Patents

Literature

61results about How to "Improve suction comfort" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

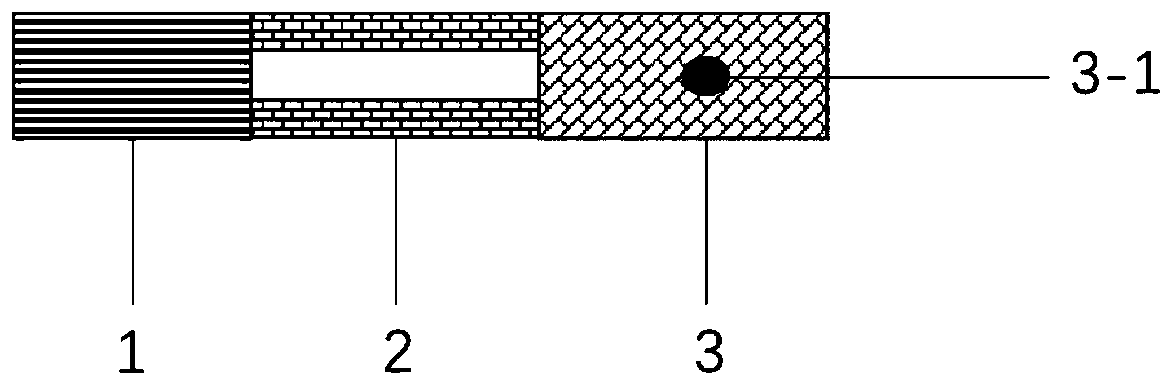

Cigarette filter stick with function of reducing main stream smoke temperature of cigarette

ActiveCN106690415AThe processing technology is simple and effectiveReduce flue gas temperatureTobacco smoke filtersAlcoholPolyethylene glycol

The invention relates to a cigarette filter stick with a function of reducing the main stream smoke temperature of a cigarette. The filter stick is added with heat-absorption gel, wherein the heat-absorption gel is prepared from the following components in parts by weight: 30-70 parts of propylene glycol, 30-60 parts of polyethylene glycol and 5-15 parts of hexadecyl alcohol. Compared with the prior art, the cigarette filter stick has the advantages that the cigarette or tobacco product which is not burnt by heating uses the cigarette filter stick, the smoke temperature can be reduced by 1.0-8.0 DEG C, the smoking comfortable feeling of the cigarette and tobacco product which is not burnt by heating can be improved.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

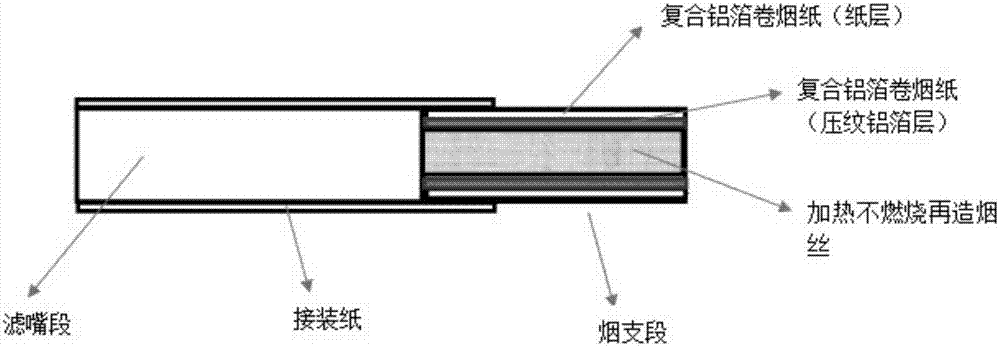

Method for preparing heating but incombustible cigarettes and application thereof

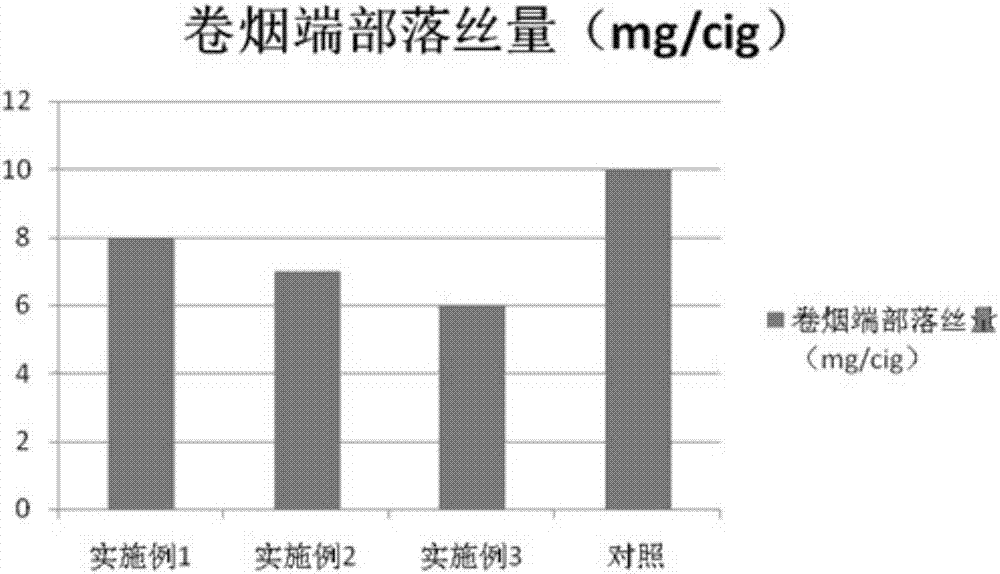

ActiveCN107981405AIncrease frictionLow costTobacco preparationCigarette manufactureKnurlingEngineering

The invention discloses a method for preparing heating but incombustible cigarettes and application thereof. The method and the application have the advantages that novel knurling rolling technologiesare adopted, accordingly, heating but incombustible reconstituted tobaccos with certain thicknesses have uneven surfaces, the surface areas can be enlarged, atomization effects can be enhanced, and surface frictional force can be enlarged; embossed composite aluminum-foil cigarette paper is adopted, accordingly, friction between the reconstituted tobaccos and aluminum-foil pattern surfaces of thecomposite aluminum-foil cigarette paper which is a cigarette making and plug assembling material can be greatly enhanced when the reconstituted tobaccos and the composite aluminum-foil cigarette paper are loaded in a cigarette making and plug assembling machine and cigarette making and plug assembling are powered on in later periods, the heating but incombustible cigarettes are easy to process, equipment shutdown frequencies can be reduced, the heating but incombustible cigarettes can be continuously produced, the production efficiency can be improved, and the material cost and the productioncost can be reduced; low-temperature cigarettes have short cut tobacco sections, accordingly, friction can be improved, the method is beneficial to reducing cut tobacco dropping, and the shortcomingsof low frictional force between smooth surfaces of existing heating but incombustible reconstituted tobaccos and non-embossed aluminum-foil paper which is a wrapping material, severe slipping, frequent equipment shutdown due to incapability of driving cigarette paper, influence on production efficiency, low frictional force due to short cut tobacco sections of existing low-temperature cigarettes,vulnerability to dropping of low-temperature cut tobaccos of the existing low-temperature cigarettes and the like can be overcome.

Owner:HUBEI CHINA TOBACCO IND

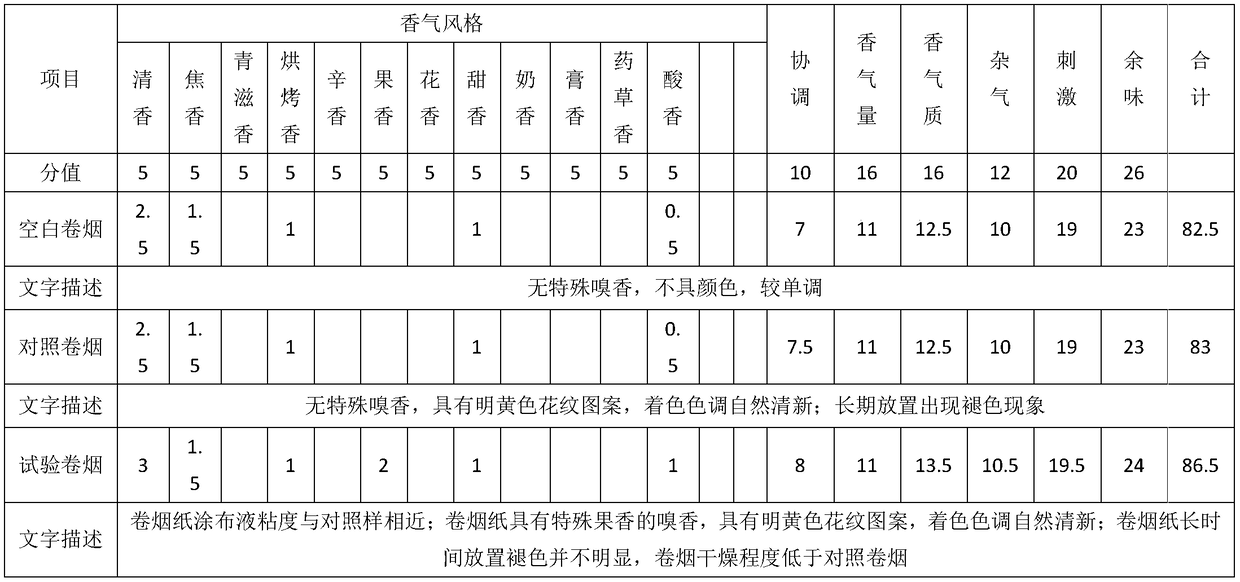

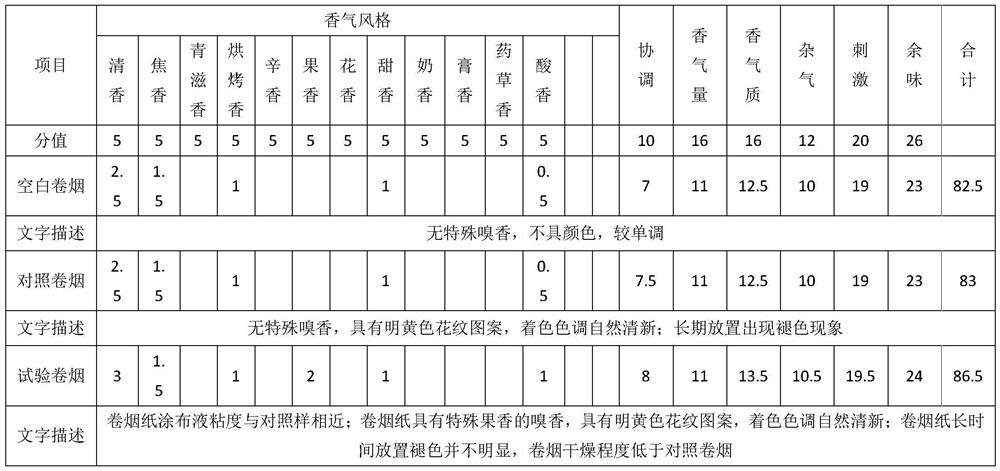

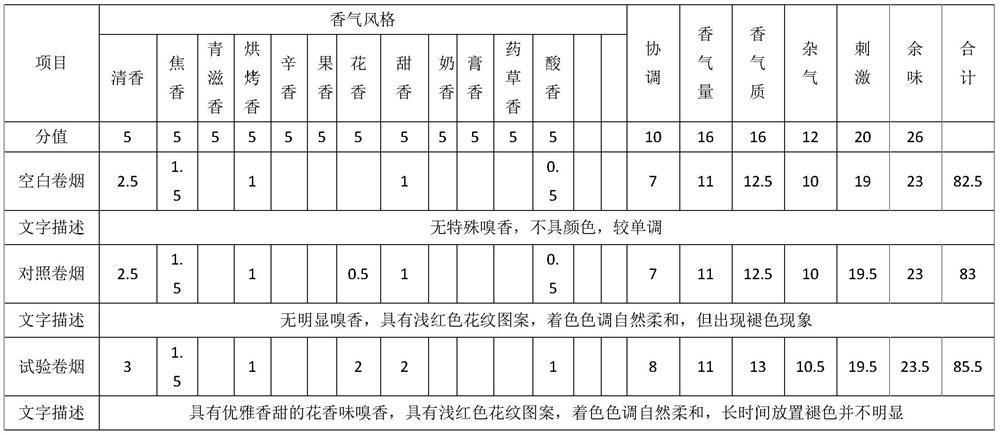

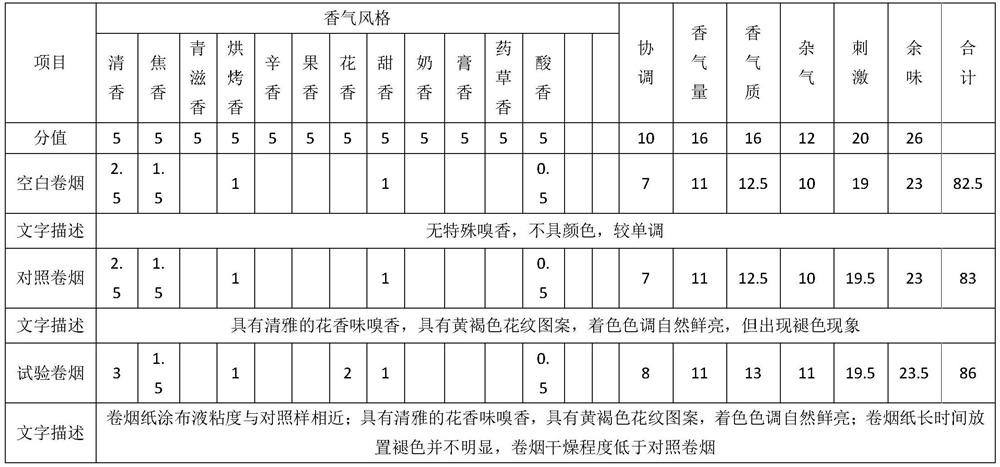

Preparation method of natural tobacco texture cigarette paper

InactiveCN103469691AIncrease the fragranceReduce mistSpecial paperPaper coatingCombustionSolid matter

The invention discloses a preparation method of natural tobacco texture cigarette paper. The method comprises the following steps: firstly weighing 5-60% of tobacco raw material and 40-95% of wood pulp by weight percentage; extracting the tobacco raw material, and separating to get a tobacco solid matter and an extraction solution; mixing the tobacco solid matter and the wood pulp to obtain mixed pulp; and preparing a cigarette paper base from the mixed pulp; concentrating the extraction solution to prepare a tobacco extract; adding 1-4% of a combustion-supporting agent, 0-4% of a natural pigment extract and 0-3% of a moisture retention agent relative to the weight of the tobacco extract into the tobacco extract to prepare a coating solution, coating the cigarette paper base with the coating solution, and directly performing embossing treatment by utilizing an embossing roller carved with tobacco textures after coating and drying to prepare the cigarette paper with the tobacco vein textures. According to the preparation method disclosed by the invention, the natural tobacco fragrance of the cigarette paper is increased, and the cigarette paper is also endowed with the tobacco characteristic appearance; the cigarette grade is upgraded; the cigarette paper miscellaneous gas during combustion is reduced, and the smoking quality is upgraded; the natural tobacco texture cigarette paper can further serve as wrappers of hand-rolled cigars.

Owner:HUBEI CHINA TOBACCO IND +1

Acetate plasticizer for improving smoking property of cigarette and method for preparing same

InactiveCN1994164AQuality improvementHigh fullnessTobacco smoke filtersVegetal fibresFlavorPlasticizer

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

Functional cigarette paper and preparation method thereof

ActiveCN101215802AImproving cigarette safetyGreat tasteNon-fibrous pulp additionFlexible coversPulp and paper industrySmoke paper

The invention discloses a functional cigarette paper, and the process for preparation comprises preparing powder which passes through 120 orders-150 orders mesh sieve after washing, drying, steaming wet, drying with steam and disintegrating root tuber, tuber, bulb or bulbodium of plant, and adding the powder in the existing cigarette paper according to the adding proposition which is 0.01%-1% relative to dry paper weight. The cigarette paper which is applied in the existing cigarette products can effectively improve absorbing taste, can improve the amenity of sucking, and can highlight the personality characteristics of products. Meanwhile, the invention pertinently removes free radical of smoke gas, which improves security of cigarette. The invention is environmental protection, which can be degraded, and can reach zero discharge.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Method for preparing tobacco extracts through fermentation by utilizing immobilized enzyme preparations to be combined with acetic bacteria

The invention provides a method for preparing tobacco extracts through fermentation by utilizing immobilized enzyme preparations to be combined with acetic bacteria. According to the method, the immobilized enzyme preparations are utilized for processing the tobacco extract raw materials to obtain processing products, then, the acetic bacteria are utilized for processing products through fermentation to obtain fermentation products, then, the fermentation products are subjected to concentration treatment, and the tobacco extracts are obtained. The method has the advantages that the contents of starch, protein, cellulose, lignin and pectin substance in the tobacco extracts can be fast and effectively reduced, in addition, the acid degree of the tobacco extracts can be properly improved, the fragrance and the smoking comfort of cigarette can be effectively improved, and the use range of the tobacco extracts can be improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

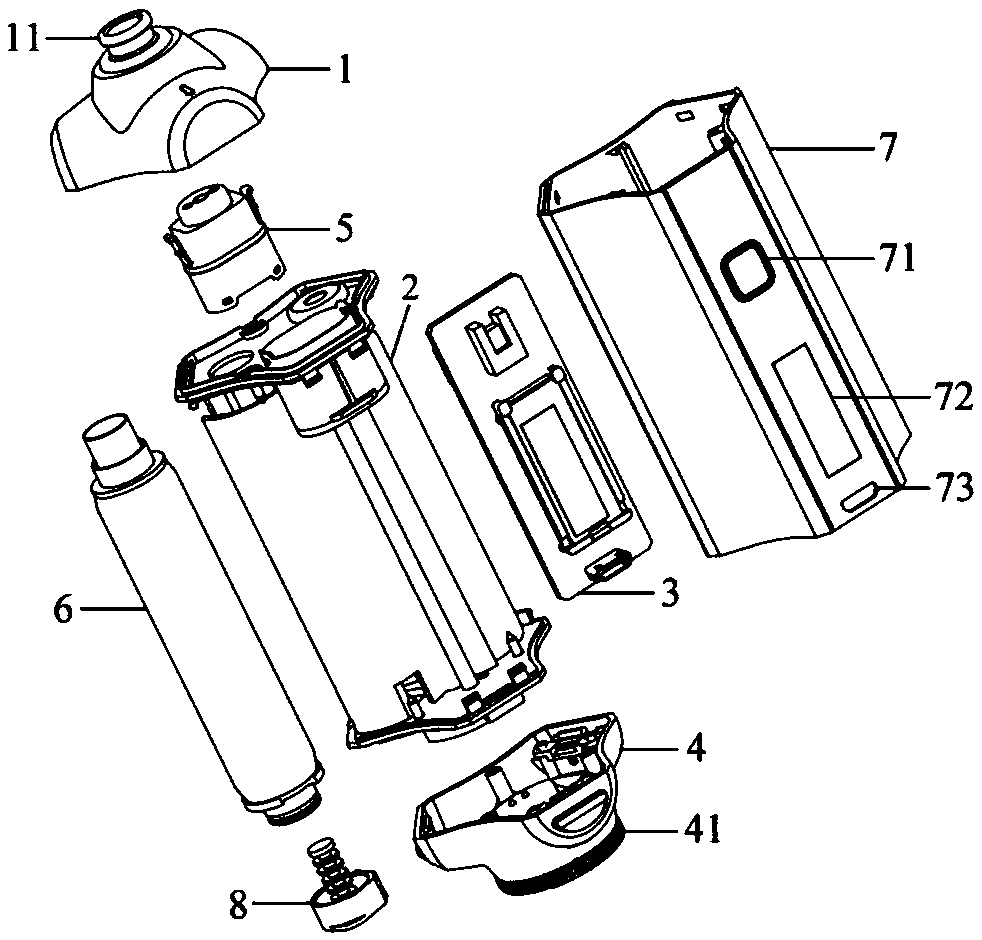

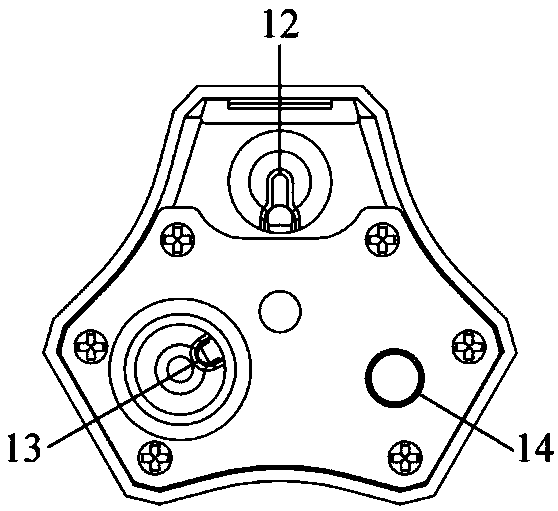

Atomizing device supporting multiple smoking modes and use method thereof

ActiveCN109602091AMeet the needs of multi-dimensional suctionEasy to operateTobacco devicesEngineeringAirflow

The invention discloses an atomizing device supporting multiple smoking modes. The atomizing device comprises the following components: a host shell (7); a main bracket (2); an upper end cover (1); anatomizer (5), arranged on an atomizer base (211); and a lower end cover (4). The invention further discloses a use method of the atomizing device. The atomizing device disclosed by the invention supports three smoking modes, and the smoking modes and air flow channels can be synchronously switched; the low-temperature baking fragrance generation temperature is controlled precisely; cigarettes arefully used; the smoking comfort is high.

Owner:CHINA TOBACCO YUNNAN IND

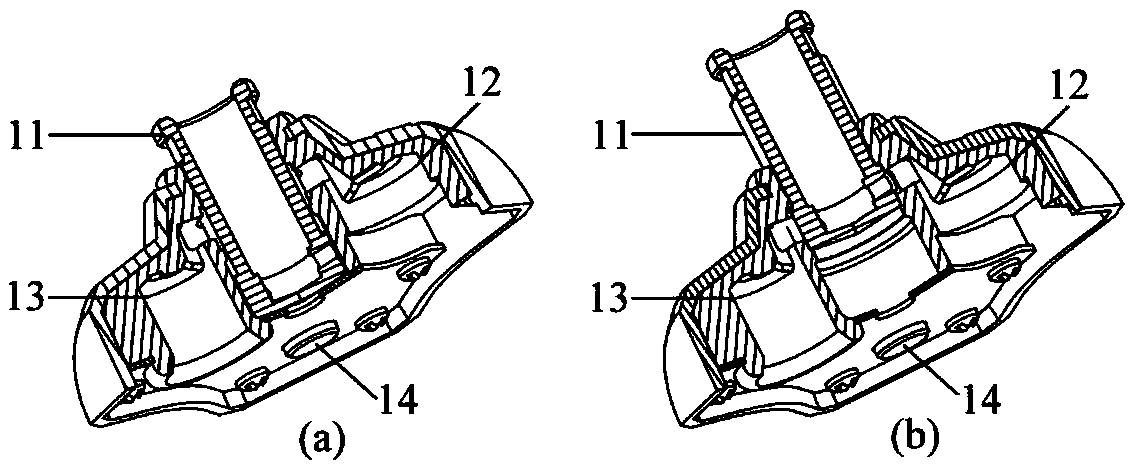

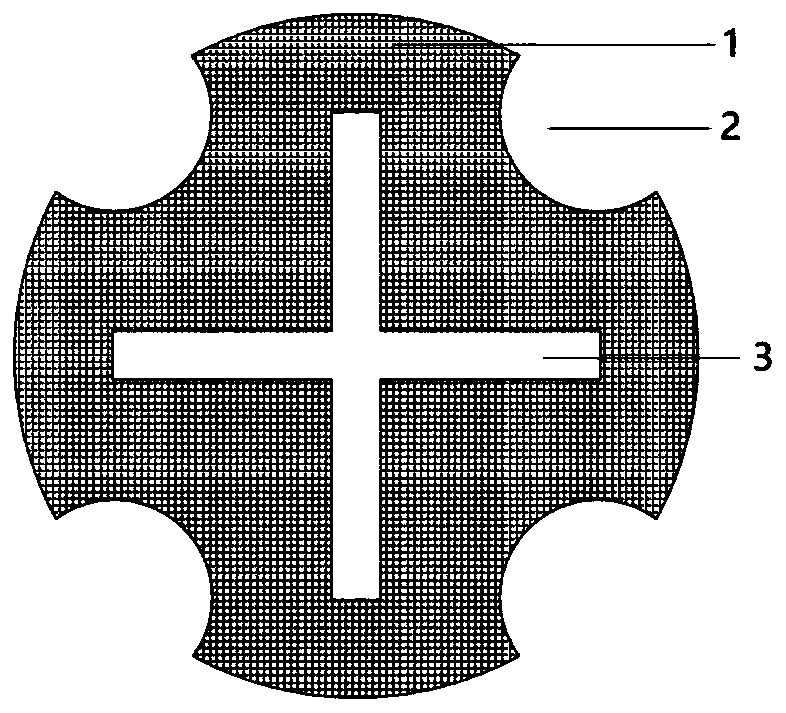

Heated incombustible cigarette and production method thereof

InactiveCN109730368ASimple preparation processShort production processTobacco treatmentTobacco devicesAdhesiveEngineering

The invention relates to a heated incombustible cigarette. The heated incombustible cigarette with a cross-shaped cavity inside and a groove in the outer wall is obtained by mixing tobacco raw material powder, tobacco extract, tobacco flavor for cigarette, a forming agent, a smoke agent, an adhesive and water to obtain tobacco paste and extruding the tobacco paste through an extruder. The sensoryquality of the heated incombustible cigarette is not obviously different from that of a heated incombustible cigarette on the market, but the heated incombustible cigarette is slightly lower in smoketemperature. The heated incombustible cigarette can reduce the smoke temperature entering the oral cavity effectively, so that the smoking quality of the cigarette is improved.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

Function cigarette overlapping glue and preparation method thereof

The invention discloses functional cigarette lap adhesive, which comprises preparing powder which can pass through a sieve with 120-150 orders after cleaning, drying, wet steaming, drying with steam, and grinding a root or a tuber or a bulb or a bulbodium of plant and then evenly mixing the powder with existing cigarette lap adhesive according to the adding proportion of 0.01%-0.1%. The functional cigarette lap adhesive is applied in existing cigarette products and can effectively improve absorbing odor, increase the comfortableness of suction, and make the personality and the characteristics of the product clear, simultaneously the invention can pertinently remove free radical in cigarette smoke and increase the safety of the cigarette. The product is environmental friendly and can be degraded to achieve 'zero discharge'.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

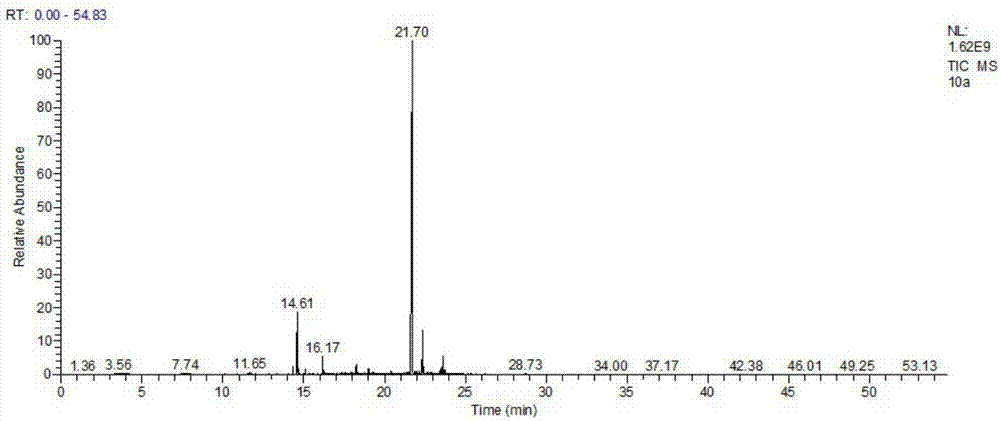

Method for preparing tobacco fragrance component through subcritical extraction and application in cigarette

ActiveCN106858716APlay a double roleSimple processTobacco smoke filtersTobacco leaf extractTriacetin

The invention discloses a preparing method of a cigarette filter stick additive. According to the cigarette filter stick additive, tobacco leaves are adopted as a raw material, and the method comprises the following steps of 1, preparing the raw material, wherein the tobacco leaves are dried at 50-80 DEG C, and are smashed to reach the mesh number of 50-100; 2, conducting subcritical extraction, wherein the smashed tobacco leaf powder in the step 1 is extracted at 0-50 DEG C and 0.5-3.0 MPa with dimethyl ether being an extraction agent and triacetin being a cosolvent; 3, preparing the filter stick additive, wherein dimethyl ether in the step 2 is recycled, and the obtained triacetin solution containing tobacco leaf extract is the cigarette filter stick additive. The invention further discloses application of the cigarette filter stick additive obtained through the preparing method in cigarette products.

Owner:CHINA TOBACCO YUNNAN IND

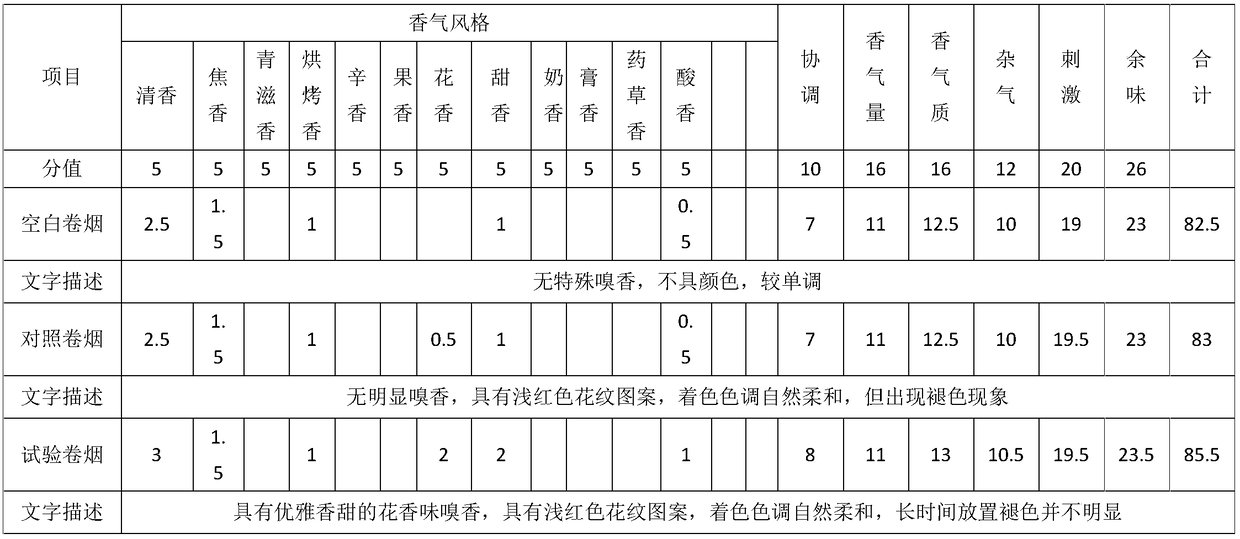

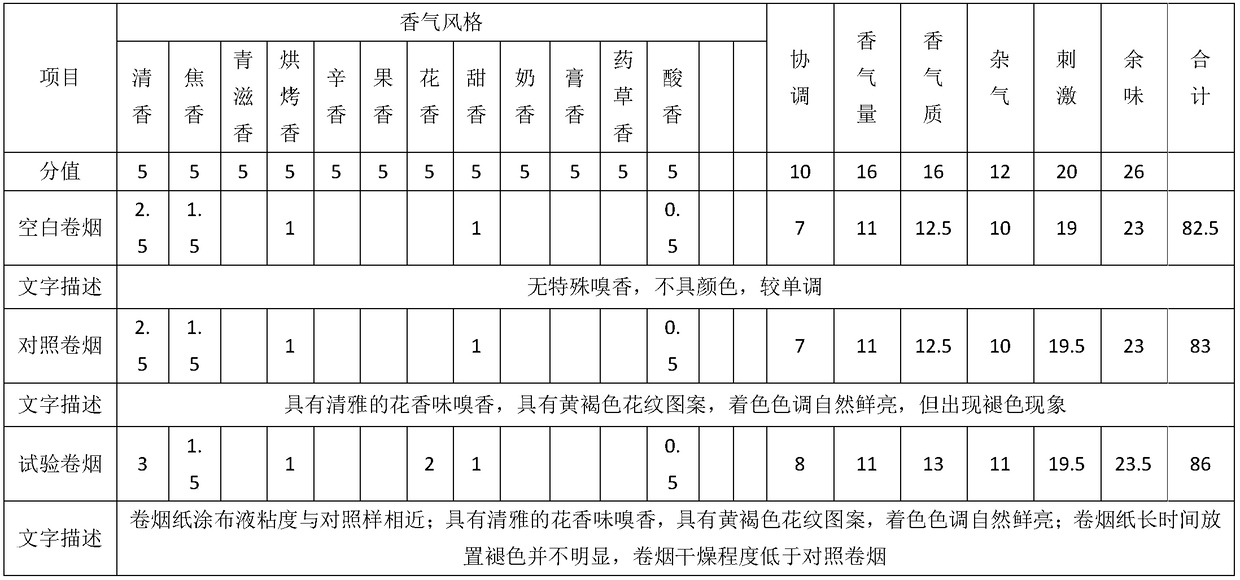

Colored cigarette paper coating solution with specific fragrance and application thereof

ActiveCN108797214APreserve the coloring functionAdjust colors flexiblySurface covering paperNon-fibrous pulp additionSocial benefitsEconomic benefits

The invention discloses a colored cigarette paper coating solution with specific fragrance and application thereof. The colored cigarette paper coating solution is prepared through the following steps: taking plants containing natural pigment as raw materials, and fermenting plant powder or pulp by sequentially using an aspergillus oryzae YNCA 9804 strain and a bacillus subtilis Van3 strain, thusforming an aroma component; carrying out solvent extraction and concentration purification; mixing the aroma component with coating solutions such as fungal polysaccharide, thus preparing a finished product. According to the colored cigarette paper coating solution disclosed by the invention, the characteristic of pleasant fragrance of the colored cigarette paper coating solution is given while acoloring function of the natural pigment is reserved; pigment powder with the fragrance obtained through treatment is independently compounded, mutually compounded or compounded with other natural pigment for use, so that the color of the colored cigarette paper coating solution can be flexibly regulated; synthetic pigment is replaced, dual sense experience on vision and olfaction can be obtainedby a cigarette product while the safety is improved, diversified color developing and fragrance increment of a tobacco paper base can be realized, and good social benefit and economic benefit are obtained.

Owner:CHINA TOBACCO YUNNAN IND

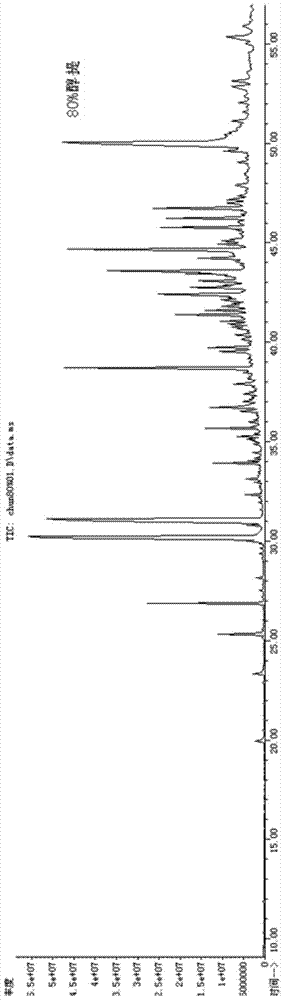

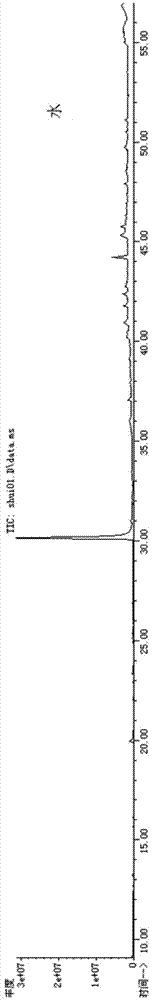

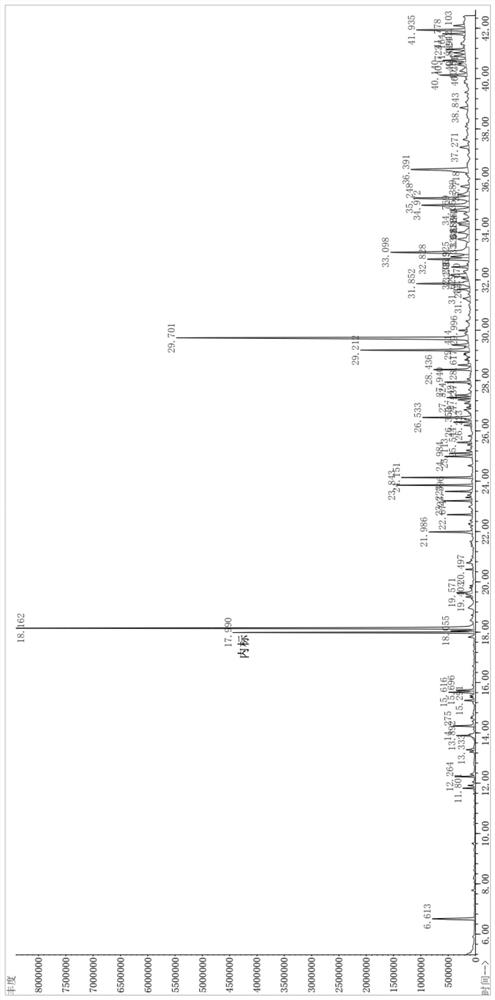

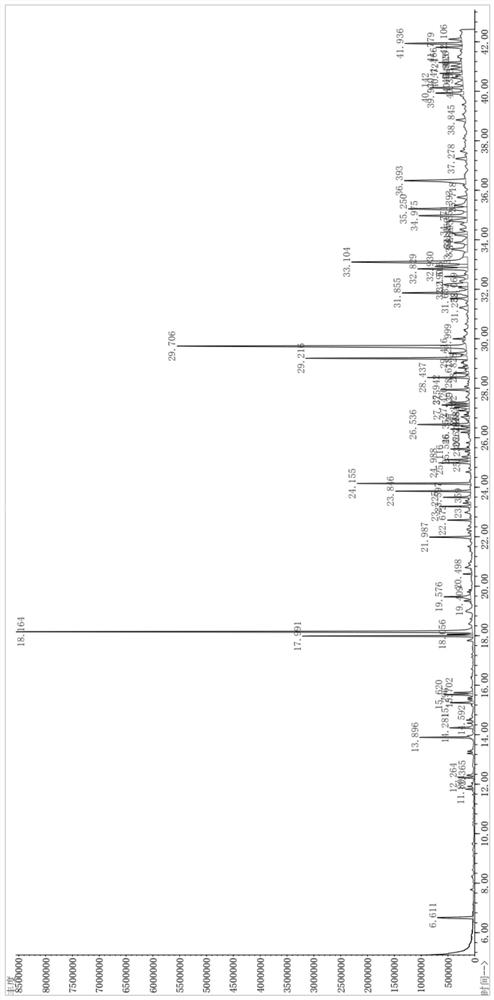

Intrinsic tobacco aroma substance directionally and compositely extracted from tobacco raw material by water extraction method and ethanol extraction method

The invention relates to an intrinsic tobacco aroma substance directionally and compositely extracted from a tobacco raw material by a water extraction method and an ethanol extraction method. The substance comprises water-extracted polar aroma substances and ethanol-extracted neutral and weakly polar aroma substances which are mixed with one another. The mass ratio of the polar aroma substances to the neutral and weakly polar aroma substances is 100:0.1-5. The intrinsic tobacco aroma substance has the advantages that the tobacco raw material is fine-grained waste such as tobacco powder, tobacco ash or tobacco stems which are generated in tobacco leaf, tobacco shred or tobacco processing procedures, accordingly, 'the waste is turned into wealth', and environmental pollution is reduced; water extraction concentrated solution for tobacco and ethanol extraction concentration solution are properly proportionally blended and are compounded with aroma materials to generate a mixture, the mixture is added into tobacco products such as reconstituted tobacco leaves, accordingly, the sensory quality can be improved, the aromatic quantity can be increased, the aromatic note can be enhanced, natural tobacco aroma is highlighted, the dry sensation of smoke of the tobacco is reduced, secretion sensation of the smoke of the tobacco can be improved, and the smoking comfort can be enhanced.

Owner:CHINA TOBACCO ZHEJIANG IND +1

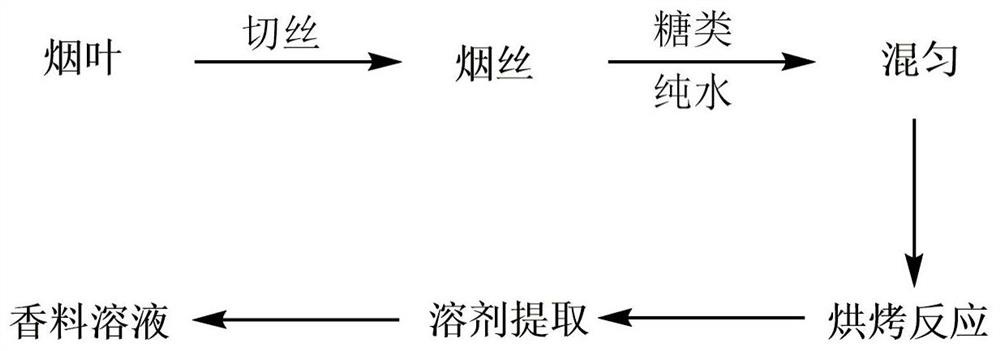

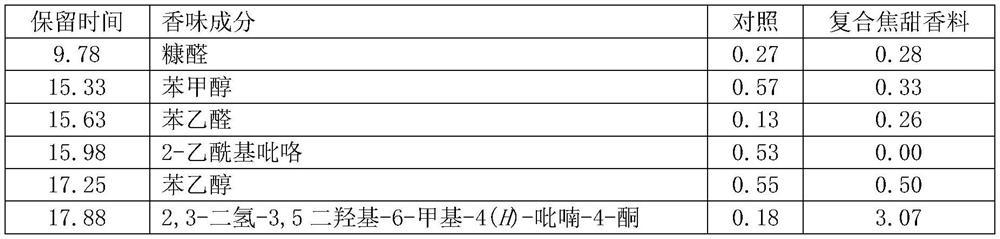

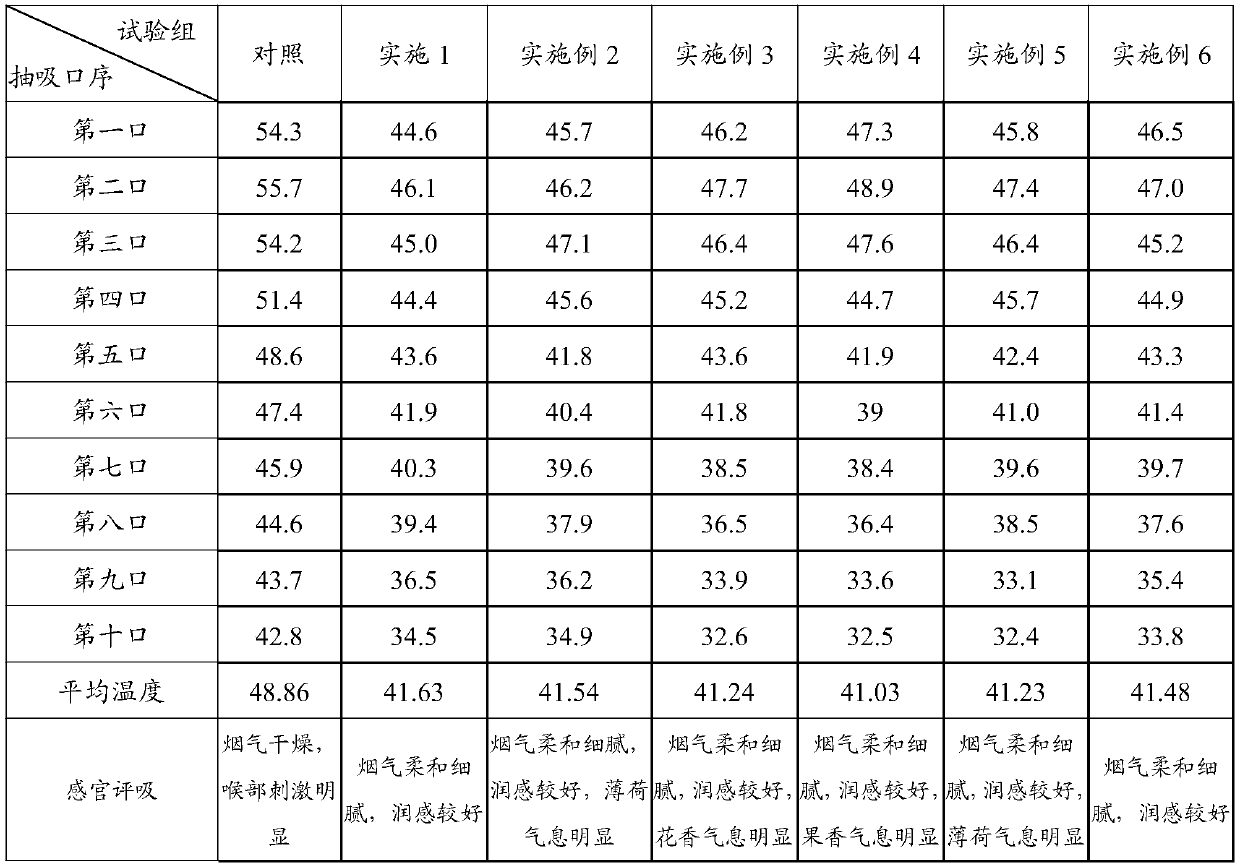

Composite caramel-flavour aroma spice, baking preparation method and application

InactiveCN112205659ARich fragranceRich and sweet aromaTobacco preparationBiotechnologyNicotiana tabacum

The invention discloses a composite caramel-flavour aroma spice, a baking preparation method and application. The composite caramel-flavour aroma spice is prepared by uniformly mixing and reacting thefollowing raw materials, by mass: 1.0-20.0 parts of tobacco leaves, 0.2-10.0 parts of saccharides and 0.1-10.0 parts of pure water. The tobacco leaf raw materials are shredded to obtain tobacco shreds, the tobacco shreds and the saccharides are evenly stirred, then pure water is sprayed into the mixture to be evenly mixed, then the mixture is baked in a baking oven preheated to 120-180 DEG C for0.1-40 min for a reaction, and after the reaction is finished, solvent extraction is conducted to obtain the spice. The composite caramel-flavour aroma spice is applied to cigarettes, inapplicable tobacco leaves, reconstituted tobacco leaves, cut stems and expanded cut tobaccos, has rich tobacco aroma and caramel aroma, and does not generate 4-methylimidazole.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

Filter rod additive for reducing cigarette smoking dryness and irritation, preparation method and use thereof

The invention discloses a filter additive which comprises the following components by mass: the mixed extract of Daphne odora and Glycyrrhiza uralensis Fisch is 20- 30 wt%, megatrienone 0.1- 0.15 wt%of bornyl acetate, 0.2 wt% of bornyl acetate, 0.2 wt% of bornyl acetate, 0.2 wt% of bornyl acetate and 0.2 wt% of bornyl acetate. 0.3 wt% of geranyl acetate, 0.2 wt% of geranyl acetate and 0.3 wt% ofgeranyl acetate. 0.3 wt%, 0.5-1wt% of Twain-80 and 0.2-0.4wt% of perilla essential oil, 1.5-2wt% of chrysanthemum extract and 1.5-2 wt% of pueraria root extract, 0.2 wt% of pueraria root extract, 0.2-0.5wt% of pueraria root extract, and the balance of glycerol triacetate. The invention also discloses a method for extracting the mixed extract of Daphne odora and Glycyrrhiza uralensis Fisch. The invention further discloses the use of the filter tip additive for reducing the smoking dryness and irritation of cigarettes.

Owner:CHINA TOBACCO YUNNAN IND

Water-soluble biological polysaccharide with low polymerization degree, using method thereof and obtained product

ActiveCN102180983AReduced prickly sensationReduce woodinessTobacco preparationSugar derivativesDepolymerizationAspergillus

The invention relates to a water-soluble biological polysaccharide with low polymerization degree, a method for preparing papermaking tobacco sheets with low fiber content by using the polysaccharide and a product obtained by the method. The water-soluble biological polysaccharide with low polymerization degree is obtained by hydrochloric acid solution immersion of aspergillus niger or shrimp bran, protein removal treatment, calcium removal, decoloration, acetyl removal treatment, depolymerization and oxidative cutting. The papermaking tobacco sheets are prepared by substituting partial wood pulp fiber for the prepared water-soluble biological polysaccharide with low polymerization degree, and the novel papermaking tobacco sheets with low fiber content has better smoking quality besides the physical properties of the original products.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

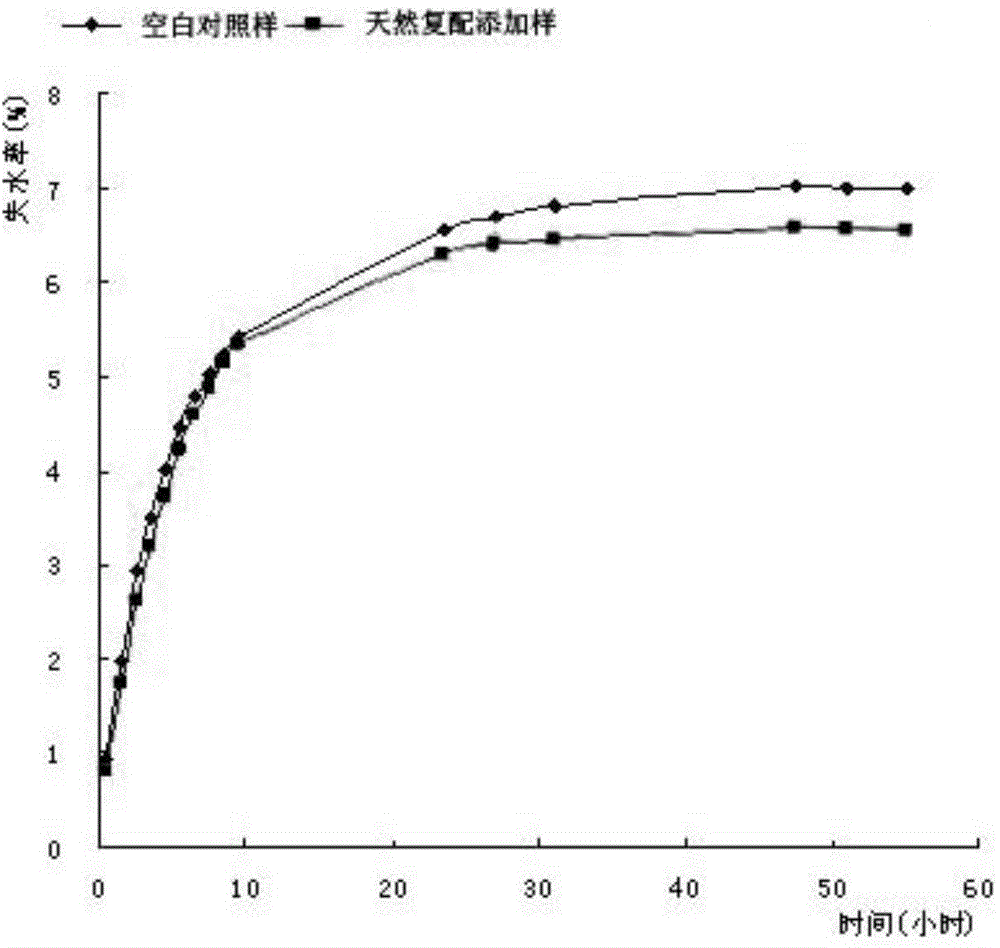

Natural compound humectant with cigarette sensory humectation function

InactiveCN104687243AMoisturizing effect is obviousImprove suction comfortTobacco treatmentPagoda treeIrritation

The invention discloses a natural compound humectant with a cigarette sensory humectation function. The humectant comprises components in parts by weight as follows: 10-30 parts of 3,3',4',5,7-pentahy-droxyflavone-3-rutinoside, 50-80 parts of sea buckthorn polysaccharide and 10-30 parts of sea buckthorn flavone. The 3,3',4',5,7-pentahy-droxyflavone-3-rutinoside is extracted and prepared from tobacco or pagoda tree flower buds respectively with an ASE (accelerated solvent extraction) method, and the sea buckthorn polysaccharide and the sea buckthorn flavone are extracted and prepared from sea buckthorn fruits with the ASE method. An extraction method of the natural compound humectant is small in solvent amount, quick and efficient, and the humectant can reduce the loss of moisture in cut tobacco in a dry environment, reduce dryness and irritation of cigarette smoke to enable the smoke to be mellower, fuller and softer, obviously improve the smoking comfort of cigarettes and enhance the sensory humectation of the cigarettes.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

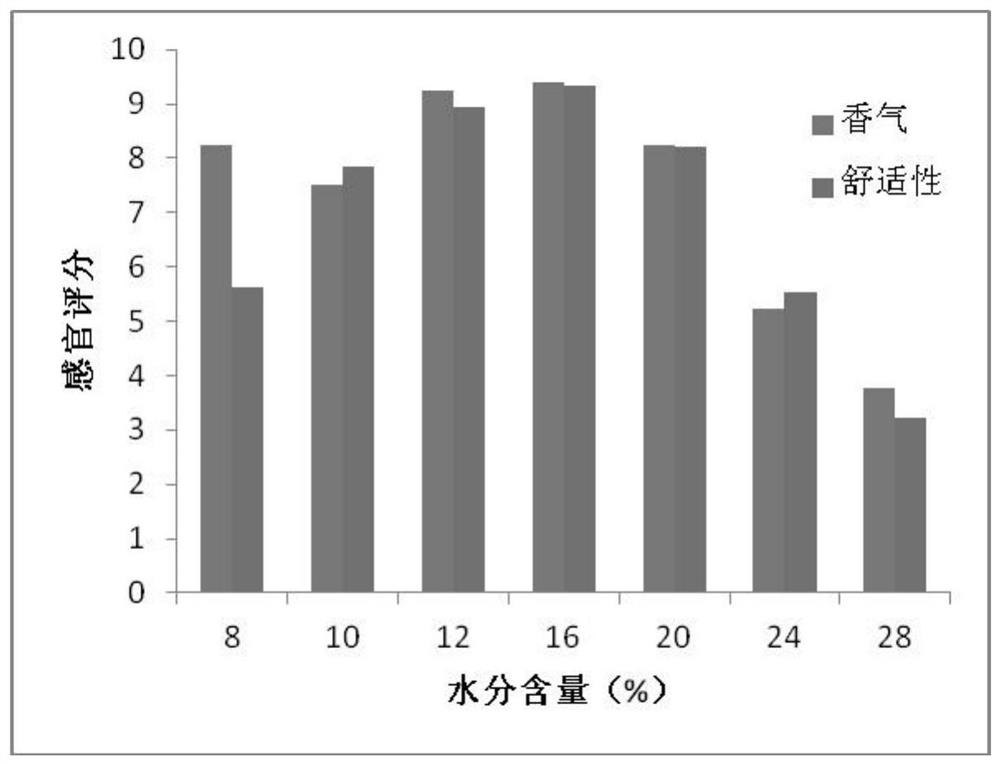

Method for improving comfort of heated cigarettes

PendingCN111772226AImprove suction comfortIncrease richnessTobacco treatmentProcess engineeringEnvironmental geology

The invention discloses a method for improving comfort of heated cigarettes. The invention belongs to the technical field of heating cigarettes, specifically, the method comprises the following steps:preparing surface fragrance, controlling the pH value to be less than 6 by utilizing an acid-base regulator, then adding the surface fragrance into a cigarette core material, adding a water-holding agent into the cigarette core material to control the moisture content to be 10-20% and the moisture activity value to be 0.35-0.7, and finally preparing the cigarette core material into a heated cigarette. According to the method, the pH value of the surface aroma is monitored in the preparation process of the heated cigarette, and meanwhile, the moisture content and the moisture activity of the cigarette core material are controlled, so that the smoking comfort of the heated cigarette is effectively improved.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

A kind of colored cigarette paper coating solution with special aroma and its application

ActiveCN108797214BPreserve the coloring functionAdjust colors flexiblySurface covering paperNon-fibrous pulp additionBiotechnologySocial benefits

The invention discloses a colored cigarette paper coating solution with specific fragrance and application thereof. The colored cigarette paper coating solution is prepared through the following steps: taking plants containing natural pigment as raw materials, and fermenting plant powder or pulp by sequentially using an aspergillus oryzae YNCA 9804 strain and a bacillus subtilis Van3 strain, thusforming an aroma component; carrying out solvent extraction and concentration purification; mixing the aroma component with coating solutions such as fungal polysaccharide, thus preparing a finished product. According to the colored cigarette paper coating solution disclosed by the invention, the characteristic of pleasant fragrance of the colored cigarette paper coating solution is given while acoloring function of the natural pigment is reserved; pigment powder with the fragrance obtained through treatment is independently compounded, mutually compounded or compounded with other natural pigment for use, so that the color of the colored cigarette paper coating solution can be flexibly regulated; synthetic pigment is replaced, dual sense experience on vision and olfaction can be obtainedby a cigarette product while the safety is improved, diversified color developing and fragrance increment of a tobacco paper base can be realized, and good social benefit and economic benefit are obtained.

Owner:CHINA TOBACCO YUNNAN IND

High-efficient preparation method and application of red jujube purified oil

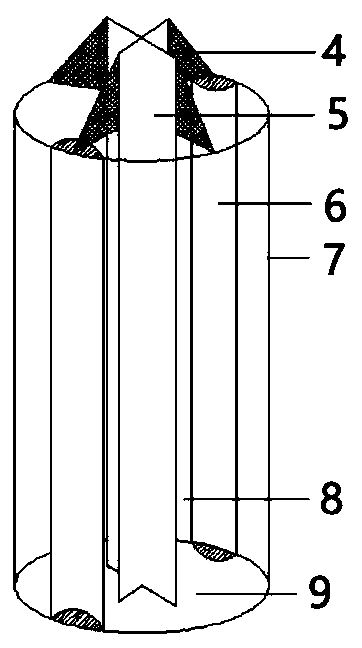

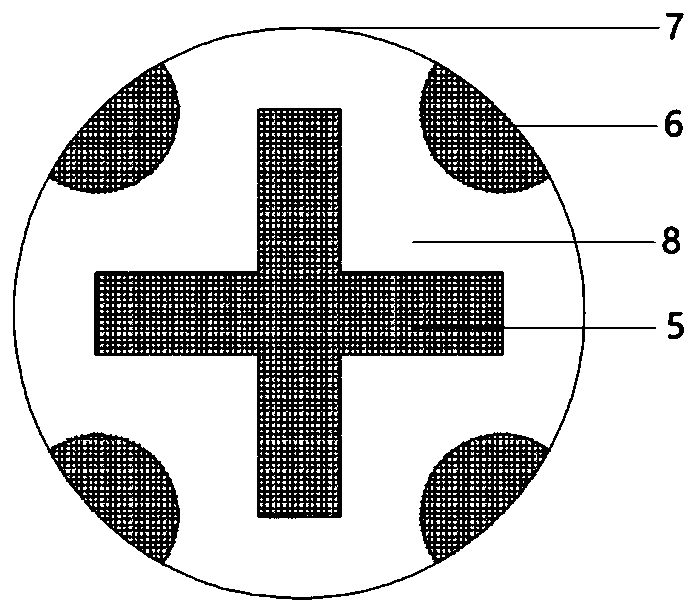

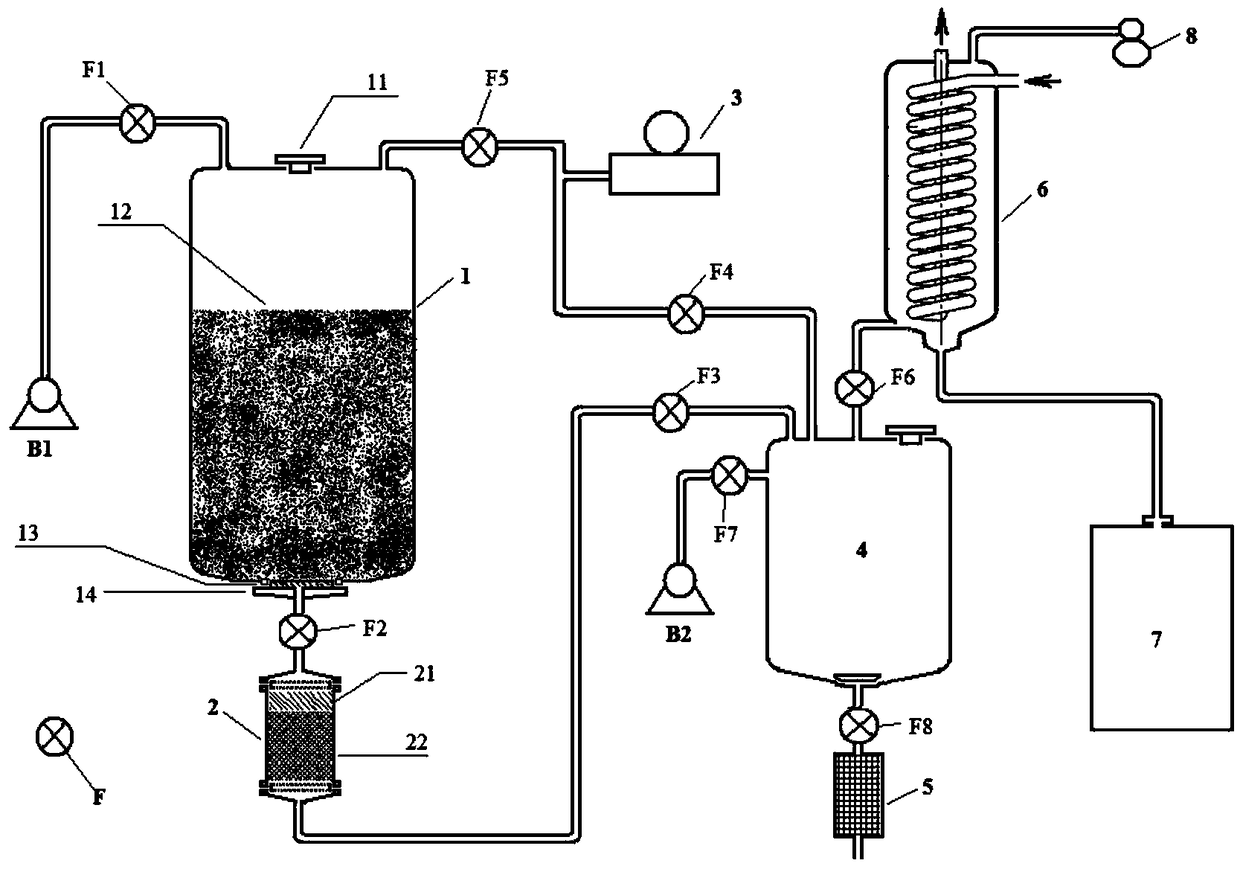

ActiveCN109123754AHigh yieldImprove qualityTobacco preparationTobacco treatmentElectronic cigaretteSolvent

The invention discloses a preparation method of red jujube clean oil, which uses the following devices: an ultrasonic extraction tank (1); a chromatographic column (2); an air compressor (3); a thickening tank (4); a reverse resin column (5); a condenser (6); a vacuum pump (8); a solvent recovery tank (7). The method includes the steps of (1) ultrasonic extraction of red jujube raw material; (2),purifying by chromatographic column; (3); concentration; (4) purifying by a reverse resin column; (5) removing ethanol under reduced pressure to obtain the pure red jujube oil. The device of the invention can efficiently extract and purify the red jujube clean oil, and the obtained red jujube clean oil can be used in cigarette, electronic cigarette or heated non-combustible cigarette, so as to effectively improve and improve the smoking comfort of the cigarette.

Owner:CHINA TOBACCO YUNNAN IND

Preparation method of water particles capable of improving smoke moist feeling

PendingCN114011329AIncrease moist feelingImprove roundnessTobacco smoke filtersGranulation by liquid drop formationAdhesivePolyethylene glycol

The invention belongs to the technical field of cigarette materials, and relates to cigarette auxiliary materials, in particular to a preparation method of water particles capable of improving smoke moist feeling, the preparation method comprises the following steps: taking water as a main material, adding polyethylene glycol, an adhesive and a structure enhancer, melting and uniformly mixing the materials, dripping into liquid drops by a pill dropping machine, quickly passing through a cooling liquid, and curing to obtain the water particles, wherein the mass ratio of the pure water to the polyethylene glycol to the adhesive is (30-40): (1-3): 1; the mass of the structure enhancer is 0.05% of that of the pure water, and the structure enhancer is one or more of potassium chloride, sodium chloride and calcium chloride. According to the water particles capable of improving the smoke moist feeling, the preparation method is simple, the prepared particles are good in roundness and high in moisture content, when the smoke passes through the particles, the particles are heated to generate slow phase change and moisture release, the moist feeling of the smoke can be effectively improved, the smoking comfort is improved, and the effects of aroma enhancement and moisture retention are achieved.

Owner:JIANGSU DAYA CIGARETTE FILTER MATERIAL CO LTD +1

Heat-not-burn cigarette in ternary composite structure

InactiveCN109645574AReduce the temperatureImprove suction comfortTobacco devicesHeat not burnBiomedical engineering

The invention relates to a heat-not-burn cigarette in a ternary composite structure. The heat-not-burn cigarette is formed by an aroma section, a hollow tube section, a filter section and cigarette shaping paper, the aroma section, the hollow tube section and the filter section are positioned in sequence, and the cigarette shaping paper externally wraps the aroma section, the hollow tube section and the filter section. The heat-not-burn cigarette is suitable for different heating modes and different heat-not-burn cigarette devices and is not only capable of filtering some harmful substances but also capable of greatly reducing the temperature of smoke entering the oral cavity, and accordingly smoking comfort of customers can be improved.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

A preparation method for reducing flue gas temperature and low suction resistance polylactic acid tow filter rod

ActiveCN108523216BDegradableLower heat transfer coefficientTobacco treatmentCigar manufacturePolymer scienceFlue gas

The invention relates to a low draw-resistance PLA tow filter stick with reduced flue gas temperature and a preparation method thereof. The preparation method comprises the steps of preparing a phase-change material mixture, preparing a phase-change material containing fragrance substances, and preparing a slow-release fragrance filter rod. The present invention combines the addition of phase-change materials with low-drawing-resistance PLA tow filter rods, improves the overall smoking taste of cigarettes and heat-not-burn cigarettes through triple cooling, and at the same time reduces the temperature of smoke, which improves consumers' satisfaction. Suction comfort, simple process, suitable for industrial production.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

Fumigating and flavoring method and application thereof in tobaccos

ActiveCN111329098AIncrease the aroma of cigarettesBig airTobacco preparationCigar manufactureNicotiana tabacumHorticulture

The invention discloses a fumigating and flavoring method. The method comprises the following steps of: fumigating natural perfume plants and tobacco leaves serving as main materials and functional auxiliary materials for 5 to 48 hours in a closed container at the temperature of between 50 and 150 DEG C, performing cooling at room temperature, and performing standing for 24 hours to obtain fumigated natural perfume plants and fumigated tobacco leaves. The invention further discloses application of the fumigated tobacco leaves or / and the fumigated natural aromatic plants obtained through the fumigating and flavoring method to cigarettes.

Owner:CHINA TOBACCO YUNNAN IND

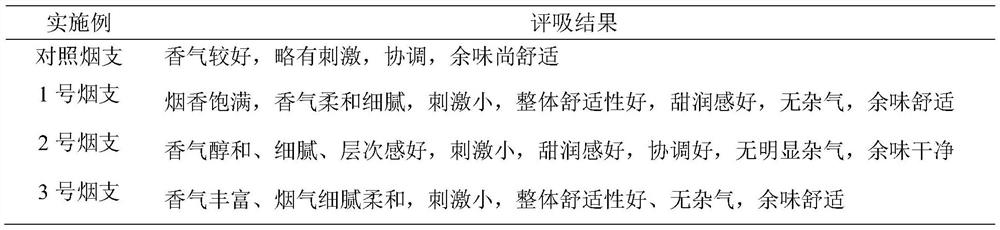

Preparation method for carica papaya leaf extract and application for same in cigarettes

ActiveCN103653238AIncrease aromaImprove satisfactionTobacco treatmentEssential-oils/perfumesAlcoholBiology

The invention discloses a preparation method for a carica papaya leaf extract and an application for the same in cigarettes. According to the application, after being extracted from carica papaya leaves with water or alcohols with different concentrations, the carica papaya leaf extract is weighed in a ratio occupying 0.02-5% of the weight of produced tobacco shreds and uniformly sprayed on the produced tobacco shreds, so as to prepare a cigarette. The result of a smoke panel test on the addition of the carica papaya leaf extract in a tested cigarette indicates that: the carica papaya leaf extract is capable of harmonizing with cigarette aroma, improving aroma quality, enriching cigarette aroma, achieving clear aroma, distinct personality, soft and smooth smoke and good lasting feeling, improving smoking satisfaction, obviously reducing irritation, increasing smoking comfort level, and keeping comfortable aftertaste and moderate concentration and strength.

Owner:CHINA TOBACCO FUJIAN IND

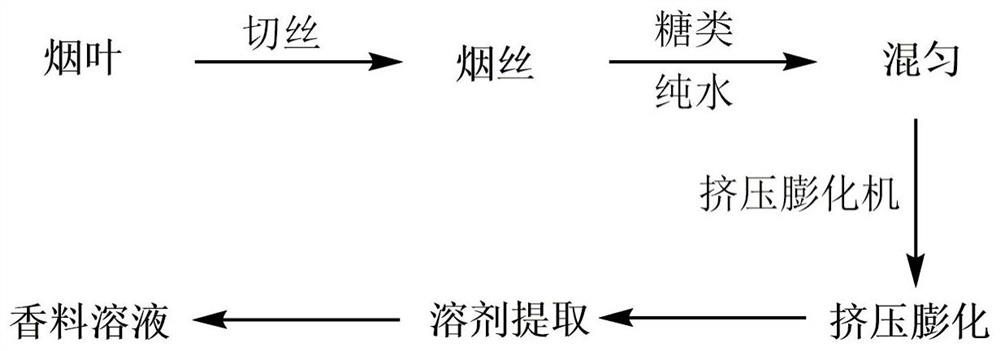

Composite caramel aroma spice, extrusion puffing preparation method and application method of composite caramel aroma spice

The invention discloses a composite caramel aroma spice as well as an extrusion puffing preparation method and an application method thereof. The composite caramel aroma spice is prepared by uniformlymixing and reacting the following raw materials, by mass: 1.0-20.0 parts of tobacco leaves, 0.2-10.0 parts of saccharides and 0.1-10.0 parts of pure water. Specifically, the tobacco leaf raw materials are shredded to obtain tobacco shreds, the tobacco shreds and the saccharides are evenly stirred, pure water is sprayed into the mixture to be evenly mixed, then the mixture is put into an extrusionbulking machine which is preheated to 120-200 DEG C in a third area and preheated to 110-190 DEG C in a second area to be subjected to extrusion bulking reaction, extrusion bulking treatment is conducted 1-5 times, and spice is obtained through solvent extraction after reaction. The spice has rich tobacco fragrance and caramel fragrance, and can be applied to cigarettes, inapplicable tobacco leaves, reconstituted tobacco leaves, cut stems and expanded cut tobaccos.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

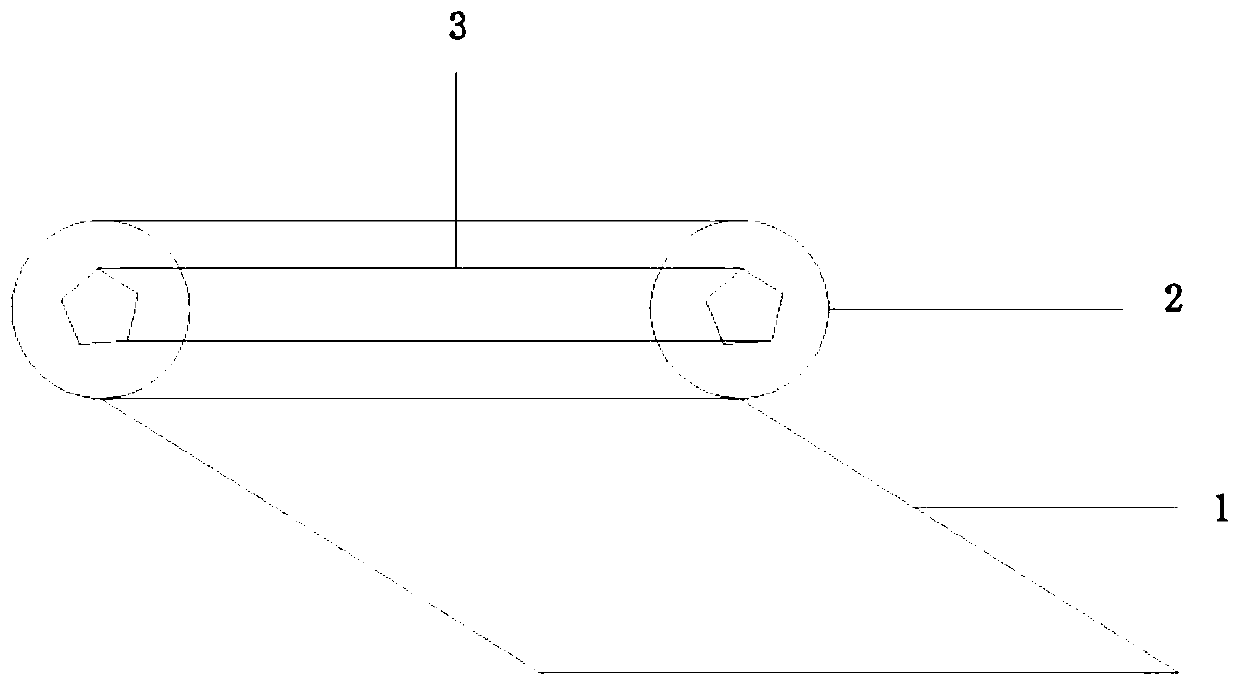

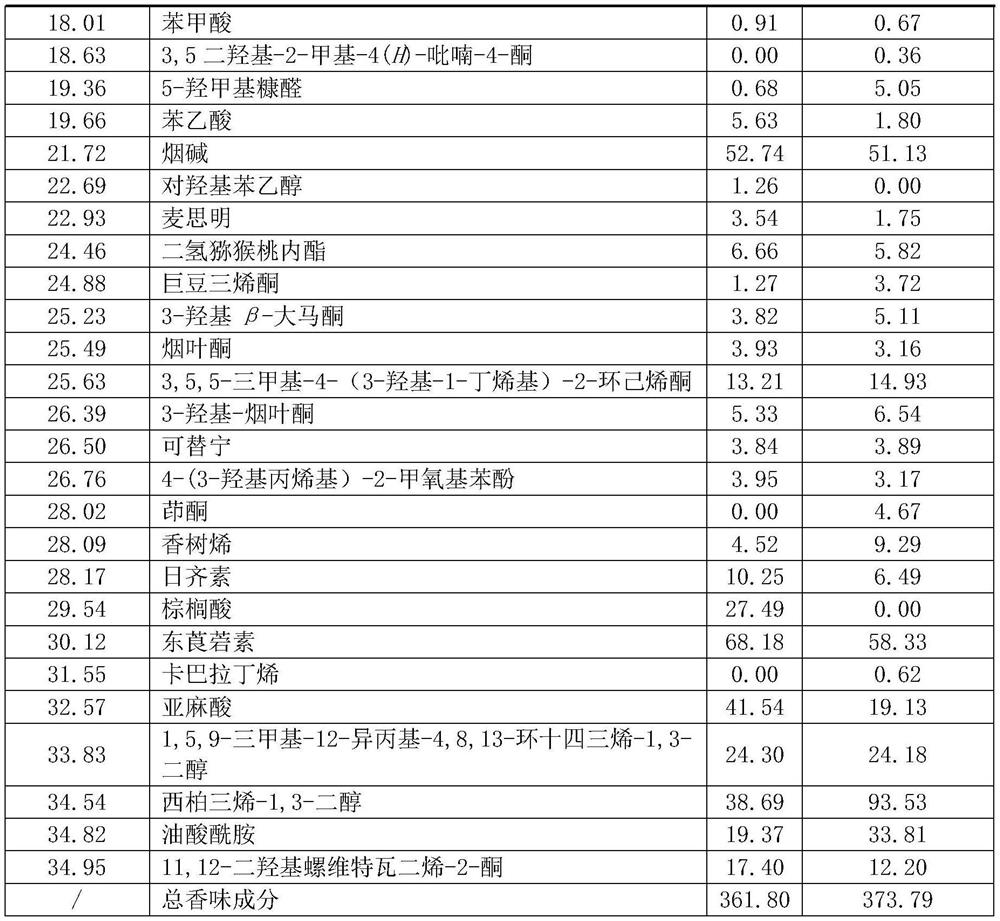

Heating non-winding combustion cigarette containing water capsule

PendingCN111329116ASimple structureReduce the temperatureTobaccoThermodynamicsMechanical engineering

The invention relates to a heating non-winding combustion cigarette containing a water capsule, which is formed by sequentially connecting a fuming section (1), a smoke guide section (2) and a filtering section (3), and the water capsule (3-1) is embedded in the filtering section (3) and plays a dual role in cooling and filtering. The heating non-winding combustion cigarette containing the water capsule is suitable for central heating or annular heating heating non-combustion heating devices sold in the market at present. The heating non-winding combustion cigarette containing the water capsule is simple in structure, industrial production is easy to achieve, and therefore the water-containing capsule heating non-combustible cigarette has very good market prospects.

Owner:YUNNAN NANZHONG TECH CO LTD

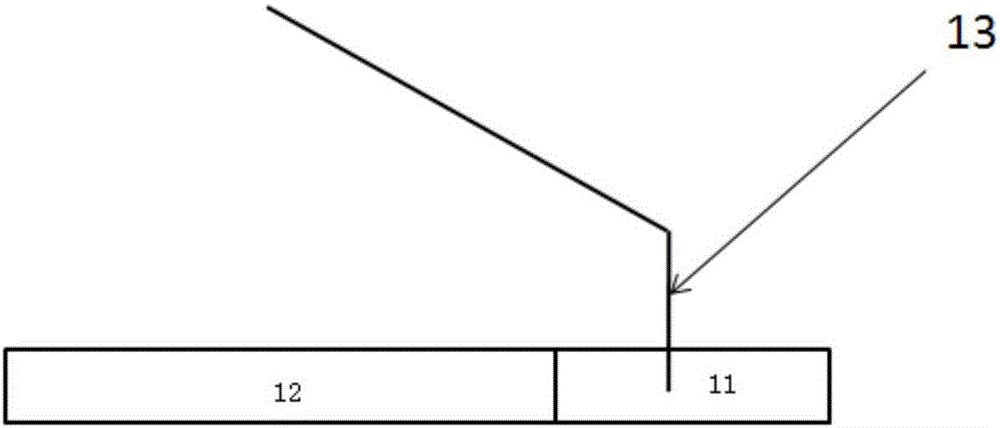

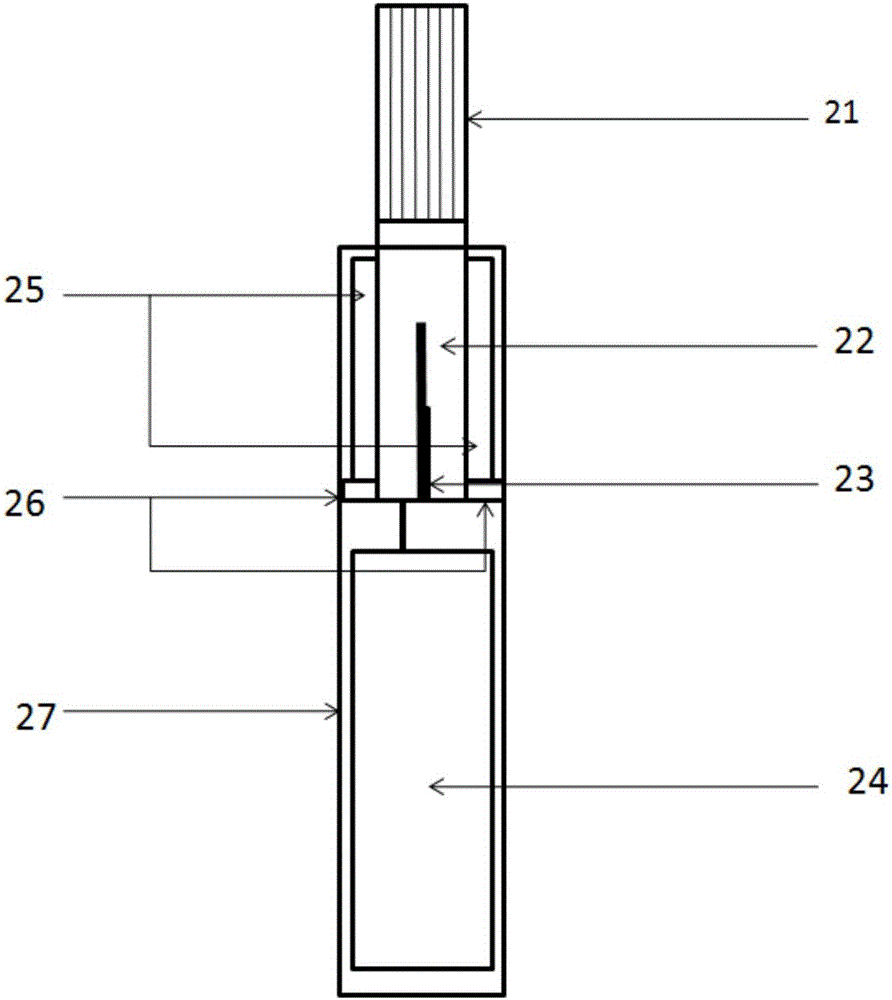

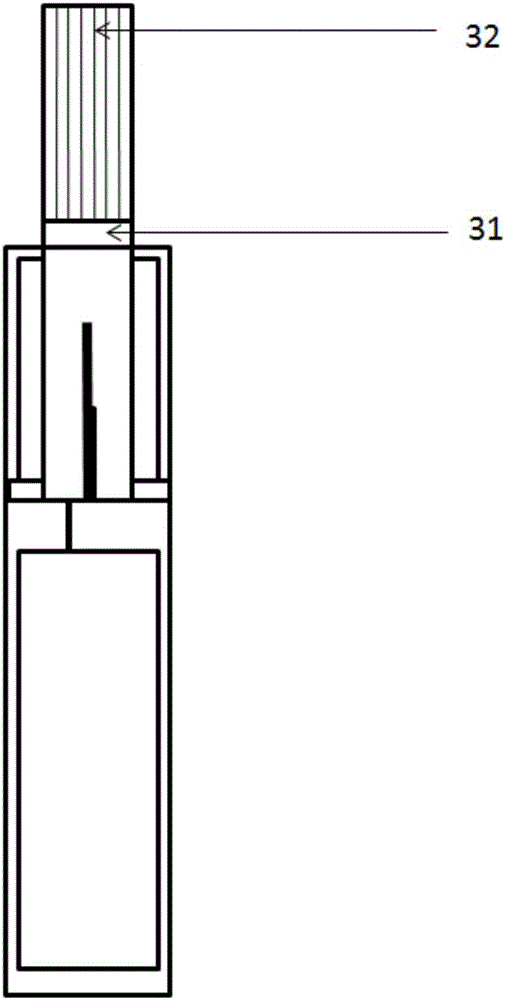

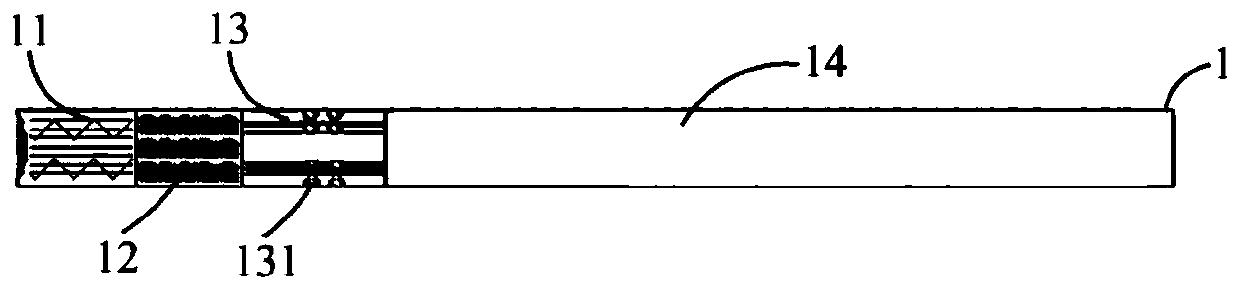

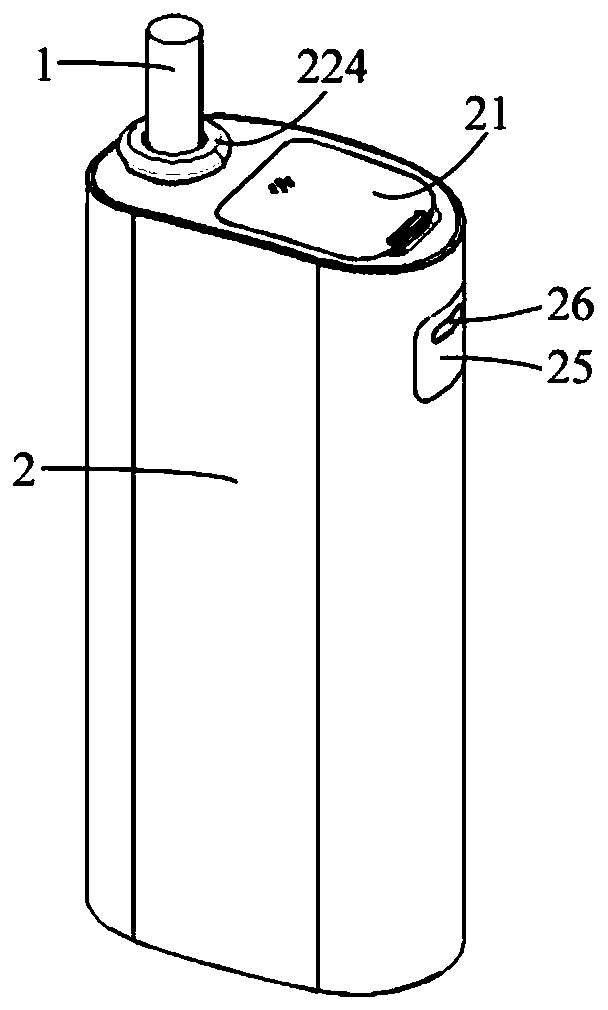

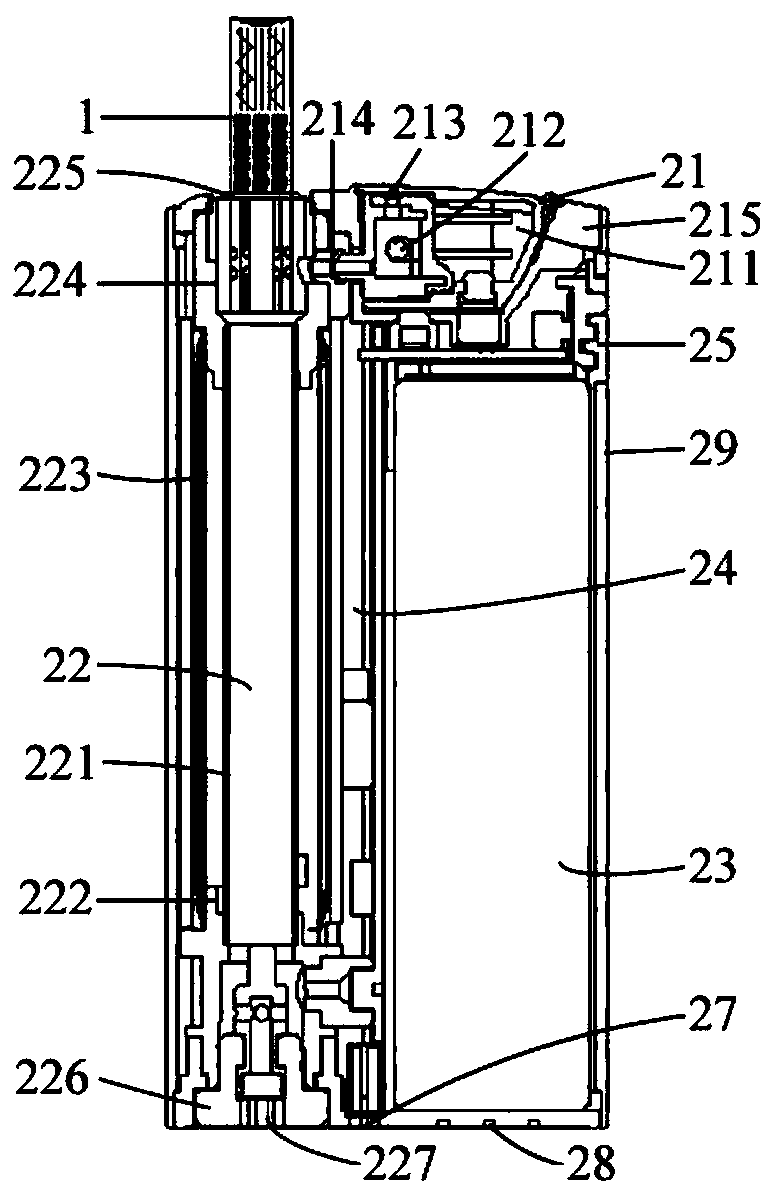

Heating cigarette and composite smoking set matched with heating cigarette

PendingCN111264912AProblems Affecting SmellAddress the risk of burning your mouthTobaccoThermodynamicsFlue gas

The invention discloses a heating cigarette and a composite smoking set matched with the heating cigarette, and the heating cigarette comprises a heating cigarette body (1) which comprises a supporting section (13), and the supporting section (13) is of a hollow structure and is provided with a vent hole (131) penetrating through the side wall in the circumferential direction; the composite smoking set (2) comprises an atomizer (21) and a heater (22); the heater (22) is matched with the heating cigarette (1); a flue gas buffer part (224) is arranged at the upper part of the heater (22); the supporting section (13) is located in the smoke buffering part (224), and an airflow channel (214) on the atomizer (21) is communicated with the flue gas buffering part (224). According to the heating cigarette and the composite smoking set matched with the heating cigarette, smoke released by the heating cigarette and tobacco tar atomized smoke generated by the atomizer are fully mixed, the utilization rate of the tobacco tar atomized smoke is increased, and the smoking quality of smoke is improved.

Owner:CHINA TOBACCO YUNNAN IND

A kind of normal temperature scenting method and application

ActiveCN111418872BIncrease softnessIncrease diversityTobacco preparationLiquid mediumNicotiana tabacum

The invention discloses a method for scenting and flavoring at room temperature. The tobacco leaves are used as the main material, functional auxiliary materials and liquid medium are added, and the flavored tobacco leaves are obtained by scenting and flavoring at normal temperature in a closed storage box. The invention also discloses the use of the method for scenting and flavoring at room temperature in tobacco. The scented tobacco leaves can significantly increase the aroma of cigarettes and significantly improve smoking comfort.

Owner:CHINA TOBACCO YUNNAN IND

Normal-temperature scenting and flavoring method and application

ActiveCN111418872AIncrease softnessIncrease diversityTobacco preparationLiquid mediumNicotiana tabacum

The invention discloses a normal-temperature scenting and flavoring method, which comprises the following steps of: adding functional auxiliary materials and a liquid medium into tobacco leaves serving as the main material, and performing normal-temperature scenting and flavoring in a closed storage box to obtain flavored tobacco leaves. The invention further discloses application of the normal-temperature scenting and flavoring method in tobacco. The scented tobacco leaves can obviously increase the aroma volume of cigarettes and obviously improve the smoking comfort.

Owner:CHINA TOBACCO YUNNAN IND

A kind of preparation method of cigarette mouth stick additive and its application in filter

ActiveCN107048475BPlay a double roleSimple processTobacco smoke filtersMaterials scienceCigarette filter

The invention discloses a preparation method of a cigarette filter rod additive. The cigarette filter rod additive takes phlomis betonicoides as a raw material and is prepared through the following steps: (1) preparation of the raw material: drying the phlomis betonicoides at the temperature of 50-80 DEG C, and pulverizing to 50-100 meshes; (2) sub-critical extraction: taking dimethyl ether as an extracting agent and glyceryl triacetate as an entrainer to extract the pulverized phlomis betonicoides powder at the temperature of 0-50 DEG C and under the pressure of 0.5-3.0 MPa; (3) preparation of the filter rod additive: recycling dimethyl ether in the step (2), and obtaining a glyceryl triacetate solution containing a phlomis betonicoides extract, namely the cigarette filter rod additive. The invention further discloses an application of the cigarette filter rod additive obtained through the preparation method to a cigarette product.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com