Patents

Literature

46results about How to "Pure white color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

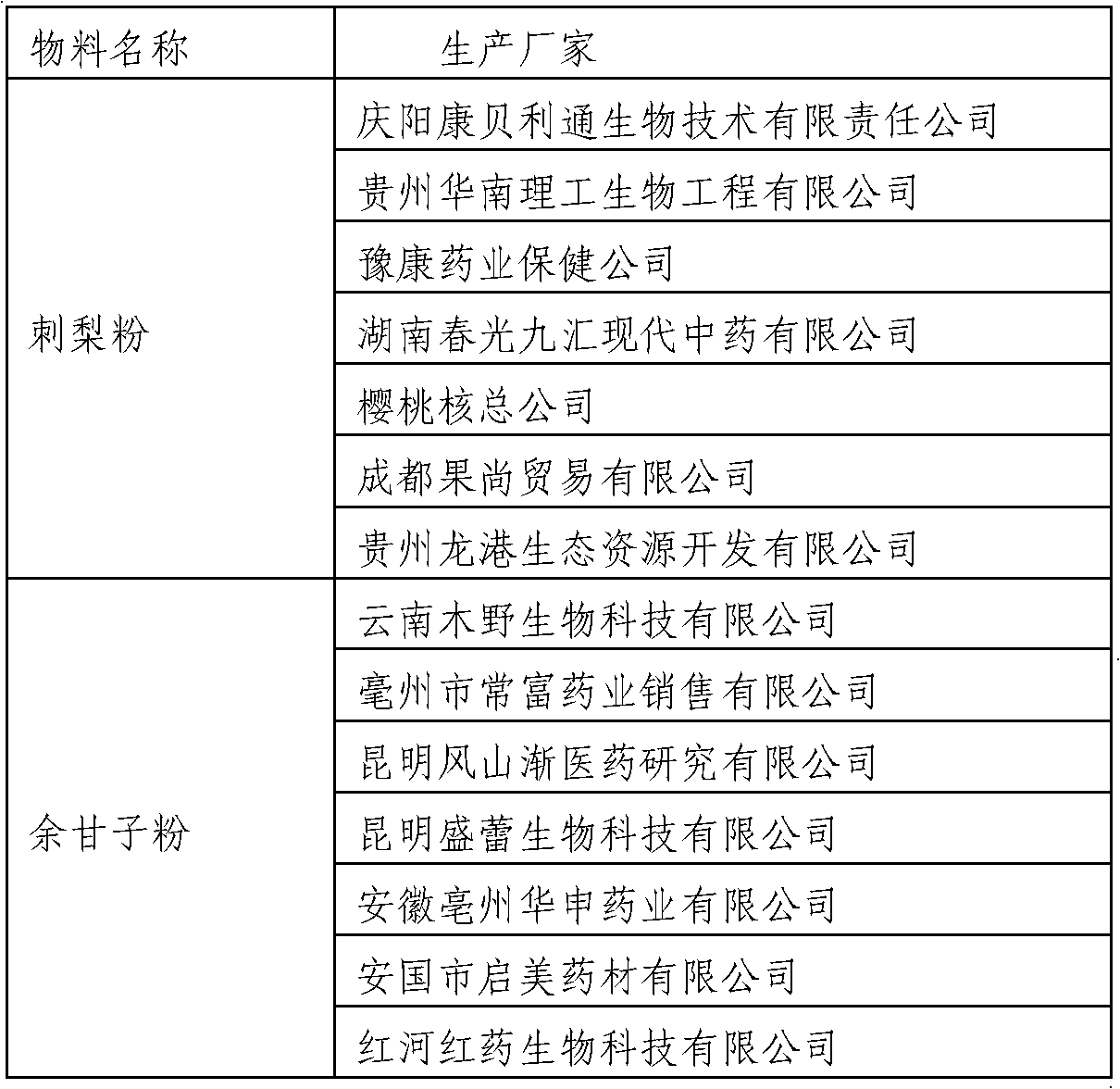

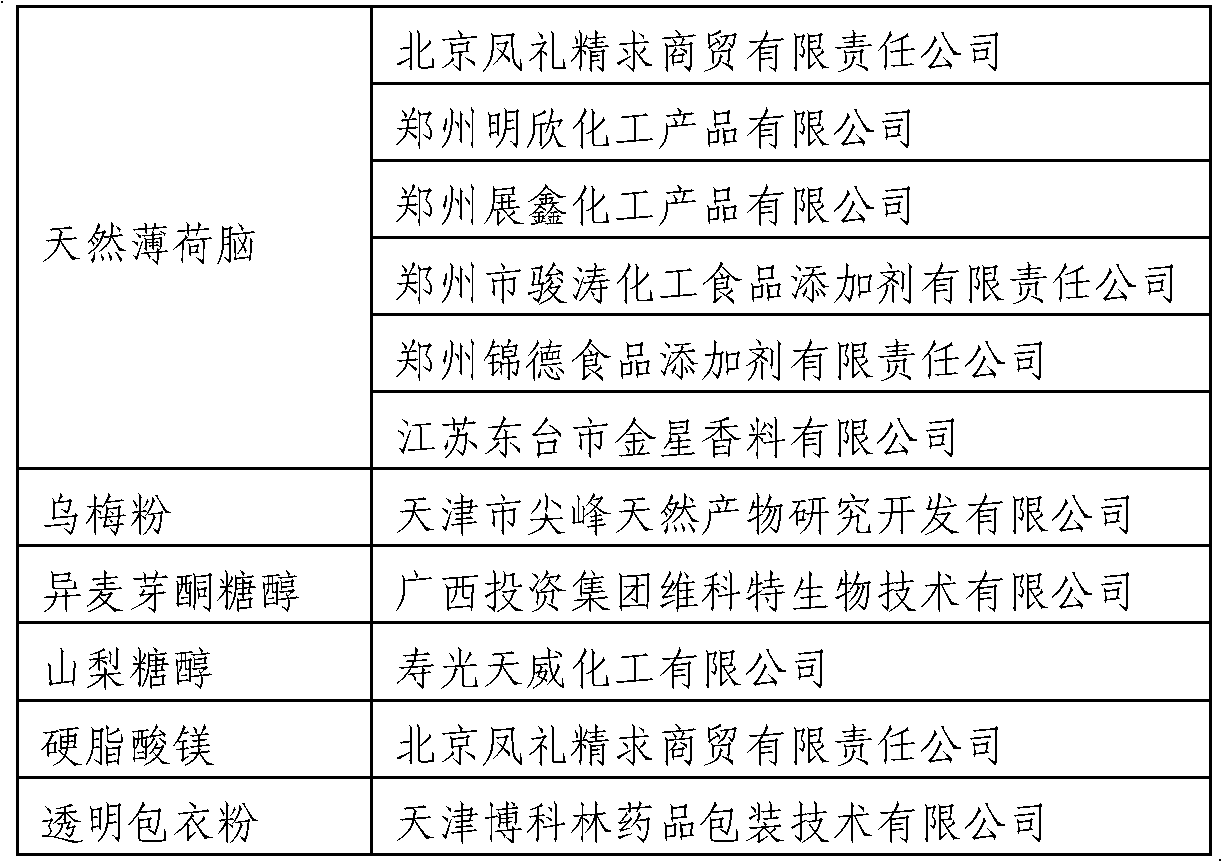

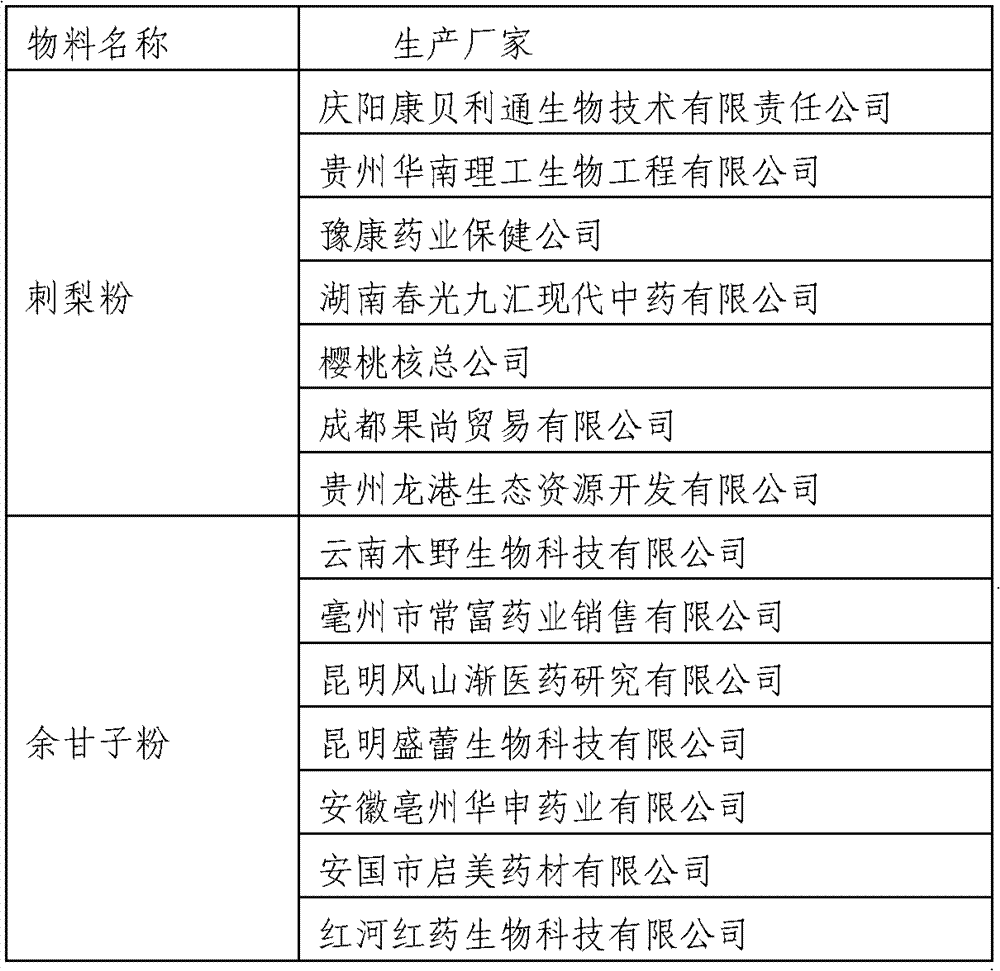

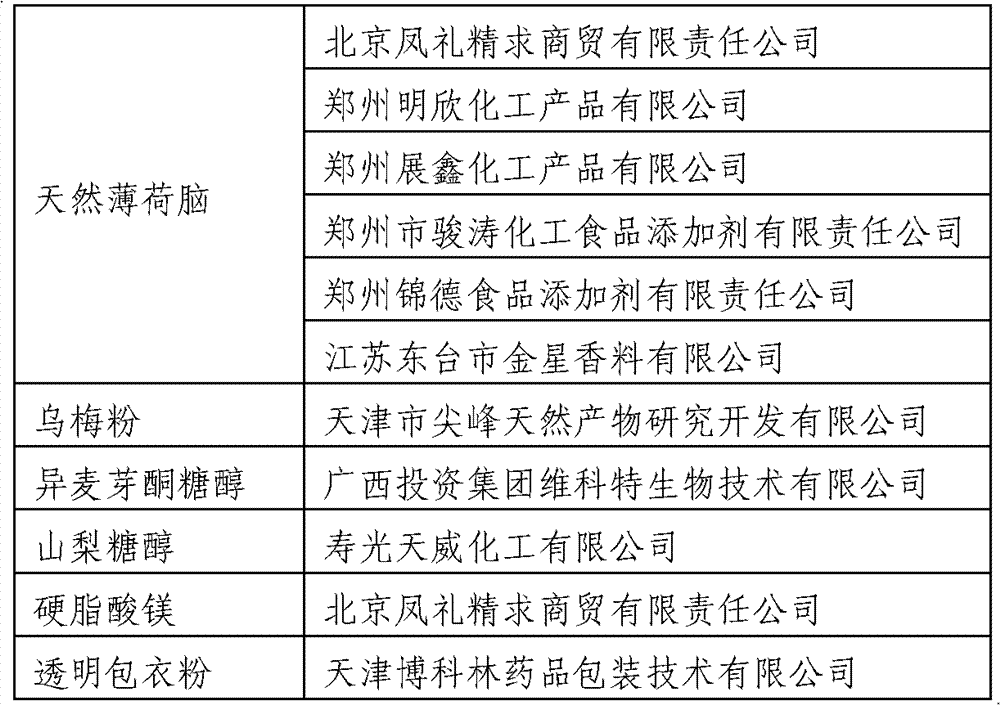

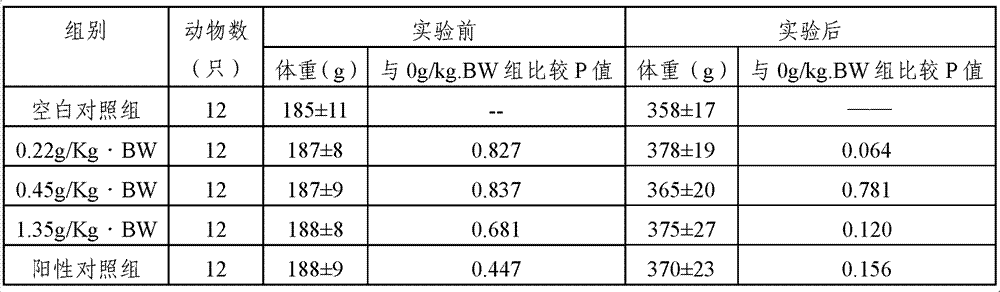

Healthcare product combination for clearing and nourishing throat and preparation method thereof

The invention relates to a healthcare product combination for clearing and nourishing the throat and a preparation method thereof. The combination comprises the following raw and auxiliary materials in parts by weight: 25-75 parts of rosa roxbughii tratt powder, 100-200 parts of phyllanthus emblica powder, 40-250 parts of sorbitol, 200-900 parts of Isomalt, 1-10 parts of stevioside and 2-18 partsof magnesium stearate. The healthcare product combination for clearing and nourishing the throat, provided by the invention, has slightly astringent taste and sweet aftertaste.

Owner:NEW ERA HEALTH IND GRP +1

Decolorized ganoderma lucidum polysaccharide extract and method for preparing hand cream by using same

ActiveCN102093486APure white colorFine textureCosmetic preparationsToilet preparationsTriethanolamineOil phase

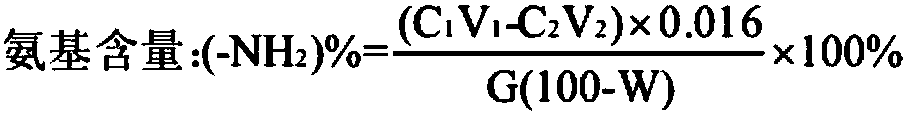

The invention relates to decolorized ganoderma lucidum polysaccharide extract and a method for preparing hand cream by using the same. The decolorized ganoderma lucidum polysaccharide extract is characterized by being prepared by the following steps: performing refluxing extraction in hot water on ganoderma lucidum fruiting body, precipitating in ethanol, performing suction filtration, drying the precipitate, grinding the precipitate to obtain ganoderma lucidum powder, adding deionized water, uniformly mixing to prepare solution, adding active carbon according to a principle that the mass of the active carbon is 1 to 3 percent based on the total mass of the solution, uniformly mixing by ultrasonic waves, centrifuging at a rotation speed of 4,000 to 10,000r.min<-1>, and collecting supernate to obtain the colorless transparent ganoderma lucidum extract; preparing a water phase by using the extract, propylene glycol, triethanolamine and propylparaben, preparing an oil phase by using mineral oil, lanolin and cetanol, heating the oil phase and water phase respectively till the solutes dissolve, adding the oil phase into the water phase, emulsifying, standing and cooling to prepare the hand cream. When the method is used, the decolorizing rate of the ganoderma lucidum reaches 99.6 percent, the retention rate of the ganoderma lucidum reaches 66.7 percent, and the hand cream prepared by the ganoderma lucidum is pure white, fine and lubricant, has obvious moisturizing effect and gives off natural fragrance of ftillgi.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

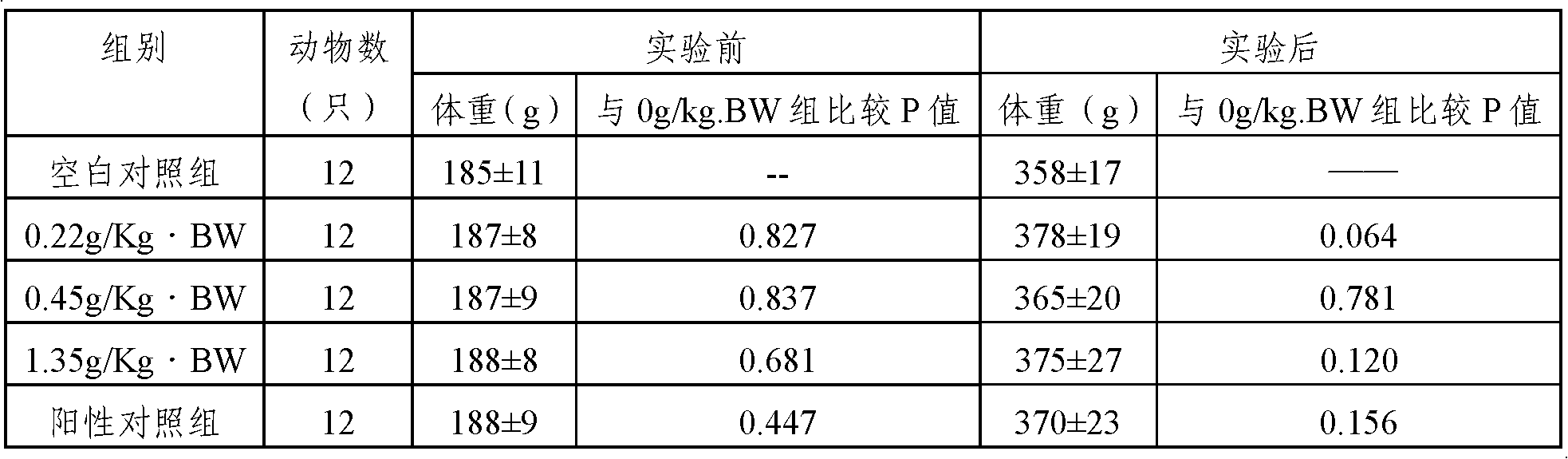

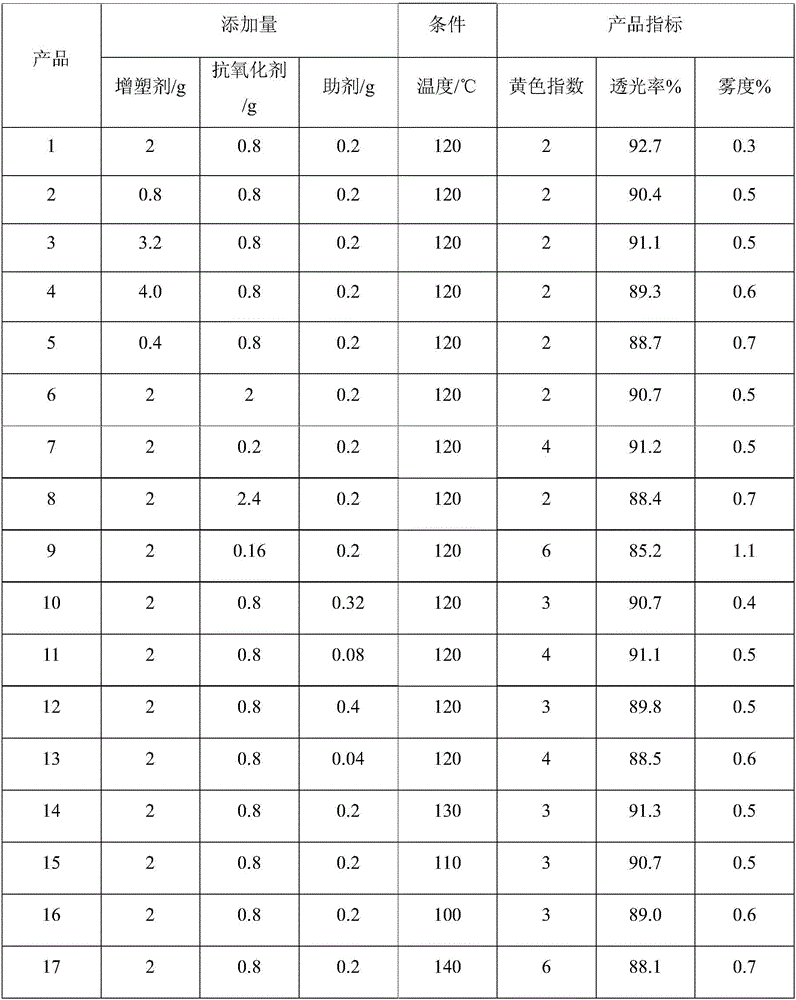

Manufacturing method of polyvinyl butyral film

The invention discloses a manufacturing method of a polyvinyl butyral film. The manufacturing method is characterized by comprising the following steps: pretreating polyvinyl alcohol and n-butanal raw materials to reduce impurities in the raw materials; then performing a condensation reaction, and performing washing and solvent soaking on generated polyvinyl butyral resin after the reaction to remove side reactions generated by the condensation reaction and residual impurities; and finally, performing heating melt plasticization and tape casting on the dried polyvinyl butyral resin together with a plasticizer, an antioxidant and an auxiliary agent in an extruding machine, thereby obtaining the polyvinyl butyral film. According to the manufacturing method disclosed by the invention, by reducing the impurities in the raw materials, the polyvinyl butyral resin with relatively high transparency is obtained, and by adding the antioxidant and the auxiliary agent, the polyvinyl butyral film can avoid aging discoloration in processing and using processes.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD

Method for refining piperazine

The invention discloses a method for refining piperazine, which comprises the following steps of: adding piperazine reaction liquid in a tower of a rectifying column for heating separation; heating the reaction liquid in the tower to 130 DEG C-140 DEG C, controlling the reflux ratio to be 0.2-1:1, collecting 100 DEG C fractional water; continuing to heat to 140 DEG C -150 DEG C, controlling reflux ratio to be 2-5:1, collecting 119 DEG C fractional ethylene diamine; continuing to heat to 160 DEG C -170 DEG C, pumping an extraction agent into the rectifying column from an extraction agent inlet at the upper part of the rectifying column by using a microinfusion pump when the scale of a thermometer shows 140 DEG C, wherein the extraction agent is one of dihydric alcohol or triatomic alcohol of C2-C5; and controlling the reflux ratio to be 3-5:1, controlling the ratio of addition mass of the extraction agent per minute to extraction mass of piperazine per minute to be 0.05-0.2:1, and collecting 148 DEG C fractional piperazine which is pure piperazine. The method can improve the purity of the product and the separation efficiency and also can greatly reduce production cost since the extraction agent can be reused after being separated simply.

Owner:山西玉龙格兰特化工有限公司

Special white washing agent for apple trees

InactiveCN104430656AGood control effectPure white colorBiocideDead plant preservationPumpkin seedApple peel

The invention discloses a special white washing agent for apple trees, belonging to the technical field of fruit tree trunk protection coatings. The white washing agent comprises the following raw materials: honey, flour, quick lime, table salt, copper sulfate, pricklyash peel extracting liquid, castor-oil plant extracting liquid, garlic extracting liquid, indigowoad root powder, ginger juice, pumpkin seed powder and sulfur powder. The white washing agent disclosed by the invention can be firmly stuck on tree barks aiming at plant diseases and insect pests of the apple trees and the tree bark properties of the apple trees; the honey, the flour and various plant source insecticidal and sterilizing medicines are added into the white washing agent so that light reflecting and warm keeping effects can be realized; and the white washing agent has remarkable prevention and treatment effects on the common plant diseases and insect pests of the apple trees. The white washing agent prepared by the method has a pure white color and long lasting time, and only needs to be coated once in early spring or late fall and early winter in one year, so that the white washing agent has the advantages of saving labor, saving time, saving resources, lasting for a long time and having good prevention and treatment effects on the plant diseases and insect pests.

Owner:孟三军

Method for manufacturing calcium aluminate cement by adopting alloy slag

InactiveCN101602581AReduce manufacturing costIncrease added valueSolid waste disposalVanadium oxidesAlloyCrusher

The invention relates to a method for manufacturing calcium aluminate cement by adopting alloy slag. The method comprises the following steps that: high-vanadium ferroalloy or vanadium-aluminum slag is crushed to 200-320 meshes by a crusher and milled; sodium carbonate or sodium chloride or sodium sulfate is added according to 10%-30% of the total weight of the powder material, the mixture is calcined at high temperature in a rotary kiln or a vertical furnace, the furnace temperature is 1000-1400DEG C, and calcination is carried out for 1-3 hours; a calcined material is leached by hot water and then is filtered; sulfuric acid or hydrochloric acid is added into filter liquor to adjust the pH value to 1.5-3.5, then ammonium sulfate or ammonium chloride is added according to the weight ratio of 1:1 of vanadium elements in the filter liquor, the mixture is heated to 80-100DEG C, multi-vanadium acid ammonium is precipitated after 30-120 minutes, and vanadium pentoxide is obtained by high-temperature smelting at 800-850DEG C; and filter slag is washed, dried, milled by 240-320 meshes and manufactured into the calcium aluminate cement. The method can use an aluminothermy reduction method to carry out the slag recovery processing of smelted vanadium iron and vanadium aluminum and can prepare the calcium aluminate cement, the manufacturing cost is low, the product quality is good, and a byproduct of the vanadium pentoxide can be produced and has high addition value; and solid wastes can be recovered and utilized, and the method conforms to the requirement of environmental protection.

Owner:李子洋

Pitaya juice and processing method thereof

ActiveCN107183433ALow calorific valueNo calorific valueNatural extract food ingredientsFood ingredient functionsFruit juiceActinidia

The invention discloses a pitaya juice and a processing method thereof, and belongs to the technical field of food processing, wherein the pitaya juice comprises the following raw materials by weight: 1000-1200 parts of pitaya flesh, 50-85 parts of pitaya pericarp, 400-500 parts of kiwifruit, 300-400 parts of cucurbita pepo l, 45-75 parts of a color protection agent, 35-65 parts of a flavoring agent, 30-45 parts of a preservative, and 15-25 parts of citric acid. The processing method comprises: 1) raw material treatment; 2) astringent taste removing treatment; 3) mixing and juice preparation; 4) seasoning; and 5) homogenization and degassing. According to the present invention, the pitaya flesh adding amount can be reduced while the cyanidin content in the pitaya juice can be increased, and the nutrients in the pitaya juice can be increased; and the pitaya juice is suitable for general people, and is further suitable for diabetes patients.

Owner:BAISE UNIV

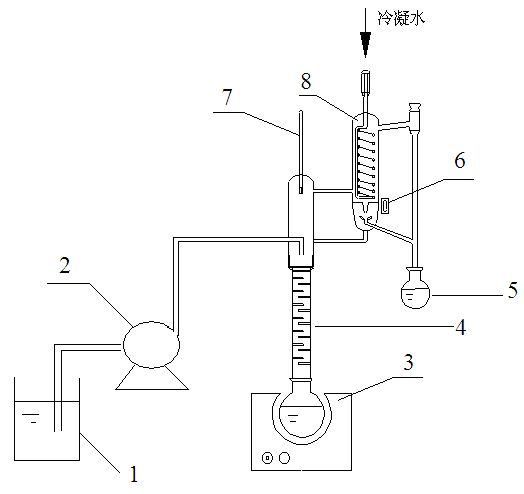

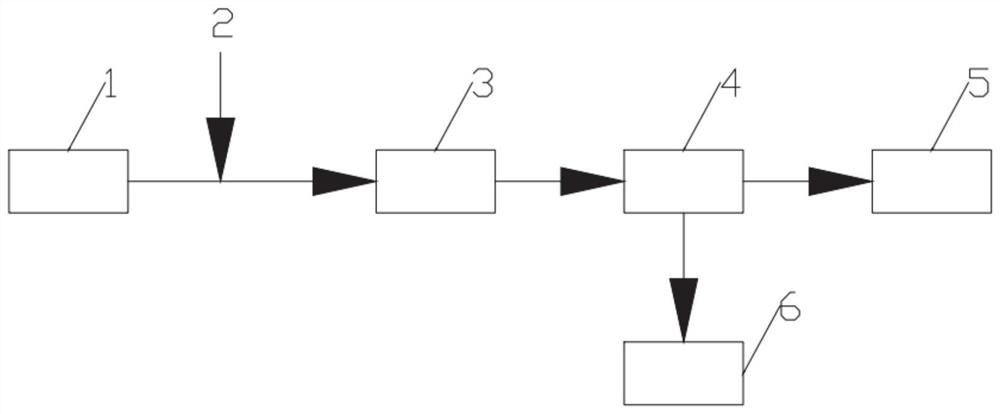

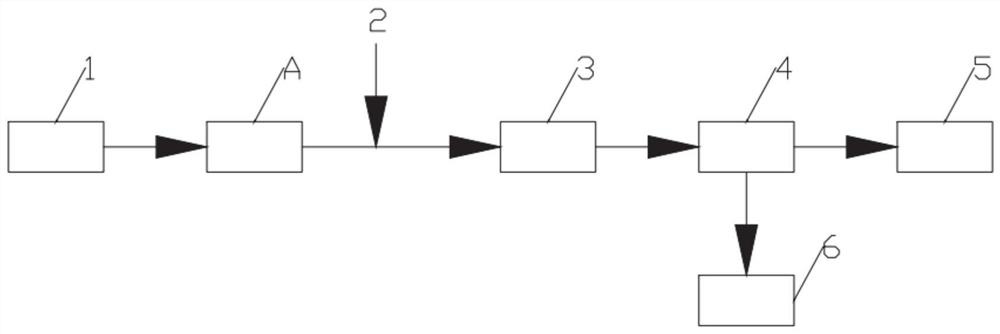

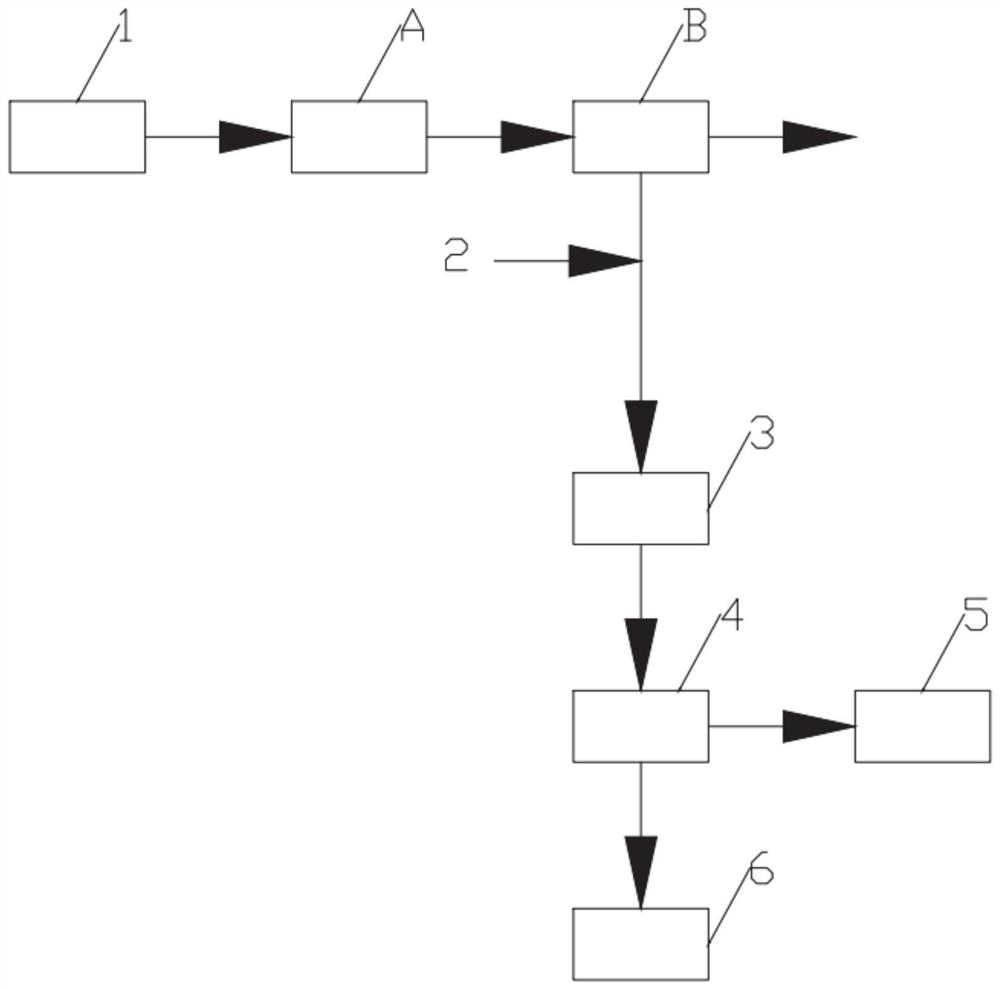

Dehydration process of multi-water sodium sulfide during polyphenyl thioether resin synthesis

The invention discloses a dehydration process of multi-water sodium sulfide during polyphenyl thioether resin synthesis. The dehydration process comprises the following steps of heating and stirring the multi-water sodium sulfide, a catalyst and an NMP (N-Methyl Pyrrolidone) solution in a reaction kettle in the dehydrating stage of the raw material multi-water sodium sulfide, continuously increasing temperature to 150-200 DEG C, and introducing nitrogen. The dehydration process disclosed by the invention can reduce the dewatering time of the multi-water sodium sulfide in the synthetic process of polyphenyl thioether, increase the dehydration efficiency, reduce the energy consumption, prevent the problems of easiness for decomposition and oxidation and the like of NMP (N-Methyl Pyrrolidone) and sodium sulfide at high temperature in air, generate extremely less NMP gas and other foreign gas in the dehydration process, can be used for carrying away the nitrogen through water vapors and is simplified in process flow and favorable to industrialized production and environmental protection.

Owner:ZHUHAI CHANGXIAN CHEM TECH

Production process of white cerium oxide

The present invention belongs to the field of wet metallurgy technology, and is especially production process of white cerium oxide. The key content of the present invention is to add fluorine into cerium oxide product to whiten and raise product hardness and life. Small amount of neodymia may be also added for further whitening. The production process includes the following steps: adding Nd in the amount of less than 1 % of REO into the cerium oxide material solution; depositing in ammonium or sodium bicarbonate solution, washing and drying; soaking the RE carbonate into solution containing F in 1-20 wt%; suction filtering and igniting to obtain white cerium oxide. The process is simple and feasible, and the product has whiteness higher than 90 %, granularity of about 1 micron and tap density 1-2 g / cu cm, and may be used in ceramic and polishing.

Owner:北京方正稀土科技研究所有限公司 +1

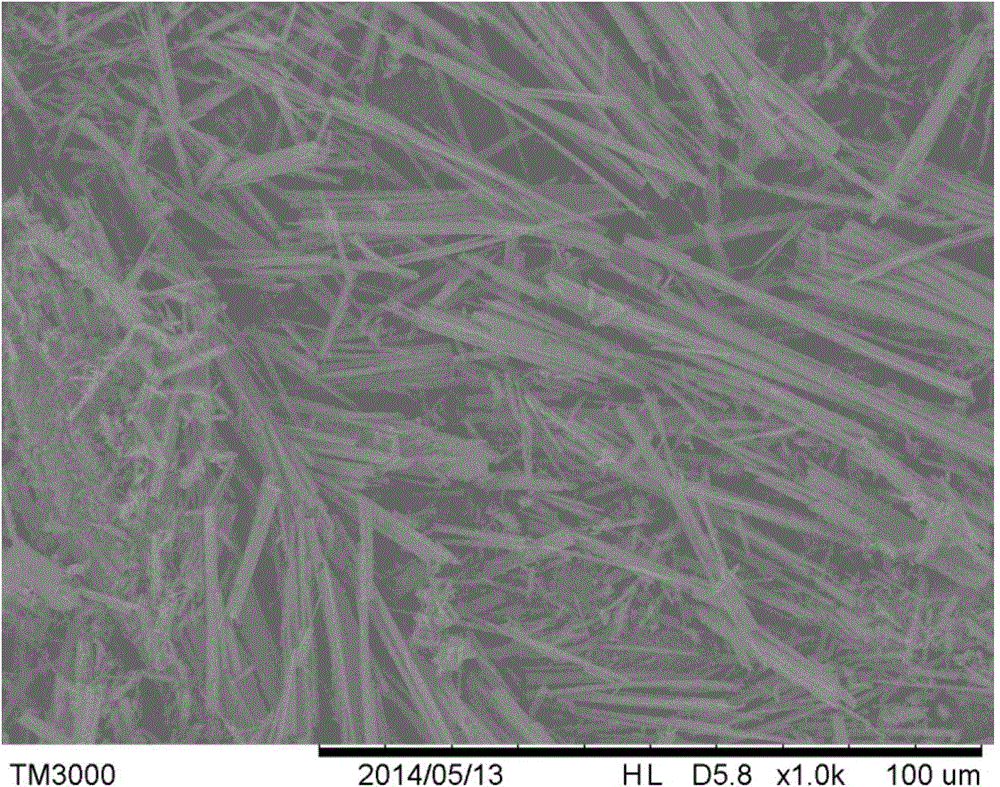

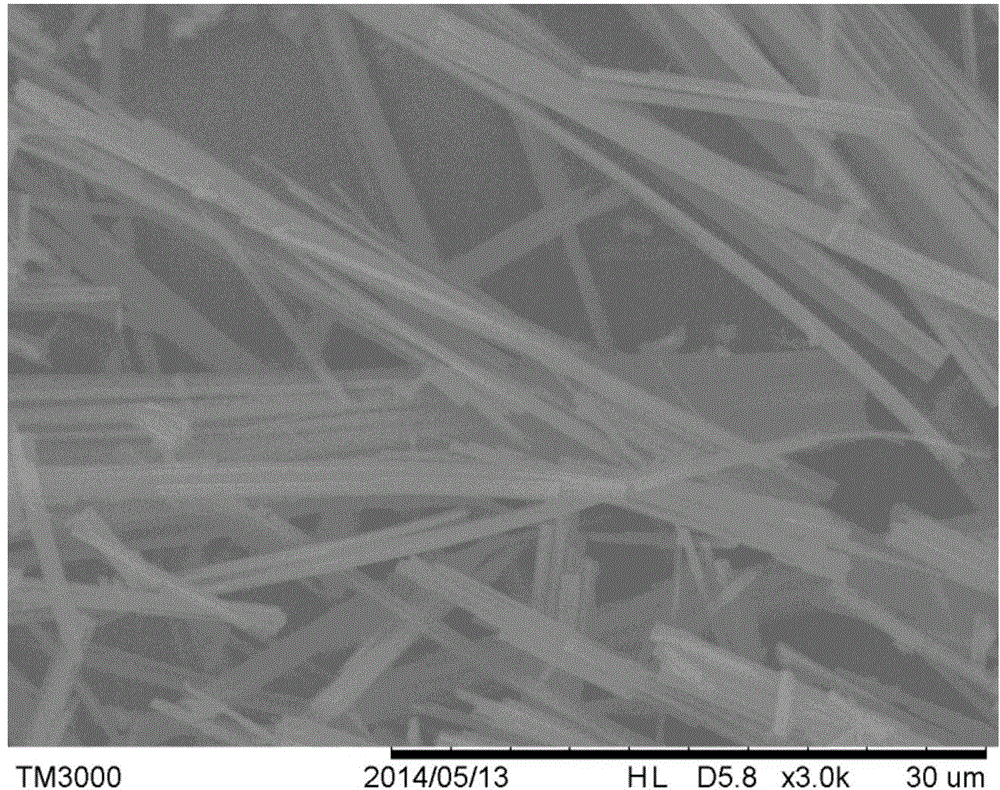

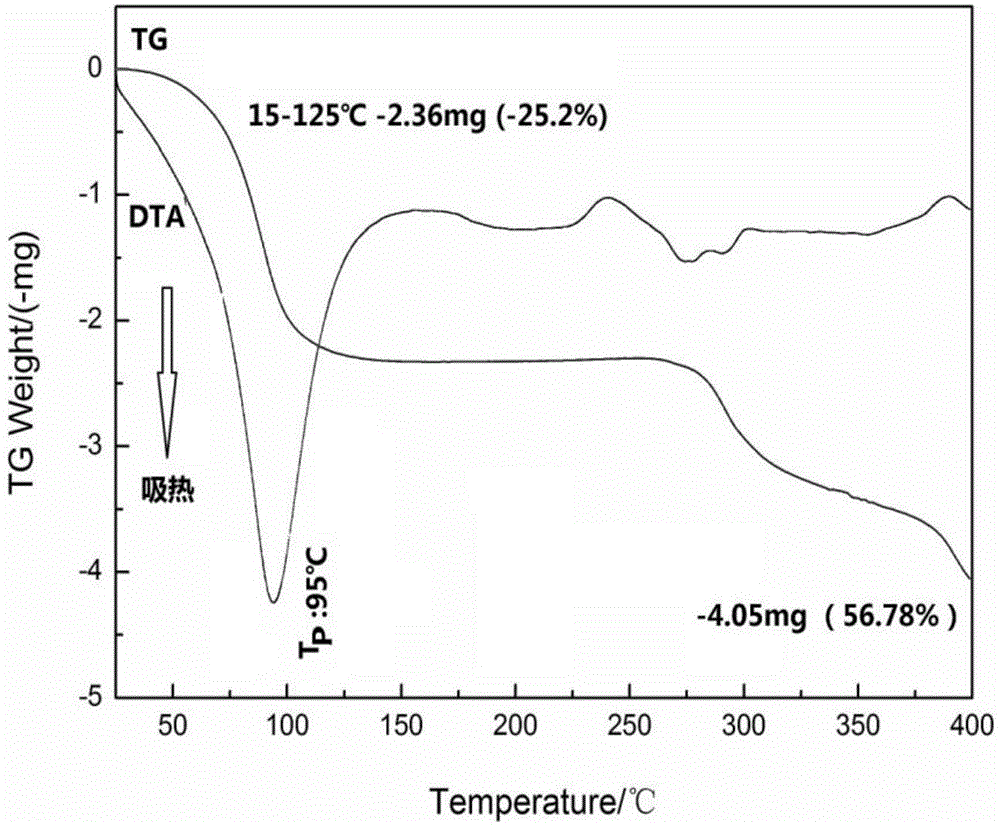

Thermal coagulation polysaccharide and fermentation bacterial strain and application thereof

ActiveCN104946572AThermosettingBiodegradableBacteriaMicroorganism based processesBiotechnologyMicroorganism

The invention discloses a bacterial strain producing novel thermal coagulation polysaccharide (PGHX), and application of bacterial strain, and belongs to the technical field of bioengineering. A method for applying the bacterial strain to prepare the novel thermal coagulation polysaccharide (PGHX) through fermentation, structural characteristics of the fermentation product (PGHX), thermal coagulation performance of the fermentation product (PGHX) and the like are involved. The invention specifically relates to an agrobacterium screening method, the bacterial strain is named as Agrobacterium HX1126 through authentication, and the preservation number is CGMCC10943. The method for producing the fermentation product (PGHX) through microorganisms is achieved. Fermentation liquid with the density of 24.9 g / L can be obtained by conducting fermentation cultivation on the microorganisms under the aerobiotic condition for 48 hours to 90 hours. The polysaccharide (PGHX) produced through the bacterial strain has good thermal coagulation performance, thermal gel can be formed after heating is conducted for 10 minutes under the concentration of 30 g / L at the temperature of 100 DEG C, the gel strength ranges from 245 g / cm<2> to 1450 g / cm<2>. Products have the pure white color and luster. Colloid is in a semitransparent shape and has elasticity.

Owner:JIANGNAN UNIV

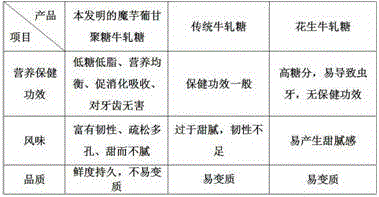

Konjac glucomannan nougat and preparation method thereof

InactiveCN106819326AImprove immunityPromote digestion and absorptionConfectionerySweetmeatsNutrientSucrose

The invention relates to a konjac glucomannan nougat and a preparation method thereof. The preparation method of the konjac glucomannan nougat comprises the steps of preparation of a protein base, preparation of a konjac glucomannan gum solution, sugar melting, sugar boiling, secondary pulping, burdening, mixing, and cooling molding. By using the unique gel performance of konjac glucomannan, the nougat is rich in toughness and elasticity, chewable and non-stick to teeth, does not contain heat, has the health effects of reducing blood fat, reducing blood glucose, improving immunity and promoting digestion and absorption of a human body; cane sugar is replaced with xylitol, so that the nougat is soft in texture; and due to addition of malt syrup, the konjac glucomannan nougat has the effects of being resistant to deliquescence, moderate and good in viscosity and good in chemical stability. The konjac glucomannan nougat is pure white in color and luster, sweet but not greasy in taste, low in sugar, chewable and free of injury to teeth, integrates nature, nutrients and health, is suitable for various people, and is low in cost, simple in process, convenient to operate and suitable for industrial continuous production.

Owner:FUJIAN AGRI & FORESTRY UNIV

PVC plastic wood composite material

The invention discloses a PVC plastic wood composite material. The composite material is prepared from, by mass, 100 parts of PVC aggregates, 20-30 parts of waste PVC, 40-55 parts of wood powder, 0.1-0.3 parts of methyl methacrylate, 0.3-0.5 parts of an AC foaming agent, 1-3 parts of a plasticizer, 1-5 parts of a foaming regulator, 1-3 parts of a calcium and zinc stabilizer, 0.2-0.5 parts of stearic acid, 10-20 parts of lightweight active carbonic acid, 7-12 parts of a titanate coupling agent, 7-12 parts of maleic anhydride , 1-3 parts of an antioxidant, 1-7 parts of titanium dioxide, 0.5-2.5 parts of carrageenan and 1-3 parts of kaolin. The above ratio of raw material components is adopted to optimize the color turbidity problem of present plastic materials, so the prepared PVC plastic wood material has very good color, the interface combination among raw materials is improved, the dosage of the wood powder is improved, and performances of the material are optimized.

Owner:脱德明

Preparation method for tree trunk whitening agent

InactiveCN106665708APure white colorNot easy to fall offBiocideDead animal preservationActivated carbonChemistry

The invention discloses a preparation method for a tree trunk whitening agent, and belongs to the technical field of agricultural material preparation. The preparation method for the tree trunk whitening agent comprises the following steps: first, sealing and fermenting bean curd, chilli powder, nutmeg powder and the like, filtering, collecting fermentation liquor, and mixing the fermentation liquor and sterile water, saccharose, citric acid and the like; then, performing constant temperature culture on a mixture, and mixing and fermenting with the plants, such as herba portulacae and chrysanthemum; sterilizing by utilizing ultraviolet light; collecting a fermented mixture, pulping, and performing centrifugal treatment with activated carbon; concentrating the obtained supernatant, and stirring uniformly with the supernatant, quick lime, hydroxymethyl cellulose and the like; finally, collecting the mixture, and performing sterilizing and disinfecting to obtain the tree trunk whitening agent. The tree trunk whitening agent prepared with the preparation method is purely white in colour and high in covering property; by adding the substances with high adhesive force and good film forming property, all of the adhesive property, the film forming property and the rainwater erosion resistance of the whitening agent can achieve a lasting effect; meanwhile, the whitening agent does not peel off easily after being used, has a relatively good heat preserving effect and a pest and disease damage preventing effect, is required to be applied only once, and has an excellent application prospect.

Owner:孙祎

Process for preparing granular pentonite

InactiveCN1155515CImprove water absorptionPure white colorSilicon compoundsPolymer scienceSodium silicate

A process for preparing granular bentone includes choosing white bentone, baking or drying in sun, adding sodium carbonate, pulverizing by 100-200 meshes, adding solution of sodium silicate and water, stirring, squeezing, baking and screening. The resultant bentone particles (0.8-4 mm) features high hydroscipicity, strength and caking performance, and high purity.

Owner:张兴华

Preparation method of white coating agent containing polyvinyl alcohol

ActiveCN102657223BExcellent adhesionPure white colorBiocideFungicidesPVA - Polyvinyl alcoholStock solution

The invention discloses a preparation method of a white coating agent containing polyvinyl alcohol. The preparation method comprises the following steps: a. mixing polyvinyl alcohol with water in a mass ratio of (1:10)-(1:14), heating the mixture to 85-95 DEG C until polyvinyl alcohol is completely dissolved in water and obtaining polyvinyl alcohol stock solution after cooling; and b. mixing the polyvinyl alcohol stock solution prepared in the step a with the raw white coating agent in a mass ratio of (1:8)-(1:12) and stirring the mixture fully and uniformly. The preparation method has the advantages of time, labor and cost saving and good effect.

Owner:河北绿岭果业有限公司

Processing method for industrially producing rabbit brain powder

The invention discloses a processing method for industrially producing rabbit brain powder. The method is characterized by comprising the following processes of: taking fresh rabbit brain, soaking the rabbit brain into cold acetone, fishing out the rabbit brain, removing blood vessels and meninges, adding the treated rabbit brain into the cold acetone, mixing the rabbit brain and the cold acetoneuniformly by using a homogenizer, performing centrifugation to remove the acetone solvent, and drying the rabbit brain powder. The method has the advantages that: because the traditional mortar for grinding is substituted by using the homogenizer, the activity of tissue factors in the rabbit brain is kept; the taken fresh rabbit brain is directly soaked into the cold acetone to substitute the traditional brine washing, so that the velocity of removing the blood vessels and the meninges in the rabbit brain is improved and the activity of the tissue factors is improved; the velocity of gas jet impact drying for rabbit brain powder protection with gas is improved by 2 to 3 times compared with the velocity of the traditional vacuum drying, and the rabbit brain powder is thinner, higher in activity and purer in color; and the whole method is high in production efficiency, and can realize industrialized large-scale production.

Owner:NINGBO UNIV

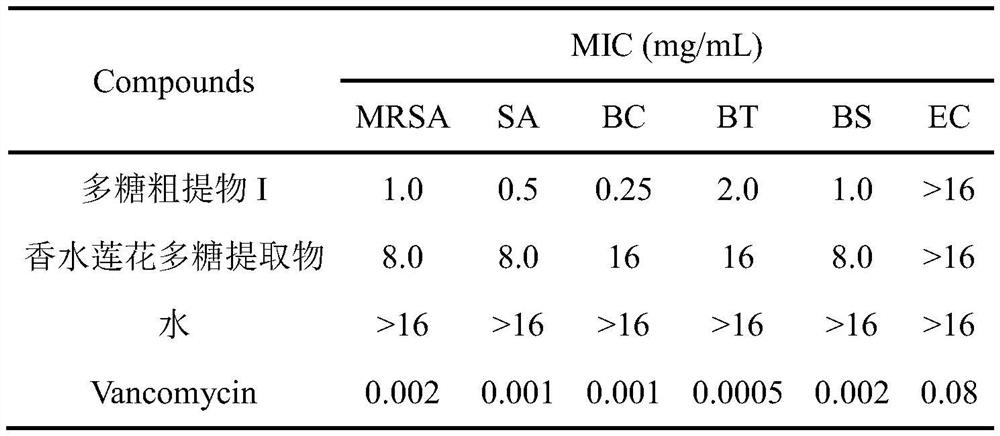

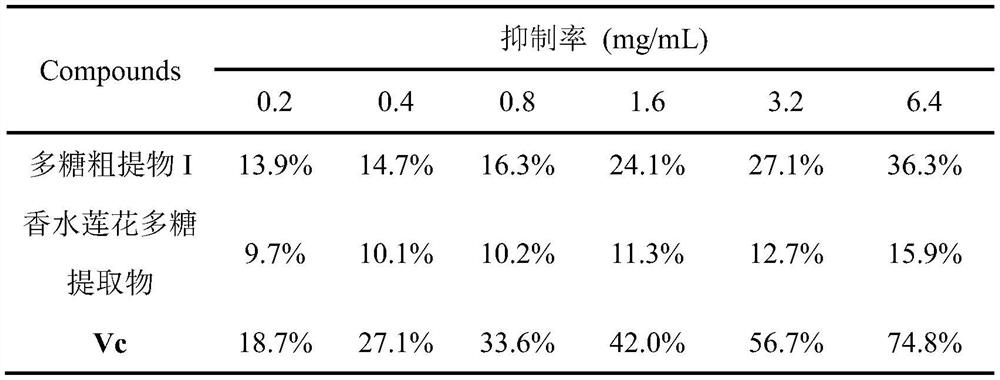

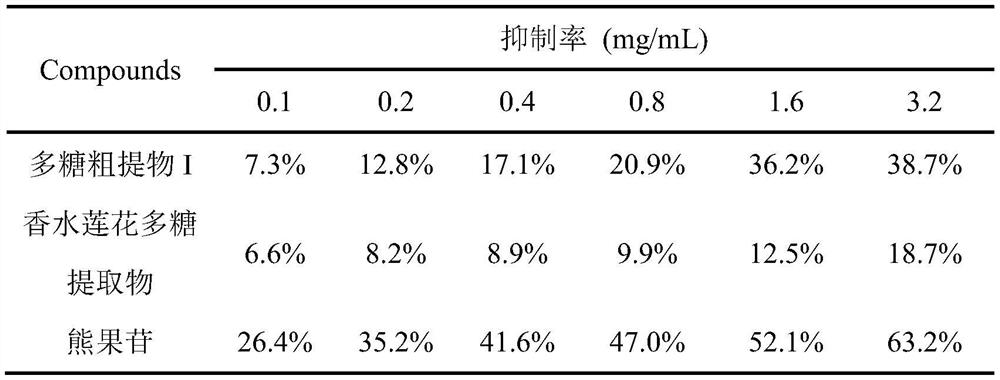

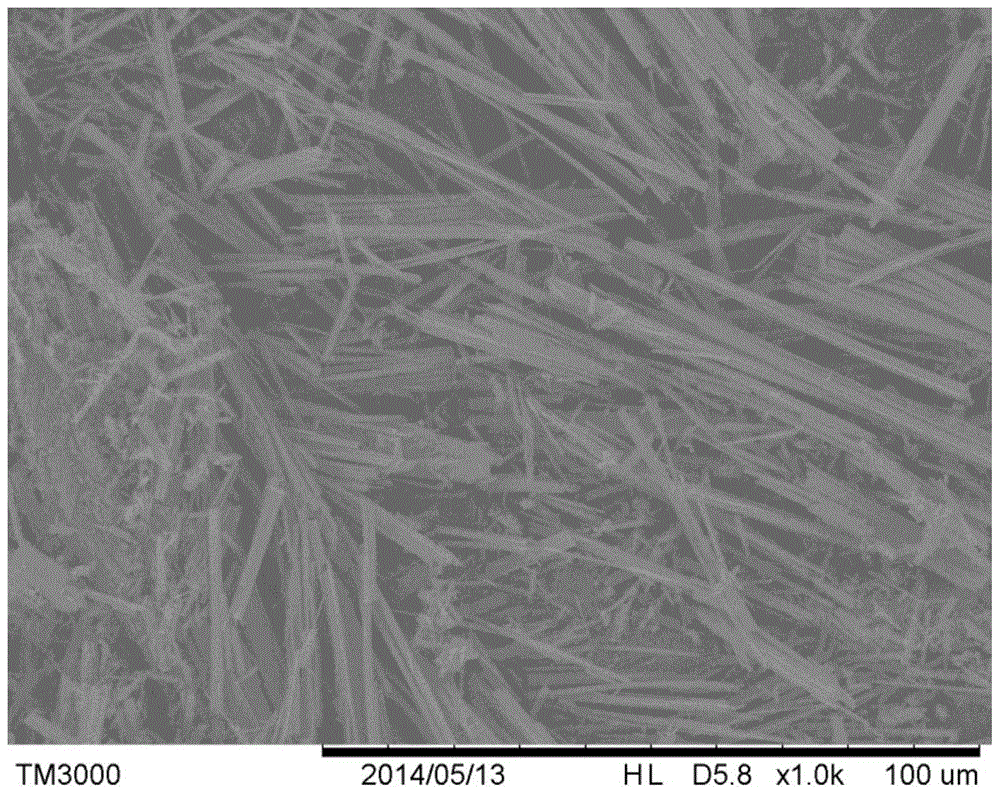

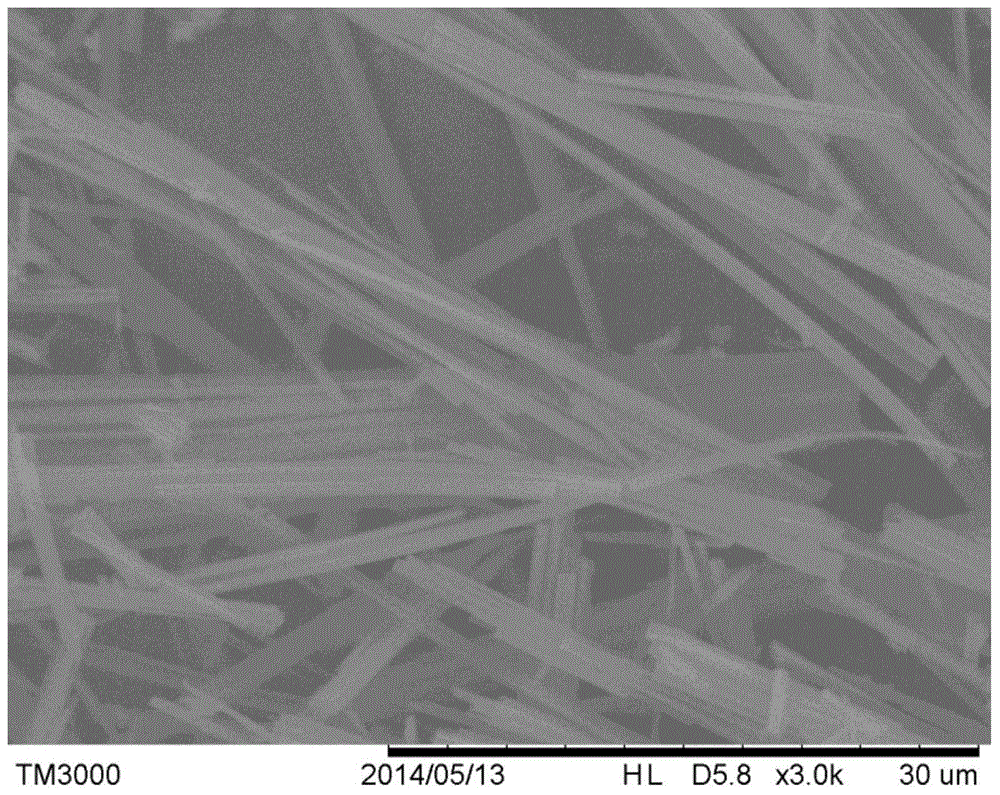

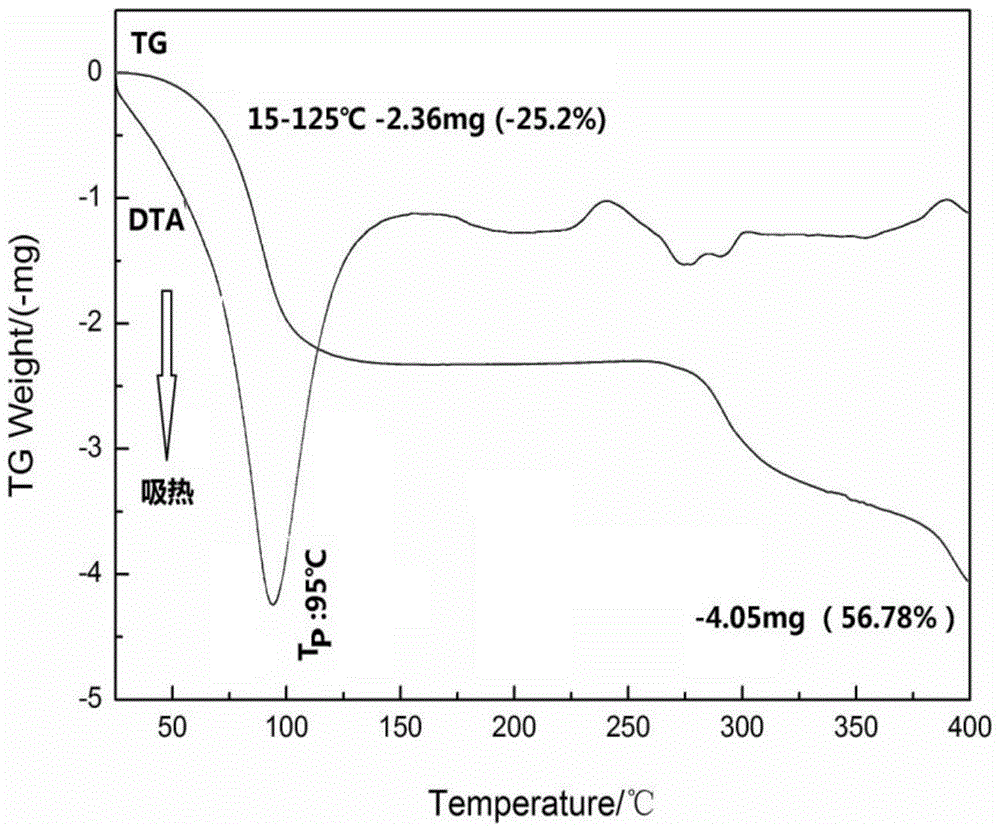

Nymphaea hybrida polysaccharide extract as well as preparation method and application thereof

PendingCN113402626AOriginal structure pure whitePure white colorCosmetic preparationsToilet preparationsDialysis membranesFreeze-drying

The invention discloses a nymphaea hybrida polysaccharide extract as well as a preparation method and application thereof. The preparation method comprises the steps of crushing nymphaea hybrida, adding water for extraction, and concentrating an extracting solution to obtain an extract; adding an ethanol solution into the extract, and conducting stirring, filtering, precipitating, freezing and drying to obtain a polysaccharide crude extract I; dissolving the polysaccharide crude extract I in water, conducting deproteinizing by using a Sevag method, washing out a precipitate, conducting filtering, and drying the precipitate to obtain a polysaccharide crude extract II; removing monosaccharide and oligosaccharide: dissolving the polysaccharide crude extract II in water, conducting dialyzing by using a dialysis membrane with the cutoff molecular weight of 8000-14000 D, adding an ethanol solution into the dialyzed polysaccharide crude extract liquid, conducting stirring until the precipitate is sucked out, conducting filtering, and drying the precipitate to obtain a polysaccharide crude extract III; and conducting gel column purification: purifying the polysaccharide crude extract III by using a gel chromatographic column, tracking fractions by using a sulfuric acid-phenol method, collecting main peaks, conducting merging, adding an ethanol solution, and conducting stirring, filtering, precipitating, and freeze-drying to obtain the nymphaea hybrida polysaccharide extract. The nymphaea hybrida polysaccharide extract has the effects of resisting bacteria, whitening, moisturizing and resisting oxidation.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

A kind of dehydration process of sodium sulfide polyhydrate in the synthesis of polyphenylene sulfide

Owner:ZHUHAI CHANGXIAN CHEM TECH

Tremella fuciformis cultivation material and preparation method thereof

InactiveCN107711293AMeeting nutritional needsAlleviate needsCalcareous fertilisersMagnesium fertilisersSaccharumSucrose

The invention relates to the technical field of tremella fuciformis cultivation and specifically relates to a tremella fuciformis cultivation material. The tremella fuciformis cultivation material comprises the following raw materials in parts by weight: 15-18 parts of cottonseed hulls, 13-16 parts of sawdust, 11-15 parts of bagasse, 6-10 parts of wheat bran, 2-4 parts of gypsum powder, 0.5-1 partof saccharose, 2-4 parts of corn flour, 0.2-0.7 part of magnesium chloride, 0.4-0.7 part of urea and 1-3 parts of soybean meal. The invention also discloses a preparation method of the tremella fuciformis cultivation material. Through reasonable match of the raw materials and the scientific preparation method, the cultivation material can fully meet the nutritional requirements of the whole growing period of tremella fuciformis, so that the cultivated tremella fuciformis is pure white, colloid, polypetalous, semitransparent, soft and elastic, a foundation is finally laid for cultivation of high-quality and high-yield tremella fuciformis, and the cultivation material provided by the invention can be widely applied to the technical field of tremella fuciformis cultivation.

Owner:GUANGXI JIPENG INVESTMENT CO LTD

A kind of preparation method of crystallization calcium lactate

ActiveCN104529751BLarge granularityEvenly distributedOrganic chemistry methodsCarboxylic compound separation/purificationActivated carbonGranularity

The invention provides a preparing method of crystal L-calcium lactate. Activated carbon is added to the crystal L-calcium lactate with the concentration ranging from 14.7 g / mL to 40.5 g / mL, and continuous stirring, decoloring and deodorizing are carried out; after filtration, the filtered liquid is moved into a crystallizer, and pH is adjusted to 6-8; poor solvent is added at the constant temperature ranging from 40 DEG C to 60 DEG C, dilution crystallization is carried out, and at the terminal point of dilution, the volume of the added poor solvent is two to eight times of the volume of fermentation liquid; cooling crystallization is carried out, wherein filtering and separating are carried out after the temperature is lowered to 5-20 DEG C, cleaning solvent is used for carrying out cleaning, and L-calcium lactate crystals are obtained after drying is carried out. According to the preparing method, the production cycle is short, and operation is easy; the crystal L-calcium lactate is pure white, crystals are complete, the granularity of the crystals is large, the crystals are distributed evenly, the main granularity is larger than 19.33 microns, and product postprocessing is facilitated; the once-through yield in the crystallizing process reaches 82.0 percent or above, and the method is suitable for large-scale industrial production and has good industrial application prospects.

Owner:TIANJIN UNIV

PVC (Polyvinyl Chloride) pipe

The invention relates to a PVC (Polyvinyl Chloride) pipe, and belongs to the technical field of new materials. The material comprises the following components in percentage by weight: 60% of PVC resin, 20% of chlorinated polyethylene, 8% of plasticizing agents, 7% of stabilizing agents and 5% of AC (Activated Charcoal) foaming agents. The PVC pipe disclosed by the invention can effectively prevent the PVC pipe from being aged and enhance the strength of the material and is high in brightness and pure white in color.

Owner:封仕燕

Method for extracting phosphorus from phosphorus-containing wastewater

PendingCN113526479AReduce outputIncrease productionSuperphosphatesTreatment involving filtrationCalcium biphosphateVegetable oil

The invention provides a method for extracting phosphorus from phosphorus-containing wastewater, and particularly relates to a method for extracting phosphorus from wastewater obtained by acidifying vegetable oil gleditsia sinensis lam with sulfuric acid. The method comprises the following steps of: performing contact reaction on wastewater obtained by acidifying vegetable oil gleditsia sinensis lam with sulfuric acid and a recycling agent A; and then carrying out solid-liquid separation through a filtering device to obtain a pure white or grey white solid mainly containing calcium hydrophosphate. The water content of the obtained phosphorus-containing solid is 30%-40%, and the solid can be dried or naturally air-dried to obtain a dried solid. The phosphorus-containing solid can be used as a phosphate fertilizer and also can be used as an additive of animal feed. The invention also provides a process for extracting phosphorus from vegetable oil saponin wastewater. The process comprises a filtering unit, a concentrating unit and a phosphorus extracting unit.

Owner:大连波美科技有限公司

Preparing method of crystal L-calcium lactate

ActiveCN104529751ALarge granularityEvenly distributedOrganic chemistry methodsCarboxylic compound separation/purificationActivated carbonFiltration

The invention provides a preparing method of crystal L-calcium lactate. Activated carbon is added to the crystal L-calcium lactate with the concentration ranging from 14.7 g / mL to 40.5 g / mL, and continuous stirring, decoloring and deodorizing are carried out; after filtration, the filtered liquid is moved into a crystallizer, and pH is adjusted to 6-8; poor solvent is added at the constant temperature ranging from 40 DEG C to 60 DEG C, dilution crystallization is carried out, and at the terminal point of dilution, the volume of the added poor solvent is two to eight times of the volume of fermentation liquid; cooling crystallization is carried out, wherein filtering and separating are carried out after the temperature is lowered to 5-20 DEG C, cleaning solvent is used for carrying out cleaning, and L-calcium lactate crystals are obtained after drying is carried out. According to the preparing method, the production cycle is short, and operation is easy; the crystal L-calcium lactate is pure white, crystals are complete, the granularity of the crystals is large, the crystals are distributed evenly, the main granularity is larger than 19.33 microns, and product postprocessing is facilitated; the once-through yield in the crystallizing process reaches 82.0 percent or above, and the method is suitable for large-scale industrial production and has good industrial application prospects.

Owner:TIANJIN UNIV

Processing method of pickled radishes

InactiveCN108464470AAvoid breakingPrevent discolorationFood ingredientsFood dryingAlcoholSweet flavor

The invention discloses a processing method of pickled radishes and belongs to the technical field of processing methods of pickled vegetables. The processing method comprises seven major steps: refining, cutting, dewatering, honey soaking, dry pickling, liquid pickling and packaging. The processing method of pickled radishes has the beneficial effects: radish strips are blanched in citric acid boiled water after being diced, so a product is kept clear white in color and has high resilience; then the radish strips are dewatered in a dehumidifying chamber to prevent the radish strips from breaking or discoloring; honey, sugar and wine are in contact with the radish strips first by performing honey soaking, and sweet flavor and alcohol flavor enter the interior of the radish strips by performing rolling and standing; liquid pickling is performed after dry pickling is performed, so the radish strips are pickled by seasonings in sequence; and finally the radish strips are cleaned and soupliquid is added to the radish strips. The pickled radishes prepared by the processing method are snow white as jade, sparkling, crystal-clear and full, crisp and tender in mouthfeel, fragrant in flavor, sour, sweet and mellow in taste and long in shelf life.

Owner:CHONGQING AGRI DEV CO LTD

A thermocoagulable polysaccharide, its fermentation strain and application

ActiveCN104946572BThermosettingBiodegradableBacteriaMicroorganism based processesBiotechnologyMicroorganism

The invention discloses a novel thermocoagulable polysaccharide (PGHX) producing strain and application thereof, belonging to the technical field of bioengineering. It includes the method for applying the above-mentioned strains to ferment and prepare a novel thermocoagulable polysaccharide (PGHX), the structural characteristics of the fermentation product (PGHX) and its thermocoagulable performance. It specifically relates to the screening method for Agrobacterium, the strain identified as Agrobacterium HX1126 and the preservation number as CGMCC 10943, and a method for producing fermentation products (PGHX) using the microorganism. The microorganism is fermented and cultured for 48 to 90 hours under aerobic conditions, and the yield can reach 24.9 g / L of fermentation broth. The polysaccharide PGHX produced by the bacteria has good thermal coagulation properties. At a concentration of 30 g / L, heated at 100°C for 10 minutes, a thermal gel can be formed. The gel strength is 245-1450 g / cm2. The color of the product is pure white, and the colloid is Translucent and elastic.

Owner:JIANGNAN UNIV

Healthcare product combination for clearing and nourishing throat and preparation method thereof

The invention relates to a healthcare product combination for clearing and nourishing the throat and a preparation method thereof. The combination comprises the following raw and auxiliary materials in parts by weight: 25-75 parts of rosa roxbughii tratt powder, 100-200 parts of phyllanthus emblica powder, 40-250 parts of sorbitol, 200-900 parts of Isomalt, 1-10 parts of stevioside and 2-18 partsof magnesium stearate. The healthcare product combination for clearing and nourishing the throat, provided by the invention, has slightly astringent taste and sweet aftertaste.

Owner:NEW ERA HEALTH IND GRP +1

Processing method of refined lilium brownii var. viridulum powder

InactiveCN106974220ARealize large-scale mechanized productionPure white colorNatural extract food ingredientsFood dryingLilium browniiMetallurgy

The present invention discloses a processing method of refined lilium brownii var. viridulum powder. The method comprises the following steps: fresh lilium brownii var. viridulum is taken, bases are removed, the treated lilium brownii var. viridulum is washed, the washed lilium brownii var. viridulum is crushed to obtain a mixture of slurry and residues, then the mixture is subjected to a slurry and residue separation, then the slurry is subjected to a water and slurry separation, then the obtained materials are subjected to a centrifugal drying, the dried materials are subjected to a hot air drying, and the dried materials are sieved to obtain finished products. The method can be used to realize a large-scale mechanized production and the obtained product has a purity of lilium brownii var. viridulum starch at more than or equal to 99% and a moisture content of less than or equal to 15%, and is bright in color and luster, and free of foreign colors.

Owner:符大国

Processing method for industrially producing rabbit brain powder

The invention discloses a processing method for industrially producing rabbit brain powder. The method is characterized by comprising the following processes of: taking fresh rabbit brain, soaking the rabbit brain into cold acetone, fishing out the rabbit brain, removing blood vessels and meninges, adding the treated rabbit brain into the cold acetone, mixing the rabbit brain and the cold acetoneuniformly by using a homogenizer, performing centrifugation to remove the acetone solvent, and drying the rabbit brain powder. The method has the advantages that: because the traditional mortar for grinding is substituted by using the homogenizer, the activity of tissue factors in the rabbit brain is kept; the taken fresh rabbit brain is directly soaked into the cold acetone to substitute the traditional brine washing, so that the velocity of removing the blood vessels and the meninges in the rabbit brain is improved and the activity of the tissue factors is improved; the velocity of gas jet impact drying for rabbit brain powder protection with gas is improved by 2 to 3 times compared with the velocity of the traditional vacuum drying, and the rabbit brain powder is thinner, higher in activity and purer in color; and the whole method is high in production efficiency, and can realize industrialized large-scale production.

Owner:NINGBO UNIV

A kind of preparation method of low molecular weight chitosan

ActiveCN106008750BSmall molecular weightLow reactive amino groupHigh molecular massLow molecular weight chitosan

The invention provides a preparation method of low-molecular weight chitosan. The method comprises a step of degrading high-molecular weight chitosan, wherein before degrading the high-molecular weight chitosan, a protecting group is introduced to perform amino protection on chitosan; and the protecting group is one of carbobenzoxy, t-butylcarbonyl, trimethyl silicon ethoxycarbonyl and fluorenylmethyloxycarbonyl. The high-molecular weight chitosan is degraded through the technology combining short-time ultrasonic and hydrogen peroxide chemical degradation. By adopting the method provided by the invention, the prepared low-molecular weight chitosan has relatively high content of active amino, the molecular weight is low, the molecular weight distribution is relatively narrow, the color is pure white, the yield is high, and the application value is greatly increased; by combining ultrasonic pretreatment and chemical oxidation, the degradation efficiency and the energy utilization rate are improved, and the production cost is greatly reduced; and moreover, the technology is simple and convenient to operate, the reaction is easy to control, the reaction conditions are mild, and the method is suitable for large-scale industrial production.

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH

A kind of preparation method of L-dibenzoyl tartrate dimethyl ester

ActiveCN109400468BAvoid it happening againImprove conversion rateOrganic compound preparationOrganic chemistry methodsChemical synthesisPtru catalyst

The invention belongs to the technical field of chemical synthesis methods, in particular to a method for preparing L-dibenzoyl dimethyl tartrate, and the preparation method of said L-dibenzoyl dimethyl tartrate comprises the following steps: S1, L tartaric acid, benzoyl chloride, thionyl chloride are raw materials, Lewis acid is a catalyst, and toluene is a solvent, through esterification, anhydride reaction, purification obtains L dibenzoyl tartaric anhydride wet product; S2, L The wet product of dibenzoyl tartaric anhydride is hydrolyzed in pure water to obtain the wet product of L-dibenzoyl tartaric acid hydrate; S3, the wet product of L-dibenzoyl tartaric acid hydrate is esterified under the action of methanol and a catalyst Reaction, purified to obtain L-dibenzoyl tartaric acid dimethyl ester. The raw materials used in the invention are cheap and easy to obtain, the reaction conditions are mild, the recovered methanol can be reused, the aftertreatment is convenient, the method is suitable for industrial production, and is worthy of popularization.

Owner:濮阳天健生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com