Process and device for recovering base oil in drilling-oil-based mud debris

A technology of oil-based mud and recovery device, which is applied in earthwork drilling, wellbore flushing, wellbore/well parts, etc. It can solve the problems that cannot be reused, cannot be used for preparation again, and the processing capacity is small. Effects of mud congestion and fluidity issues, improved reliability and operational efficiency, and reduced treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The drilling oil-based mud cuttings in the present invention are collected from a certain shale gas drilling platform in Sichuan, and the specific components and properties are shown in Table 1.

[0034] Table 1 Composition and properties of waste drilling oil-based mud cuttings

[0035]

Embodiment 2

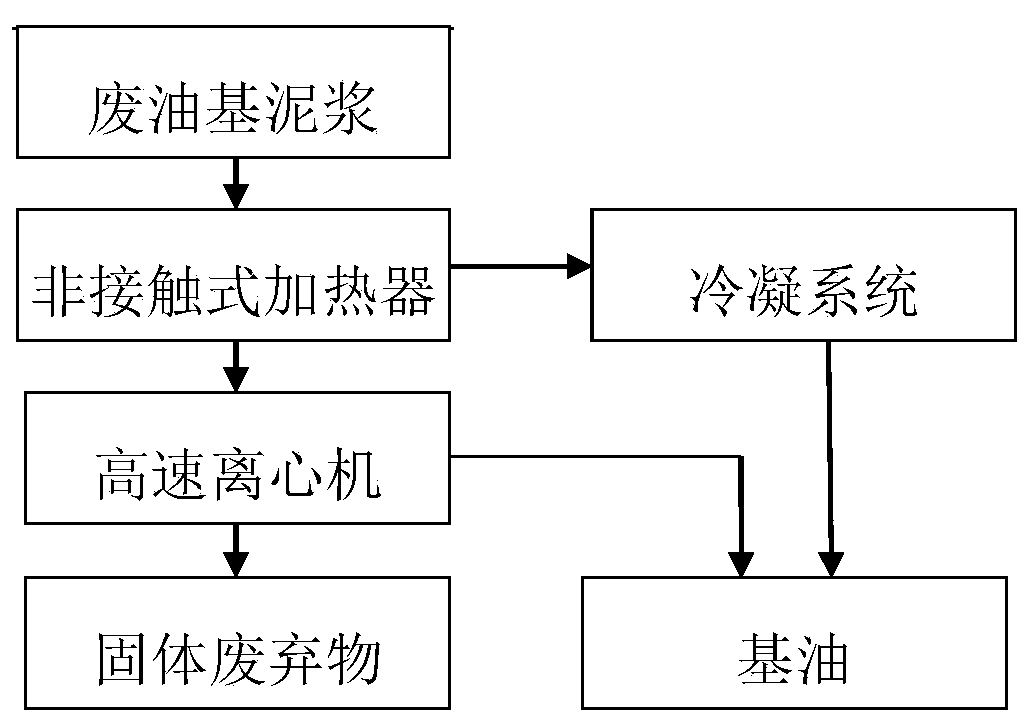

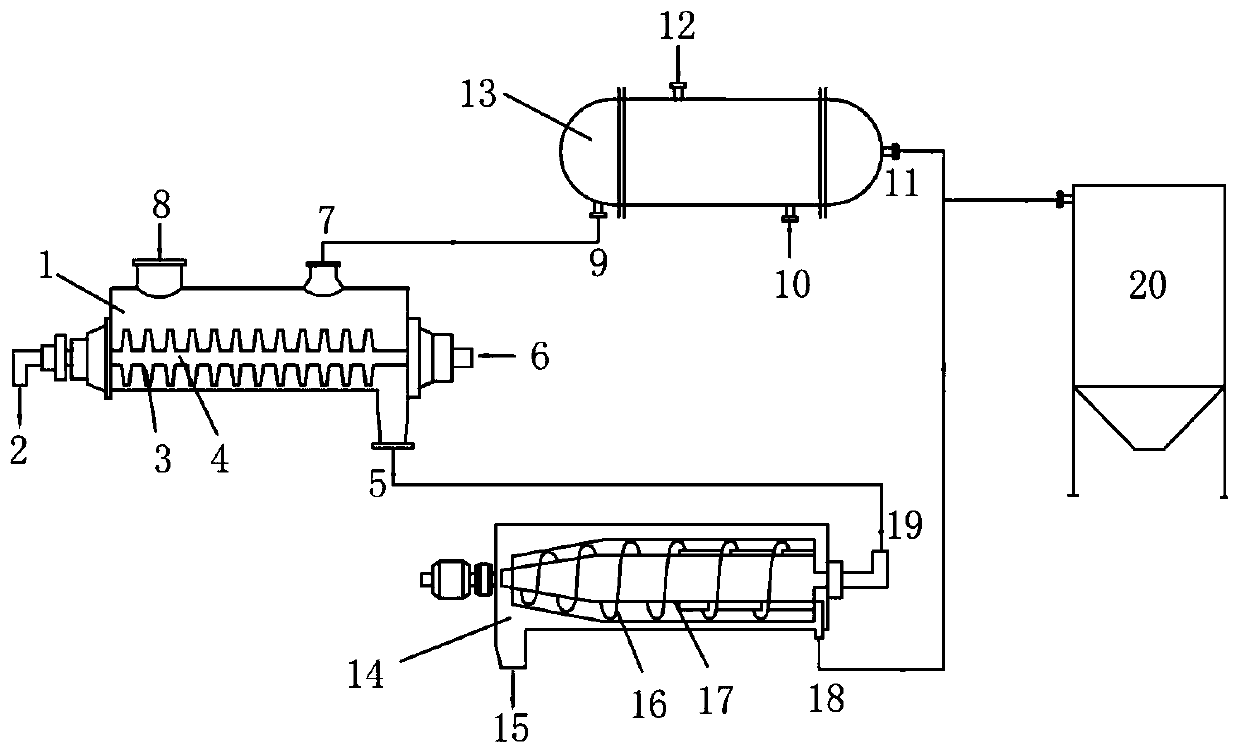

[0037] Drilling oil-based mud cuttings processing equipment consists of a slurry heater, a horizontal screw centrifuge, a high-temperature steam pipeline, a condensing device, a drilling fluid storage tank, an oil and gas collection pipeline, a waste water collection pipeline and an exhaust gas pipeline. The specific implementation steps are:

[0038] Drilling oil-based mud cuttings are sent into the slurry heater from the feed port, filling the space between the shell and the hollow disc, and the drilling oil-based mud cuttings are stirred by the action of the propeller / stirrer on the disc , advance. The hot steam at the end of the cement kiln enters from the entrance of the heat source, flows through the hollow shaft and the hollow disc, and the high-temperature steam enters the heating hollow disc of the slurry heater to indirectly heat the drilling oil-based mud cuttings. The heating and condensation process will produce hot drilling oil-based mud cuttings, oily gas, non-...

Embodiment 3

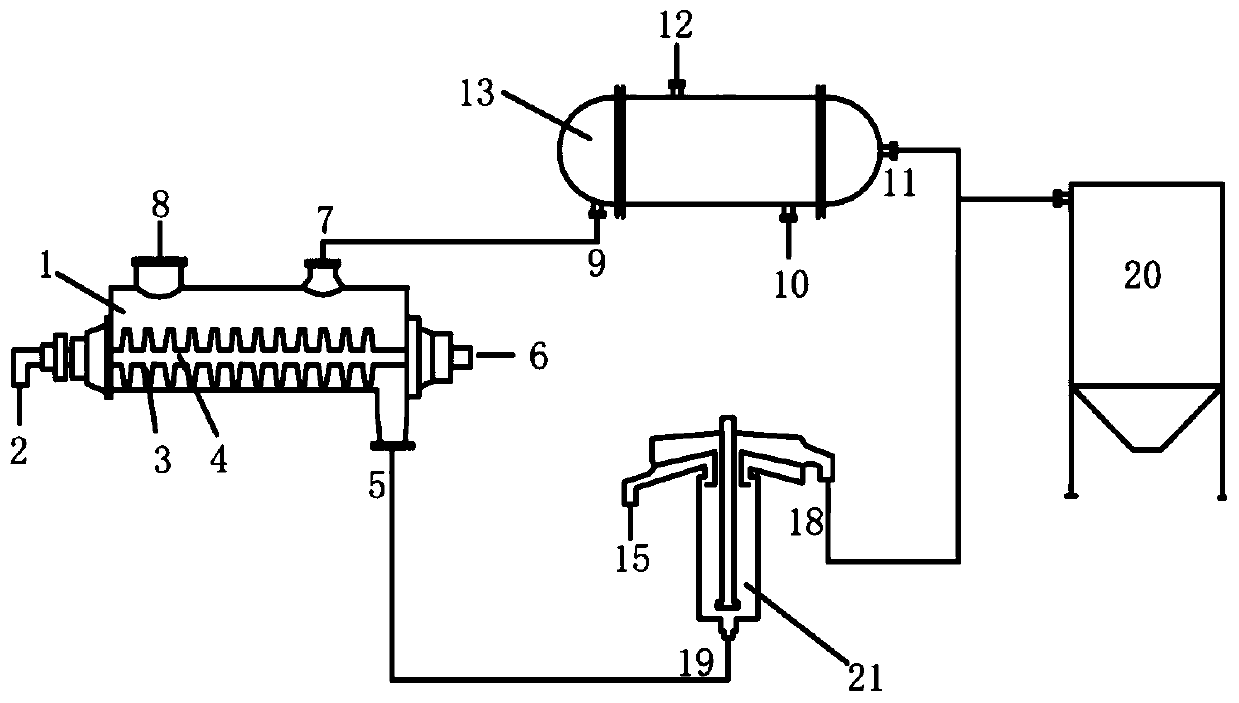

[0041]Drilling oil-based mud cuttings processing equipment consists of slurry heaters, tubular centrifuges, high-temperature steam pipelines, condensing devices, drilling fluid storage tanks, oil and gas collection pipelines, waste water collection pipelines and exhaust gas pipelines.

[0042] Drilling oil-based mud cuttings are sent into the slurry heater from the feed port, filling the space between the shell and the hollow disc, and the drilling oil-based mud cuttings are stirred by the action of the propeller / stirrer on the disc , advance. The hot steam at the end of the cement kiln enters from the entrance of the heat source, flows through the hollow shaft and the hollow disc, and the high-temperature steam enters the heating hollow disc of the slurry heater to indirectly heat the drilling oil-based mud cuttings. The heating process will produce hot drilling oil-based mud cuttings, oily gas, non-condensable gas, oily sewage, and dirty cold water. The hot drilling oil-base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Kinematic viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com