Novel method for synthetizing vinyl acetate by calcium carbide acetylene method

A vinyl acetate, calcium carbide acetylene technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid esters, etc., can solve the problems of vinyl acetate, etc., to reduce the generation of by-products, reduce costs, and save land occupation area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

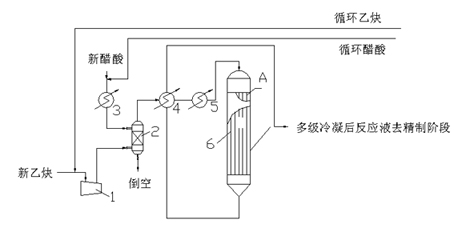

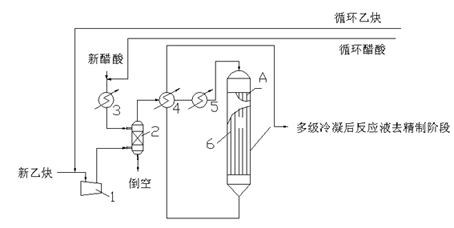

[0035] After the fresh acetylene produced by calcium carbide is boosted with the blower booster 1, it is added to the lower part of the gas-liquid mixed evaporator 2, and at the same time, the acetic acid preheated in the first preheater 3 is added to the gas-liquid mixed evaporator 2 In the upper part, acetylene and acetic acid are mixed according to the volume ratio of 5-8:1. When the excess acetylene is saturated with preheated acetic acid, it enters the second preheater 4 and the third preheater 5 in sequence, and is heated to a temperature close to the reaction temperature with the high-temperature heat transfer oil introduced between the tubes of the preheater, that is, close to 443-488K. It is sent to the upper part of the tubular fixed-bed reactor 6.

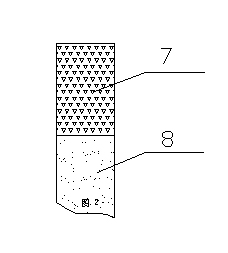

[0036] The tubes of the tube-and-tube fixed-bed reactor are filled with catalyst zinc acetate 8. In order to make the gas distribution uniform, a gas distributor is installed at the entrance of the reactor, and an inert ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com