Method for extracting phosphorus from phosphorus-containing wastewater

A technology of waste water and recovery agent, which is applied in the field of phosphorus extraction, can solve the problems of phosphorus resource loss, etc., and achieve the effect of pure white color and good extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

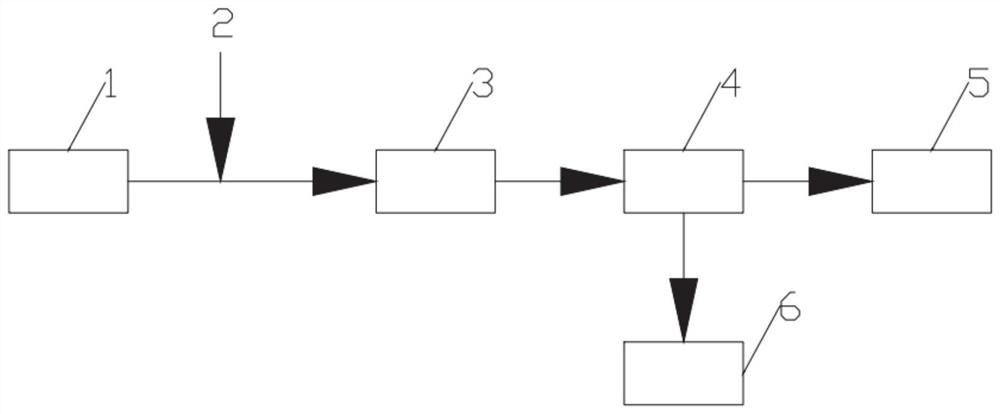

[0035] Such as figure 1 Shown is a flowchart of an embodiment of the present invention. The source of waste water 1 is the waste water produced by the acidification of plant saponins with sulfuric acid, the hardness of waste water 1 is 9000 mg / L, and the phosphate is 5000 mg / L. The recovery agent is Ca(OH) 2 , Filtration device 4 for filtering I uses a candle filter with a filtration precision of 1 μm.

[0036] The specific implementation method is: add recovering agent 2 to waste water 1, adjust the pH value of waste water to 7.2, enter the reaction tank 3 for contact reaction for 30 minutes, and the turbid liquid after the contact reaction enters the filter device 4 of filtration I for solid-liquid separation, and obtains The main component is CaHPO 4 , MgHPO 4 The recycled material 6, and the separation liquid 5. The moisture content of recycled material 6 is 30%, which can be used directly or after being dried. The separation liquid 5 can be reused or discharged afte...

Embodiment 2

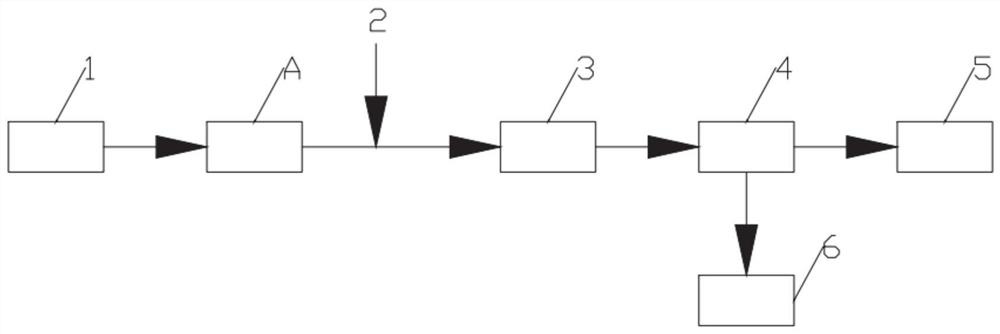

[0039] Such as figure 2 Shown is the flow chart of the second embodiment of the present invention. The source of waste water 1 is the waste water produced by the acidification of plant saponins with sulfuric acid, the hardness of waste water 1 is 9000 mg / L, and the phosphate is 5000 mg / L. The recovery agent is Ca(OH) 2, the filtering device 4 for filtering I and the filtering device A for filtering II adopt a candle filter with a filtering precision of 1 μm.

[0040] The specific implementation method is: firstly, the waste water 1 passes through the filter device A of the filter II to remove suspended solids and grease in the water; then, the recovery agent 2 is added to the produced water of the filter device A of the filter II, and the pH value of the wastewater is adjusted to 7.2, and then enters the reaction tank 3 The turbid liquid after the contact reaction enters the filter device 4 of Filtration I for solid-liquid separation, and the main component is CaHPO 4 , Mg...

Embodiment 3

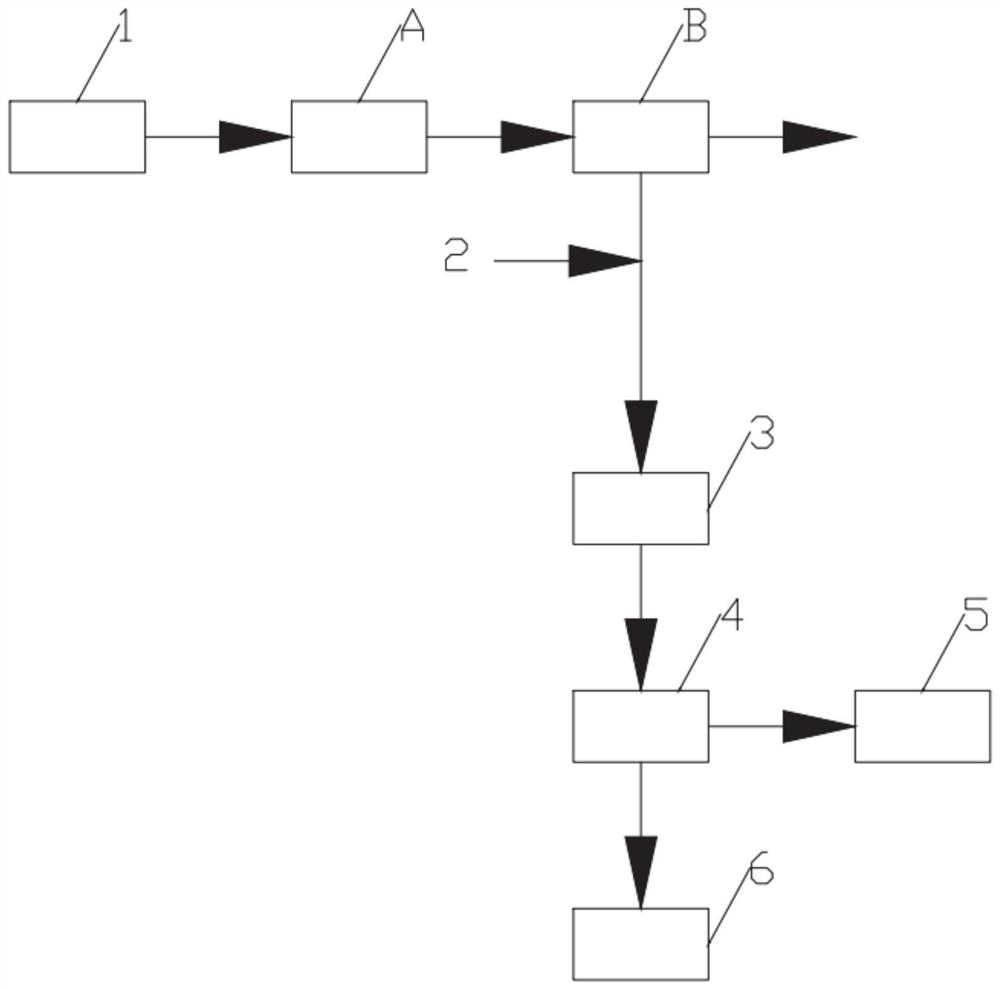

[0043] like image 3 Shown is the flowchart of the third embodiment of the present invention. The source of waste water 1 is the waste water produced by the acidification of plant saponins with sulfuric acid, the hardness of waste water 1 is 9000 mg / L, and the phosphate is 5000 mg / L. The recovering agent A is Ca(OH) 2 , what filter device 4 adopts is the candle type filter that filter accuracy is 1 μm.

[0044] The specific implementation method is as follows: Wastewater 1 first passes through the filter device A of Filtration II to remove suspended solids and grease in the water; then enters the concentration device B to concentrate the phosphate in the water to the concentrated water side of the concentration device B; Desalted water can be treated by other processes. Add recovering agent 2 to the concentrated water of concentration device B, adjust the pH value of the wastewater to 7.2, enter the reaction tank 3 for a contact reaction for 30 minutes, and the turbid liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com