Patents

Literature

105results about How to "Big air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

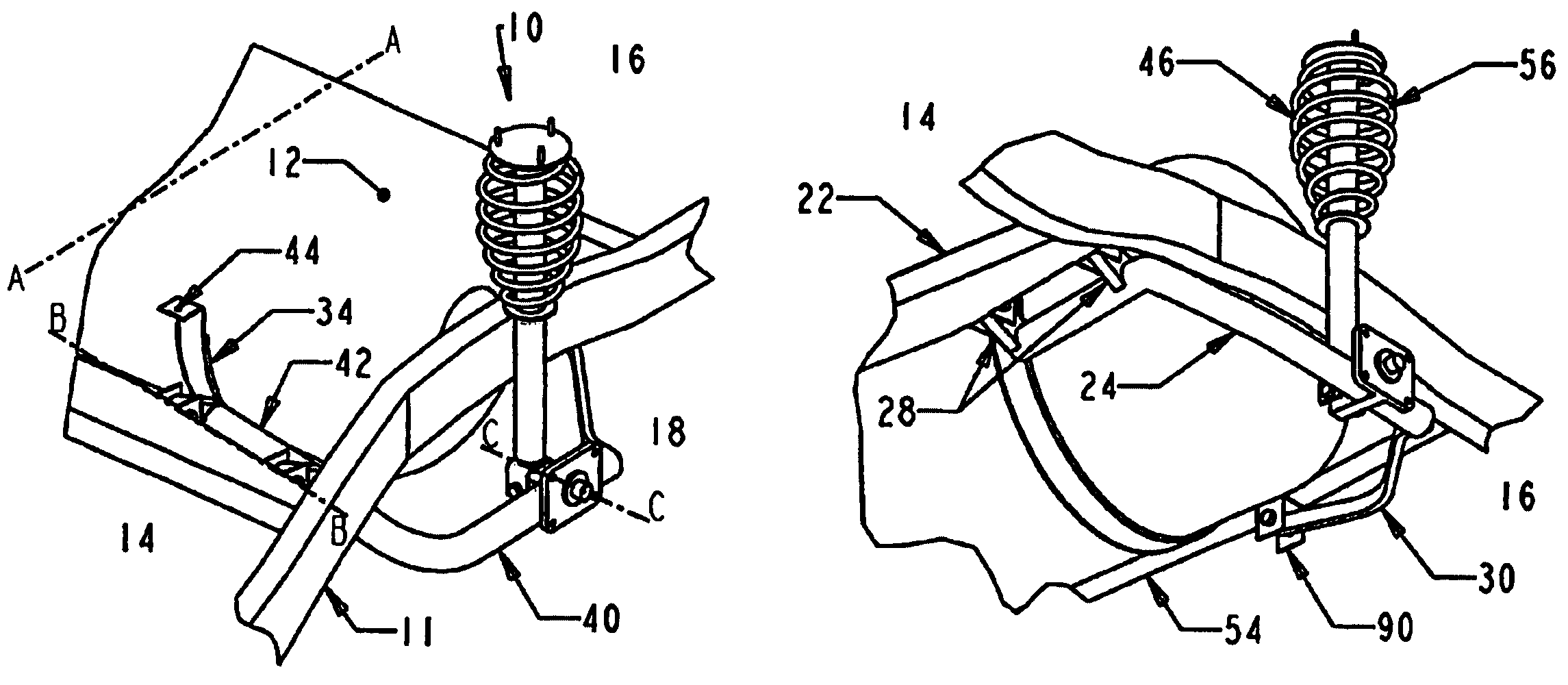

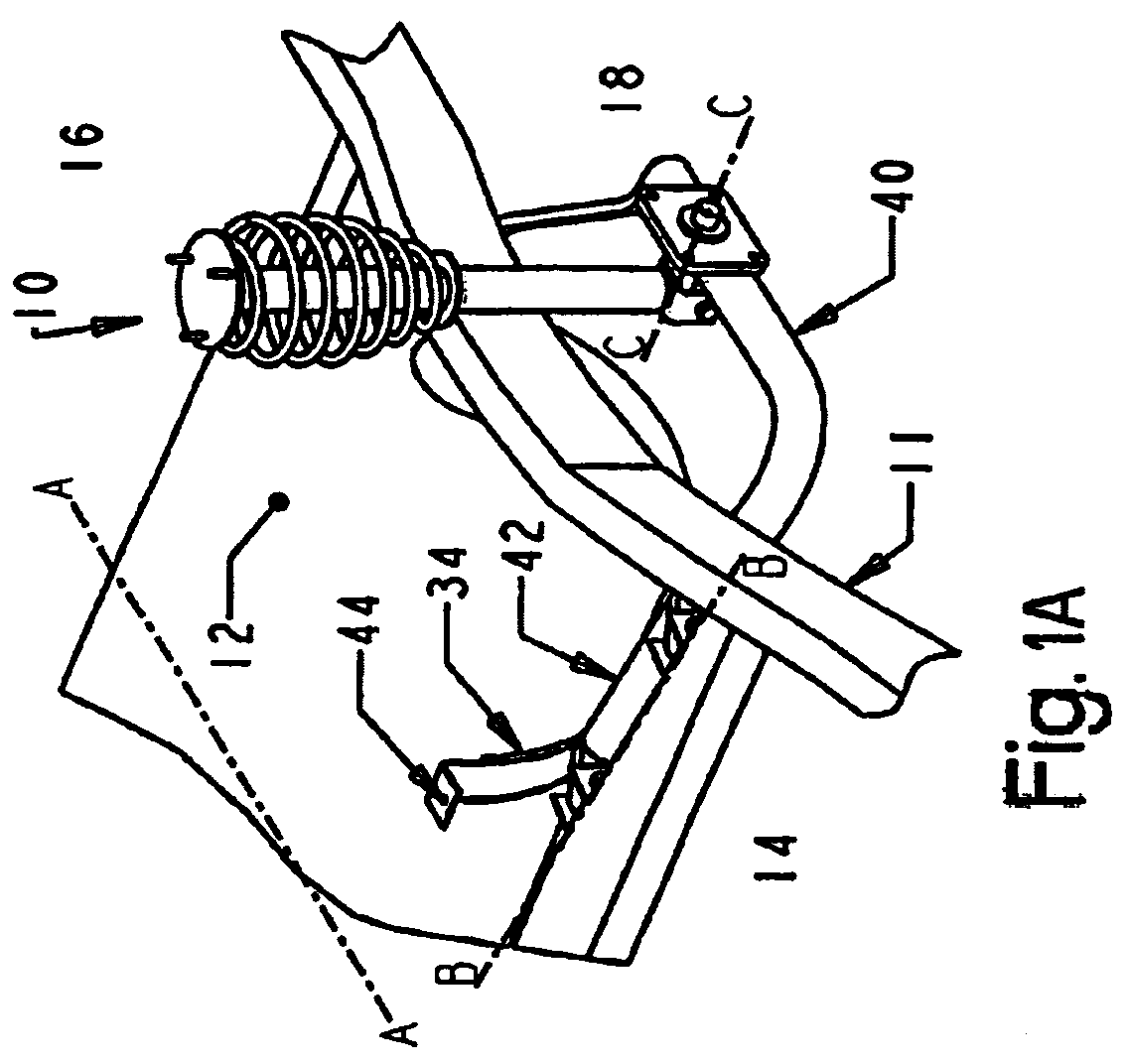

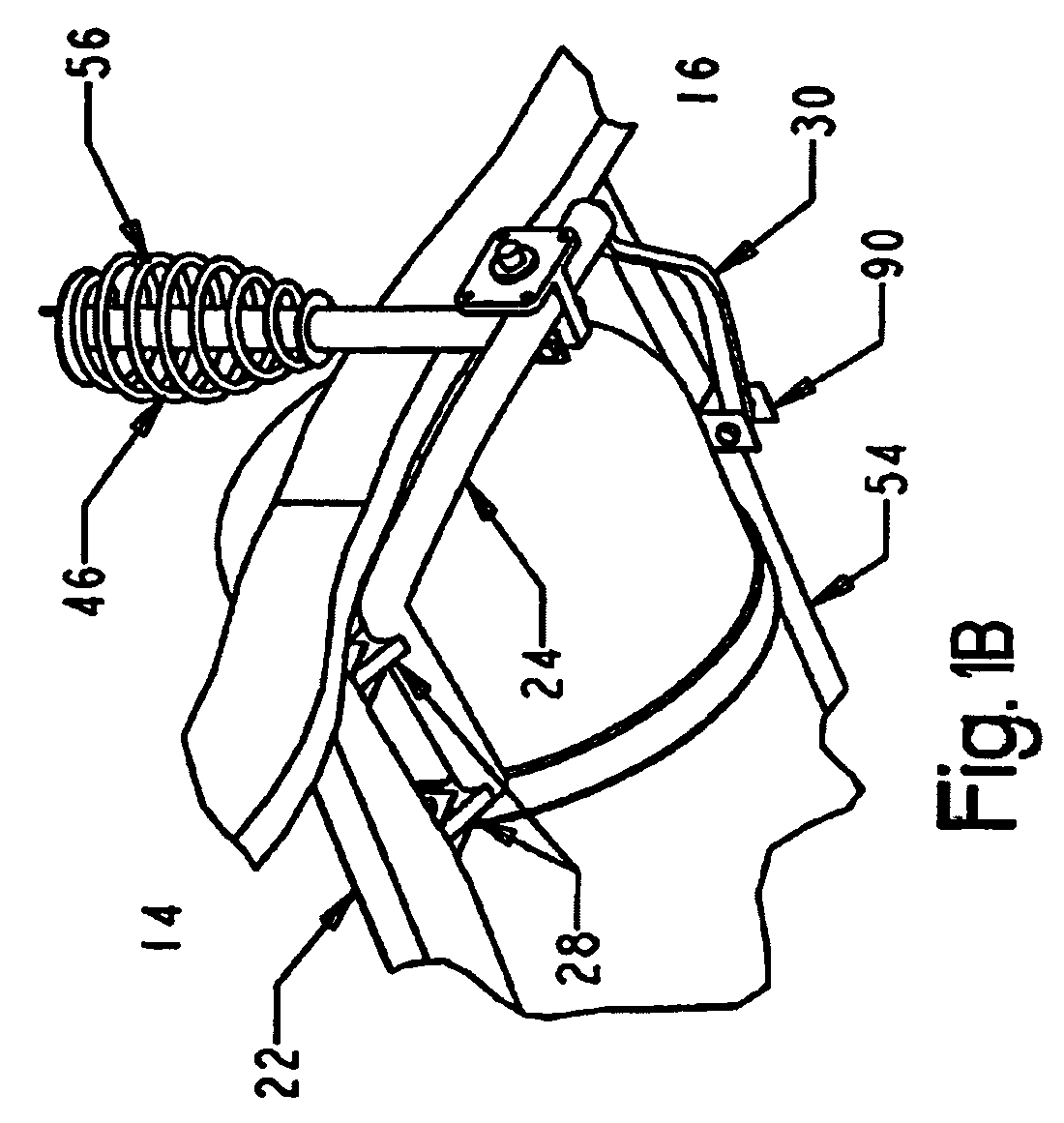

Suspension system for a vehicle with a tank for liquified gas

A suspension system for carrying a compressed gas fuels in vehicle. The suspensions arms and springs are configured to maximize the space between the wheels while providing a high degree of suspension stiffness to maintain proper wheel alignment during cornering, braking and in rough terrain. The suspension arms have two broadly-spaced attachment points to the chassis that provides structural rigidity to the rear suspension subassembly.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

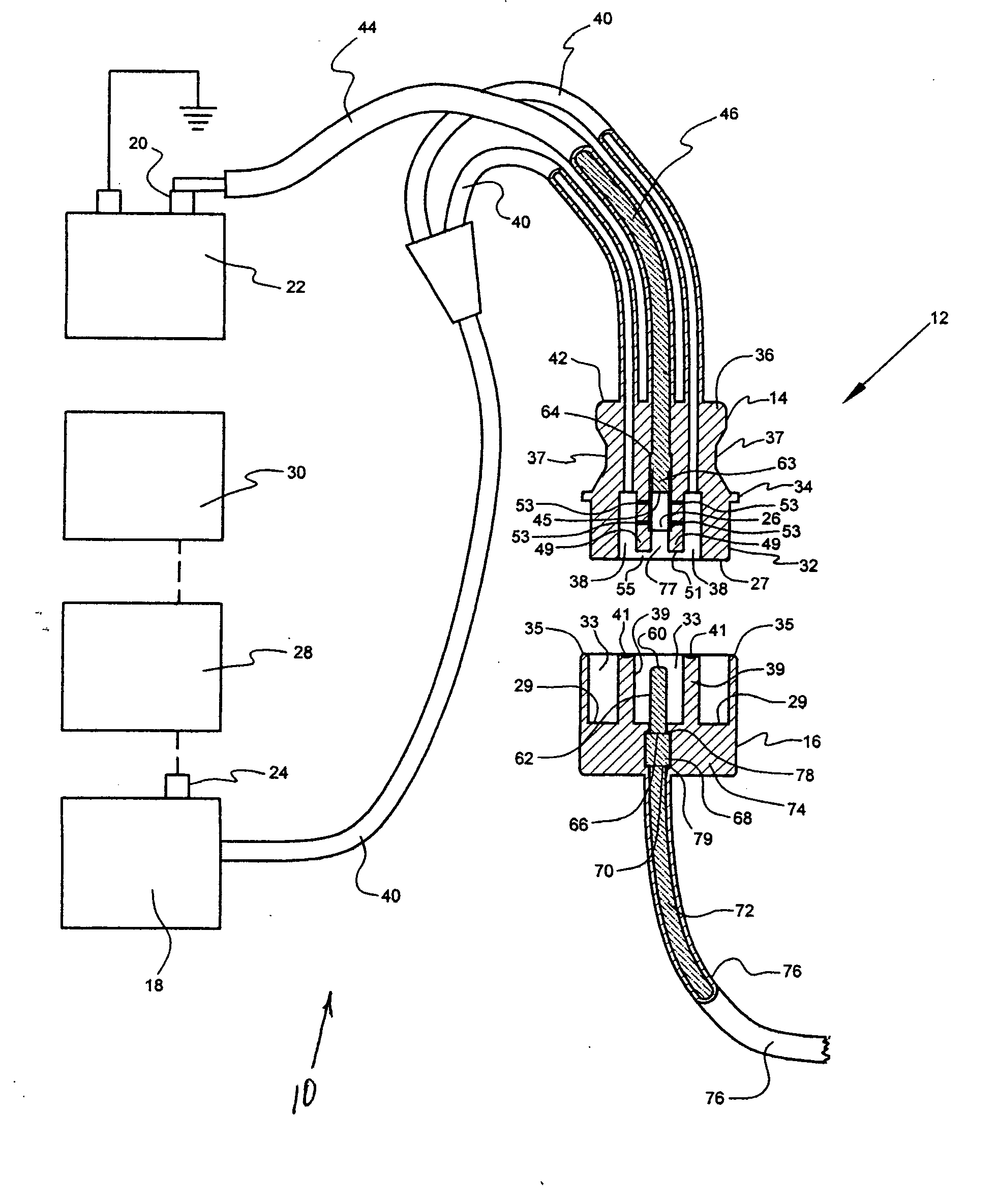

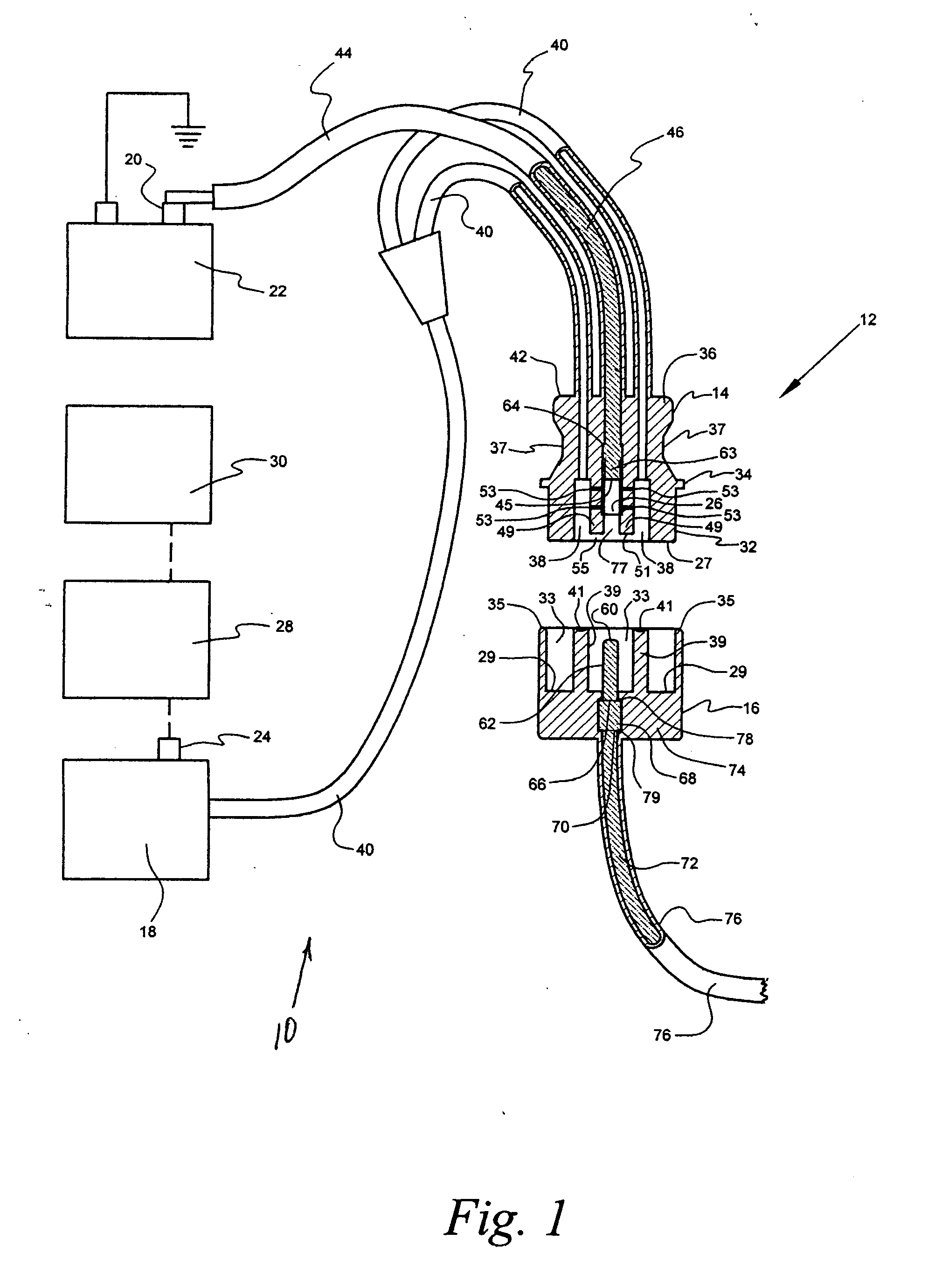

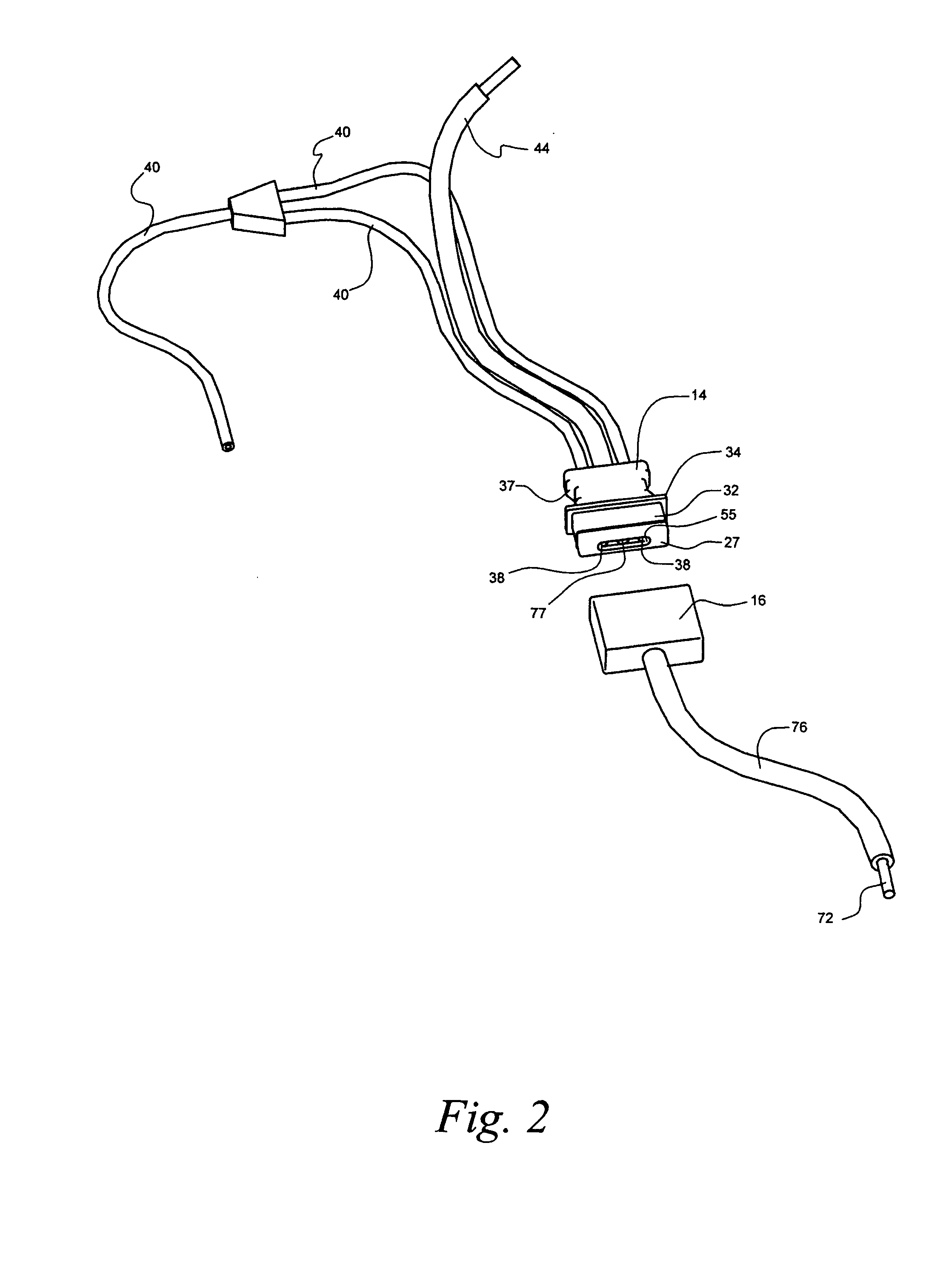

System and method for reducing the chance of fires and/or explosions

InactiveUS20070257557A1Evenly distributedHigh strengthElectric devicesPedestrian/occupant safety arrangementInternal pressureAccelerometer

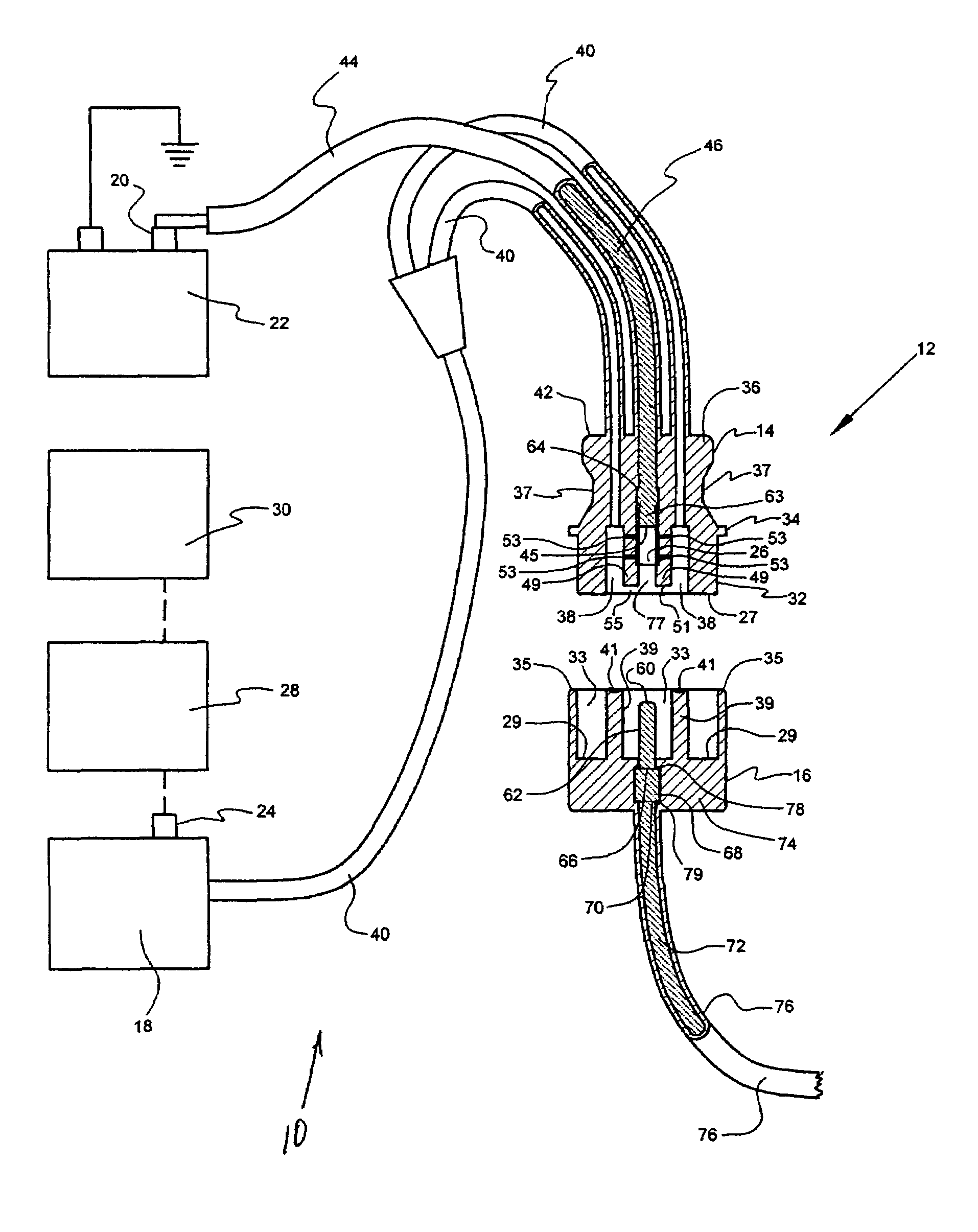

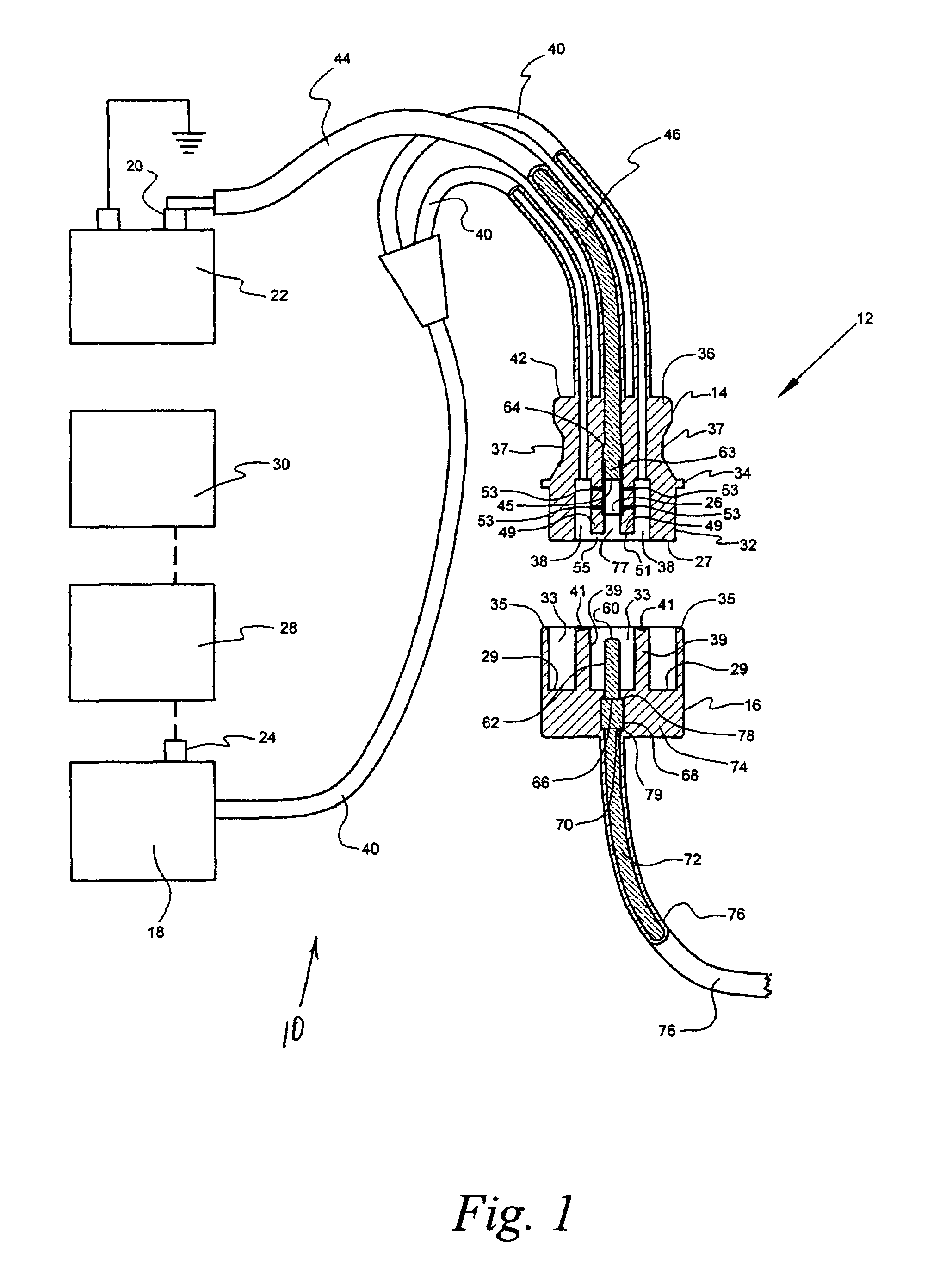

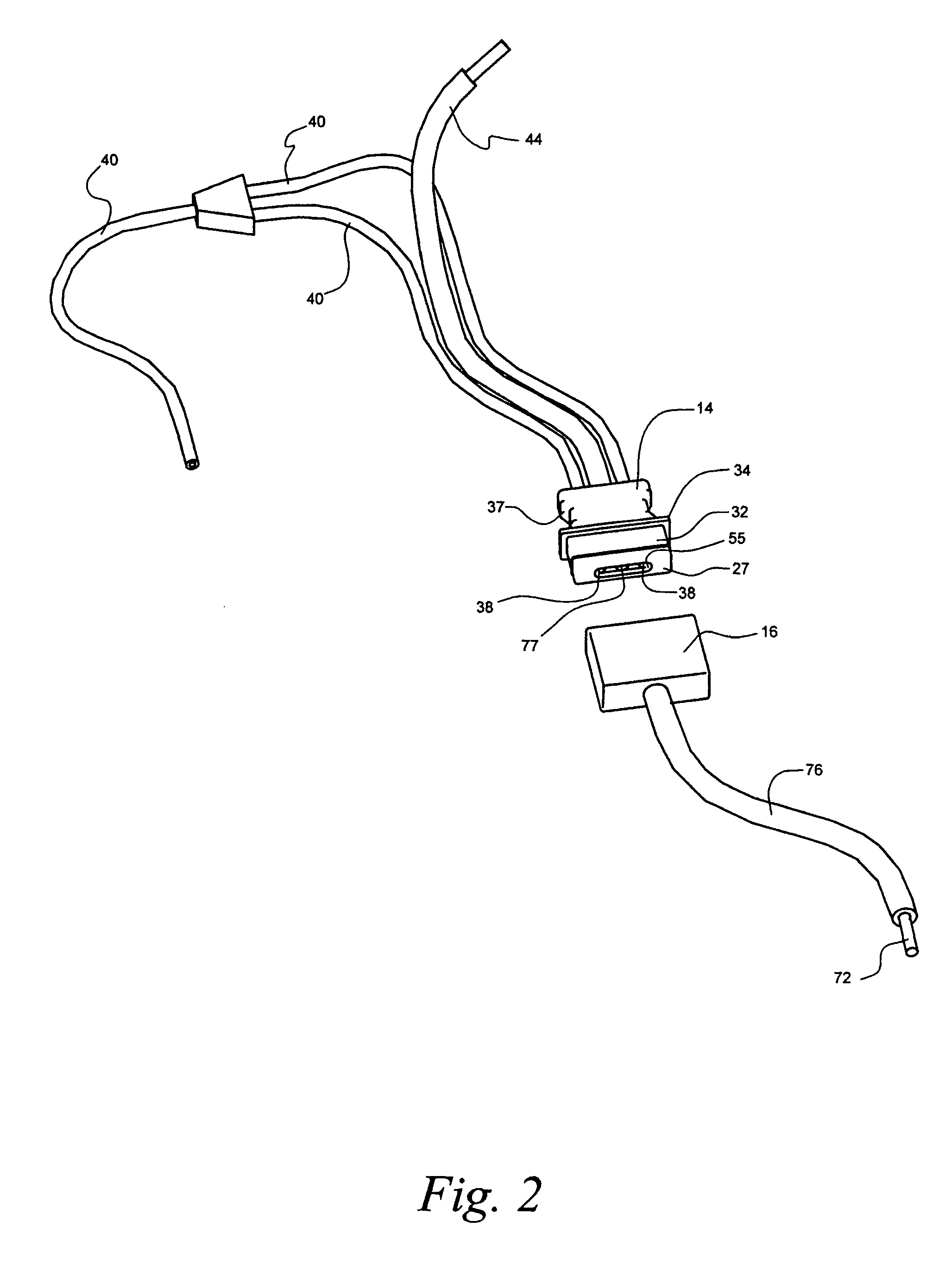

A system 10 and method for reducing the possibility of fires and / or explosions when a vehicle impacts an object includes a cable connector 12 having a first portion 14 connected to an ungrounded terminal 20 of a battery 22 in the vehicle and a second portion 16 connected to all vehicle electrical components requiring power from battery 22, an inert gas canister 18 having an internal pressure that facilitates the separation of the first and second portions 14 and 16 of the cable connector 12 when predetermined conditions are satisfied, electric squib means 24 for initiating pressurized inert gas flow from the canister 18 to the first portion 14 of the cable connector 12, an accelerometer 28 for sensing impact between the vehicle and the object, and a microprocessor 30 for signaling the accelerometer 28 to “fire” the squib means 24 when the magnitude of impact requires an inert gas flow to the first portion 14 whereby the second portion 16 is forcibly ejected from the first portion 14 and the area adjacent to the first portion 14 is blanketed with inert gas thereby reducing the possibility of fire and / or explosion resulting from fuel vapors engaging electrical arcs or vehicle “hot spots.”

Owner:GORS DONALD

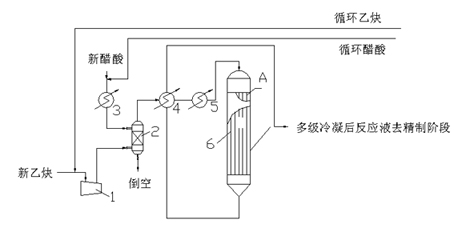

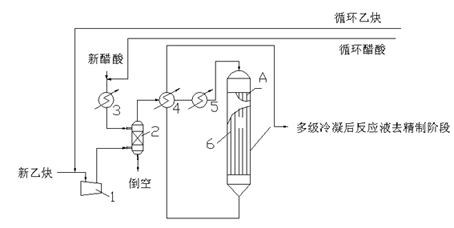

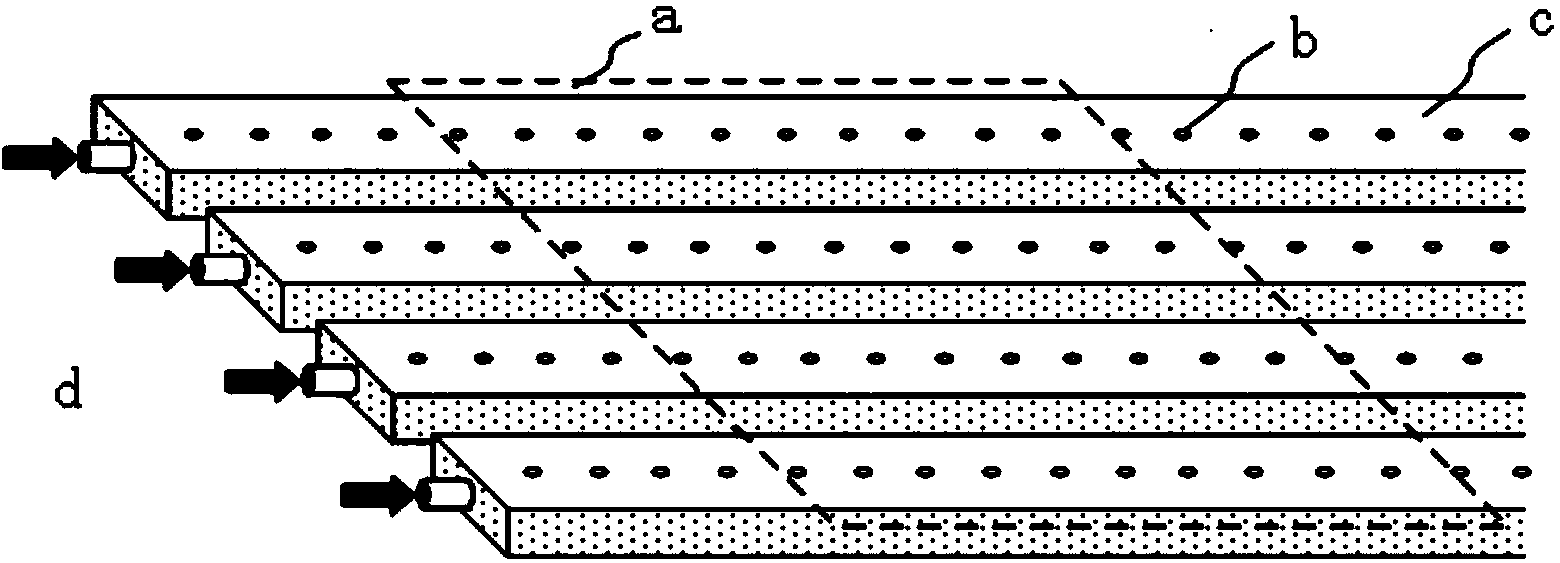

Novel method for synthetizing vinyl acetate by calcium carbide acetylene method

InactiveCN101928217AReduce generationGuaranteed circulation volumeOrganic compound preparationCarboxylic acid esters preparationFixed bedCarvacryl acetate

The invention relates to a novel method for synthetizing vinyl acetate by a calcium carbide acetylene method, which is characterized in that synthetic reaction is carried out on acetylene gas produced by adopting calcium carbide and acetic acid in a tube array type fixed bed reactor. The novel method is realized by utilizing a fixed bed technology in a process for synthetizing the vinyl acetate by the calcium carbide acetylene method, and especially, acetic acid simultaneously enters a gas-liquid mixed evaporator under the action of the acetylene gas after being preheated by changing an acetic acid feed mode into a gas-liquid mixed feed mode, and then enters the reactor through a second preheater and a third preheater, and the gas mixture passes through an inert heat transfer filler and then passes though a corresponding catalyst to be synthetized into the vinyl acetate. By adopting the mode, the novel method can reduce reaction byproducts and has the advantages of easy separation, raw material use ration improvement, production cost reduction, conversion rate improvement, small investment, high product purity, high quality and low impurity content.

Owner:国能英力特能源化工集团股份有限公司

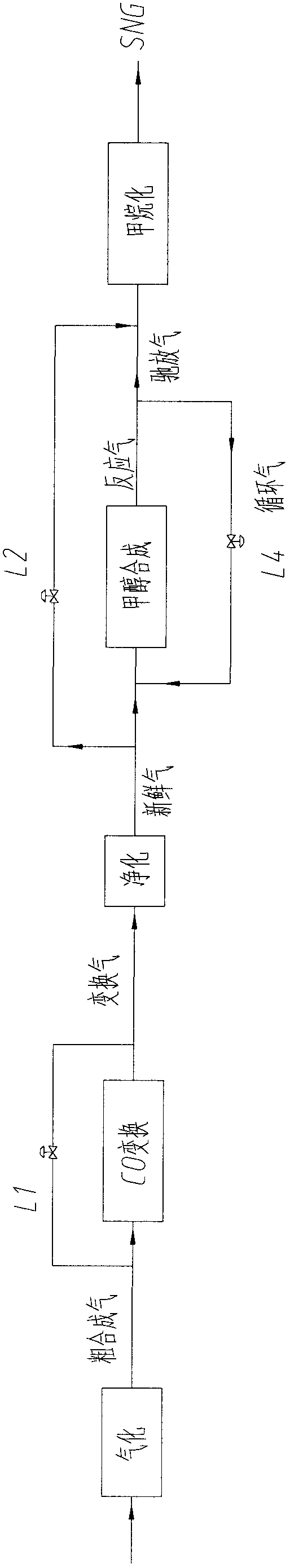

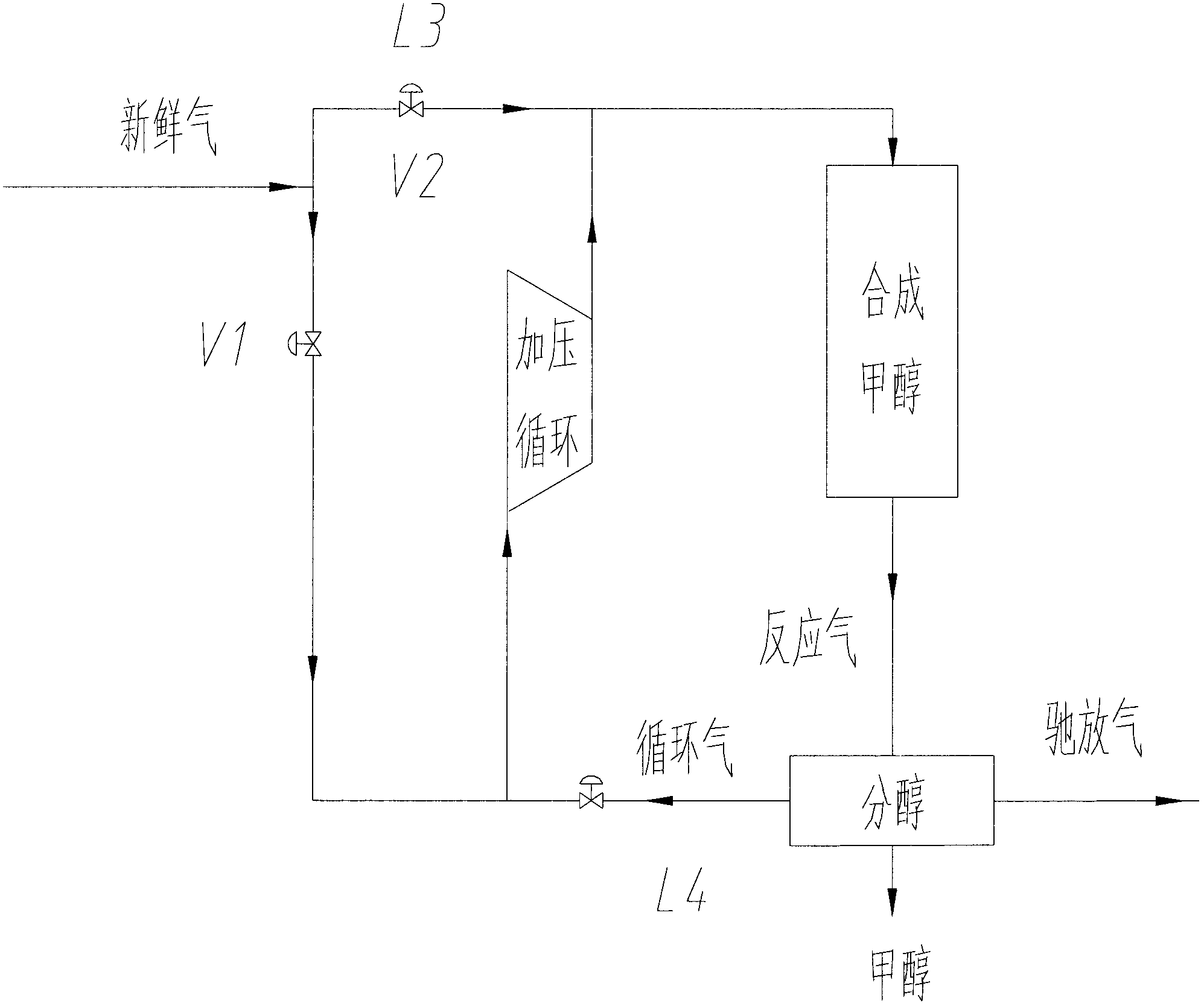

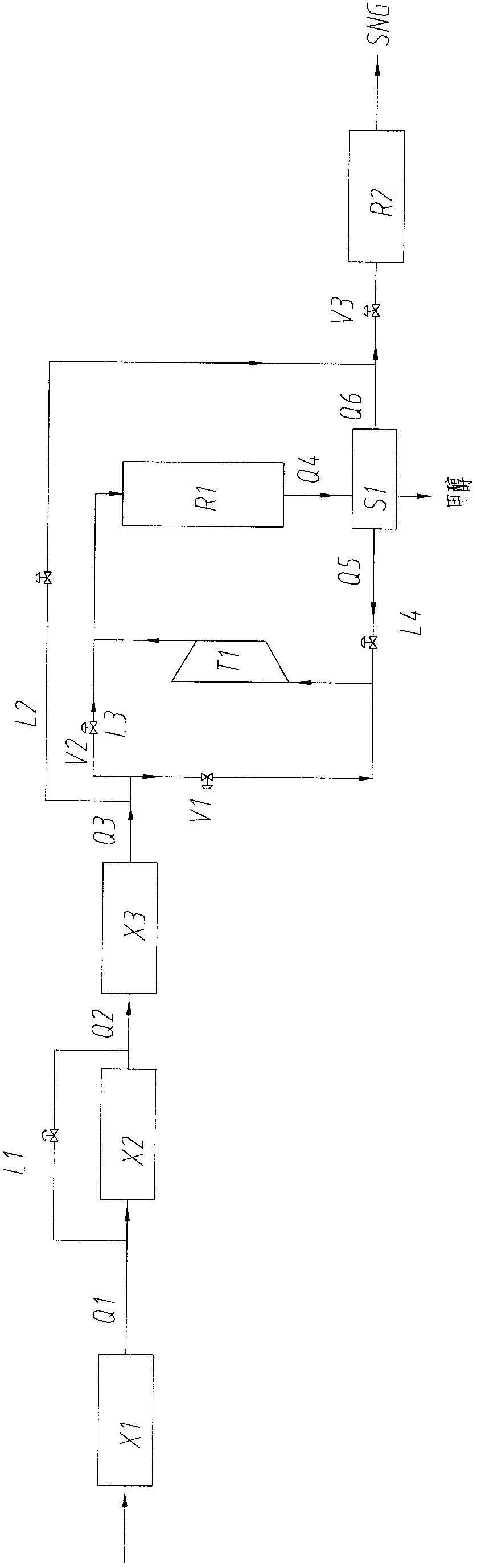

Synthesized methanol and synthesized methane co-production method and equipment

ActiveCN103524299AIncrease profitReduce loadHydrocarbon from carbon oxidesOrganic compound preparationMethanationEconomic benefits

The invention discloses a synthesized methanol and synthesized methane co-production method comprising the steps: carrying out pressure gasification on a carbon-containing raw material to obtain crude synthesis gas containing the main components: CH4, H2, CO and CO2, adding a part or all of crude synthesis gas into steam to carry out conversion reaction so as to convert a part of CO into H2 and CO2, then, and purifying and removing sulfides and most of CO2 to increase the ratio of hydrogen to carbon and obtain fresh gas; carrying out methanol synthesis by using a part or all of the fresh gas, and carrying out methanation reaction by using a part or all of the reaction gas after methanol synthesis to obtain artificially synthesized natural gas; adjusting the yield of the synthesized natural gas through adjusting the CO conversion rate and the gas flow and yield of synthesized methanol. The invention also discloses a device for the synthesized methanol and synthesized methane co-production method. According to the invention, the yield of the synthesized natural gas is adjusted through adjusting the CO conversion rate at a CO conversion section and the gas flow and yield of synthesized methanol; meanwhile, the surge of circulating equipment is avoided, the production cost and investment are reduced, and the economic benefit is increased.

Owner:杭州林达化工技术工程有限公司

Low-resilience highly air-permeable polyurethane foam and use thereof

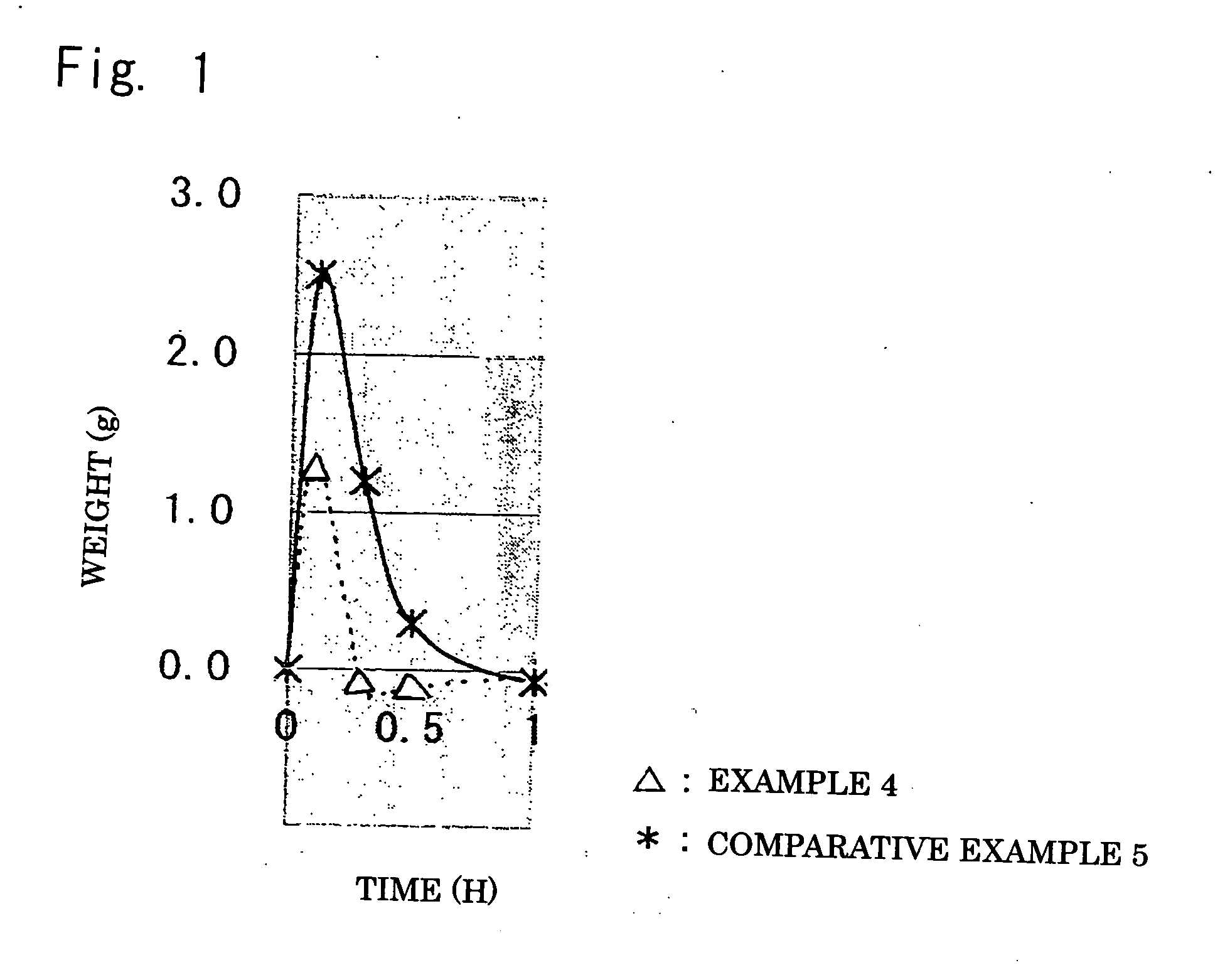

InactiveUS20070197675A1Improve breathabilityGood drainagePillowsStuffed mattressesVitrificationPolyol

A low-resilience highly air-permeable polyurethane foam is prepared by the foaming of a polyurethane raw material containing a polyol component, a polyisocyanate component, a catalyst, and a blowing agent, followed by removal of a foam skin (reticulation). This polyurethane foam has a glass transition point near room temperature and a cell number (cell count) of 25 PPI or less. The polyurethane foam has a large air bubble size as indicated by a cell number of 25 PPI or less. In addition, because the skin of the polyurethane foam is removed, it has high air permeability. Since the polyurethane foam comes into contact with human body at fewer points, unpleasantness, such as “stuffy” feeling, can be reduced. Since the polyurethane foam has large air bubbles, it exhibits excellent drainability and dries in a shorter time.

Owner:BRIDGESTONE CORP

System and method for reducing the chance of fires and/or explosions

InactiveUS7521817B2Reduce the possibilityIncrease currentCoupling device connectionsDrilling rodsInternal pressureAccelerometer

Owner:GORS DONALD

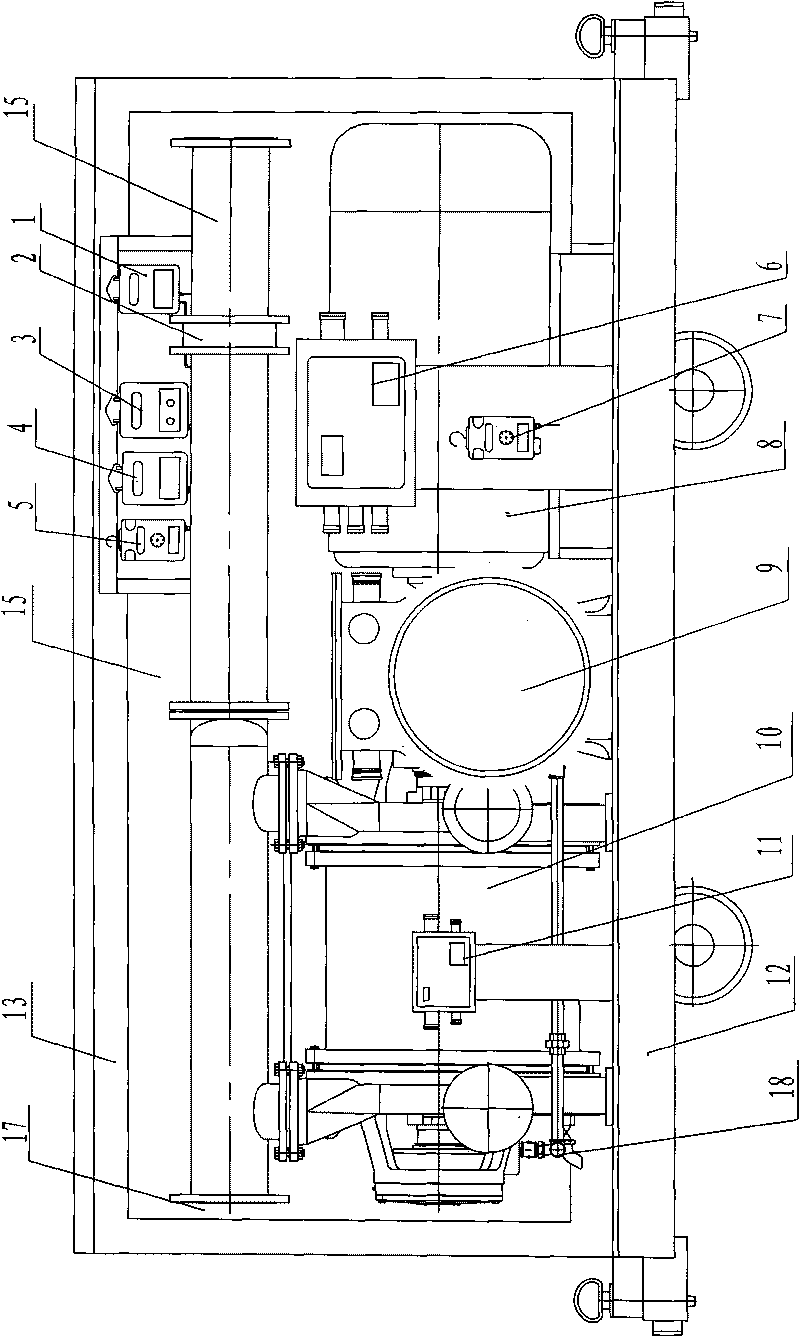

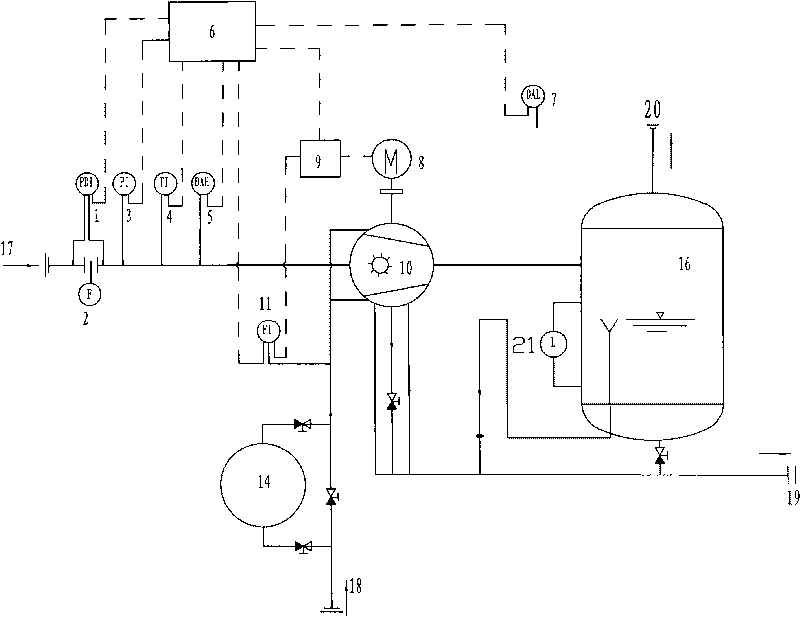

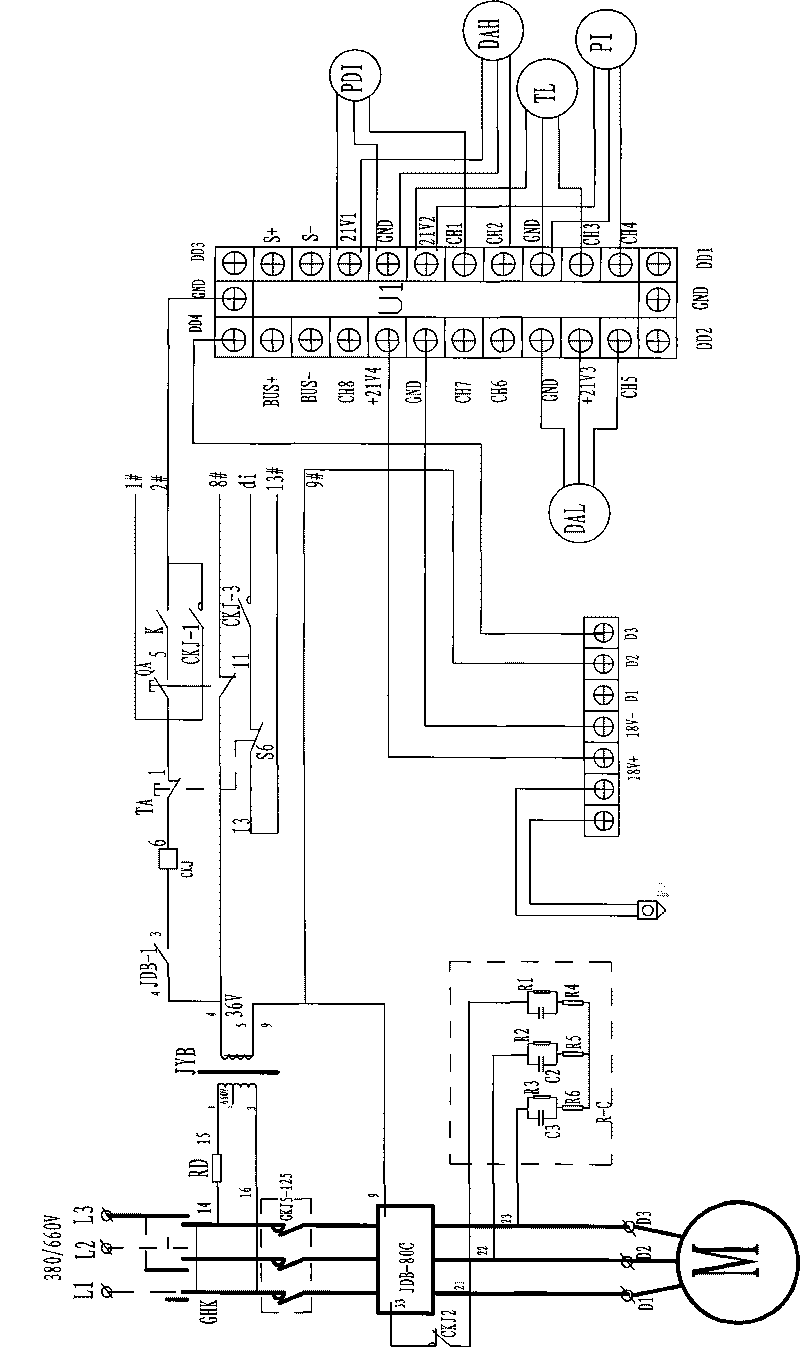

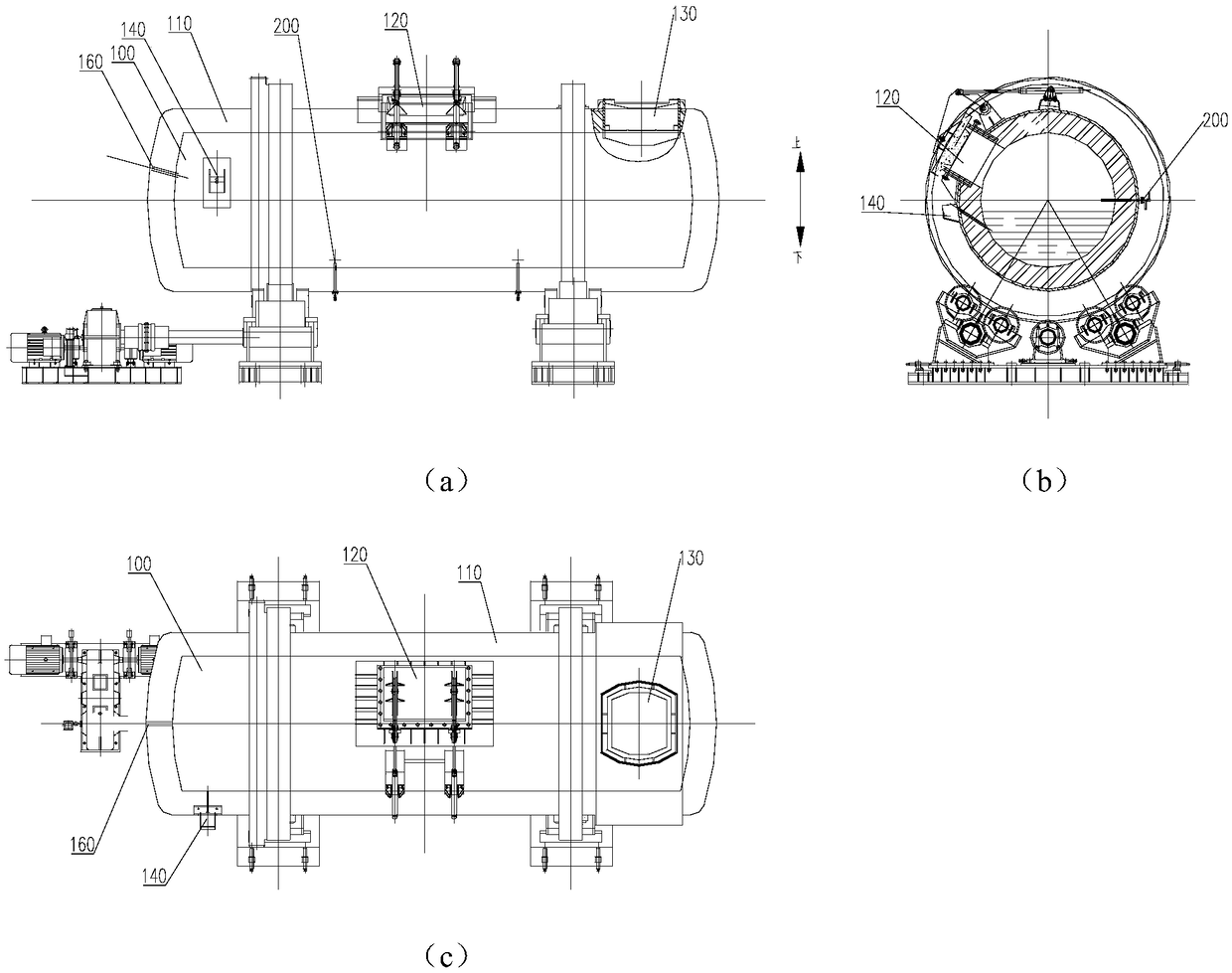

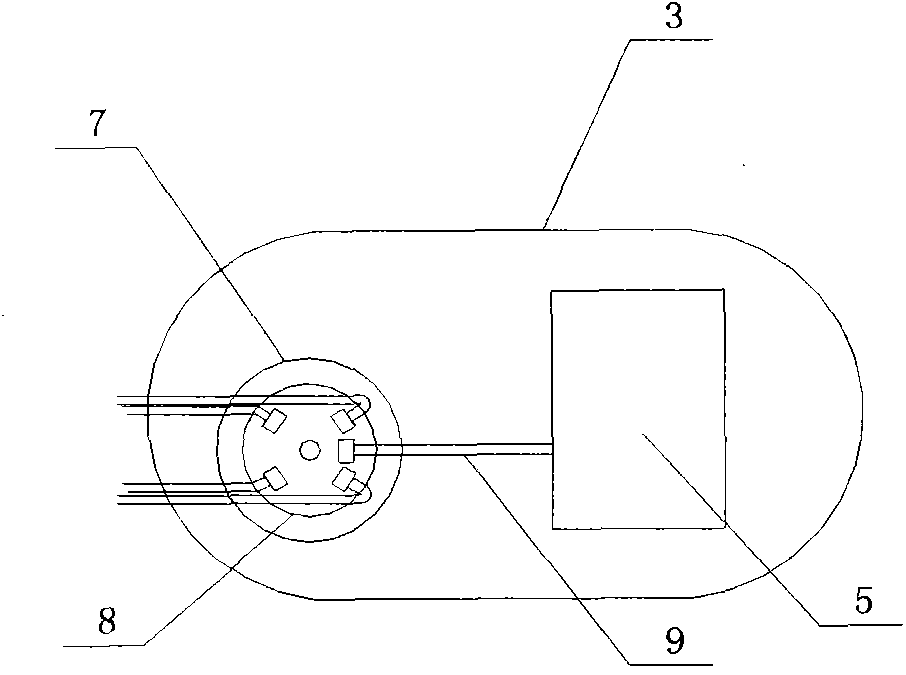

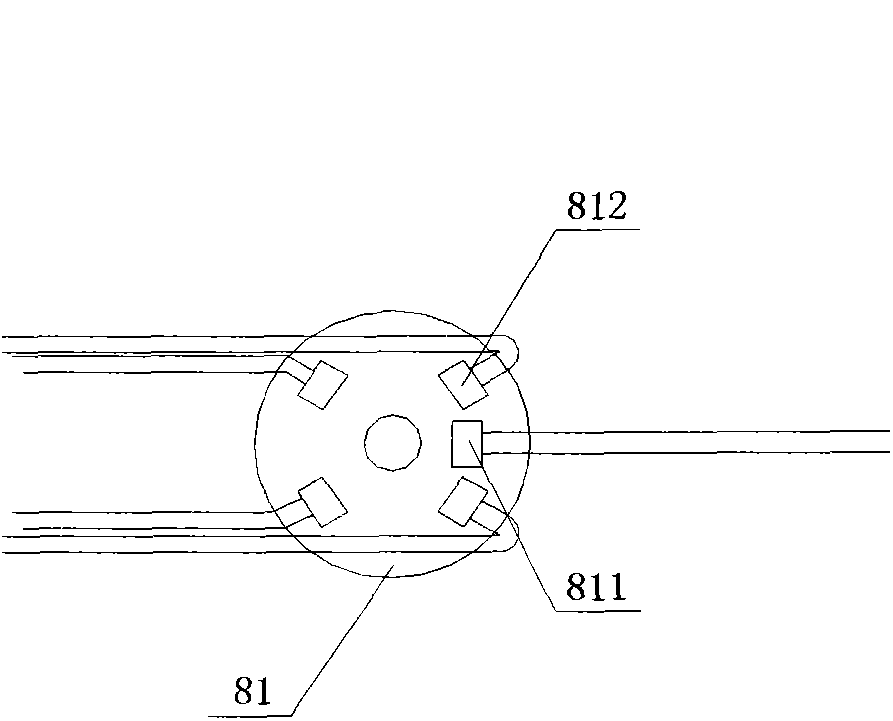

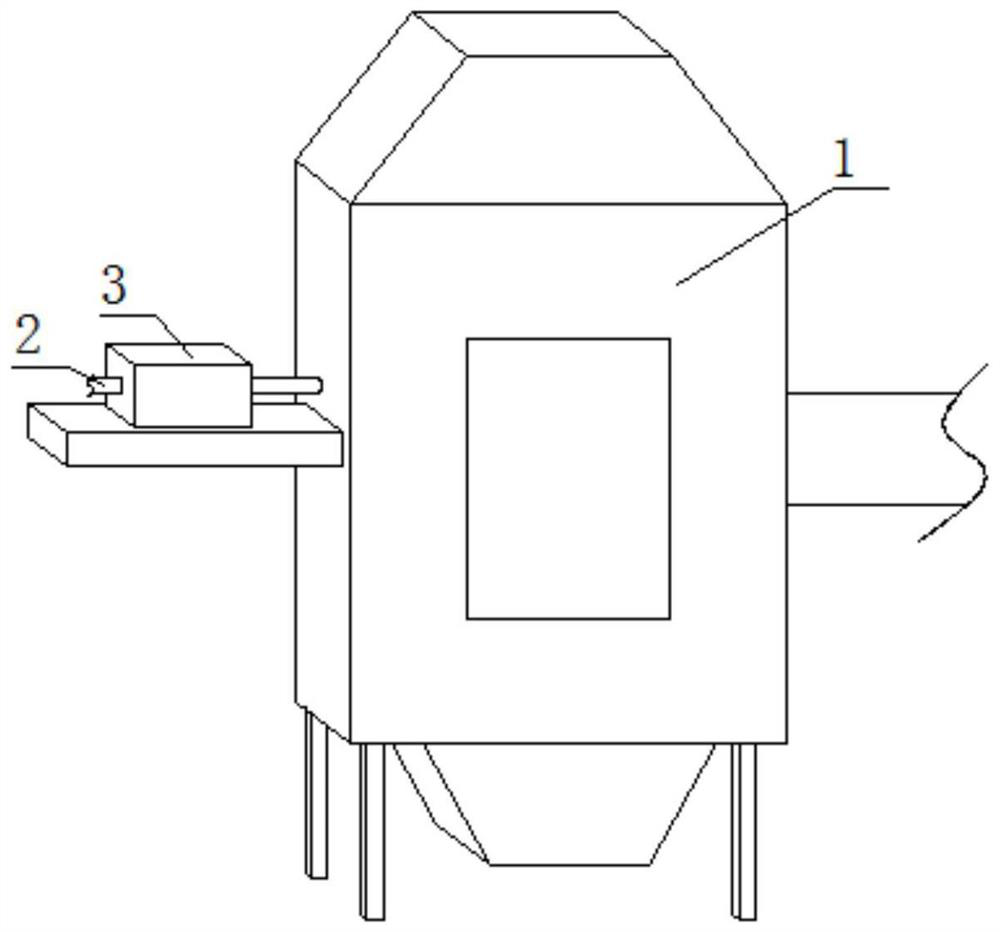

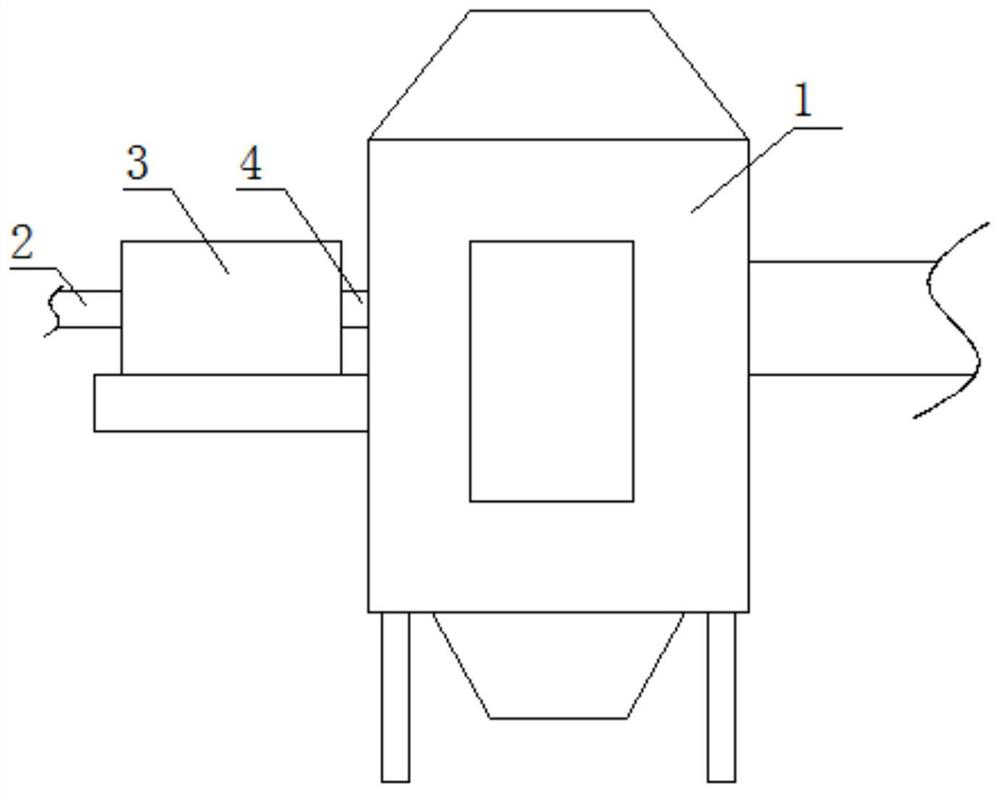

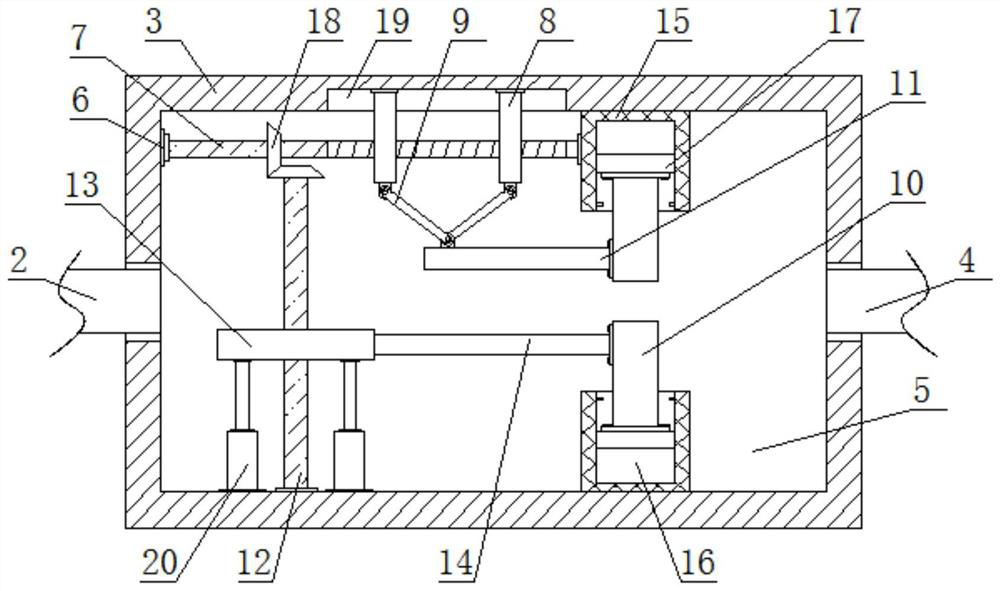

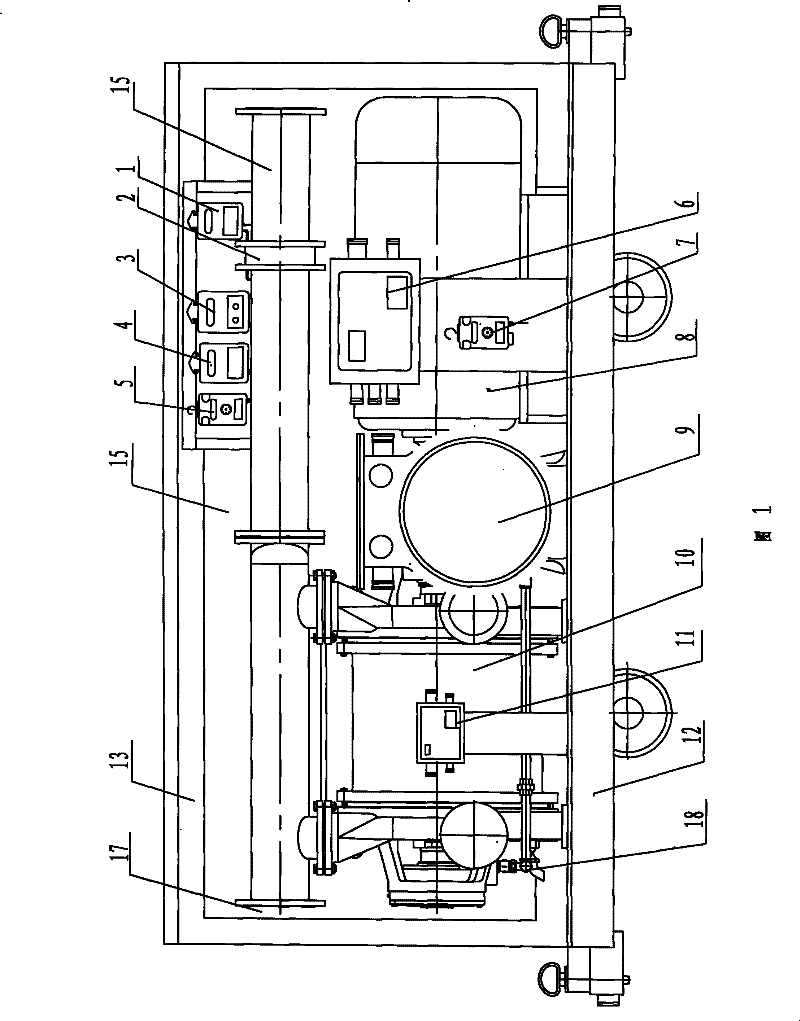

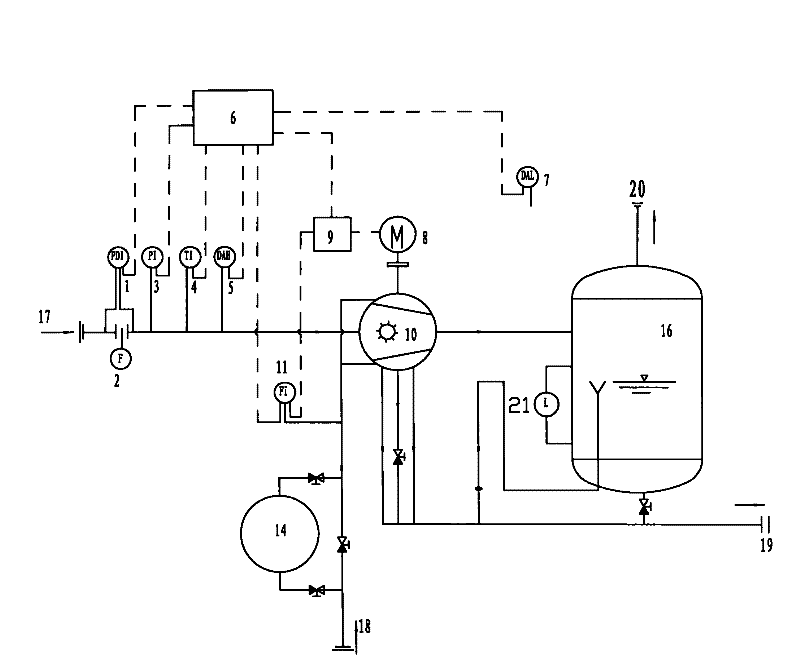

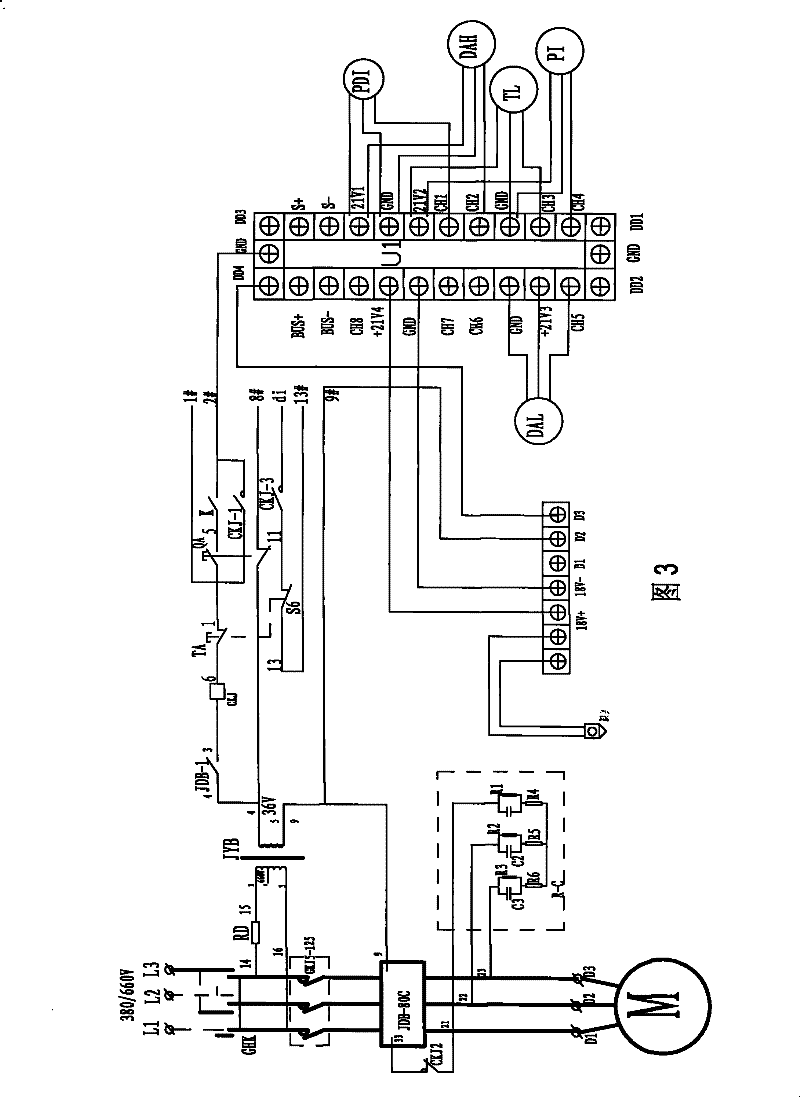

Intelligent movable gas pumping station for mine

ActiveCN101749044ARealize on-site display and real-time monitoring functionAchieve long-term storageGas removalCouplingThree phase asynchronous motor

An intelligent movable gas pumping station for mine belongs to the technical field of mine device, in particular relates to a movable gas pumping station for mine. The gas pumping station is characterized in that the station is provided with an intelligent monitoring substation and a softening water device (14); the intelligent monitoring substation comprises a processor (6), a pressure difference sensor (1) for mine, a pressure senor (3) for mine, a temperature sensor (4) for mine and a pipeline methane consistency sensor (5); an exploding insulating three-phase asynchronous motor (8) is connected with a water ring vacuum pump (10) through a shaft joint; the inlet of the water ring vacuum pump (10) is connected with a gas pumping pipeline (15), and the outlet of the water ring vacuum pump (10) is connected with a constant water level gas-water separating device (16). Making use of the intelligent movable gas pumping station for mine, the parameters can be displayed on site and monitored in real time, such as flow rate, consistency, temperature and negative pressure of gas; the station can be linked with the computer of the ground central station to remotely monitor and control and store each parameter in long time.

Owner:ZIBO WATER RING VACUUM PUMP FACTORY

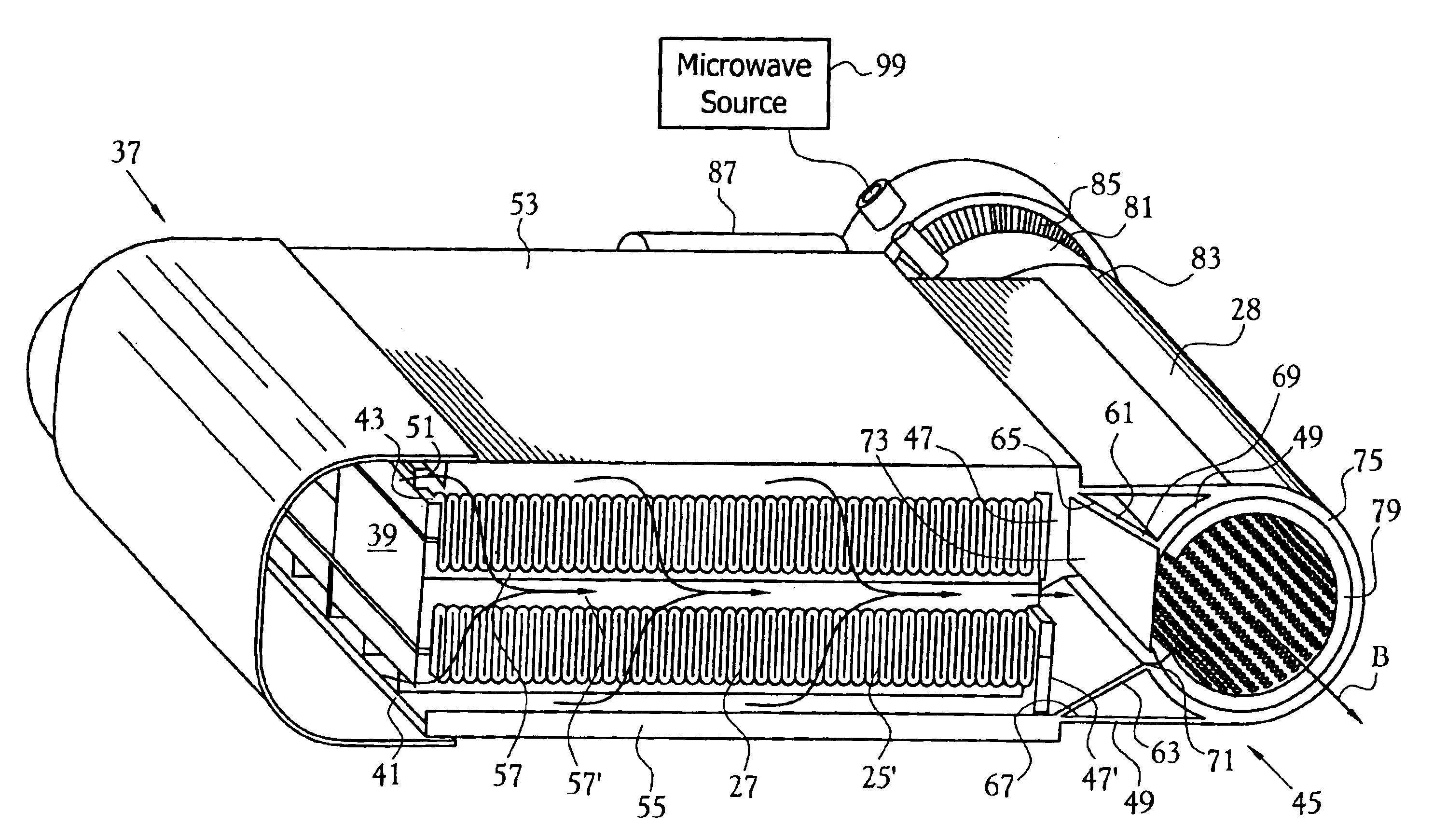

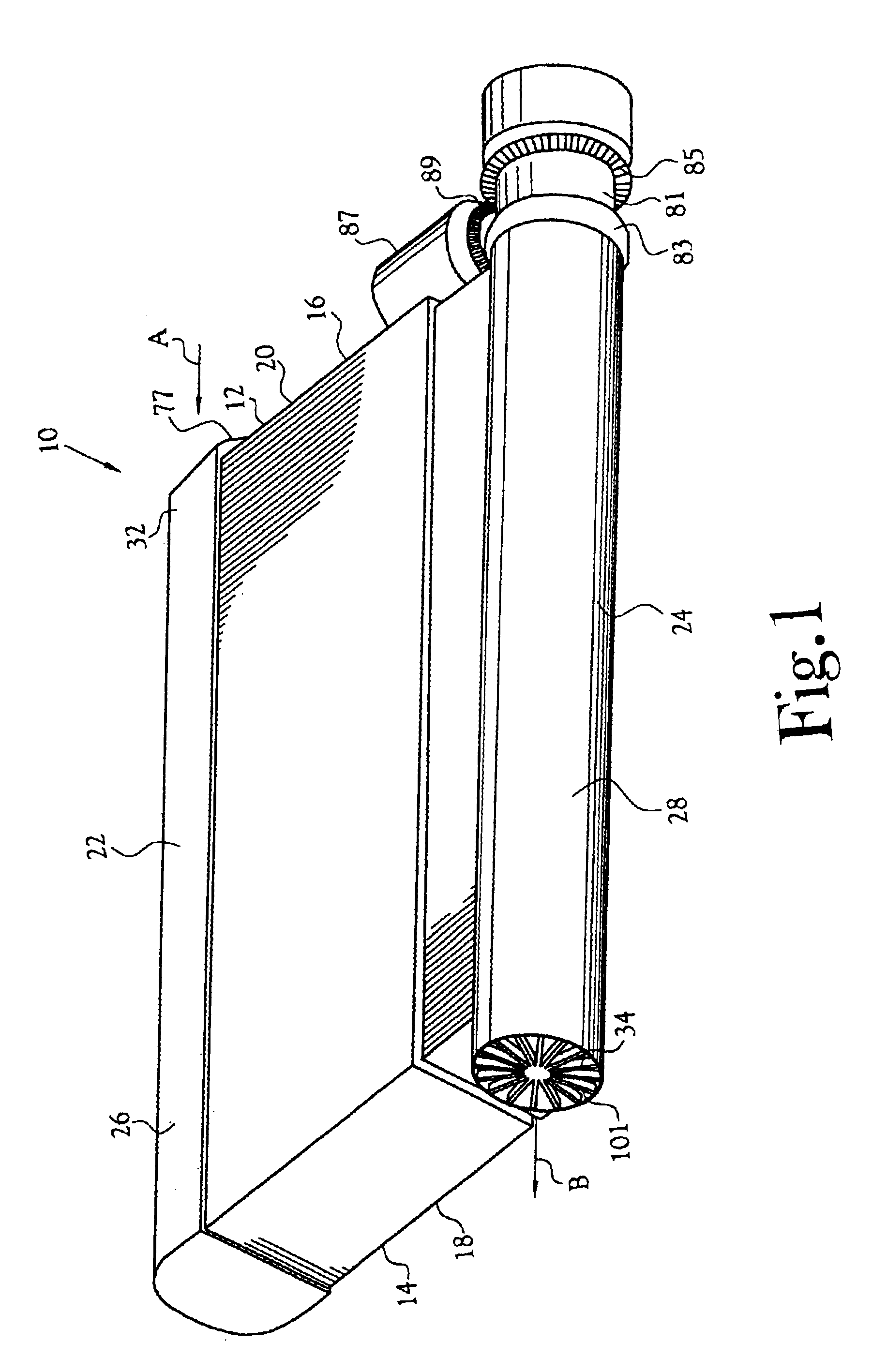

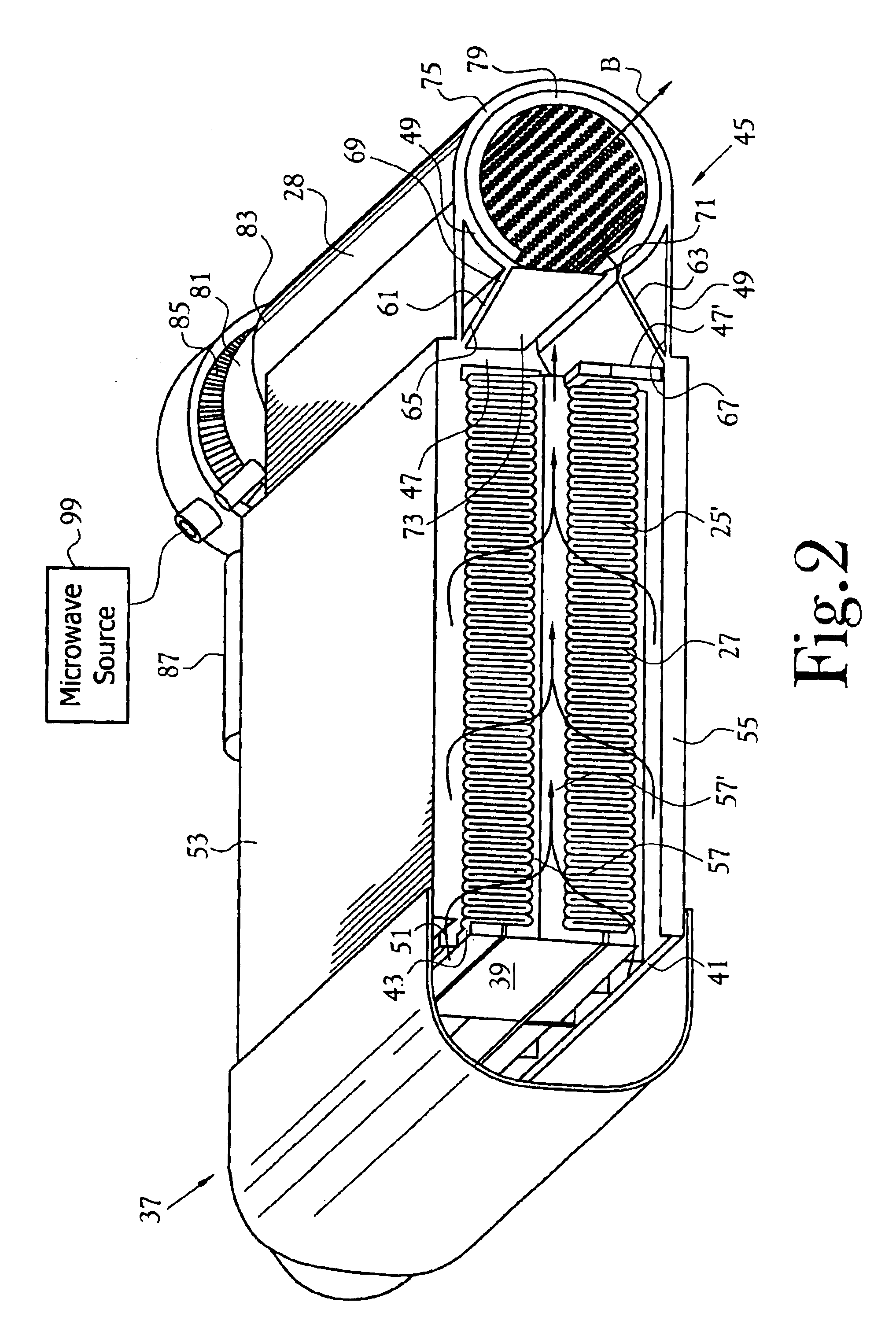

Filter system employing microwave regeneration

InactiveUS6855250B2Prevent pressureBig airCombination devicesAuxillary pretreatmentMicrowaveFiltration

A filtration system (10) operable at elevated temperatures and regenerateable in situ employing microwave energy (99). In one embodiment, the system includes multiple channels (35) with means for selectively placing individual ones of the channels on-line for filtration and off-line for regeneration.

Owner:INDAL CERAMIC SOLUTIONS

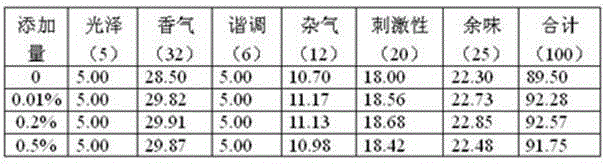

Fructus phyllanthi porous particle for cigarette filter and application of porous particle

The invention discloses a fructus phyllanthi porous particle for a cigarette filter and an application of the porous particle. Fructus phyllanthi serves as a raw material, the raw material is pulped and super-finely grinded, acquired mixture is processed by combining compound enzyme, processed mixture is freeze-dried to obtain fructus phyllanthi powder, fungal polysaccharide serves as a binding agent, and top spraying is performed by a fluidized bed to prepare the fructus phyllanthi porous particle. 1-2 mg of particles are applied into the cigarette filter per millimeter in the production process of compound cigarette filters, the contents of phenol and crotonic aldehyde in cigarette smoke can be effectively reduced, and the porous particle has double functions of increasing flavor and keeping humidity. The fungal polysaccharide serves as the binding agent, loss of flavor substance in the particle making process can be effectively made up, flavor content in a cigarette is remarkably increased, fine and smooth degree and sweet feeling of the smoke are obviously improved, and oral comfort is improved. The acquired particle furthest keeps flavor substances of the fructus phyllanthi and has the functions of relieving throat discomfort, promoting fluid, quenching thirst and the like. The particle is simple in production process, convenient to operate and low in cost and has good application values, raw materials are easily acquired, and industrial production is conveniently achieved.

Owner:CHINA TOBACCO YUNNAN IND

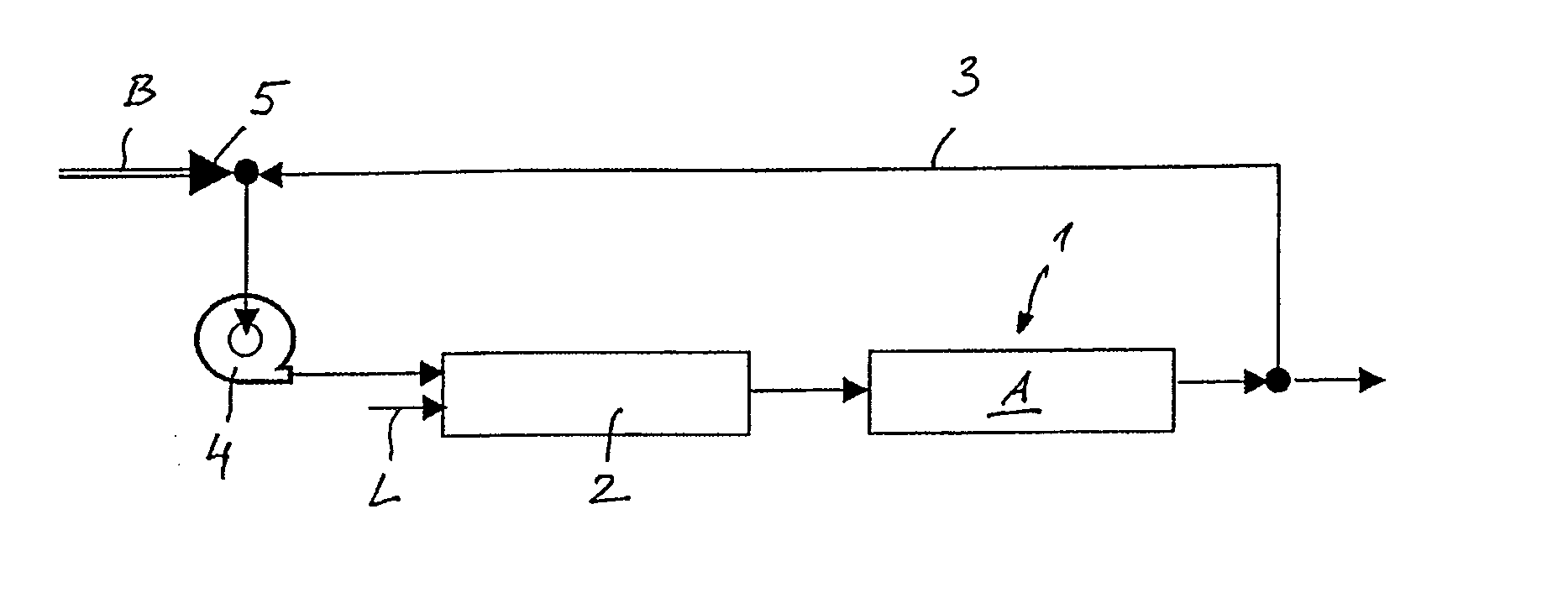

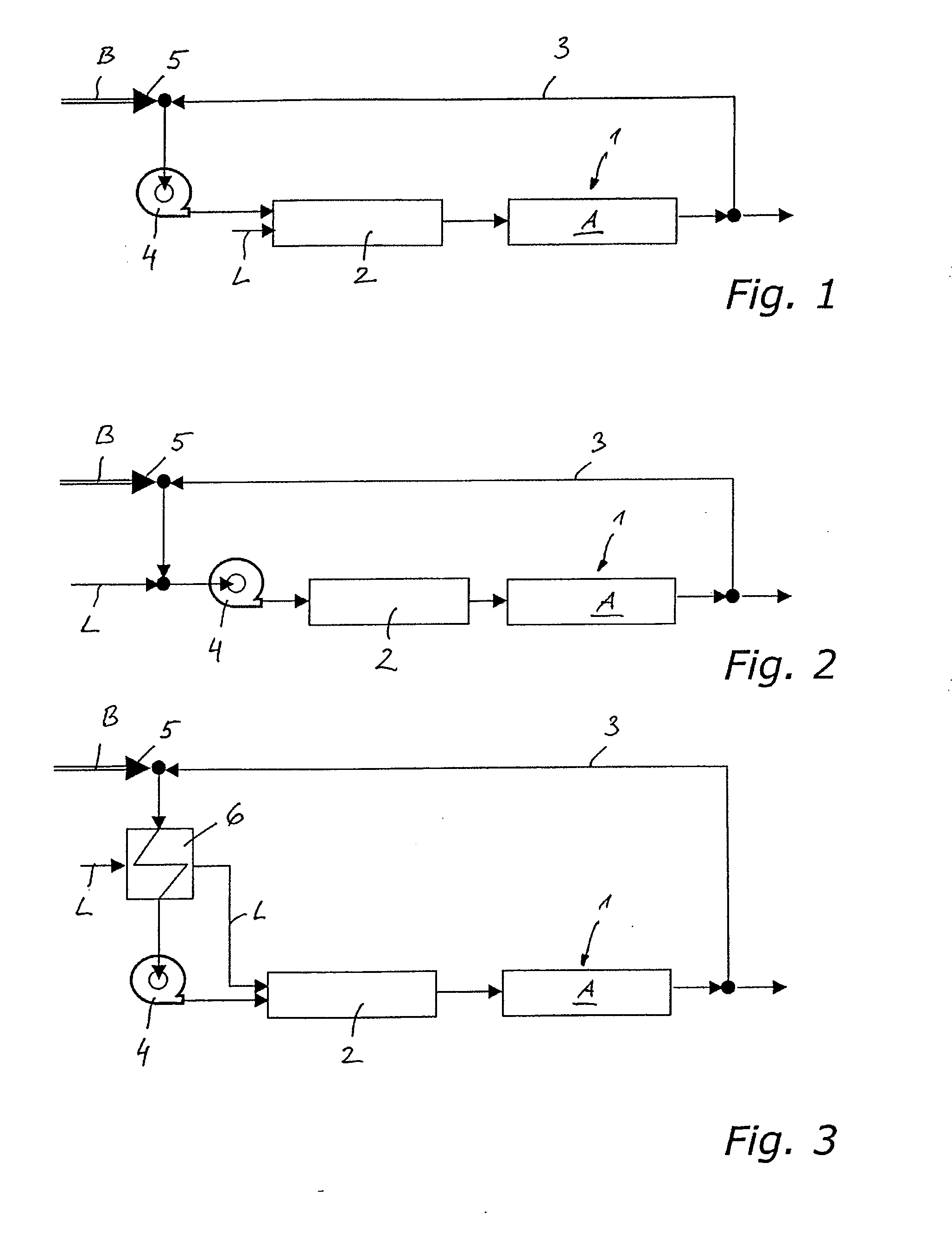

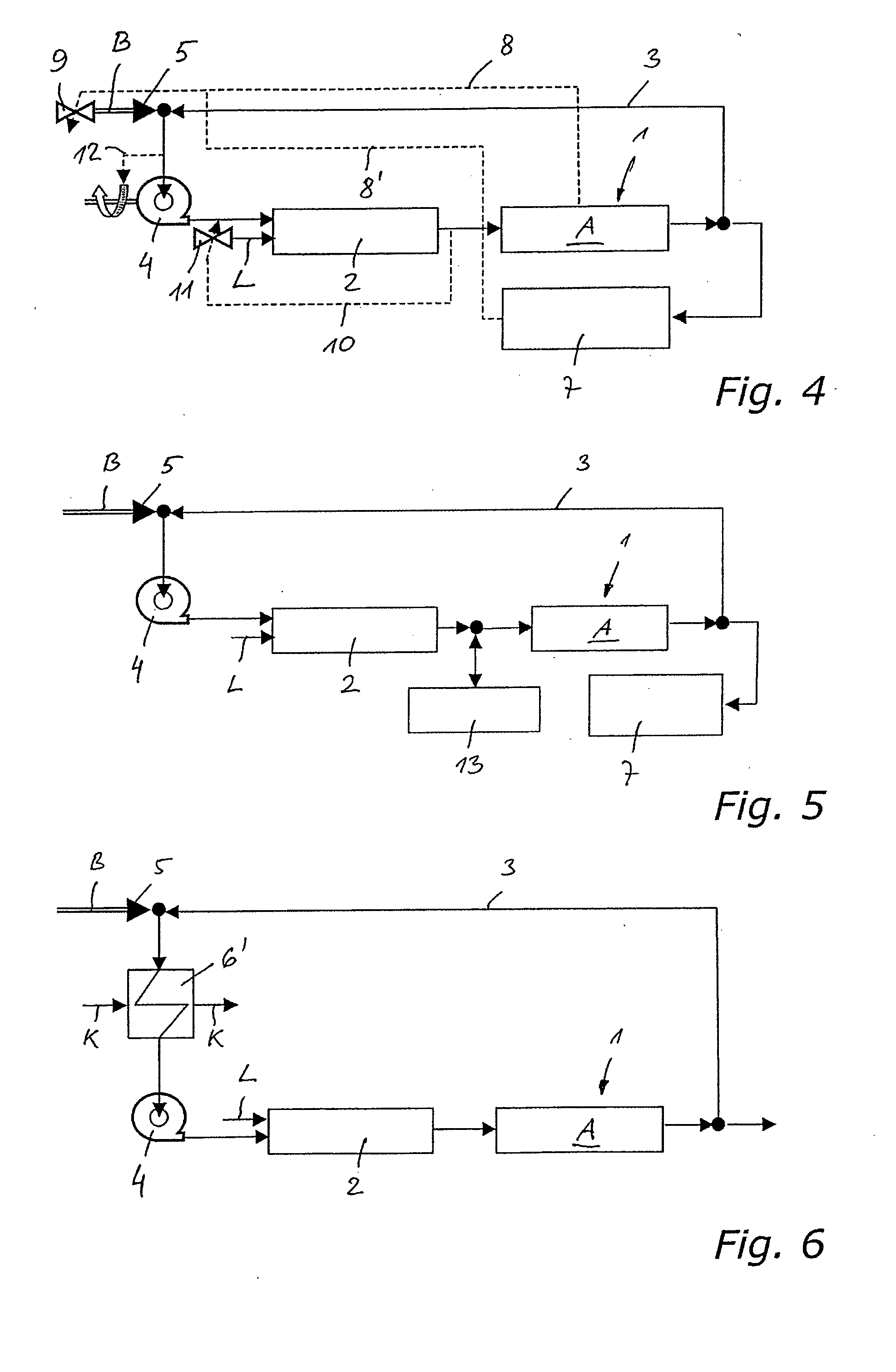

Device and a method for operation of a high temperature fuel cell

InactiveUS20080182141A1Quick responseBig airFuel cell heat exchangeReactant parameters controlFuel cellsRotary pump

The invention relates to a method and a device for operating a high-temperature fuel cell using liquid fuel, preferably diesel oil, where a reformer for the liquid fuel precedes the high-temperature fuel cell on the anode side. A recirculation line for the hot anode exhaust gas is provided, which departing from the outlet side of the anode of the high-temperature fuel cell leads to the inlet side of the reformer, an injector for spraying or injecting the liquid fuel into the hot anode exhaust gas being located upstream of a compressor preceding the reformer. The resulting cooling of the anode exhaust gas will permit the use of conventional positive displacement or rotary pumps in the anode circuit.

Owner:AVL LIST GMBH

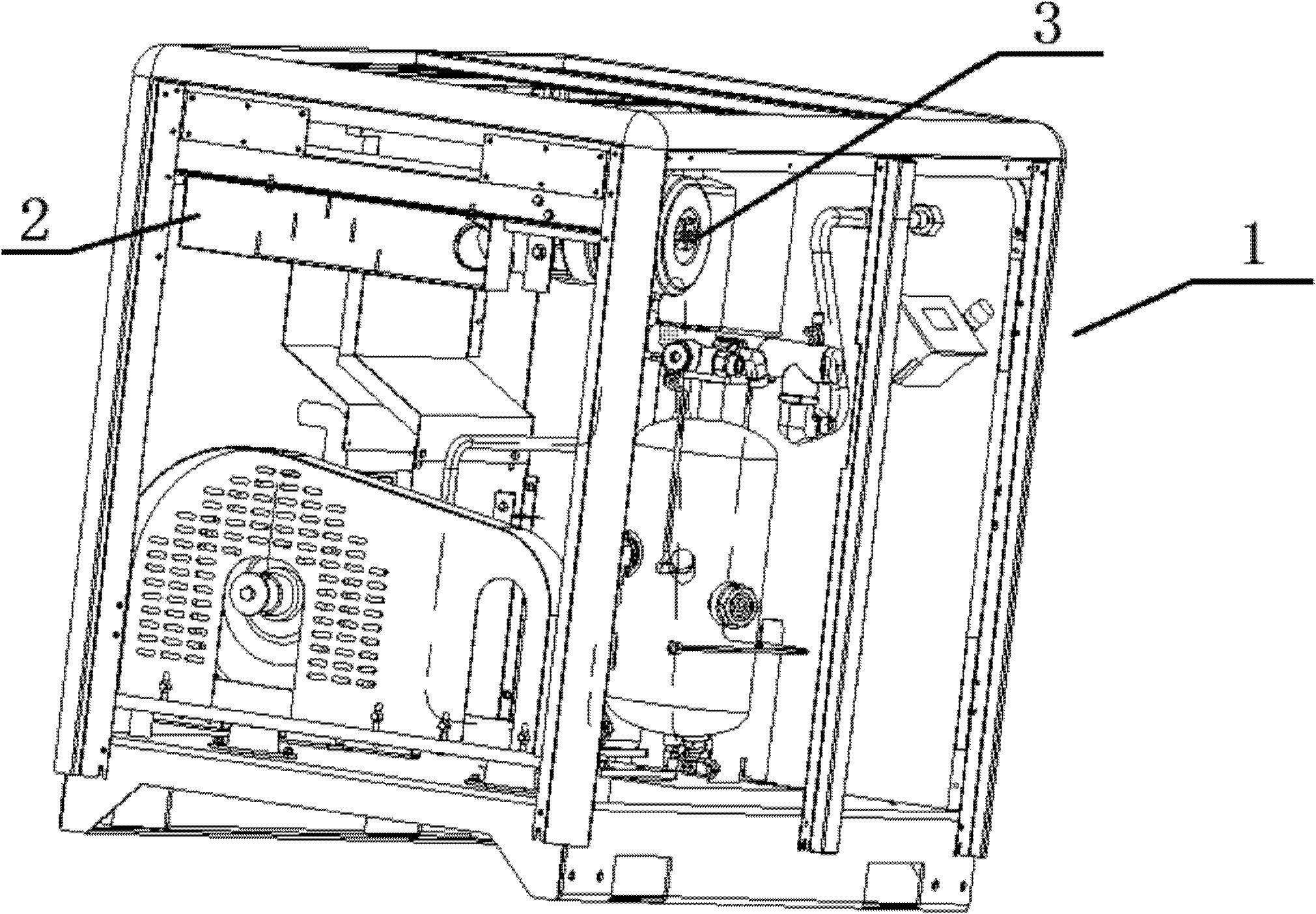

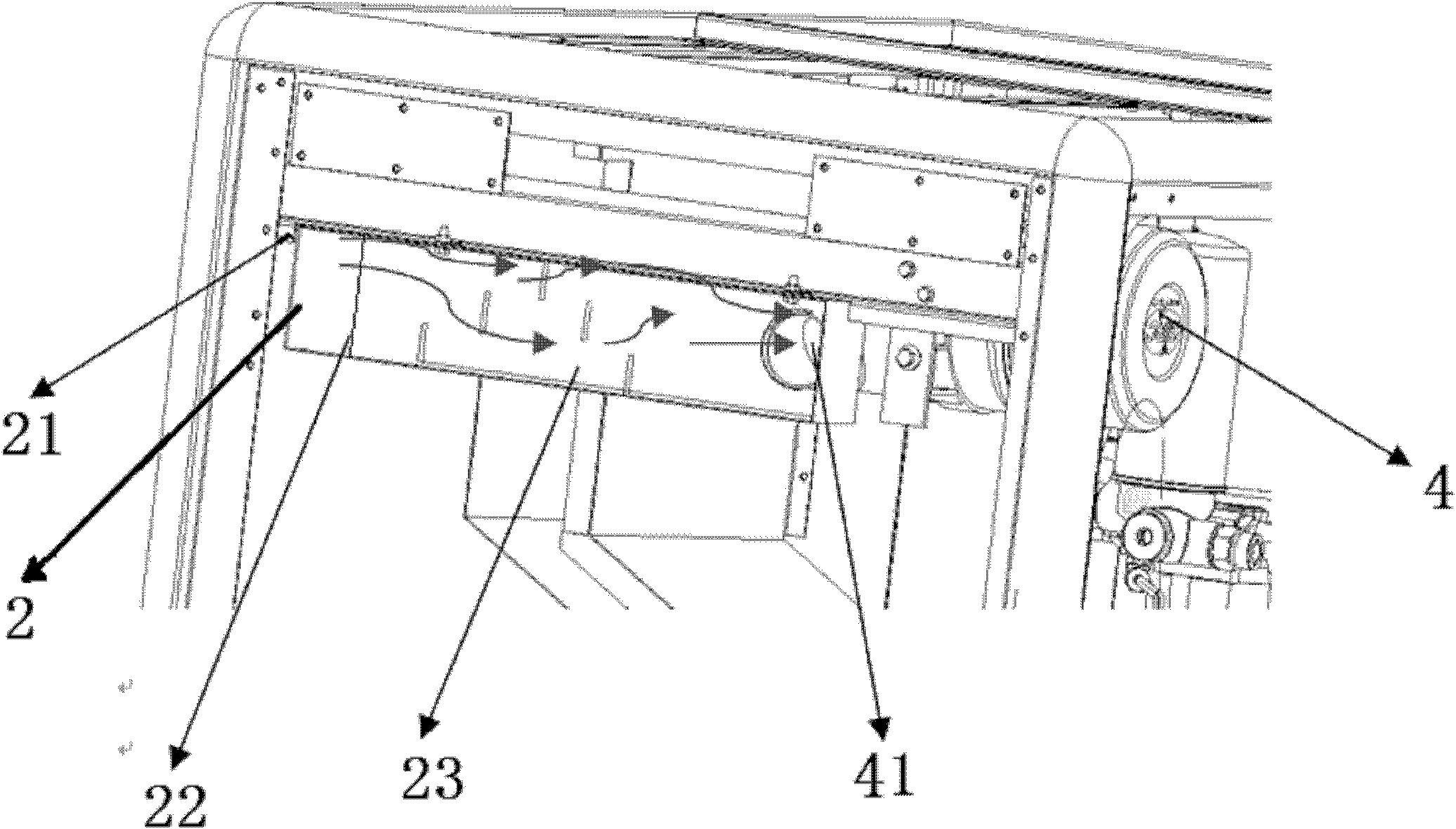

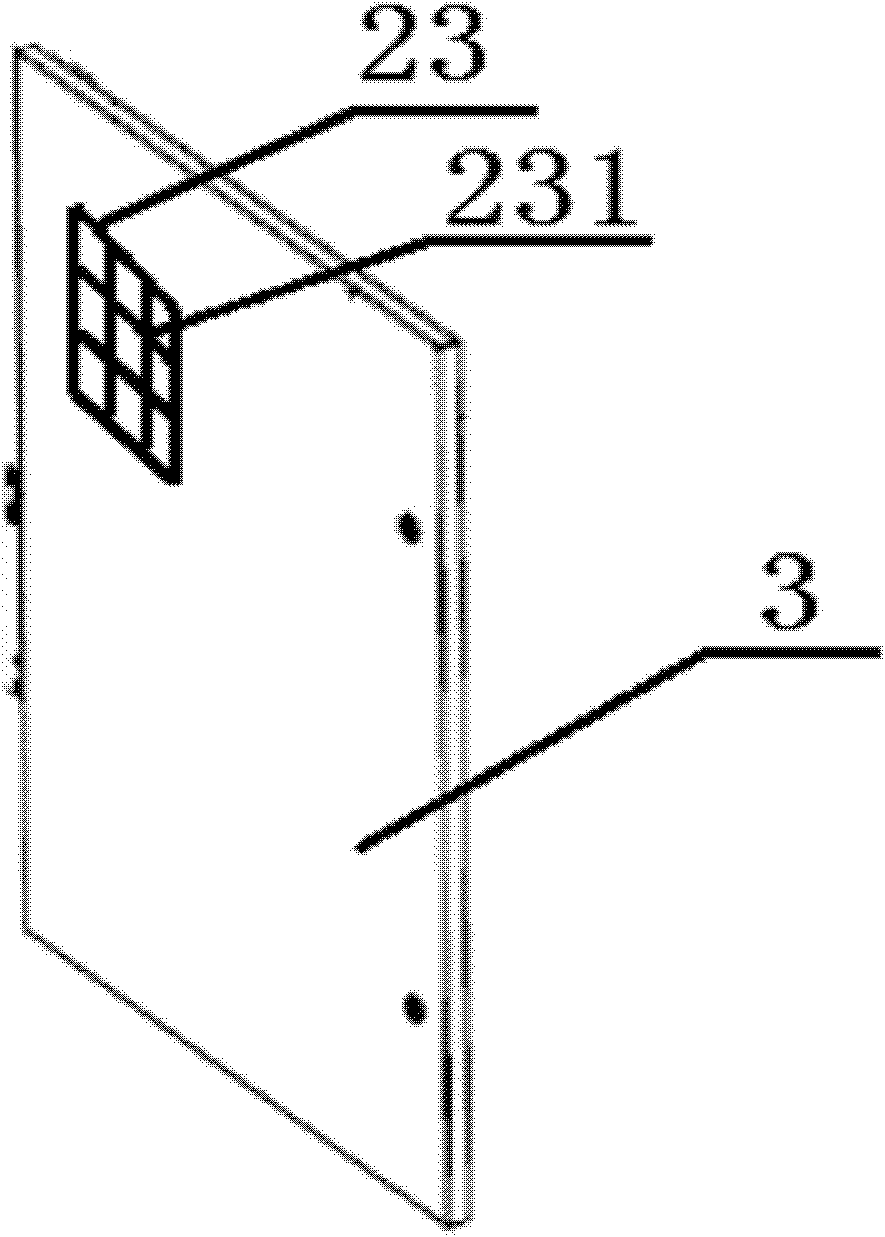

Screw-type air compressor with external air intake and dust filtering functions

InactiveCN102162452AWith electrostatic dust removal effectBig airRotary/oscillating piston pump componentsLiquid fuel engine componentsAir filterReducer

The invention discloses a screw-type air compressor with external air intake and dust filtering functions. The air compressor comprises a compressor body, wherein the compressor body comprises an air intake system. The air compressor is characterized in that the air intake system comprises an independent air intake channel which is composed of a rectangular box; the air intake channel box is isolated from an internal heat source of the compressor; the start end of the air intake channel is an air inlet; the air inlet is arranged on a door plate of the compressor; a noise reducer and a partition board are arranged behind the air inlet in sequence; the surface of the partition board is provided with sound absorption foam; and the tail end of the air intake channel is connected with an air filter of the air compressor. Through the air intake system provided by the invention, the air sucked by the machine is completely cool air, and a filter screen on the door plate has the function of electrostatic precipatation; and the partition board in the air intake channel box can block part of sucked dust, thus air entering in the compressor is cleaner, and simultaneously the sound absorption foam on the partition board can absorb the air intake noise.

Owner:SHANGHAI INGERSOLL RAND COMPRESSOR CO LTD

Industrial preparation method of producing nano calcium carbonate by recycling filter-pressing water

InactiveCN103523813AEasy to achieve industrializationQuick responseCalcium/strontium/barium carbonatesCALCIUM HYDROXIDE SOLUTIONCarbonization

The invention relates to an industrial preparation method of producing nano calcium carbonate by recycling filter-pressing water, and is used for solving a problem that a nano calcium carbonate product is poor in repeatability and unstable in quality after the existing water treatment technology is utilized to treat the filter-pressing water in an existing preparation method. The industrial preparation method comprises the following steps: filtering the filter-pressing water in a nano calcium carbonate producting process by using a high temperature resistant filter press, keeping the water temperature at 65 DEG C-85 DEG C, modulating the mass concentration of digested calcium hydroxide liquor to 6%-10%, and controlling the temperature to 22 DEG C-35 DEG C; then, filling into a reaction kettle, regulating the temperature of Ca(OH)2 suspension liquid to 25 DEG C-40 DEG C; ventilating a gas mixture of carbon dioxide and nitrogen gas into a carbonization reaction kettle at the velocity of 0.6-0.8 cubic meter / second, adding a dispersing agent which accounts for 0.02%-0.05% of the total weight of the Ca(OH)2 in the suspension liquid of the Ca(OH)2, heating a nano calcium carbonate sizing agent to 55 DEG C-65 DEG C, and adding a coating agent. The industrial preparation method disclosed by the invention realizes the closed cycle of nano calcium carbonate process water.

Owner:SHANXI LANHUA HUAMING NANO MATERIALS

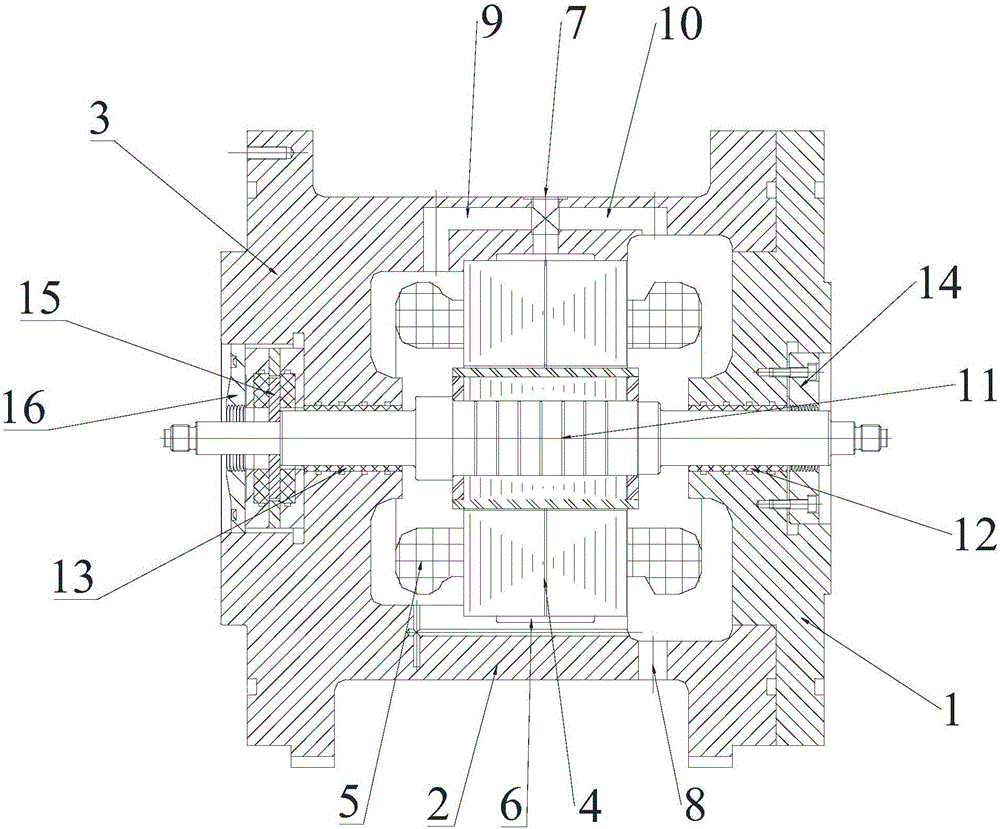

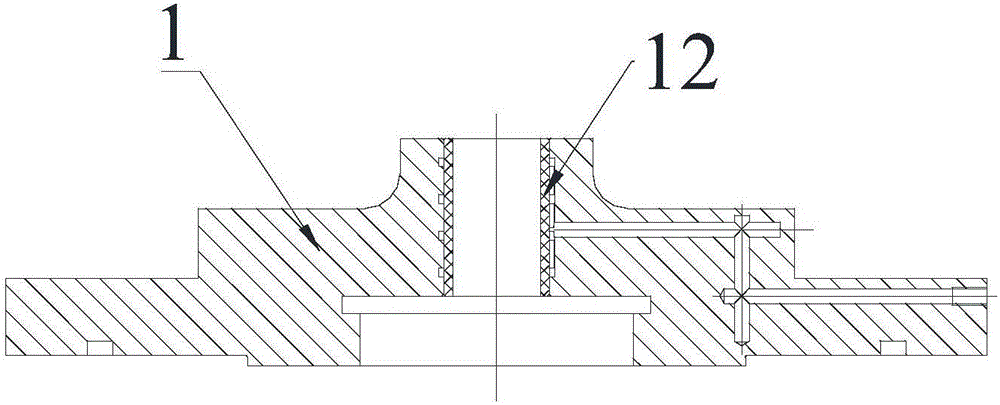

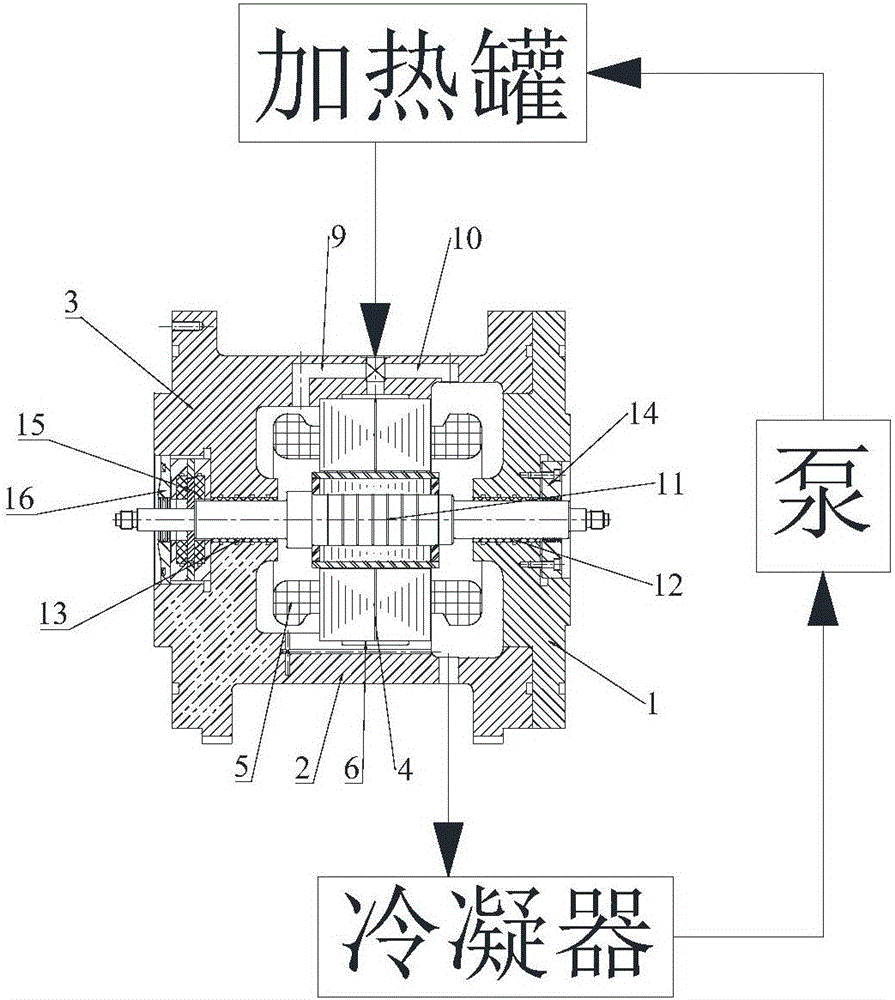

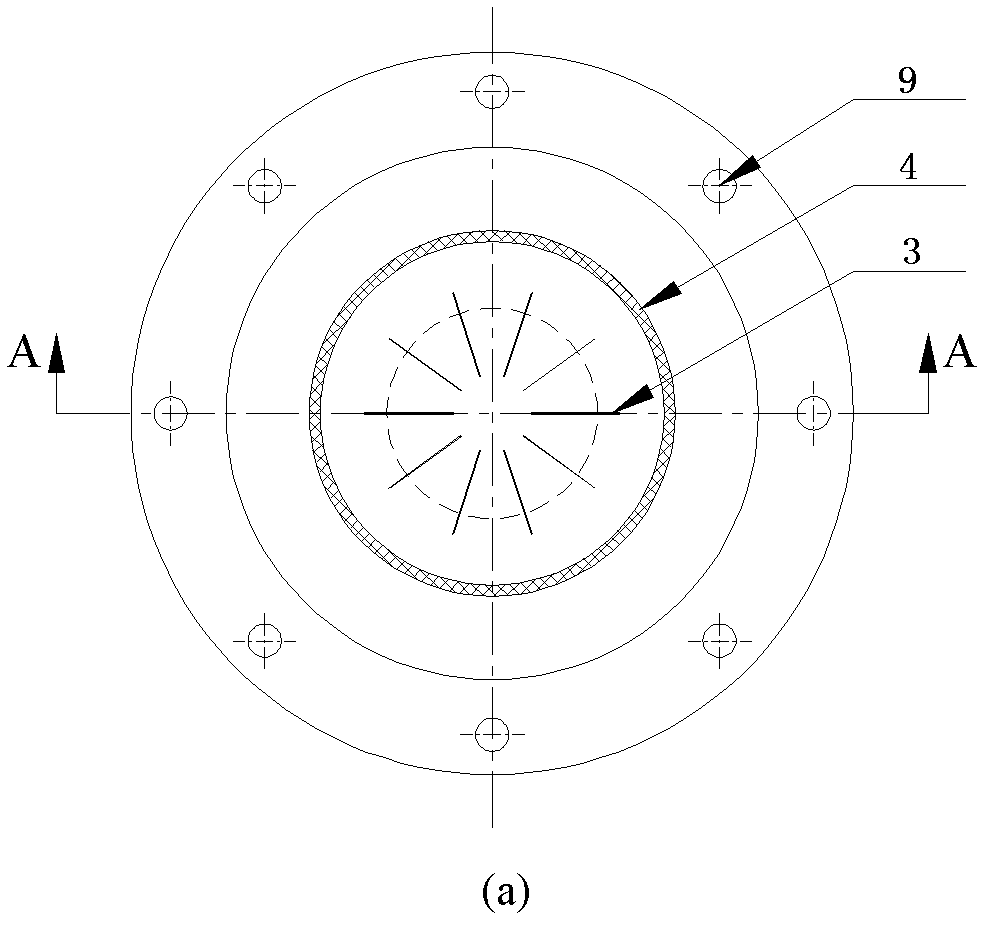

High-speed permanent magnet motor

ActiveCN105871101AImprove carrying capacityPreserve Position AccuracyGas cushion bearingsShaftsEngineeringPermanent magnet motor

The invention discloses a high-speed permanent magnet motor. The high-speed permanent magnet motor comprises a motor casing and a radial bearing seat, wherein a rotor is supported to the motor casing and the radial bearing seat through a left radial hydrostatic bearing, a right radial hydrostatic bearing and an axial hydrostatic bearing; the left radial hydrostatic bearing, the right radial hydrostatic bearing and the axial hydrostatic bearing are porous hydrostatic bearings adopting a low-viscosity gaseous and liquid two-phase fluid as a lubricating medium. The liquid phase of the low-viscosity two-phase fluid of the high-speed permanent magnet motor has the characteristic of low viscosity coefficient, so that the fluid can penetrate through a porous bushing, part of the liquid is gasified due to pressure reduction in the process, and part of the liquid arrives to gaps between the bearings and the rotor; the part of liquid of the low-viscosity two-phase fluid is continuously gasified when discharged from the bearings in the axial direction, so that the amount of gas in the gaps is increased, the bearing capacity of the high-speed permanent magnet motor is improved, and the position precision of the hydrostatic gas bearings is maintained; besides, the liquid part of the low-viscosity two-phase fluid cools the hydrostatic bearings and the motor rotor in the gasifying process.

Owner:浙江福腾流体科技有限公司

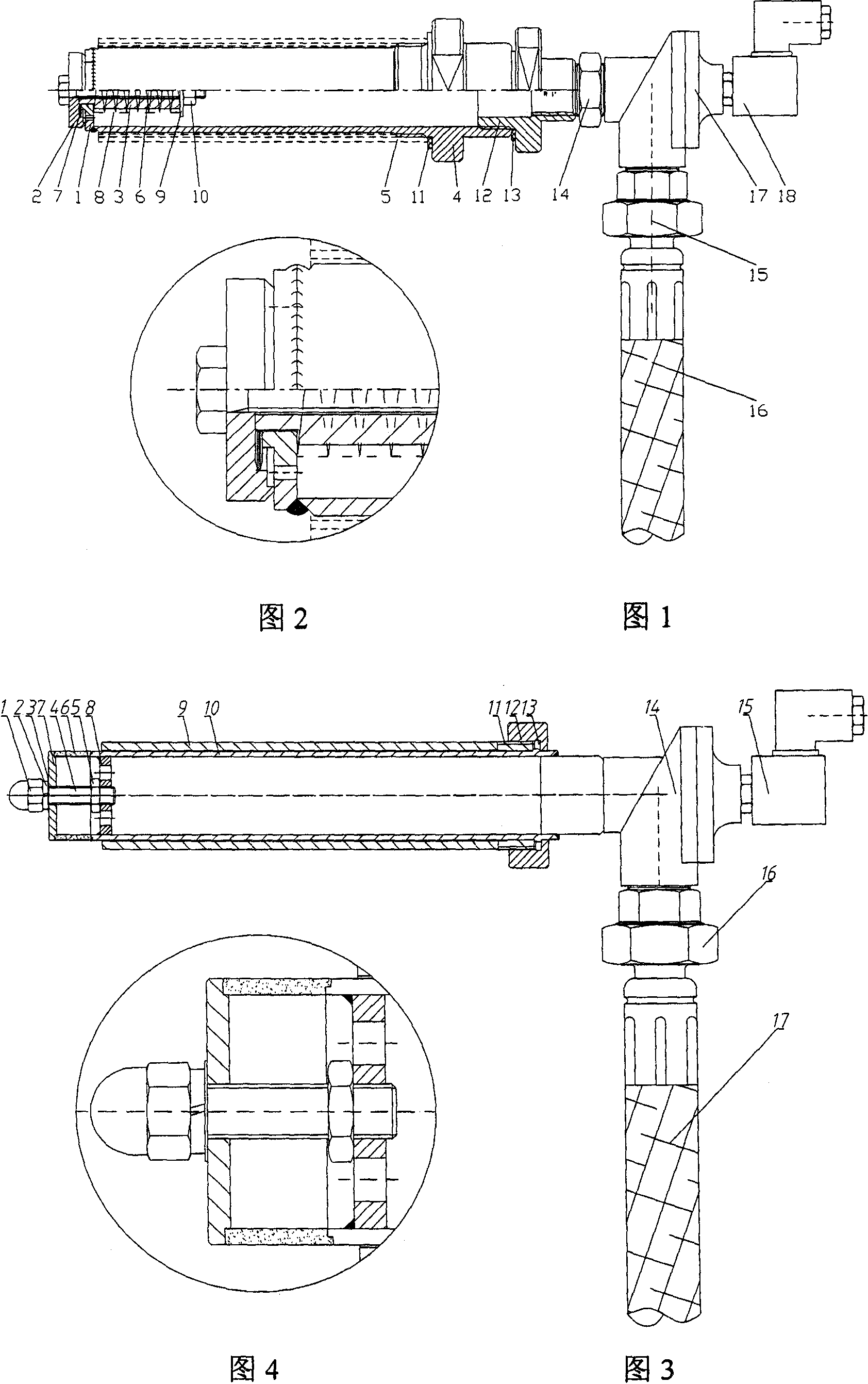

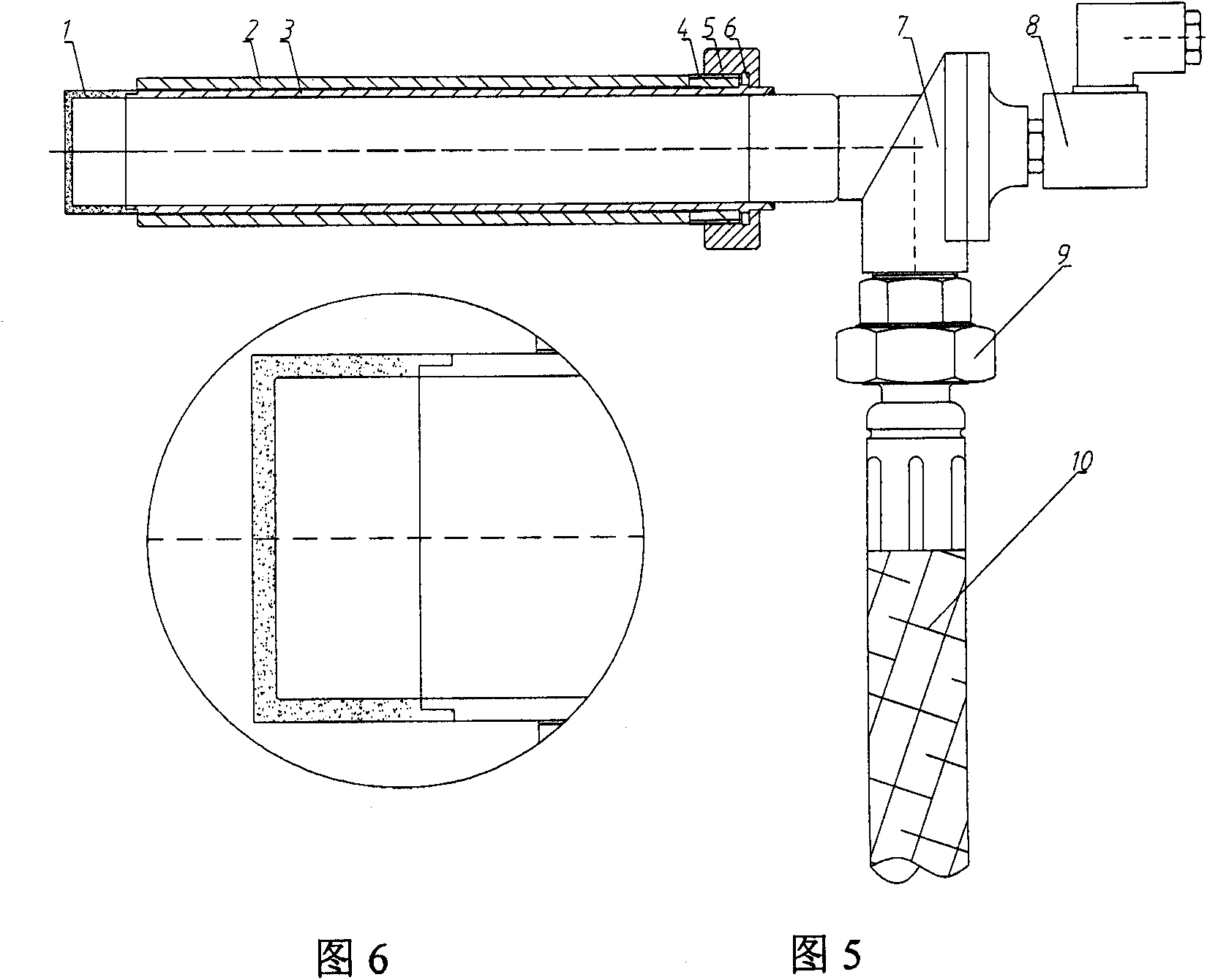

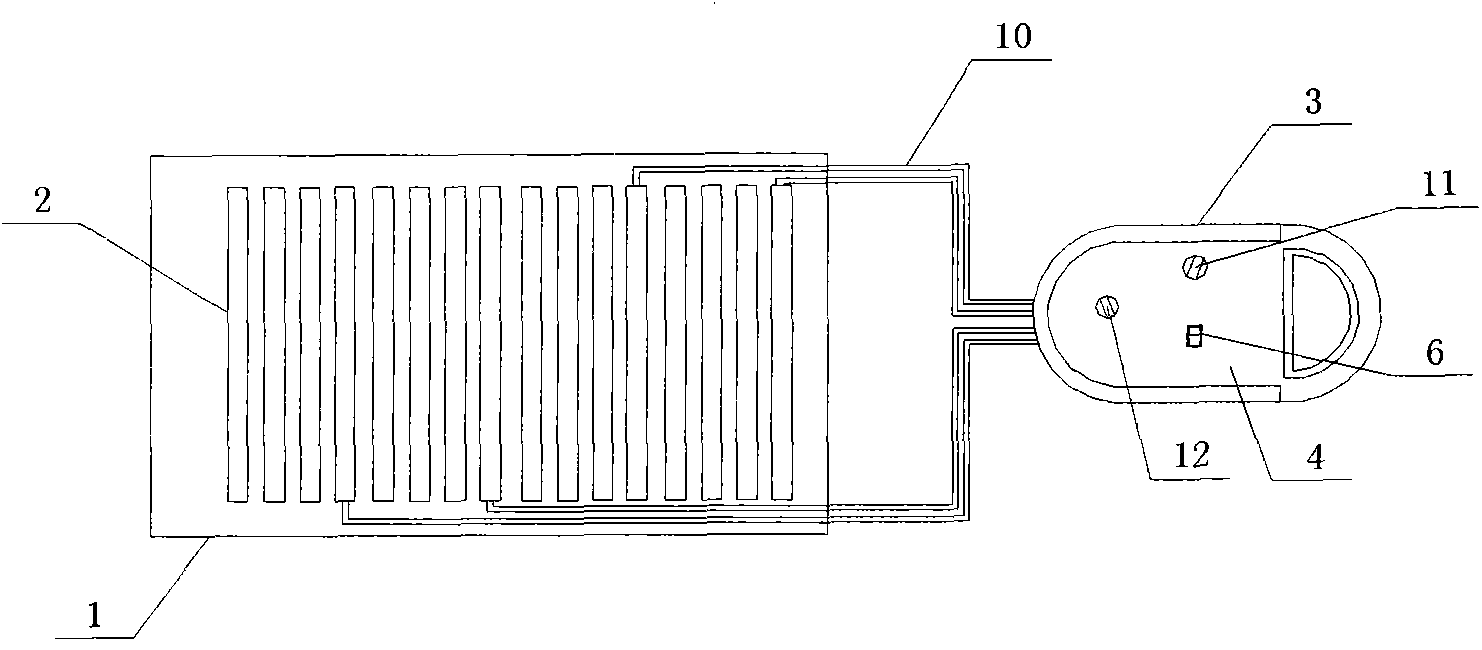

Gasification nozzle

ActiveCN101773889ABlowing forceGood gasification effectSpray nozzlesLiquid spraying apparatusFly ashElectromagnetic valve

The invention relates to a gasification nozzle in a gasification system of containers for storing powdery materials. A spray head (1) is welded at the front end of a nozzle body (4); a pressing plate (2) is connected with the spray head (1); a polytetrafluoroethylene gasket (11) is arranged between a connecting cylinder (5) outside the gasification nozzle and the nozzle body (4) for sealing and the connecting cylinder and the nozzle body are connected through internal threads; a polytetrafluoroethylene gasket (13) is arranged between a reducing connector (14) and the nozzle body (4) for sealing and the reducing connector and the nozzle body are connected through internal threads; the reducing connector (12) is connected with the air outlet end of a pulse electromagnetic valve body (17) through a short thread (14); a pulse electromagnetic valve coil (18) is arranged on the pulse electromagnetic valve body (17); and an air inlet rubber pipe (16) is connected to the air inlet of the pulse electromagnetic valve body (17) through a rubber pipe movable joint (15). The invention can be used in the gasification places of storage devices (transit warehouses, ash buckets and the like) of the powdery materials and the like generated by coal fired power plants (fly ash), cement plants (clinker), iron and steel companies (sintering machines) and the like.

Owner:岳波

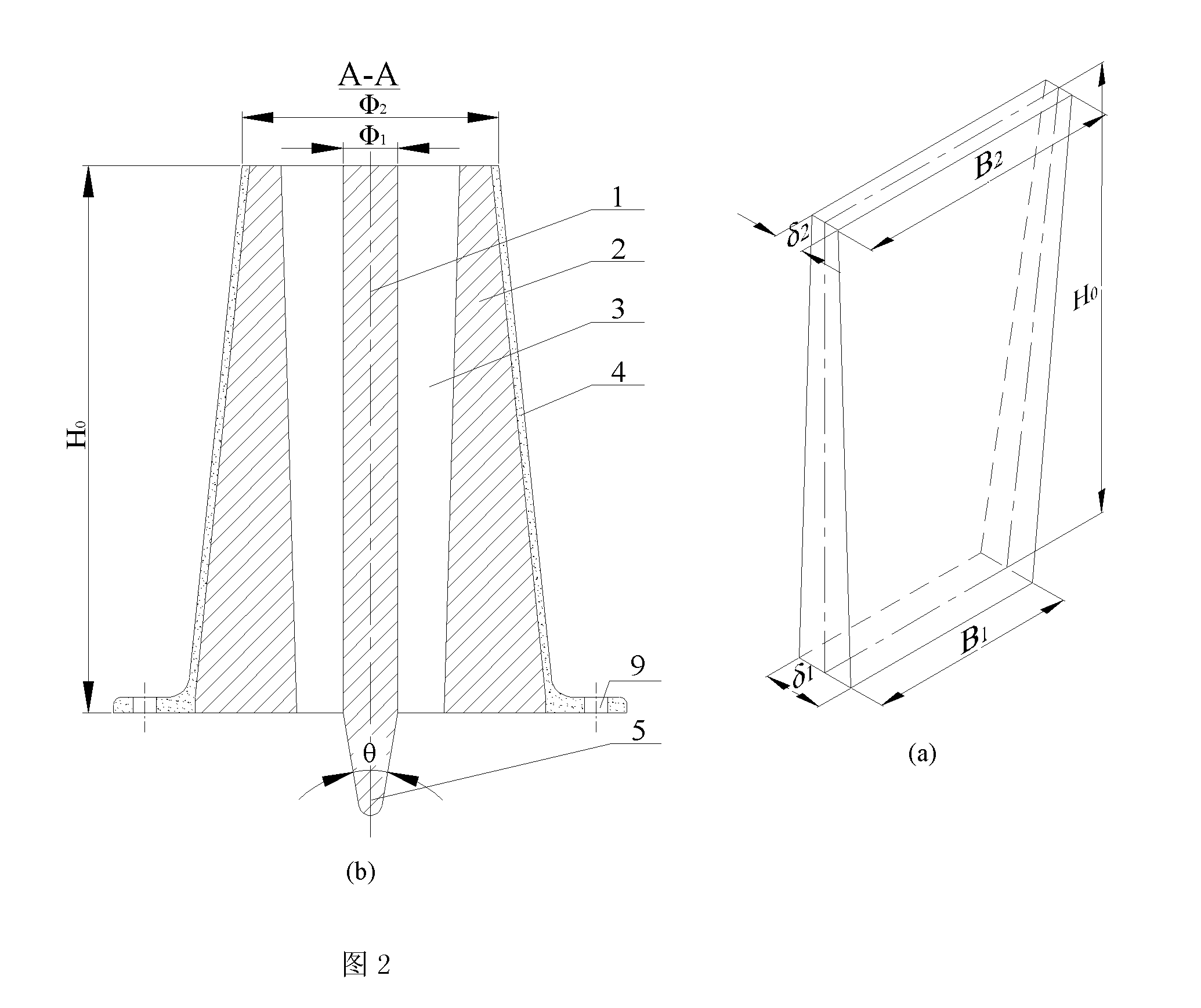

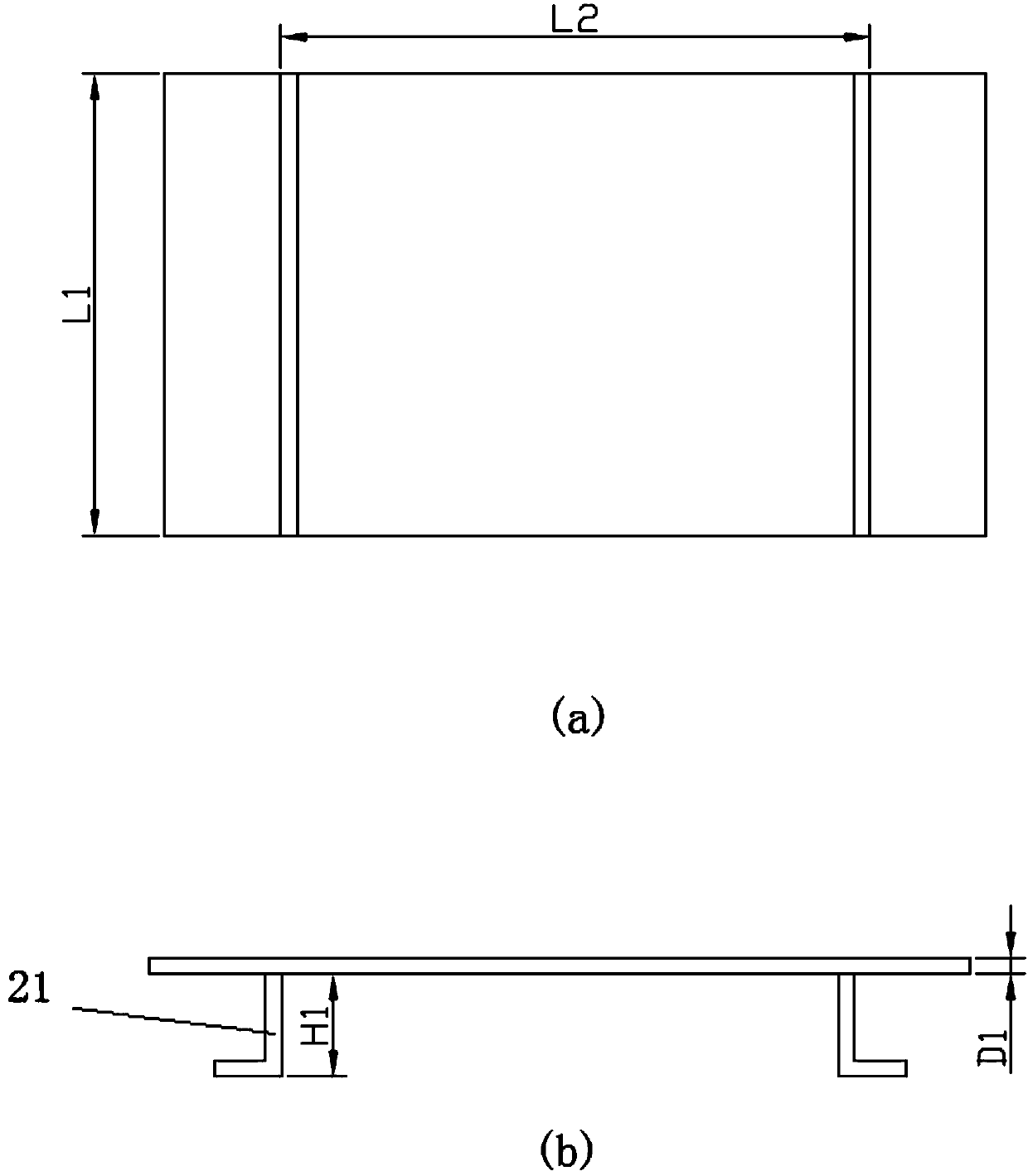

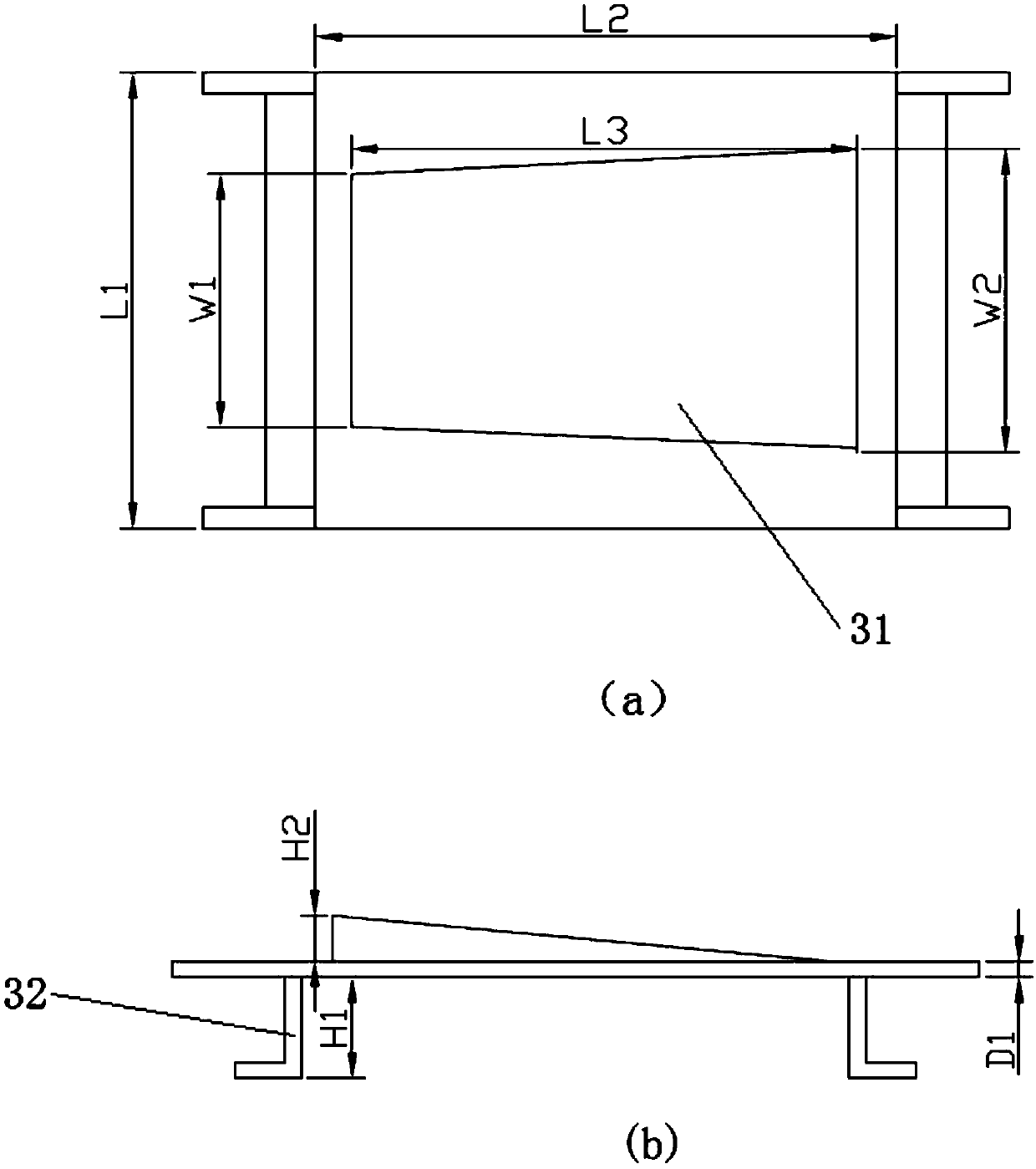

Pillar slot type anti-blocking ladle bottom blowing powder spraying device

InactiveCN102274958AAvoid Dusting RequirementsReduce kinetic energy lossMelt-holding vesselsBrickRefractory

The invention relates to a frustum slit type anti-blocking ladle bottom-blown powder injection device, and belongs to the technical field of steel refining. A frustum slit type powder injection component is filled with refractory material, and four frustum-shaped slits are symmetrically distributed in the refractory material. The frustum slit type anti-blocking ladle bottom-blown powder injectiondevice realizes high-efficiency, continuous and stable injection, has high injection rate and low pulsing probability, can obviously improve uniform powder air flow delivery rate in slits, and is stable in injection, low in abrasion of air bricks, safe and reliable.

Owner:NORTHEASTERN UNIV

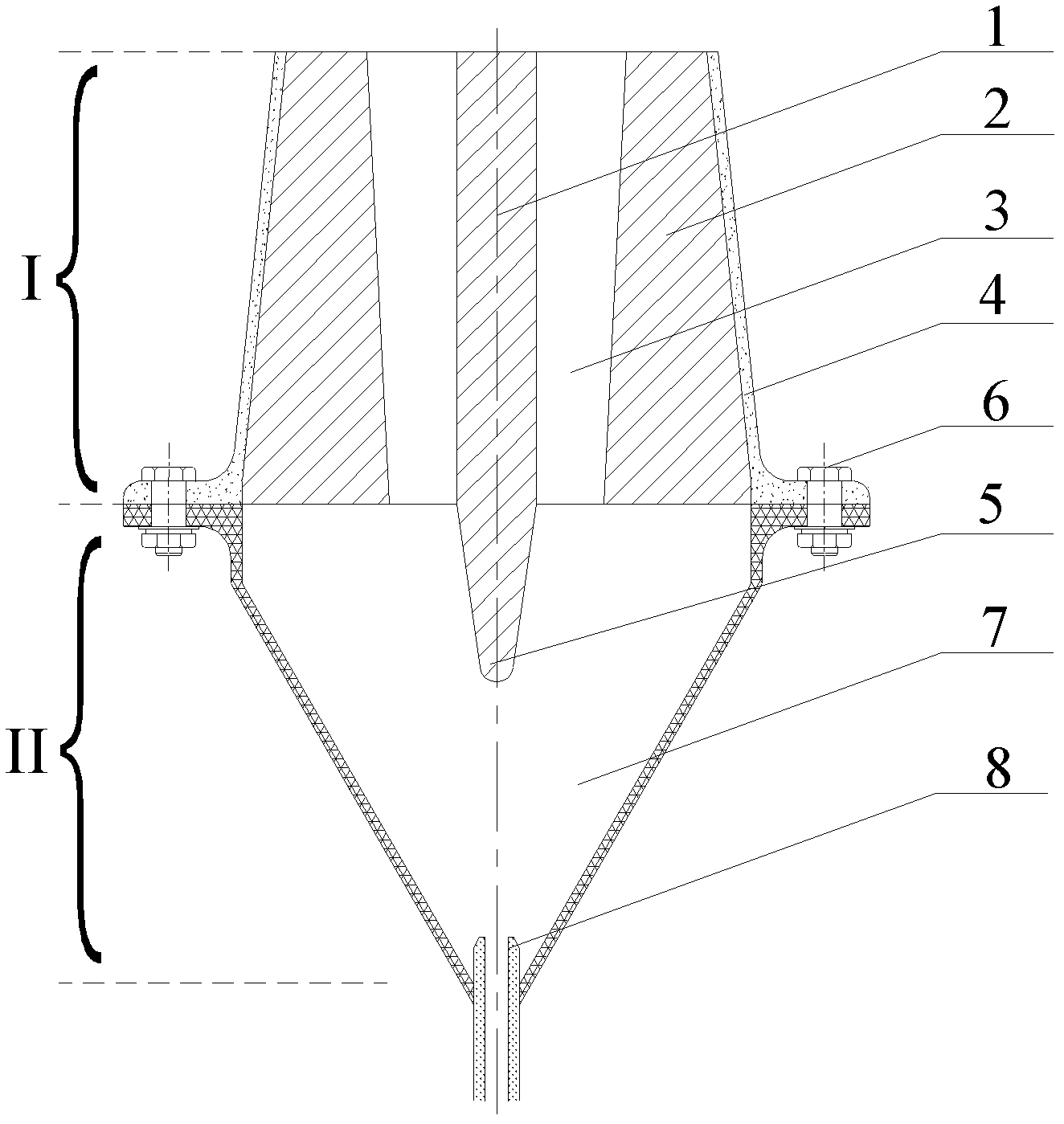

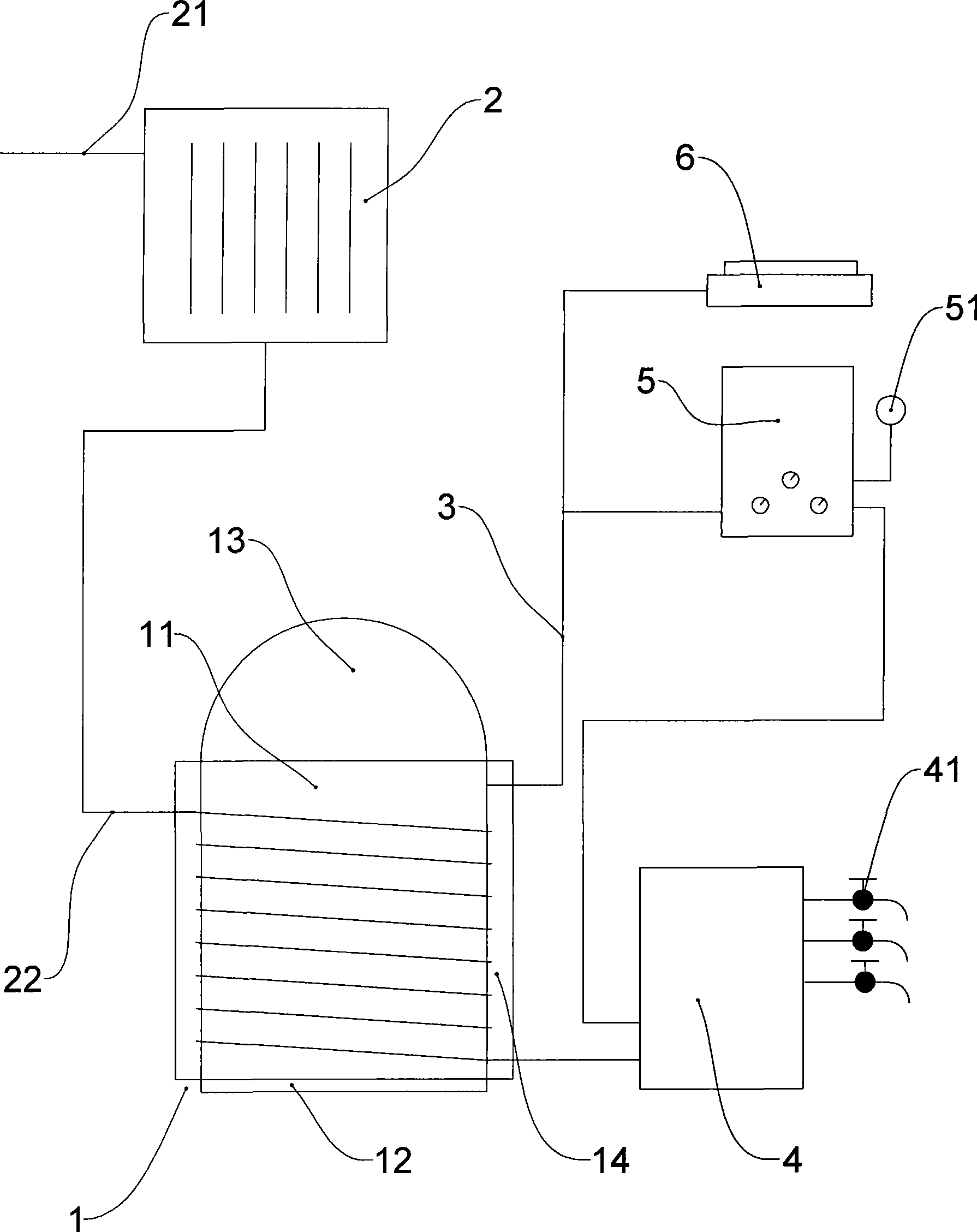

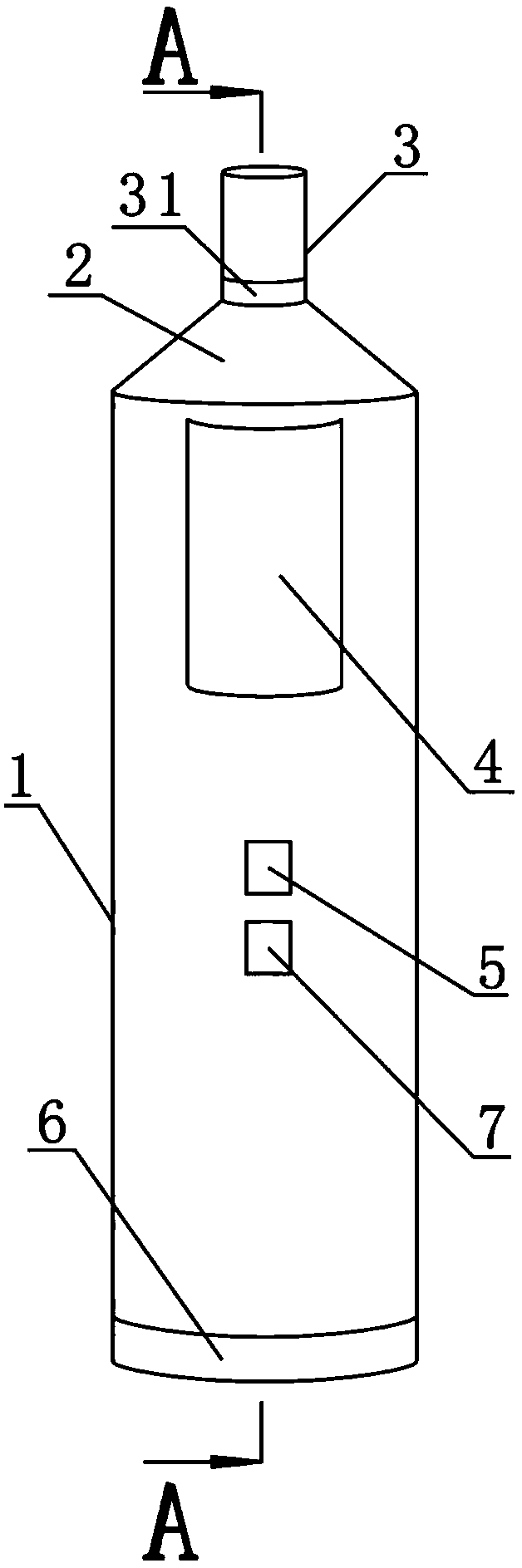

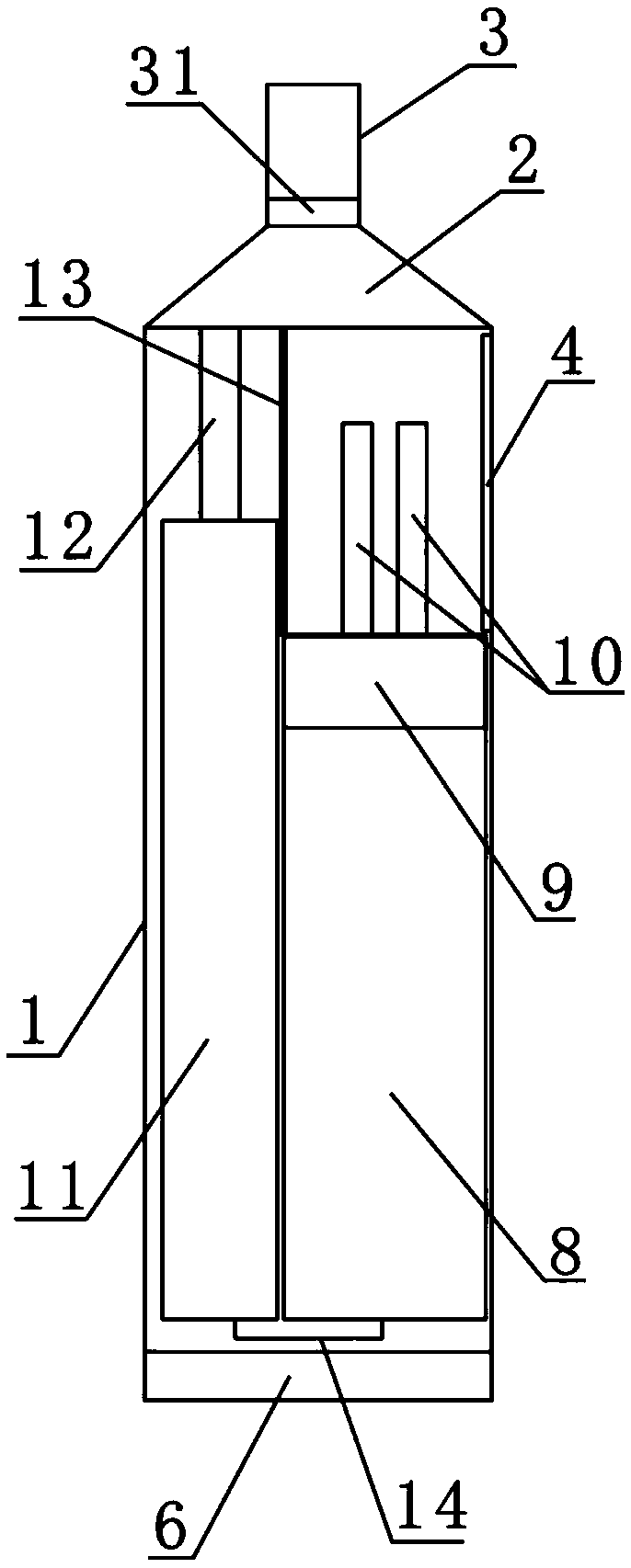

Solar biomass methane heat system

InactiveCN101363643AGenerate fastShort construction periodBioreactor/fermenter combinationsSolar heat devicesGas heaterEngineering

The invention discloses a solar biomass biogas thermodynamic system which is energy-saving and environment-friendly and comprehensively utilizes the solar energy and the biogas. The solar biomass biogas thermodynamic system has the advantages of short construction time, small floor area, quick gas generation, large air flow and easy maintenance, and comprises a biogas generating tank (1) and a solar thermal collector (2); the biogas generating tank (1) is connected with a biogas pipe (3) and comprises a tank body (11), a bottom cover (12) and an upper cover (13); the solar collector (2) is connected with a cold water inlet pipe (21) and a hot water outlet pipe (22); the hot water outlet pipe (22) is coiled on the outer wall of the tank body (11) and is connected to a hot water storage tank (4); the end of the biogas pipe (3) is provided with a gas heater (5) and a gas stove (6); the water outlet of the gas heater (5) is respectively connected with a shower head (51) and the hot water storage tank (4); and the water outlet of the hot water storage tank (4) is connected with a hot water end of a user(41).

Owner:ZHUHAI HUISHENG ENERGY SOURCE TECH DEV

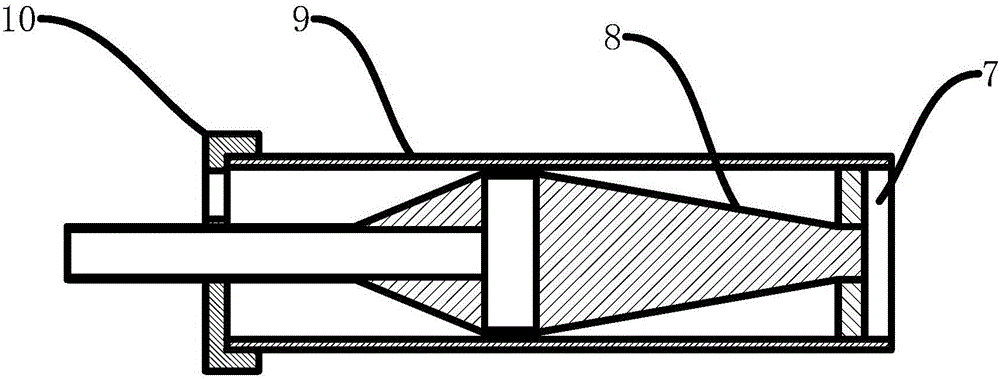

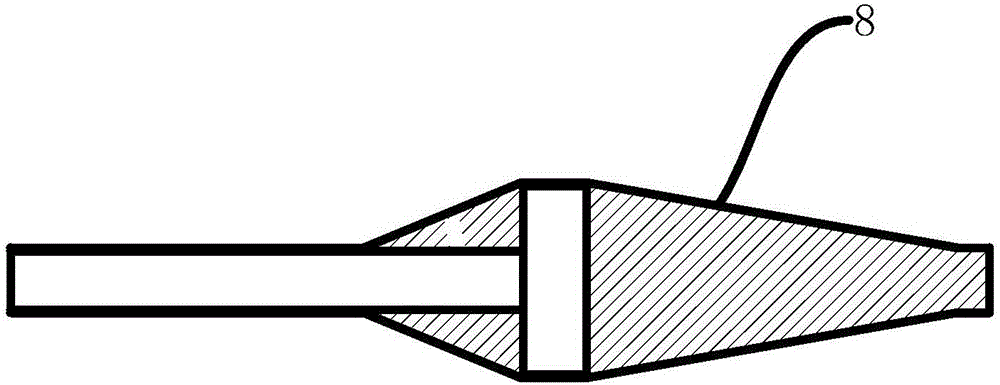

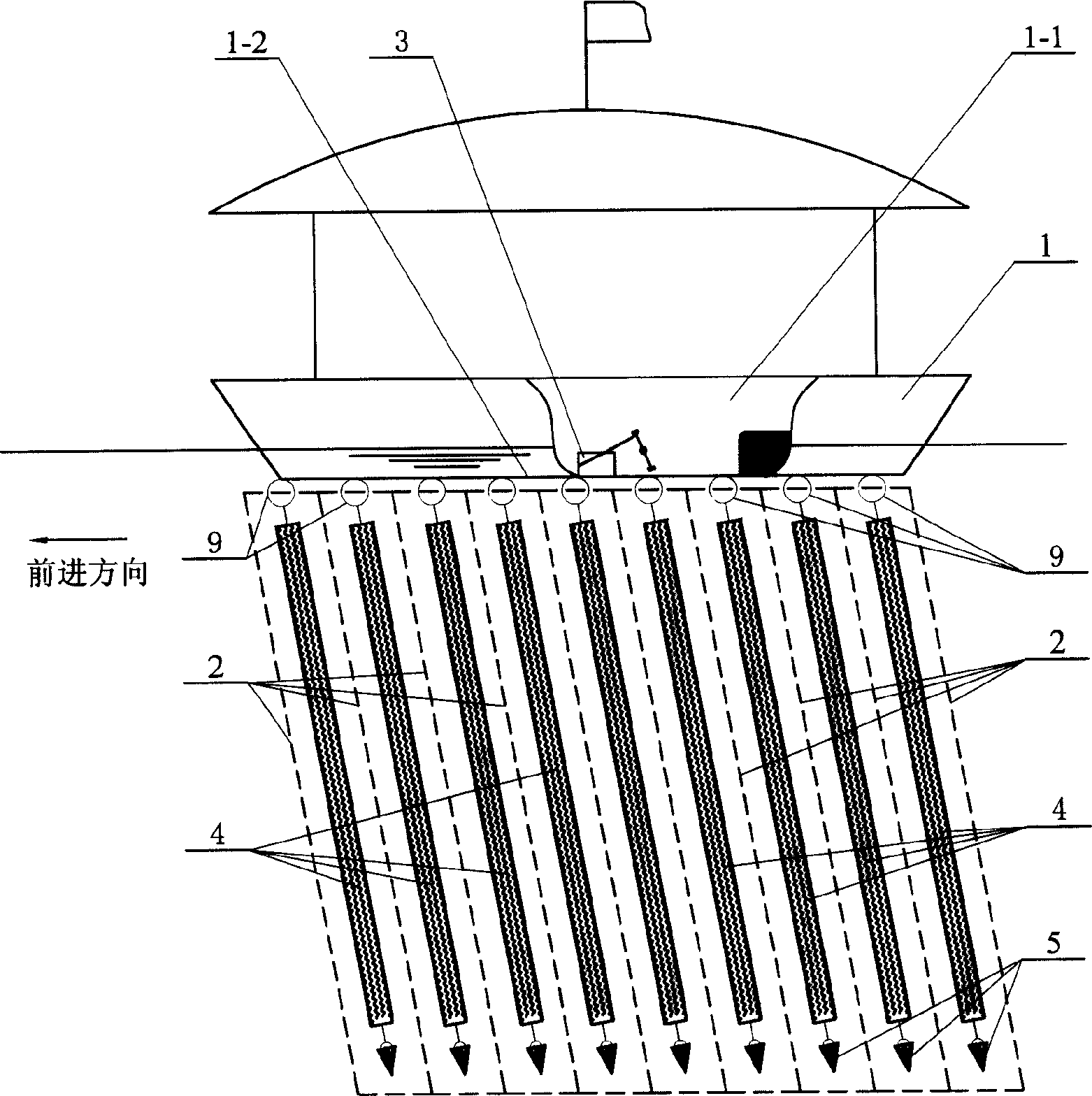

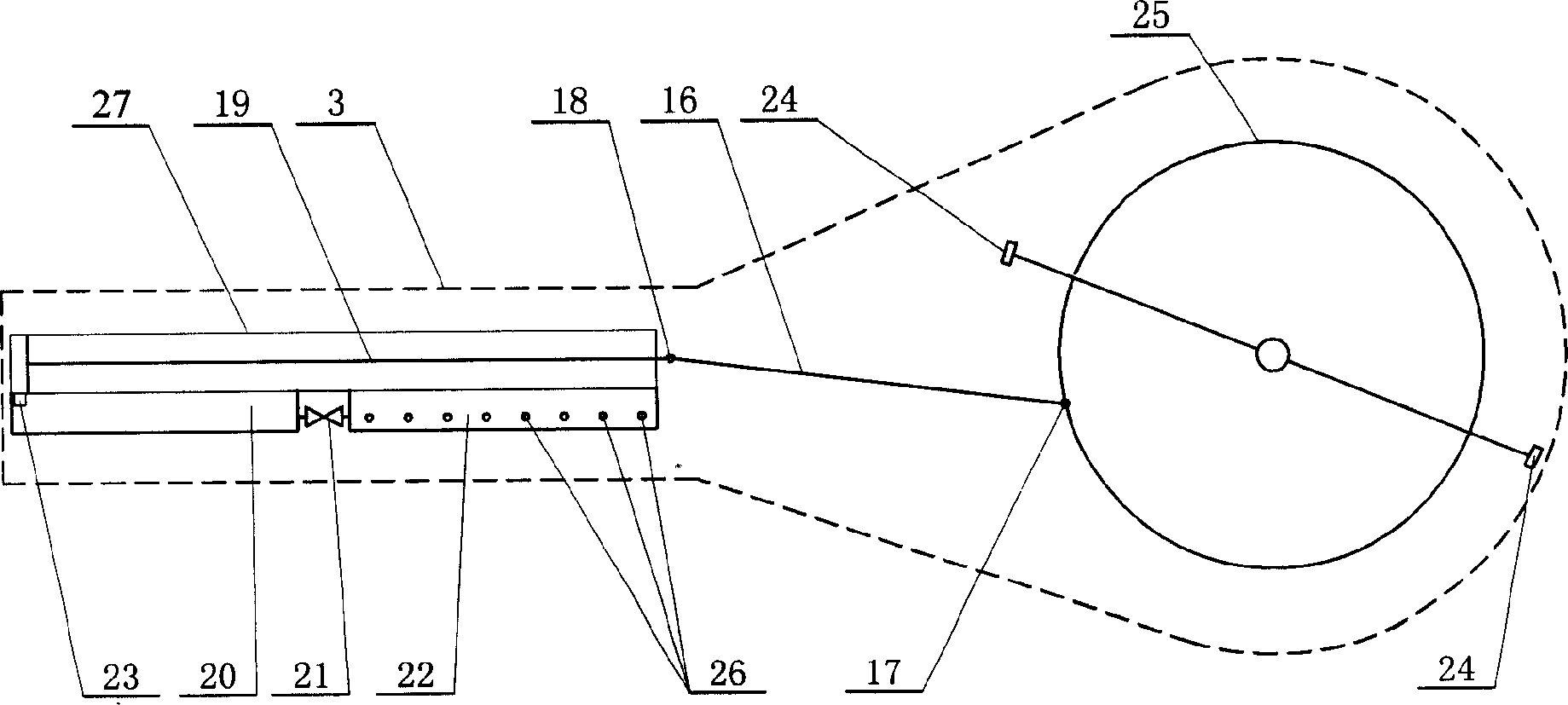

Micro bubble generator and diffusion crushing technology-based ship micro bubble generating device

InactiveCN105857511AEasy flow controlGood drag reduction effectWatercraft hull designHydrodynamic/hydrostatic featuresMicro bubbleMaximum diameter

The invention discloses a micro bubble generator, comprising a bubble nozzle, a fluid core, a shell and an end cover. A water inlet is formed in the shell or the end cover; the fluid core is of a hollow shuttle structure, and an exhaust vent is formed around the maximum diameter of the cross section of the fluid core; the fluid core is arranged in the shell of the bubble generator; one end of the shell is sealed by the end cover and the other end of the shell is provided with the bubble nozzle. A diffusion crushing technology-based 10000-ton class ship micro bubble generating device comprises a water inlet pipe, a filter unit, a water pump, a connection hose, the micro bubble generator, an air inlet pipe and an air blower. The water inlet pipe is connected with the water pump; the filter unit is arranged on the water inlet pipe; the water pump is connected with the water inlet of the micro bubble generator through the connection hose; an air inlet of the micro bubble generator is connected with the air blower through the air inlet pipe. The micro bubble generator and the diffusion crushing technology-based ship micro bubble generating device overcome the problems that, in the existing air curtain drag reduction technology, small air bubble diameter and great air flow cannot be realized simultaneously, the manufacturing cost is high, and manufacturing is difficult.

Owner:ZHEJIANG UNIV

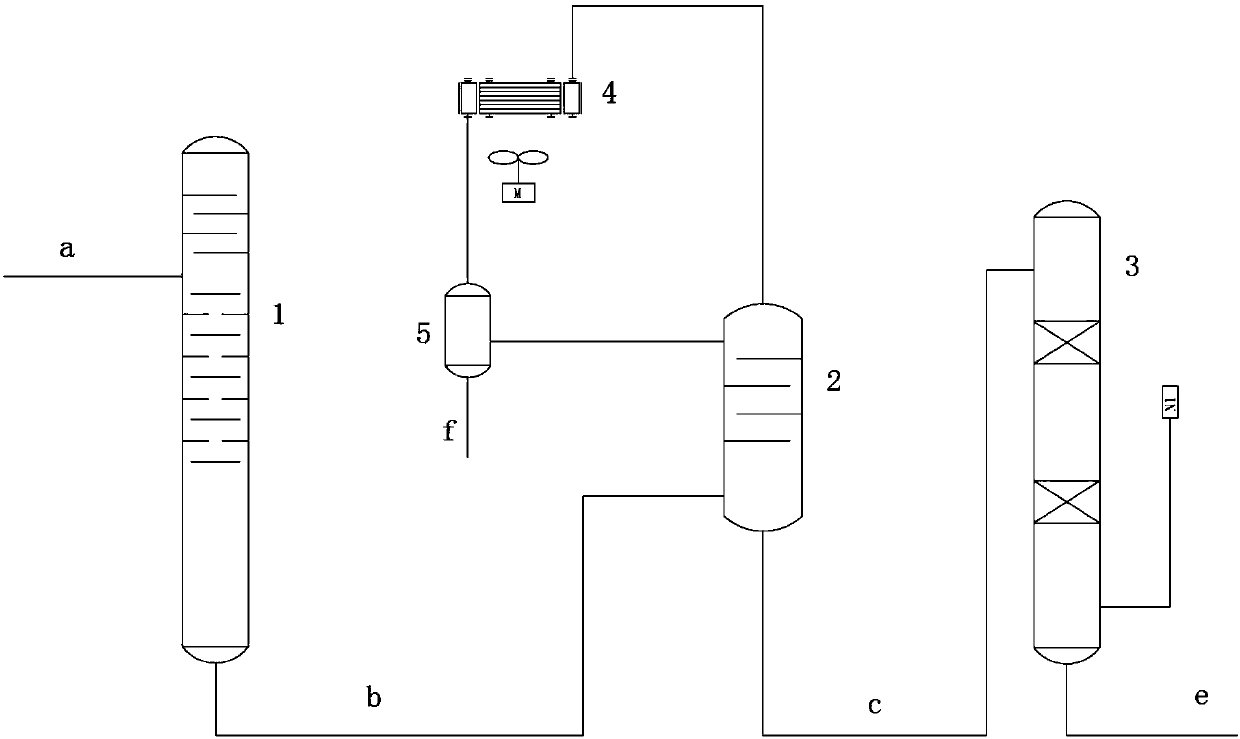

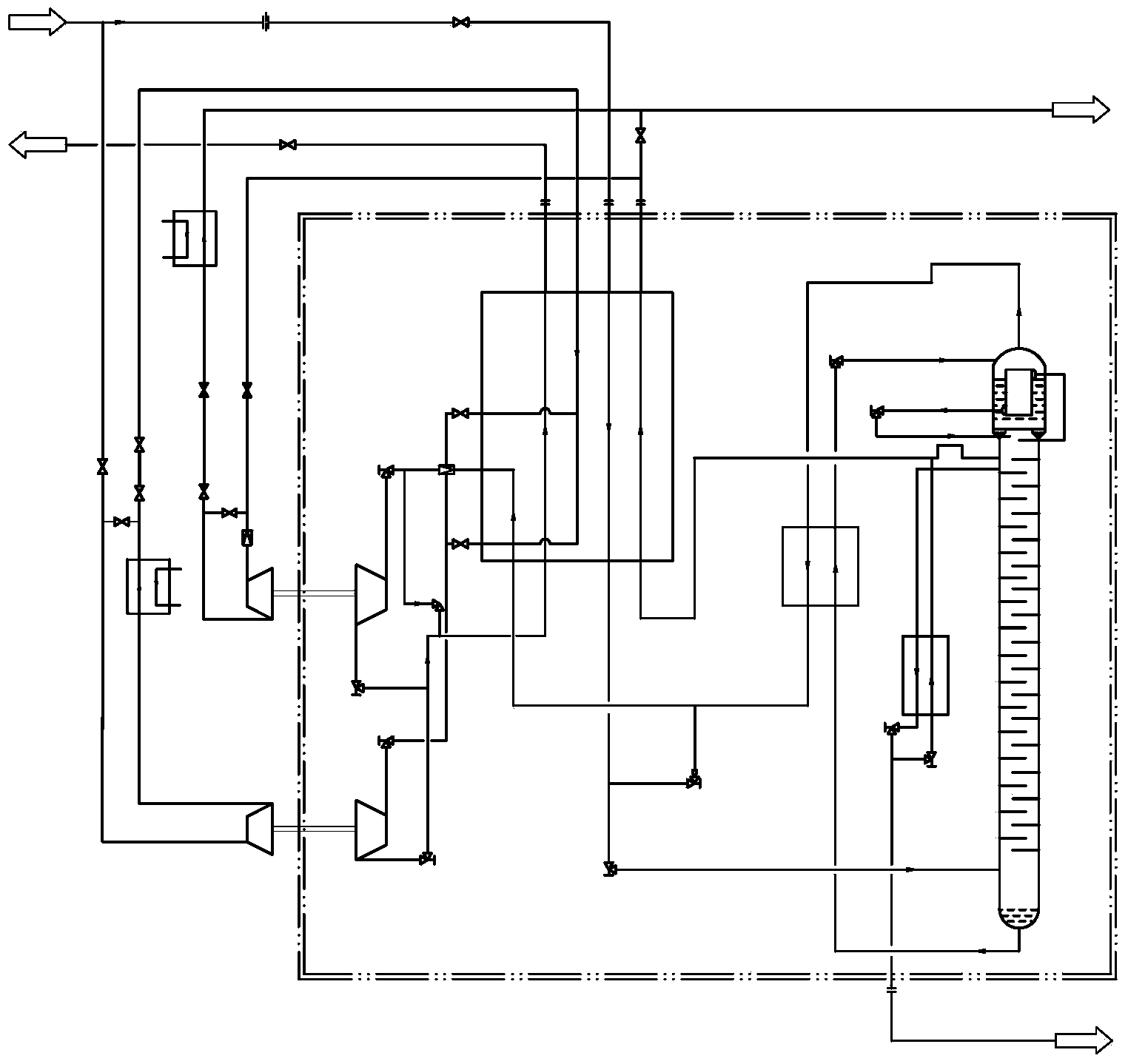

Method and system for removing solvents from isocyanates obtained from phosgenation reaction

ActiveCN107652208ABig airReduce fluid volumeChemical industryIsocyanic acid derivatives purification/separationReboilerOperational stability

The invention relates to a method and system for removing solvents from isocyanates obtained from phosgenation reaction with an aim to reduce content of heavy components in the solvents, improving purity of the solvents and increasing operation elasticity. Corresponding amine and the solvents are mixed through the phosgenation reaction and then mixed and reacted with phosgene in a mixer to obtainmixed liquor with materials including isocyanate, the solvents, the phosgene, HCI and the like, the phosgene and the solvents are removed from the mixture via a phosgene removing tower and a solvent removing tower respectively, and crude isocyanates free from the phosgene and the solvents and solvents containing the phosgene and HCl light components and trace isocyanate heavy components are obtained. With the method, content of the heavy components in the cyclic solvents can be effectively reduced, plugging frequency of the amine and the phosgene mixer is reduced, self-polymerization pollutionin a tray and scaling pollution in a reboiler are reduced, operation stability is improved, and meanwhile, energy consumption during solvent removal can be reduced; the method and system is simple inprocess, convenient in operation, energy saving, high in production efficiency and environment friendly.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD

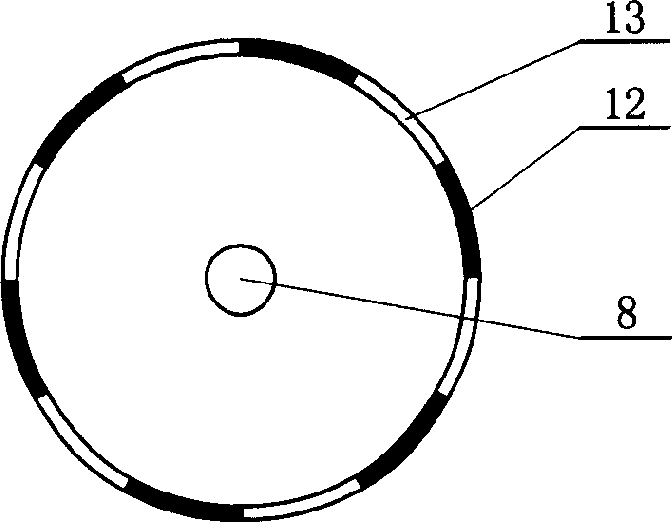

Apparatus on ship for purifying water

InactiveCN1623929ASolve pollutionGuaranteed decontaminationSustainable biological treatmentBiological water/sewage treatmentDrive shaftMarine engineering

A pleasure-boat type movable water quality improving apparatus is composed of a pleasure-boat, an air supplying unit in said boat, and a living things carrier under said boat. Said carrier consists of the cylindrical fillers composed of mass transfer bodies, the pile loop bodies as planting carrier and fixing rings, and two fixing sleeve pipes arranged at both ends of fillers.

Owner:HARBIN INST OF TECH

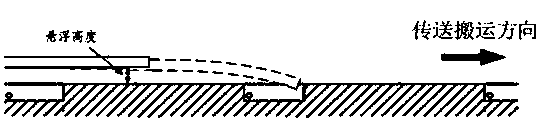

Cyclonic air current suspension device

ActiveCN103662835AIncrease the air volume of the suspensionBig airConveyorsCharge manipulationCycloneSpray nozzle

The invention discloses a cyclonic air current suspension device which comprises a suspension plane. The suspension plane is provided with an inward-concave swirl cavity which generates negative pressure through air cyclone, the cross section of the swirl cavity is circular, a through hole which is communicated with the atmosphere is formed in the bottom of the swirl cavity, the through hole is placed in the center of the swirl cavity, and the diameter of the through hole is smaller than the diameter of the bottom of the swirl cavity. The swirl cavity is connected with a compressed air supply air source which is connected with a nozzle in the wall face of the swirl cavity, and the nozzle faces the tangent line direction of the wall face of the swirl cavity. Rotational flow in the swirl cavity forms center negative pressure and sucks air flow from the through hole to be used for increasing the air flow for supporting workpieces to be suspended. Meanwhile, the sucked air flow can lower the negative pressure at the center so as to weaken the downward pulling effect of the negative pressure on the workpieces. Accordingly, the suspension height of the workpieces can be increased by forming the through hole in the center of the swirl cavity.

Owner:ZHEJIANG UNIV

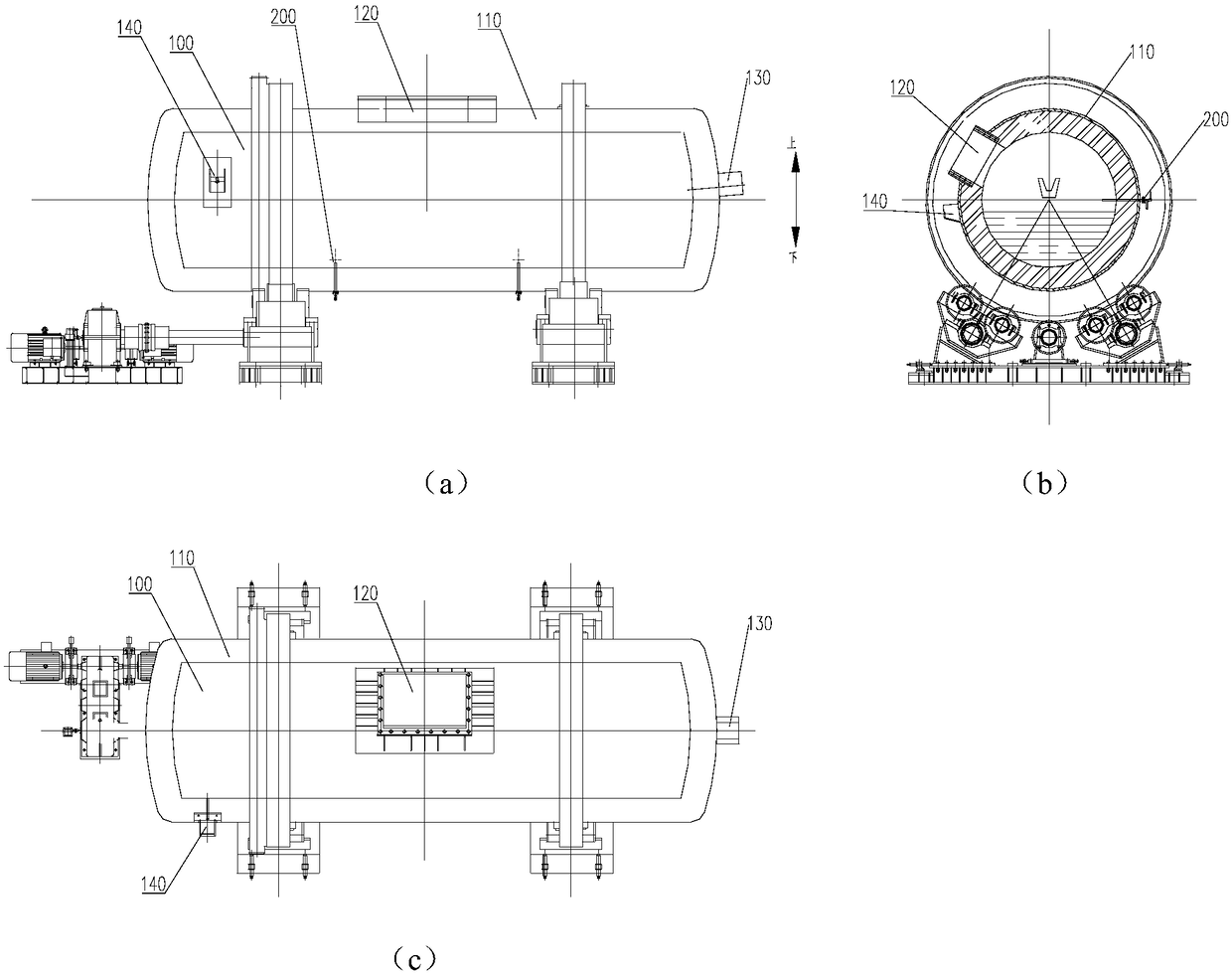

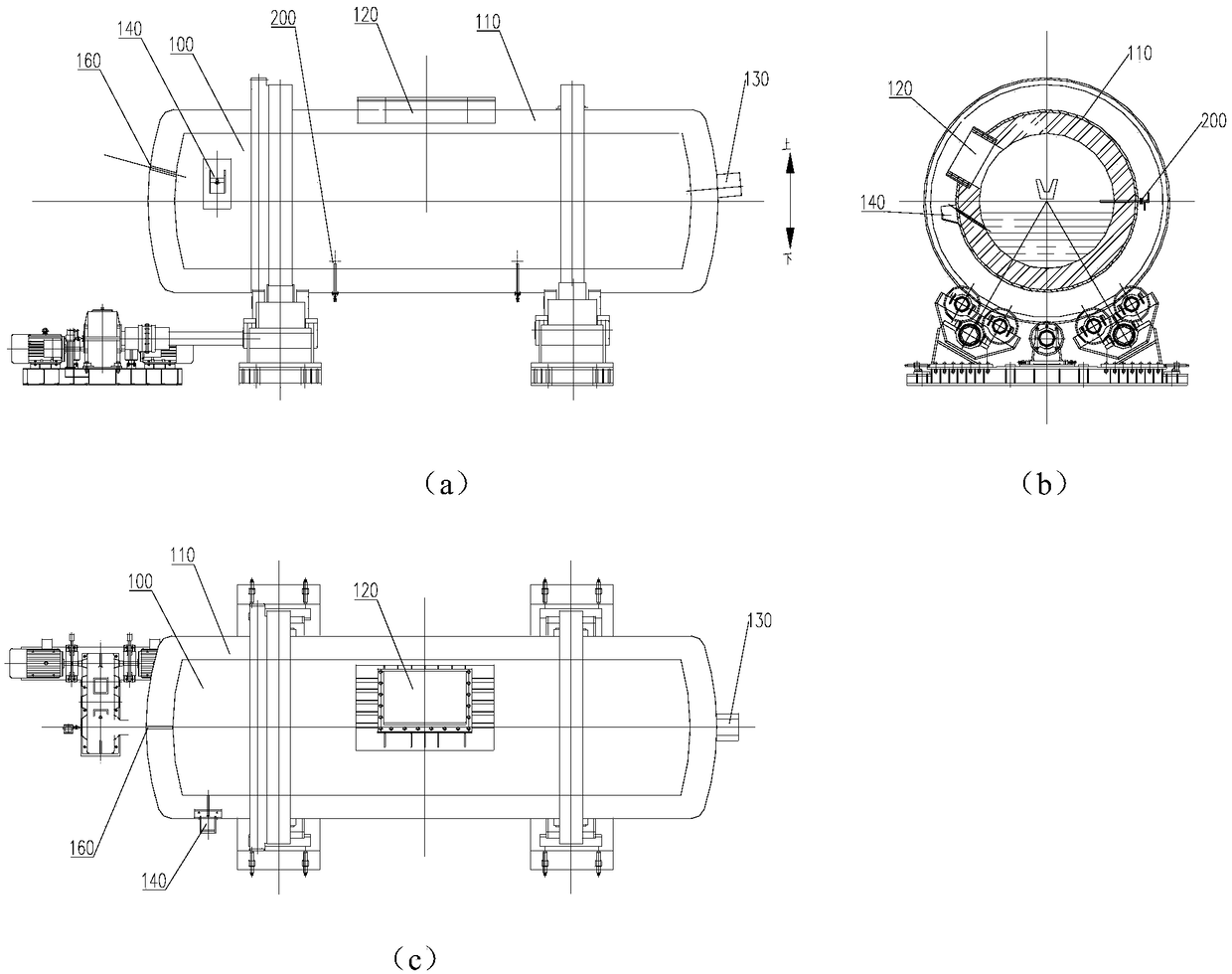

Bottom blowing refining furnace and application thereof

The invention discloses a bottom blowing refining furnace and application thereof. The bottom blowing refining furnace comprises a rotary furnace and a bottom blowing redox gun; specifically, the rotary furnace comprises a rotary furnace casing, a furnace opening, a copper inlet and a copper outlet; a hearth space is limited in the rotary furnace casing; the furnace opening is formed in the upperpart at the middle section of the rotary furnace casing; the copper inlet is formed in the rotary furnace casing; the copper outlet is formed in the side wall of the end part of the rotary furnace casing; the bottom blowing redox gun is arranged at the bottom of the rotary furnace casing and extends into the hearth space; the diameter of the bottom blowing redox gunrefining furnace is 38 to 75 cm.The bottom blowing refining furnace does not need to arrange gas permeable bricks or separately arrange a smoke outlet or a burner; a furnace body is simple in structure and low in equipment cost, and can avoid energy consumption loss because the gas permeable bricks are blown with nitrogen; besides, when the bottom blowing refining furnace refines crude copper, the redox efficiency can be remarkably improved, the refining cycle of the crude copper is shortened and the refining effect is improved.

Owner:CHINA ENFI ENGINEERING CORPORATION

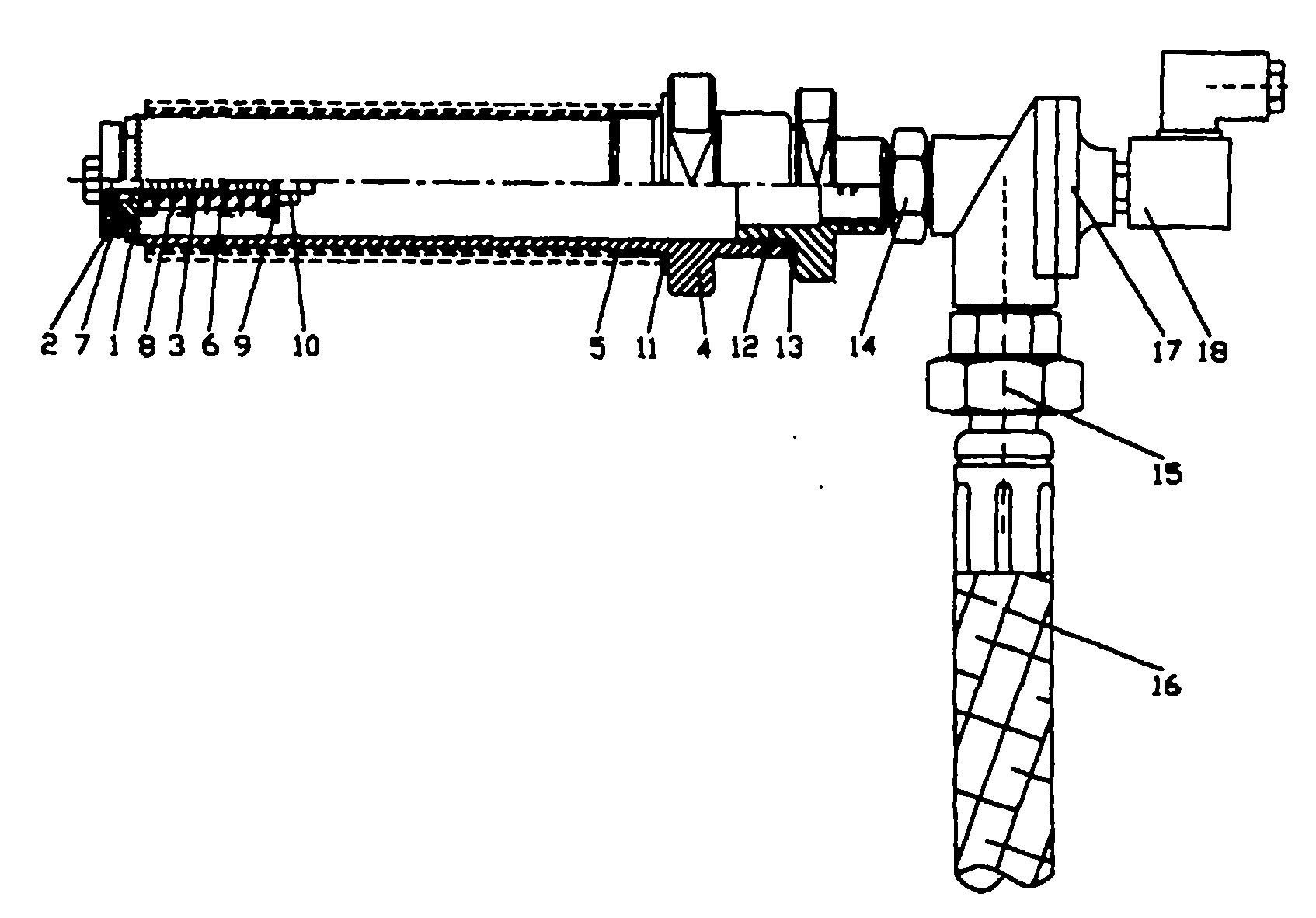

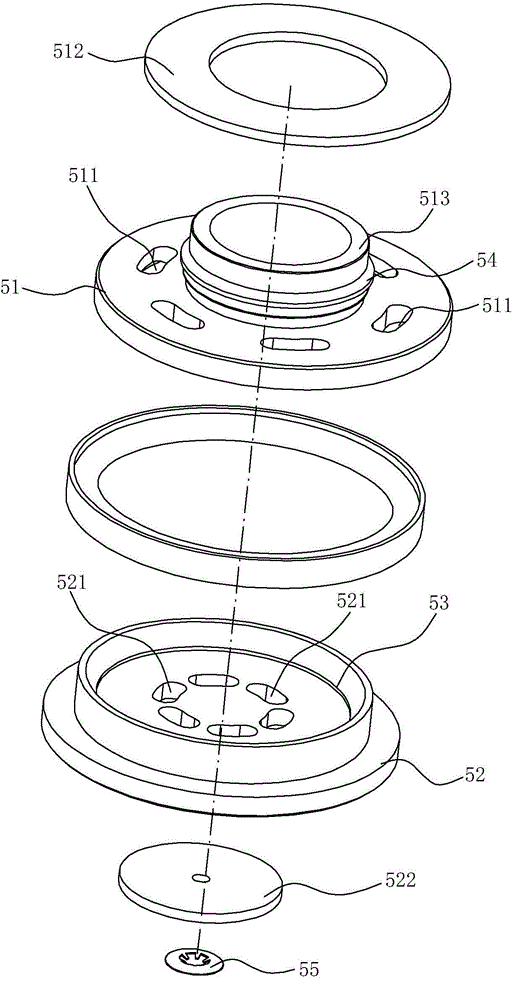

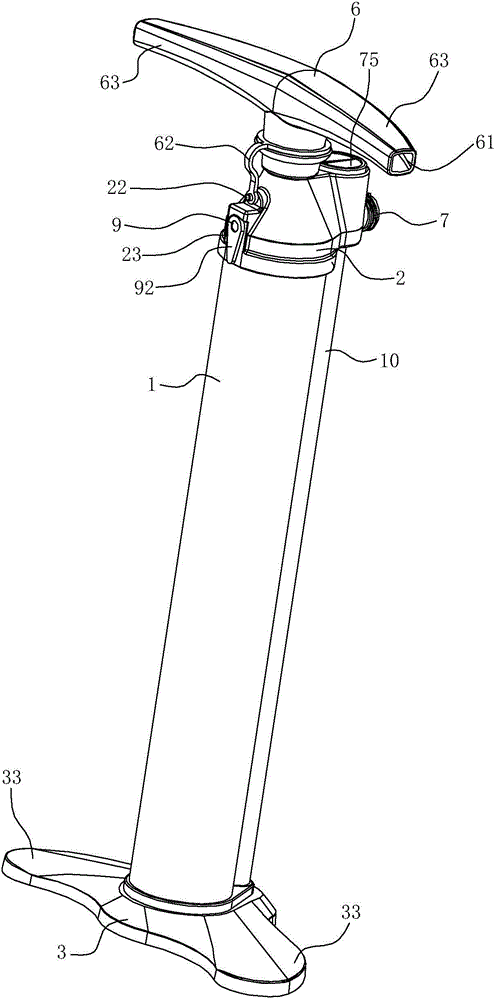

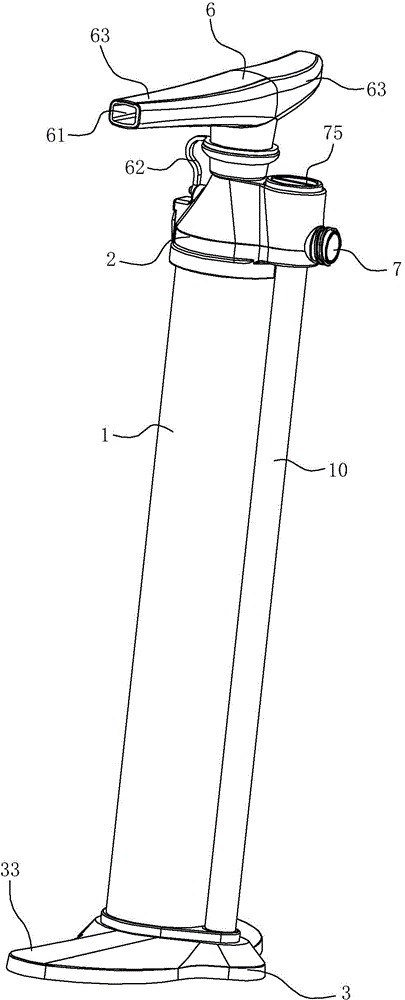

Bothway air inflation hand-pulling air cylinder

ActiveCN104791217AAvoid troubleImprove inflation efficiencyPositive displacement pump componentsPumpsBreatherEngineering

The invention relates to a bothway air inflation hand-pulling air cylinder. The bothway air inflation hand-pulling air cylinder comprises a cylinder body and a piston. The piston divides the inside of a cylinder main body into an upper air chamber and a lower air chamber. The cylinder body comprises the cylinder main body, an upper cover and a base. A linkage pipe penetrates through the center of the upper cover. The bothway air inflation hand-pulling air cylinder is characterized in that the air cylinder further comprises an upper air outlet channel, a lower air outlet channel, a connecting pipe and an air guide chamber; an upper air outlet valve plate is arranged in the upper air outlet channel, a lower air outlet valve plate is arranged in the lower air outlet channel, the connecting pipe is arranged outside the cylinder main body, and the upper end and the lower end of the connecting pipe are connected and communicated with the upper air outlet channel and the lower air outlet channel respectively; the air guide chamber is arranged inside the piston, the upper surface of the piston is provided with an upper valve port and an upper breather valve plate, and the lower surface of the piston is provided with a lower valve port and a lower breather valve plate. Due to the fact that the upper air outlet channel is formed in the cylinder body, the trouble brought to customers due to the fact that the connecting pipe moves up and down along with a handle in the air inflating process is saved; in the air inflating process, the entire linkage pipe is filled with air during air inflation or air suction, the air amount is greatly increased compared with a traditional two-way inflation air cylinder, and thus the air inflation efficiency of the air cylinder is also greatly improved.

Owner:NINGBO BRAVO MFG OF INFLATORS & ACCESSORIES

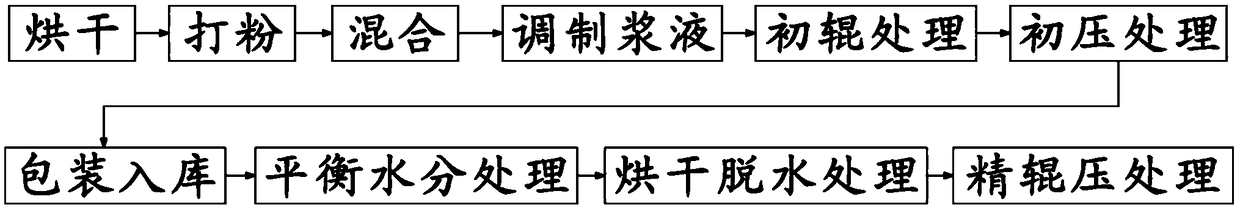

Plant reconstituted sheet, preparation method and electric heating method

The invention discloses a plant reconstituted sheet, a preparation method and an electric heating method. The plant reconstituted sheet is prepared by conducting papermaking on slurry, and the slurryis prepared by mixing, by weight, 3-5 parts of cellulose, 1-2 parts of natural rubber, 50-70 parts of dried plant leaves, 10-15 parts of a humectant, 8-12 parts of fibers and 2-5 parts of a food additive. The slurry is prepared from the cellulose, the natural rubber, the dried plant leaves, the humectant, the fibers and the food additive, and then the plant reconstituted sheet is prepared from theslurry by papermaking. The plant reconstituted sheet is separated from tobacco materials and can be used for absorbing atomized gas generated by an electronic cigarette liquid, a smoking effect withsaturate gas amount is achieved on the atomized gas, and at the same time, few heating non-combustion harmful substances are generated; moreover, the food additive and the like which are useful for the human body are added and can produce gas which has fragrant components and a health care effect on the human body, a better experience can be brought, and physiological demands can be met.

Owner:何书杰 +1

Multifunctional fluctuation massage type pressure sore prevention air mattress

The invention discloses a multifunctional fluctuation massage type pressure sore prevention air mattress, and relates to the technical field of pressure sore prevention air mattresses. A plurality of sets of air bags are arranged on the air mattress, the number of air bags of each set is 3-10, the air bags in each set are communicated in sequence, an air pump box cover covers an air pump box, an air pump is arranged in the air pump box, an air pump starting switch is arranged on the air pump box cover, a rotating motor is arranged on one side of the air pump, a ventilation valve is arranged at the upper end of the rotating motor, the air pump is connected with the ventilation valve through an air pump air-feeding pipe, and the ventilation valve is connected with the sets of air bags through a plurality of air bag air-feeding pipes. The air bag air-feeding pipes are adopted, the air bags on the air mattress are divided into the sets, each air bag air-feeding pipe corresponds to one set of air bags and charges or deflates one whole set of air bags one by one, circulation is conducted sequentially, the air flow is large, the comfort degree is good, and the real massage effect and the pressure sore prevention effect can be achieved.

Owner:刘霄鹏

Muskmelon extract, and preparation method and application thereof

ActiveCN105132164AIncrease the amount of aromaImprove aromaTobacco preparationEssential-oils/perfumesMusk melonAqueous extract

The invention discloses a muskmelon extract, and a preparation method and an application thereof in cigarettes. Provided are the muskmelon extract, and the preparation method and the application thereof in the cigarettes. During preparation, the preparation method includes the following steps: taking muskmelon pulp, muskmelon seeds and softer flesh of a muskmelon inner layer, and homogenizing to obtain a muskmelon thick liquid; after decompression filtration of the muskmelon thick liquid, centrifuging, collecting the supernatant which is a muskmelon aqueous extract; adding an organic solvent in muskmelon filter residues, and then carrying out heating reflux to obtain an organic solvent extract liquid; carrying out primary and secondary molecular distillation on the organic solvent extract liquid under certain conditions, mixing a distilled light phase and the muskmelon aqueous extract, and thus obtaining the muskmelon extract. The cost is low, the process is simple, the muskmelon extract is evenly sprayed on tobacco shreds through a cigarette flavoring process, the milky aroma, faint scent and sweet aroma are increased, and the smoking quality and the sensory comfort are improved.

Owner:CHINA TOBACCO HENAN IND

Multifunctional nitrogen making device

ActiveCN103776239AOutstanding and Beneficial Technical EffectsRelieve pressureSolidificationLiquefactionOxygenNitrogen gas

The invention relates to the technical field of nitrogen making, and relates to a multifunctional nitrogen making device. A part of purified air is fed to the bottom of a rectifying tower after heat exchange is carried out through a main heat exchanger, the other part of the purified air is pressurized through a supercharger, is cooled after heat exchange is carried out through the main heat exchanger and then is fed into an ET2 expansion machine to be refrigerated and fed into a waste nitrogen pipe network, oxygen-enriched liquid air is obtained at the bottom of the rectifying tower and is fed to the top of a condensing evaporator after passing through a liquid air subcooler and after throttling, liquid nitrogen in the condensing evaporator flows back to the top of the rectifying tower to serve as backflow liquid of the rectifying tower, waste nitrogen obtained on the top of the a lower pressure side of the condensing evaporator is fed into an ET1 expansion machine for expansion refrigeration, the reheated waste nitrogen is fed into a purifying system, high-purity nitrogen is obtained on the top of the rectifying tower, the high-purity nitrogen is output externally after being reheated by the main heat exchanger or after being reheated by the main heat exchanger and passing through the supercharger in sequence, and liquid nitrogen is output externally after high-purity liquid nitrogen passes through a liquid nitrogen subcooler. The multifunctional nitrogen making device has the advantages of being low in energy consumption, high in extraction ratio, good in economic benefit, flexible and reliable in adjustment and suitable for gas making industries.

Owner:浙江海畅气体股份有限公司

Coke oven smoke flue capable of adjusting airflow and adjusting method

InactiveCN112524965AIncrease air flow pressureIncrease temperatureControl devices for furnacesWaste heat treatmentThermodynamicsFlue gas

The invention belongs to the field of coke ovens, in particular to a coke oven smoke flue capable of adjusting airflow and an adjusting method. Based on the problems that the interior of the existingcoke oven smoke flue has a flat hollow cavity structure, the overall flue gas in the coke oven is uniformly distributed and the airflow of the smoke flue cannot be adjusted so that the temperature ata furnace head is difficultly increased, the coke oven smoke flue disclosed by the invention is invented. The coke oven smoke flue comprises a coke flue main body and a smoke flue main body, wherein asupport plate is fixedly connected to one side of the coke flue main body; an adjusting base is fixedly connected to the top of the support plate; a mounting chamber is arranged on the adjusting base; and one end of the smoke flue main body extends into the mounting chamber. The coke oven smoke flue disclosed by the invention has a reasonable structure and is simple to operate; through a drivingmotor, two adjusting plates can be mutually approached to each other or mutually away from each other, so that the airflow volume in the smoke flue main body can be regulated; and through changing airflow pressure distribution in the smoke flue main body, the airflow dynamic pressure of the furnace head part is increased, the volume of gas of a blast furnace for heating the furnace head part is increased, and the temperature of the furnace head is increased.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

Intelligent movable gas pumping station for mine

ActiveCN101749044BRealize on-site display and real-time monitoring functionAchieve long-term storageGas removalCouplingThree phase asynchronous motor

Owner:ZIBO WATER RING VACUUM PUMP FACTORY

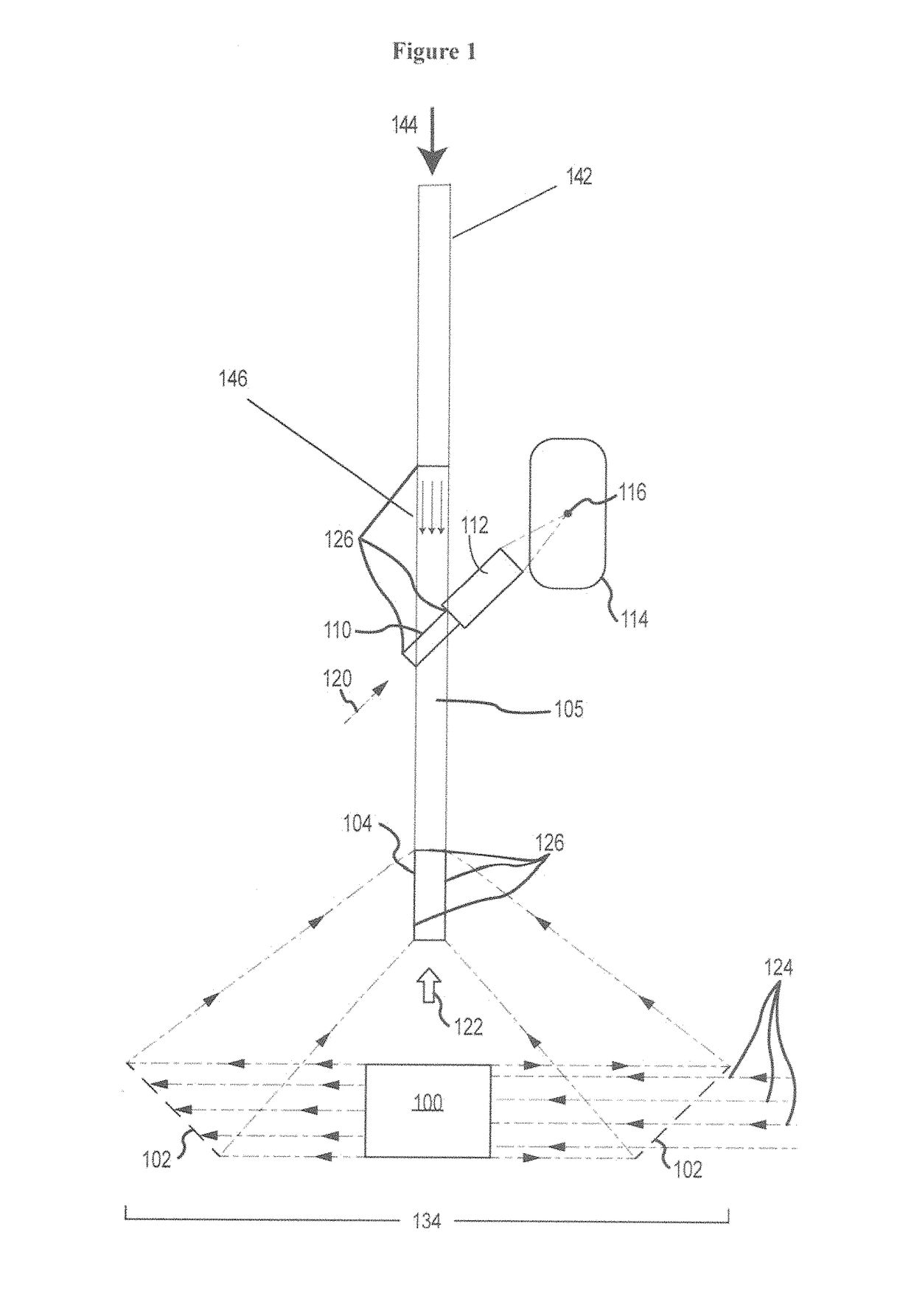

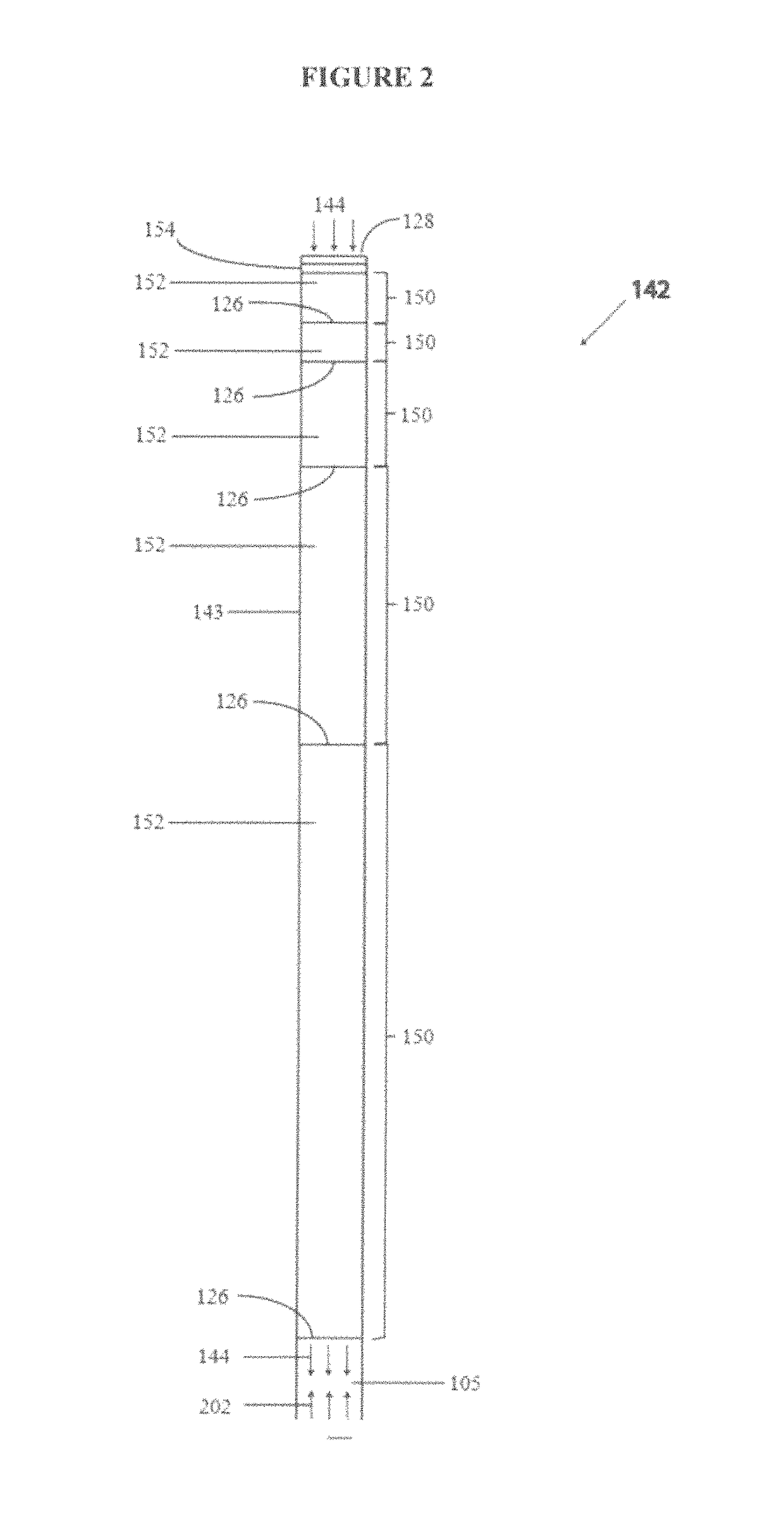

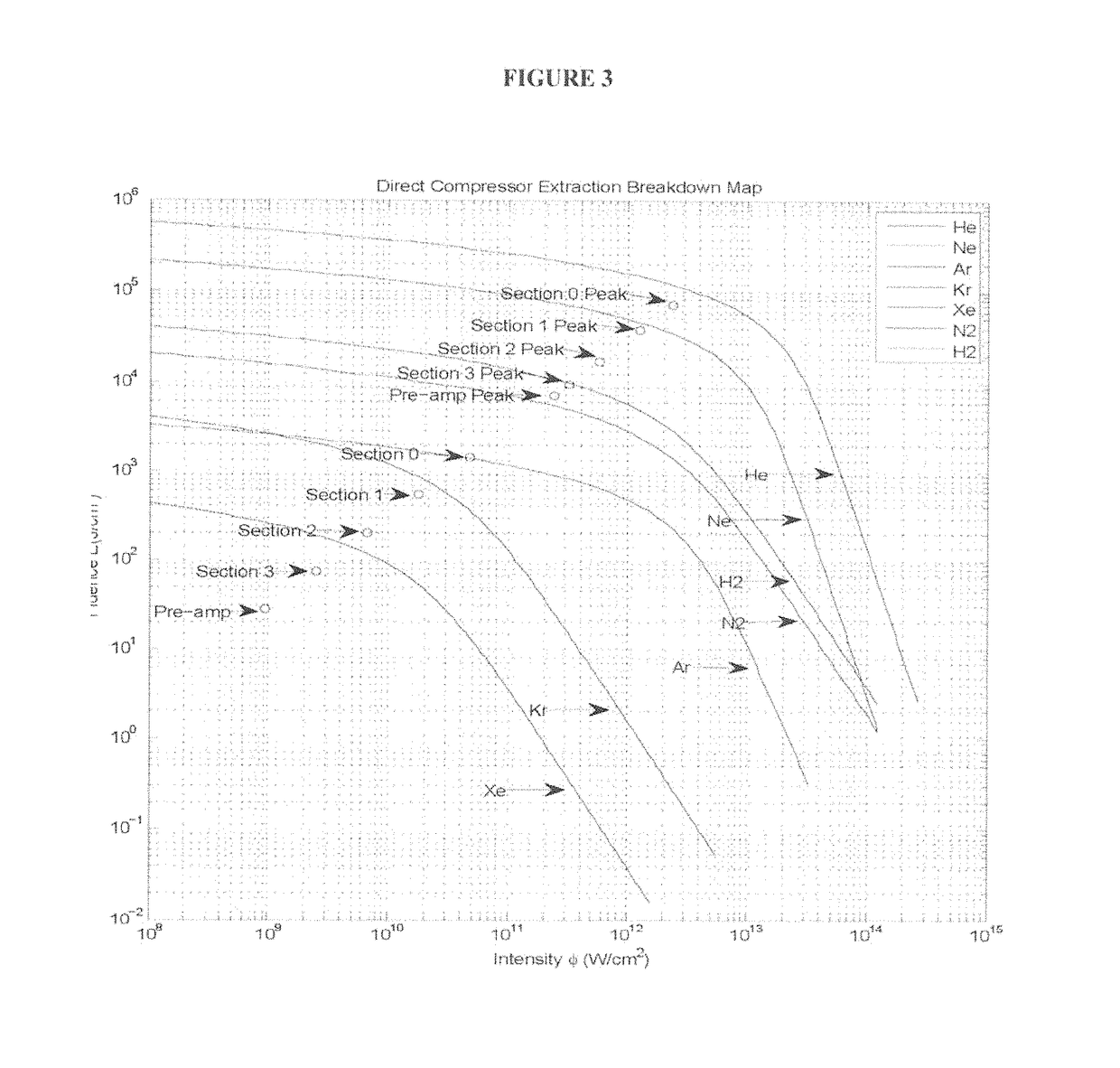

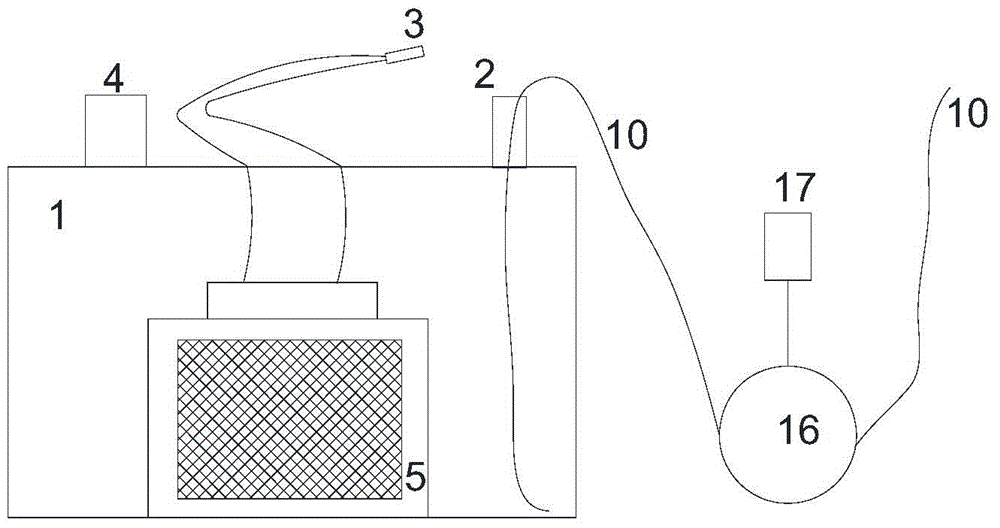

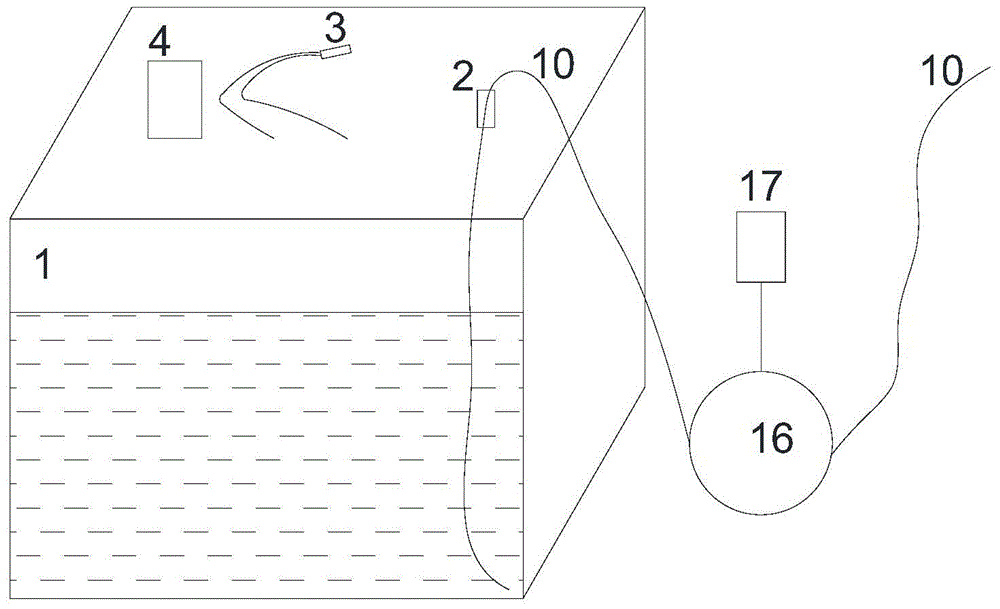

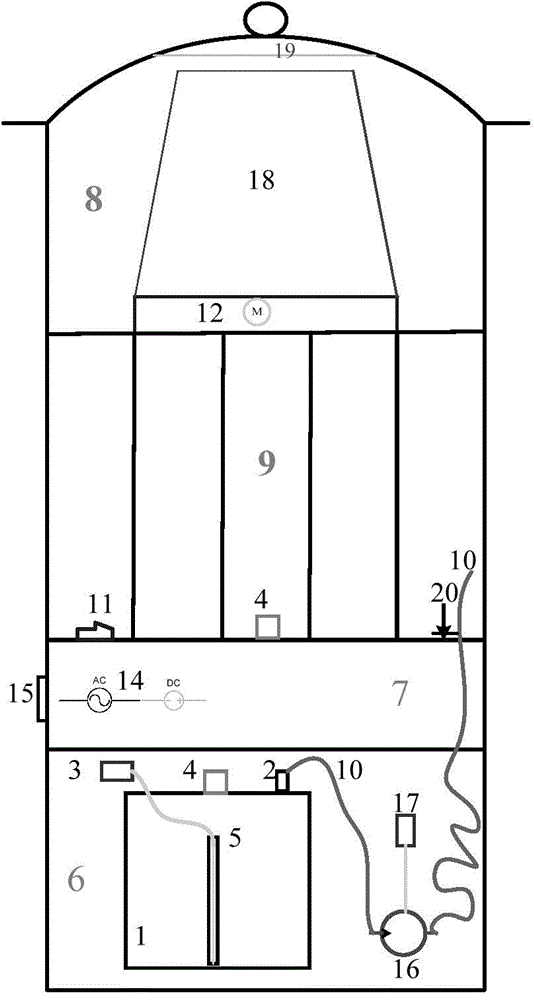

Method for direct compression of laser pulses with large temporal ratios

ActiveUS10170883B1High temporal compression ratioLow costLaser using scattering effectsLaser arrangementsMultiplexingEngineering

The present architecture utilizes a Nonlinear Scattering Aperture Combiner that does not need to be optically multiplexed and then drives a Direct Compressor stage that produces a large temporal compression ratio to pump a Fast Compressor. This eliminates the need for a separate array of ATDMs, multiplexing optical elements, and, at the approximate 107 joule energy output required for ICF, reduces the number of mechanical elements and gas interfaces from the order of 103 to about 10. In addition, this provides a large reduction of the volume of the gas containment region. In order to accomplish this, a technique for transversely segmenting by color and / or polarization of the optical extraction beams of the Direct Compressor has been invented. In particular, it emphasizes the simplicity and uniqueness of design of the Direct Compressor. The Direct Compressor is unique in terms of high fluence, high temporal compression ratios, and high stage gain, leading to a very large reduction in laser costs. It may separately have many other applications than ICF.

Owner:INNOVEN ENERGY

Carbon dioxide generator, mosquito killing device comprising carbon dioxide generator and application of mosquito killing device

ActiveCN104855355AImprove induction abilityImprove work efficiencyInsect catchers and killersElectrolytic agentControl mosquito

The invention relates to a carbon dioxide generator. The carbon dioxide generator is an electrolyzer with a sealing cap; a positive electrode plate and a negative electrode plate are arranged inside the electrolyzer; the electrode plates are platinized titanium meshes; the distance between the positive electrode plate and the negative electrode plate is 3-7 mm; the electrode plates are connected with a DC power supply nonpolar wiring female plug. The invention also provides a mosquito killing device comprising the carbon dioxide generator and application of the mosquito killing device. Under the same conditions, the mosquito killing device provided by the invention is larger in carbon dioxide generation amount and higher in mosquito guiding capability, so that the mosquito killing efficiency is higher, and the cost is reduced; as a DC nonpolar power supply is adopted, the use is more convenient and safer; a self-suction and self-discharge pump is mounted, so that the addition of an electrolyte solution and the cleaning of the electrolyzer are more convenient and smoother, and the working efficiency of working personnel or users is improved.

Owner:ICDC CHINA CDC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com