Gasification nozzle

A technology of nozzles and nozzle bodies, which is applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc., can solve the problems of lack of gasification effect, complex gasification structure, and large power consumption, and solve the problem of poor ash discharge , gasification effect is obvious, the effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

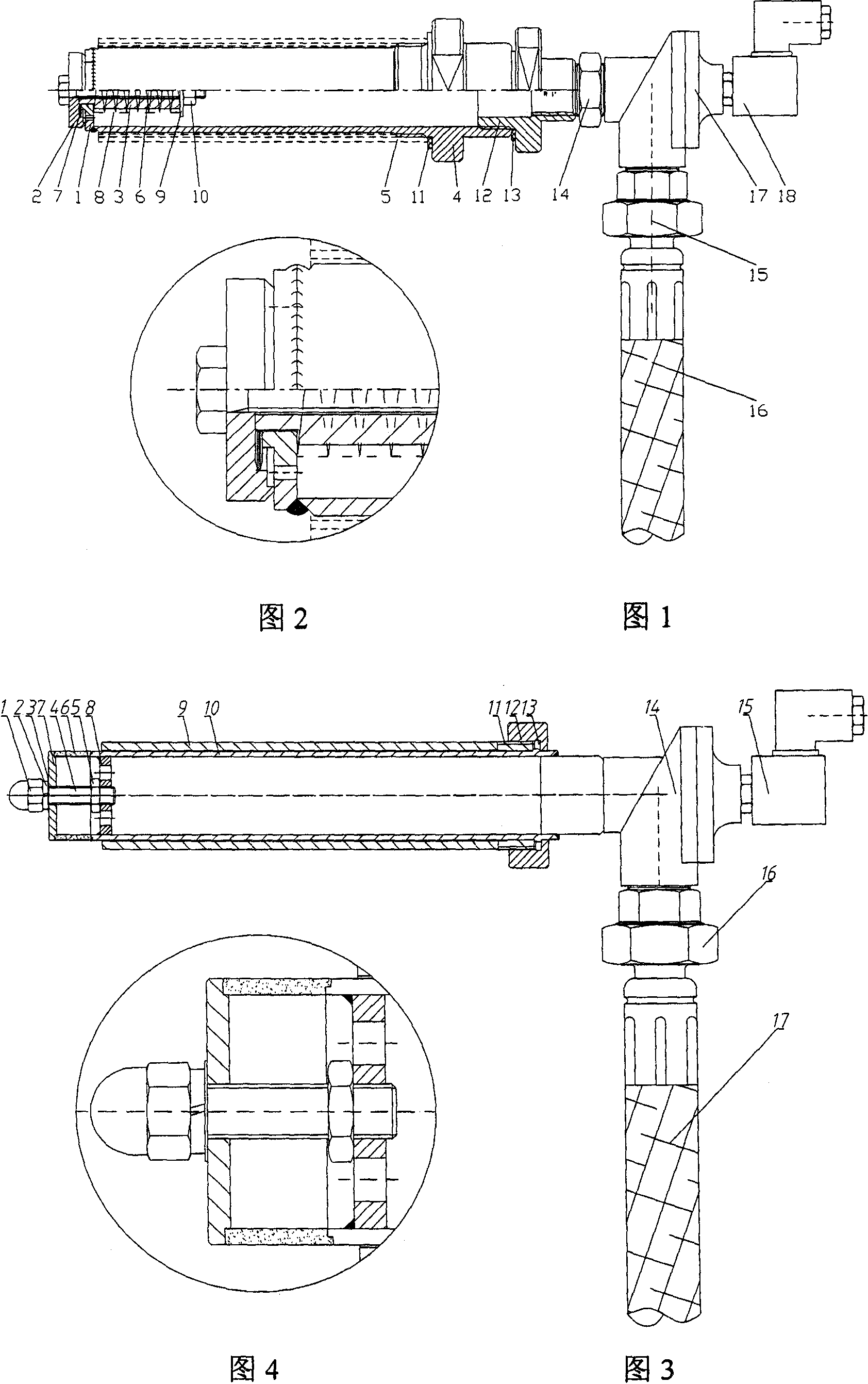

[0030] attached figure 1 The name of the gasification nozzle components shown: nozzle 1, pressure plate 2, spring seat 3, nozzle body 4, gasification nozzle outer connection cylinder 5, hexagonal bolt 6, butterfly spring 7, spring 8, flat washer 9, nut 10, Polytetrafluoro pad 11, variable-diameter connector 12, polytetrafluoro pad 13, short wire 14, rubber hose union joint 15, air intake rubber tube 16, pulse solenoid valve body 17, pulse solenoid valve coil 18.

[0031] As shown in the figure: the spray head 1 is welded on the front end of the nozzle body 4 . Pressing plate 2, nozzle 1, butterfly spring 7, spring 8, and spring seat 3 are connected together by hexagonal bolt 6 M10×85 flat washer 9∮11 and nut 10M10. A polytetrafluoro gasket 11∮75×∮61×3 is installed between the outer connecting cylinder 5 of the gasification nozzle and the nozzle body 4 for sealing, and is connected by an internal thread. A polytetrafluoro gasket 13∮70×∮51×5 is installed between the variable-d...

Embodiment 2

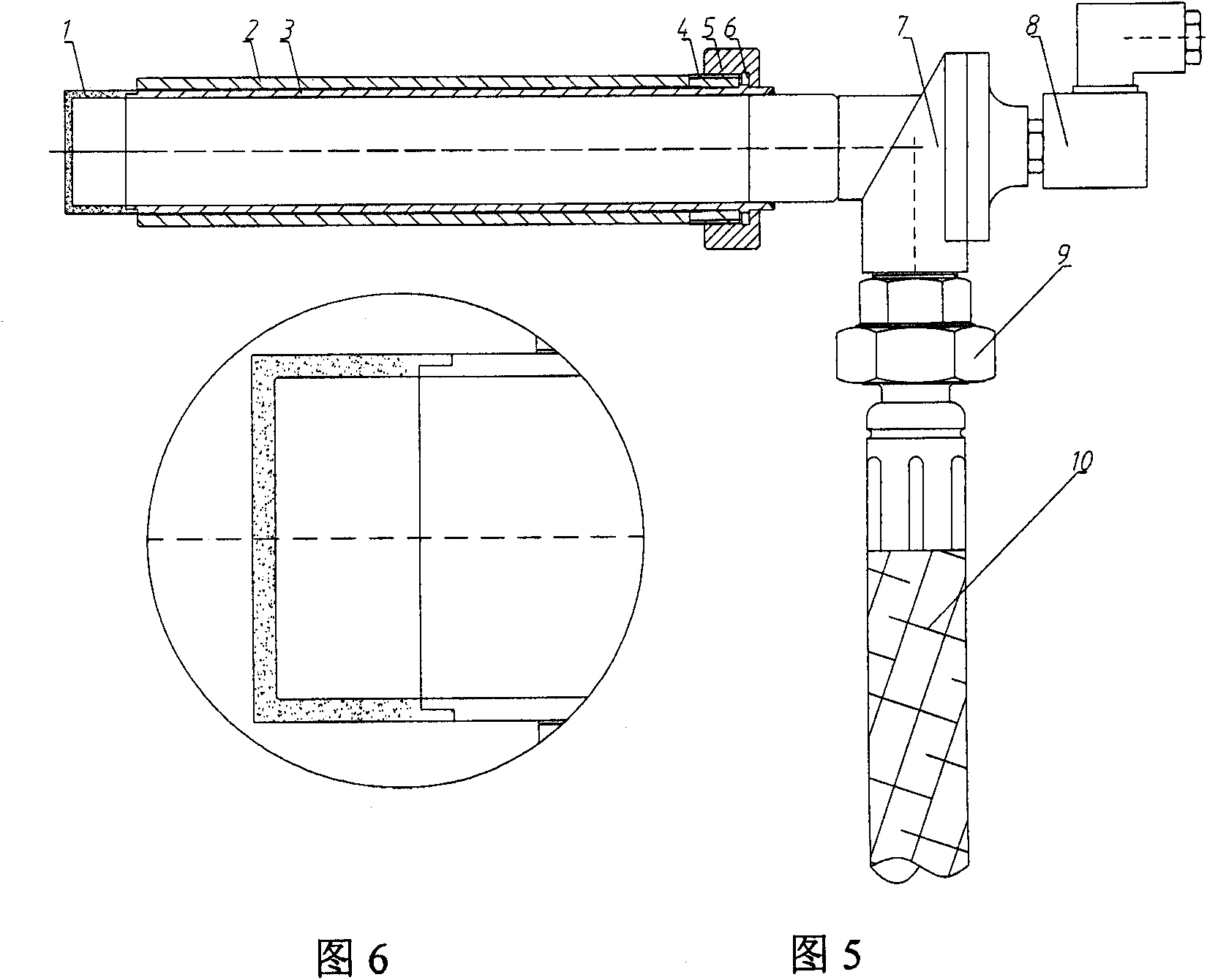

[0035] attached image 3 Gasification nozzle component name: cap nut 1, spring washer 2, flat gasket 3, hexagonal bolt 4, locking thin nut 5, nozzle 6, pressure plate 7, nozzle connection plate 8, nozzle outer connection cylinder 9, nozzle body 10 , Retaining ring 11, PTFE gasket 12, lock nut 13, pulse solenoid valve body 14, pulse solenoid valve coil 15, rubber hose union joint 16, intake rubber tube 17.

[0036]As shown in the figure: the nozzle connecting plate 8 is welded on the front end of the nozzle body 10 . The annular nozzle 6 is fixed on the nozzle connecting plate 8 through the cap nut 1 spring washer 2 flat gasket 3 pressure plate 7 hexagonal bolt 4M10×20 thin locking nut 5 . The nozzle outer connecting cylinder 9 is fixed on the ash hopper or the ash storehouse by welding. A polytetrafluoro gasket 12∮75×∮61×3 is installed between the nozzle body 10 and the nozzle outer connecting cylinder 9 for sealing, and is connected together by a retaining ring 11 and a loc...

Embodiment 3

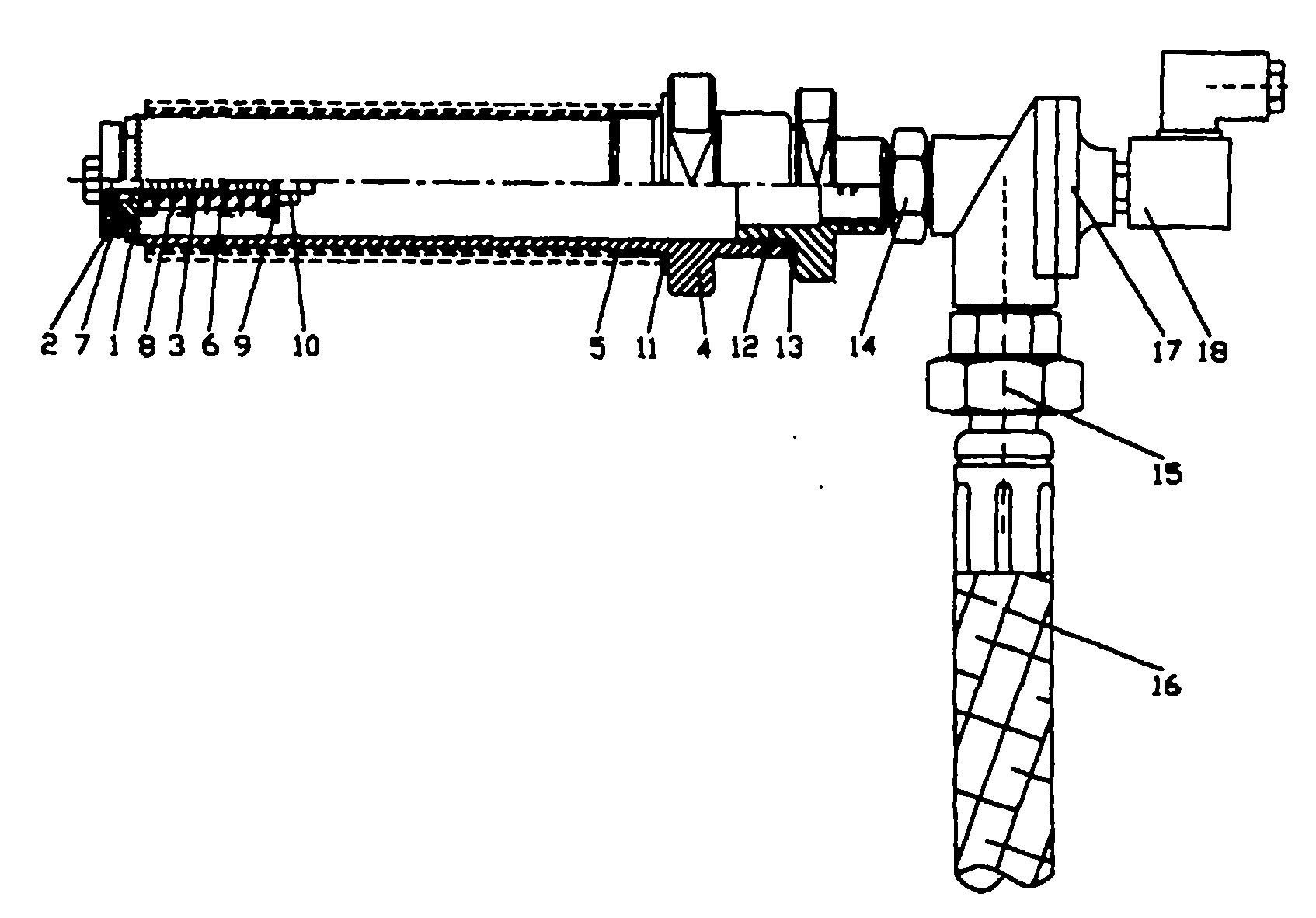

[0040] attached Figure 5 Gasification nozzle component name: annular nozzle 1, nozzle outer connection cylinder 2, nozzle body 3, retaining ring 4, PTFE gasket 5, lock nut 6, pulse solenoid valve body 7, pulse solenoid valve coil 8, rubber hose Union joint 9, air intake rubber pipe 10.

[0041] As shown in the figure: the annular nozzle 1 is welded on the front end of the nozzle body 3 . The nozzle outer connecting cylinder 2 is fixed on the ash hopper or the ash storehouse by welding. A polytetrafluoro gasket 5∮75×∮61×3 is installed between the nozzle body 3 and the nozzle outer connecting cylinder 2 for sealing, and it is connected together through the retaining ring 4 and the lock nut 6G2 to achieve the purpose of fixing the gasification nozzle. The retaining ring 4 on the nozzle body is welded on the nozzle body 3 . The nozzle body 3 is connected to the gas outlet of the pulse solenoid valve body 7 . The pulse solenoid valve coil 8 is installed on the pulse solenoid v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com