Patents

Literature

44 results about "Piperazine phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Piperazine Phosphate. Certain types Piperazine Phosphate medicines are present in the market but most of the seller prefer products from the Adani Pharmaceutical industries to sell. It takes to defend against the infection like pinworms and roundworms.

Flame retardant composition with improved fluidity, flame retardant resin composition and molded products

ActiveUS20070176154A1Improve flame retardant performanceImproved powder property and hygroscopic propertyDyeing processMelamine phosphateAdditive ingredient

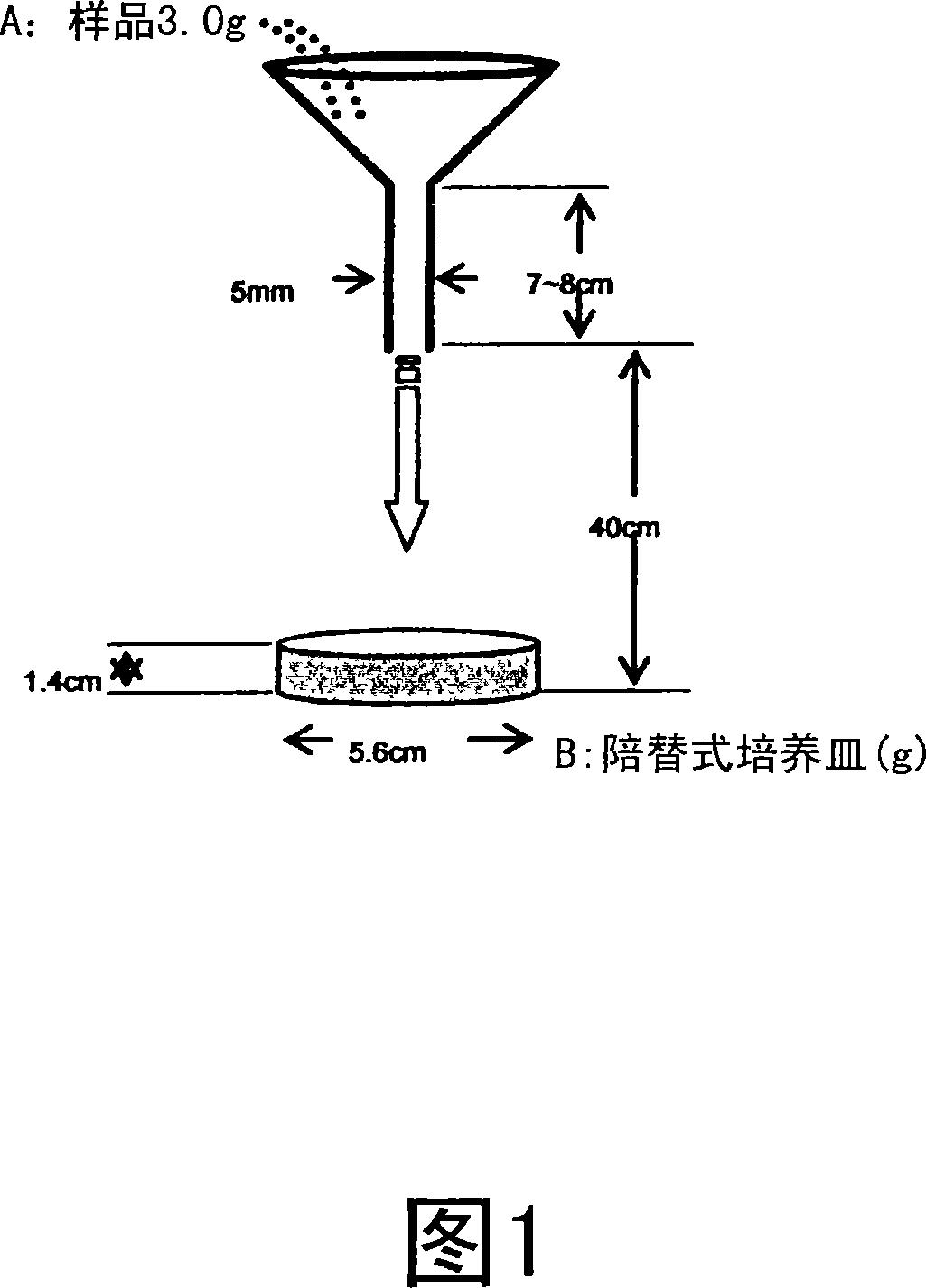

The invention provides a flame retardant composition comprising 1-99 weight parts of a salt of piperazine and an inorganic compound selected from among piperazine phosphate, piperazine pyrophosphate and piperazine polyphosphate, or a mixture of two or more of these piperazine salts (ingredient (A)), 99-1 weight parts of a salt of melamine and an inorganic compound selected from among melamine phosphate, melamine pyrophosphate and melamine polyphosphate, or a mixture of two or more of these melamine salts (ingredient (B) ) (wherein, the sum of ingredient (A) and ingredient (B) is 100 weight parts), 0-50 weight parts of an arbitrary ingredient (ingredient (C)), and 0.01-20 weight parts of a silicone oil having a viscosity at 25° C. of 5000 mm2 / s (ingredient (D)) which is added thereto. This flame retardant not only has superior flame retarding properties, but also has enhanced powder properties and anti-hygroscopic properties, and when it is added to a resin, there is little change of electrical resistance.

Owner:ADEKA CORP

Flame retardant composition having improved processability, flame-retardant synthetic resin composition, and molded article of the flame-retardant synthetic resin composition

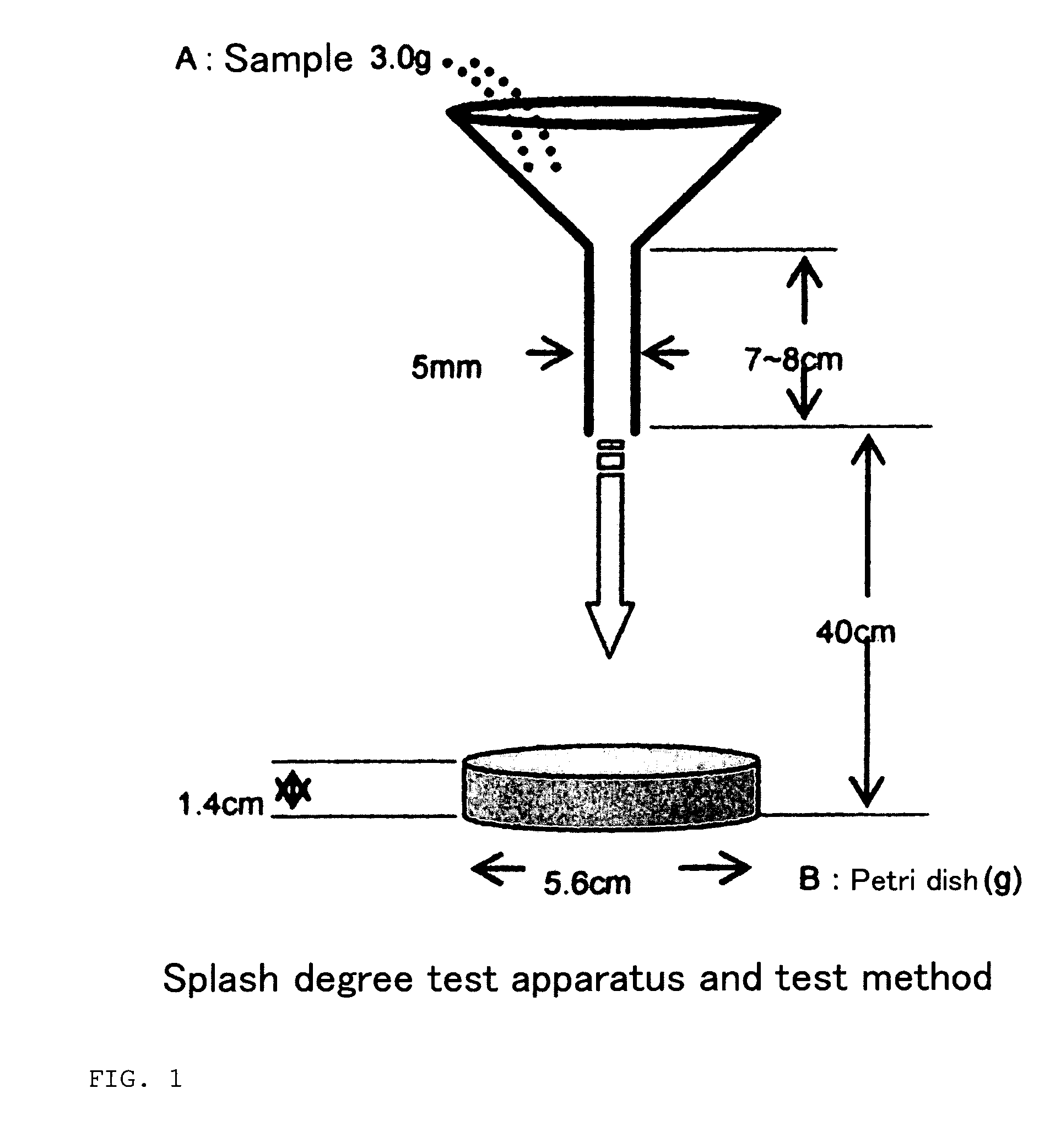

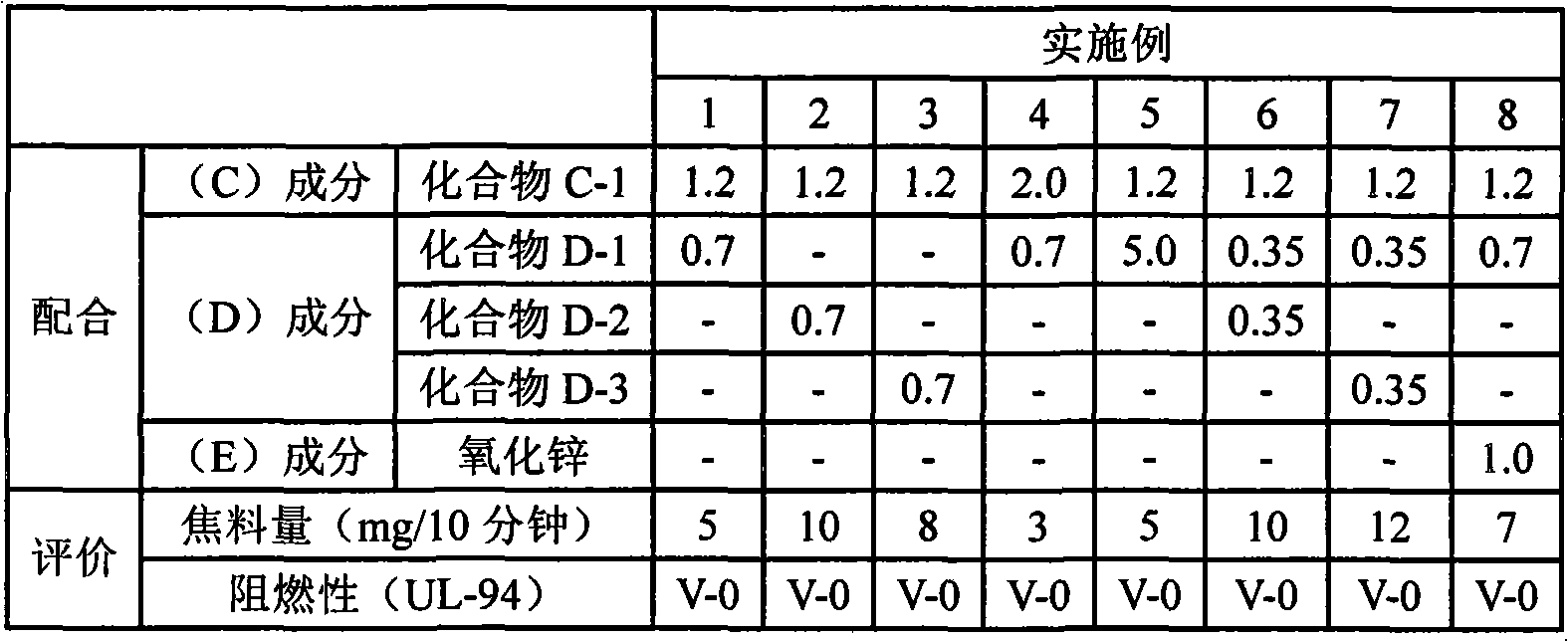

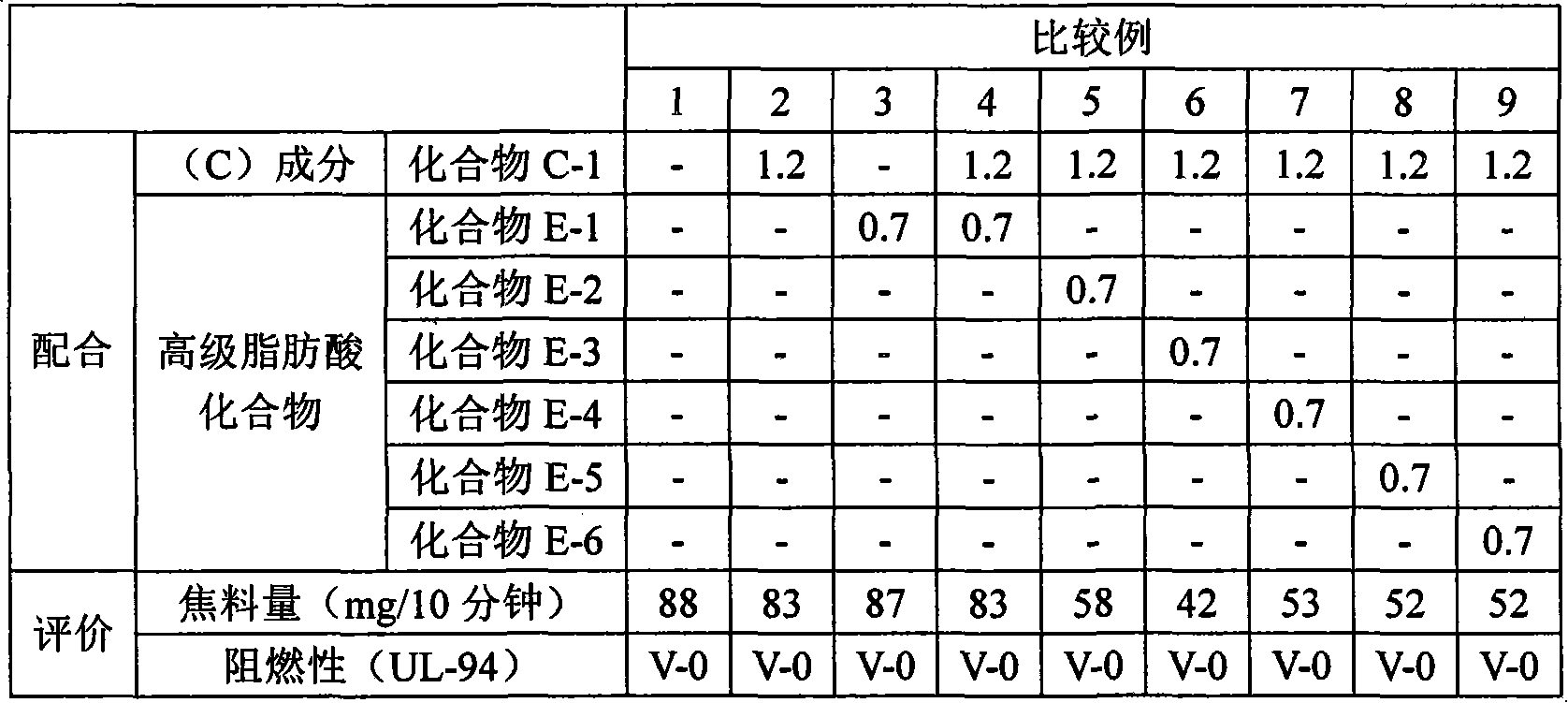

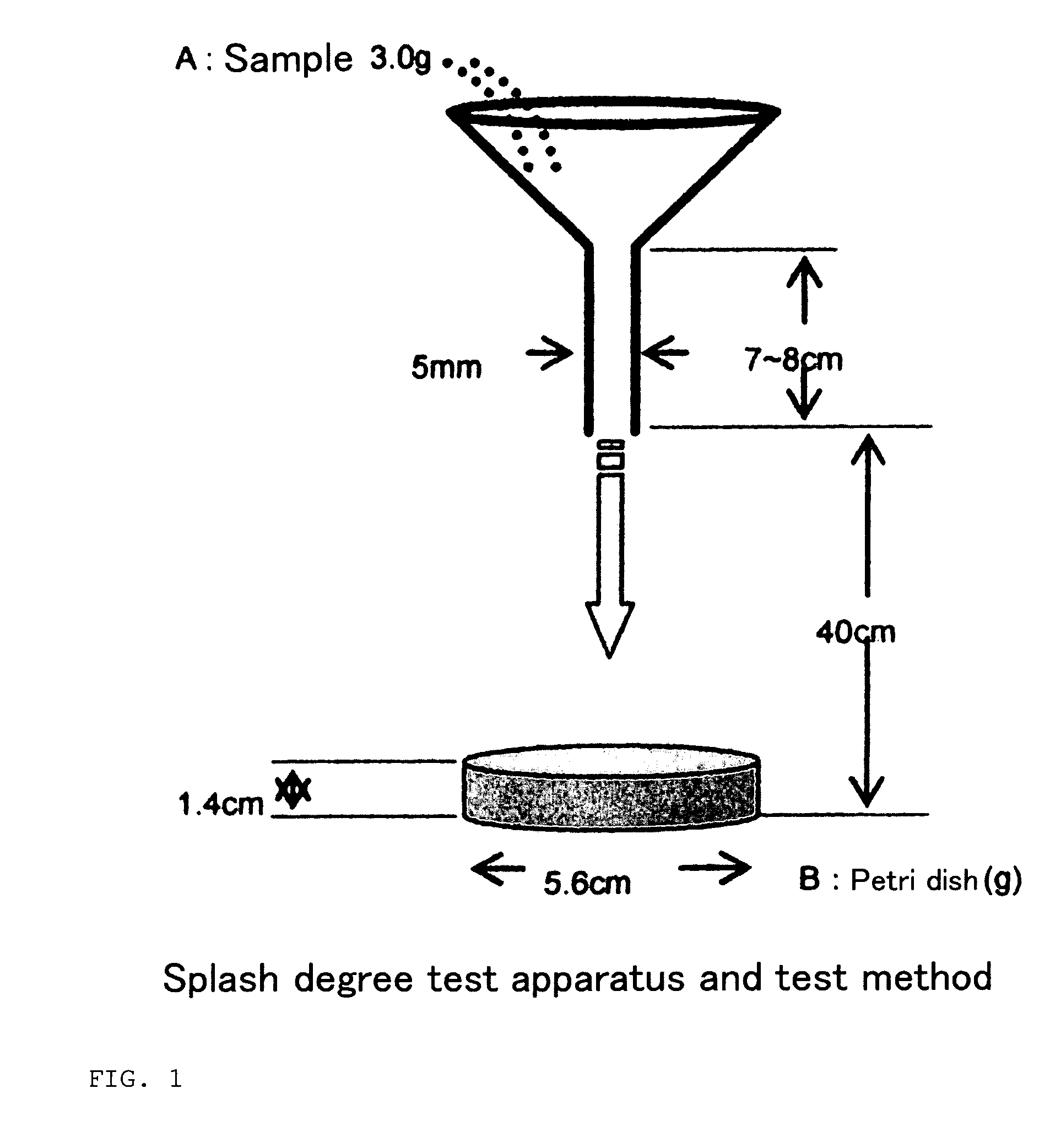

Disclosed is a flame retardant composition which comprises: a flame retardant composition comprising 1 to 99 parts by mass of a salt of piperazine with an inorganic phosphorus compound selected from piperazine phosphate, piperazine pyrophosphate, piperazine polyphosphate and a mixture of two or more of these piperazine salts (component (A)), and 99 to 1 part by mass of a salt of melamine with an inorganic phosphorus compound selected from melamine phosphate, melamine pyrophosphate, melamine polyphosphate and a mixture of two or more of these melamine salts (component (B)) (provided that the total amount of the components (A) and (B) is 100 parts by mass); 0.01 to 10 parts by mass of a silicone oil (component (C)); and 0.01 to 20 parts by mass of a monoester compound (component (D)) produced by reacting a monoamide compound of a higher aliphatic carboxylic acid and / or a higher aliphatic carboxylic acid with a univalent to trivalent alcoholic compound.

Owner:ADEKA CORP

Flame retardant composition having improved processability, flame-retardant synthetic resin composition, and shaped article thereof

InactiveUS20100249286A1Improve processing stabilityAbility to suppress occurrence of “die buildup”Fireproof paintsAlcoholCarboxylic acid

A flame retardant composition contains, with respect to a flame retardant composition containing 1 to 99 parts by mass of a salt of piperazine and an inorganic phosphorus compound (component (A)) selected from piperazine phosphate, piperazine pyrophosphate, piperazine polyphosphate, or a mixture of at least two of the piperazine salts, and 99 to 1 parts by mass of a salt of melamine and an inorganic phosphorus compound (component (B)) selected from melamine phosphate, melamine pyrophosphate, melamine polyphosphate, or a mixture of at least two of the melamine salts (wherein the total of the component (A) and the component (B) is 100 parts by mass): 0.01 to 10 parts by mass of silicone oil; and 0.01 to 20 parts by mass of a monoamide compound of a higher aliphatic carboxylic acid and / or a monoester compound produced by reacting a higher aliphatic carboxylic acid with a monovalent to trivalent alcohol compound.

Owner:ADEKA CORP

Flame retardant composition with improved fluidity, flame retardant resin composition and molded products

ActiveUS7465761B2Improve flame retardant performanceImproved powder property and hygroscopic propertyDyeing processInorganic compoundPiperazine salt

The invention provides a flame retardant composition comprising 1-99 weight parts of a salt of piperazine and an inorganic compound selected from among piperazine phosphate, piperazine pyrophosphate and piperazine polyphosphate, or a mixture of two or more of these piperazine salts (ingredient (A)), 99-1 weight parts of a salt of melamine and an inorganic compound selected from among melamine phosphate, melamine pyrophosphate and melamine polyphosphate, or a mixture of two or more of these melamine salts (ingredient (B)) (wherein, the sum of ingredient (A) and ingredient (B) is 100 weight parts), 0-50 weight parts of an arbitrary ingredient (ingredient (C)), and 0.01-20 weight parts of a silicone oil having a viscosity at 25° C. of 5000 mm2 / s (ingredient (D)) which is added thereto. This flame retardant not only has superior flame retarding properties, but also has enhanced powder properties and anti-hygroscopic properties, and when it is added to a resin, there is little change of electrical resistance.

Owner:ADEKA CORP

Flame retardant composition with enhanced fluidity, flame retardant resin composition and molding thereof

ActiveCN1922260AGood dispersionExcellent resistance to moisture absorptionInorganic compoundPiperazine salt

The invention provides a flame retardant composition comprising 1-99 weight parts of a salt of piperazine and an inorganic compound selected from among piperazine phosphate, piperazine pyrophosphate and piperazine polyphosphate, or a mixture of two or more of these piperazine salts (ingredient (A)), 99-1 weight parts of a salt of melamine and an inorganic compound selected from among melamine phosphate, melamine pyrophosphate and melamine polyphosphate, or a mixture of two or more of these melamine salts (ingredient (B)) (wherein, the sum of ingredient (A) and ingredient (B) is 100 weight parts), 0-50 weight parts of an arbitrary ingredient (ingredient (C)), and 0.01-20 weight parts of a silicone oil having a viscosity at 25 DEG C of 5000mm 2 / s (ingredient (D)) which is added thereto. This flame retardant not only has superior flame retarding properties, but also has enhanced powder properties and anti-hygroscopic properties, and when it is added to a resin, there is little change of electrical resistance.

Owner:ADEKA CORP

Thermoplastic resin composition and molded item formed from same

InactiveUS20120329920A1Improve heat resistanceEasy to processDyeing processPolymer scienceMelamine phosphate

Provided is a thermoplastic resin composition comprising 1 to 100 parts by weight of a flame retardant (B) containing any one or more flame retardants (B-1) selected from melamine phosphate, melamine pyrophosphate, and melamine polyphosphate and any one or more flame retardants (B-2) selected from piperazine phosphate, piperazine pyrophosphate, and piperazine polyphosphate, based on 100 parts by weight of a thermoplastic resin (A) comprising polylactide resin, wherein, according to transmission electronic microscopy, the major axis of the largest particle of the flame retardant (B) in the composition is not more than 10 μm, and the ratio of the number of particles of the flame retardant (B) having a major axis of not more than 3 μm relative to the number of particles of the flame retardant (B) per an area of 1,000 μm2 is 70% or more.

Owner:TORAY IND INC

Halogen-free flame-proofing agent

ActiveUS20100298474A1Improve flame retardant performanceLow water solubilityFireproof paintsTriazine derivativeTriallyl isocyanurate

Halogen-free flame retardant for incorporation into a polymer matrix, wherein the flame retardant contains at least ammonium polyphosphate(s) and / or derivatives thereof and an oligomeric or polymeric 1,3,5-triazine derivative or mixtures of several thereof and at least one compound selected from monozinc phosphate, zinc borate, trizinc phosphate, zinc pyrophosphate, zinc polyphosphate, zinc hydroxystannate, zinc stannate, boron phosphate, monoaluminium phosphate, trialuminium phosphate, aluminium metaphosphate and mixtures thereof, precondensed melamine derivatives, melamine salts and adducts, ethylenediamine phosphate, piperazine phosphate, piperazine polyphosphate, 1,3,5-trihydroxyethyl isocyanurate, 1,3,5-triglycidyl isocyanurate and triallyl isocyanurate.

Owner:CHEM FAB BUDENHEIM AG

Flame-proofed polymer material

ActiveUS20100227952A1Improve flame retardant performanceLow water solubilityFireproof paintsPhosphateTriazine derivative

The invention relates to a polymer material comprising a halogen-free flame-proofing agent incorporated into the polymer matrix, the flame-proofing agent comprising at least ammonium polyphosphate(s) and / or derivatives thereof and an oligomer or polymer 1,3,5-triazine derivative or mixtures of a plurality thereof and at least one compound selected from phosphates, pyrophosphates, polyphosphates, organic and inorganic phosphonates, organic and inorganic phosphinates, stannates, molybdates or borates of the elements of the main groups II, III, IV or of the sub-group elements Fe, Zn, Ti, Mn, Zr, Mo, pre-condensed melamine derivatives, melamine salts and addition compounds, ethylene diamine phosphate, piperazine phosphate, piperazine polyphosphate, 1,3,5-trihydroxyethyl isocyanurate, 1,3,5-triglycidyl isocyanurate and triallyl isocyanurate. The weight ratio of constituents A to constituents B is 10:1 to 1:1, constituents A and B together amounting to between 60 and 99 wt. % and constituents C and D to between 1 and 40 wt. % of the total weight of constituents A, B, C and D. The polymer material is a thermoplastic elastomer (TPE).

Owner:CHEM FAB BUDENHEIM AG

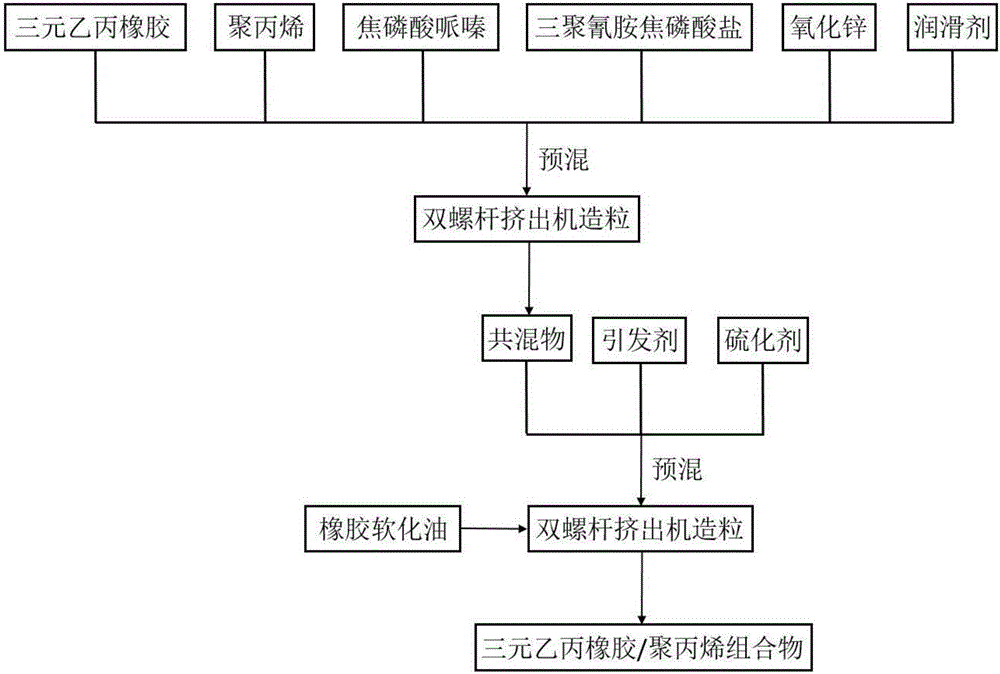

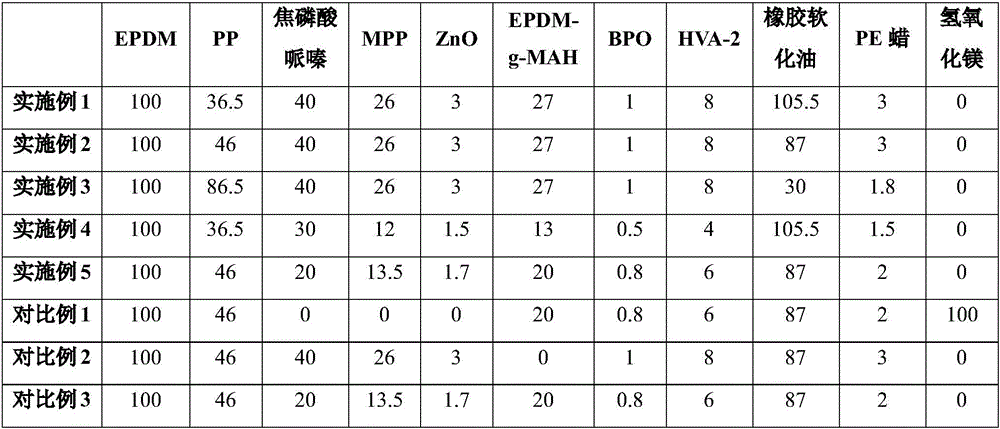

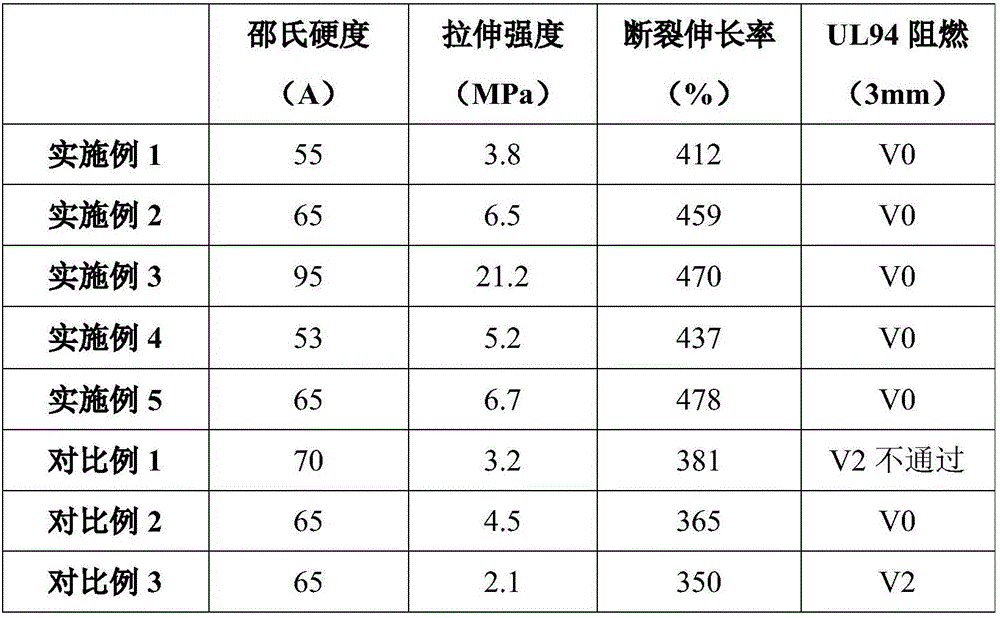

Halogen-free flame-retardation thermoplastic dynamic sulfurated ethylene-propylene-diene monomer rubber/polypropylene composition and preparation method thereof

The invention discloses a halogen-free flame-retardation thermoplastic dynamic sulfurated ethylene-propylene-diene monomer rubber / polypropylene composition and a preparation method thereof. The ethylene-propylene-diene monomer rubber / polypropylene composition is prepared by ethylene-propylene-diene monomer rubber, polypropylene, coked piperazine phosphate, melamine pyrophosphate, zinc oxide, ethylene-propylene-diene-grafted maleic anhydride, an initiator, a vulcanizing agent, rubber softening oil and a lubricant. The preparation method comprises the following steps: 1) mixing EPDM, PP, coked piperazine phosphate, MPP, ZnO, EPDM-g-MAH and the lubricant, and dispersing the materials; 2) performing melt extrusion on a premix obtained in the step 1) and performing granulation on the premix; and 3) mixing the premix, the initiator, the vulcanizing agent and the rubber softening oil, extruding a mixture, and granulating the mixture. The ethylene-propylene-diene monomer rubber / polypropylene composition has the advantages of heat resistance, aging resistance, excellent mechanical property and flame resistance performance, enables thermoplastic processing, has a production process, and can be widely used for wire and cable compounds with high flame-resistance requirements.

Owner:广东省石油化工研究院

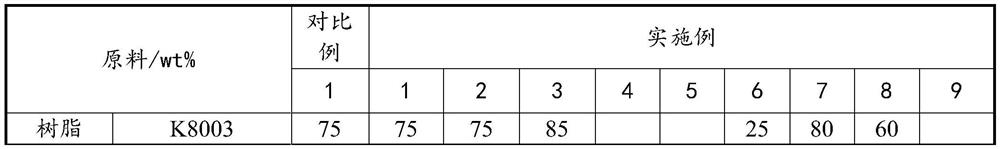

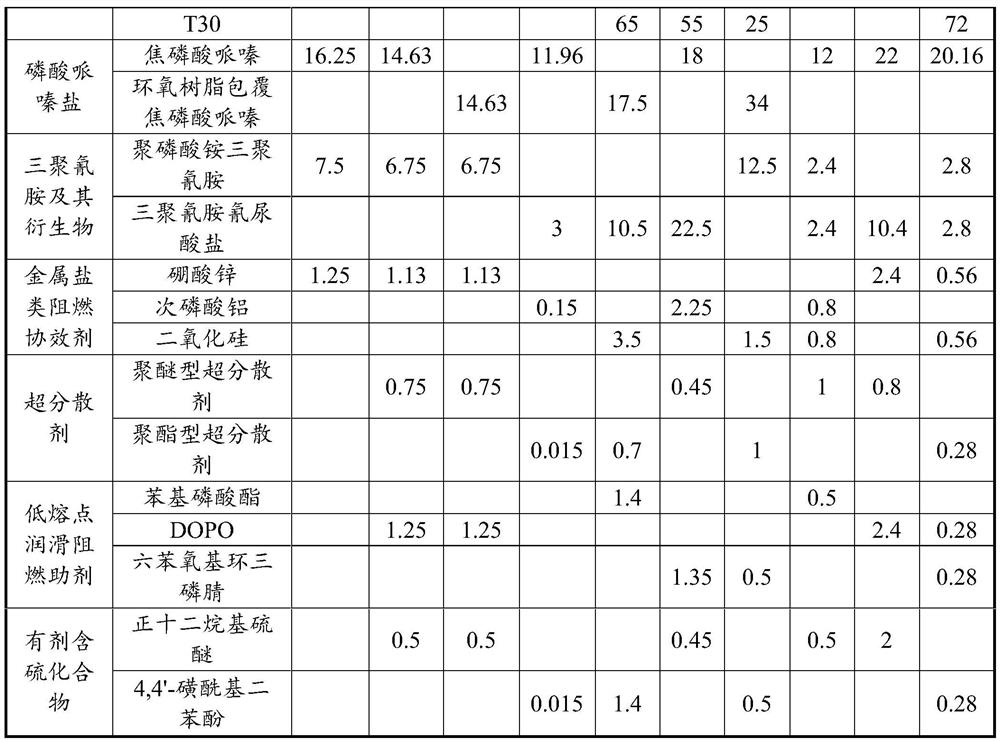

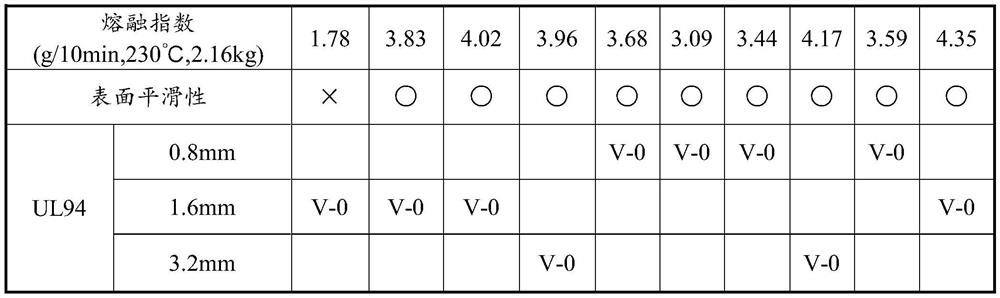

Halogen-free flame retardant and flame-retardant resin composition with good flame retardance and processability

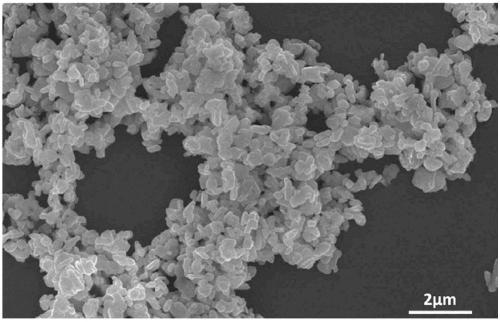

ActiveCN112409693AInhibition of secondary agglomerationImprove featuresPolymer sciencePerylene derivatives

The invention discloses a halogen-free flame retardant with good flame retardance and processability and a flame retardant resin composition. The halogen-free flame retardant with good flame retardance and processability is prepared from piperazine phosphate, melamine and derivatives thereof, a metal salt flame retardant synergist, a hyperdispersant, a low-melting-point lubricating flame retardantadditive and an organic sulfur-containing compound. The flame-retardant resin composition is composed of the halogen-free flame retardant with good flame retardance and processability and resin, andthe mass percent of the halogen-free flame retardant with good flame retardance and processability is 15-50%. The halogen-free flame retardant disclosed by the invention is excellent in flame retardance, relatively good in compatibility and dispersity in resin, smooth in surface of a flame-retardant product, free of white points and high in yield.

Owner:ZHEJIANG XUSEN NON HALOGEN SMOKE FLAME RETARDANT CO LTD

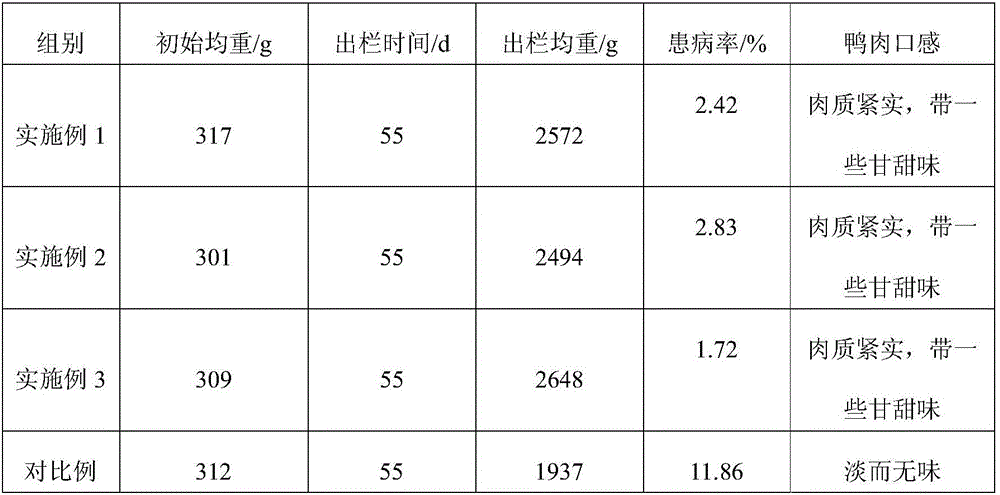

Duck breeding method

InactiveCN106577488AImprove palatabilityAvoid coldBiocideAnimal feeding stuffSilphium perfoliatumPumpkin seed

The invention belongs to the technical field of livestock breeding and particularly relates to a duck breeding method. The duck breeding method comprises the following steps that (1) a duck shed is built; (2) breed ducks are selected; (3) feeding management is carried out, specifically, the breed ducks are fed with feed and supplied with fresh water without limitation, the feed is composed of maize, cooked rice, rice bran, natto, pickles, pork livers, pumpkin seeds, endives, water hyacinth, silphium perfoliatum, bone meal, dead fish, earthworms, calcium gluconate, oysters, blende and piperazine phosphate, and lactein, table salt, multiple vitamins and plantain juice are added to the water; and (4) the duck shed is managed, specifically, the duck shed is sprayed with a disinfectant every morning, and a layer of sand is laid on excrement every evening. The duck breeding method can supplement nutrients for the ducks to achieve balance, promote digestion and absorption of the ducks, provide a clean and sanitary living environment for the ducks, reduce the possibility of illness, and promote quick and healthy growth of the ducks.

Owner:南丹县三丰绿色生态农牧开发有限责任公司

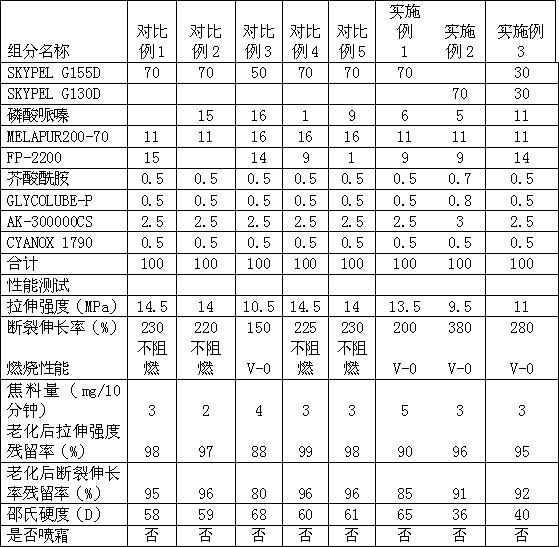

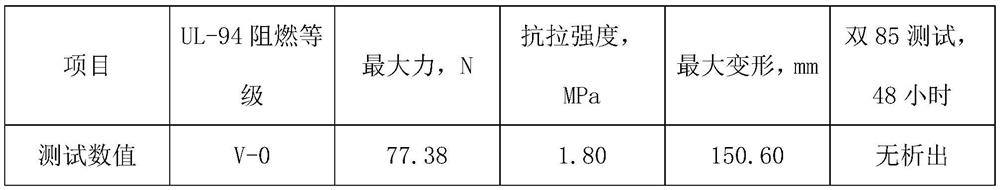

Halogen-free flame-retardant elastomer composition

The invention discloses a halogen-free flame-retardant elastomer composition. The halogen-free flame-retardant elastomer composition comprises the following components in percentage by weight: 15-70% of thermoplastic polyester elastomer, 0-50% of styrene type elastomer and / or polyolefin type elastomer, 25-40% of flame retardant and 2-5% of processing aids, wherein the flame retardant is of a mixture containing piperazine phosphate, melamine phosphate and ammonium polyphosphate. The halogen-free flame-retardant elastomer composition disclosed by the invention can effectively inhibit the precipitation of coke charge during the processing process and improve the processing performances of the composition, has the characteristics of high halogen-free flame-retardant grade, good mechanical properties, good anti-aging performance and easiness in extrusion molding and processing, and is very suitable for power cords, data transmission lines and the like of high-end consumptive electronic and electrical appliances.

Owner:KINGFA SCI & TECH CO LTD +2

High-fluidity anti-separation-out halogen-free flame retardant and preparation method and application thereof

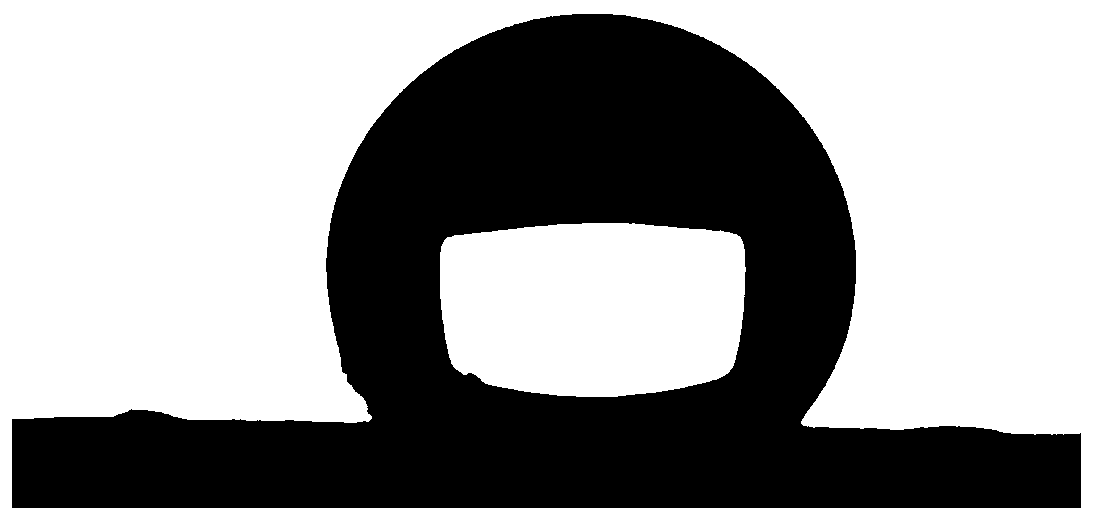

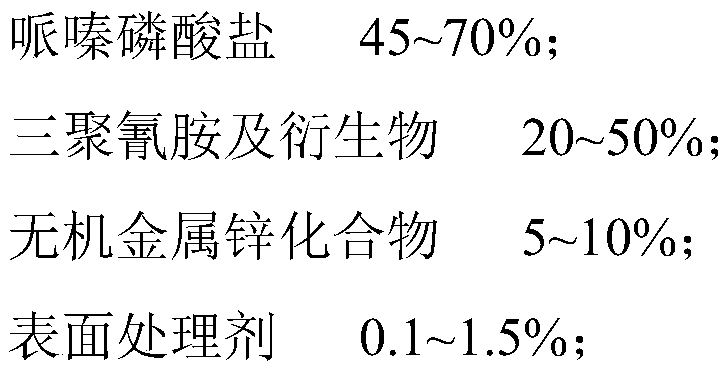

The invention relates to a high-fluidity anti-separation-out halogen-free flame retardant, which comprises the following raw materials by weight: 45-70% of piperazine phosphate, 20-50% of melamine andderivatives thereof, 5-10% of an inorganic metal zinc compound and 0.1%-1.5% of a surface treating agent; wherein the surface treating agent comprises a lubricating agent and a silicone oil substance, and the mass ratio of the lubricating agent to the silicone oil substance is 0.5-1.2; and the silicone oil substance forms a capsule wall outside the powder body of the halogen-free flame retardant.Compared with the prior art, the invention has the advantages of great hydrophobicity, flowability, flame retardancy and the like, and solves the problems of agglomeration, caking and bridging in theprocessing process of the flame retardant powder.

Owner:SHANGHAI RES INST OF CHEM IND

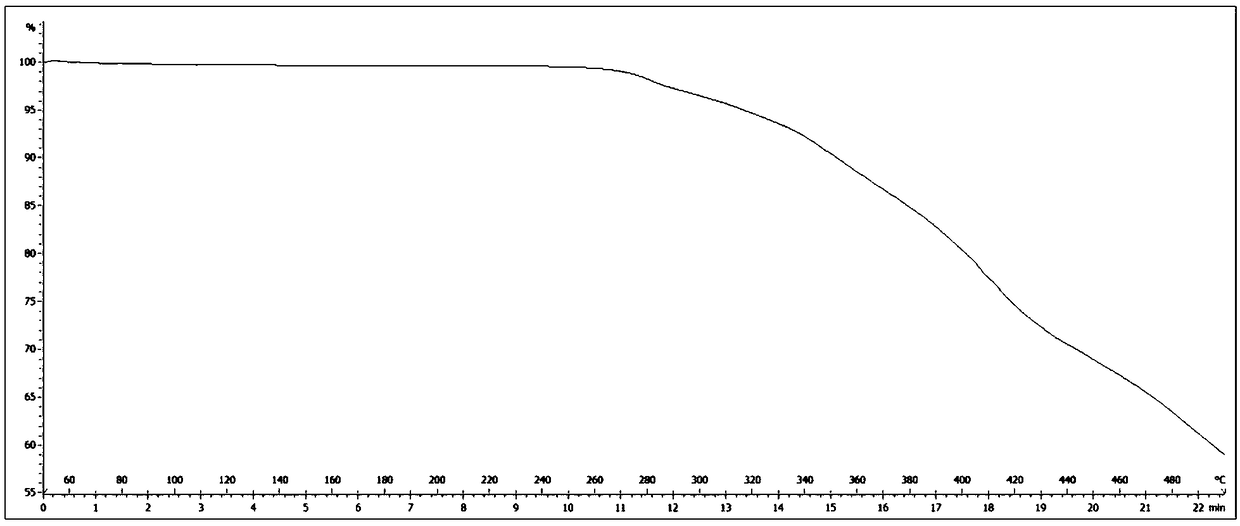

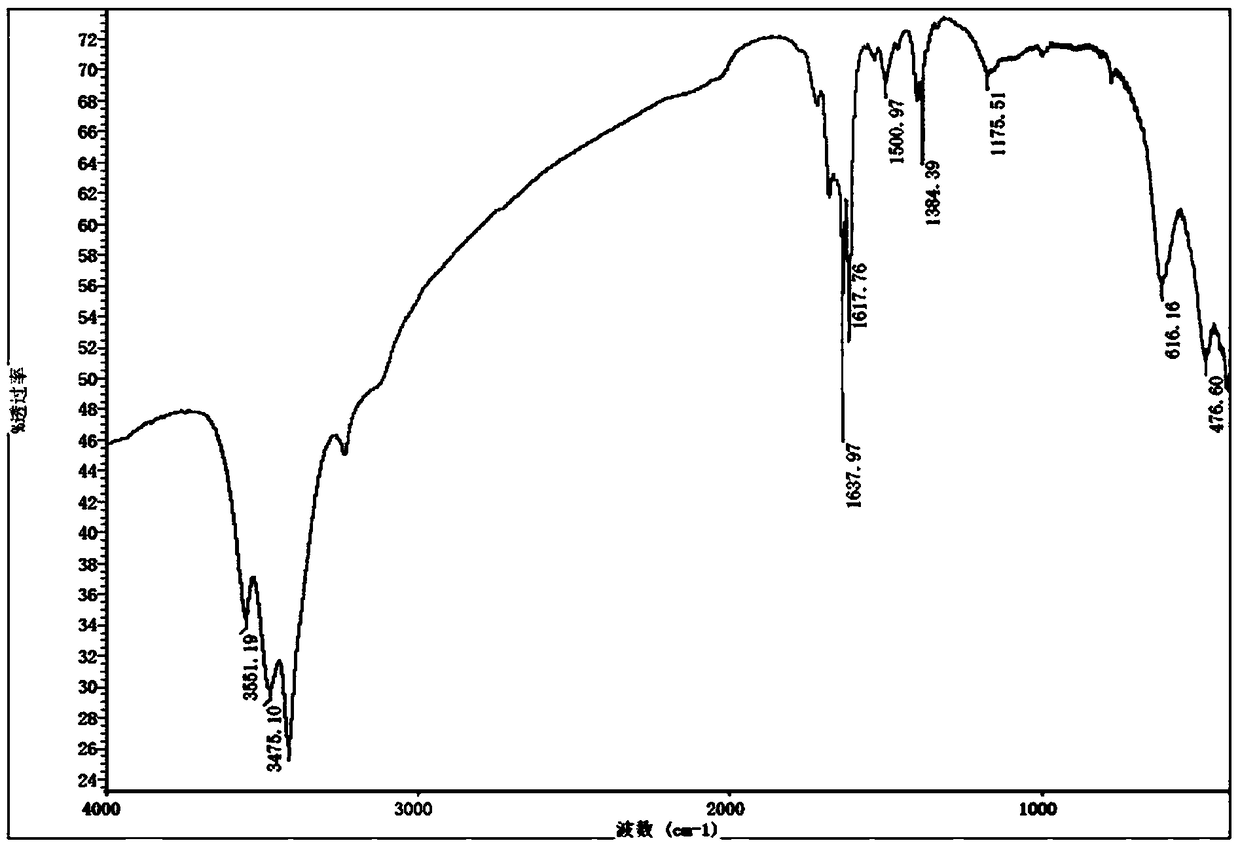

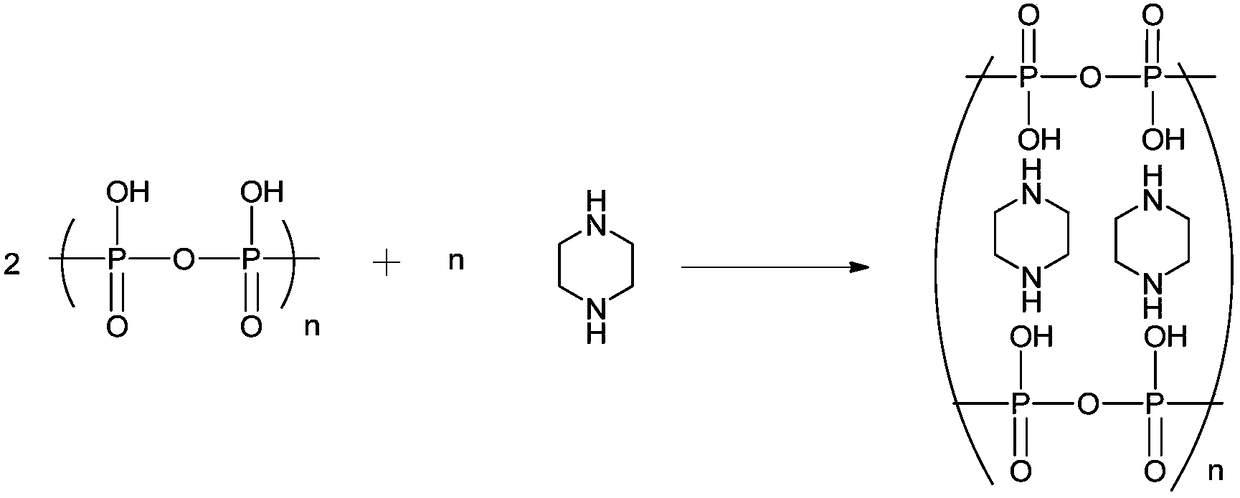

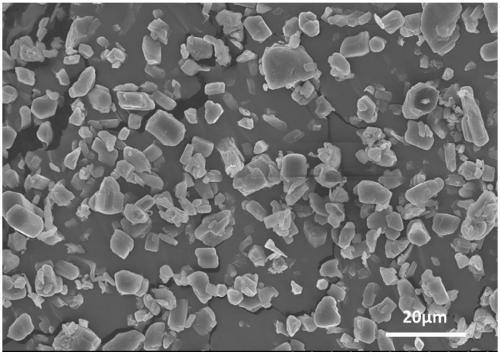

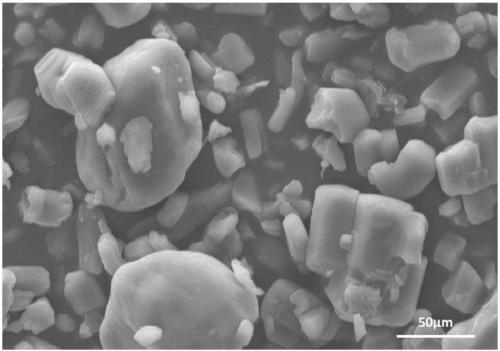

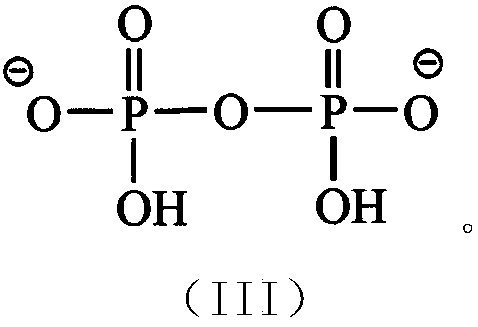

Polyphosphate piperazine and preparation method and application thereof

The invention provides a polyphosphate piperazine and a preparation method and application thereof. The preparation method of the poly piperazine phosphate includes a salt forming step and an aging step, wherein the salt forming step includes stirring piperazine for 5-30 minutes, then slowly adding polyphosphoric acid preheated to 80-100 DEG C, maintaining the temperature at 45-65 DEG C, and stirring and reacting for 0.5-3 hours to obtain a primary product of the polyphosphate piperazine; and the aging step includes vacuumizing to a vacuum degree of 1000-2000 Pa, replacing inert gas for multiple times and maintaining the vacuum degree, continuously stirring and heating to 150-200 DEG C, and maintaining for 1-4 hours to obtain the polyphosphate piperazine.

Owner:HANGZHOU JLS FLAME RETARDANTS CHEM +1

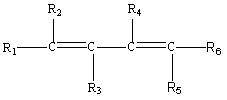

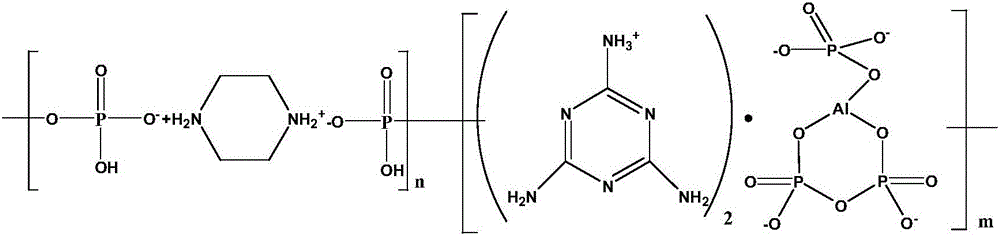

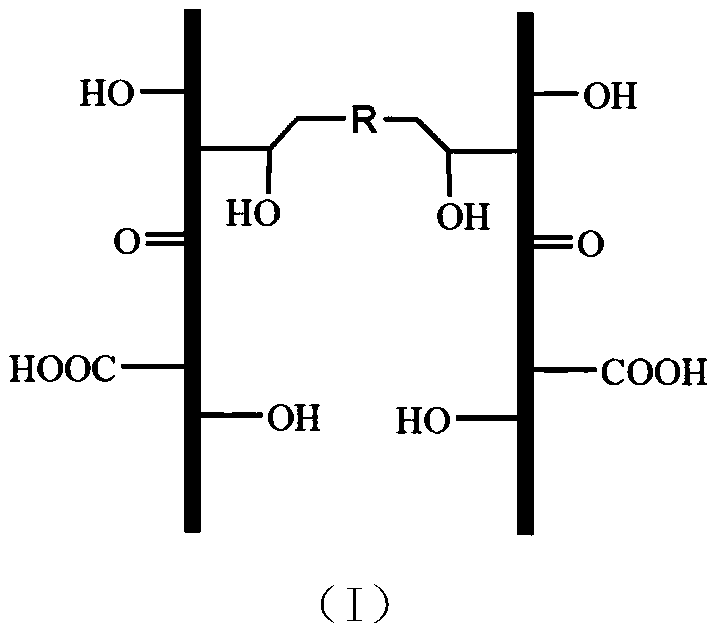

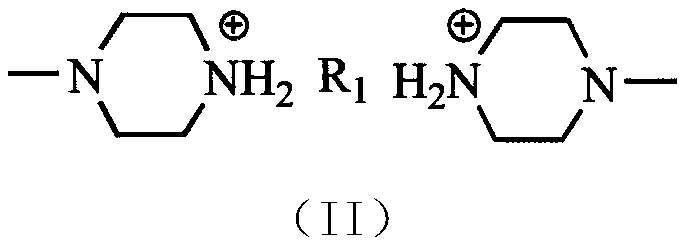

Preparation method of halogen-free intumescent flame retardant composition containing metal ions and formed halogen-free flame retardant polyolefin composition

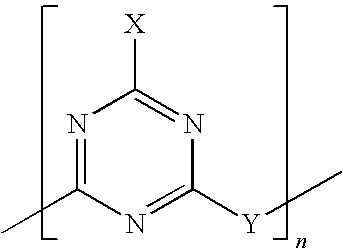

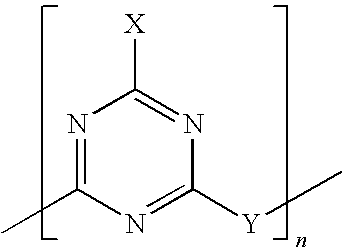

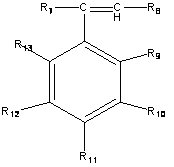

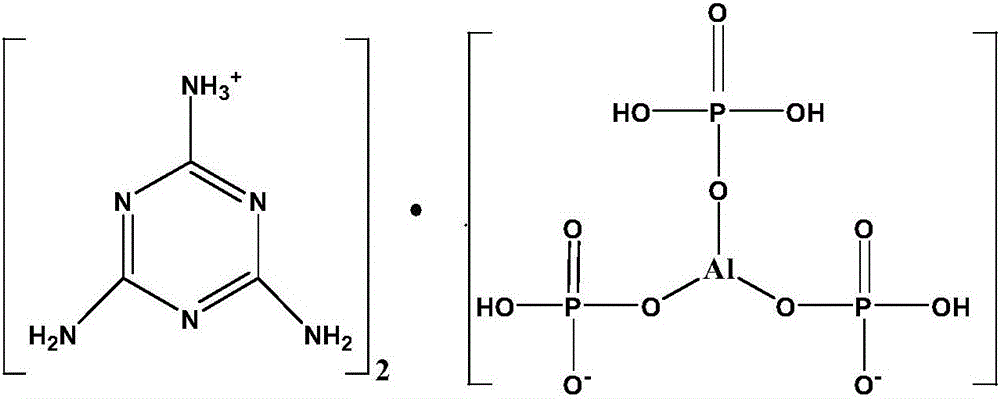

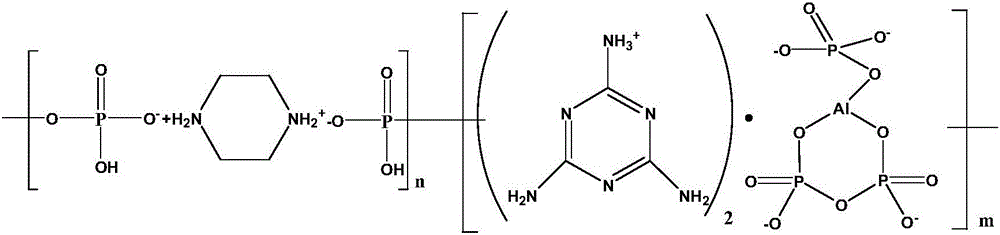

The invention discloses a preparation method of a halogen-free intumescent flame retardant composition containing metal ions, relating to the technical field of intumescent flame retardant polyolefin compositions. The method comprises the steps of (1) weighing diphosphate piperazine and aluminum dihydrogen phosphate dimelamine salt according to the ratio, stirring and mixing evenly in a high-speed stirring mixer to obtain a halogen-free intumescent flame retardant composition premix containing the metal ions, wherein n in the structural general formula is an integer of 0-100, preferably 2-50, and m is an integer of 0-50, preferably 2-10; and (2) carrying out dehydration-condensation reaction on the premix to obtain halogen-free intumescent flame retardant composition containing the metal ions, which comprises poly(charred) piperazine phosphate and polymelamine phosphate aluminum in structure, wherein the synthesis method of the aluminum dihydrogen phosphate dimelamine salt in the step (1) comprises the steps of reacting aluminum dihydrogen phosphate and melamine in a water phase at a certain temperature according to a certain molar ratio for a period of time, carrying out suction filtration, washing and drying.

Owner:广东顺德同程新材料科技有限公司

Halogen-free, flame retardant composition for wire and cable applications

ActiveUS20150155075A1Improve flame retardant performanceLow densityFireproof paintsPlastic/resin/waxes insulatorsMorpholineThermoplastic elastomer

Owner:DOW GLOBAL TECH LLC

Halogen-free, flame retardant composition for wire and cable applications

ActiveUS9336927B2Low densityImprove flame retardant performanceFireproof paintsPlastic/resin/waxes insulatorsMorpholineThermoplastic elastomer

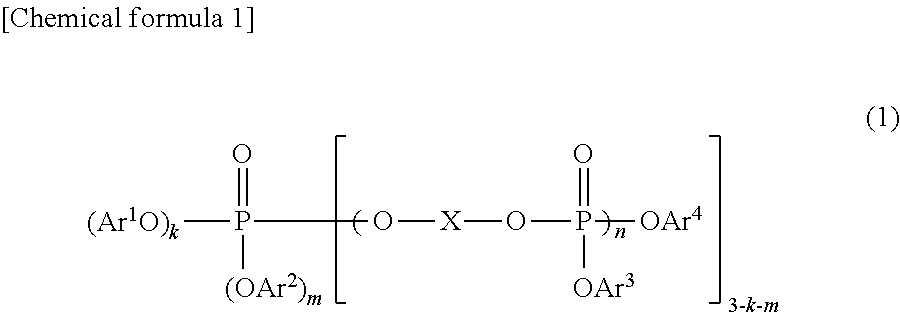

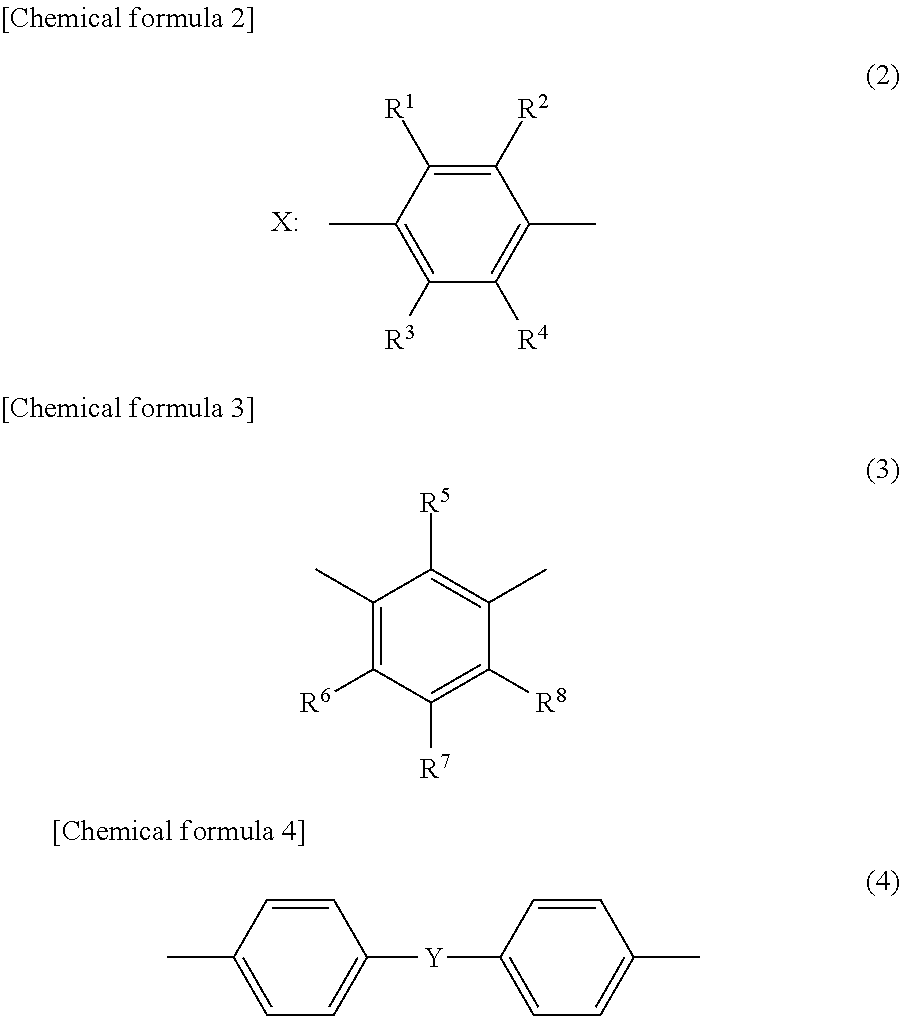

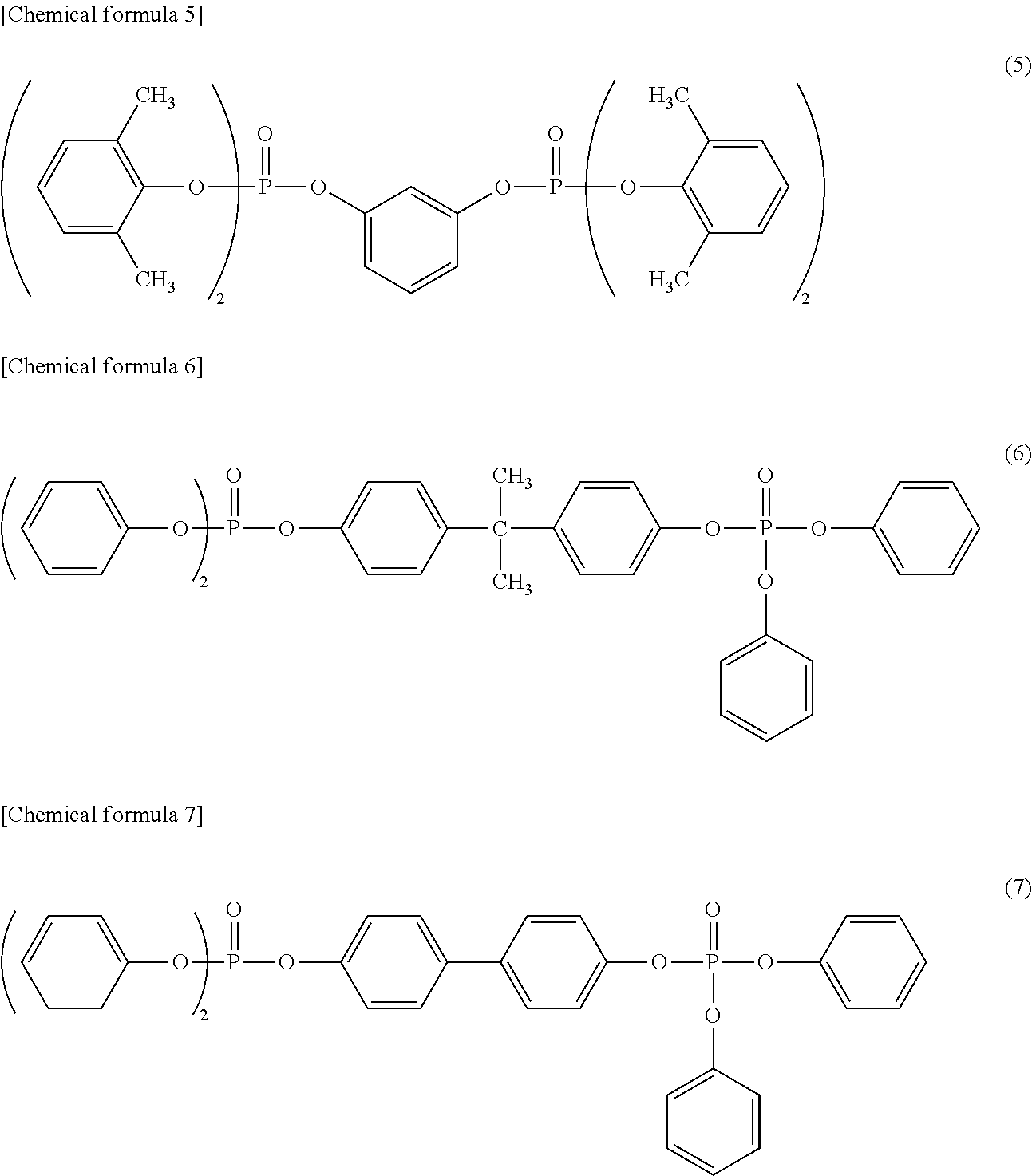

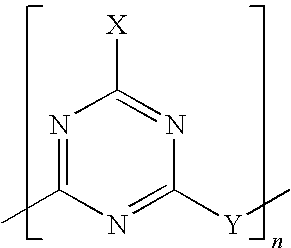

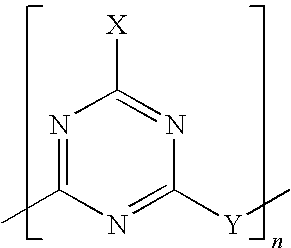

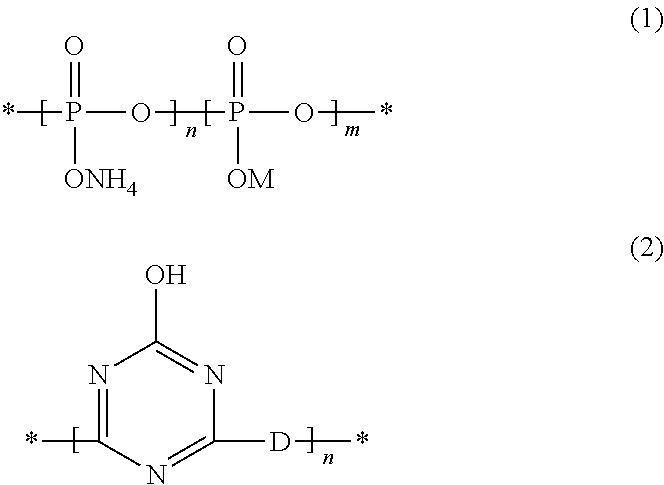

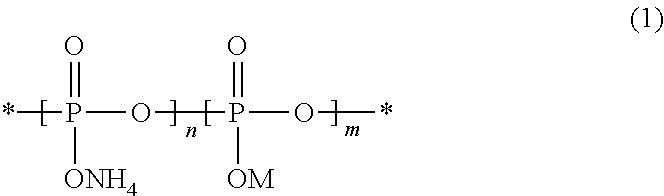

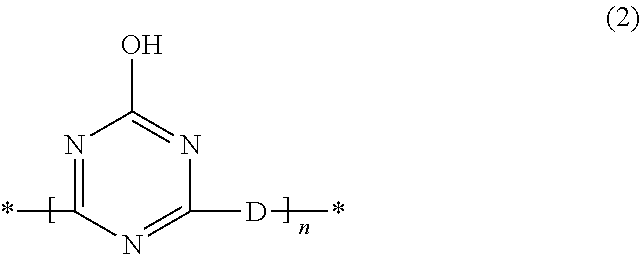

A halogen-free, flame retardant composition comprises: A. A polymer blend comprising: 1. Polypropylene, and 2. Thermoplastic elastomer (TPE) other than the polypropylene of (A)(1), and B. An intumescent flame retardant comprising at least one of: 1. A compound of Formula 1 where M is at least one of melamine, morpholine, piperazine, piperidine, alkyl hydroxyl and a triazine polymer of Formula 2 where D is a heterocyclic or polyamine moiety, and m and n are independently integers the sum (m+n) of which is less than 1000, and 2. A piperazine phosphate.

Owner:DOW GLOBAL TECH LLC

Glass fiber enhanced flame retardant PP material and preparation method thereof

InactiveCN109486021AImprove flame retardant performanceHigh critical radiant fluxGlass fiberMelamine phosphate

The invention relates to a glass fiber enhanced flame retardant PP material which is prepared from the following raw materials in percent by mass: 47-67% of PP resin, 9-29% of a flame retardant, 1-5%of a flame retardant synergist, 5-20% of glass fibers, 5-20% of a glass fiber compatilizer, 0.1-0.6% of an antioxidant and 0.3-1% of a lubricant. The flame retardant is selected from one or more of melamine phosphate, the average grain sizes of which are 0.1-10 [mu]m and piperazine phosphate, the average grain sizes of which are 0.1-10 [mu]m. The flame retardant synergist is selected from one or more of molybdenum disulfide and tungsten disulfide, the average grain sizes of which are 0.1-10 [mu]m. The glass fiber enhanced flame retardant PP material has excellent mechanical properties while keeping efficient flame retardance.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

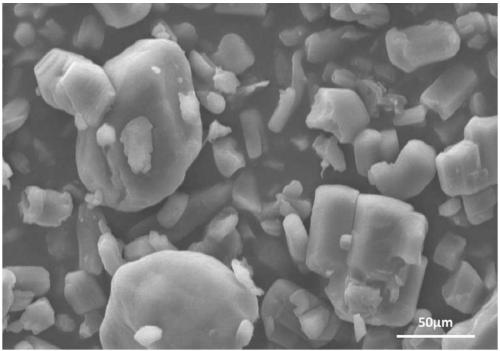

Preparation method of piperazine phosphate

The invention relates to a preparation method of piperazine phosphate. The method includes: fully dissolving phosphoric acid and anhydrous piperazine in an organic solvent, and conducting filtering, salifying the two substances in a reaction kettle under suitable reaction conditions, and after complete reaction, carrying out cooling crystallization, centrifugation, washing, and vacuum drying, thus obtaining the piperazine phosphate. The method provided by the invention employs fewer organic solvent, achieves a yield up to over 90%, the product has high purity, also the process is simple, the operation is easy, the cost is greatly lowered, and the method is easy for industrial production. The piperazine phosphate provided by the invention is often used for treating children's ascaris and pinworm infection.

Owner:江苏黄河药业股份有限公司

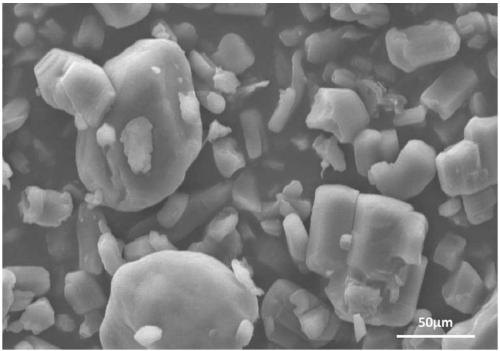

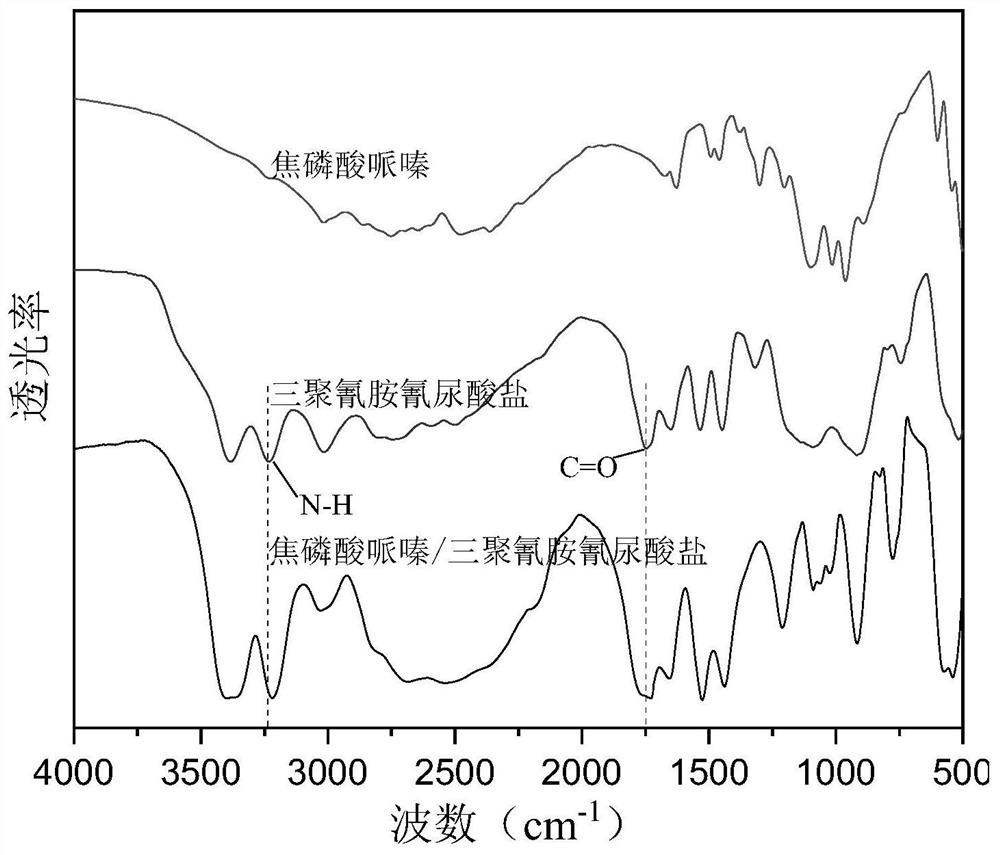

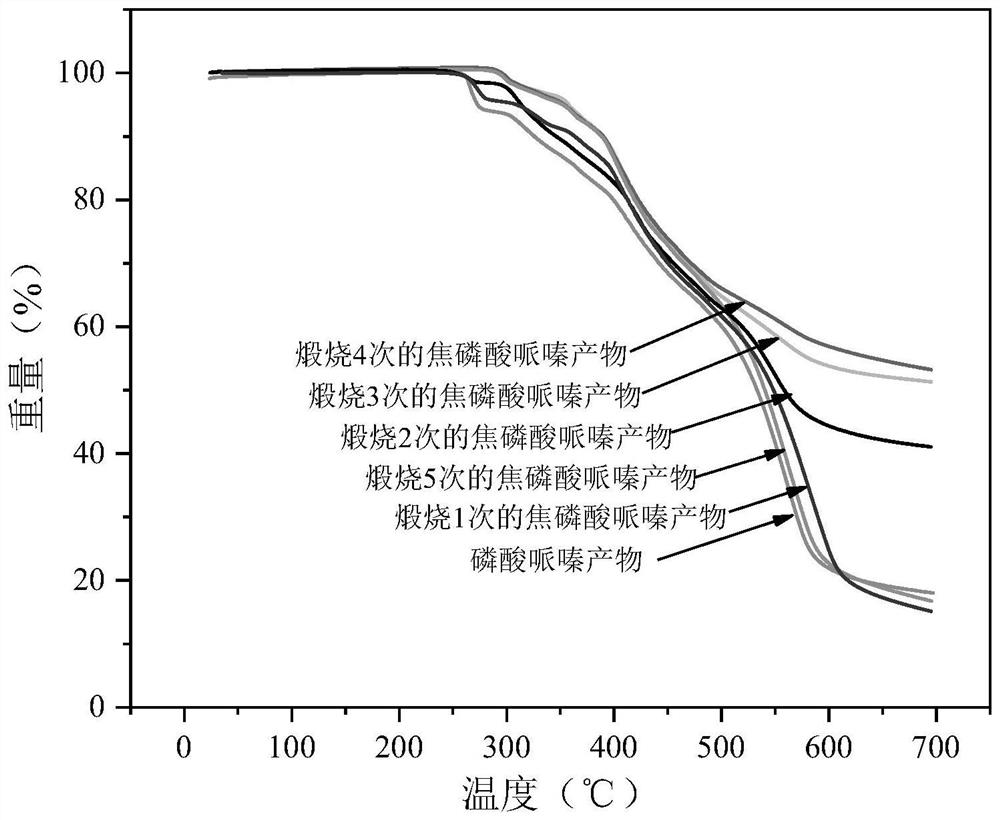

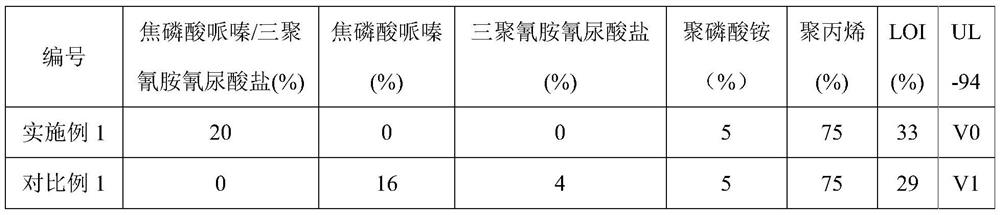

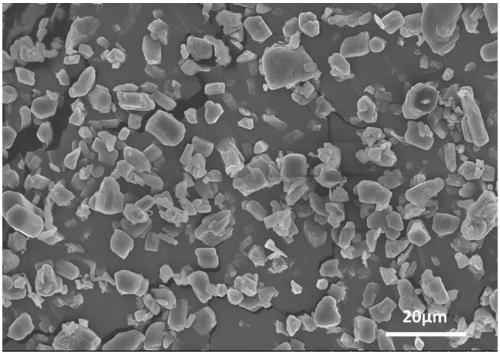

Preparation method of intumescent flame retardant based on piperazine pyrophosphate/melamine cyanurate/ammonium polyphosphate

ActiveCN114015115AIncrease productivityRealize continuous productionPolymer sciencePyrophosphoric acid

The invention relates to a preparation method of an intumescent flame retardant based on piperazine pyrophosphate / melamine cyanurate / ammonium polyphosphate. The preparation method comprises the following specific preparation steps of: preparing piperazine phosphate; preparing piperazine pyrophosphate; preparing a piperazine pyrophosphate / melamine cyanurate flame retardant system; and preparing a piperazine pyrophosphate / melamine cyanurate / ammonium polyphosphate compound intumescent flame retardant.

Owner:SHENYANG POLYTECHNIC UNIV

Inorganic material filled flame retardant PP material and preparation method thereof

InactiveCN109486022AImprove flame retardant performanceHigh critical radiant fluxMelamine phosphatePhosphate

The invention relates to an inorganic material filled flame retardant PP material which is prepared from the following raw materials in percent by mass: 57-77% of PP resin, 9-29% of a flame retardant,1-5% of a flame retardant synergist, 3-20% of inorganic material filler, 0.1-0.6% of an antioxidant and 0.3-1% of a lubricant. The flame retardant is selected from one or more of melamine phosphate,the average grain sizes of which are 0.1-10 [mu]m and piperazine phosphate, the average grain sizes of which are 0.1-10 [mu]m. The flame retardant synergist is selected from one or more of molybdenumdisulfide and tungsten disulfide, the average grain sizes of which are 0.1-10 [mu]m. The inorganic material filled flame retardant PP material has efficient flame retardance.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

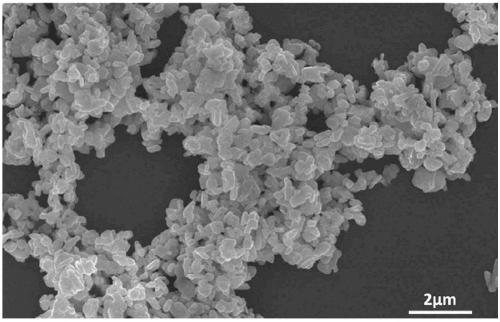

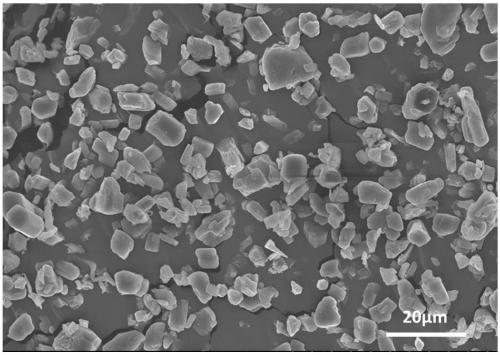

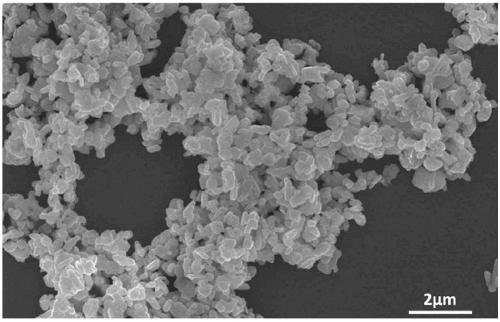

Graphene/piperazine pyrophosphate nano composite and preparation method thereof

InactiveCN108947936AAvoid the restore stepSolve the problem of fragmentationOrganic chemistryHeat-exchange elementsEpoxyPhosphoric acid

The invention discloses a graphene / piperazine pyrophosphate nano composite and a preparation method thereof. The preparation method comprises the following steps: reacting and grafting piperazine andan epoxy functional group onto graphene oxide GO, adding phosphoric acid to form piperazine phosphate, and finally performing high temperature dehydration, thereby obtaining the graphene / piperazine pyrophosphate nano composite. Due to the existence of graphene, the graphene / piperazine pyrophosphate nano composite disclosed by the invention has excellent flame retardant efficiency and thermal conductivity, and the preparation method is that the graphene oxide GO is introduced into the synthetic process of piperazine pyrophosphate, so that the dispersion problem of the nanometer material is effectively solved. Meanwhile, by utilizing alkalinity of piperazine and strong acid (phosphoric acid) dehydration as well as high-temperature conditions, the graphene oxide GO is reduced, the reduction step in the graphene preparation process is effectively avoided, and the graphene / piperazine pyrophosphate nano-composite is efficiently prepared in an environment-friendly manner at low cost and has excellent industrialization application prospects.

Owner:安徽融英新材料科技有限公司

Flame retardant waterborne polyurethane resin

The invention discloses flame retardant waterborne polyurethane resin which comprises a component A and a component B. The component A is prepared from the following ingredients in parts by weight: 30-50 parts of diethylene glycol phthalic anhydride polymer, 40-60 parts of polybutylene glycol, 15-30 parts of diphenylmethane diisocyanate, 5-10 parts of chain extender, 2-5 parts of triethylamine, 1-2 parts of dibutyltin dilaurate, and 300-500 part of water. The component B is prepared from the following ingredients in parts by weight: 10-20 parts of melamine polyphosphate, 20-30 parts of piperazine phosphate, 10-20 parts of piperazine pyrophosphate, 10-20 parts of tetraphenyl pyrophosphate, 30-40 parts of halogen alkyl phosphate, and 10-20 parts of bisphenol A phosphate. The weight mixing ratio of the component A to the component B is 1:(0.5-1). The flame retardant waterborne polyurethane resin, disclosed by the invention, is high in flame retardance and high in film-forming property.

Owner:苏州博莱特新材料有限公司

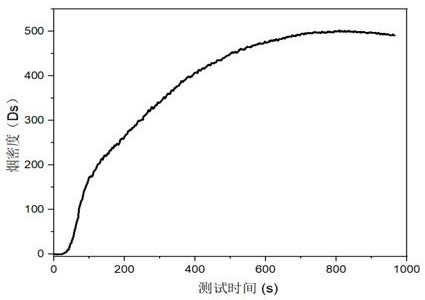

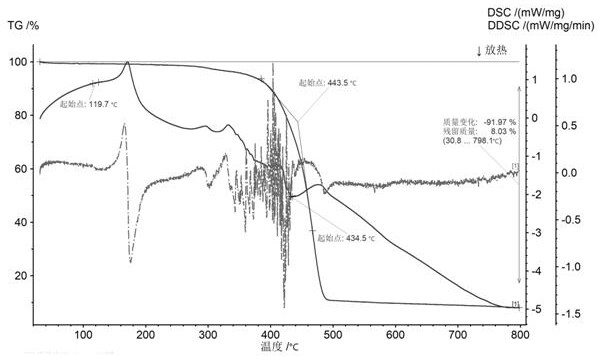

Tin-phosphorus-nitrogen intumescent flame-retardant polypropylene composite material and preparation method thereof

PendingCN114031850AHigh char formationReduce smoke productionPolypropylene compositesMelamine phosphate

The invention discloses a tin-phosphorus-nitrogen intumescent flame-retardant polypropylene composite material which comprises the following components in percentage by mass: 55-80% of polypropylene, 18-40% of a phosphorus-nitrogen intumescent flame retardant, 0.1-10% of a tin-based flame-retardant smoke suppressant, 0.5-1% of an antioxidant, 0.3-2% of an anti-dripping agent, 0.3-1% of a lubricant and 0.2-2% of a silane coupling agent, wherein the phosphorus-nitrogen intumescent flame retardant is prepared from a piperazine phosphate flame retardant, a melamine phosphate flame retardant and a charring agent. The phosphorus-nitrogen intumescent flame retardant and the tin-based flame-retardant smoke suppressant are compounded for use, the charring performance of the material is greatly improved, flame spreading is prevented, and the tin-based flame-retardant smoke suppressant is added, so that the tin-based flame-retardant smoke suppressant is used as a flame-retardant synergist, and meanwhile, the smoke generation amount during material combustion is effectively reduced. According to the tin-phosphorus-nitrogen intumescent flame retardant, the defects that an existing phosphorus-nitrogen flame retardant is large in adding amount, low in flame retardant efficiency, poor in smoke suppression performance and the like are overcome, and the adverse effect of the flame retardant on the mechanical performance of a resin matrix is reduced.

Owner:云南锡业集团(控股)有限责任公司研发中心

Silicone rubber halogen-free flame retardant as well as preparation method and application thereof

ActiveCN114539618AHigh flame retardant efficiencyOvercoming the problem of easy precipitationPolymer scienceZinc borate

The invention relates to the technical field of flame retardants, in particular to a silicone rubber halogen-free flame retardant and a preparation method and application thereof.The silicone rubber halogen-free flame retardant is prepared from, by weight, 10-60 parts of piperazine pyrophosphate, 10-60 parts of melamine cyanurate, 1-20 parts of diethyl aluminum hypophosphite, 1-10 parts of zinc borate and 0.5-8 parts of a modification treatment agent; the modification treating agent comprises at least one of vinyl silicone oil, hydroxyl silicone oil, hydrogen-containing silicone oil, a silane coupling agent KH570 or a silicone oil dispersing agent; the flame retardant is prepared from piperazine phosphate, melamine cyanurate, aluminum diethyl hypophosphite and zinc borate according to certain parts by weight, belongs to a phosphorus-nitrogen flame retardant, is high in flame retardant efficiency, and can be used for flame retardance of ultrathin materials; meanwhile, the problem that the flame retardant is easy to separate out is well solved, a silicone rubber product which is flame-retardant by using the flame retardant is good in heat resistance, and the materials for forming the flame retardant are materials which are industrially produced in batches.

Owner:东莞市宏泰基阻燃材料有限公司

Dyeing and finishing process for garment materials

InactiveCN105350290AGood antibacterialImprove mildew resistanceBiochemical treatment with wool-protecting/anti-moth agentsHeat resistant fibresEthylenediamineCoconut diethanolamide

The invention discloses a dyeing and finishing process for garment materials. The process comprises the following steps: 1) preprocessing; 2) dyeing; 3) finishing: sequentially putting 1 to 2 parts by weight of polyvinylpyrrolidone, 1.4 parts by weight of sodium pyrophosphate, 1.1 parts by weight of cinnamon oil and 0.9 parts by weight of schisantherin into 25 parts by mass of deionized water, and uniformly stirring; simultaneously putting 1.3 parts by weight of sandalwood powder, 0.7 parts by weight of piperazine phosphate, 1.3 parts by weight of coconut diethanolamide and 0.7 parts by weight of hydroxyethyl ethylenediamine into the mixture, continuously stirring, till being fully uniformly mixed, so that finishing liquor is prepared; then enabling the garment materials to be subjected to padding treatment in the finishing liquor, taking the garment materials out, and drying at a constant temperature. By adopting the dyeing and finishing process for the garment materials, the dyed and finished garment materials have the excellent performances of being antibacterial, mildew-proof, mothproof, flame retardant and antistatic, are strong in washability and soft in hand feel.

Owner:常熟市庄丹奴服饰有限公司

Flame retardant composition and flame-retardant resin composition containing same

ActiveUS20200115634A1Reduce dustImprove flame retardant performanceFireproof paintsPolymer scienceMelamine phosphate

A flame retardant composition containing a piperazine phosphate, a melamine phosphate, and an oil having a siloxane bond and a specific gravity of 0.930 to less than 0.970 at 25° C. The oil is present in an amount of 0.01 to 5 parts by mass per 100 parts by mass of the sum of the piperazine phosphate and the melamine phosphate. The flame retardant composition preferably further contains 0.01 to 5 parts by mass, per 100 parts by mass of the sum of the piperazine phosphate and the melamine phosphate, of a methylhydrogen silicone oil having hydrogen as part of the side chains of polysiloxane and a specific gravity of 0.970 to less than 1.01 at 25° C.

Owner:ADEKA CORP

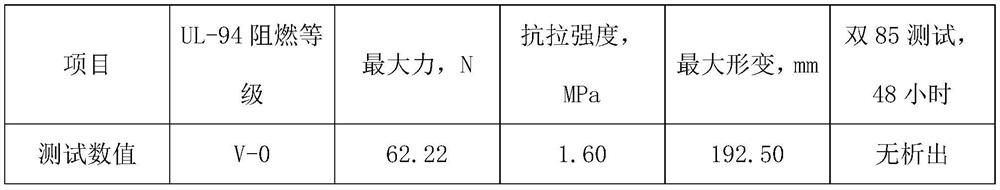

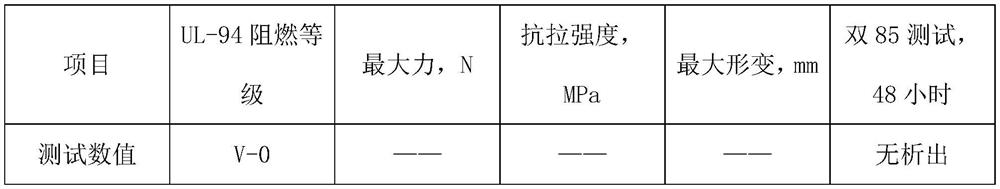

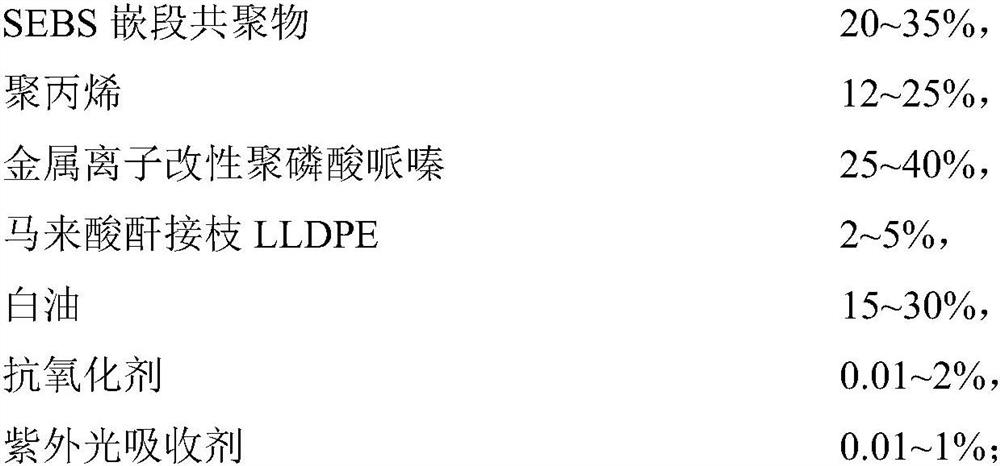

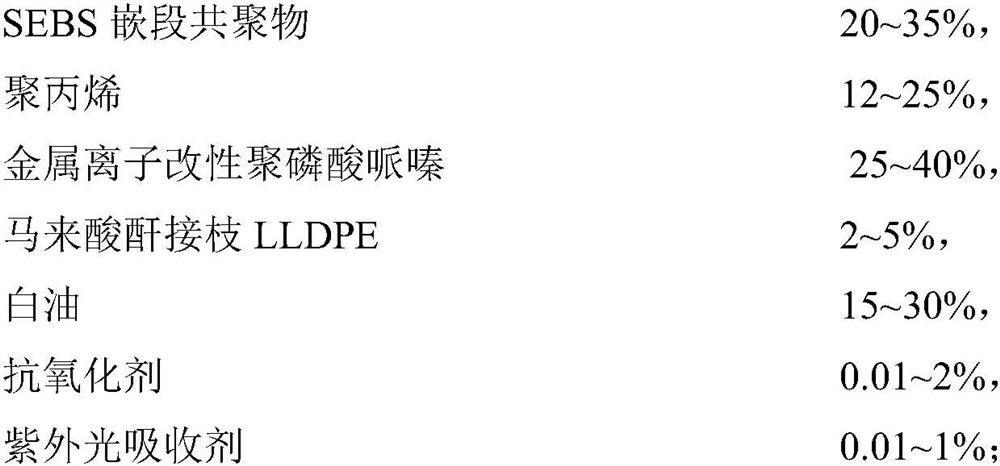

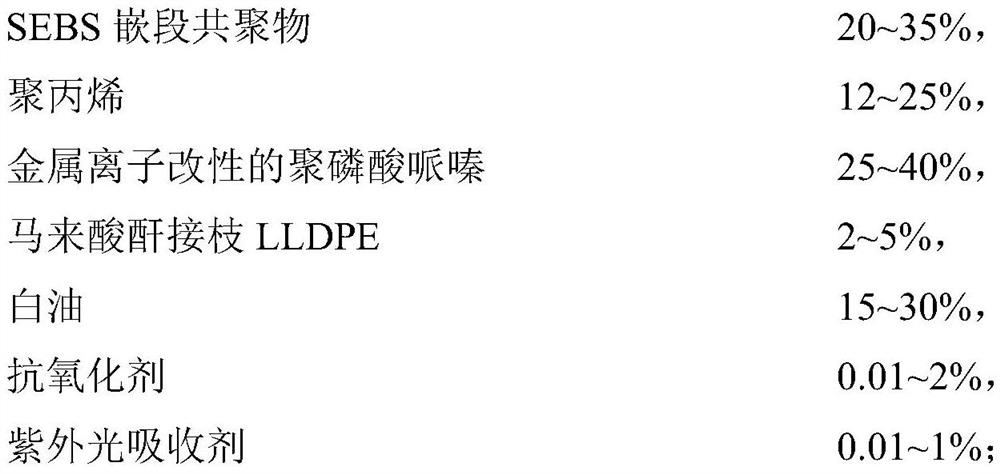

Ultraviolet-yellowing-resistant halogen-free flame-retardant thermoplastic elastomer composition and preparation method thereof

The invention discloses an ultraviolet-yellowing-resistant halogen-free flame-retardant thermoplastic elastomer composition and a preparation method thereof. The preparation method comprises the following steps: stirring polyphosphoric acid, piperazine and a metal salt according to a specific ratio to obtain a metal ion modified piperazine phosphate halogen-free flame retardant, conducting treatment with a coupling agent, and adding SEBS, PP and maleic anhydride grafted LLDPE to form the halogen-free intumescent flame-retardant composition with excellent ultraviolet yellowing resistance. The composition retains excellent mechanical properties and flame retardancy at the same time, especially greatly improves the yellowing resistance, and meets the requirements of current electronic products on halogen-free flame-retardant plastics.

Owner:HANGZHOU JLS FLAME RETARDANTS CHEM

Flame-retardant PP material and preparation method thereof

InactiveCN109627593AImprove flame retardant performanceHigh critical radiant fluxPolymer scienceMelamine phosphate

The invention relates to a flame-retardant PP material and a preparation method thereof. The flame-retardant PP material is prepared from, by mass, 57-87% of PP resin, 9-39% of a flame retardant, 1-5%of a flame-retardant synergist, 0.1-0.6% of an antioxidant and 0.3-1% of a lubricant; the flame retardant is selected from one or more of melamine phosphate with the average particle size of 0.1-10 microns and piperazine phosphate with the average particle size of 0.1-10 microns; the flame-retardant synergist is selected from one or more of molybdenum disulfide and tungsten disulfide with the average particle size of 0.1-10 microns. The flame-retardant PP material has efficient flame retardant properties.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

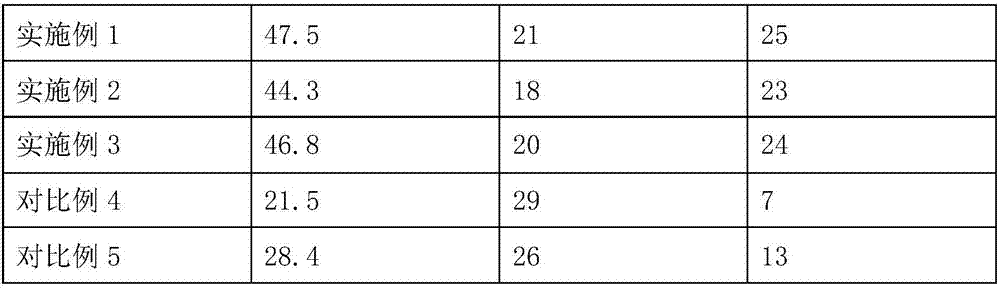

Piperazine phosphate controlled-release agent and preparation method thereof

InactiveCN107213133ASlow degradationExtension of timeOrganic active ingredientsPharmaceutical non-active ingredientsControlled releaseInsect repellent

The invention belongs to the field of biological medicines and particularly relates to a piperazine phosphate controlled-release agent and a preparation method thereof. The invention provides a piperazine phosphate controlled-release agent and a preparation method thereof for the problem that an existing piperazine phosphate table is too fast in release and poor in insect repellent effect. The method comprises the steps of (a) mixing piperazine phosphate powder and oligosaccharide at the weight ratio of (3-5):(1-2) evenly, adding edible gelatine which accounts for 3-5wt% of weight of the raw materials, adding water until the moisture content is 5-8 and mixing evenly to obtain a material A; (b) tabletting the material A to prepare a uniform tablet; (c) weighing the raw materials in parts by weight: 10-20 parts of a polycation electrolyte, 10-20 parts of a polyanion electrolyte, 30-35 parts of a small molecule crosslinking agent and 5-10 parts of oligosaccharide, mixing evenly and then adding water to prepare 0.01-0.02g / ml of solution; and (d) spraying the solution obtained in the step (c) on the surface of the tablet obtained in the step (b) and drying to form a coating membrane to prepare the piperazine phosphate controlled-release agent. The controlled-release agent is capable of prolonging the action time in an intestinal tract and strengthening the insect repellent effect and is suitable for promotion and use.

Owner:江苏黄河药业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com