Konjac glucomannan nougat and preparation method thereof

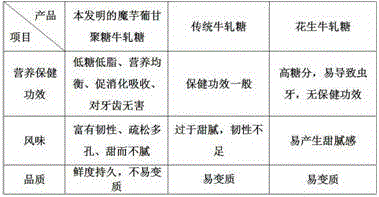

The technology of konjac glucomannan and nougat is applied in the direction of confectionery, confectionery industry, and the function of food ingredients, which can solve the problems of short shelf life, high sucrose content, single nutrition, etc., and achieve soft texture and good taste. , the effect of low heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, a kind of preparation method of konjac glucomannan nougat, comprises the following steps:

[0022] (1) Preparation of protein base: by weight, take 1.8 parts of egg white liquid at 275 r / min, beat for 0.7 min, add 10 parts of xylitol, continue to beat for 4 min to obtain protein base;

[0023] (2) Preparation of konjac glucomannan sol solution: take 20 parts of purified water, heat to 45°C, add 0.4 part of konjac glucomannan, mix well, and keep the constant temperature for 25 minutes to prepare konjac glucomannan sol solution;

[0024] (3) Dissolving sugar and boiling sugar: Take 15 parts of xylitol, under the constant temperature of 50 °C, 500- / min, stir and dissolve, continue to add 4 parts of corn syrup and 10 parts of maltose syrup, and gradually heat up and boil, wait for When the temperature of the syrup solution rises to 115°C, the heating is stopped to obtain a syrup solution;

[0025] (4) Secondary brewing: flush the syrup prepared in step (3) in...

Embodiment 2

[0028] Embodiment 2, a kind of preparation method of konjac glucomannan nougat, comprising the following steps:

[0029] (1) Preparation of protein base: by weight, take 2.0 parts of egg white liquid, beat at 285 r / min for 1.5 min, add 15 parts of xylitol, continue to beat at 285 r / min for 7 min to obtain protein base;

[0030] (2) Preparation of konjac glucomannan sol solution: take 30 parts of pure water, heat it to 55°C, add 0.7 part of konjac glucomannan, mix well, and keep at constant temperature for 35 minutes to prepare konjac glucomannan sol solution;

[0031] (3) Dissolving sugar and boiling sugar: Take 20 parts of xylitol, stir and dissolve at 600 r / min at a constant temperature of 60 °C, continue to add 6 parts of corn syrup and 15 parts of maltose syrup, and gradually heat up and cook until the syrup When the temperature of the solution rises to 125°C, the heating is stopped to obtain a syrup;

[0032] (4) Secondary brewing: pour the syrup prepared in step (3) int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com