Plant reconstituted sheet, preparation method and electric heating method

A technology of remanufacturing flakes and electric heating, which is applied in the fields of tobacco preparation, food science, fat production, etc., can solve the problems of low acceptance of smokers, damage of smokers, and small air volume, etc., and achieve the effect of solving the problem of raw material demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

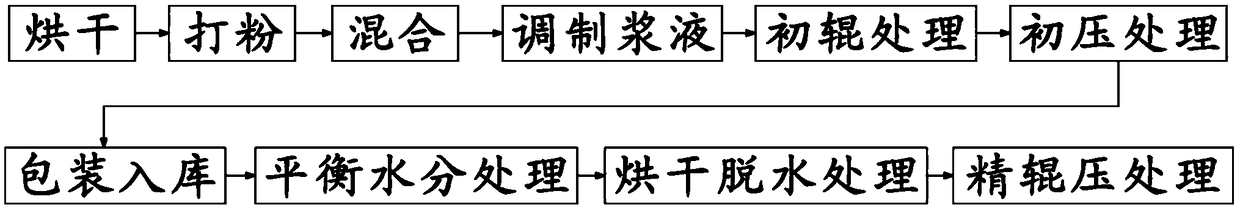

Method used

Image

Examples

Embodiment

[0050] A plant-reconstituted sheet, wherein the plant-reconstituted sheet is prepared from slurry by papermaking, and the slurry is prepared by mixing the following raw materials by weight:

[0051] Cellulose: 3 to 5 servings;

[0052] Natural rubber: 1 to 2 parts;

[0053] Plant dry leaves: 50 to 70 parts;

[0054] Moisturizer: 10 to 15 parts;

[0055] Fiber: 8 to 12 servings;

[0056] Food additives: 2 to 5 servings.

[0057] The cellulose in the raw material formulation of the plant-reconstituted flakes of the present invention is preferably cellulose extracted from wood pulp.

[0058] The natural gum in the raw material formulation of the plant reconstituted sheet of the present invention is preferably one or more of gum arabic and pectin.

[0059] The fibers in the raw material formulation of the plant-reconstituted flakes of the present invention are preferably fibers extracted from natural wood pulp.

[0060] The food additives in the raw material formula of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com