud secondarily, the waste-oil-based mud is heated through waste heat from the kiln tail of a cement kiln, the utilization rate of the heat of the cement kiln is further increased, the operation cost of the separation process is lowered, the waste-oil-based mud is heated through indirect contact, and the security coefficient of equipment operation is effectively increased.

Owner:成都华寰环保科技有限公司

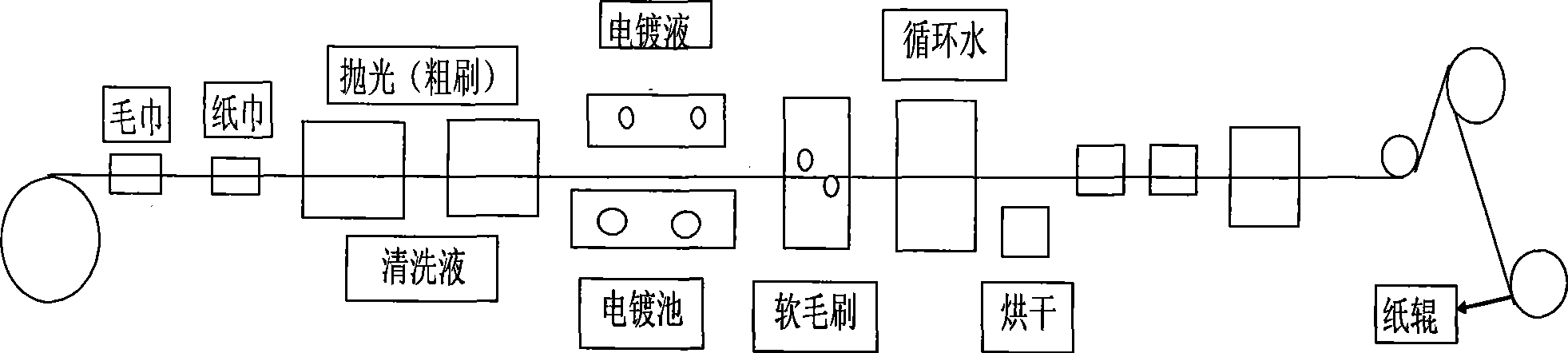

Nickel-copper composite metal textile and preparation method thereof

InactiveCN1268803CImprove conductivityLow conductivityFibre treatmentLiquid/solution decomposition chemical coatingCopperLow frequency

The fabric with compounded metal nickel and copper is prepared with dacron or nylon fabric, and through surface roughening, sensitizing, activating, chemically plating one layer of metal nickel, electroplating one intermediate copper layer, and finally electroplating one protecting nickel layer. The formed Ni-Cu-Ni layers have nickel amount o 5-20 g / sq m and Cu / Ni weight ratio of 1.5-3; and the metal fabric has excellent electromagnetic shielding effect on low frequency electromagnetic wave, and the shielding effect is 60-90 dB in the frequency range of 10 KHz-3 GHz, and 50-70 dB in the frequency below 10 KHz.

Owner:HUNAN CORUN NEW ENERGY CO LTD

Antibacterial and antiviral express packaging bag special material and preparation method thereof

The invention belongs to the field of antibacterial and antiviral polyolefin packaging bag special materials, and particularly relates to an antibacterial and antiviral express packaging bag special material and a preparation method thereof. The preparation method comprises the following steps: mixing polyolefin powder, an antioxidant, an auxiliary antioxidant, a halogen absorbent and an antibacterial agent in a high-speed stirrer for 2-3 minutes to obtain a mixture, and extruding and granulating the mixture by a double-screw extruder to obtain the antibacterial and antiviral express packaging bag special material. Polyolefin materials such as polypropylene and polyethylene have permanent antibacterial, mildew-proof and antiviral properties, and an express packaging bag produced by using the special material also has permanent antibacterial, mildew-proof and antiviral properties, so that the diffusion of pathogens is effectively prevented.

Owner:NORTH HUAJIN CHEM IND CO LTD

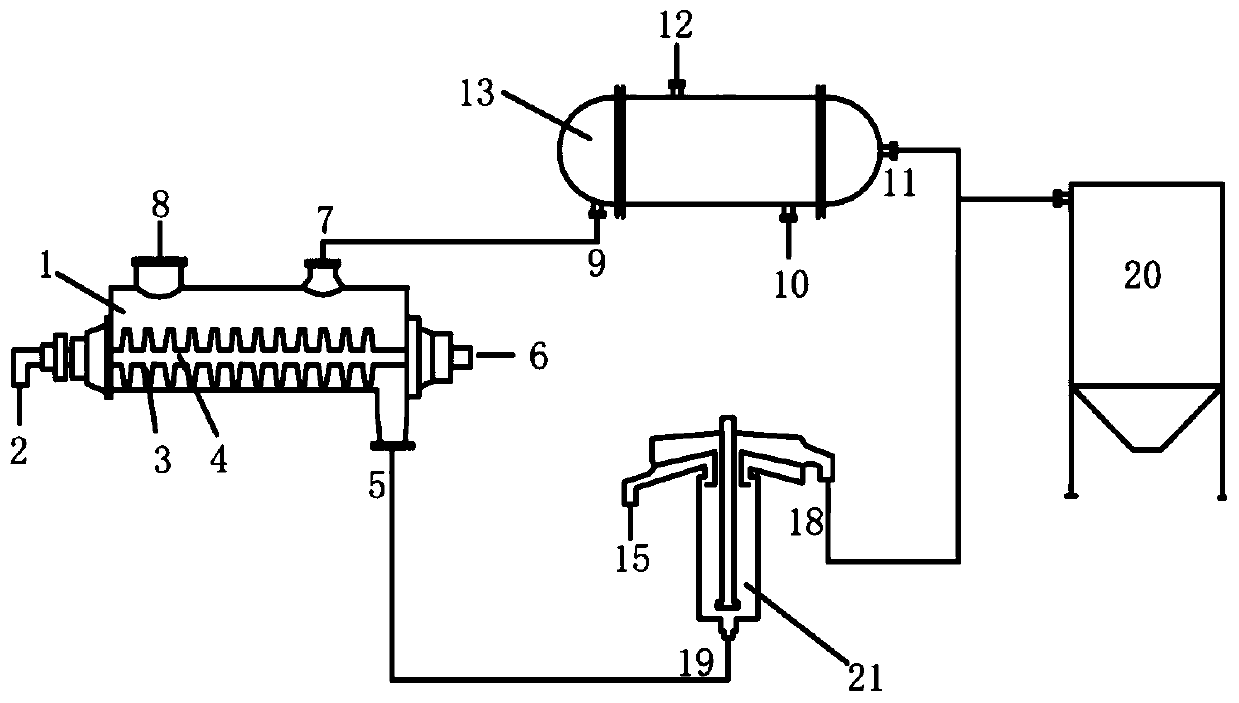

Device for recovering oil in drilling oil-based mud rock debris

ActiveCN113404452ARinse cleanGood degreasing effectCement productionFlushingParticulatesWell drilling

The invention belongs to the technical field of hazardous waste treatment, and particularly relates to a device for recovering oil in drilling oil-based mud rock debris. The device comprises a heating kettle, a swirler, a condensing device, an oil liquid storage tank and a solid phase storage tank, wherein a feed port, a discharge port, an oil-containing steam outlet and a gas medium inlet are formed in the heating kettle; the discharge port of the heating kettle communicates with a feed port of the swirler; and the condensing device comprises a cooler, a cooling water unit and a high-speed centrifugal machine. According to the scheme, the swirler and the centrifugal machine are arranged, so that oil-containing solid particles are deoiled twice, additionally, non-condensable gas and gas media which flow out of the condensing device are heated and then are introduced into the high-speed centrifugal machine, so that oil on the oil-containing solid particles is flushed cleanly, the deoiling effect is good, the oil content of solid particles in the finally produced oil-based mud rock debris is low, and additionally, the solid particles with low oil content are fed into a cement kiln to be incinerated and decomposed at high temperature, so that the environment is not polluted.

Owner:重庆森士环保科技有限公司

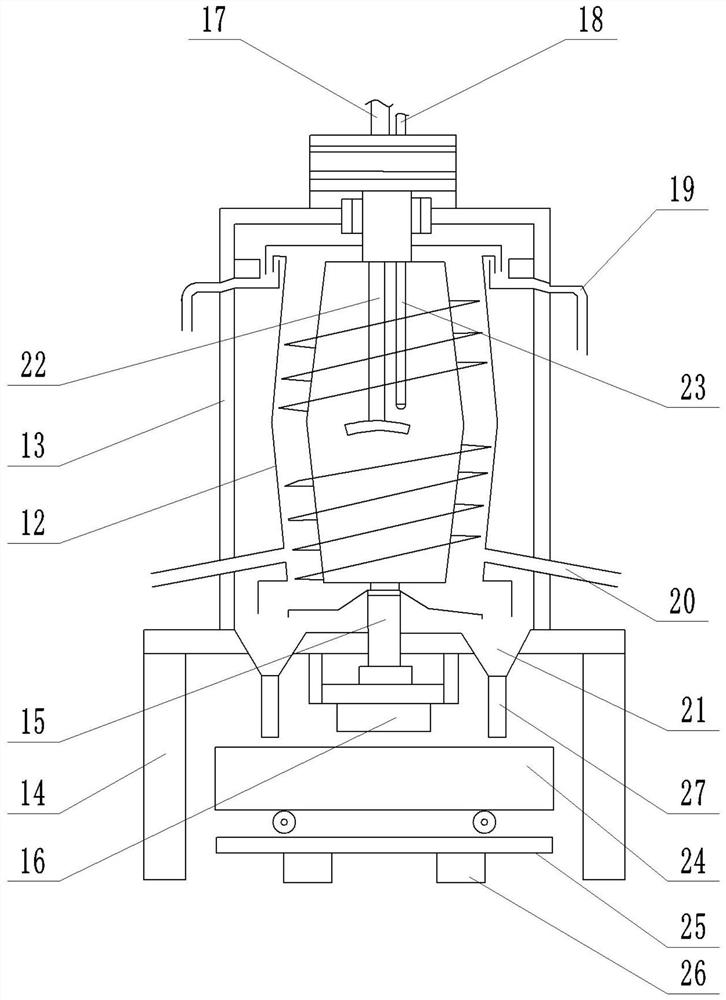

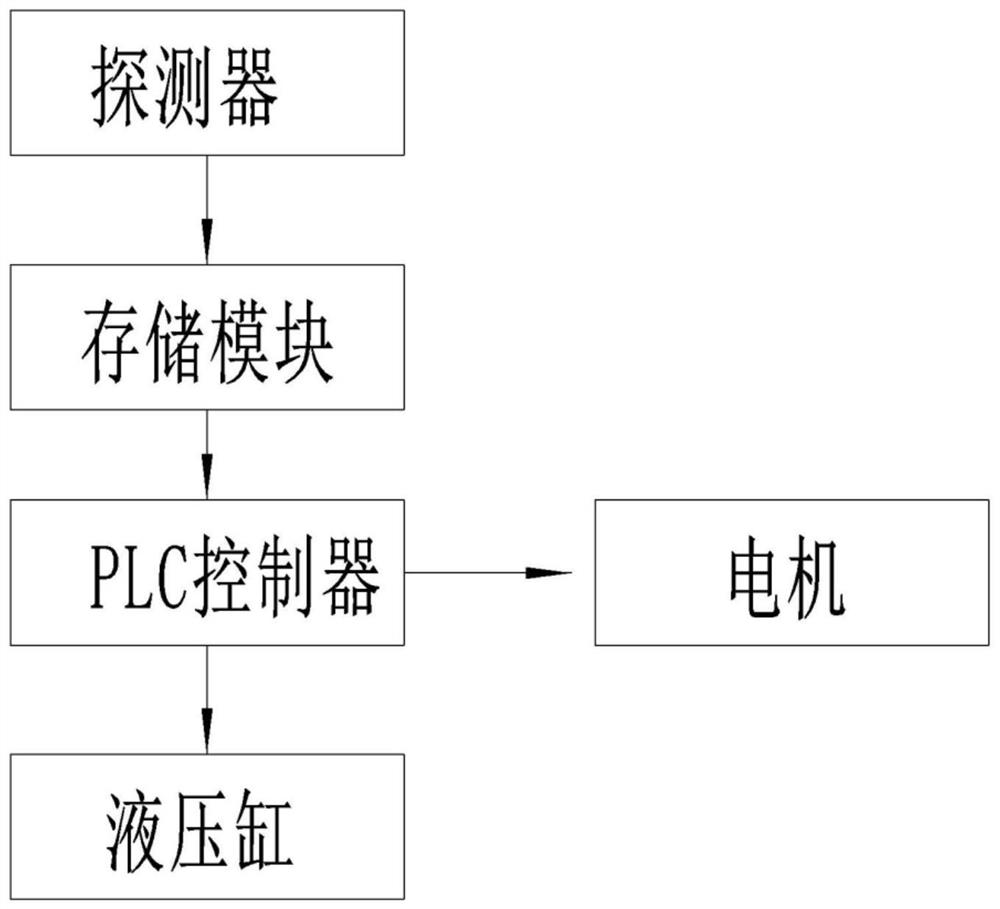

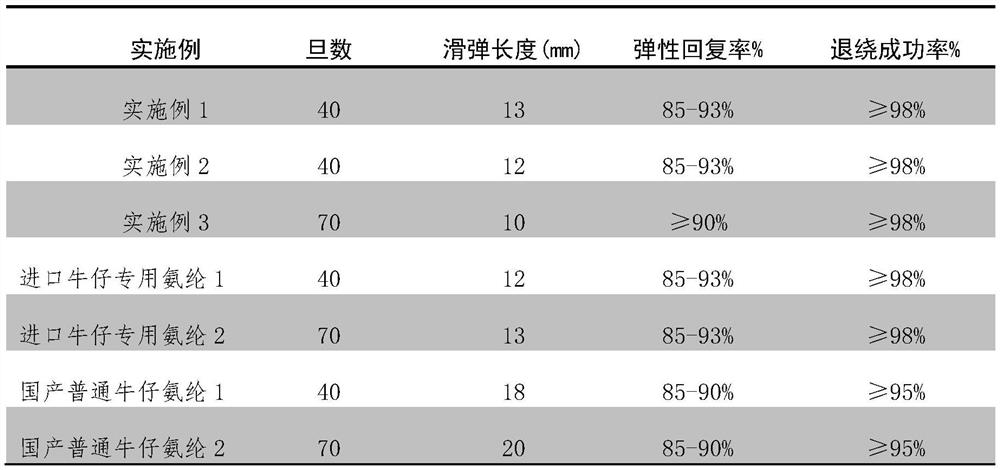

Preparation method of anti-skid elastic spandex core-spun yarn suitable for jean fabric

ActiveCN112210860AIncrease coefficient of frictionIncrease surface frictionArtificial thread manufacturing machinesFibre typesYarnFiber

The invention discloses a preparation method of anti-skid elastic spandex core-spun yarn suitable for jean fabric. The method comprises the following steps of (1) preparing a prepolymer solution, (2)adding a certain amount of a mixed amine solution into the prepolymer solution, and carrying out a chain extension reaction and a chain termination reaction to prepare a polyurethane urea solution; (3) adding specific auxiliary agent slurry containing hydrotalcite and trace stearate into the polymer solution, stirring, and curing to prepare a spinning solution; (4) performing dry spinning, and adopting a specific spinning oil agent consisting of high-carbon silicone oil and stearate in an oiling process to prepare spandex fiber; and (5) twisting the spun fiber and short fiber to obtain the anti-skid elastic spandex core-spun yarn. The invention relates to the preparation method of the anti-skid elastic spandex core-spun yarn suitable for the jean fabric, and the method can effectively improve the friction performance of the spandex fiber and outer covering yarn, show a lower slipping and elastic degree, and meet the requirements of the field of the jean fabric for the anti-skid elasticspandex fiber.

Owner:ZHENGZHOU ZHONGYUAN SPANDEX ENG TECH

Shoe sole made of polyester based polyurethane material and preparation process of shoe sole

The invention discloses a shoe sole made of a polyester based polyurethane material. The shoe sole comprises a component A and a component B, wherein the component A is prepared from the following components in parts by weight: 90-110 parts of polyester diol, 14-18 parts of butanediol, 0.2-0.6 part of water, 0.2-0.6 part of an emulsifier, 0.7-1.1 parts of a catalyst and 0.2-0.6 part of melanin; and the component B is prepared from the following components in parts by weight: 30-50 parts of polyester diol and 50-70 parts of dipropyl cyanate ester. According to the shoe sole, all components in the component A are physically mixed in a mixing container and are uniformly stirred, and the physical performances of the materials are not changed, so that the mechanical strength of the product is improved; contrary to the component A, the component B is a half-prefabricated polymer, each raw material performs effective chemical reactions in a vacuum or nitrogen filled reactor, and the reacted product has good heat resistance and solvent resistance.

Owner:NANJING DONGYA RUBBER & PLASTICS

Substrate corrosive liquid for preparing Si-based mercury cadmium telluride chip dislocation observation sample

InactiveCN104988505AGood choiceChange physical propertiesPreparing sample for investigationTetramethylammonium hydroxideWater baths

The invention discloses a substrate corrosive liquid for preparing a Si-based mercury cadmium telluride chip dislocation observation sample. The substrate corrosive liquid is characterized in that the substrate corrosive liquid is prepared by organic base solution tetramethylammonium hydroxide, deionized water and oxidizing agent ammonium persulfate; a preparation method of the substrate corrosive liquid comprises the steps that: first, tetramethylammonium hydroxide and the deionized water are mixed to form a mixed solution with the concentration of 5-20%; then, 1-3g / l ammonium persulfate is added according to the volume of the mixed solution; and finally the mixed solution is placed in a water bath with the temperature over 80 degrees to be heated, and used at the temperature of 50-65 degrees. The substrate corrosive liquid has the characteristics that using conditions of the corrosive liquid are compatible with a mercury cadmium telluride technology, so that the physical properties of a mercury cadmium telluride chip are not changed, and the precision of analysis results is ensured. The corrosive liquid is good in selectively, can remove a Si substrate completely, but does not corrode buffer layer cadmium telluride and epitaxial film mercury cadmium telluride, so that a complete clear epitaxial material observation interface is obtained, and the good observation sample is provided for dislocation observation from a buffer layer cadmium telluride interface.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Sewing-free pressing method capable of replacing high frequency operation

InactiveCN105231590AReduce usageMeet appearance requirementsShoemaking devicesLaminationEngineeringHigh-frequency ventilation

The invention discloses a sewing-free pressing method capable of replacing high frequency operation, and relates to the technical field of articles for daily life. The sewing-free pressing method comprises the following steps of sequentially overlapping materials according to design requirements; placing the overlapped materials in a specific position of a machine; electrifying and machining for a period of time; and then taking out finished products. After operation, embossing or concave-convex effects of the materials are obvious, and requirements of appearance are met; after operation, the physical property of the materials is not changed, and requirements for strength and functions are met; the method is easier to operate, and the required number of professional technical workers can be reduced; and radiation is not generated in an operation process.

Owner:YUYAN SHOES IND LIANYUNGANG

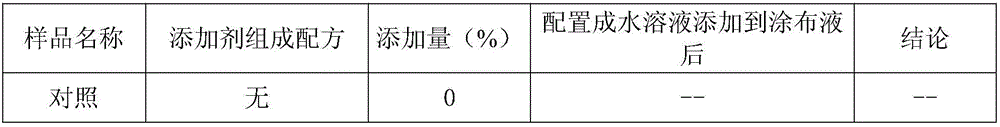

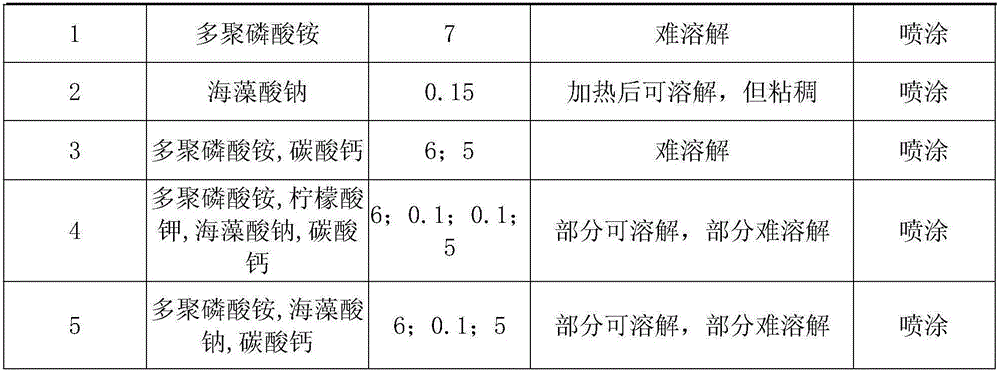

Additive capable of reducing CO in papermaking process reconstituted tobacco and application method of additive

InactiveCN105768178ALow costWill not change the intrinsic quality qualityTobacco preparationCITRATE ESTERPhosphate

The invention relates to an additive capable of reducing CO in papermaking process reconstituted tobacco and an application method of the additive. The additive comprises one or a mixture of citrate, carbonate, bicarbonate, phosphate and hydrophosphate, or one or a mixture of alginate, citrate, carbonate, bicarbonate, phosphate and hydrophosphate. According to the application method, an aqueous solution is prepared from the additive, the additive aqueous solution is added to a coating solution of papermaking process reconstituted tobacco in the ratio of 0.1%-11.2% of the absolute dry weight of the papermaking process reconstituted tobacco, and the CO in the papermaking process reconstituted tobacco is reduced. The additive can reduce release amount of the CO in the papermaking process reconstituted tobacco, is safe and economical and can realize industrial production.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com