Coke oven smoke flue capable of adjusting airflow and adjusting method

A technology for coke oven flue and adjustment method, which is applied to furnaces, furnace components, furnace control devices, etc., can solve the problems of inability to adjust flue gas flow, uniform distribution of flue gas, and difficulty in raising the temperature at the furnace head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

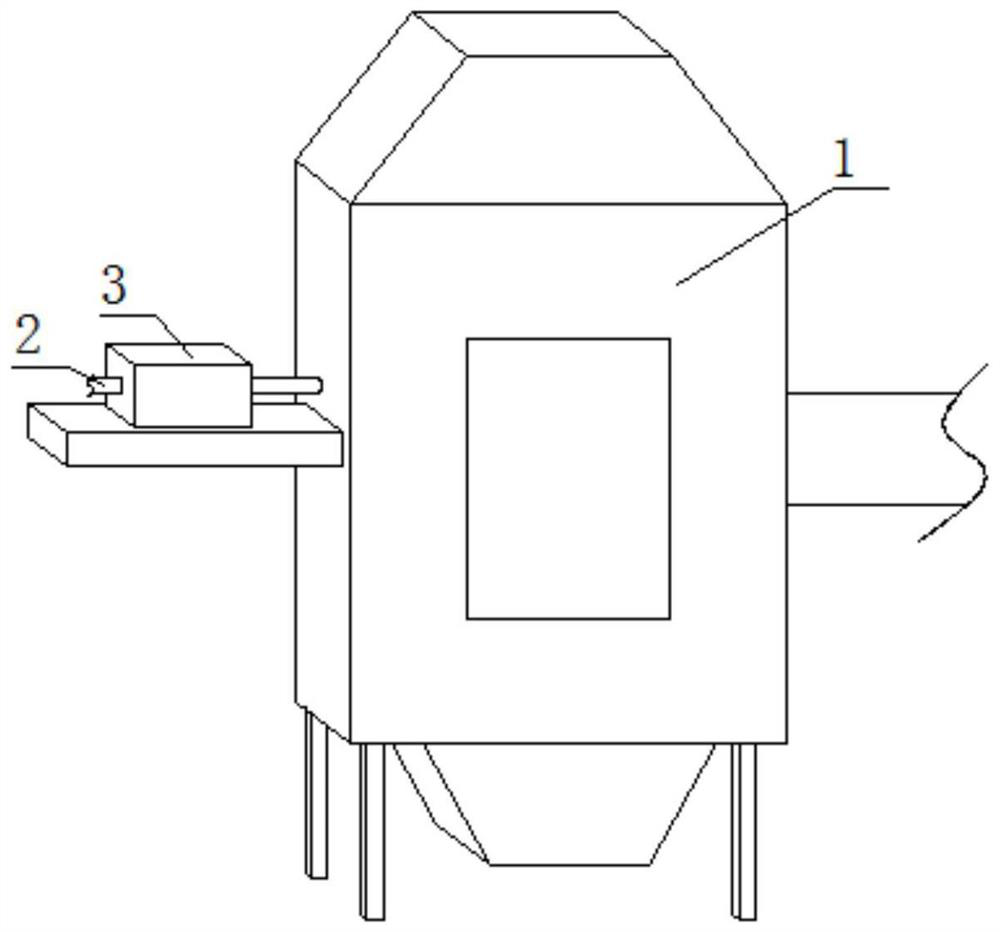

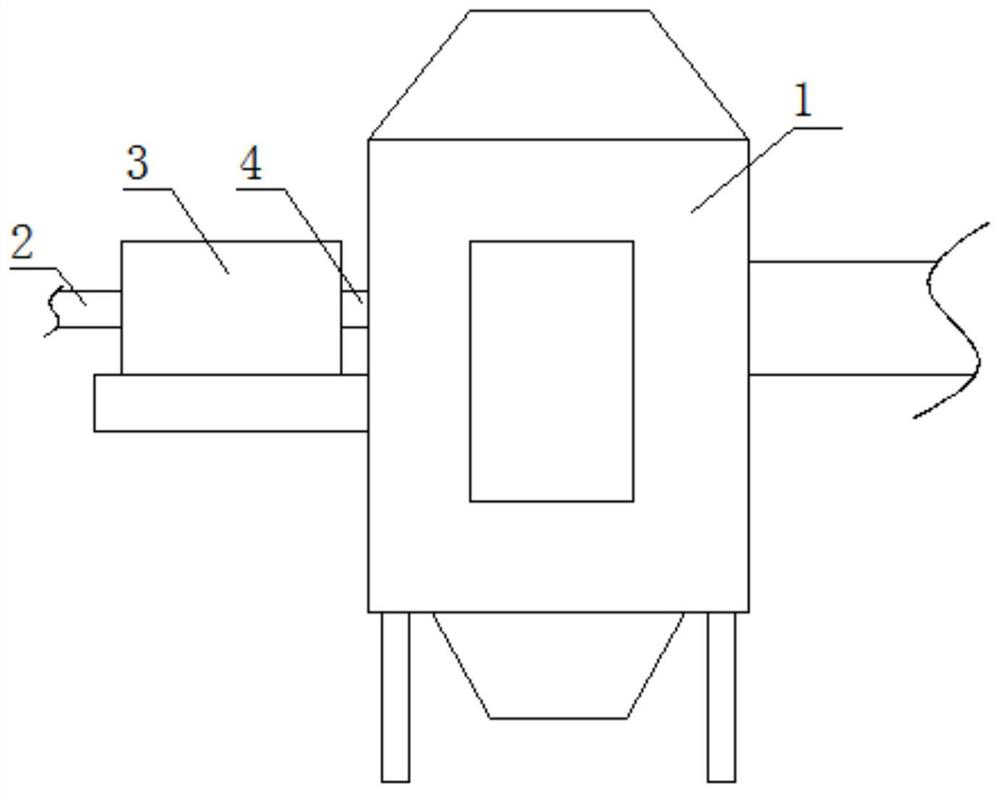

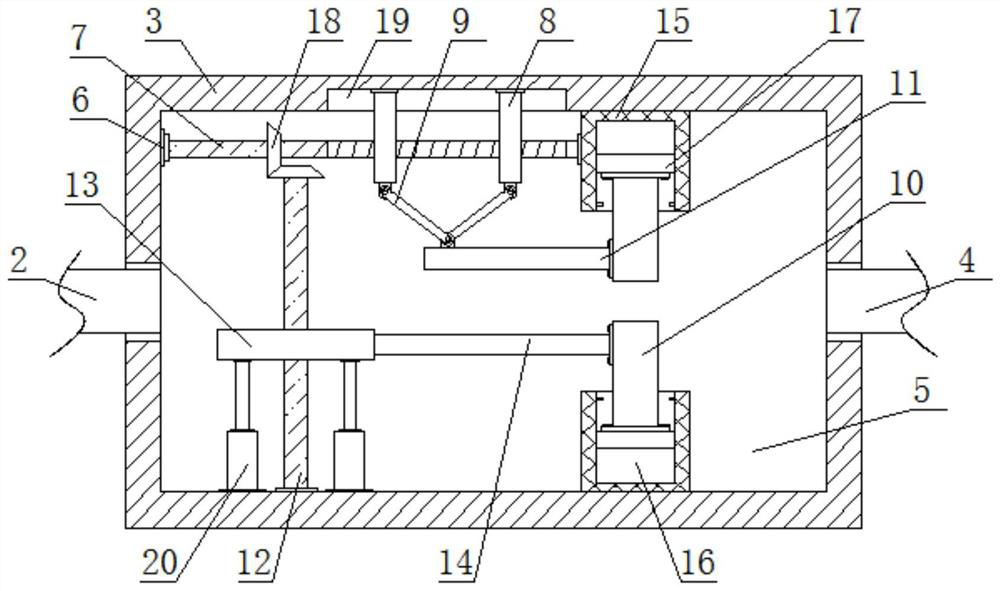

[0032] refer to Figure 1-3, a coke oven flue with adjustable airflow, comprising a coke oven main body 1 and a flue main body 2, a support plate is fixedly connected to one side of the coke oven main body 1, an adjustment seat 3 is fixedly connected to the top of the support plate, and the adjustment seat 3 There is an installation chamber 5 on it, one end of the flue main body 2 extends into the installation chamber 5, and a connecting pipe 4 is sealed and fixedly connected to one side of the inner wall of the installation chamber 5, and one end of the connecting pipe 4 extends to the coke oven main body 1 Inside, a driving motor 6 is fixedly connected to the inner wall of one side of the installation chamber 5, and a rotating shaft 7 is fixedly connected to the output shaft of the driving motor 6, and two moving plates 8 are symmetrically threaded on the rotating shaft 7, and the two moving plates 8 The threads are opposite, and there are two adjusting plates 10 symmetrical...

Embodiment 2

[0034] In the present invention, the top inner wall and the bottom inner wall of the installation chamber 5 are fixedly connected with a rectangular seat 15, and the sides of the two rectangular seats 15 close to each other are provided with limiting grooves 16, and the two limiting grooves 16 are slidingly connected. Limiting plate 17, the side of two limiting plates 17 close to each other is fixedly connected with the side of two adjusting plates 10 that are far away from each other respectively, rectangular seat 15, limiting groove 16 and limiting plate 17 are provided, can adjust The plate 10 is limited, so that the adjusting plate 10 can move stably without position deviation.

[0035] In the present invention, a chute 19 is provided on the top inner wall of the installation chamber 5, and the tops of the two moving plates 8 all extend into the chute 19 and are slidably connected with the top inner wall of the chute 19, and the chute 19 can reduce friction , so that the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com