Fumigating and flavoring method and application thereof in tobaccos

A kind of use and technology of tobacco leaves, applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problem of not obvious improvement of tobacco smoking quality, and achieve the effect of rich aroma, elegant smoke aroma, and increased coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 3 parts of aloe vera gel, 5 parts of potassium sodium citrate, and 3 parts of aspartic acid, dissolve potassium sodium citrate in ultrapure water, heat and stir at 50°C, and add propylene glycol according to the mass ratio of 1:1 , and then sequentially add aloe vera gel and aspartic acid, and continue heating and stirring at 50°C for 0.5h to obtain the required functional auxiliary material.

[0024] Fumigate 50 parts of tobacco leaves, 20 parts of Pu'er tea, and 3 parts of functional auxiliary materials in a closed container at 120°C for 10 hours, cool at room temperature and place it for 24 hours before taking it out for use.

[0025] Carry out microwave-assisted steam distillation to the Pu'er tea after fumigation, use the mixed solution of ethanol and water (volume ratio 1:1) as extraction solvent, carry out microwave-assisted steam distillation according to the ratio of raw material and solvent mass ratio being 1:10, The microwave power is 550W, the radiation...

Embodiment 2

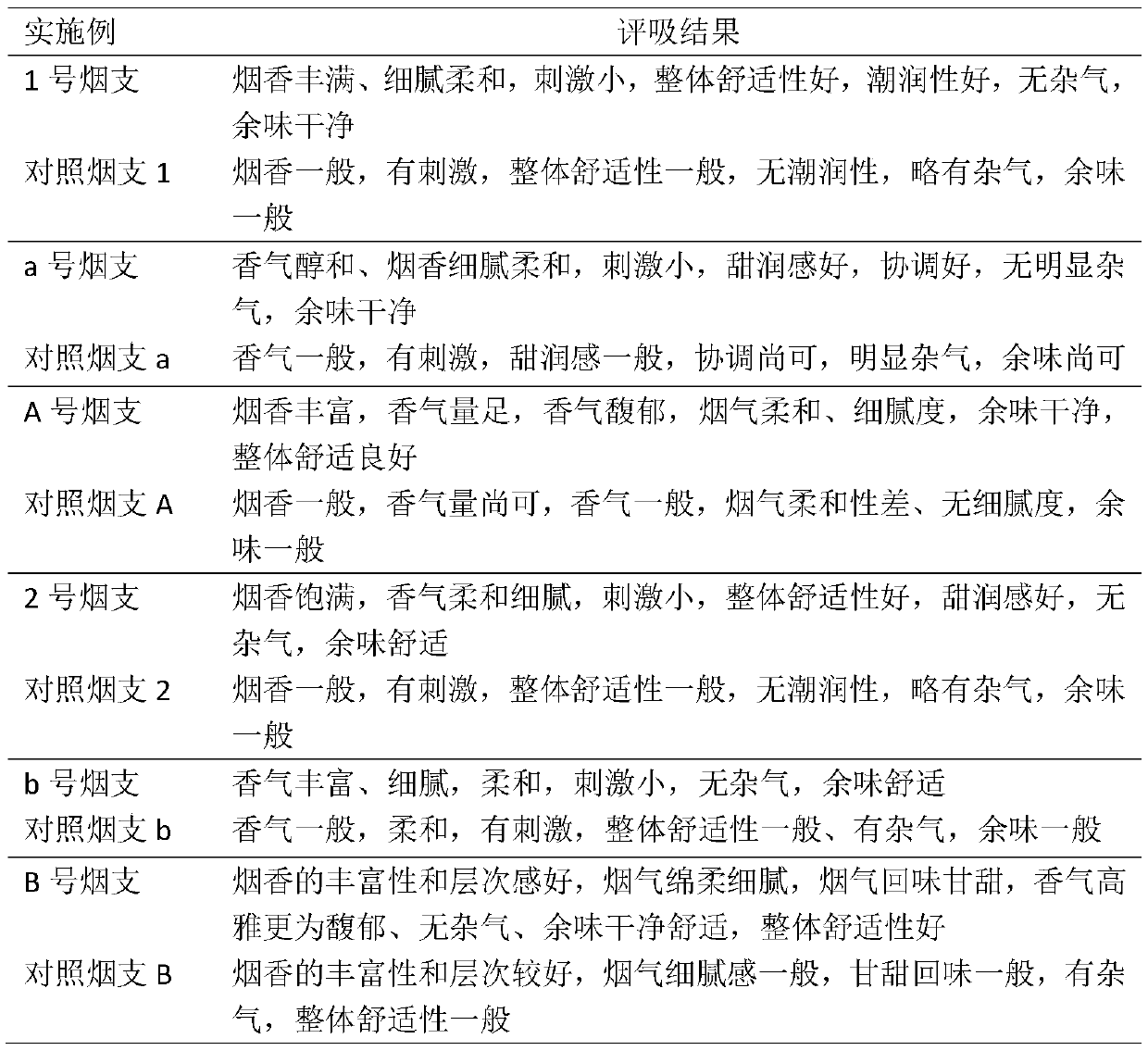

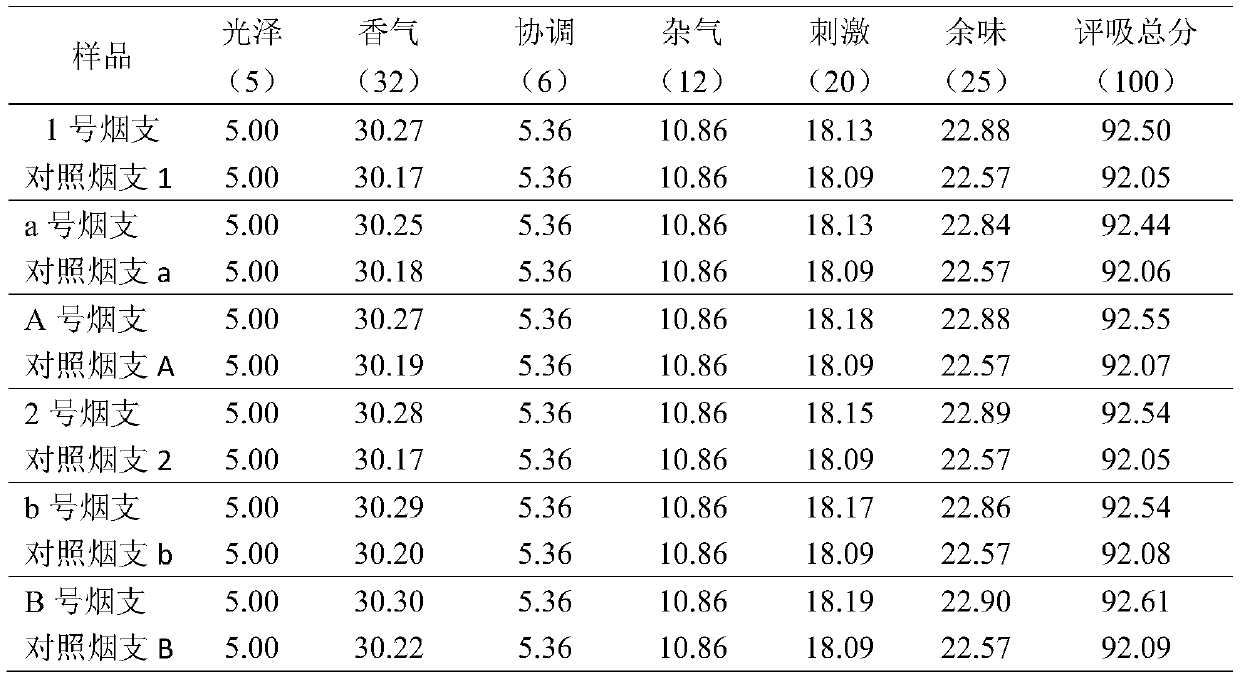

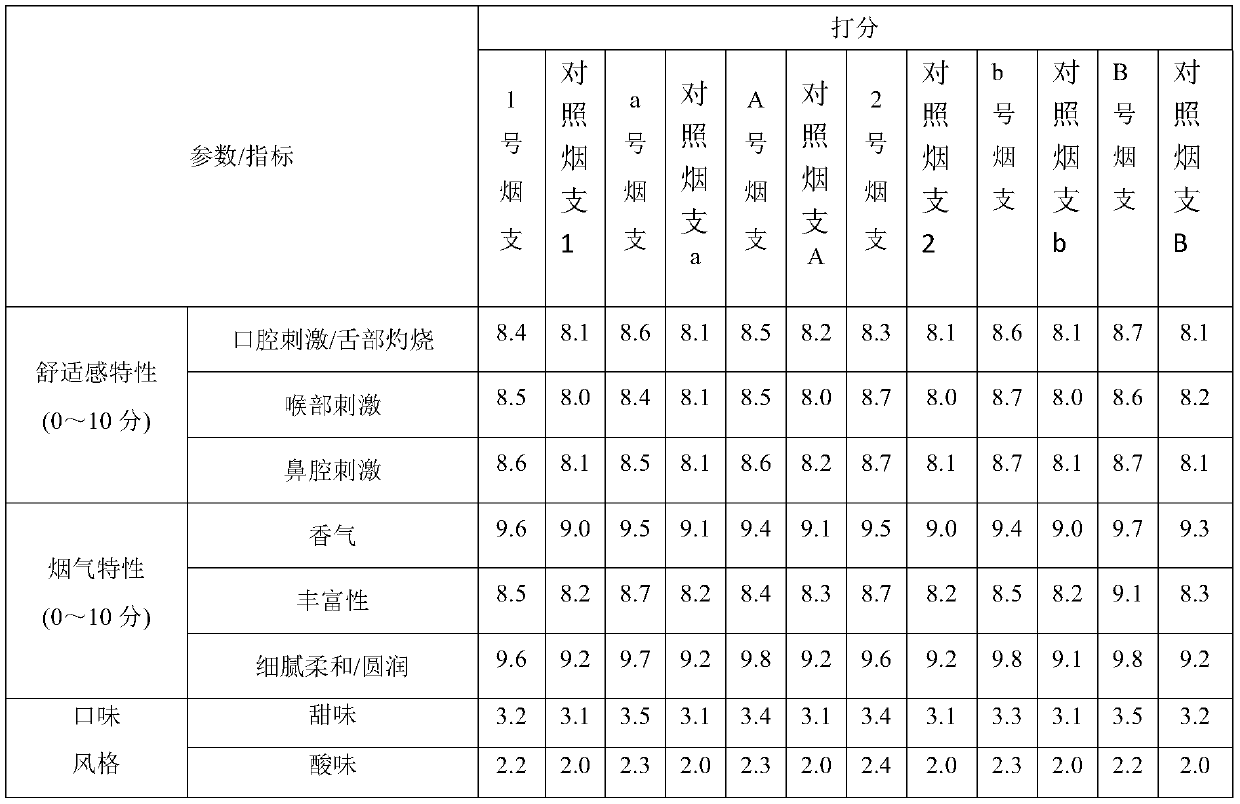

[0027] The fumigated tobacco leaves of Example 1 were added to the shredded tobacco formula at a mass ratio of 2%, and then rolled into cigarettes according to the conventional cigarette making process, shredded, flavored and wrapped, and named as No. 1 cigarettes respectively. On the same production line, the control cigarette 1 was rolled according to the same cigarette process, and the control cigarette 1 was a cigarette added with unfumigated tobacco leaves. Then adjust the moisture content of the cigarette samples to 12% according to the national standard "GB / T16447-1996 Atmospheric Environment for Conditioning and Testing of Tobacco and Tobacco Products", and smoke the cigarettes according to the provisions of "GB5606.4-1996 Sensory Technical Requirements for Cigarettes" Sensory evaluation. The evaluation results are shown in Table 1.

[0028] Mix 0.2 g of the fumigated Pu-erh tea extract prepared in Example 1 with the feed liquid containing conventional spices and the ...

Embodiment 3

[0031] Take 7 parts of hyaluronic acid, 10 parts of potassium lactate, and 8 parts of proline, dissolve potassium lactate in ultrapure water, heat and stir at 60°C, add propylene glycol according to the mass ratio of 1:1, and then add transparent Glycolic acid, proline, and continue heating and stirring at 70° C. for 0.5 h to obtain the required functional auxiliary materials.

[0032] Fumigate 40 parts of tobacco leaves, 10 parts of peppermint, 15 parts of coffee, and 2 parts of functional auxiliary materials in a self-made airtight container at 60°C for 48 hours, cool at room temperature and place it for 24 hours before taking it out for use.

[0033] The fumigated peppermint and coffee were subjected to microwave-assisted steam distillation, and the mixed solution of ethanol and water (volume ratio 1:1) was used as the extraction solvent, and the microwave-assisted water distillation was carried out according to the ratio of raw material to solvent mass ratio of 1:30. Steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com