Method for refining piperazine

A piperazine and rectifying column technology, which is applied in the field of refining piperazine, can solve the problems of light yellow color of piperazine, many by-products, affecting use, etc., and achieve the effects of pure white product color, improved production efficiency, and high separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

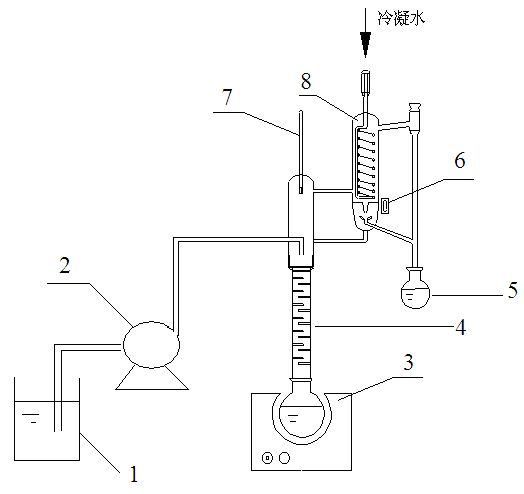

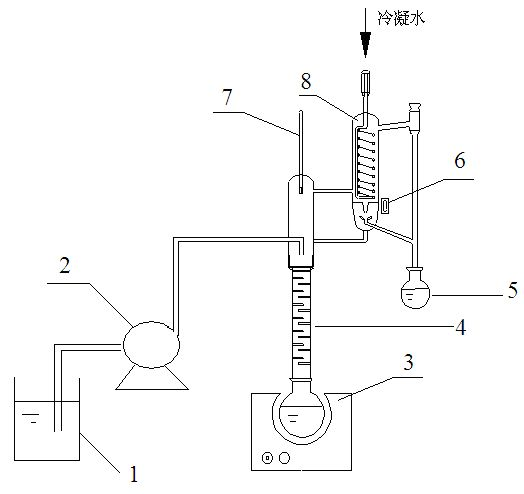

Image

Examples

Embodiment 1

[0017] Add 1000g of piperazine reaction liquid prepared from ethanolamine and ammonia to the bottom of the rectification tower for temperature rise and separation. The reaction liquid in the bottom of the bottom is heated to a temperature of 130°C, the reflux ratio is controlled at 0.2:1, and the fraction at 100°C is collected. 75g of water, continue to heat to 140°C, control the reflux ratio to 2:1, collect 105g of ethylenediamine fraction at 119°C, continue to heat to 160°C, and when the thermometer shows that it reaches 140°C, use a micropump to pump the extractant from the rectification tower The upper extractant inlet is poured into the rectification column, the extractant is ethylene glycol, the reflux ratio is controlled at 3:1, and the ratio of the mass of the extractant added per minute to the mass of piperazine produced per minute is 0.05:1. 641g of piperazine was collected at 148°C, and the purity of piperazine was 99.2% as detected by gas chromatography. The residu...

Embodiment 2

[0019] Add 1000g of piperazine reaction solution prepared from ethanolamine and ammonia to the bottom of the rectification tower for temperature rise and separation. The reaction solution in the bottom of the tower is heated to a temperature of 140°C, the reflux ratio is controlled at 1:1, and 70g of distillate water at 100°C is collected. , continue heating to 150°C, control the reflux ratio to 5:1, collect 110g of distillate ethylenediamine at 119°C, continue heating to 160-170°C, and when the thermometer shows 140°C, use a micropump to pump the extractant from the rectification tower The upper extraction agent inlet is poured into the rectification column, the extraction agent is glycerol, the reflux ratio is controlled at 5:1, and the ratio of the mass of the extraction agent added per minute to the mass of piperazine produced per minute is 0.2:1. The fraction piperazine at 148°C was collected to obtain 640 g of piperazine. The purity of piperazine detected by gas chromatog...

Embodiment 3

[0021] Add 1000g of piperazine reaction solution prepared from ethanolamine and ammonia to the bottom of the rectification tower for temperature rise and separation. The reaction solution in the bottom of the tower is heated to a temperature of 135°C, the reflux ratio is controlled at 0.5:1, and 72g of distillate water at 100°C is collected , continue heating to 145°C, control the reflux ratio to 3:1, collect 108g of distillate ethylenediamine at 119°C, continue heating to 165°C, and when the thermometer shows 140°C, use a micropump to pump the extractant from the upper part of the rectification tower The inlet of the extractant is poured into the rectification column, the extractant is 1,5-pentanediol, the reflux ratio is controlled at 4:1, and the ratio of the mass of the extractant added per minute to the mass of piperazine produced per minute is 0.1: 1. Collect 646g of piperazine at 148°C, and the purity of piperazine detected by gas chromatography is 99.1%. The residual m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com