Patents

Literature

209results about How to "Increase surface friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

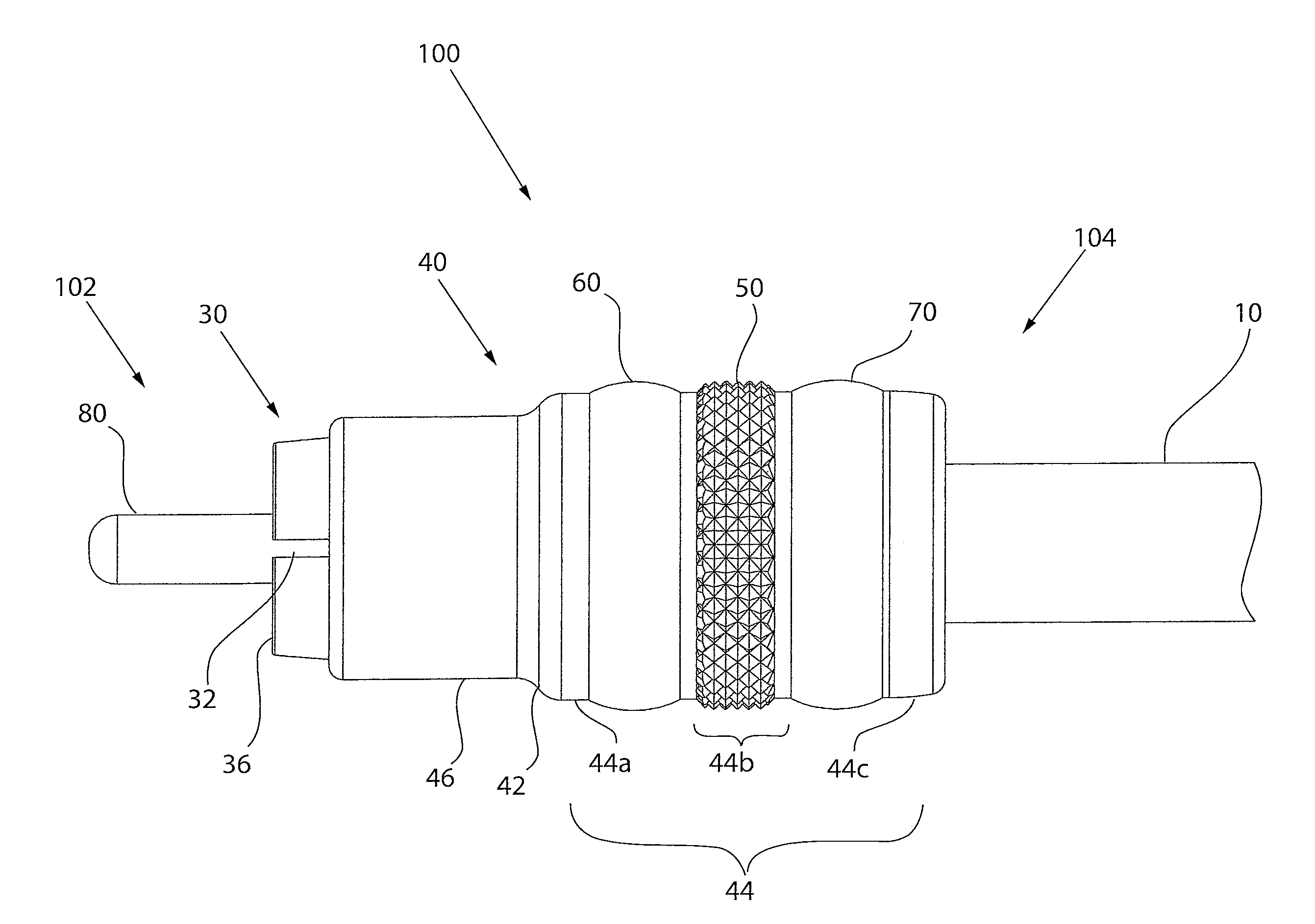

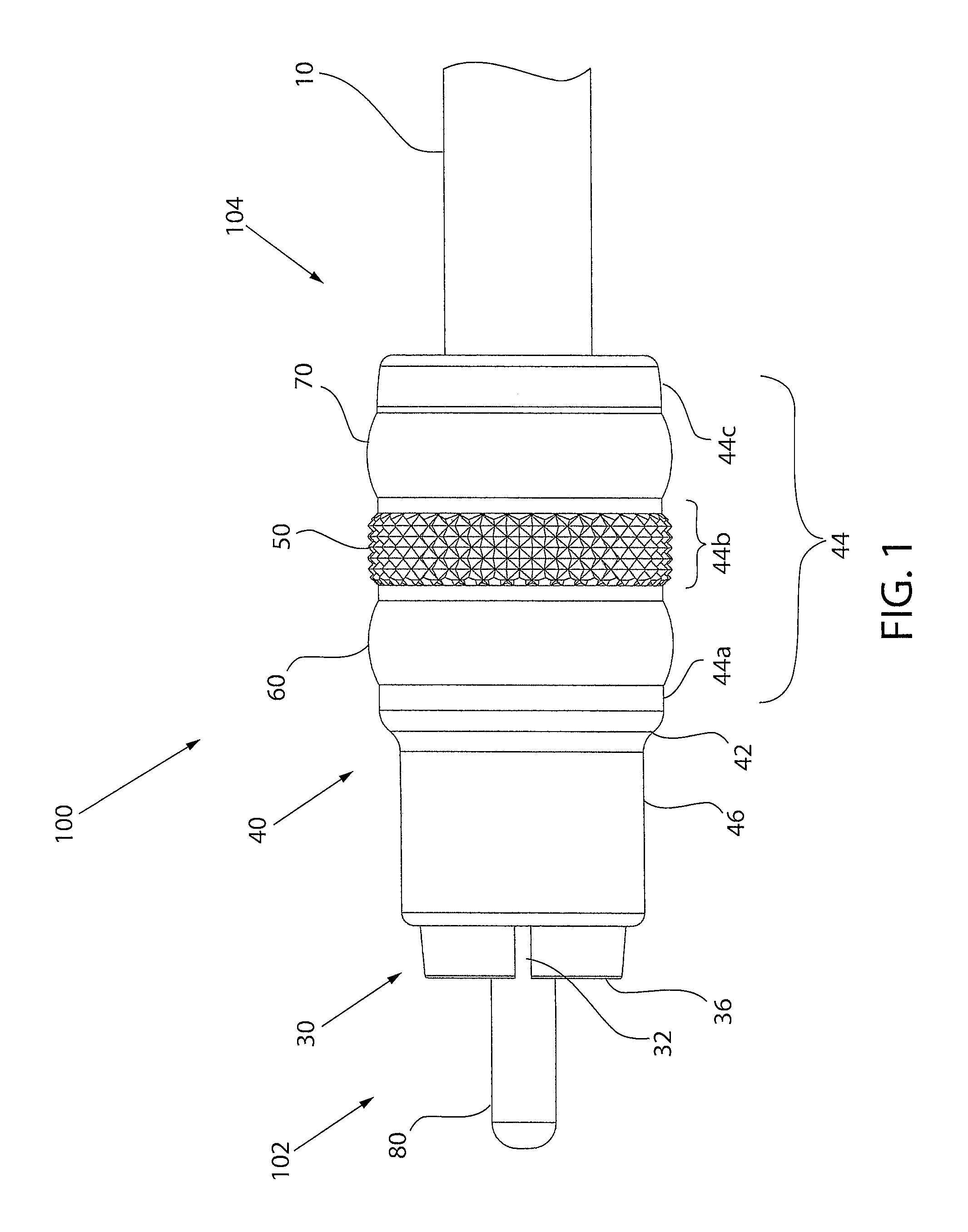

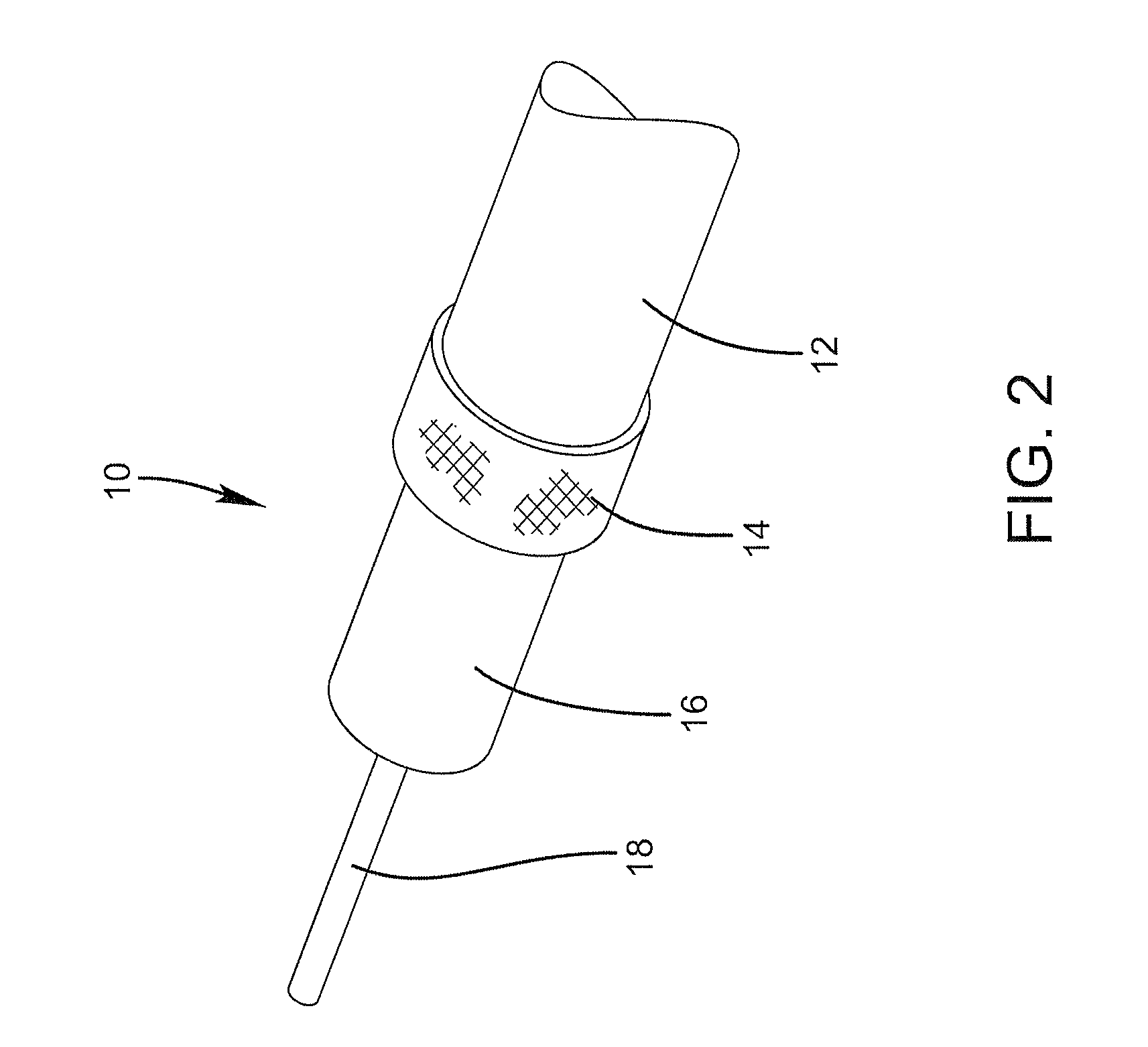

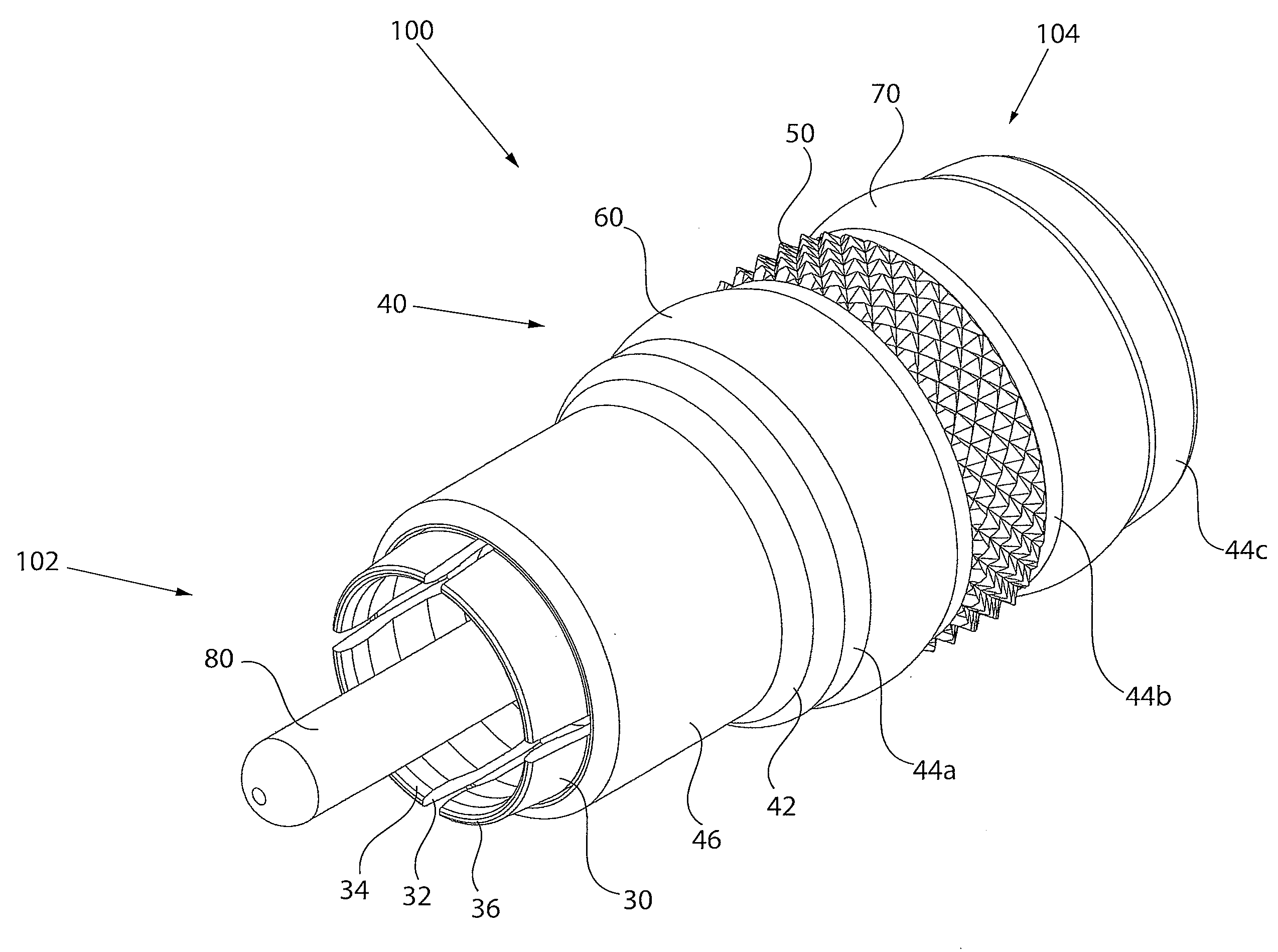

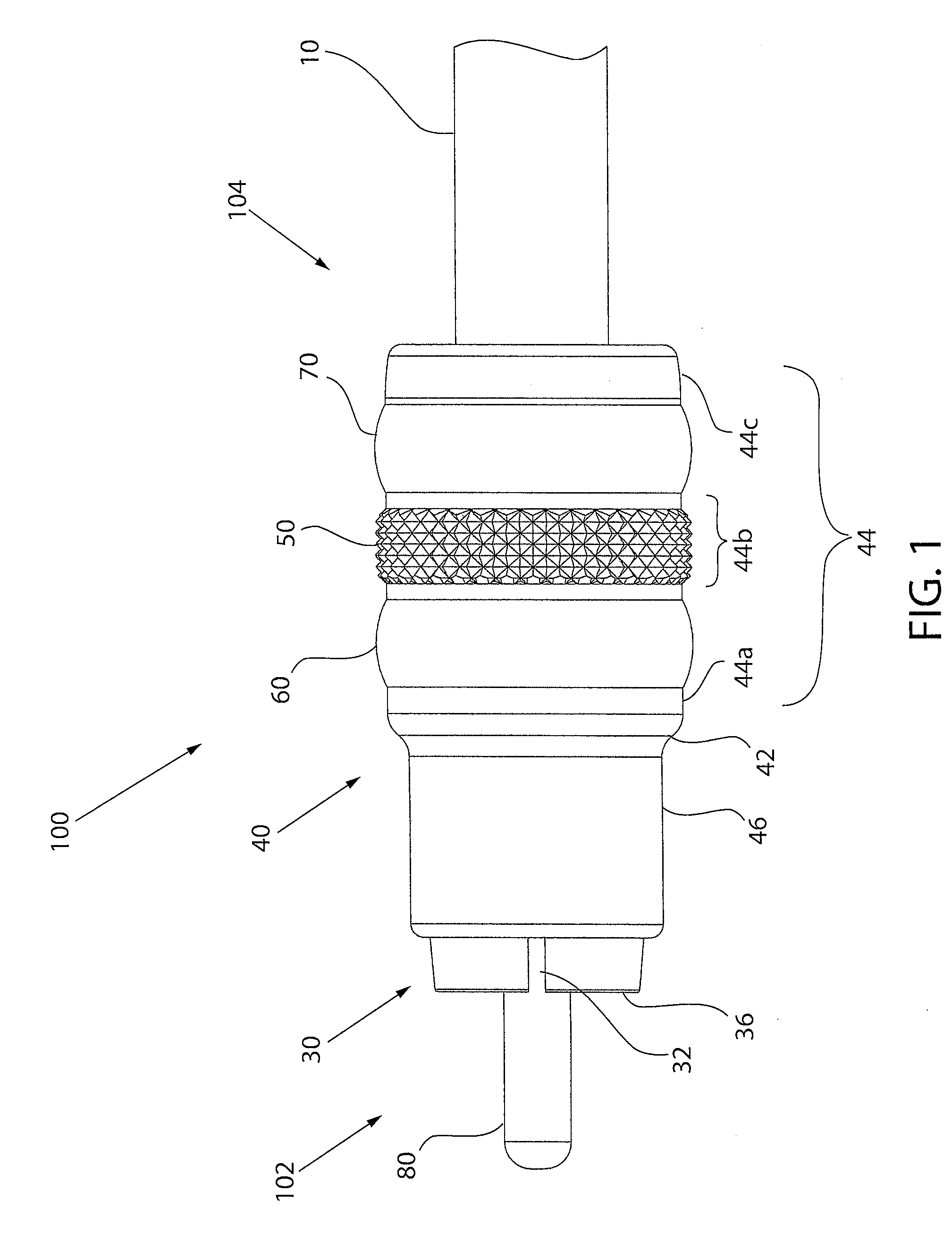

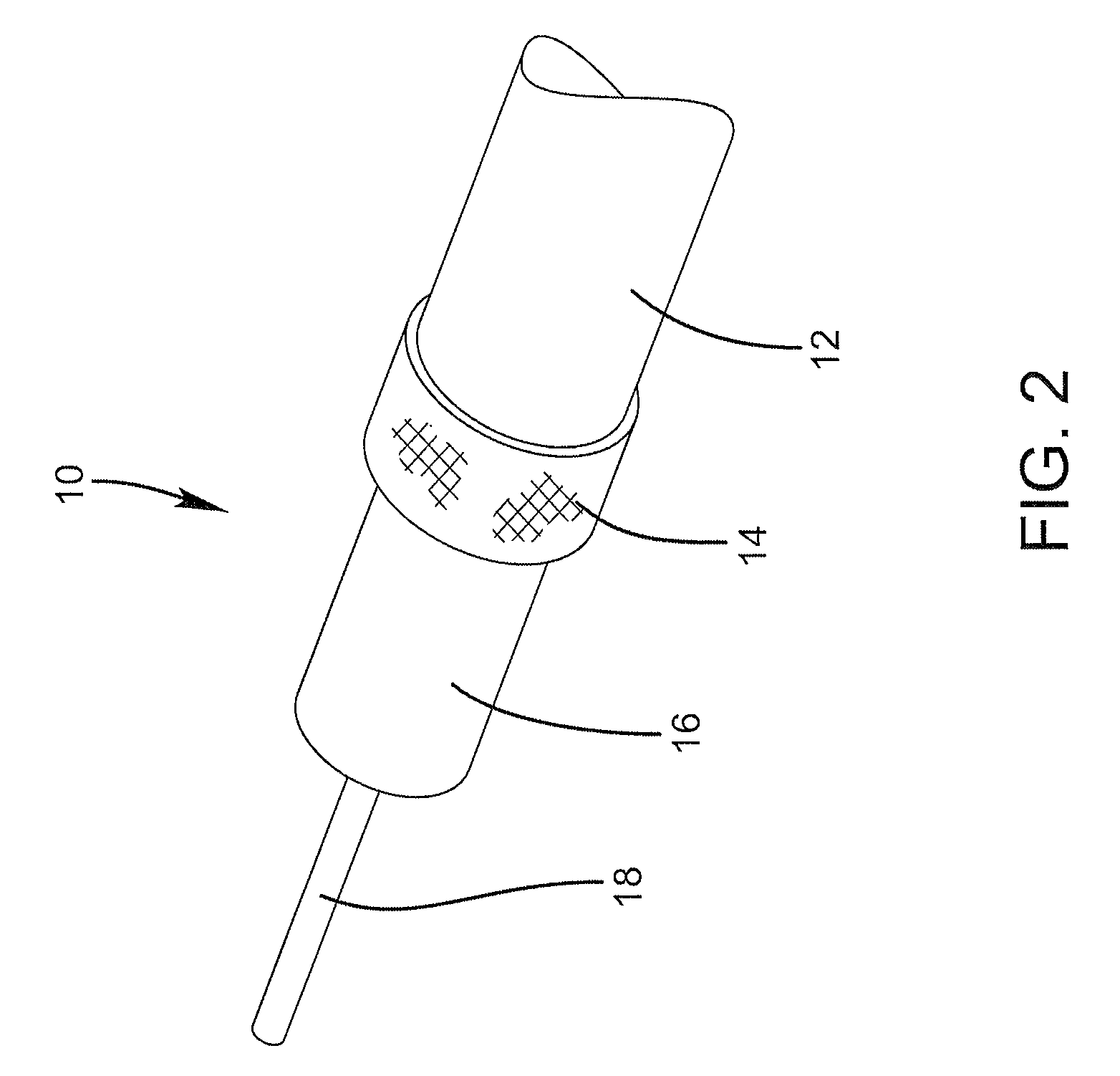

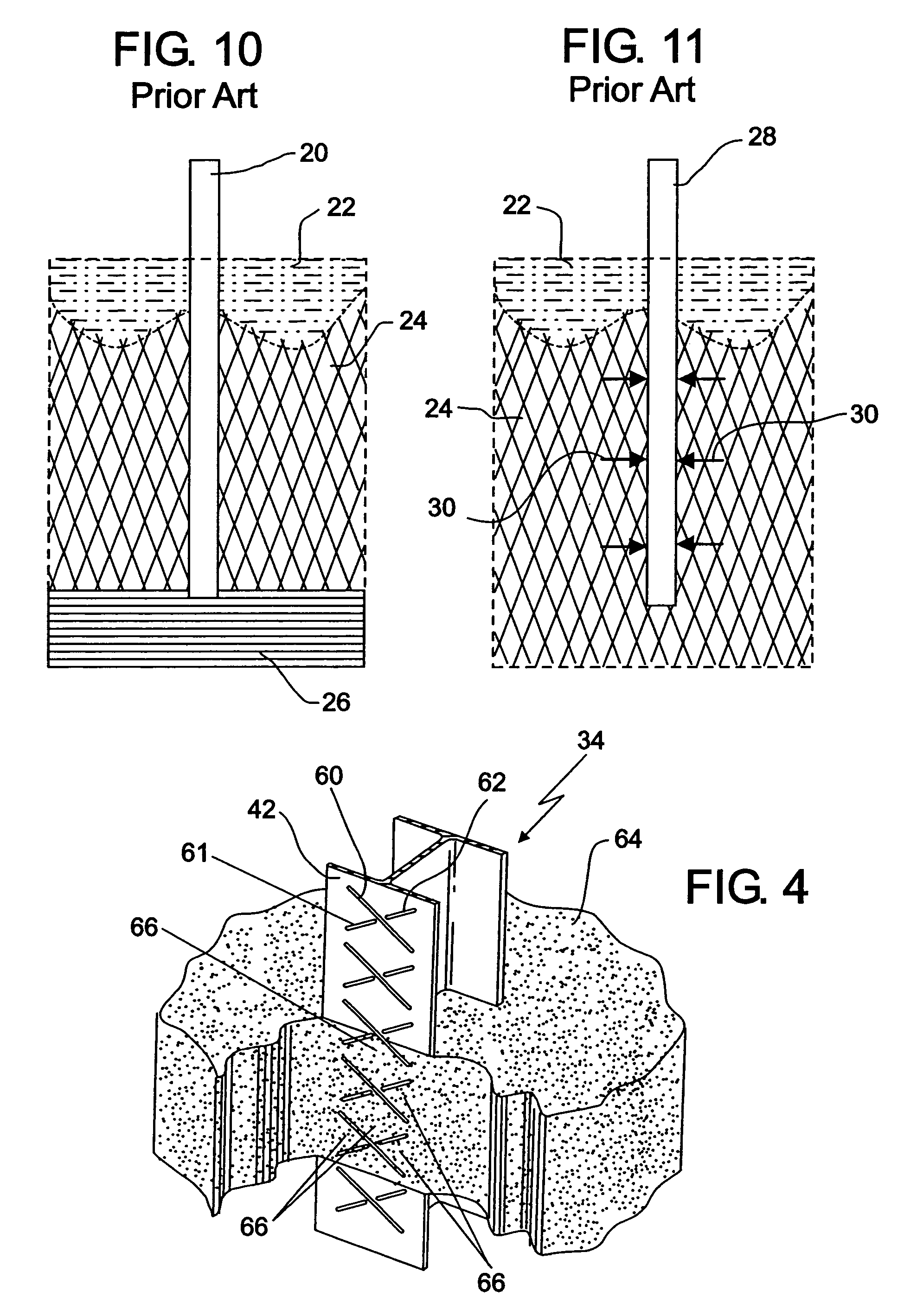

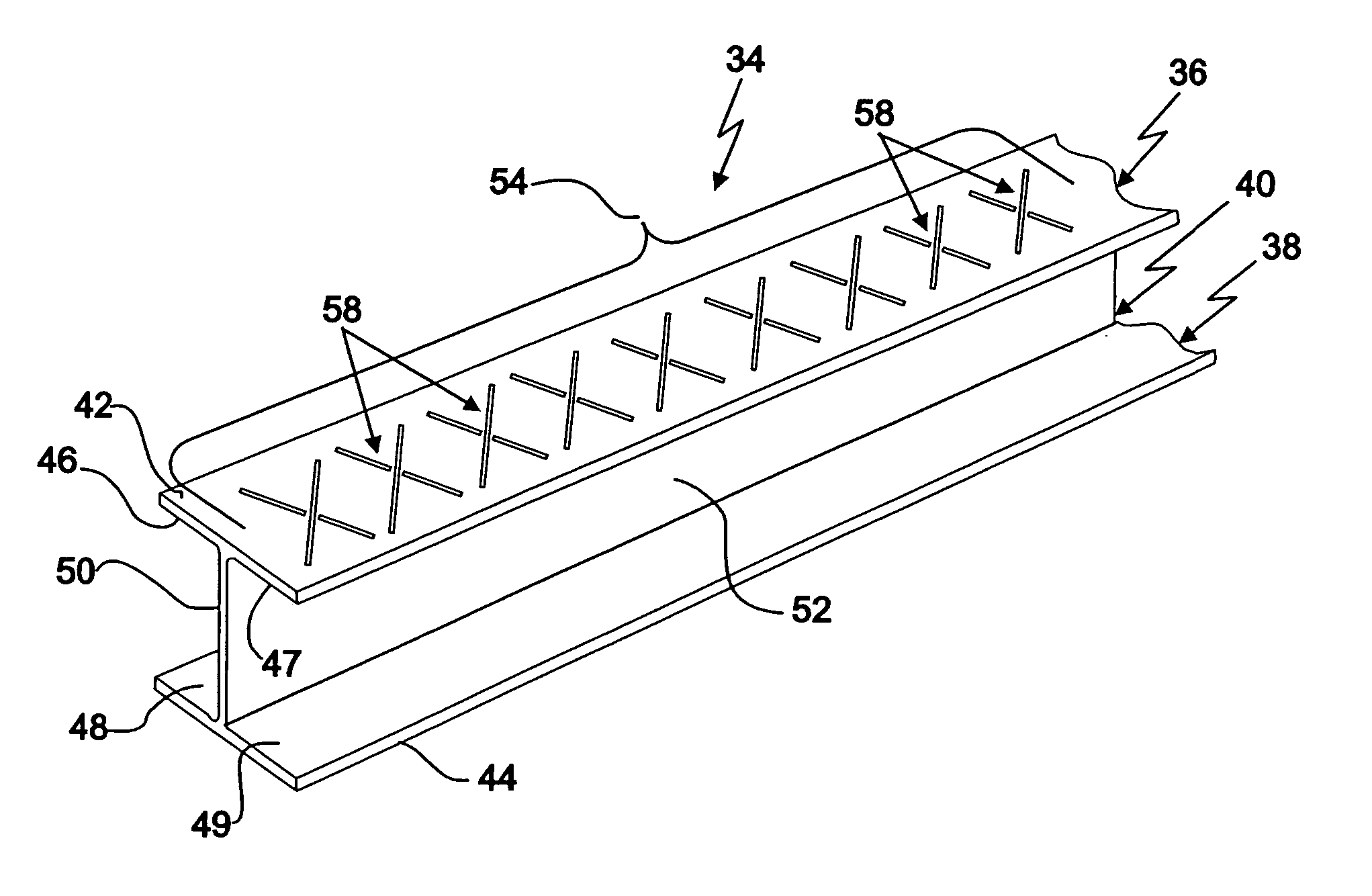

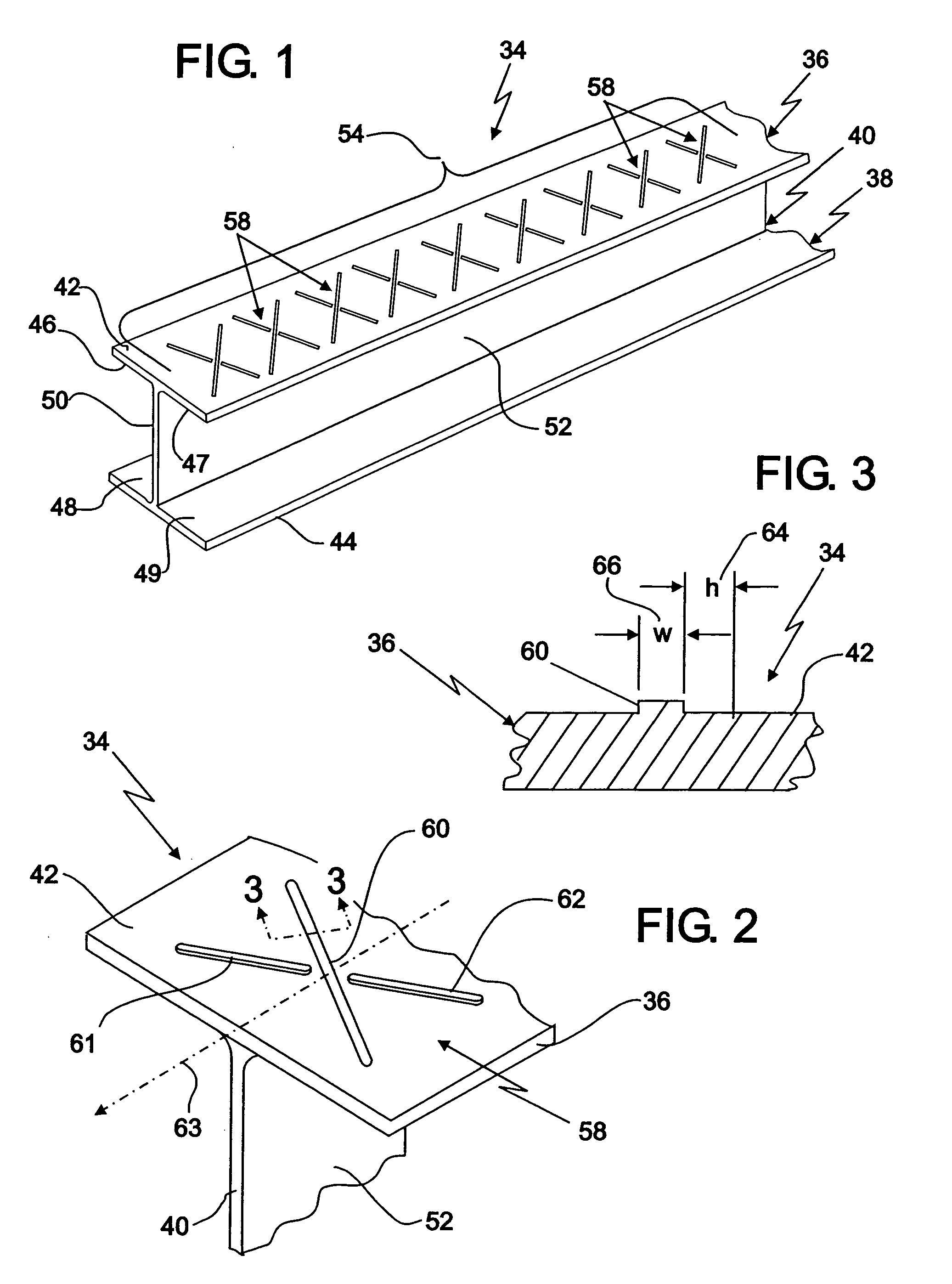

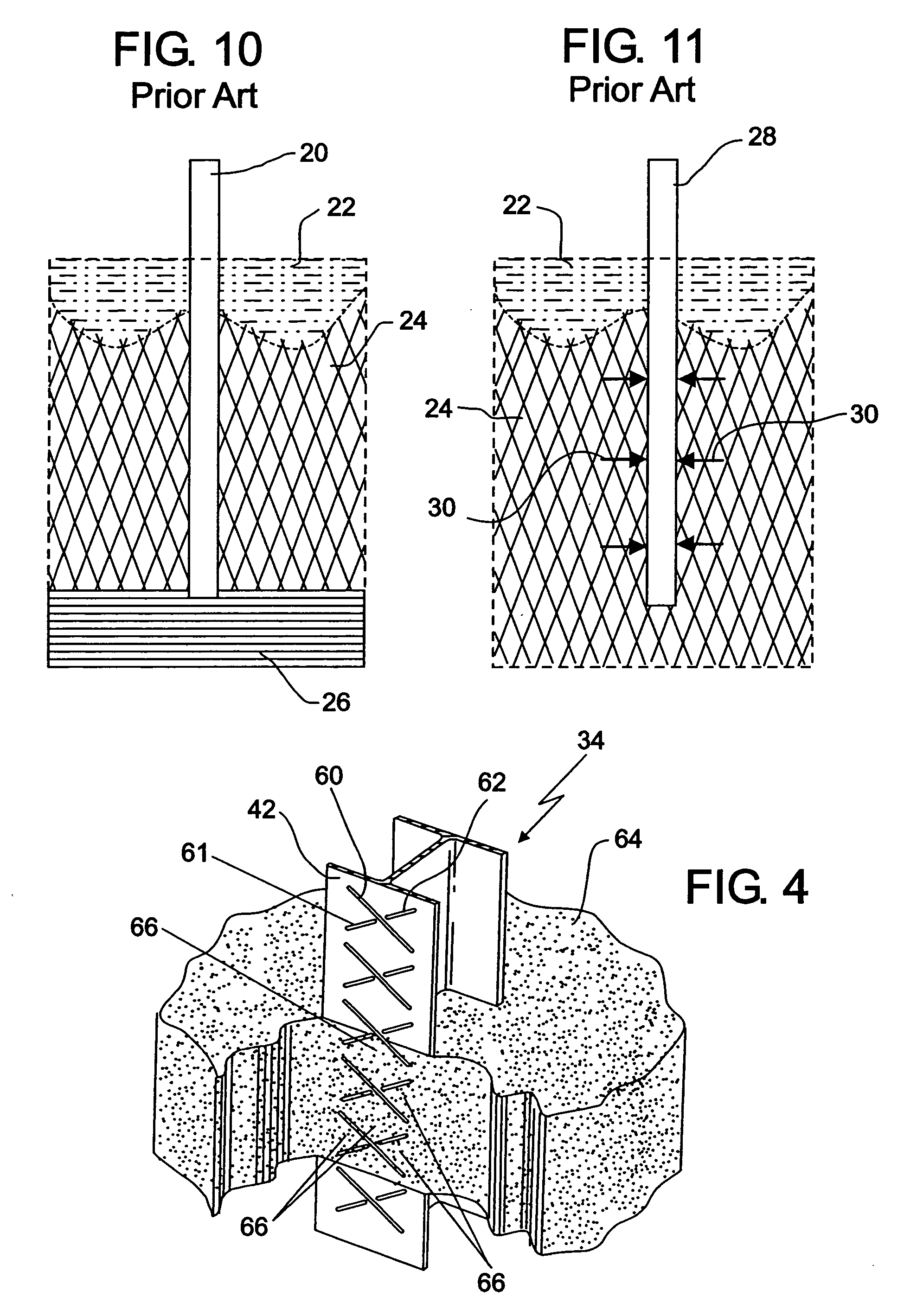

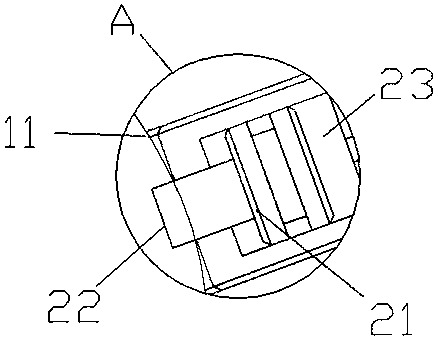

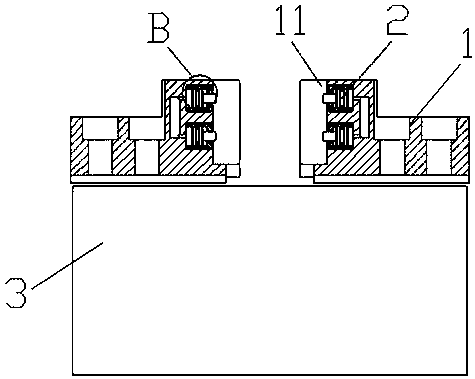

Sure-grip RCA-type connector and method of use thereof

InactiveUS7462068B2Improve reliabilityIncrease surface frictionElectrically conductive connectionsCoupling device detailsCoaxial cableMechanical engineering

A sure-grip RCA-type coaxial cable connector is provided, wherein the connector comprises a connector body having an external surface upon which at least two gripping rings are securely located. Friction-enhancing surface features are positioned upon at least a portion of the external surface of the connector body between at least two of the gripping rings. Sure-grip fastening of the connector to an interface port is provided by gripping the connector so as to engage the gripping rings and the friction-enhancing surface features while maneuvering the connector onto an interface port.

Owner:PPC BROADBAND INC

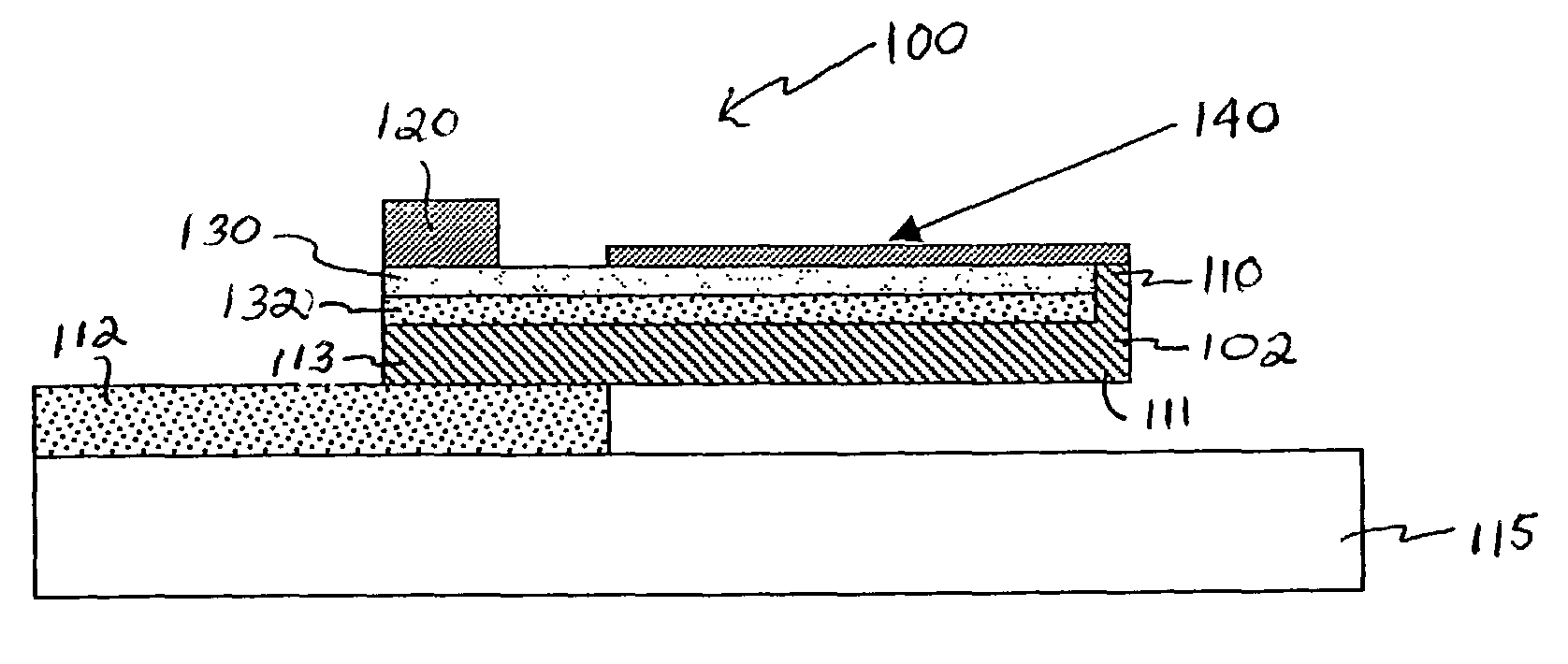

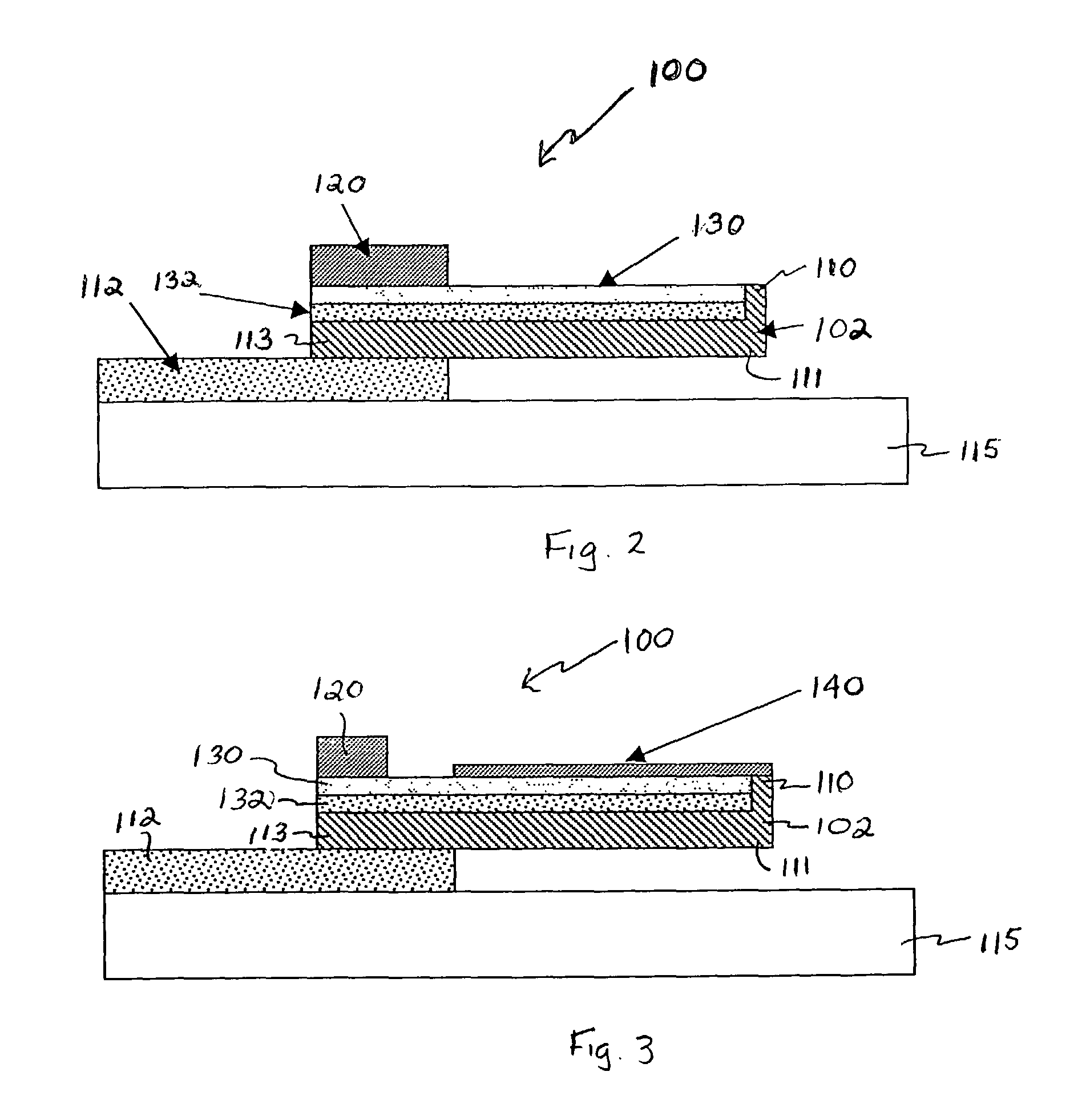

Tunable cantilever apparatus and method for making same

InactiveUS7006376B2Alter characteristicAlter mass distributionImpedence networksSolid-state devicesEngineeringSolid solution

Mass distribution within programmable surface control devices is controlled growing or dissolving an electrodeposition of metal and / or metal ions from a solid solution upon application of a suitable electric field. One such programmable surface control device includes a tunable cantilever assembly whose resonant frequency is changed by depositing and dissolving an electrodeposit on a surface of the assembly using an electric field.

Owner:AXON TECH

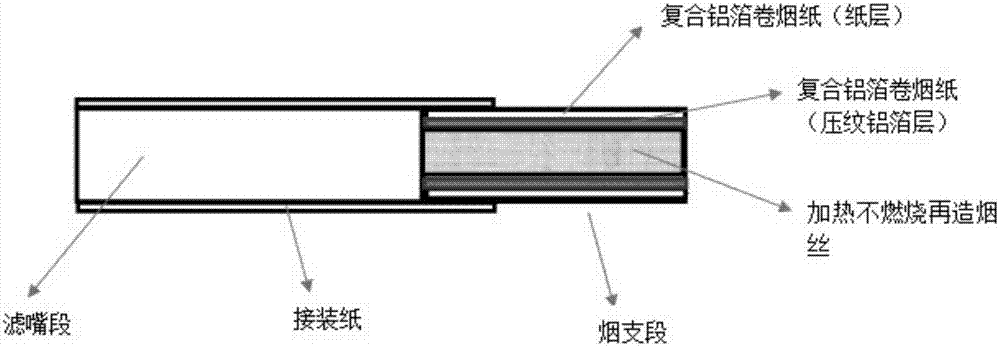

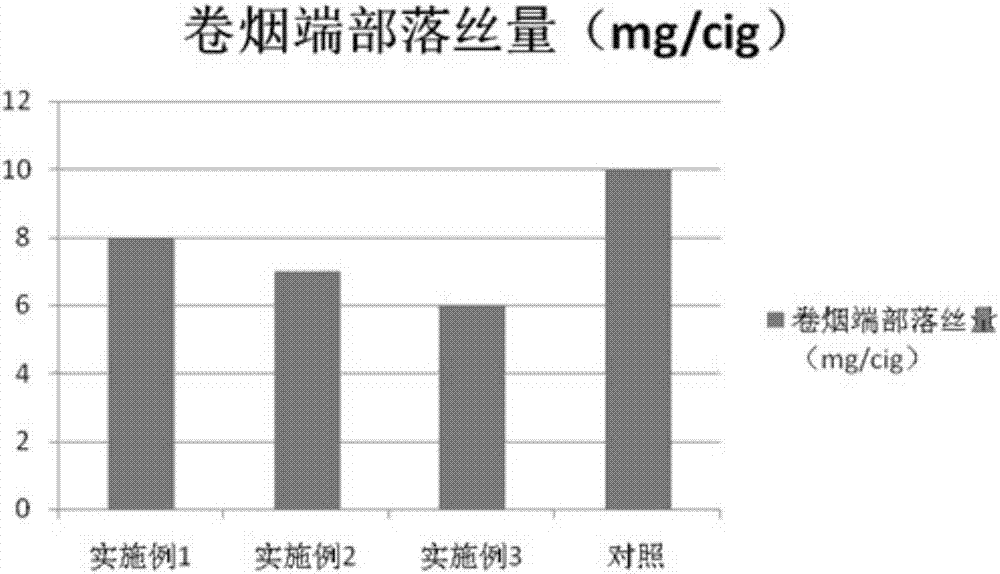

Method for preparing heating but incombustible cigarettes and application thereof

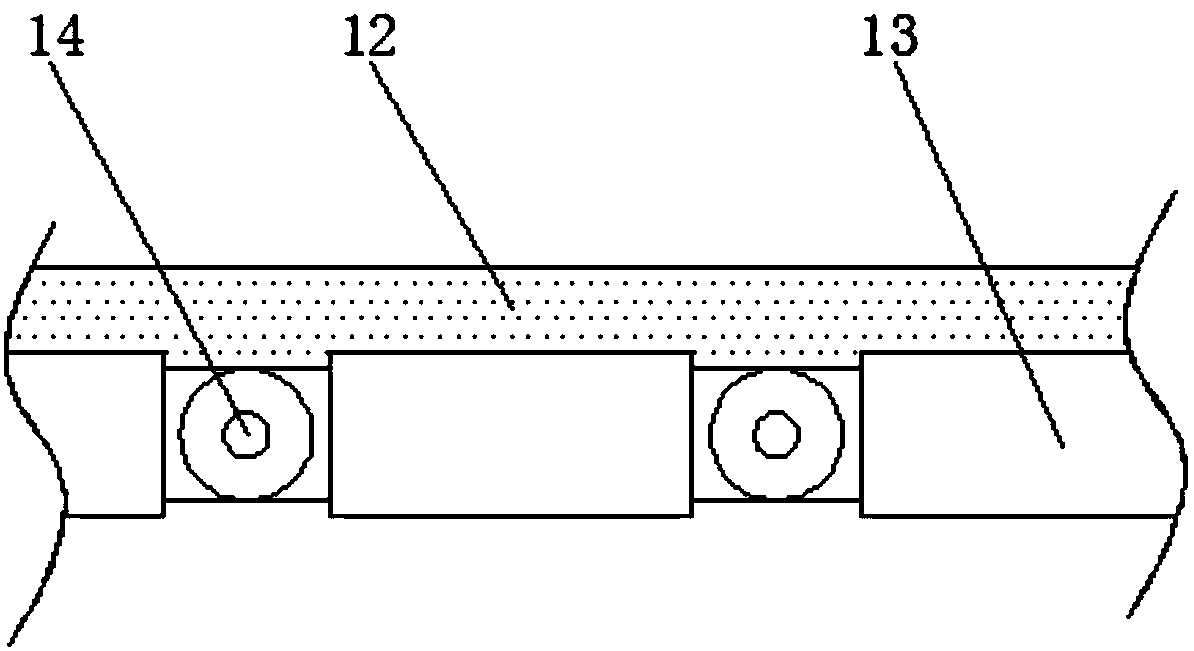

ActiveCN107981405AIncrease frictionLow costTobacco preparationCigarette manufactureKnurlingEngineering

The invention discloses a method for preparing heating but incombustible cigarettes and application thereof. The method and the application have the advantages that novel knurling rolling technologiesare adopted, accordingly, heating but incombustible reconstituted tobaccos with certain thicknesses have uneven surfaces, the surface areas can be enlarged, atomization effects can be enhanced, and surface frictional force can be enlarged; embossed composite aluminum-foil cigarette paper is adopted, accordingly, friction between the reconstituted tobaccos and aluminum-foil pattern surfaces of thecomposite aluminum-foil cigarette paper which is a cigarette making and plug assembling material can be greatly enhanced when the reconstituted tobaccos and the composite aluminum-foil cigarette paper are loaded in a cigarette making and plug assembling machine and cigarette making and plug assembling are powered on in later periods, the heating but incombustible cigarettes are easy to process, equipment shutdown frequencies can be reduced, the heating but incombustible cigarettes can be continuously produced, the production efficiency can be improved, and the material cost and the productioncost can be reduced; low-temperature cigarettes have short cut tobacco sections, accordingly, friction can be improved, the method is beneficial to reducing cut tobacco dropping, and the shortcomingsof low frictional force between smooth surfaces of existing heating but incombustible reconstituted tobaccos and non-embossed aluminum-foil paper which is a wrapping material, severe slipping, frequent equipment shutdown due to incapability of driving cigarette paper, influence on production efficiency, low frictional force due to short cut tobacco sections of existing low-temperature cigarettes,vulnerability to dropping of low-temperature cut tobaccos of the existing low-temperature cigarettes and the like can be overcome.

Owner:HUBEI CHINA TOBACCO IND

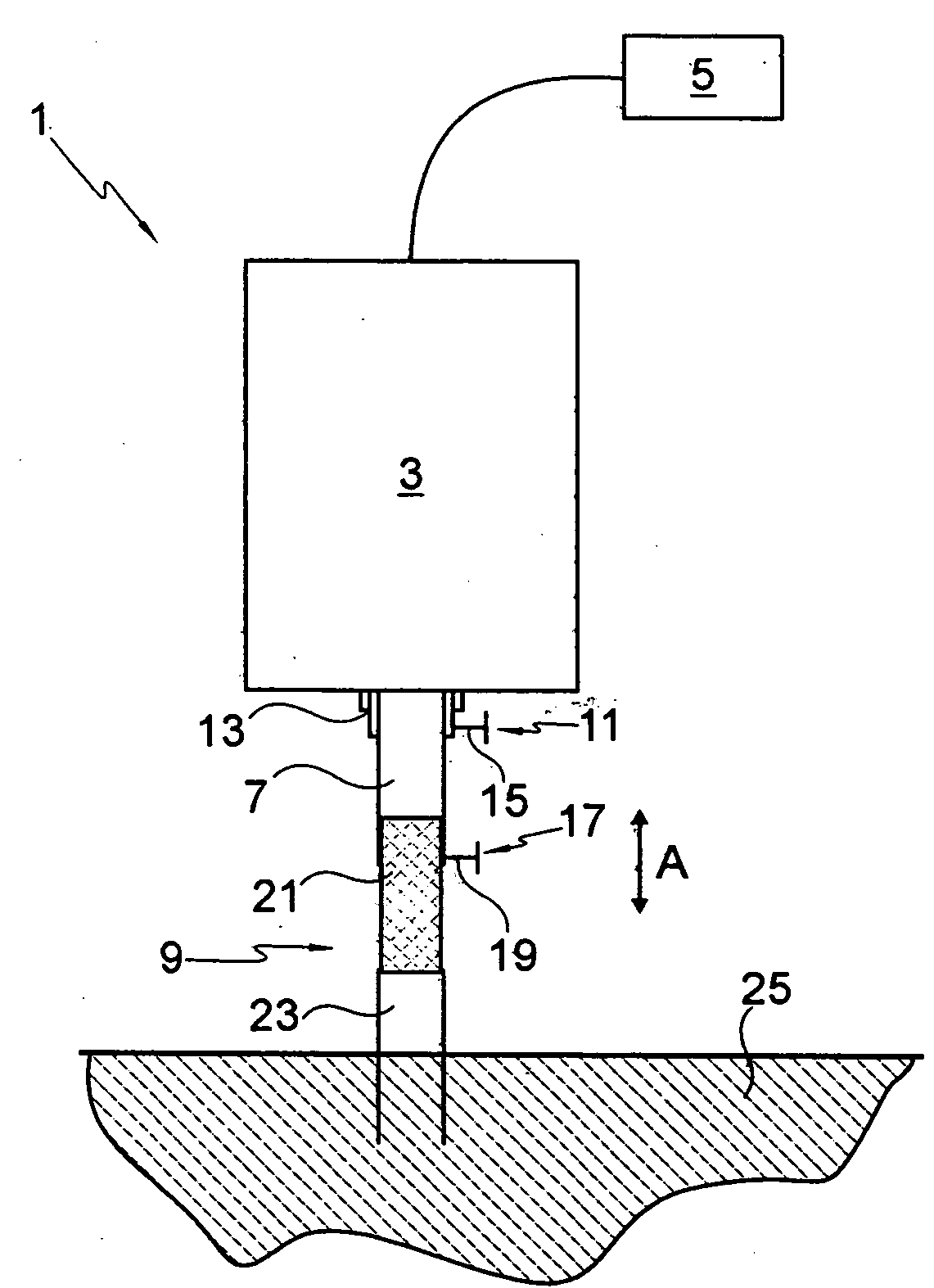

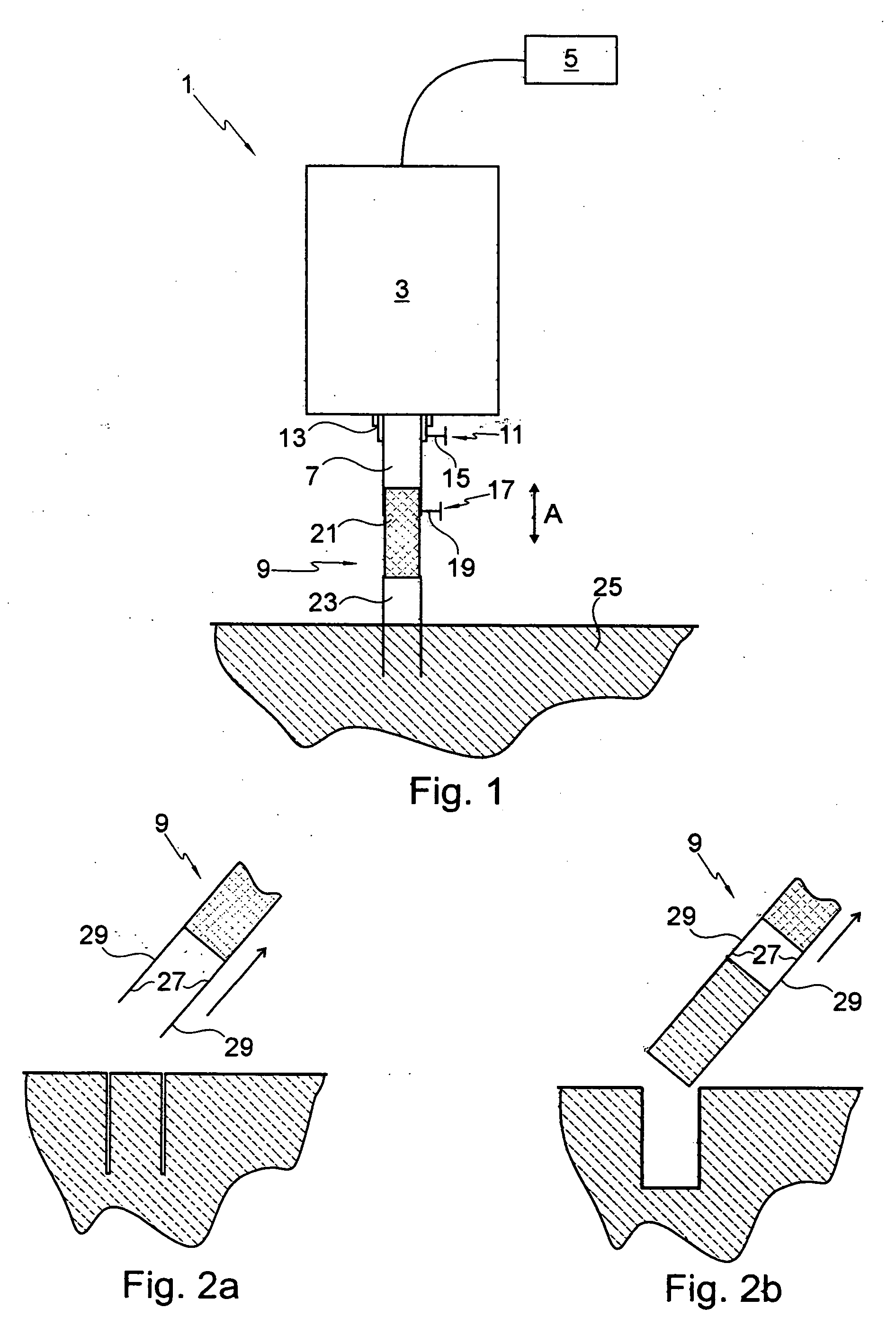

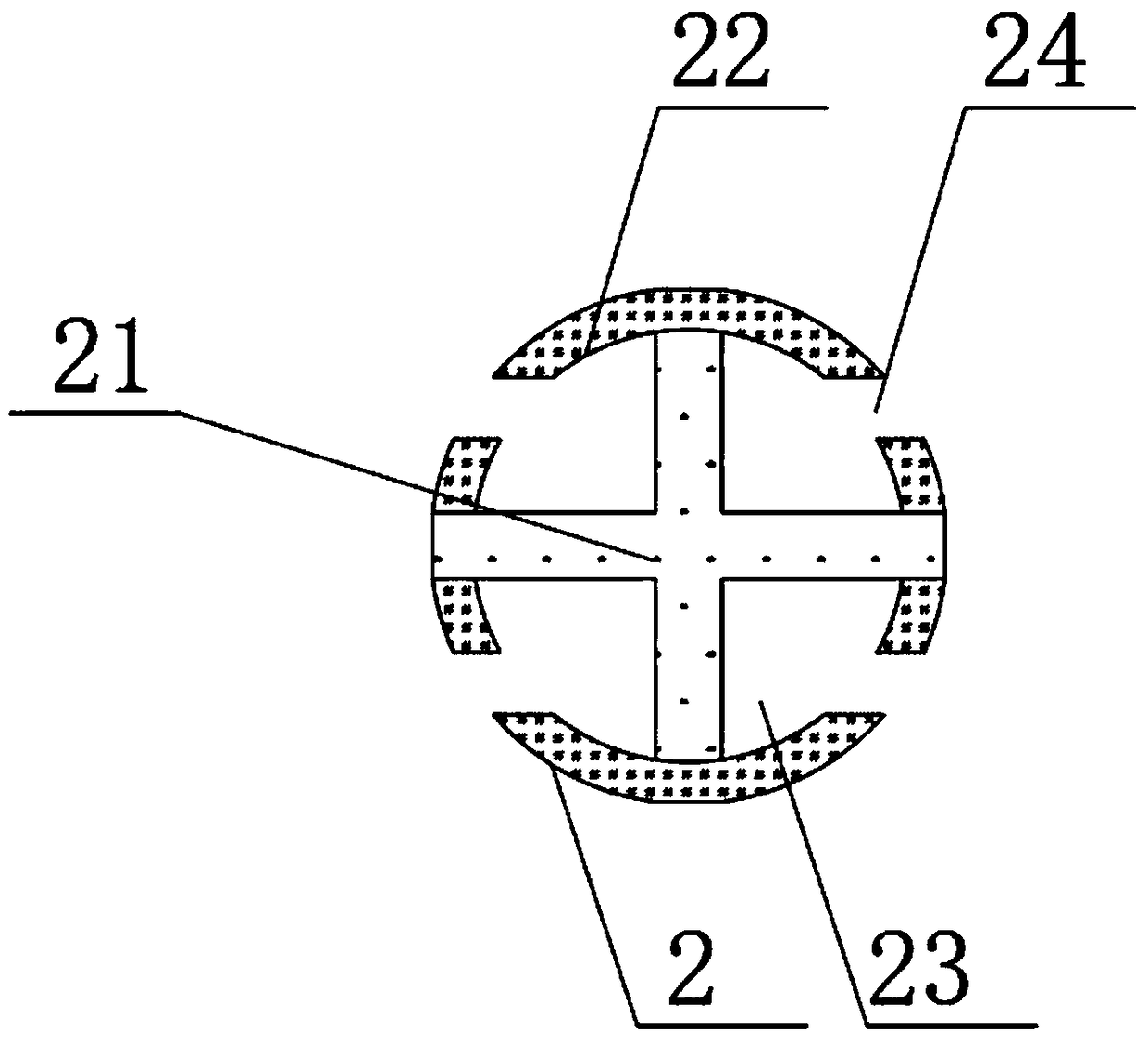

Device and method for preparing a recess in a bone

InactiveUS20080269649A1Avoid necessityAvoid interferences from occurringChiropractic devicesVaccination/ovulation diagnosticsPunchingEngineering

A punching device for preparing a recess in a bone has a punching tool usable for such a punching device. An implant usable with the punching tool is provided and a method for preparing a recess in a bone are disclosed. The punching device comprises an ultrasonic sonotrode and a punching tool which is fixable to the sonotrode at its proximal extremity. At its distal extremity, the punching tool has a thin-walled portion having a non-rotational symmetric cross-section. By ultrasonic vibration of the punching tool, the thin-walled portion can be forced into a bone thereby preparing a recess of which is not rotationally symmetric. Subsequently, an implant can be held in such recess. Due to its lack of rotational symmetry, the implant may absorb rotational forces around its longitudinal axis.

Owner:STRYKER EURO OPERATIONS HLDG LLC +1

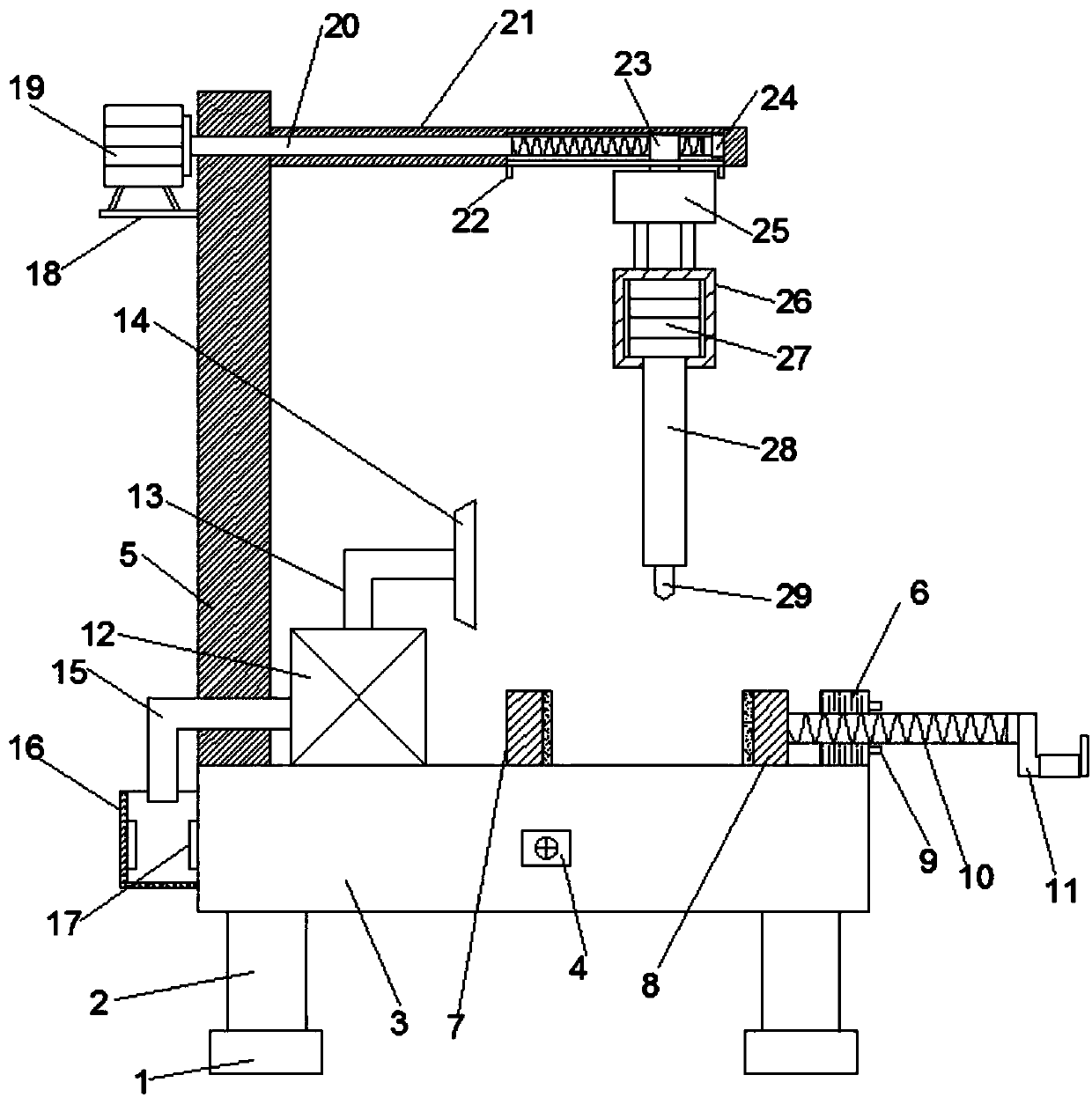

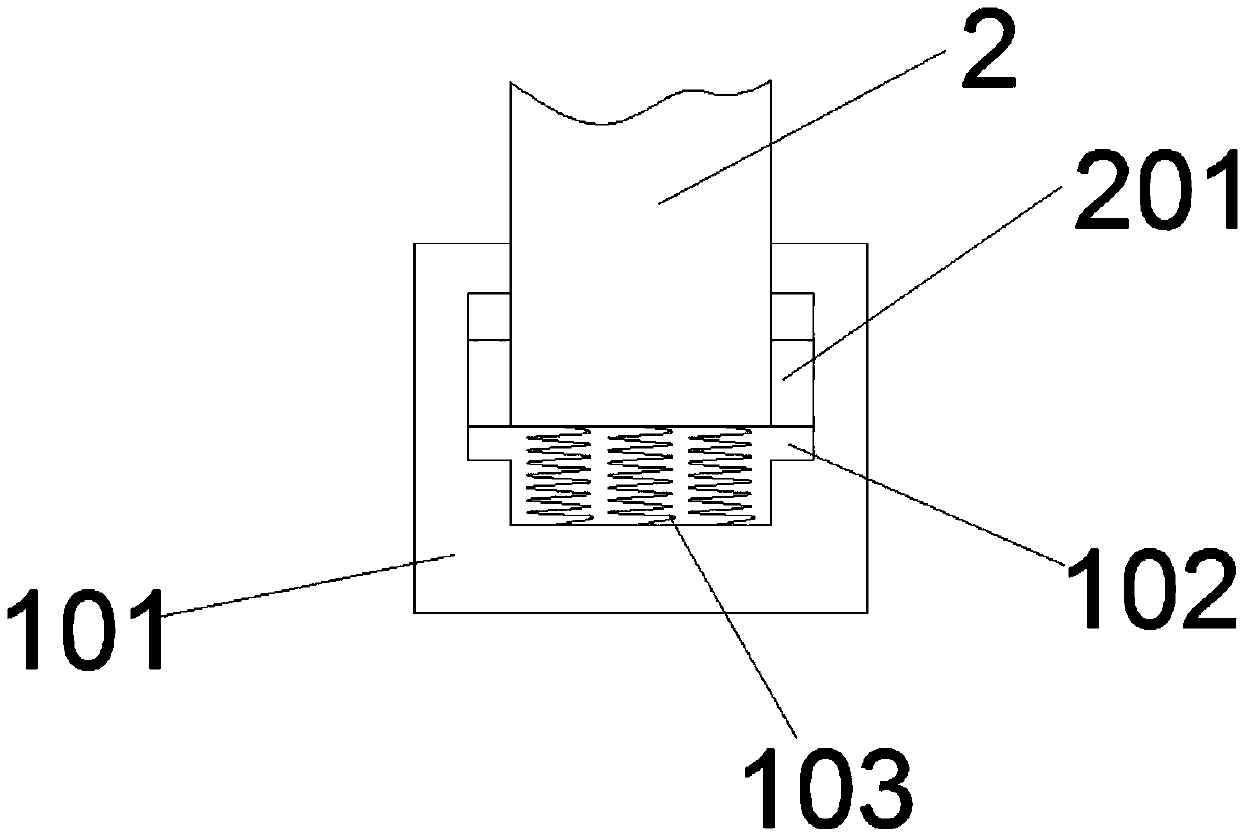

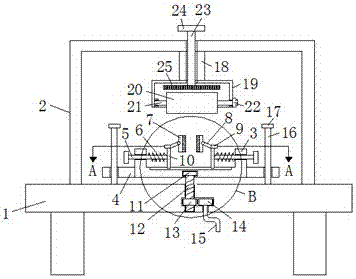

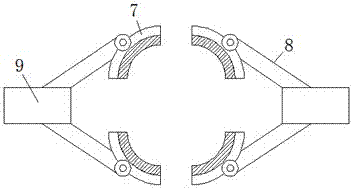

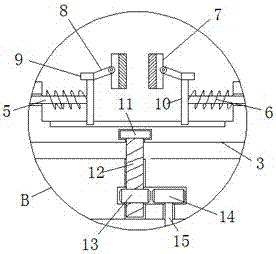

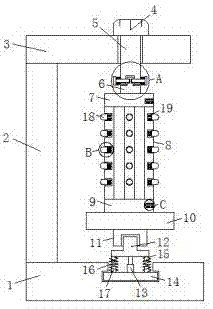

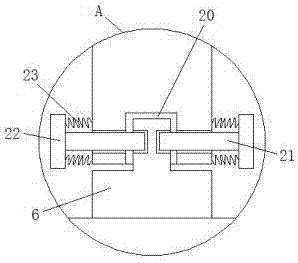

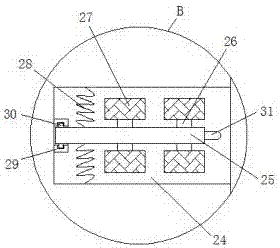

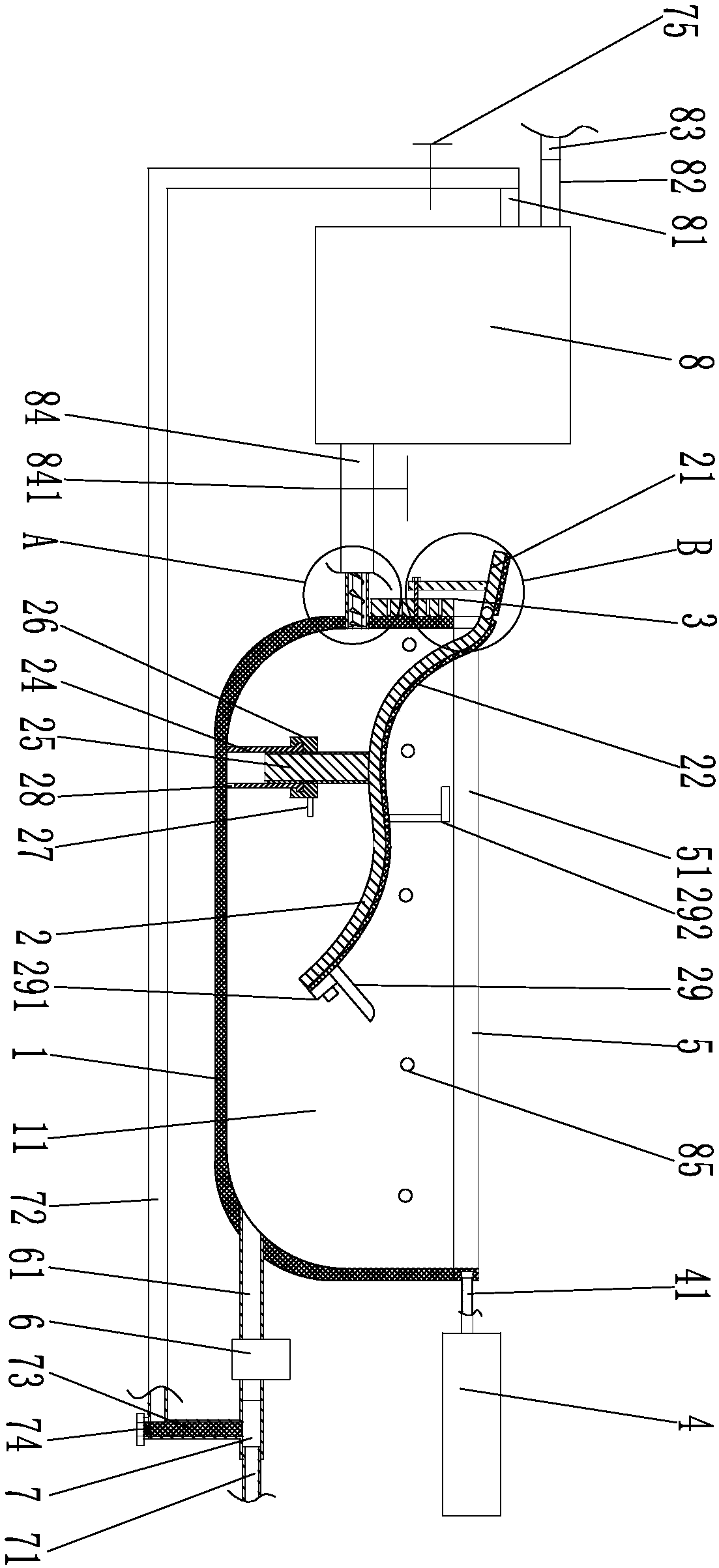

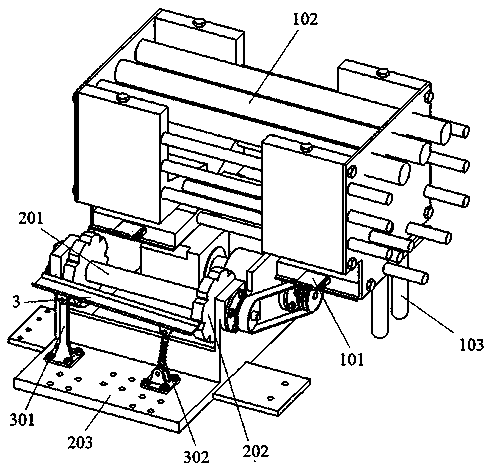

Drilling machine for machining hardware fittings

InactiveCN107824835AEasy to adjust the widthEasy to collectNon-rotating vibration suppressionDirt cleaningShock mountEngineering

The invention discloses a drilling machine for machining hardware fittings. The drilling machine comprises damping seats, wherein the damping seats comprise shells; sliding grooves are formed in the left sides and the right sides of the interiors of the shells; springs are arranged at the bottom ends of the interiors of the shells; supporting columns are arranged at the upper ends of the springs;and first sliding blocks are arranged at the left sides of the bottoms of the supporting columns and the right sides of the bottoms of the supporting columns. According to the drilling machine, the structure is simple, and the operation is easy; a movable clamping plate is moved by shaking a handle so as to clamp a machined workpiece, so that the operation is more convenient and labor-saving, andthe widths of the clamping plates can be conveniently adjusted for machining machined workpieces with different sizes; meanwhile, anti-slip mats are arranged on one sides of the outer walls of the clamping plates respectively, so that the surface friction force between the contact surfaces of the clamping plates and the machined workpiece is increased; after a fan works, the influence of debris particles on normal operation is avoided, the working efficiency is improved, and potential safety hazards caused by the debris particles to physical health of workers are eliminated; and the damping seats are arranged at the bottom of the drilling machine, so that the effects of damping and noise reduction are achieved when the drilling machine works.

Owner:WUXI WEI KELAI TECH CO LTD

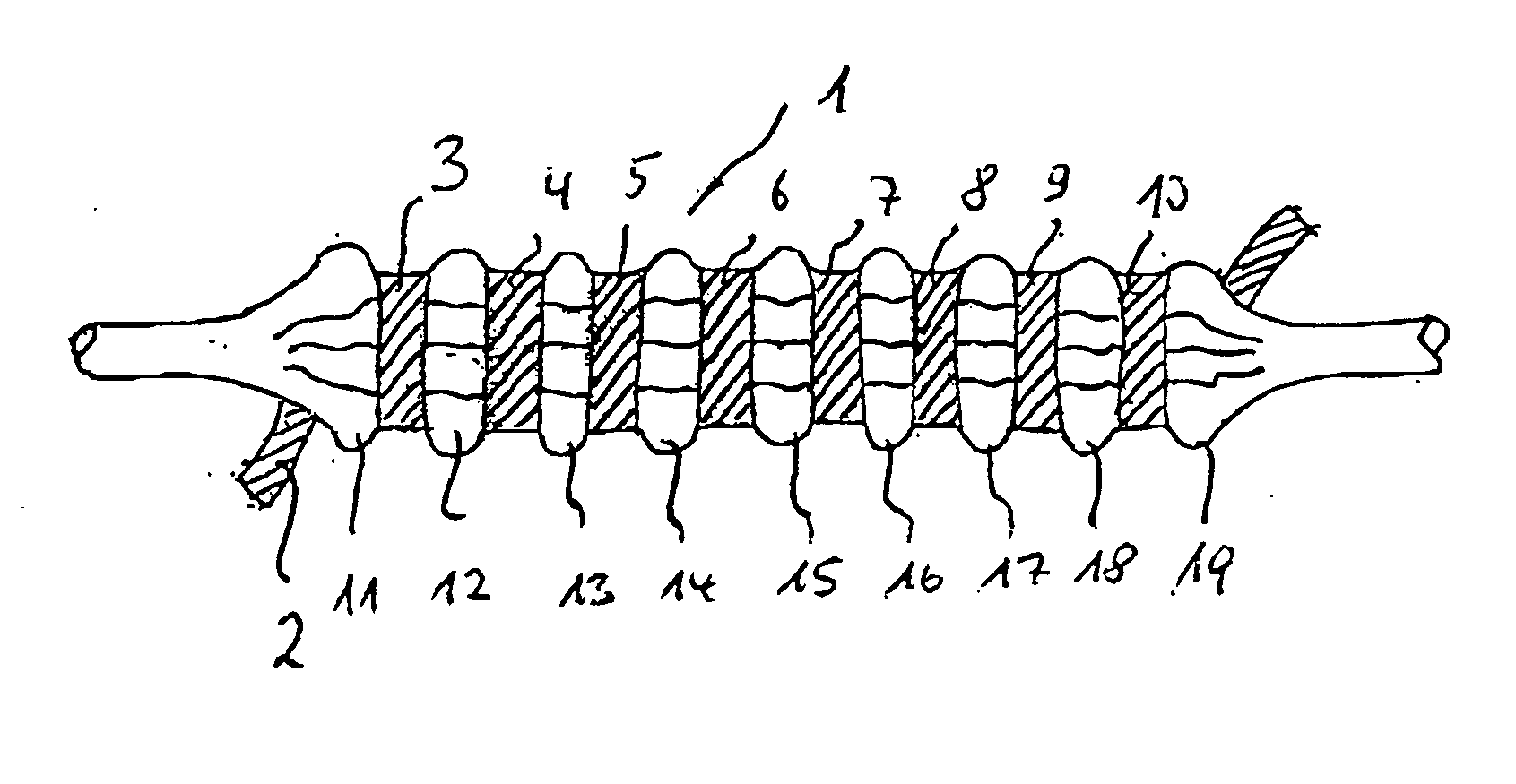

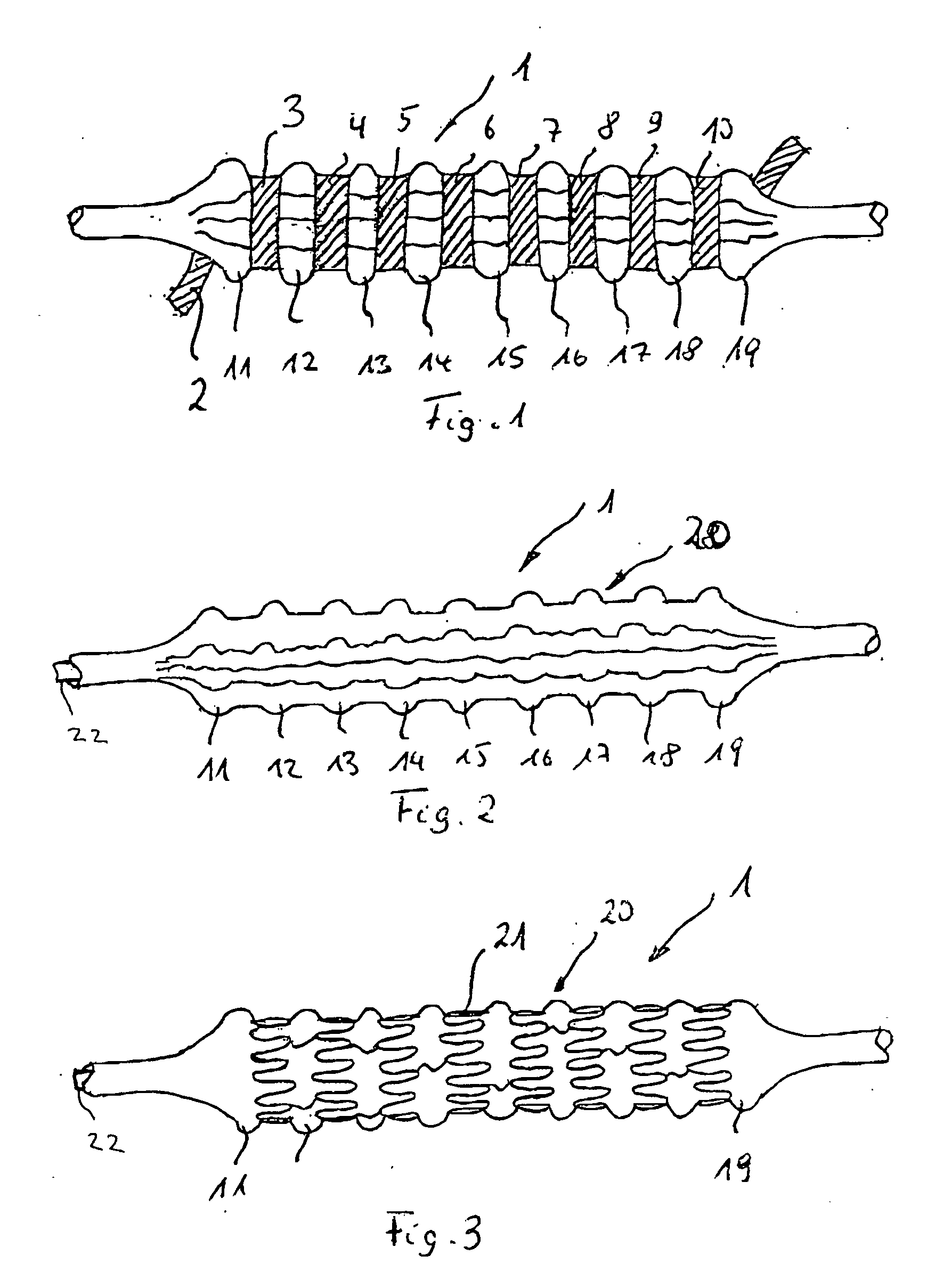

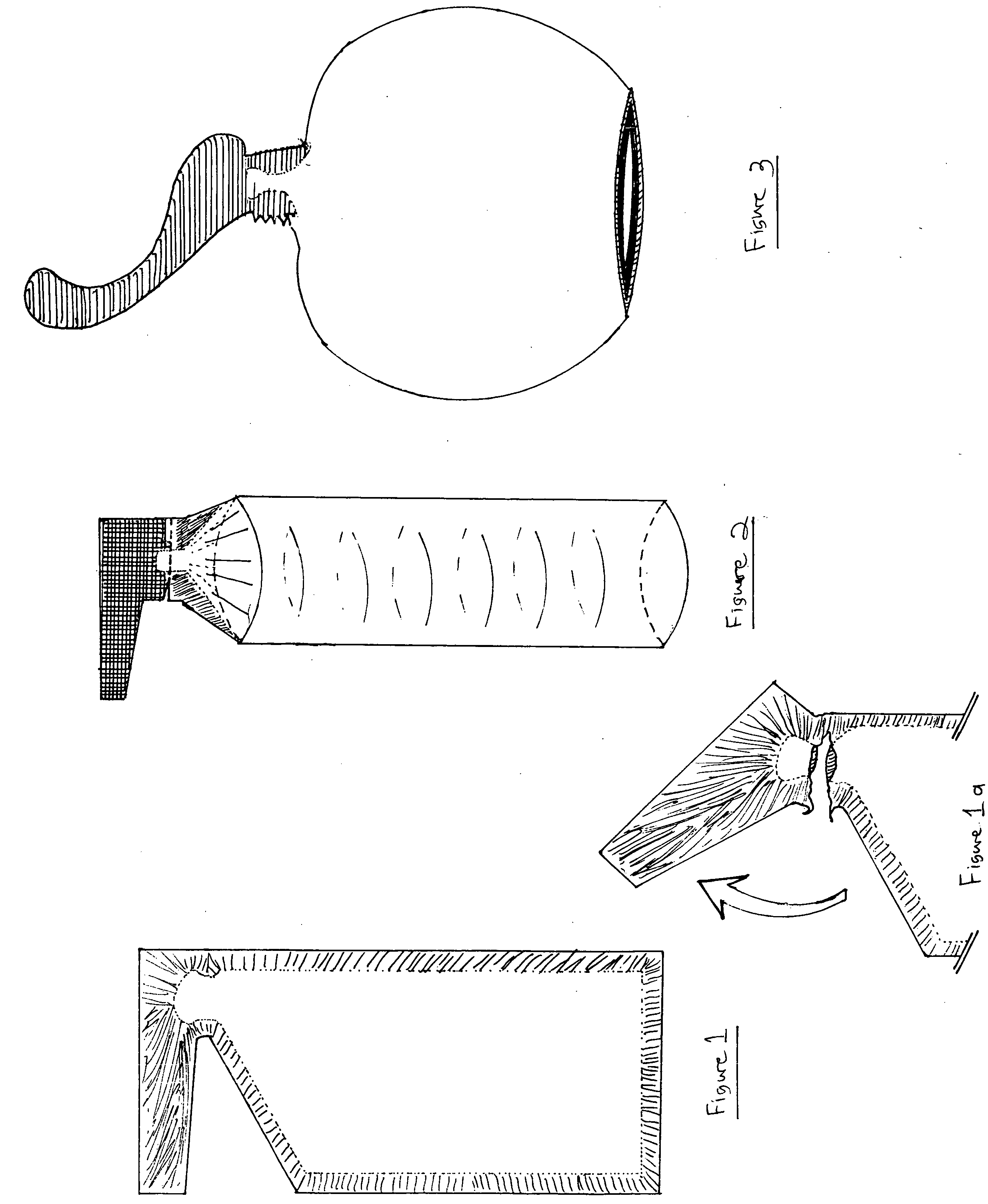

Method of trimming a balloon of a balloon catheter

InactiveUS20050151304A1Improved stent fastening characteristicPromote repairStentsBalloon catheterBalloon catheterWrap around

A method of trimming a balloon of a balloon catheter is provided that includes creating protrusions on the balloon by wrapping a member around the balloon, leaving the member wrapped around the balloon and removing the member from the balloon. The member is wrapped around the balloon such that spaced-apart loops of the member wrapped around the balloon compress the balloon leaving uncompressed portions of the balloon between the spaced apart loops of the member wrapped around the balloon to form the protrusions on the balloon. The member wrapped around the balloon is left for a predetermined period of time. The member is removed from the balloon after the predetermined period of time. A balloon catheter is also provided that is constructed in accordance with this method.

Owner:ABBOTT LAB VASCULAR ENTERPRISE

Artware polishing grinding device bringing convenience to positioning

InactiveCN107350951AIncrease frictionGood positioning and clamping effectPolishing machinesGrinding drivesEngineering

The invention discloses a handicraft polishing and polishing device which is convenient for positioning, which comprises a fixed frame and a workbench. A grinding cover is fixedly connected to the lower end of the grinding cover, and a grinding roller is arranged inside the grinding cover. The limit rod is fixed on the upper end of the fixed frame. A pull rod is connected, the outer wall of the pull rod is sleeved with a spring, and the end of the pull rod is fixedly connected with a movable rod, the upper end of the movable rod is fixedly connected with a fixed block, and the outer wall of the fixed block is symmetrically provided with connecting rods, The end of the connecting rod away from the fixed block is rotatably connected with a clamping block. The invention is simple in structure, easy to operate, can effectively locate handicrafts, has good clamping effect, and avoids damage during polishing.

Owner:浙江千鹤工艺品有限公司

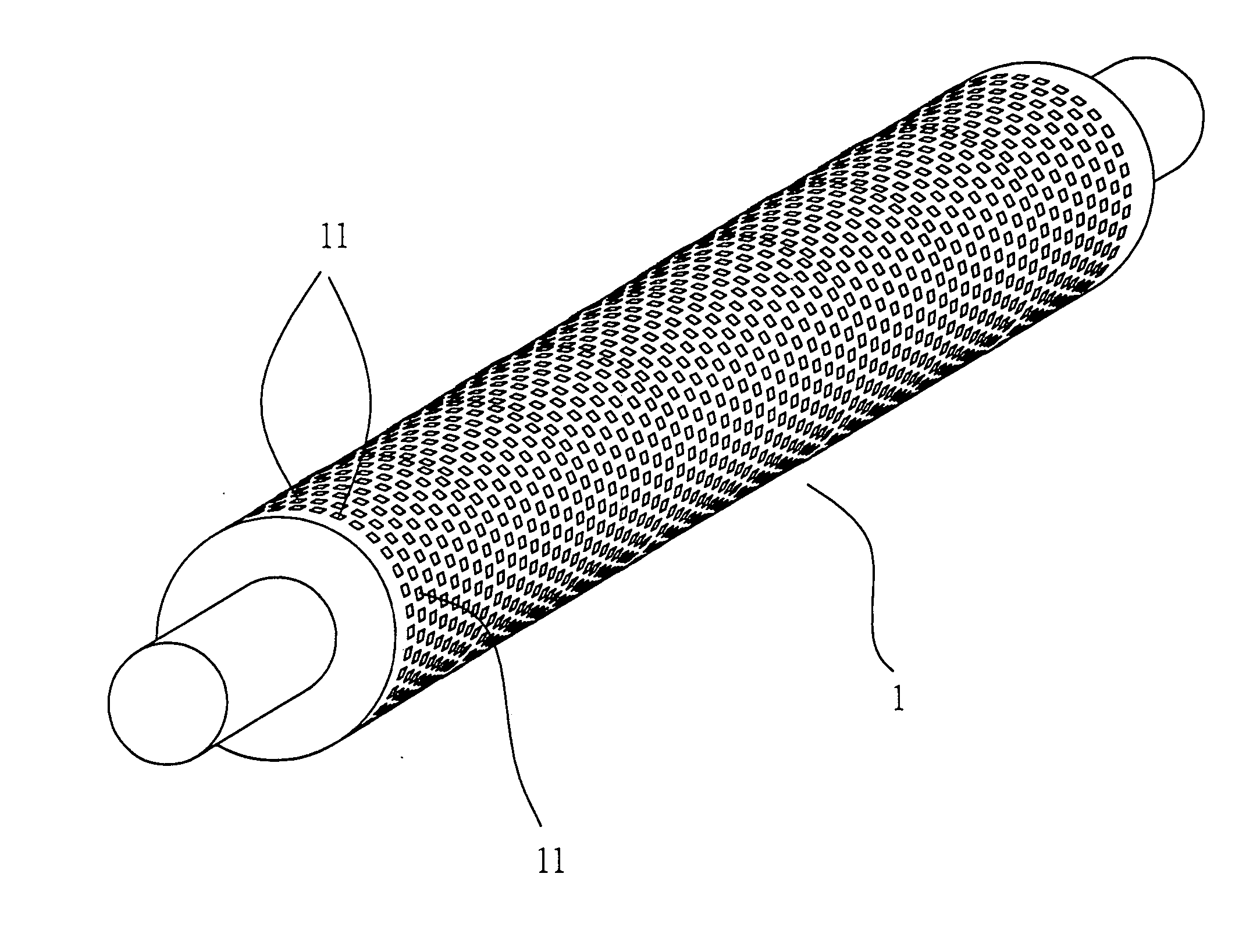

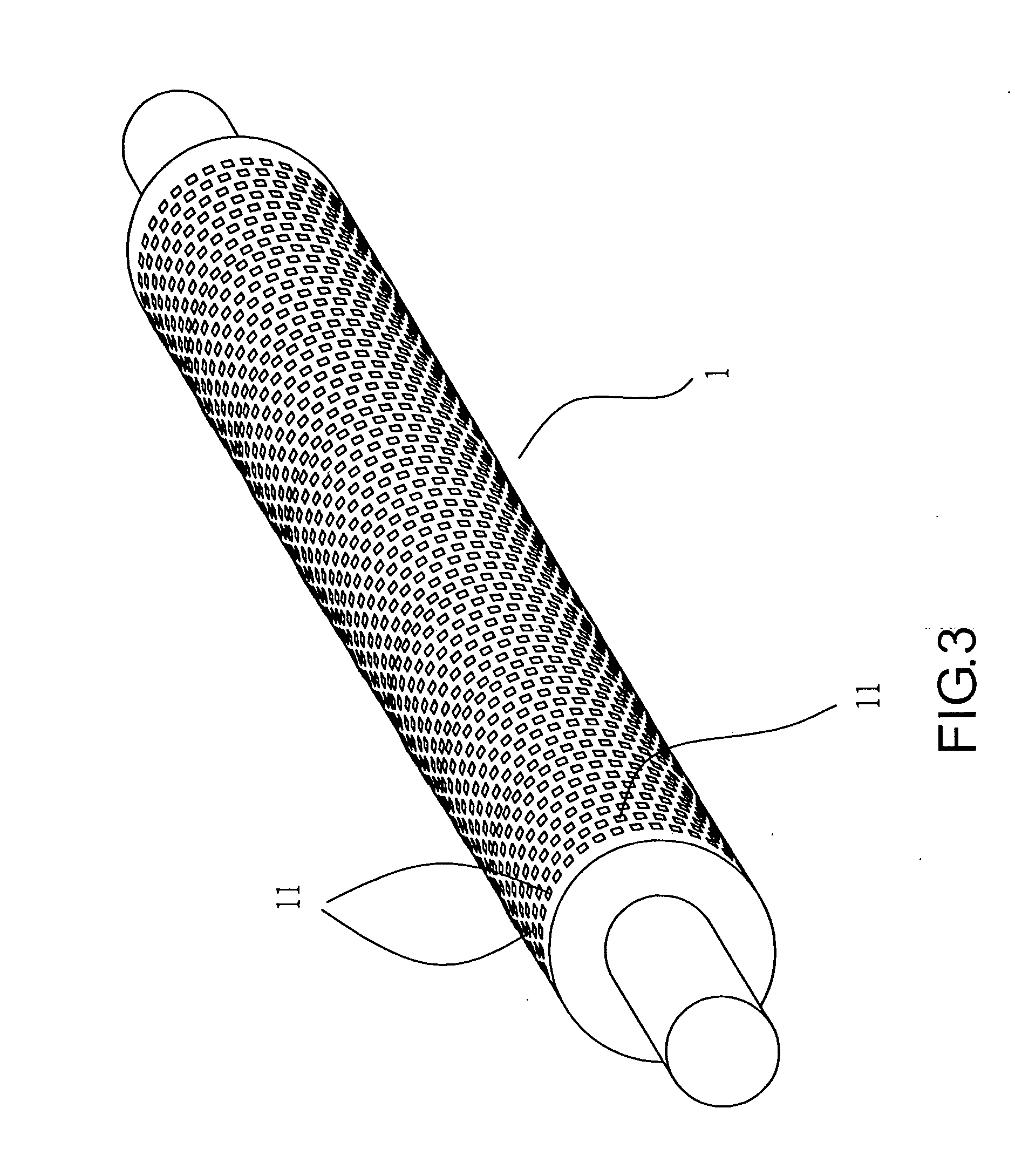

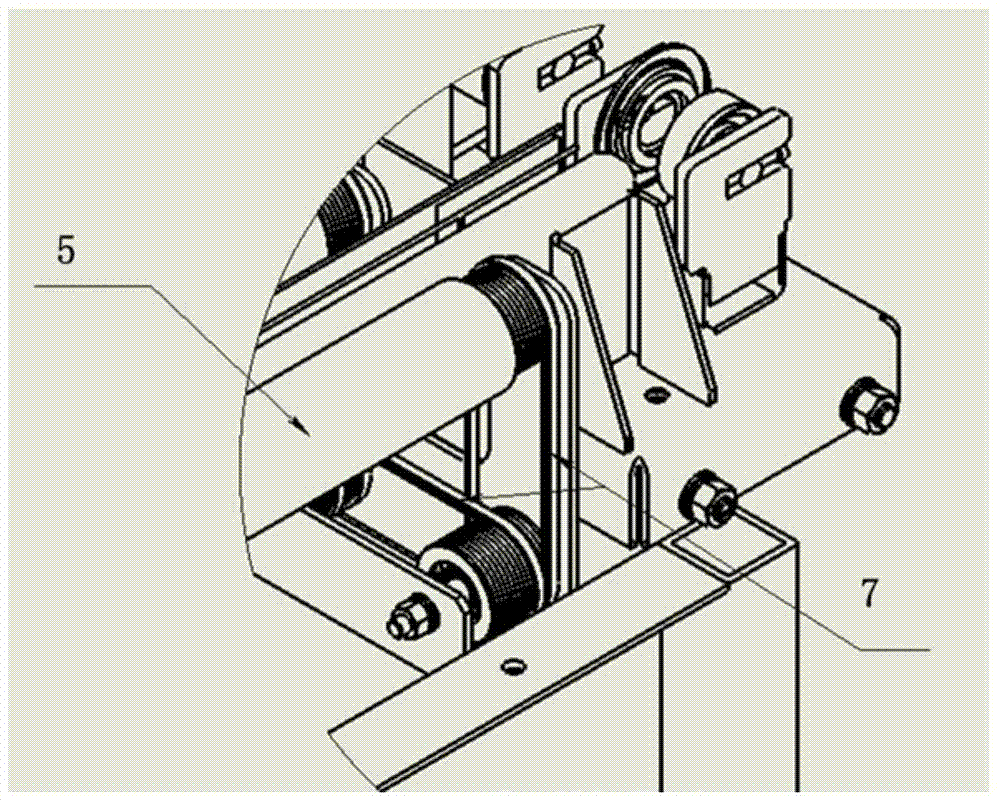

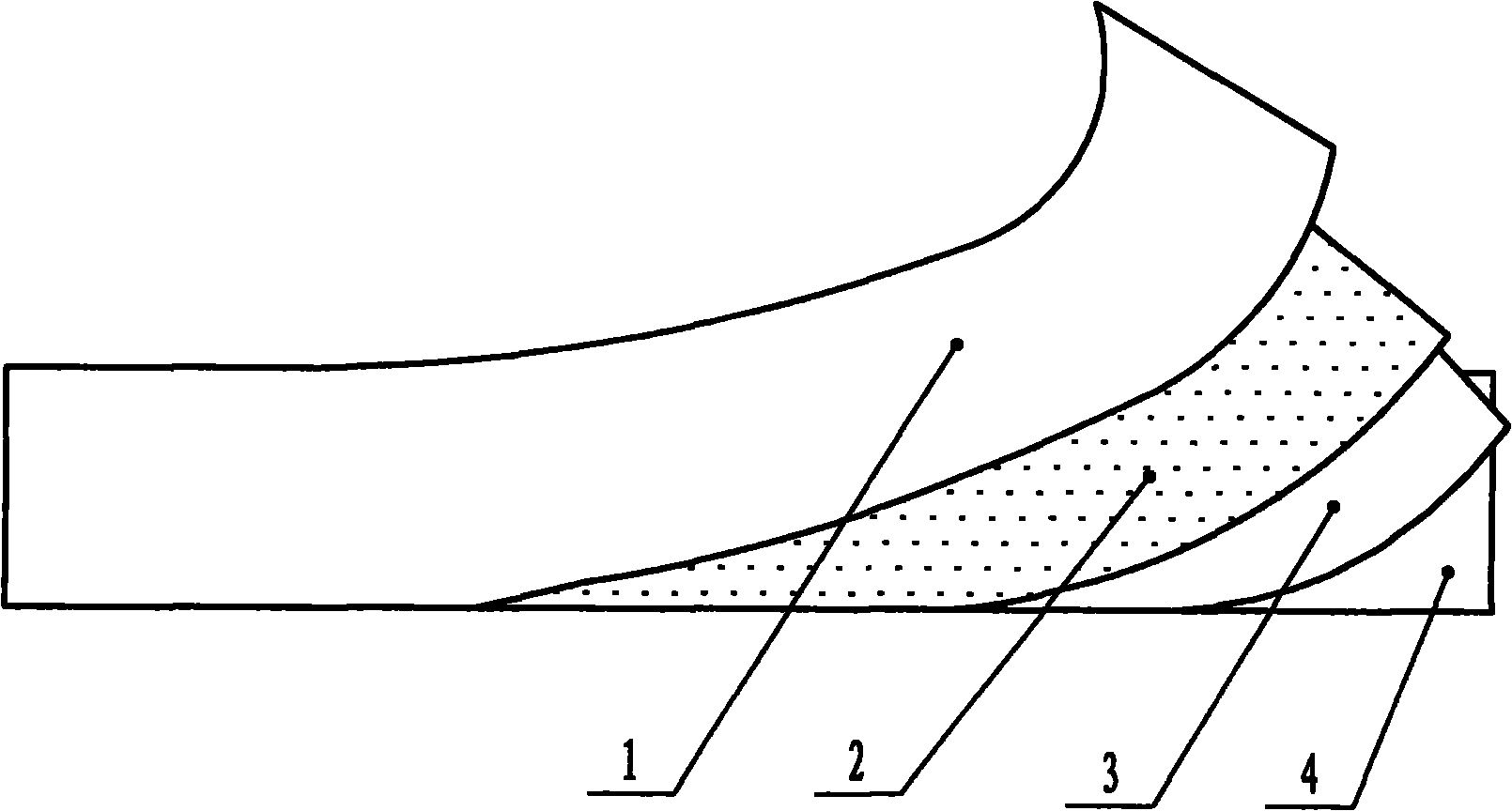

Etched type inkjet printer roller

InactiveUS20060111223A1Conveniently achieving requisite frictionEasy to controlAgricultural rollersRoads maintainenceInk printerEngineering

An etched type inkjet printer roller embodying a frictional surface that actuates conveying of paper sheets that is configured on a surface of the roller possessing standard precisions. The frictional surface is configured by employing etching technology that actualizes etch points below the standard precision surface, and which effectively preserves original degrees of precision possessed by the roller, thereby realizing convenience in manufacture of the roller, and ensuring requisite degrees of precision. The present invention improves upon shortcomings of current roller manufacturing processes that impair degrees of precision of the roller, creates enhanced effectiveness in functional practicability, and is a new model having practical value.

Owner:CHOU CHIH HUANG

Cloth winding drum device for textile machinery

InactiveCN107472951ARealize automatic windingConvenient coilingWebs handlingAgricultural engineeringDrive motor

The invention discloses a cloth reel device for textile machinery, comprising a base, a support column is fixedly connected to one side of the upper end of the base, and a top plate is fixedly connected to the top end of the support column, and a driving motor is arranged on the upper end of the top plate. And the lower end of the driving motor is provided with a rotating shaft, and the outward extension end of the rotating shaft passing through the inner wall of the top plate is provided with a limiting groove, and a first protrusion is inserted in the limiting groove, and the lower end of the first protrusion is fixedly connected with a The first fixed plate, the bottom end of the first fixed plate is evenly surrounded by several reels, the lower end of the second fixed plate is fixedly connected with the first fixed block through the disc, the lower end of the first fixed block A second protruding block is inserted through the groove, and the second protruding block is fixedly connected with a circular clamping block through the telescopic rod. The invention has the advantages of simple structure, easy installation and disassembly, more convenient cloth coiling, no manual winding, reduced labor force, improved production efficiency, and is suitable for wide popularization.

Owner:湖州胎福工艺品有限公司

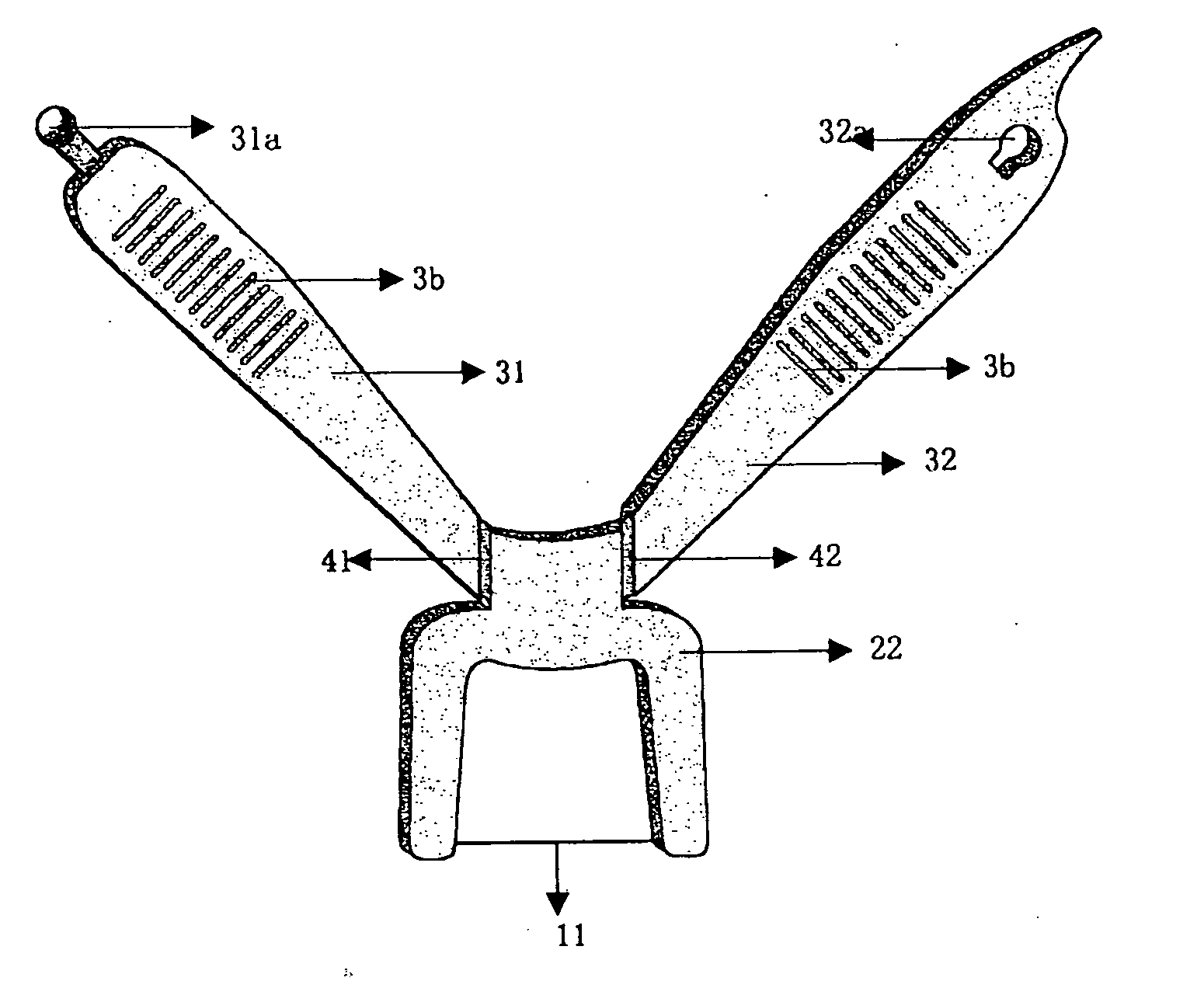

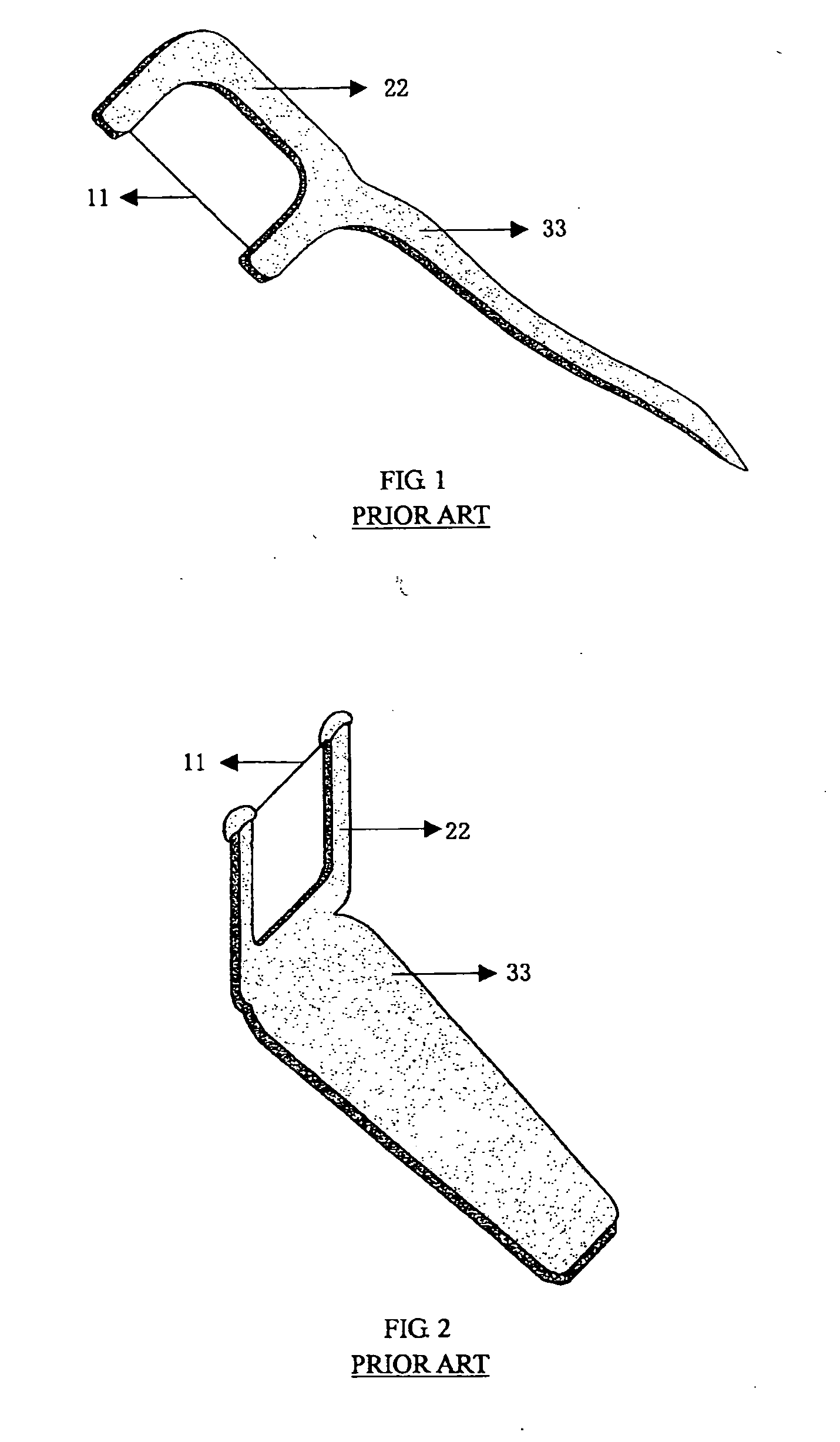

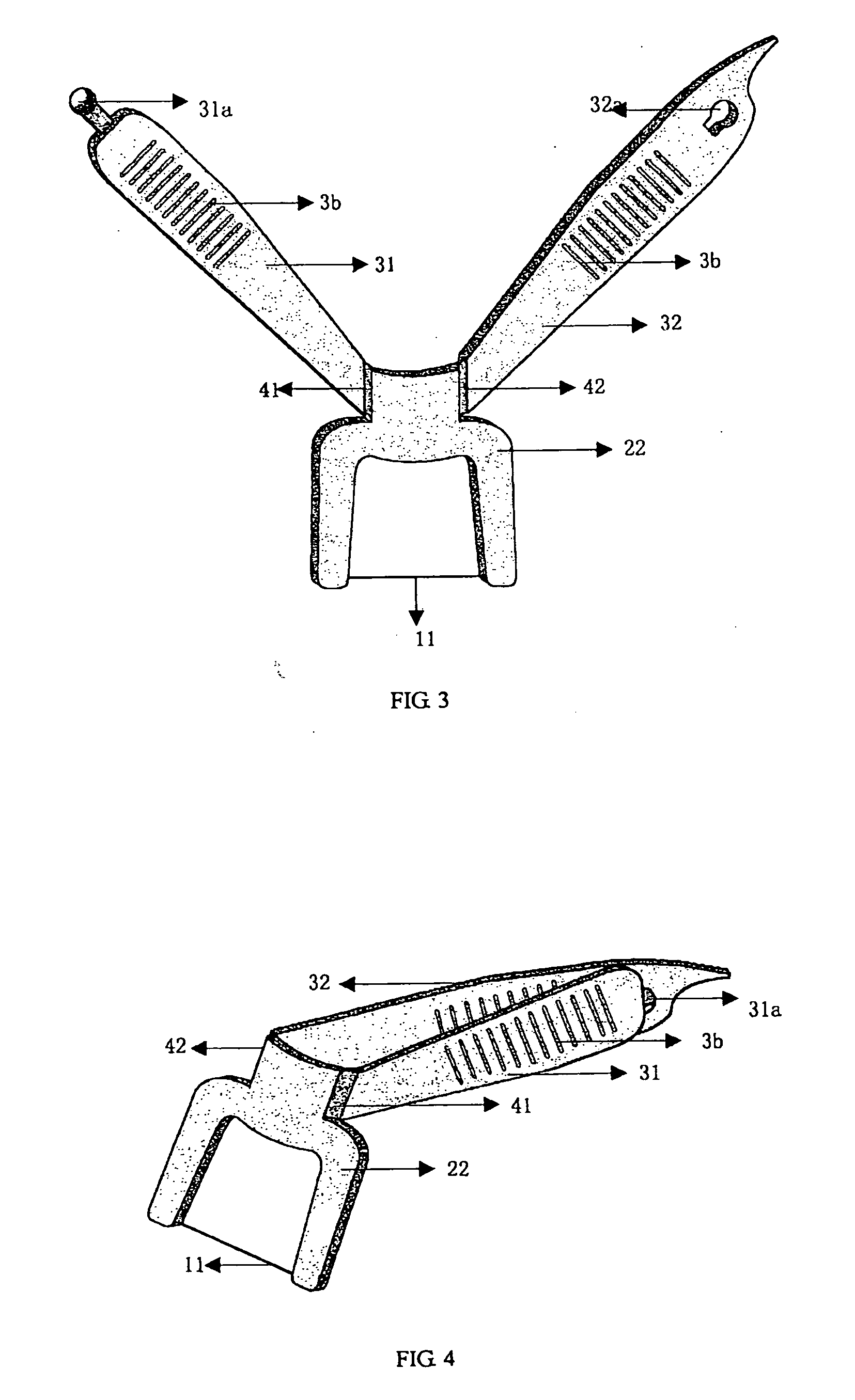

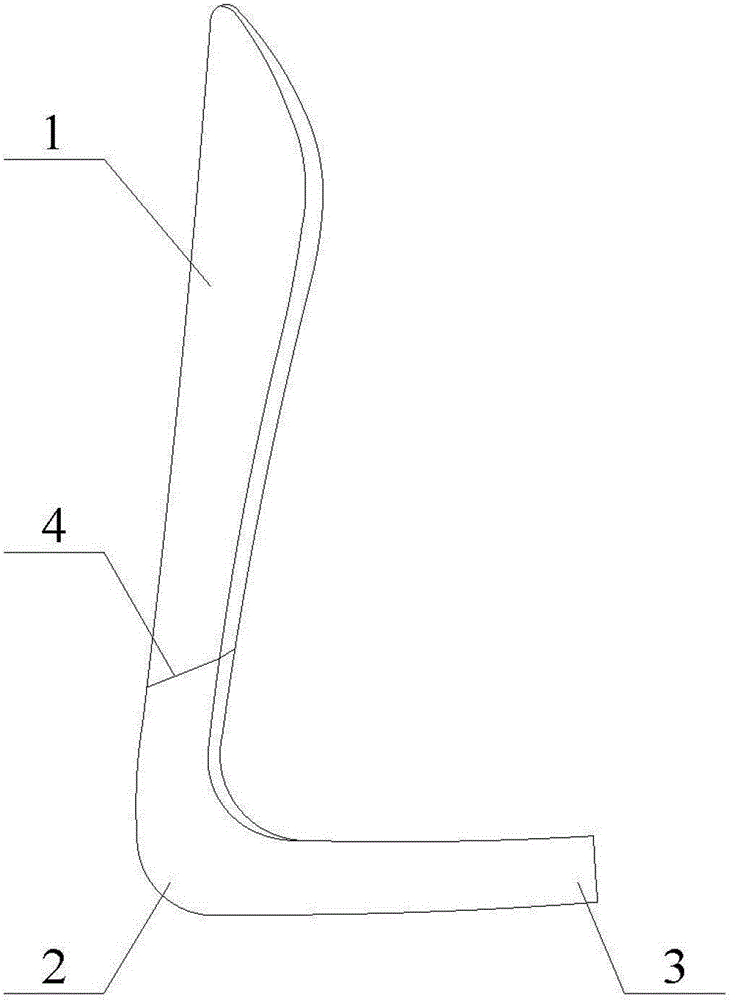

Dental flosser

InactiveUS20050133058A1Easy to packEasy portabilityGum massageDental flossDental flossingBuilding construction

A dental floss indicating a 2D construction in its non-use status and an L-shaped construction in use includes a U-shaped holder, a floss secured and bridged between two tops of the U-shaped holder, a left handle and a right handle respectively connected to both sides at the base of the U- shaped holder; a left hinge and a right hinge made thinner and allowing easy bending being respectively provided at where both handles are connected to the U-shaped holder; a left and a right locking means being respectively provided to both of the left and the right handles; the surface each of the left and the right handles being disposed with multiple ribs; and a tail hinge being disposed at where both ends from the left and the right handles are connected to each other.

Owner:DING SONGJUN

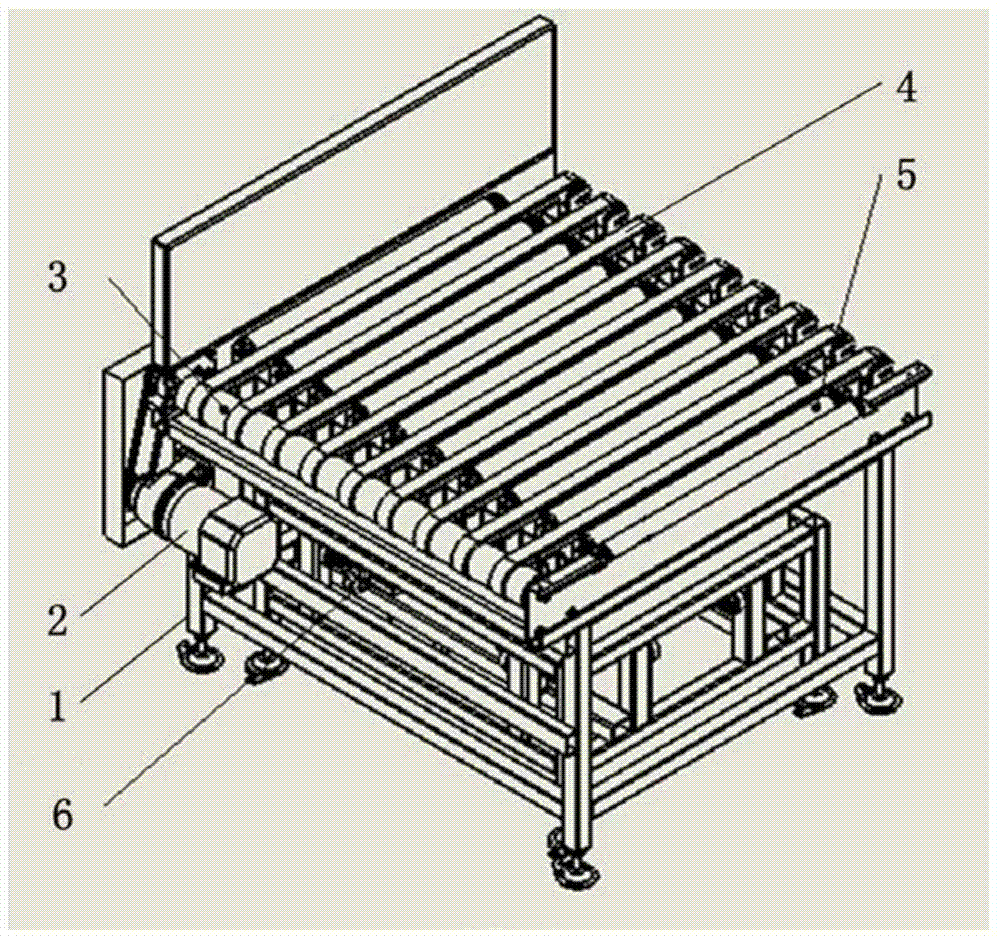

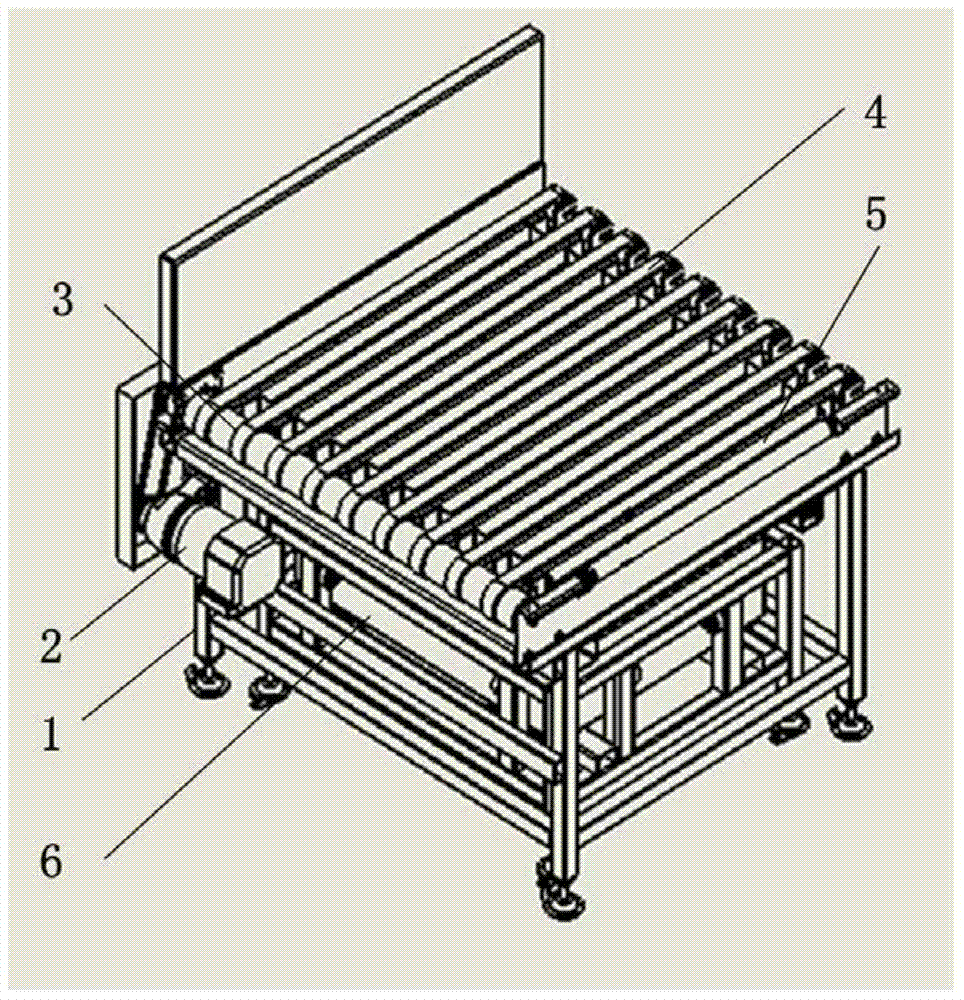

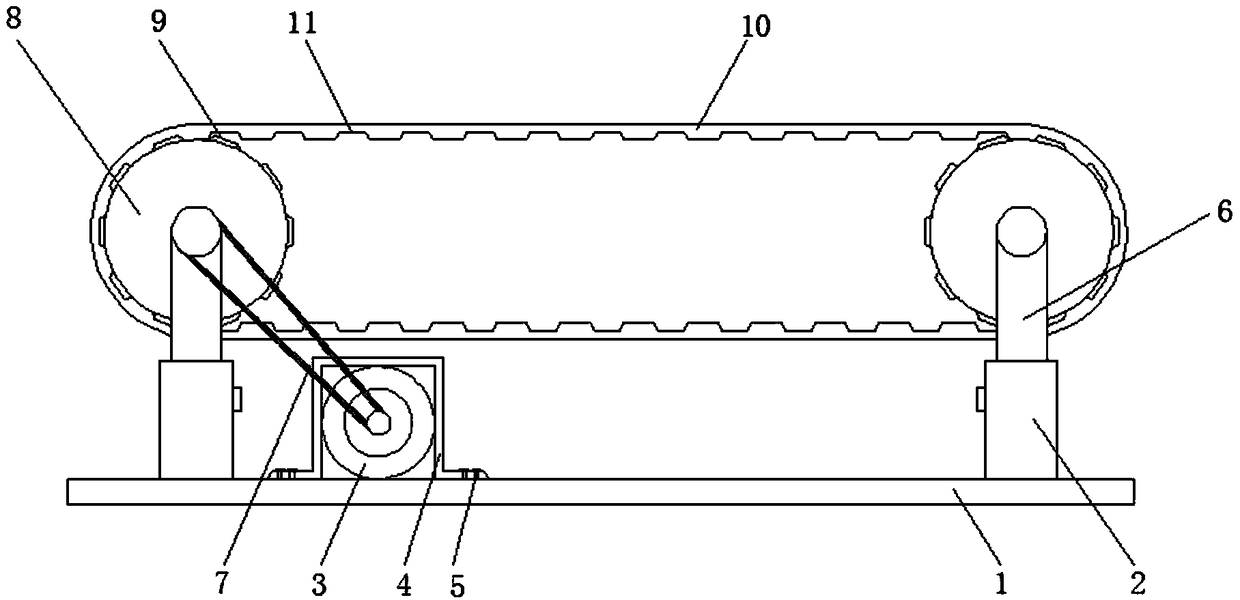

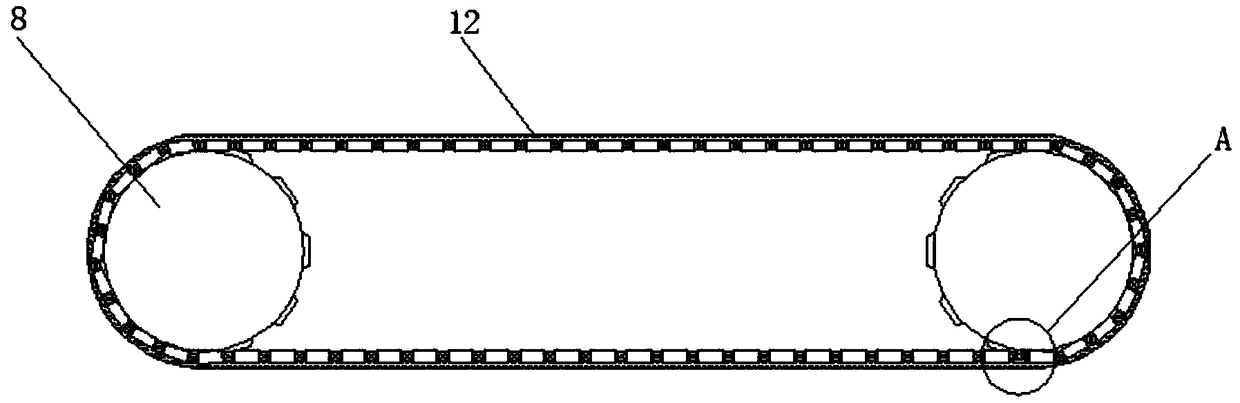

Belt type heavy transport machine

InactiveCN104261109AIncrease surface frictionNo slippageConveyor partsEngineeringMechanical engineering

The invention discloses a belt type heavy transport machine, comprising a main frame, a belt type transport module, a conveying module and a jacking module, wherein the belt type transport module is arranged at the top of the main frame, the conveying module is arranged under the belt type transport module, the jacking module is arranged under the conveying module for lifting the same, and the conveying module moves in the space between the jacking module and the belt type transport module. The belt type heavy transport machine is applicable to transporting heavy objects, has the advantages of being low in noise, high in stability and easy to maintain, and is applicable to the field of industrial and logistic transport.

Owner:SHANGHAI REFINE AUTOMATION SYST

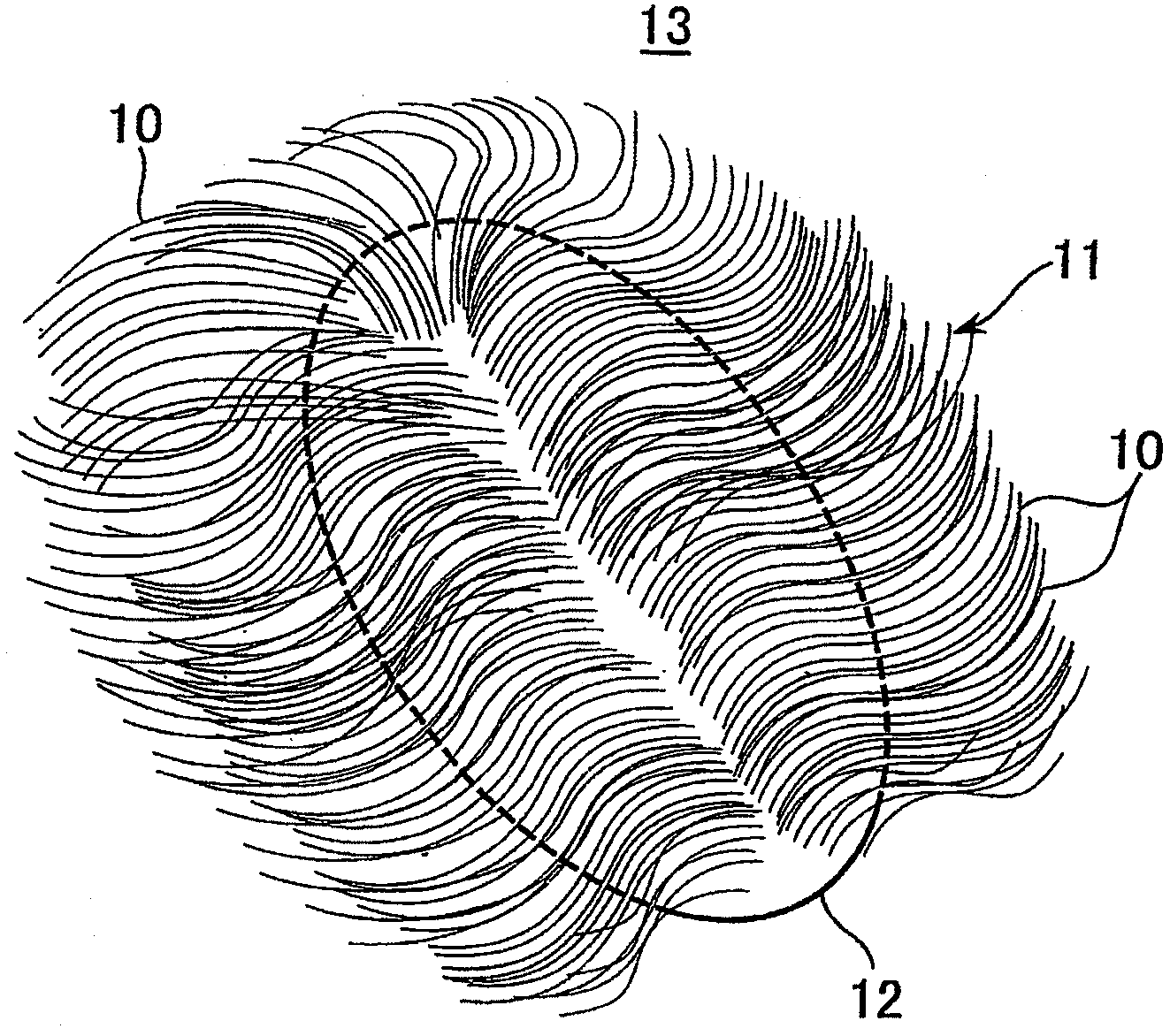

Wig

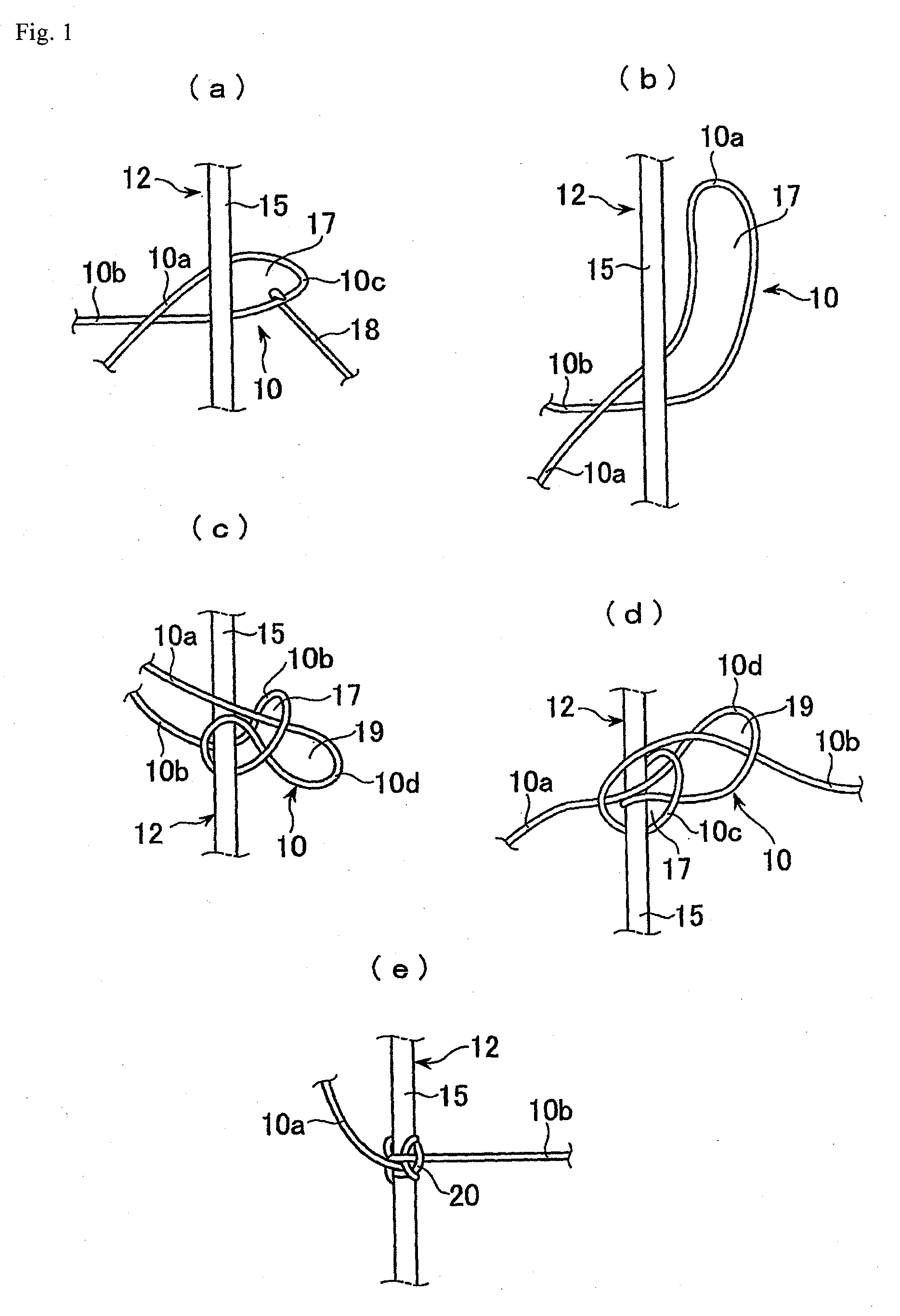

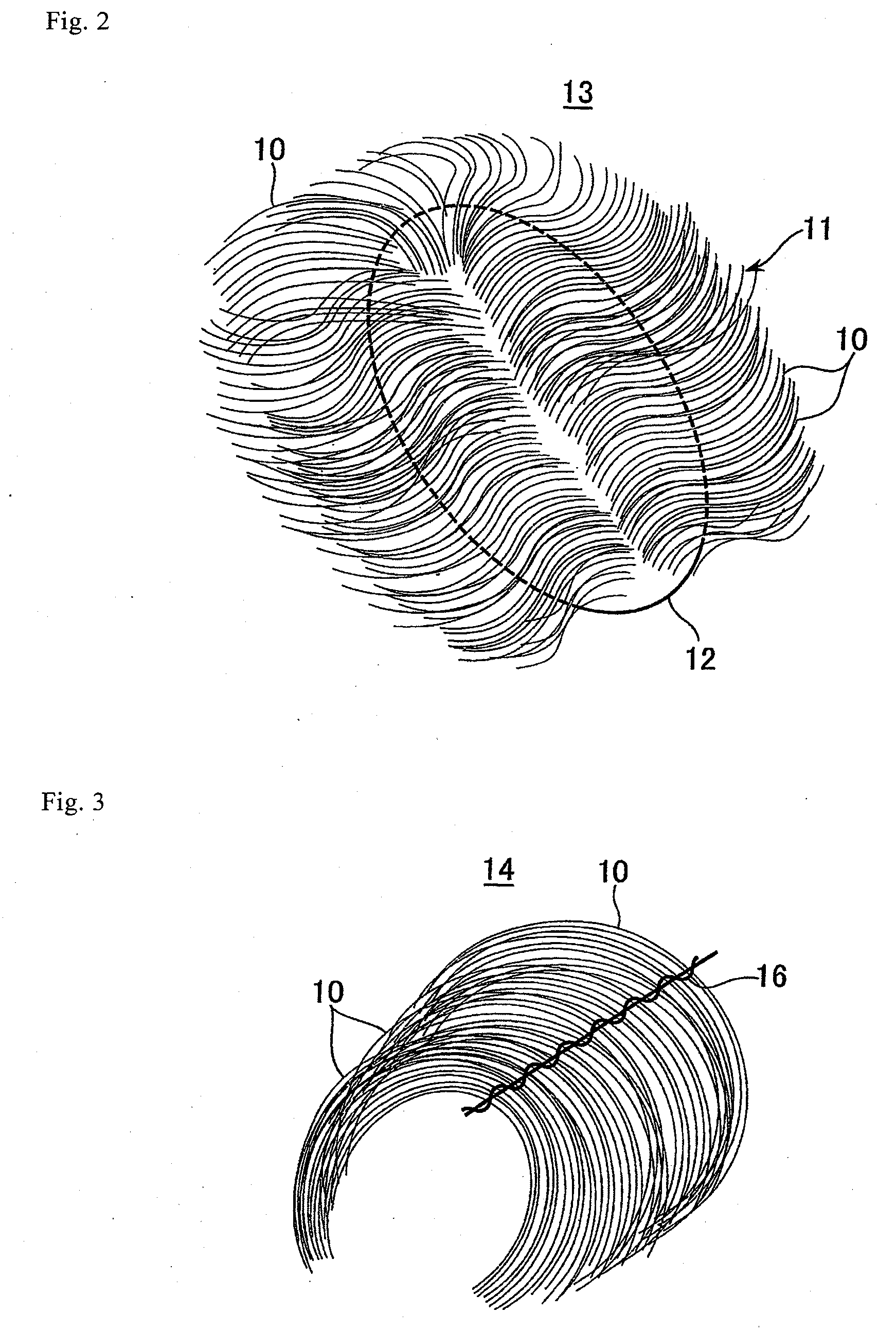

InactiveUS20090165810A1Easy to getIncrease freedomHair accessoriesToupeesMechanical engineeringHair - material

A hair material for a wig is preliminarily curled and then bound to a wig base to thereby orient the curled hair in a definite direction. A folded part (10c) of a hair material (10) is penetrated from one side of a filament (15) to the other side under a wig base (12) so that a first loop (17) is formed in the inner side of the folded part (10c). A curved part (10d) is inserted though the first loop (17) so that a second loop (19) is formed in the inner side of the curved part (10d). A part (10b) of the hair material is inserted through the second loop (19). Next, the hair material parts (10a, 10b) are pulled in directions opposite to each other and tied with the filament (15) to (20). Thus, the hair material (10) is bound to the filament (15).

Owner:ADERANS HLDG CO LTD

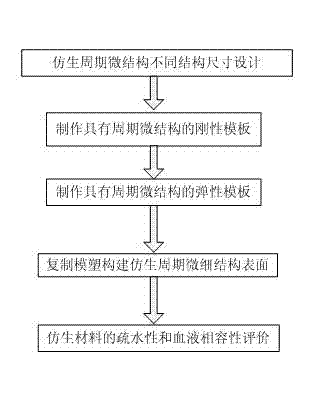

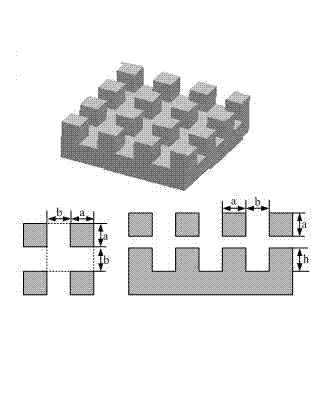

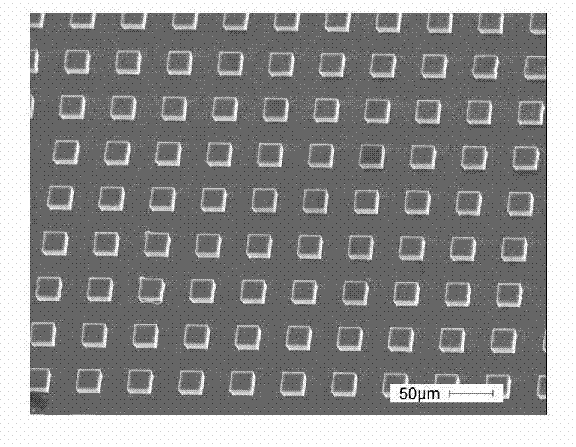

Method for constructing hemocompatible material surface with bionic periodic structure

The invention relates to a method for constructing a hemocompatible material surface with a bionic periodic structure. The method comprises the following steps of: deducing a theoretical prediction formula of surface appearance contact angle of the periodic micro-structure surface according to a micro-pillar surface model, and determining whether the designed micro-structure surface has ideal super-hydrophobicity according to the formula; etching to form a micro-pillar hard template with array structure according to the periodic micro-structure, casting PDMS (polydimethylsiloxane) on the hard template, allowing cross-linking and curing of the PDMS, and stripping off the cured film as an elastic template; and casting a prepolymer on the elastic template, and curing to form a micro-pattern on the polymer surface, which is complementary to the elastic template but similar to the original template. The bionic hemocompatible material constructed by the invention can effectively inhibit adhesion and deformation of platelets, prevent activation of coagulation pathway and increase duration of anticoagulation. Besides, the wetting property of the interface is improved by reasonable regulation of surface geometric dimension, so that the hemocompatibility of the material is improved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

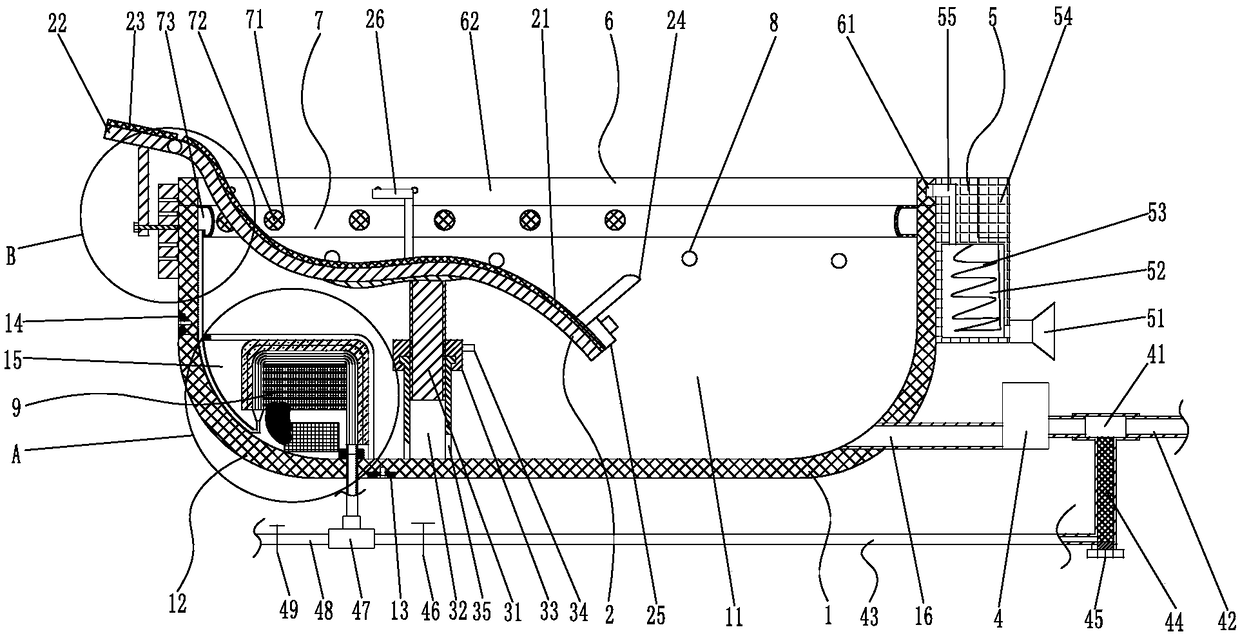

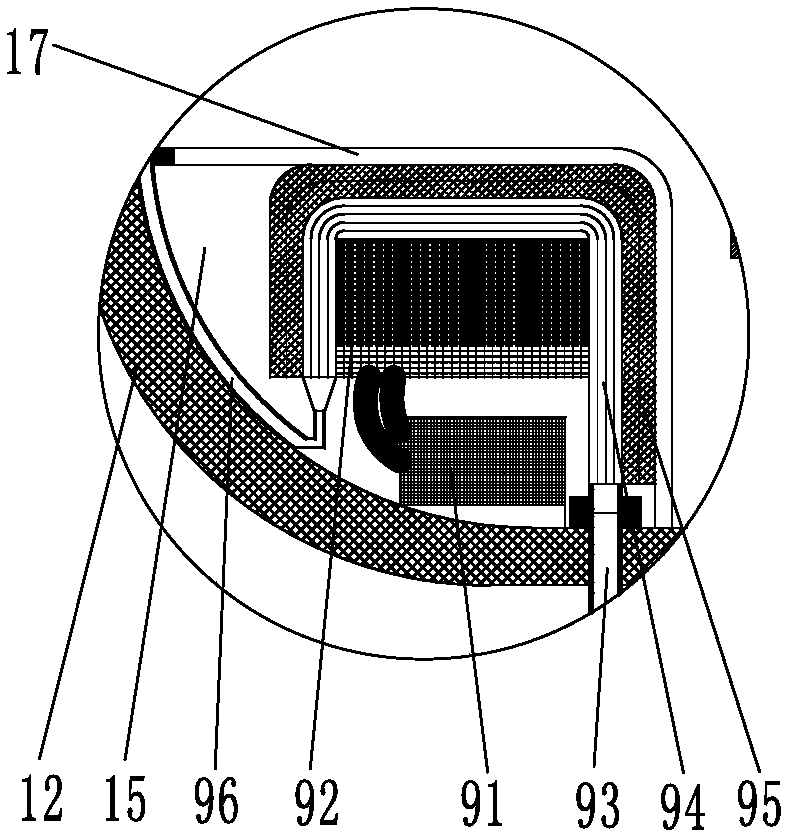

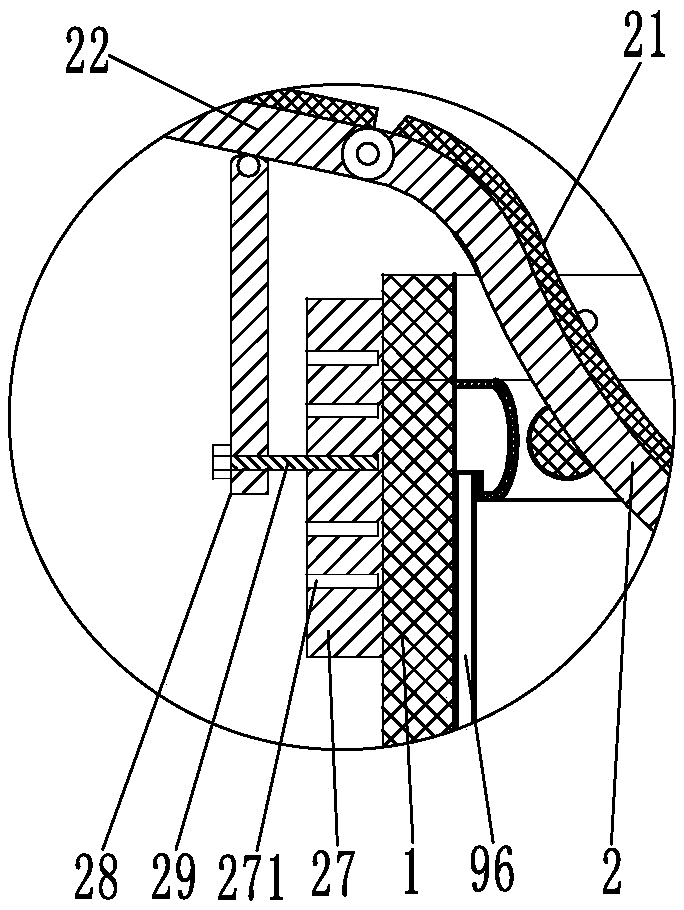

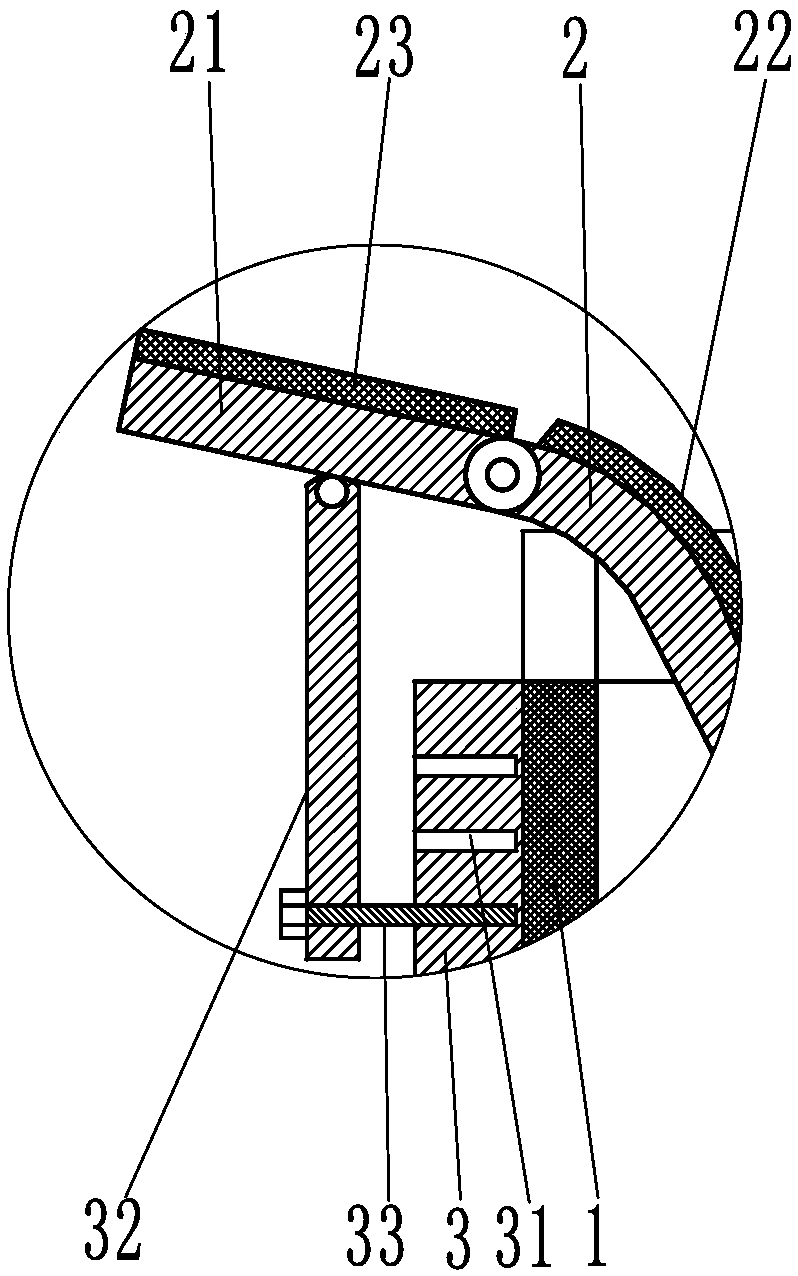

Midwifery delivery bed

ActiveCN108245355AIncrease surface frictionPrevent slippingDiagnosticsOperating tablesEngineeringCirculating pump

The invention discloses a midwifery delivery bed. The midwifery delivery bed is used for underwater delivery. The bed comprises a delivery pool, a delivery bed body, a lifting mechanism, a circulationpump, a heating mechanism, a drainage pipe, a circulation water pipe and a controller. The delivery bed body is arranged in the delivery pool and connected with the lifting mechanism, the lifting mechanism is fixed to the bottom of the delivery pool, and an equipment mounting cavity of a closed structure is separated from the interior of the delivery pool through an arc partition plate; the heating mechanism is arranged in the equipment mounting cavity and provided with a water inlet and a water outlet, and the water outlet is communicated with the delivery pool through a hot water pipe; thecirculation pump is connected to a drainage port of the delivery pool, an outlet of the circulation pump is connected with the drainage pipe and the circulation water pipe separately, and the water inlet of the heating mechanism is connected with an external water supply pipe and the circulation water pipe separately. When water of the circulation water pipe or the external water supply pipe enters the heating mechanism, the water is heated by the heating mechanism, and the heated water is conveyed into the delivery pool through the hot water pipe connected with the water outlet of the heatingmechanism. The midwifery delivery bed is reliable to implement, convenient to operate and low in cost.

Owner:仇迪

Obstetric midwifery bed

InactiveCN108245354AImprove water qualityIncrease surface frictionOperating tablesAmbulance serviceActivated carbon filtrationObstetric history

The invention discloses an obstetric midwifery bed for water delivery. The obstetric midwifery bed comprises a water heater, a delivery pool, a delivery bed, a lifting mechanism, a circulating pump and a controller. The delivery bed is arranged in the delivery pool, the middle of the lower surface of the delivery bed is connected with the lifting mechanism, the lifting mechanism is fixed to the bottom of the delivery pool, the delivery pool is provided with a hot water inlet and a drain port, the drain port is connected with the circulating pump, and the water heater is provided with a first water inlet, a second water inlet and a water outlet. The first water inlet is connected with an external water supply pipeline, a three-way pipe is connected to the outlet of the circulating pump, oneconnector on the trunk of the three-way pipe is connected with the outlet of the circulating pump, the other connector on the trunk of the three-way pipe is connected with a drain pipe, the branch ofthe three-way pipe is connected with the second water inlet of the water heater through a circulating water pipeline, the branch connecting part of the circulating water pipeline and the three-way pipe is filled with an activated carbon filtration column, and the water outlet of the water heater is connected with the hot water inlet of the delivery pool through a pipeline. The obstetric midwiferybed has the advantages of implementation reliability, operation convenience and low cost.

Owner:马红英

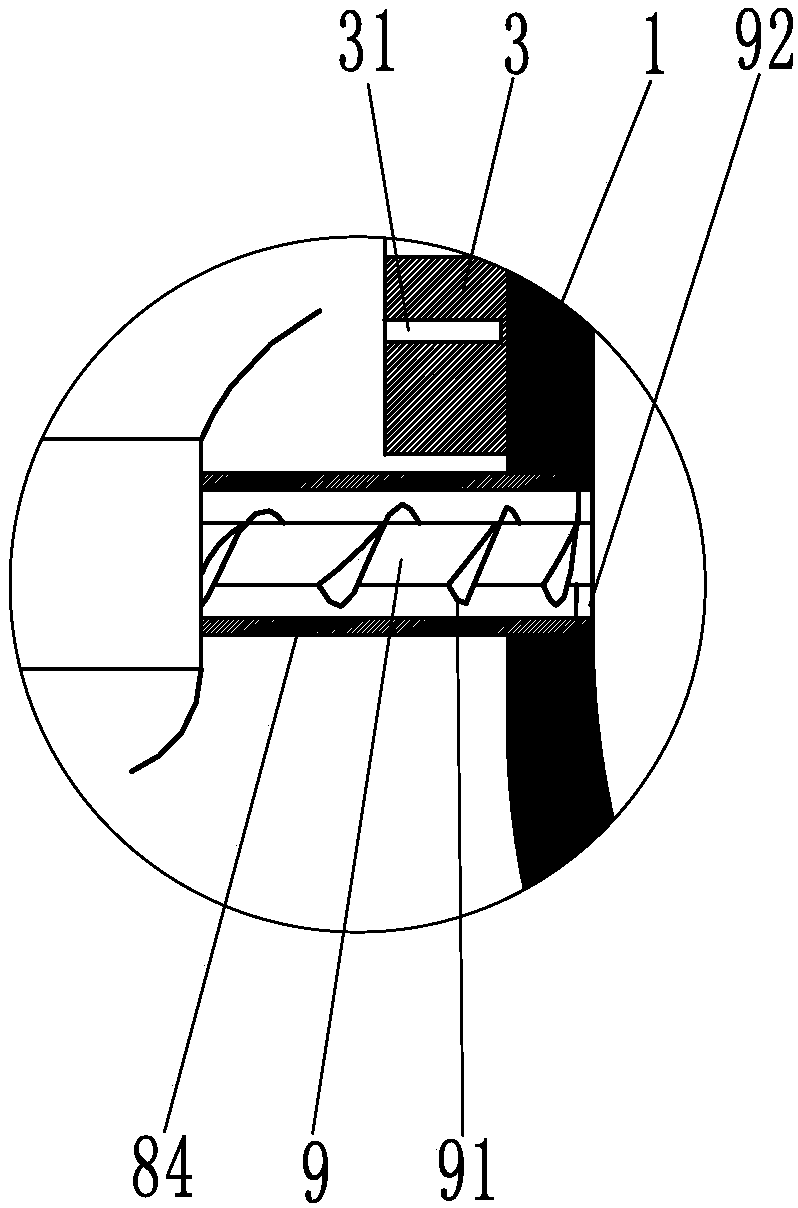

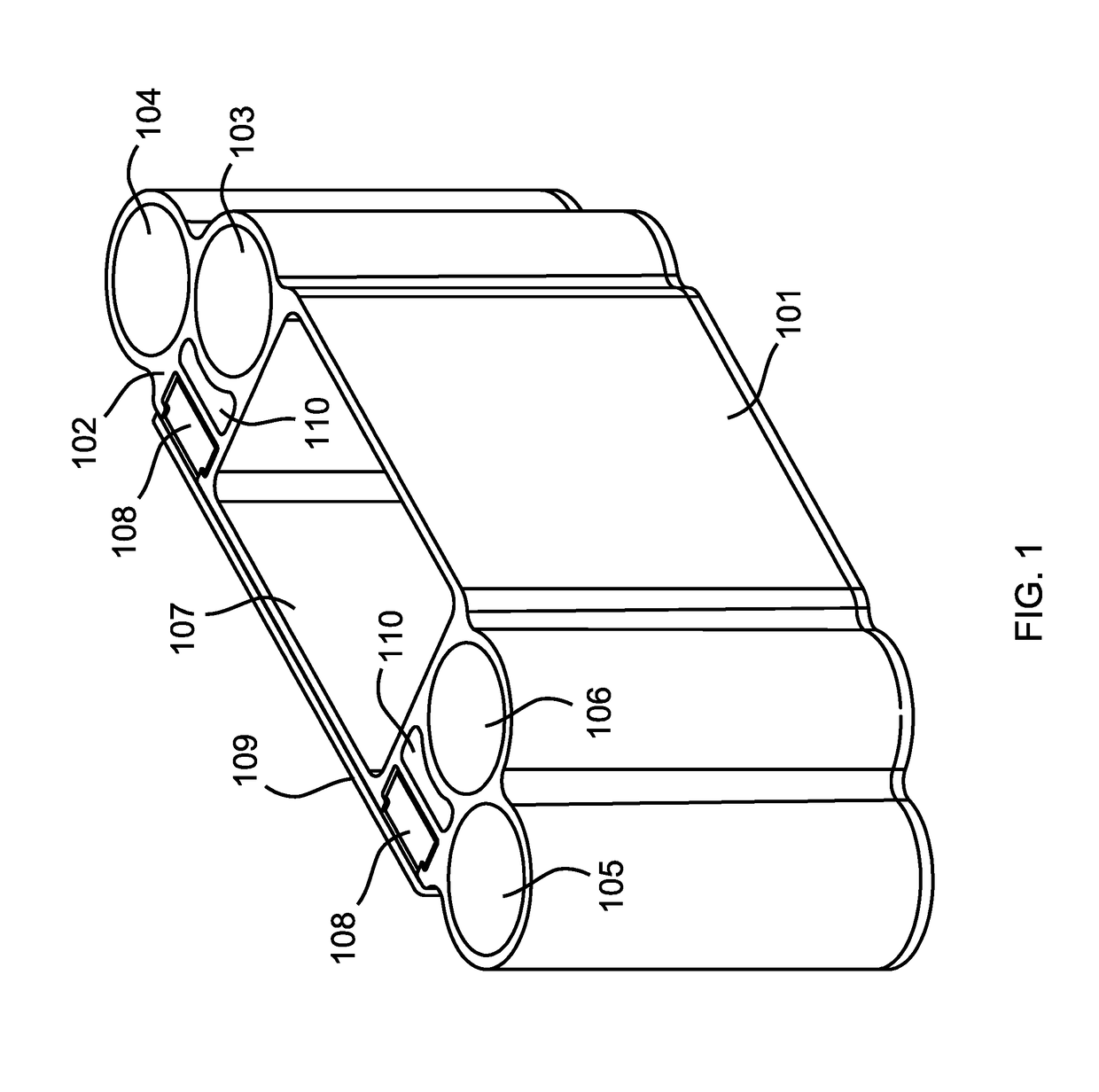

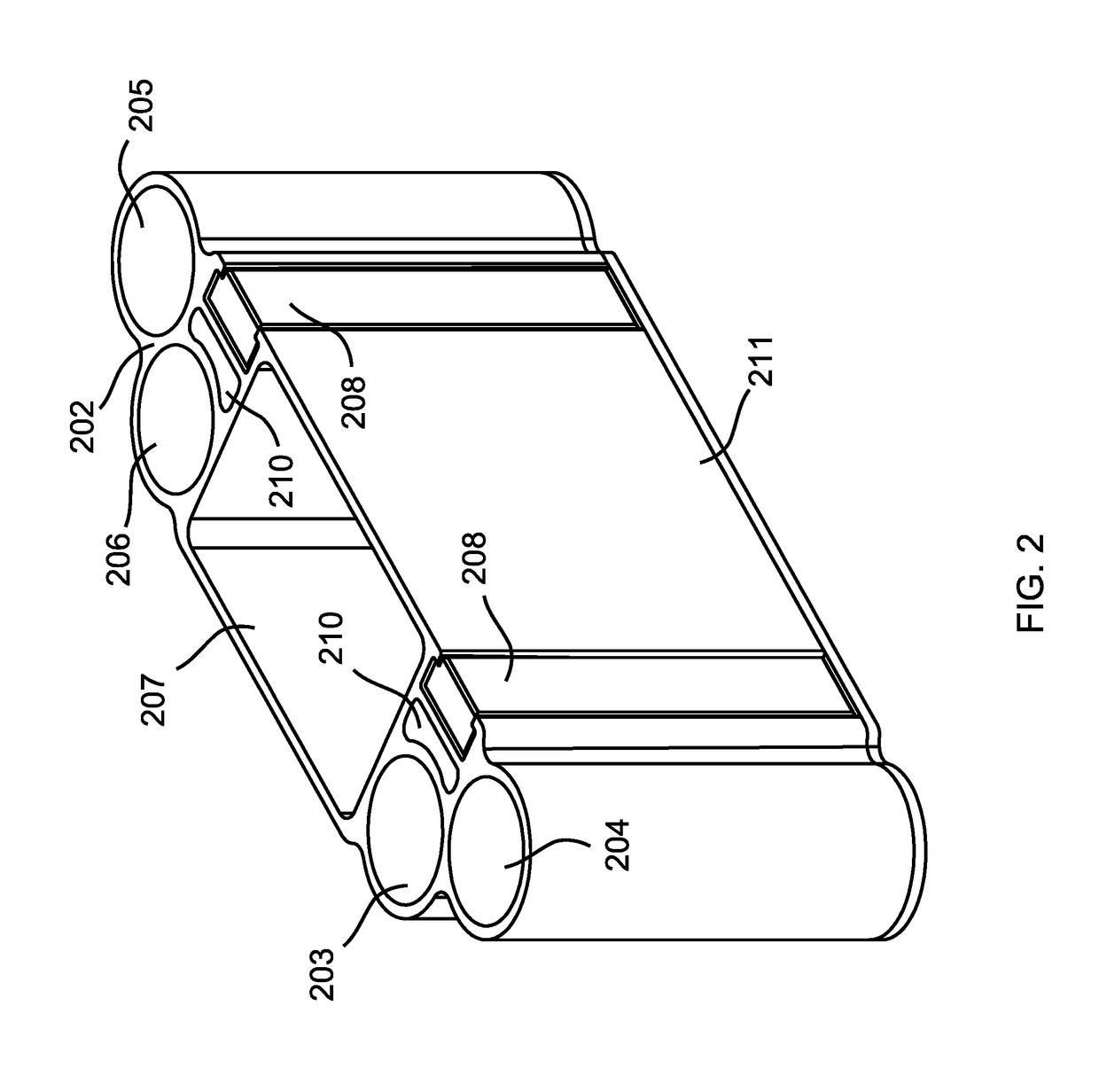

Sure-grip rca-type connector and method of use thereof

InactiveUS20080248688A1Improve reliabilityIncrease surface frictionElectrically conductive connectionsCoupling device detailsCoaxial cableMechanical engineering

A sure-grip RCA-type coaxial cable connector is provided, wherein the connector comprises a connector body having an external surface upon which at least two gripping rings are securely located. Friction-enhancing surface features are positioned upon at least a portion of the external surface of the connector body between at least two of the gripping rings. Sure-grip fastening of the connector to an interface port is provided by gripping the connector so as to engage the gripping rings and the friction-enhancing surface features while maneuvering the connector onto an interface port.

Owner:PPC BROADBAND INC

Height-adjustable spliced conveying device

The invention discloses a height-adjustable conveying device. The height-adjustable conveying device comprises an underframe, a belt, connecting blocks, hydraulic cylinders, sliding grooves and sliding blocks. Supporting columns and a motor are arranged on the underframe. The supporting columns are located on the two sides of the motor. Telescopic shafts penetrate into the supporting columns. Rotary shafts are movably mounted at the upper ends of the telescopic shafts. The rotary shafts are provided with outer teeth. A conveyor belt is arranged on the outer sides of the rotary shafts. Groovesare reserved in the inner side of the conveyor belt. Splicing blocks are arranged on the outer sides of the rotary shafts. The left and right ends of the splicing blocks are connected with fixed shafts. Each connecting block is arranged between the two corresponding fixed shafts. The hydraulic cylinders are arranged in the supporting columns. The sliding grooves are reserved in the underframe. Thesliding blocks are fixedly mounted below a fixed frame. The height-adjustable conveying device has the advantages that the height of the conveying device and the length of the conveyor belt can be adjusted, andthe surface friction force is large, and is suitable for material conveying on various occasions.

Owner:安吉飞龙金属制品厂

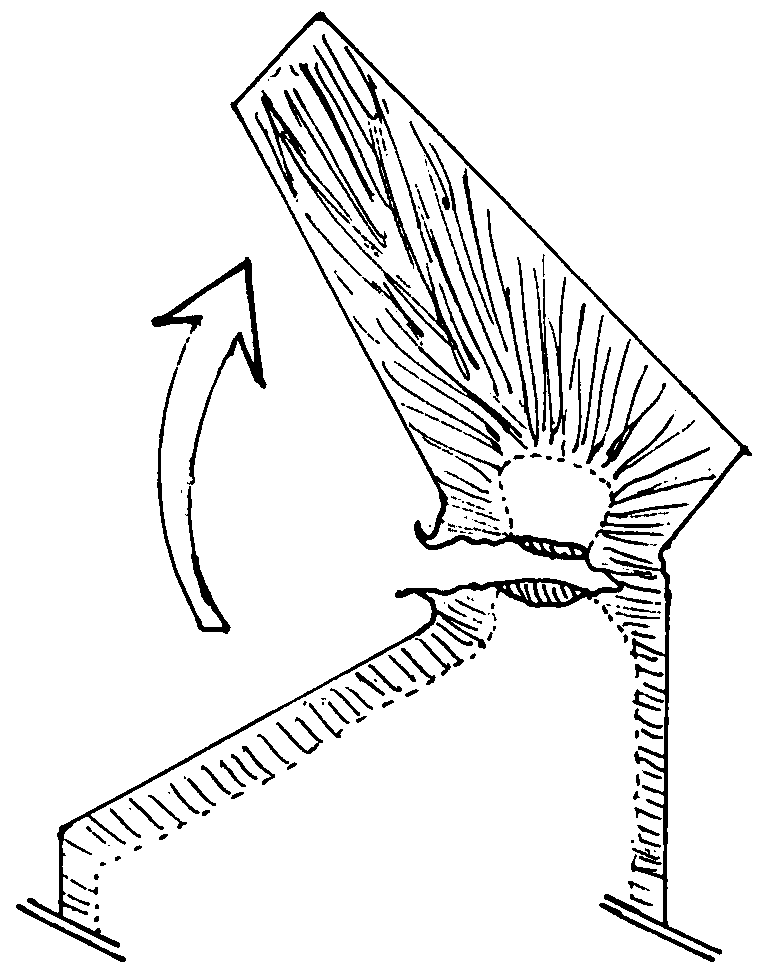

Irregularly surfaced H pile

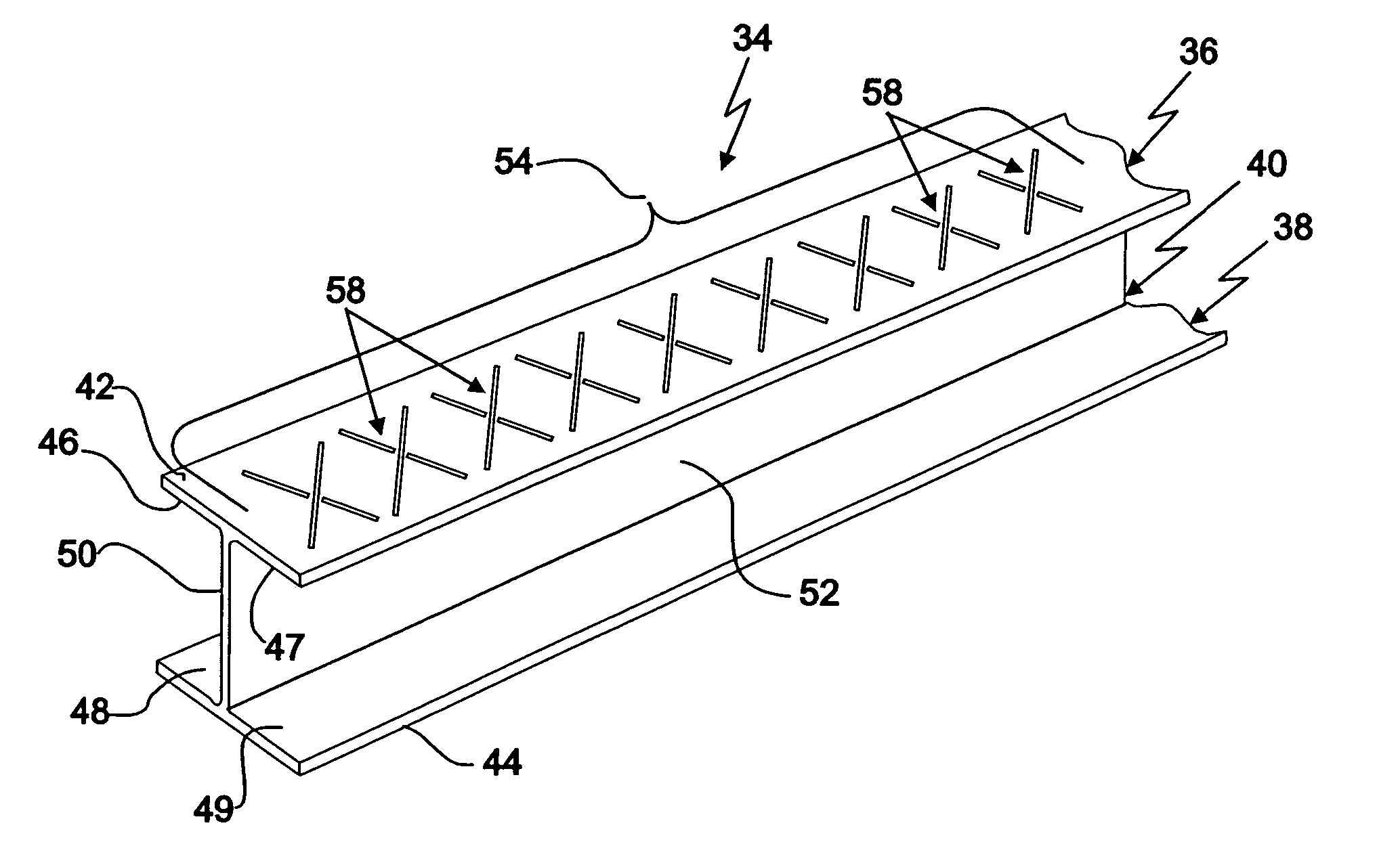

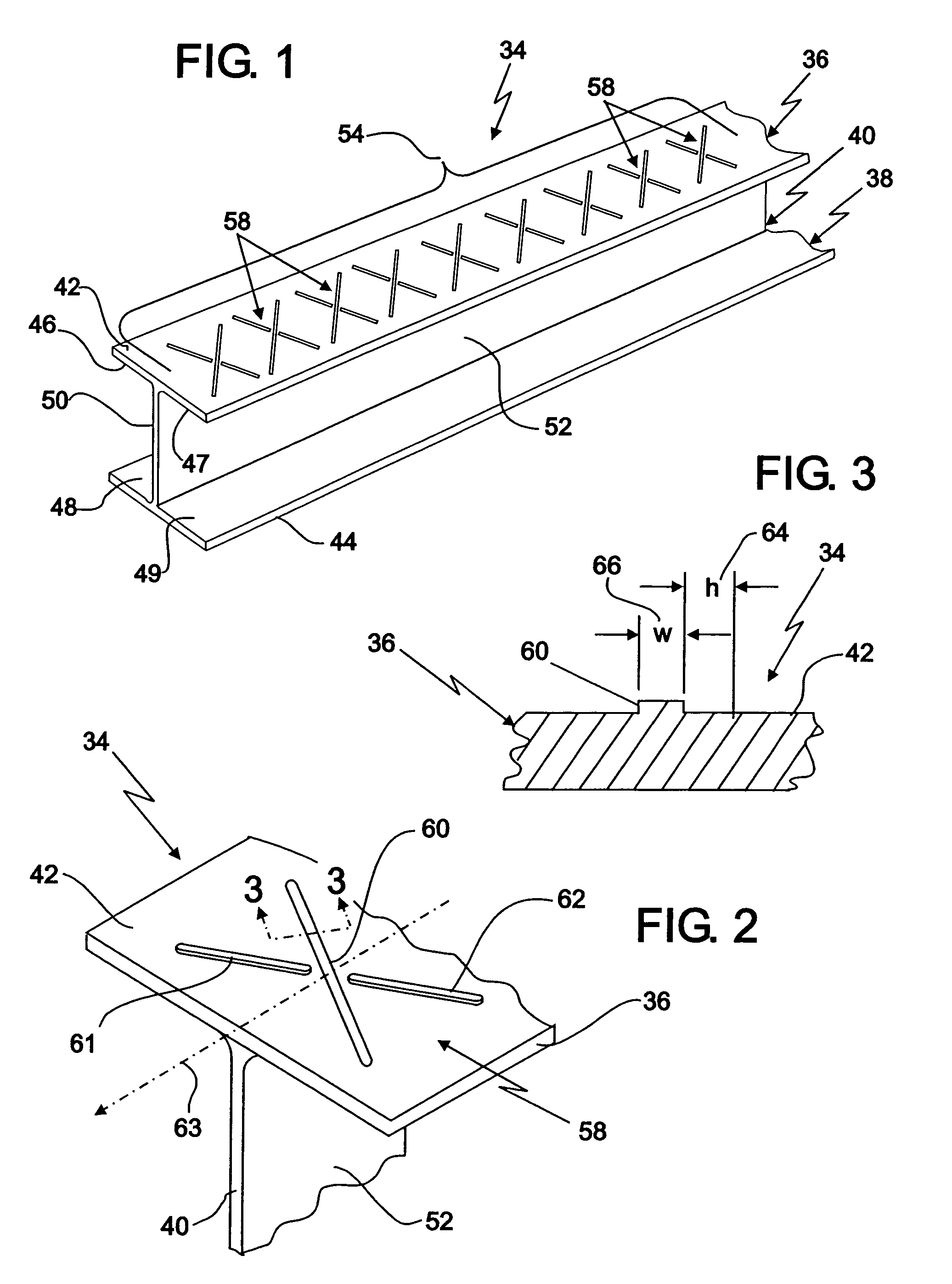

ActiveUS7556454B2Increase surface frictionImprove carrying capacityBulkheads/pilesFlangeSurface friction

A steel H pile has a relief design embossed on one or more major surfaces of either or both of its steel flanges and its web to provide surface irregularities thereon which increase the pile's surface friction and its friction pile load bearing capacity.

Owner:NUCOR YAMATO STEEL

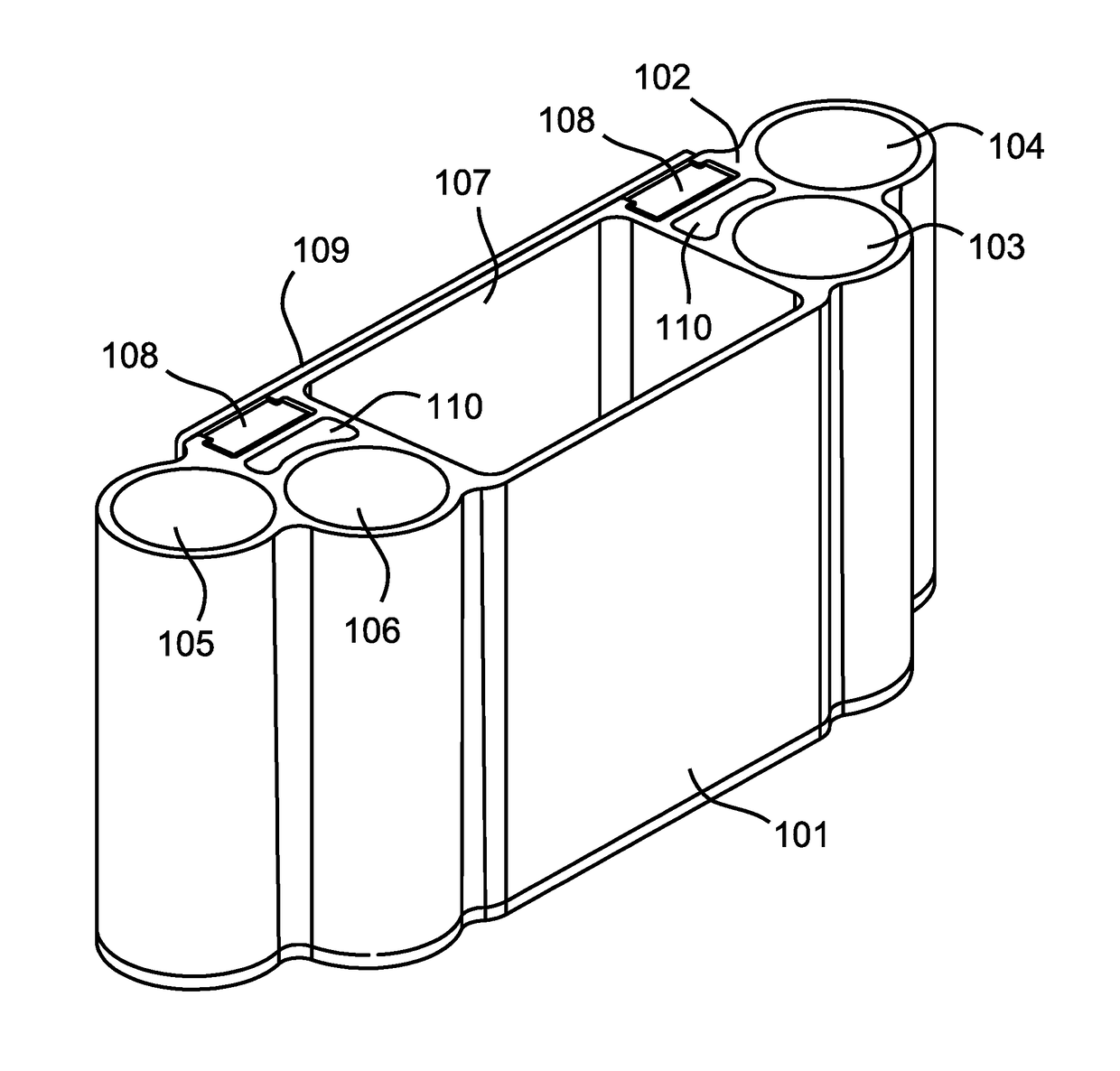

Magnetic whiteboard utility holder

InactiveUS9969208B1Increase surface frictionImprove magnetic propertiesBoard cleaning devicesErasing devicesWhiteboardEngineering

The utility holder was designed to allow stored markers an extended life of working effectiveness. The design has one or more cylindrical recesses with a tapered bottom in which a dry-erase marker cap may be held in place in order that a dry-erase marker may be placed inside the cylindrical recess upside down, snapping into the dry-erase marker cap. The upside down placement of the markers in the magnetic whiteboard utility holder allows the markers maximum life. There are one or more magnets on the back surface of the utility holder which allows for it to adhere to a magnetic whiteboard. The utility holder also has a cuboid recess, which allows for a dry-erase eraser to be stored.

Owner:HALL LABS LLC

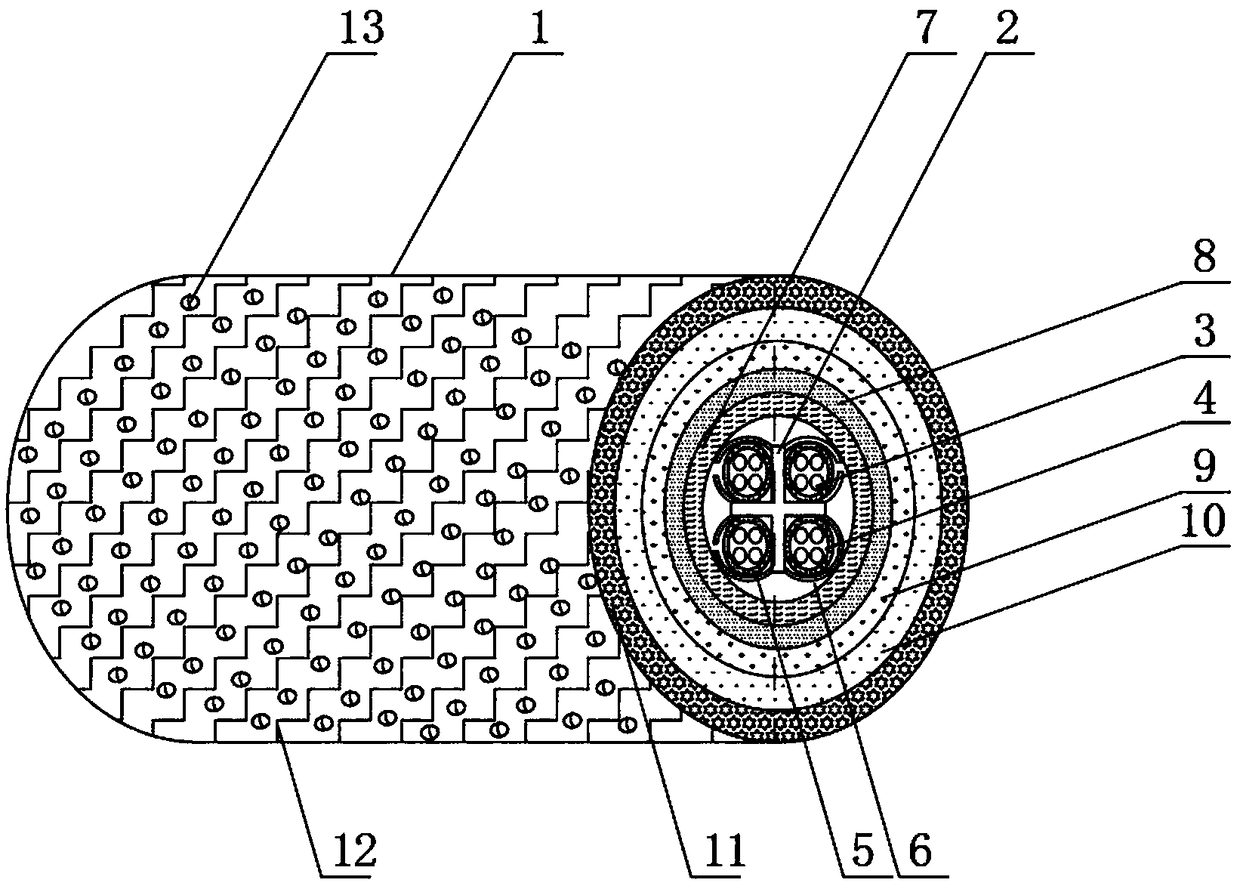

A copper-core armored power cable with a fire extinguishing function

InactiveCN109087743AImprove stabilityAvoid breakingPower cables with screens/conductive layersInsulated cablesPower cableEngineering

The invention discloses a copper-core armored power cable with a fire extinguishing function, the cable includes an armored cable body, the inside of the armored cable body is fixedly connected with afixing device, a cable core is fixedly connected to the inside of the fixing device, the outer side of the cable core is fixedly connected with an insulating layer, the outer side of the insulating layer is fixedly connected with a shielding layer, the outside of the fixing device is filled with a filling layer, and a first protective layer is fixedly connected to the outer side of the filling layer. The fixing device is arranged to fix the cable core and a fixing baffle plate is arranged as a member made of heat dissipating silicone rubber which has good elasticity and extensibility and playing a fixing role, so that the stability of the cable core is improved, and the cable core damage phenomenon is prevented;, at the same time, heat dissipation silicone rubber has good heat dissipationperformance, dissipates the heat generated by the cable core in time, avoids the high temperature of the armored cable body, and prolongs the service life of the armored cable body.

Owner:安徽华上电缆科技有限公司

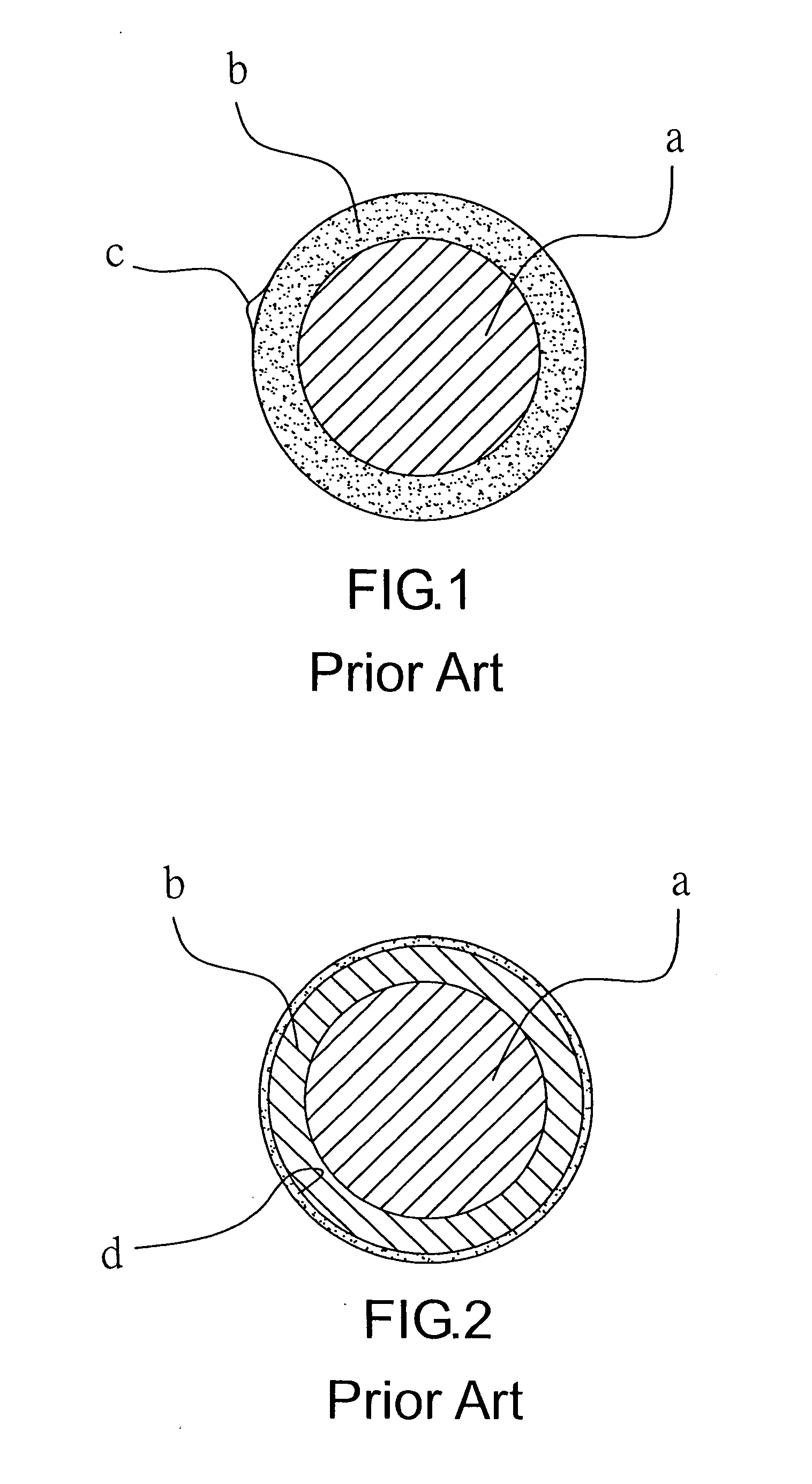

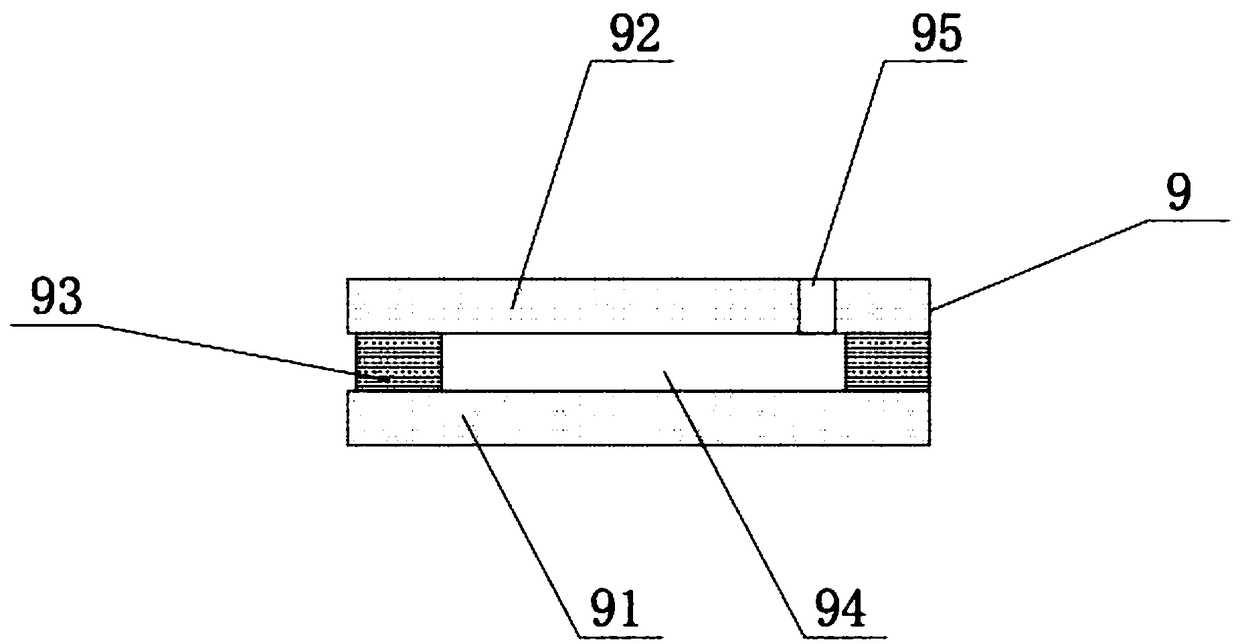

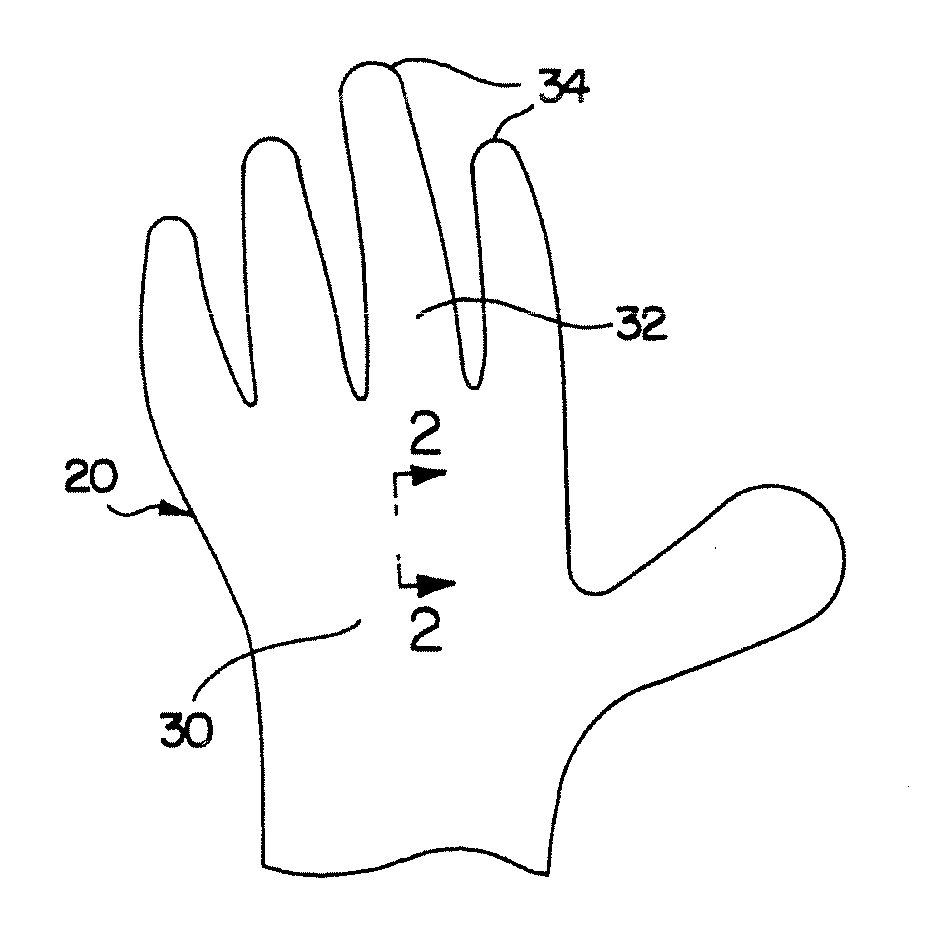

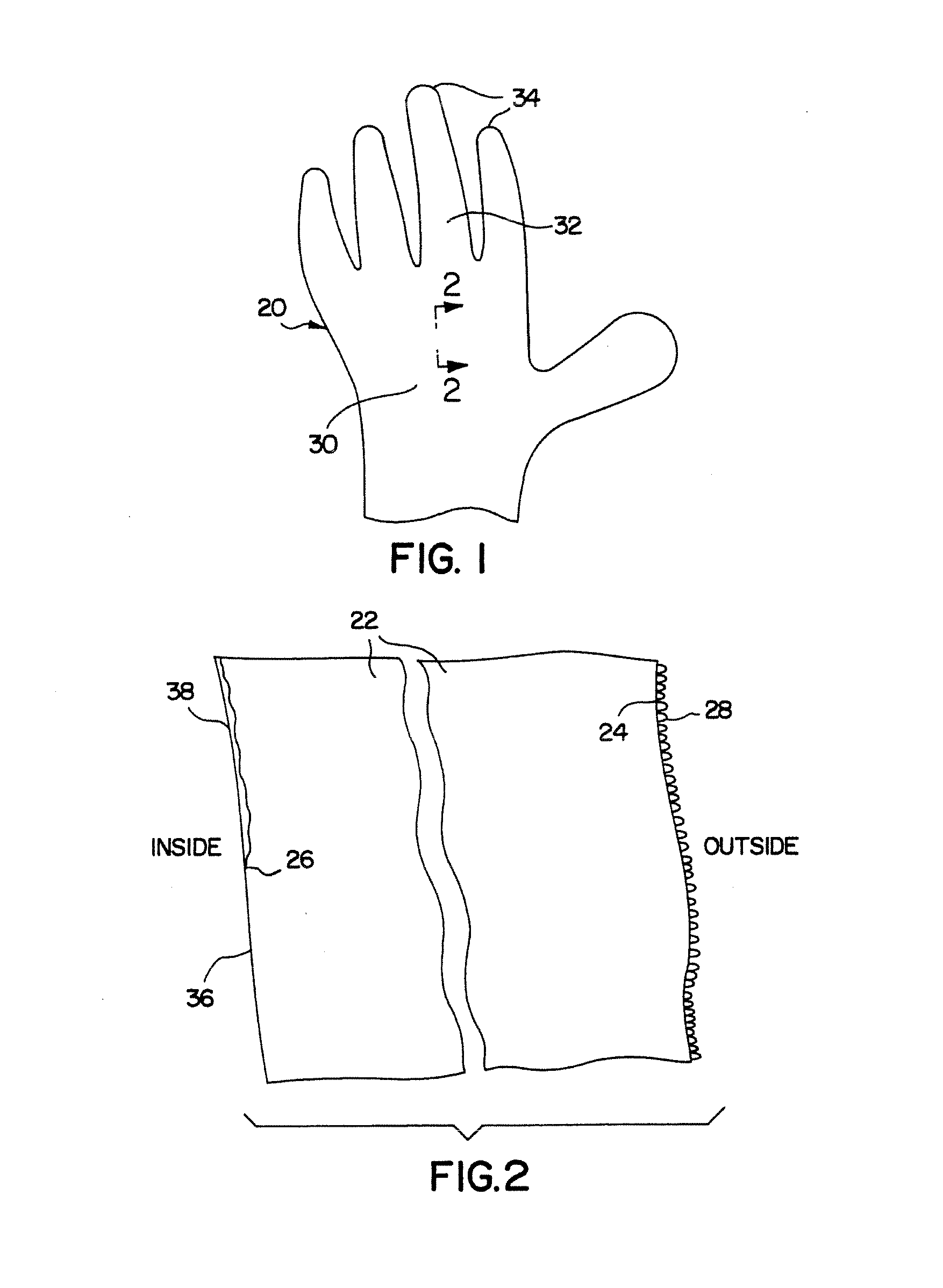

Elastomeric article with fine colloidal silica surface treatment, and its preparation

InactiveUS7582343B1Increase surface frictionLittle increase costDiagnosticsGlovesColloidal silicaElectrically conductive

A surface-modified article is formed of an elastomeric matrix, such as a glove shape, and a plurality of fine silica particles affixed to at least a portion of the surface of the matrix, the outside surface in the case of the glove. The fine silica particles increase the coefficient of friction of the article surface. The fine silica particles may also be made electrically conductive, so that static charge at the surface of the article is dissipated. The silica particles are applied by mixing them into a coating composition, applying the coating composition to the surface of a mold, and solidifying a flowable elastomeric composition against the coated surface. The coating composition may include a coagulant or a parting agent.

Owner:O&M HALYARD INC

Automatic feeding and discharging device

ActiveCN110802180APrevent fallingIncrease productivityMetal-working feeding devicesStripping-off devicesElectric machineryEngineering

The invention discloses an automatic feeding and discharging device. The automatic feeding and discharging device comprises a hopper. A slope is arranged at the inner bottom of the hopper. A materialport communicating with the lower end of the slope is formed in the side wall of the hopper, and a shifting piece which can rotate up and down is arranged below the material port. An elastic reset mechanism is arranged between the bottom surface of the shifting piece and the outer side face of the bottom of the hopper. A rotary workbench is arranged below the shifting piece. A rotary table motor and a rotary table shaft parallel to the material port are arranged on the rotary workbench. Rotary tables are fixedly connected to the two ends of the rotary table shaft. When the rotary table shaft drives the rotary tables to rotate outwards, pipes falling into clamping grooves of the rotary tables form the shifting piece by self gravity can sequentially reach a feeding station, a machining station and a discharging station. By the adoption of the automatic feeding and discharging device, the technical problems that in the prior art, the efficiency of manual feeding and discharging is low, and an automatic feeding and discharging structure is complete are solved.

Owner:重庆理工清研凌创测控科技有限公司

Preparation method of nose bridge prosthesis for plastic surgery

The invention discloses a preparation method of a nose bridge prosthesis for plastic surgery, relates to the field of orthopedic medical technology, and aims to solve the problem that the existing silicone rubber nose bridge prosthesis is easy to shift and to be worn after being implanted. The preparation method comprises the following steps: a, pressing a nose back part substrate and a nose tip part substrate; b, surface treating of the nose back part substrate; and c, connecting the nose back part substrate and the nose tip part substrate. The surface treating of the nose back part substrate comprises the following steps: (1), preparation, preparing casting feed liquid; (2), infusion, submerging the nose back part substrate totally into the feed liquid and drying after taking out; (3), sanding, performing sanding operation to the nose back part substrate after submerging; and (4), vulcanization, vulcanizing, cleaning and drying the nose back part substrate after sanding. The invention is especially suitable for manufacturing the nose bridge prosthesis.

Owner:SHANGHAI KANGNING MEDICAL DEVICE

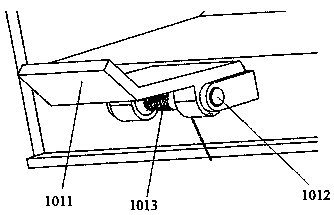

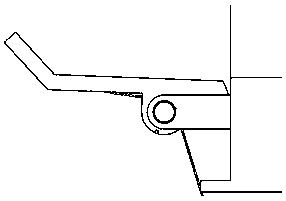

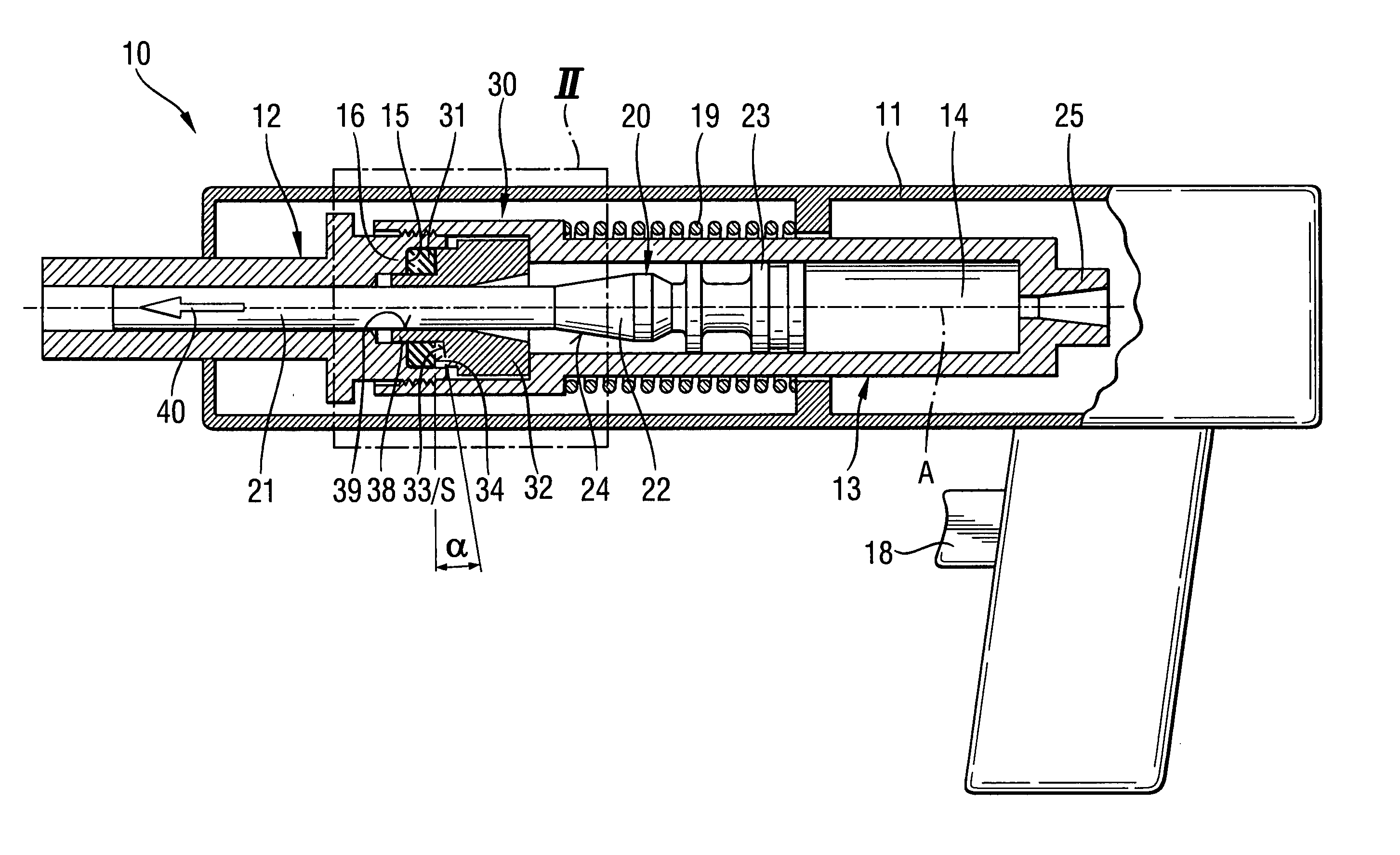

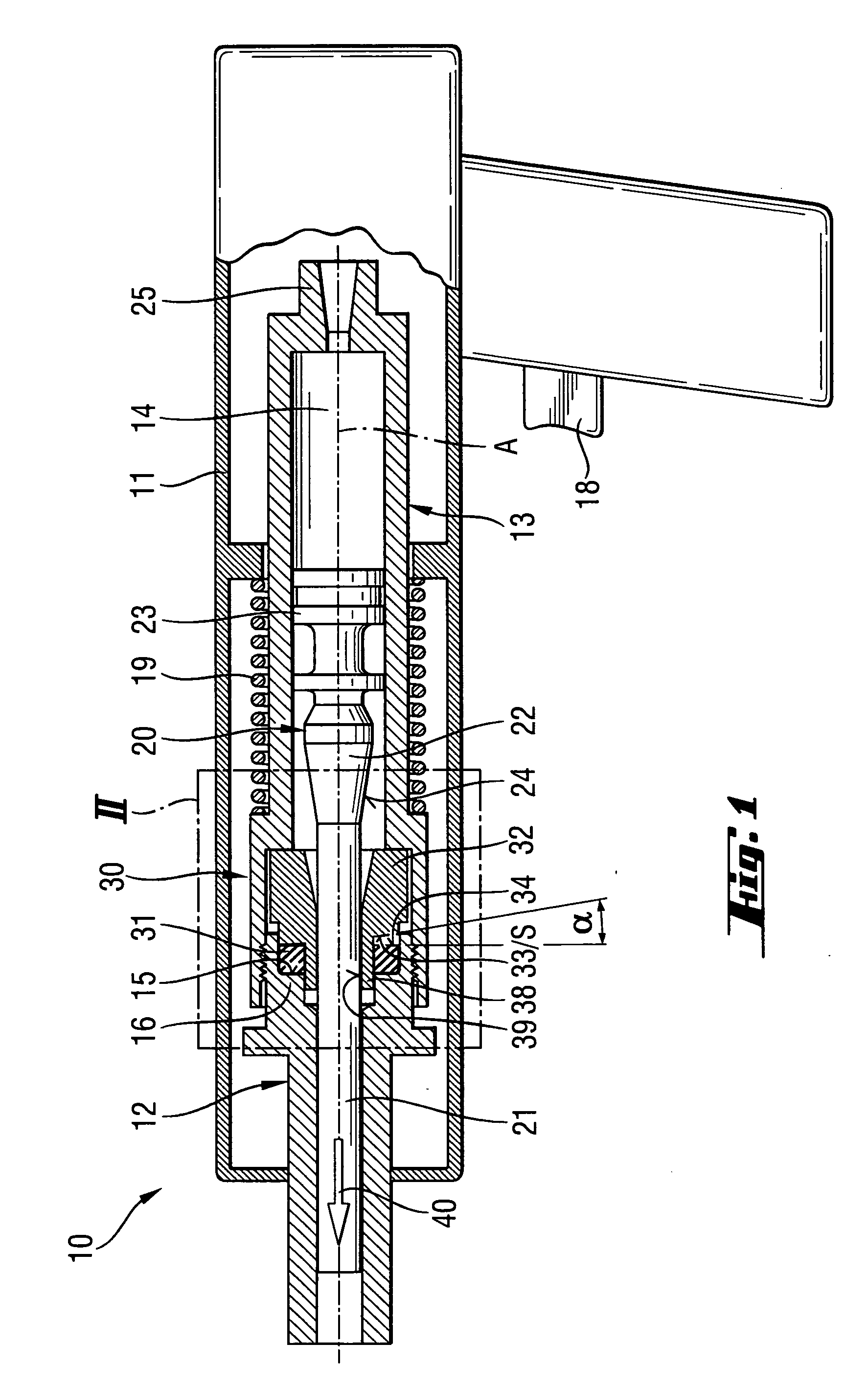

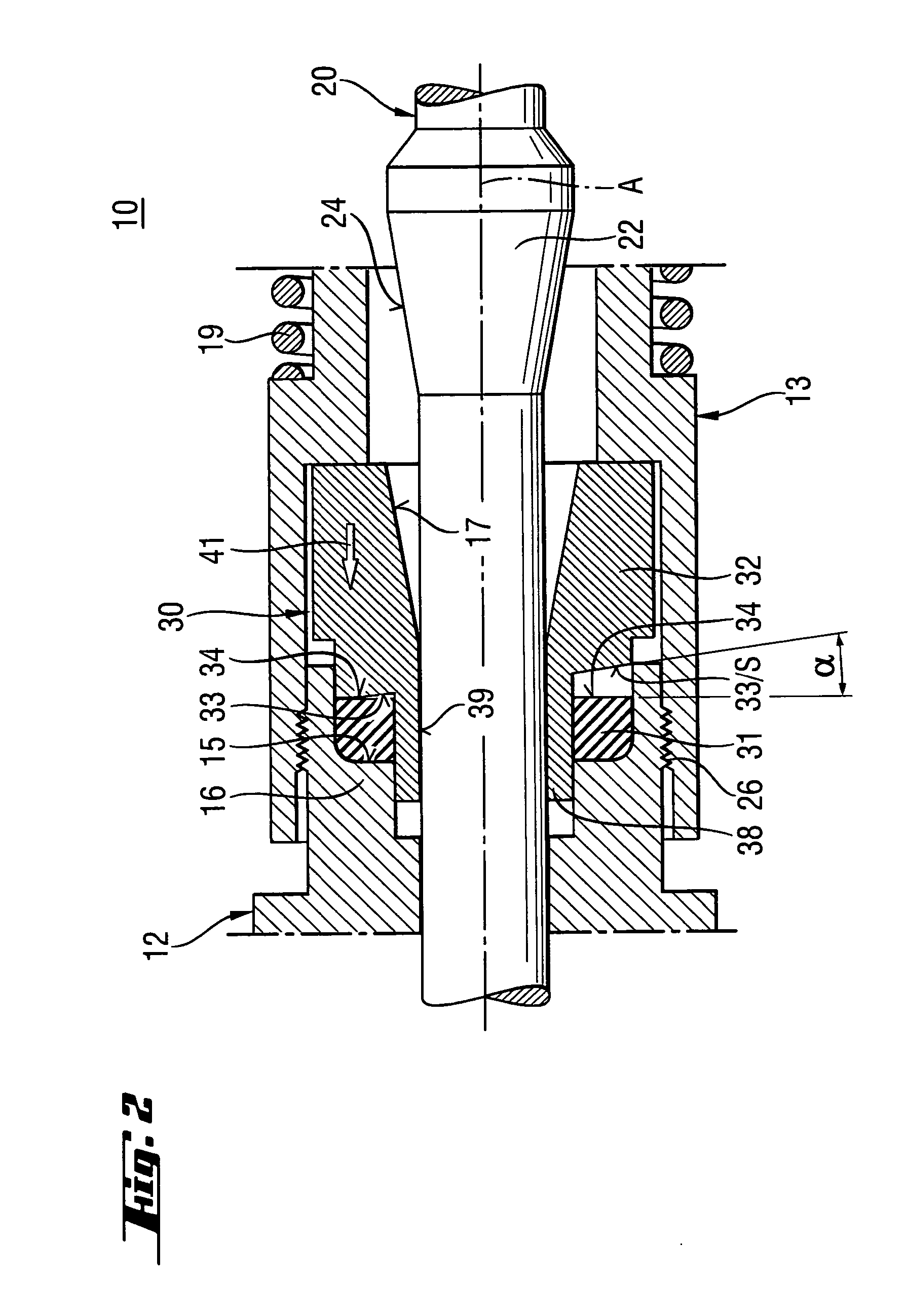

Setting tool

ActiveUS20070057008A1Minimum of additional costProduced economicallyStapling toolsPortable percussive toolsPiston GuideEngineering

A setting tool for driving in fastening elements includes a setting piston (20) axially displaceable in a piston guide (13) which is adjoined by a bolt guide (12), and a piston stop device (30) for the setting piston (20) and arranged at an end region of the piston guide (13) adjacent to the bolt guide (12) and having a damping element (31) supported against a stop (15), and a stop member (32) for the setting piston (20) and adjoining the damping element (31) in a direction toward the piston guide (13), with the damping element (31), the stop member (32) and the stop (15) having respective surfaces (33, 34; 35, 36) arranged axially opposite each other at least one of which is formed as an inclined surface (S) forming with a respective opposite surface an angle of from 2° to 20°.

Owner:HILTI AG

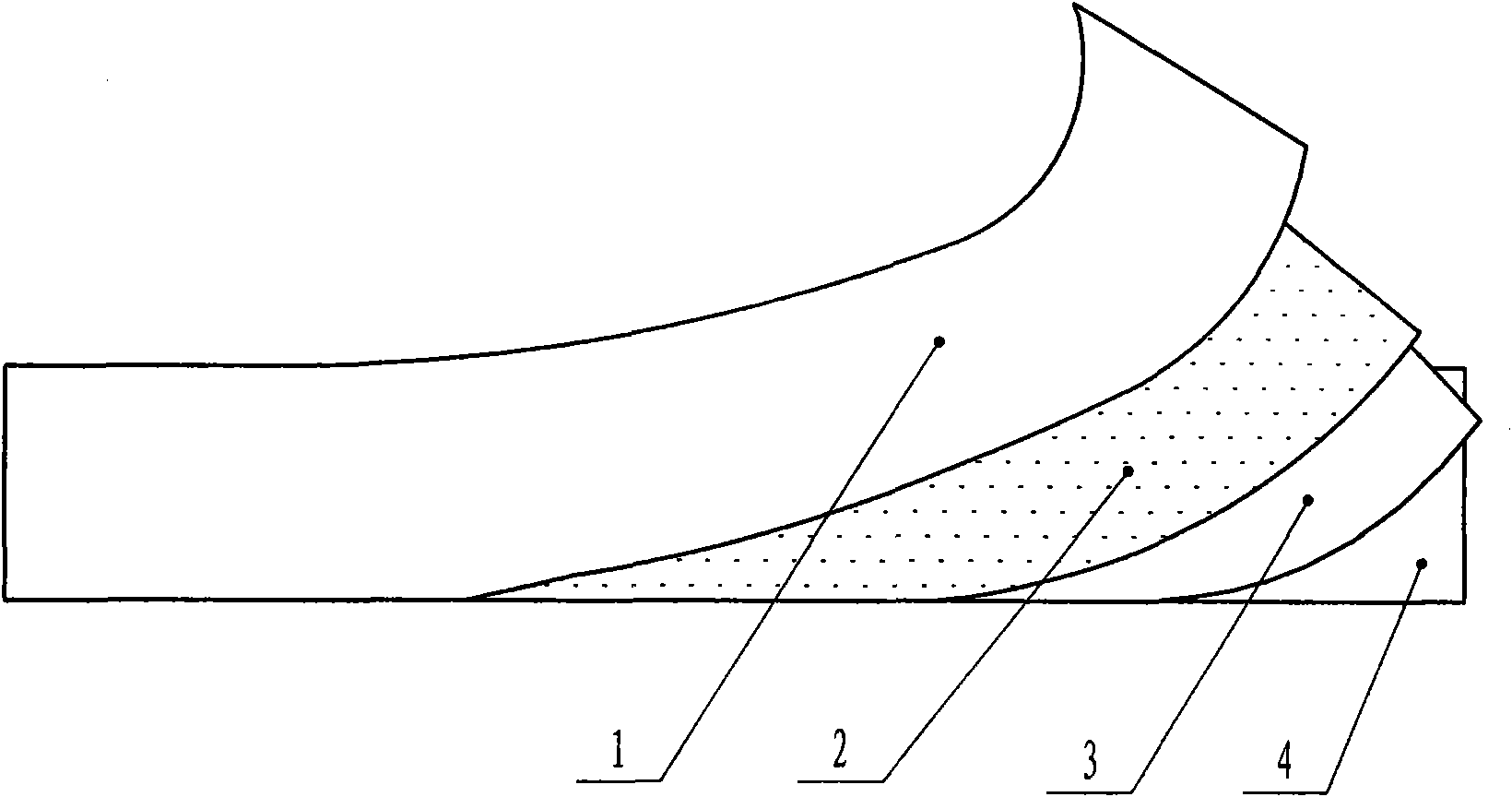

Superspeed fiber reinforced resin abrasive cut-off wheel

The invention relates to a superspeed fiber reinforced resin abrasive cut-off wheel which comprises an abrasive wheel main body, wherein a center hole is formed in the middle of the abrasive wheel main body, three layers of glass fiber grid cloth are arranged on the abrasive wheel main body and are respectively located on the top face, the middle portion and the bottom face of the abrasive wheel main body and are composite with the abrasive wheel main body. The abrasive wheel main body is formed by 70%-86% of abrasive materials, 7%-19% of binding agent and 5%-12% of padding in a composite mode. According to the superspeed fiber reinforced resin abrasive cut-off wheel, the three layers of the grid cloth are utilized and are formed by being matched with a closed non-metal elastic die, operation is easy, an opening form is easy to achieve, a used linear speed can reach 120 meters per second, and the abrasive cut-off wheel is suitable for being used by a high-speed machine tool with multi-shaft or more than three shafts. A grinding speed can be improved by 100%, radiating performance is good, cutting and grinding are sharp and quick, cutting notch of a workpiece does not be burnt or oxidized, machined materials and self materials of the abrasive wheel are saved, if the size of each of the three layers of the grid cloth is 106*1.5*16, the abrasive cut-off wheel can be used on the multi-shaft high-speed machine tool, once feed is more than 3mm, and the superspeed fiber reinforced resin abrasive cut-off wheel is particularly suitable for machining on deep grooves of hard materials such as die steel and tool steel.

Owner:FUJIAN YISHENGDUO GRINDING WHEEL

Irregularly surfaced h pile

ActiveUS20060110220A1High friction load bearing capabilityBroad utilityBulkheads/pilesFlangeSurface friction

A steel H pile has a relief design embossed on one or more major surfaces of either or both of its steel flanges and its web to provide surface irregularities thereon which increase the pile's surface friction and its friction pile load bearing capacity.

Owner:NUCOR YAMATO STEEL

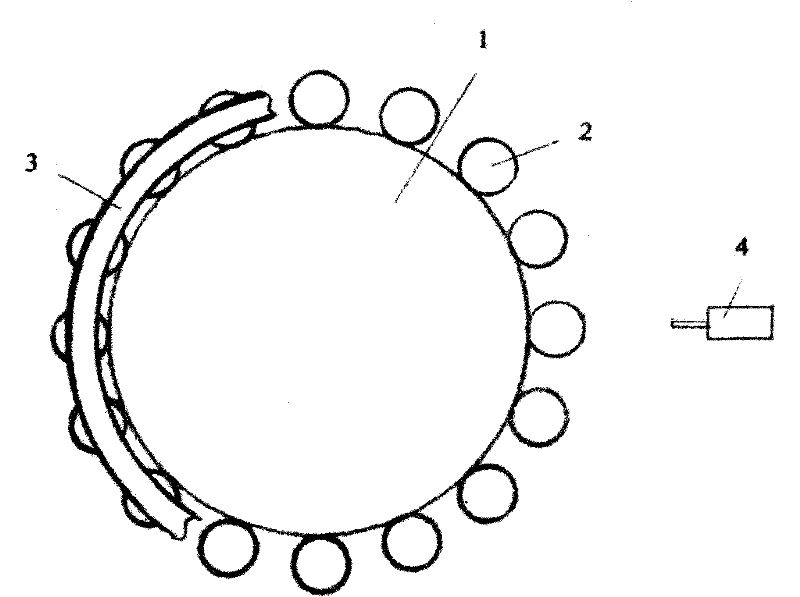

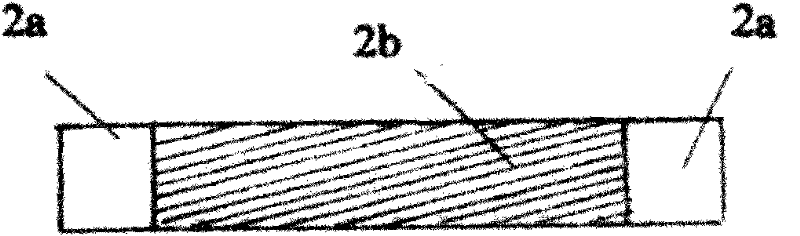

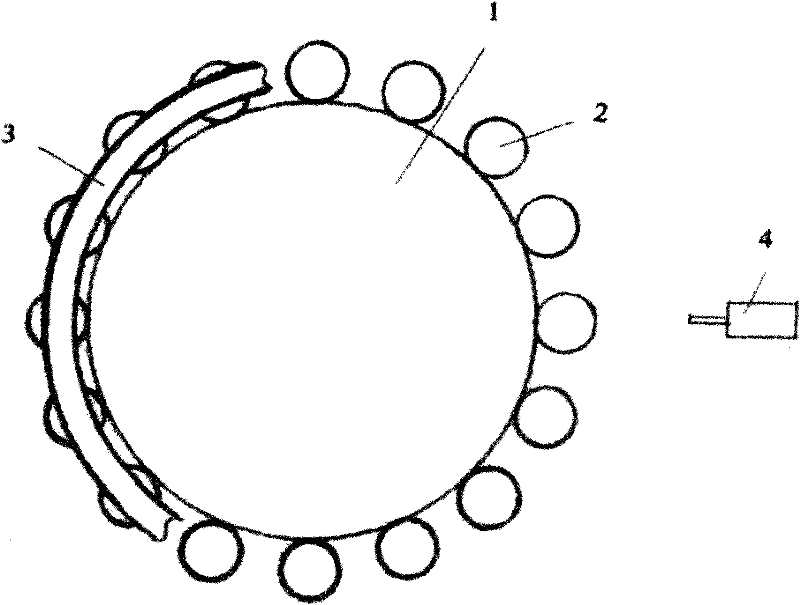

A kind of tubular membrane preparation method for membrane distillation

InactiveCN102284404APlay a conditioning roleIncrease surface frictionLiquid surface applicatorsFilament/thread formingFiberPorosity

The invention relates to a preparation method of a tubular membrane for membrane distillation, and relates to a preparation method of a nanofiber tubular membrane. Aiming at the shortcomings of conventional preparation methods of tubular membranes, the present invention proposes a membrane preparation scheme with low equipment investment, simple and easy operation, and high porosity of the prepared tubular membranes. In this scheme, a solution of a polymer material suitable for membrane distillation is sprayed on a tubular support by the electrospinning method to form a tubular uniform membrane layer. The equipment is an electrospinning tubular film preparation device, and the film receiving system is a plurality of supporting tubes that rotate respectively. The support tubes are arranged around the surface of a central circular roller and are held against the surface. A circular bracket supports and defines both ends of the support tube. The rotation of the central round roller drives the support tube to rotate relative to the circular bracket, the circular bracket rotates concentrically relative to the central round roller, and electrospinning forms a uniform nanofiber tubular film on the support tube.

Owner:北京承峰纳泰科技有限公司

Road surface traffic marking line sticker

InactiveCN102071656AImprove wear resistanceImproved color stabilityTraffic signalsRoad signsRoad surfaceEngineering

The invention discloses a road surface traffic marking line sticker, belongs to the field of traffic marking lines of a road surface, and aims to provide the traffic marking line sticker which can be laid on site and has the advantages of anti-aging property, long service life and low manufacturing cost. According to the adopted scheme, the sticker comprises a colored rubber layer, a cord fabric and an adhesive layer which are arranged from top to bottom, and is characterized in that: the colored rubber layer is prepared from the following raw materials in part by weight: 40 to 55 parts of natural rubber, 30 to 50 parts of cis-butadiene rubber, 3 to 7 parts of fluorescent powder, 0.5 to 3 parts of anti-aging agent and 1 to 5 parts of paint. The sticker can be widely applied to production situations of various traffic marking lines on the road surface.

Owner:梁鑫

Handheld packet for one-handed operation

InactiveUS20100254637A1Weaken structural integrityMinimize forceFlexible coversWrappersNetwork packetHand held

A handheld packet designed for one-handed operation with an elongated tab portion that can be gripped between the thumb and forefinger of the hand holding the packet. The elongated tab serves as a moment arm for breaching the neck of the packet when the elongated tab is pulled away from the packet. Breaching the neck portion of the packet permits the contents of the packet can be removed. The neck portion of the packet can be scored or serrated to further facilitate breaching the neck portion and opening the packet. The tab portion can be made from a textured material to increase grip, and the packet can be formed from layers of materials with different properties to enable storage of food, medicine, dangerous or sensitive chemicals, or other substances.

Owner:LESKO JOSEPH JOHN

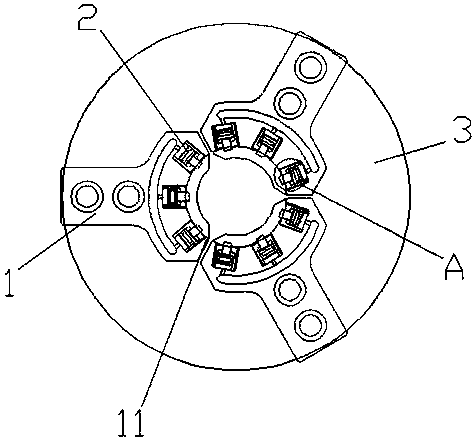

Multi-point equal clamping device

The invention discloses a multi-point equal clamping device applied to the field of mechanical tools. The multi-point equal clamping device is characterized by structurally comprising a plurality of claw fingers and a claw finger drive device, wherein each claw finger comprises a clamping part, and the position, towards a clamped object, of each clamping part is uniformly equipped with a pluralityof hydraulic cylinders; each hydraulic cylinder comprises an oil cylinder piston and a pressure cavity; the pressure cavity on the same claw finger is in communication; and each oil cylinder piston comprises a clamping end which extends to the outside of the corresponding clamping part. The clamping ends of the hydraulic cylinders are utilized to perform clamping operation; pressure cavities of the hydraulic cylinders communicate with one another, so that the position of hydraulic oil also can be transferred according to different pressure, and therefore, the occurrence of a condition that acting force between the clamping ends and workpieces is too high is avoided. Circulating action of the hydraulic oil guarantees stress uniformity of the surface of the clamped object, so that a workpiece damage rate is effectively reduced, and the take-up effect of the clamped object is guaranteed. Meanwhile, weakening, caused by stress deformation, of clamping force can be eliminated during claw clamping by uniform stress, so that guarantee is provided for clamping force, on the clamped objects, of the claw fingers.

Owner:苏州磐岩精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com