Composite caramel aroma spice, extrusion puffing preparation method and application method of composite caramel aroma spice

An extrusion puffing, sweet and fragrant technology, which is applied in the application and preparation of tobacco, tobacco, etc., can solve the problems of insufficient aroma and harmful components, and achieve the natural coordination of tobacco aroma, increase the richness of smoke, and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of Glucose Compound Burnt Sweet Spice, Fragrance Component Analysis and Application

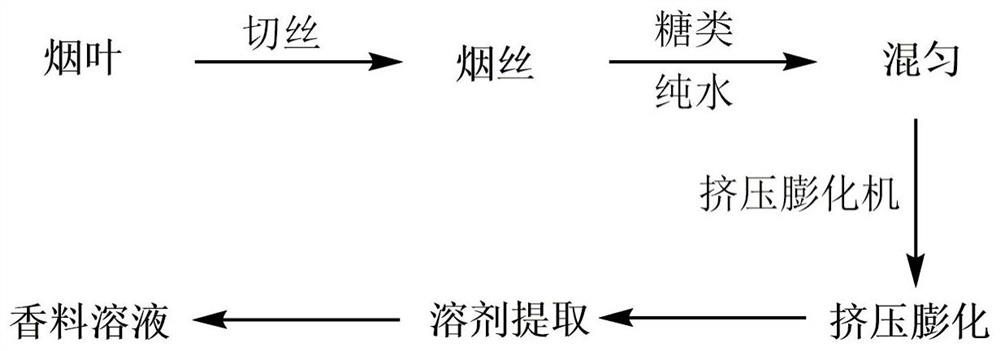

[0028] Such as figure 1 As shown, take 10.0 parts of tobacco leaves (the grade is B2F, the production place is Yibin, Sichuan, and the year is 2013) after shredding, add 3.0 parts of glucose and mix well, then spray 2.0 parts of pure water and mix well. Add the temperature of the third zone to 170°C and preheat the temperature of the second zone to 150°C in an extruder. Set the frequency of the main motor as 12.4Hz, and the number of times of extrusion and puffing as 3 times. The reaction product was cooled, then added to a round bottom flask, added 50.0 parts by mass of 50% ethanol-water solution, and extracted under reflux for 40 min. Filter to obtain the compound burnt sweet spice solution.

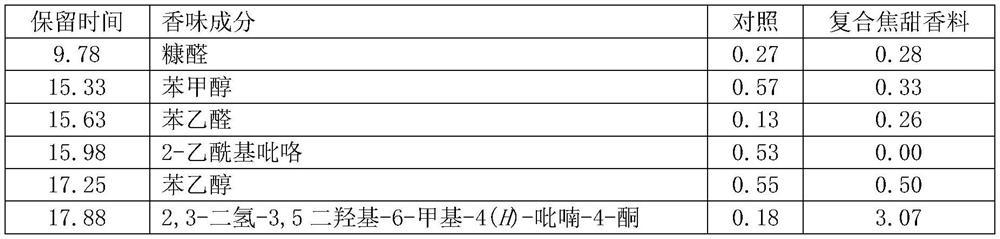

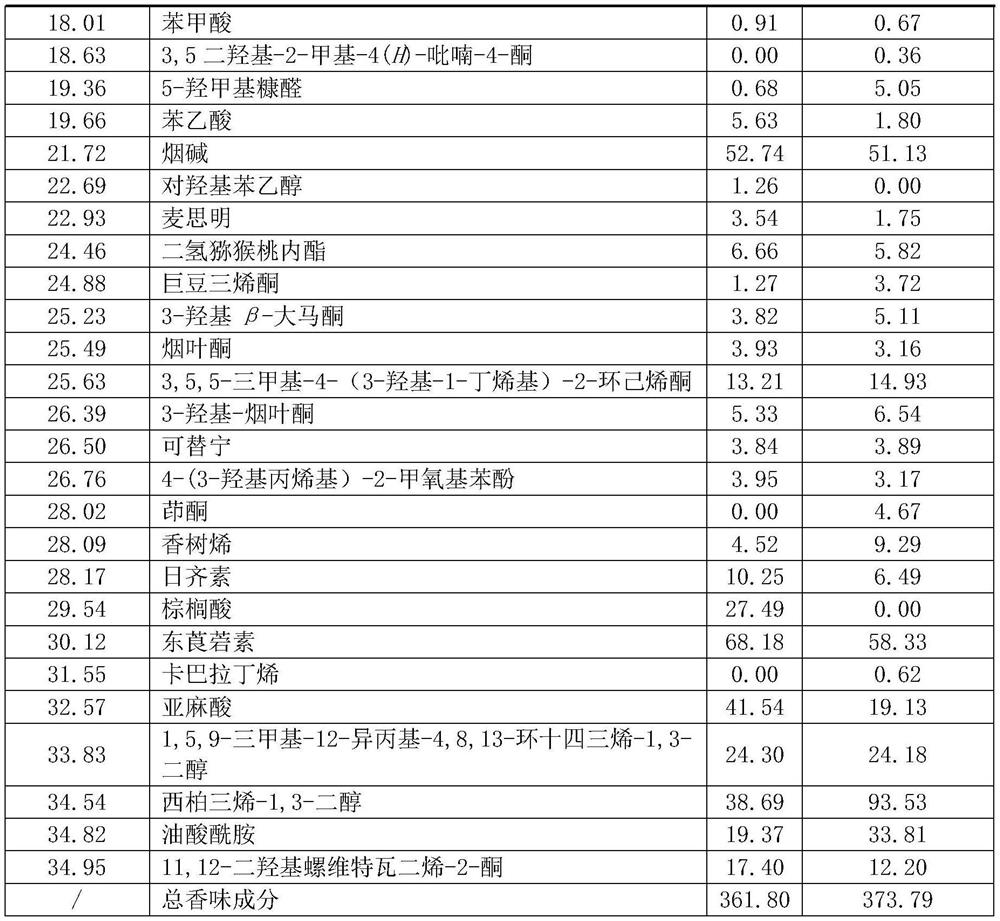

[0029] Take 15.0 mL of compound burnt sweet spice solution, add 15.0 mL of pure water, add 10.0 mL of dichloromethane, and extract. The dichloromethane layer was trans...

Embodiment 2

[0041] Preparation and Application of Example 2 Fructose Compound Burnt Sweet Spice

[0042] Tobacco leaves (grade B2F, produced in Yibin, Sichuan, year 2013) were shredded and 10.0 parts were taken, mixed with 3.0 parts of fructose, then sprayed with 2.0 parts of pure water and mixed. Add the temperature of the third zone to 170°C and preheat the temperature of the second zone to 150°C in an extruder. Set the frequency of the main motor as 12.4Hz, and the number of times of extrusion and puffing as 3 times. The reaction product was cooled, then added to a round bottom flask, added 50.0 parts by mass of 50% ethanol-water solution, and extracted under reflux for 40 min. Filter to obtain the compound burnt sweet spice solution.

[0043] Add the fructose compound burnt sweet flavor solution to Sichuan Zhongyan 2 at an amount of 1 μL per cigarette. #Module blank cigarette stick. The sensory evaluation was carried out with the blank cigarette without adding the above product as...

Embodiment 3

[0044] Example 3 Preparation and Application of Compound Scorched Sweet Spices with Different Tobacco Leaf Raw Materials

[0045] Tobacco leaves (grade YQ1, produced in Qujing, Yunnan, year 2014; grade B4F, produced in Liangshan, Sichuan, year 2011) were shredded and 10.0 parts were taken, mixed with 3.0 parts of glucose, and then sprayed with pure water 2.0 parts Mix well. Add the temperature of the third zone to 170°C and preheat the temperature of the second zone to 150°C in an extruder. Set the frequency of the main motor as 12.4Hz, and the number of times of extrusion and puffing as 3 times. The reaction product was cooled, then added to a round bottom flask, added 50.0 parts by mass of 50% ethanol-water solution, and extracted under reflux for 40 min. Filter to obtain the compound burnt sweet spice solution.

[0046] Add the compound burnt sweet flavor solution to Sichuan Zhongyan 2 at an amount of 1 μL per cigarette. # Module blank cigarette stick. The sensory eval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com