A preparation method for reducing flue gas temperature and low suction resistance polylactic acid tow filter rod

A technology of flue gas temperature and polylactic acid, applied in e-liquid filter elements, tobacco, applications, etc., can solve the problems of increasing the amount of fragrance added to incense sticks and filter sticks, and achieve improved smoking taste, low heat transfer coefficient, and increased richness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

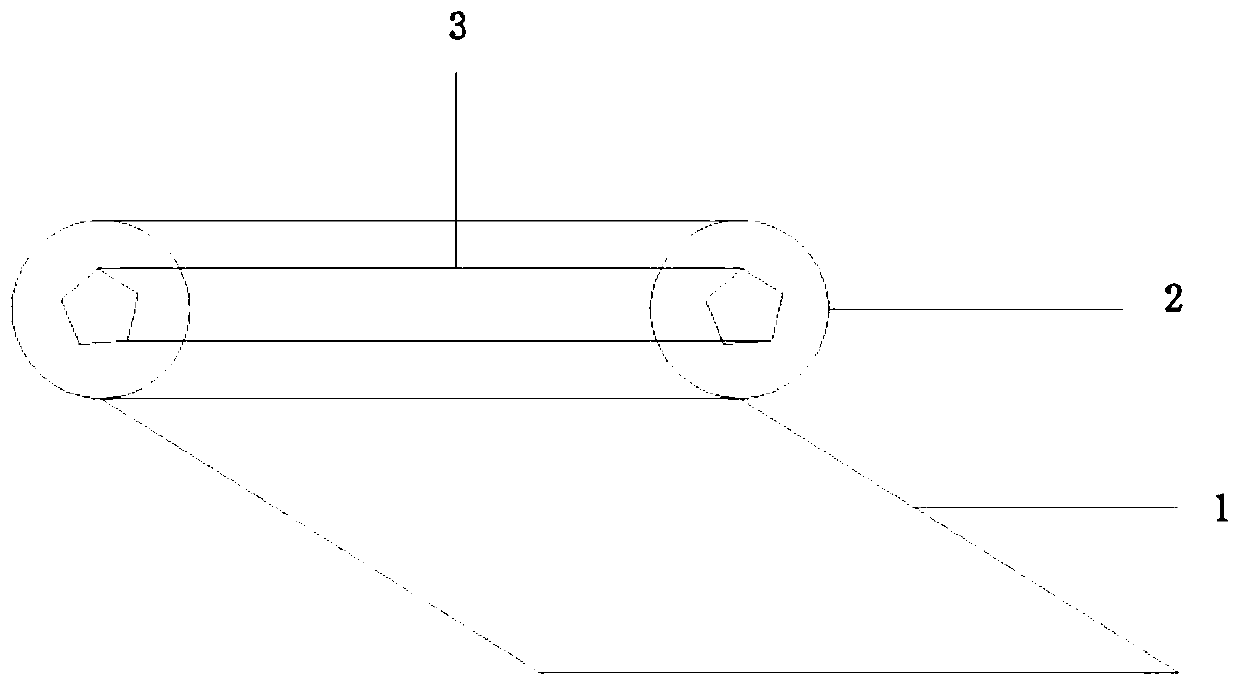

Image

Examples

Embodiment 1

[0035] Example 1: Preparation of PLA tow filter sticks with reduced flue gas temperature and low draw resistance

[0036] The implementation steps of this embodiment are as follows:

[0037] A. Preparation of phase change material mixture

[0038] Mix polyethylene glycol 400, polyethylene glycol 1000, polyethylene glycol 1500, water and stearic acid in a mass ratio of 15:22:46:11:6 to obtain the phase change material mixture;

[0039] B. Preparation of phase change materials containing fragrance substances

[0040] Mix the tree moss extract with the phase change material mixture obtained in step A according to the mass ratio of 46:54, then add it to a sealed water bath, heat and dissolve at a temperature of 67°C with stirring, and then keep it warm at a temperature of 90°C. Obtaining the phase change material solution containing fragrance substances;

[0041] C, preparation of slow-release fragrance filter stick

[0042] According to the mass ratio of the phase change mate...

Embodiment 2

[0044] Example 2: Preparation of PLA tow filter sticks with reduced flue gas temperature and low draw resistance

[0045] The implementation steps of this method are as follows:

[0046] A. Preparation of phase change material mixture

[0047] Mix polyethylene glycol 400, polyethylene glycol 1000, polyethylene glycol 1500, water and stearic acid according to the mass ratio of 21:24:39:9:7 to obtain the phase change material mixture;

[0048] B. Preparation of phase change materials containing fragrance substances

[0049] Mix the tangerine peel mint flavor essence with the phase change material mixture obtained in step A according to the mass ratio of 53:47, then add it into a sealed water bath, heat and dissolve at a temperature of 72°C and stirring, and then keep it warm at a temperature of 90°C. Obtaining the phase change material solution containing fragrance substances;

[0050] C, preparation of slow-release fragrance filter stick

[0051] According to the mass ratio...

Embodiment 3

[0053] Example 3: Preparation of PLA tow filter sticks with reduced flue gas temperature and low draw resistance

[0054] The implementation steps of this method are as follows:

[0055] A. Preparation of phase change material mixture

[0056]Mix polyethylene glycol 400, polyethylene glycol 1000, polyethylene glycol 1500, water and stearic acid in a mass ratio of 23:14:46:12:5 to obtain the phase change material mixture;

[0057] B. Preparation of phase change materials containing fragrance substances

[0058] Propylene glycol and sorbitol are mixed according to the mass ratio of 1:2 to obtain a fragrance substance, which is then mixed with the phase change material mixture obtained in step A according to the mass ratio of 39:61, and then added to a sealed water bath, at a temperature of 65 ° C and Heating and dissolving under stirring conditions, and then keeping warm at a temperature of 90° C., to obtain the phase change material solution containing fragrance substances; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com