Patents

Literature

234 results about "Electronic microscopy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

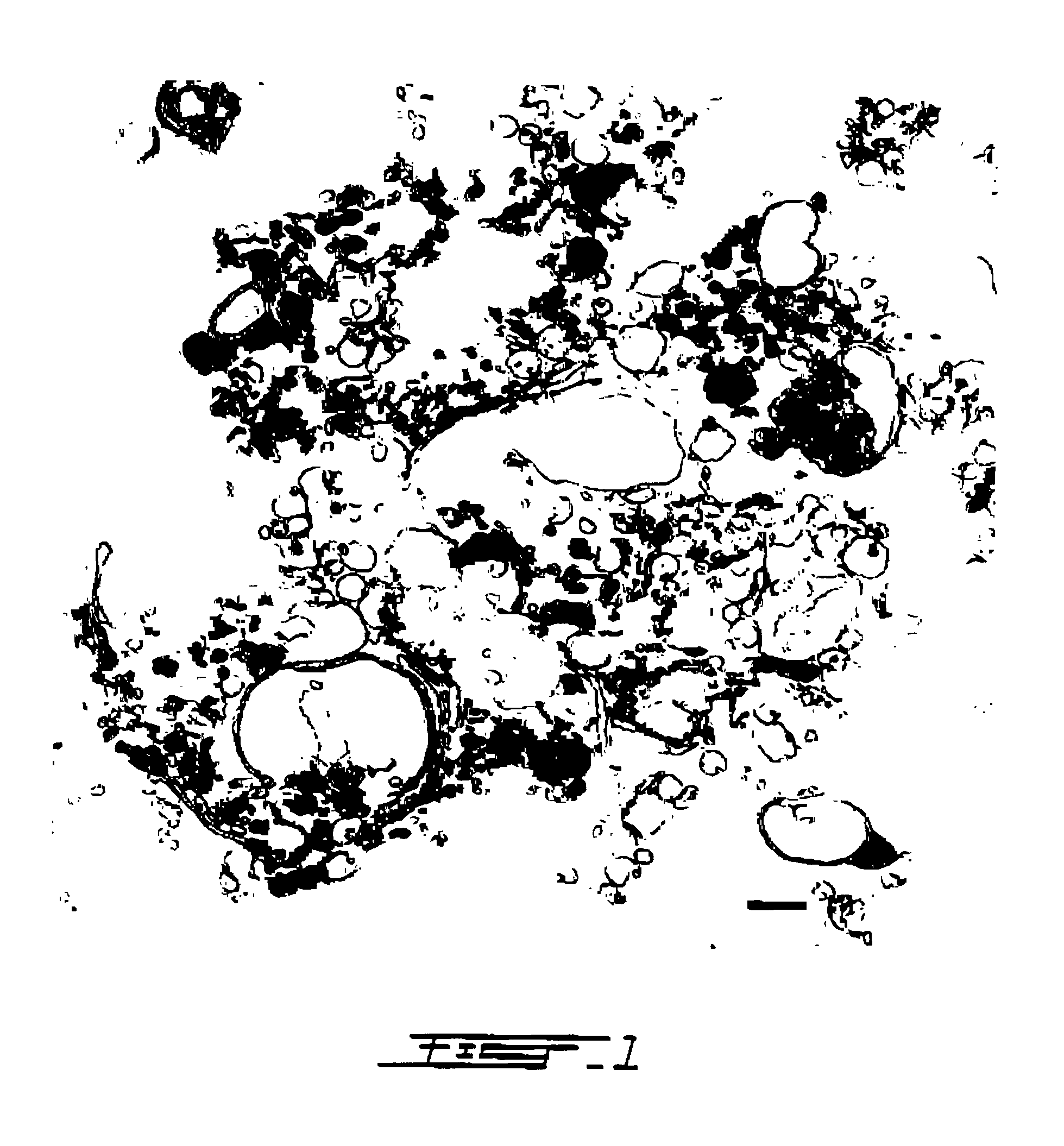

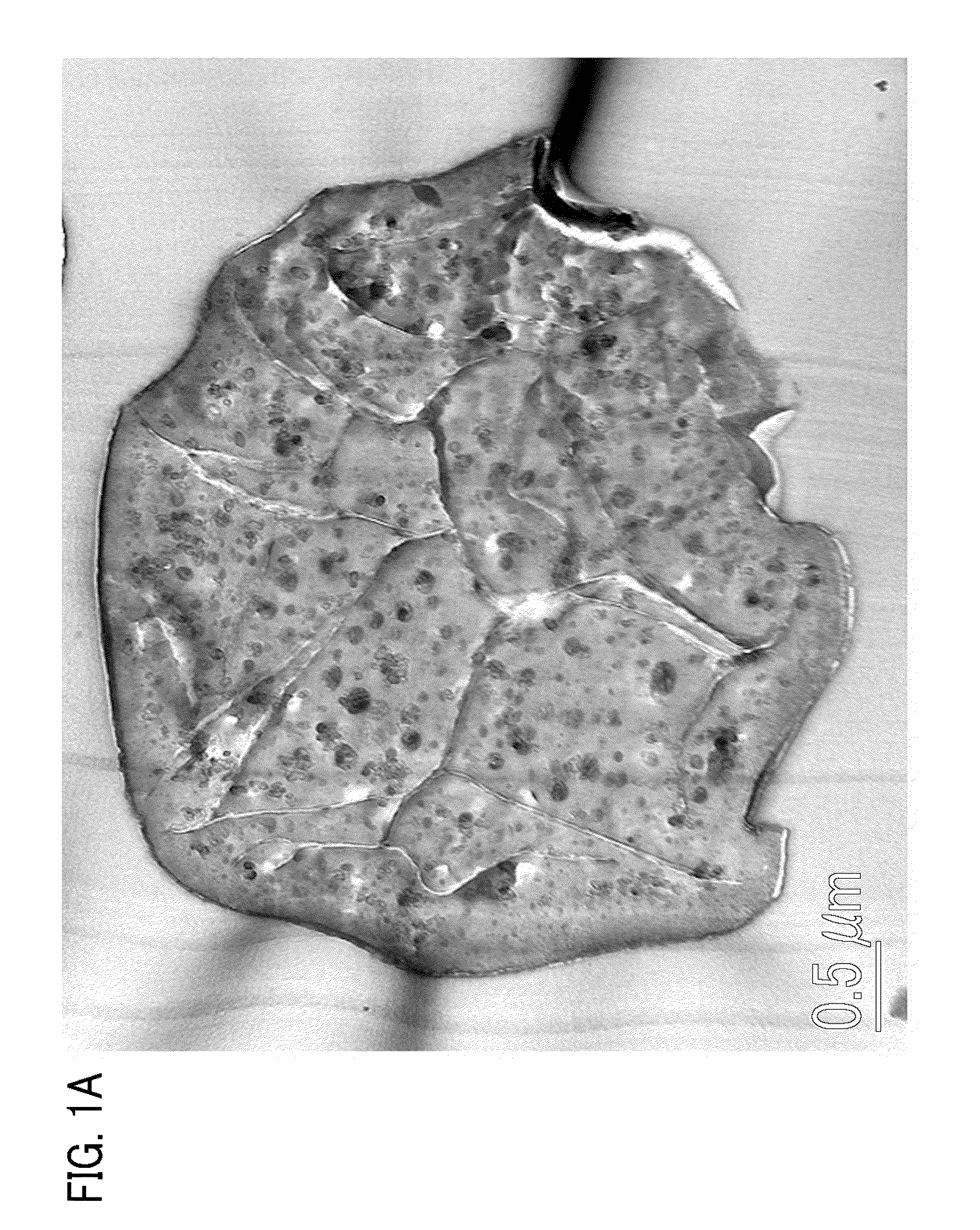

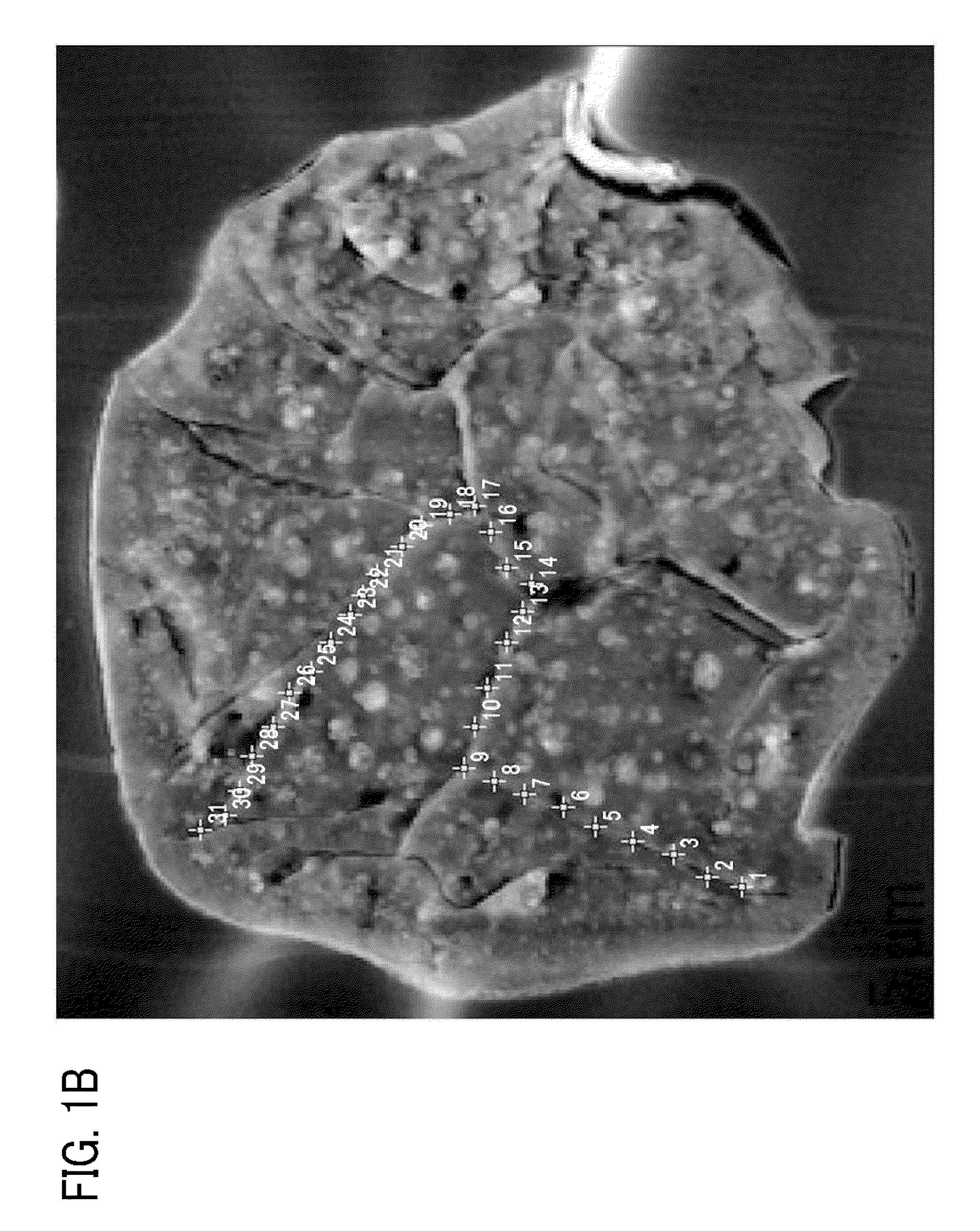

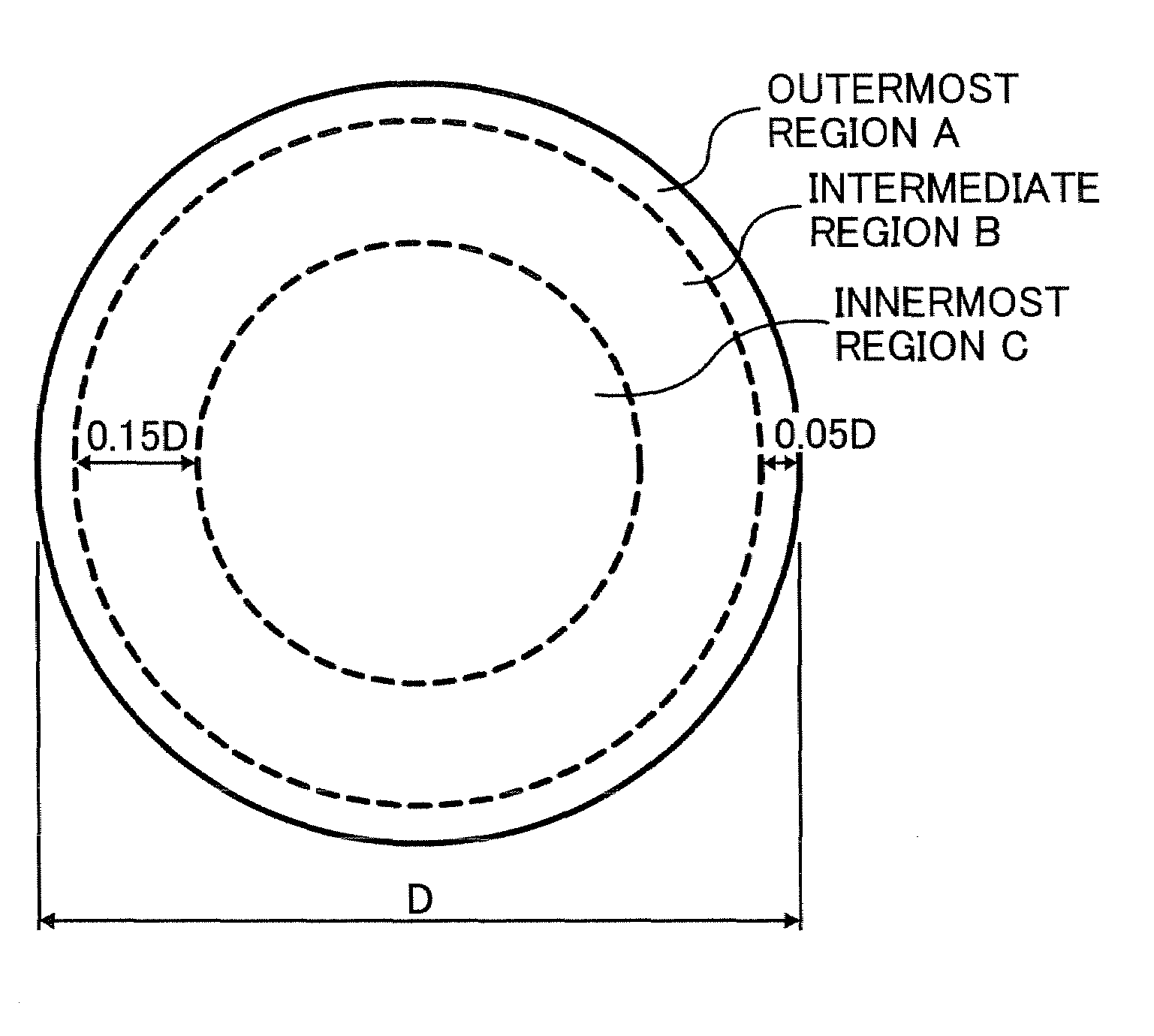

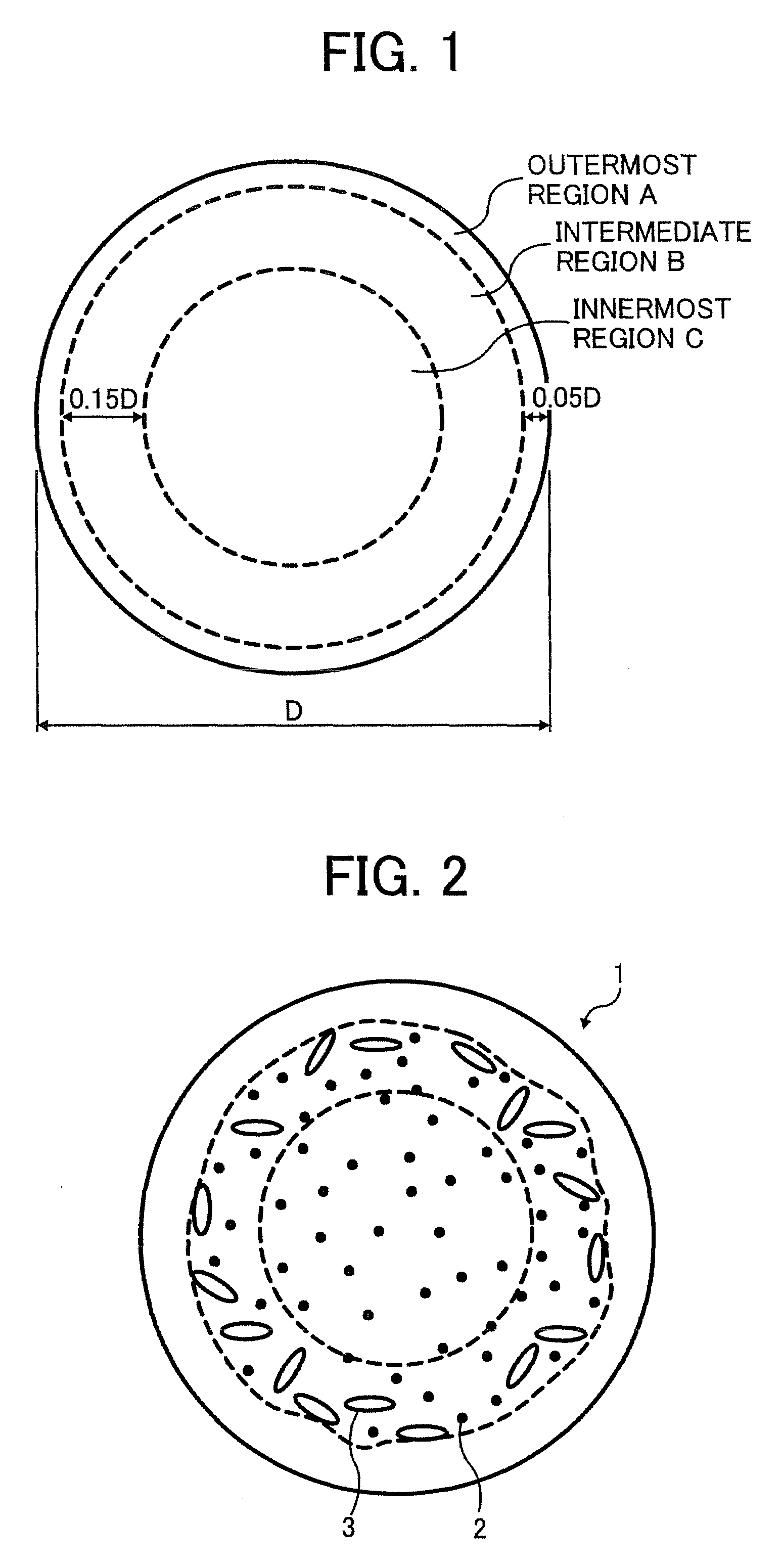

Toner and method of preparing the toner

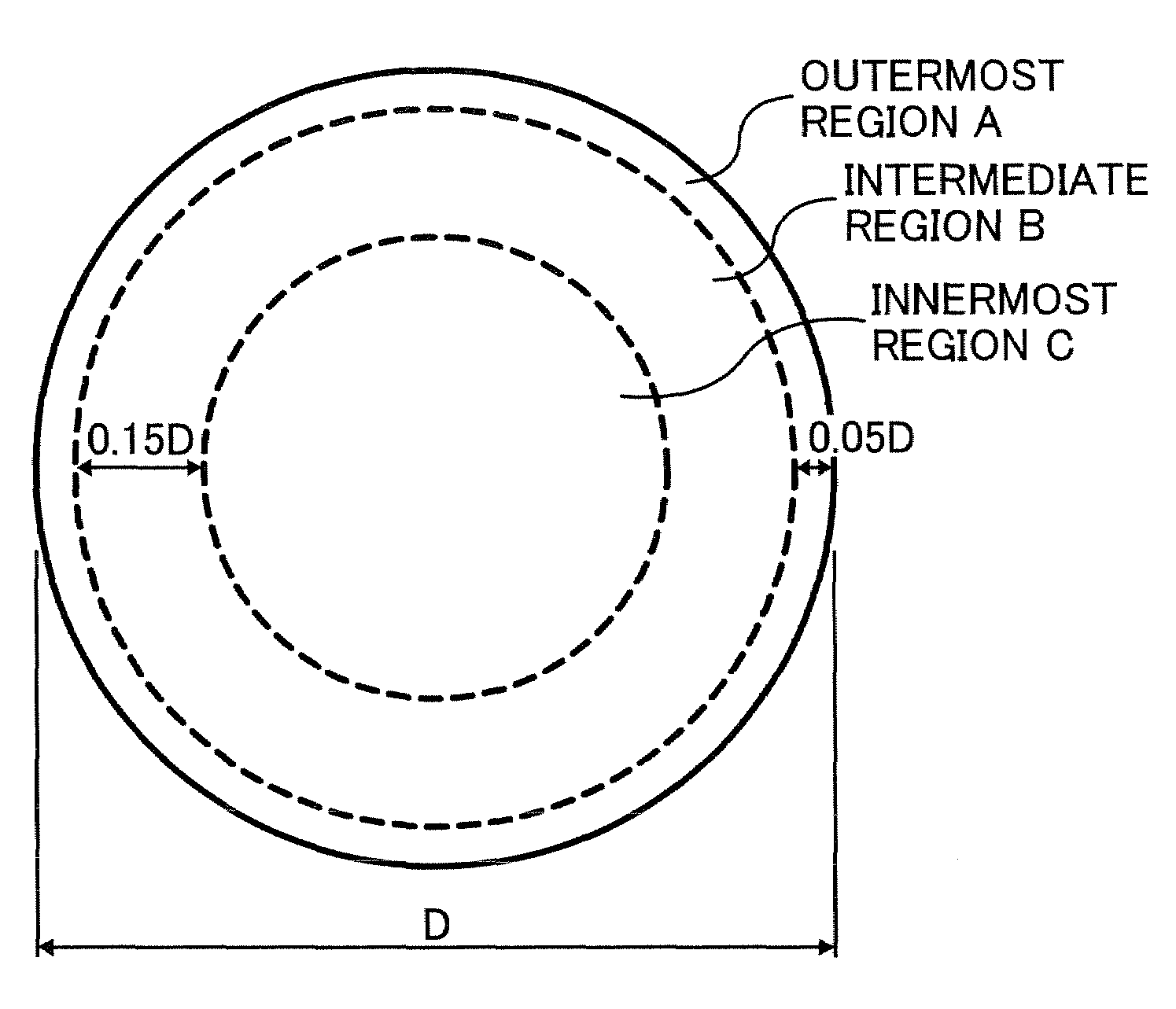

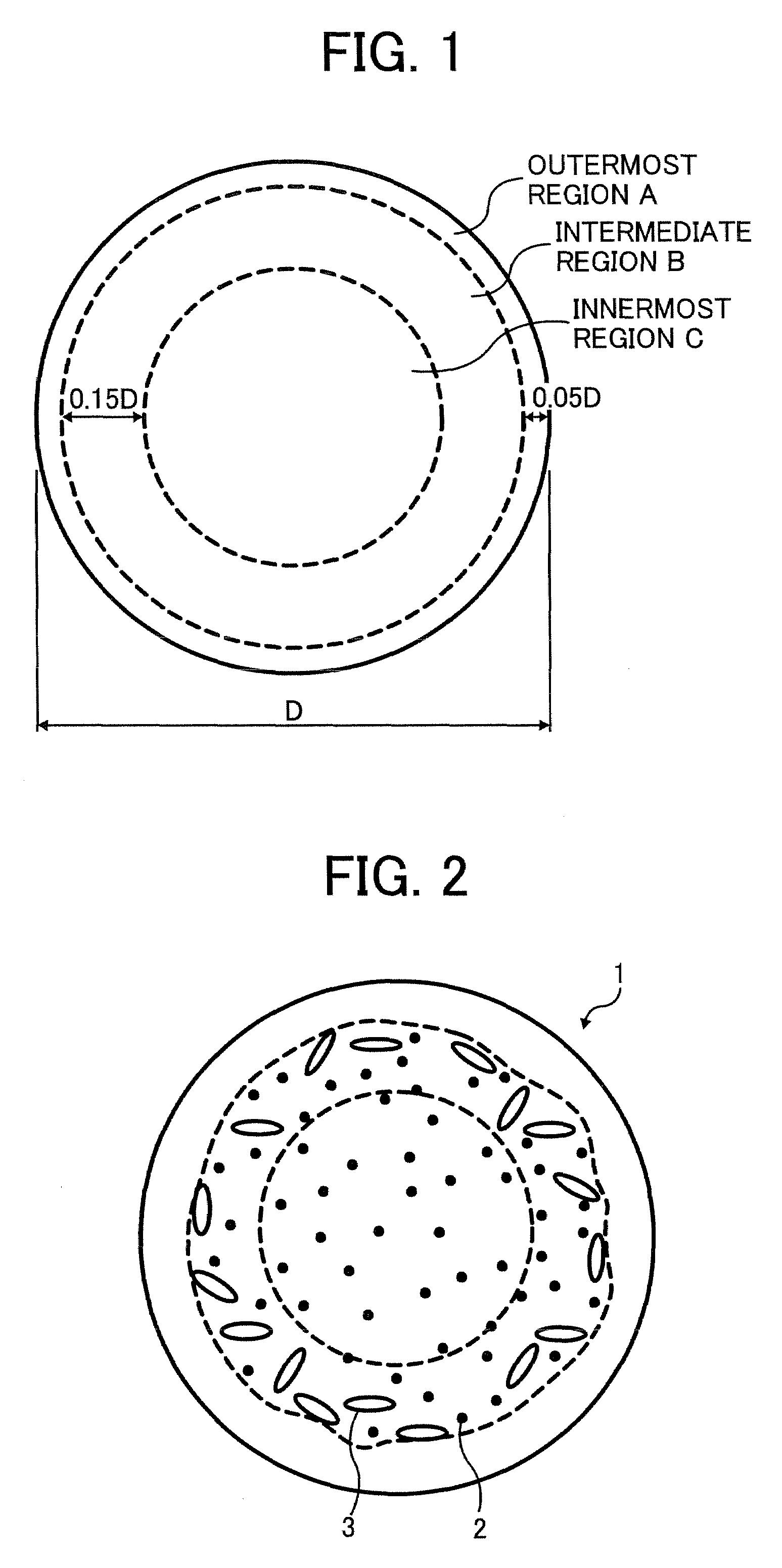

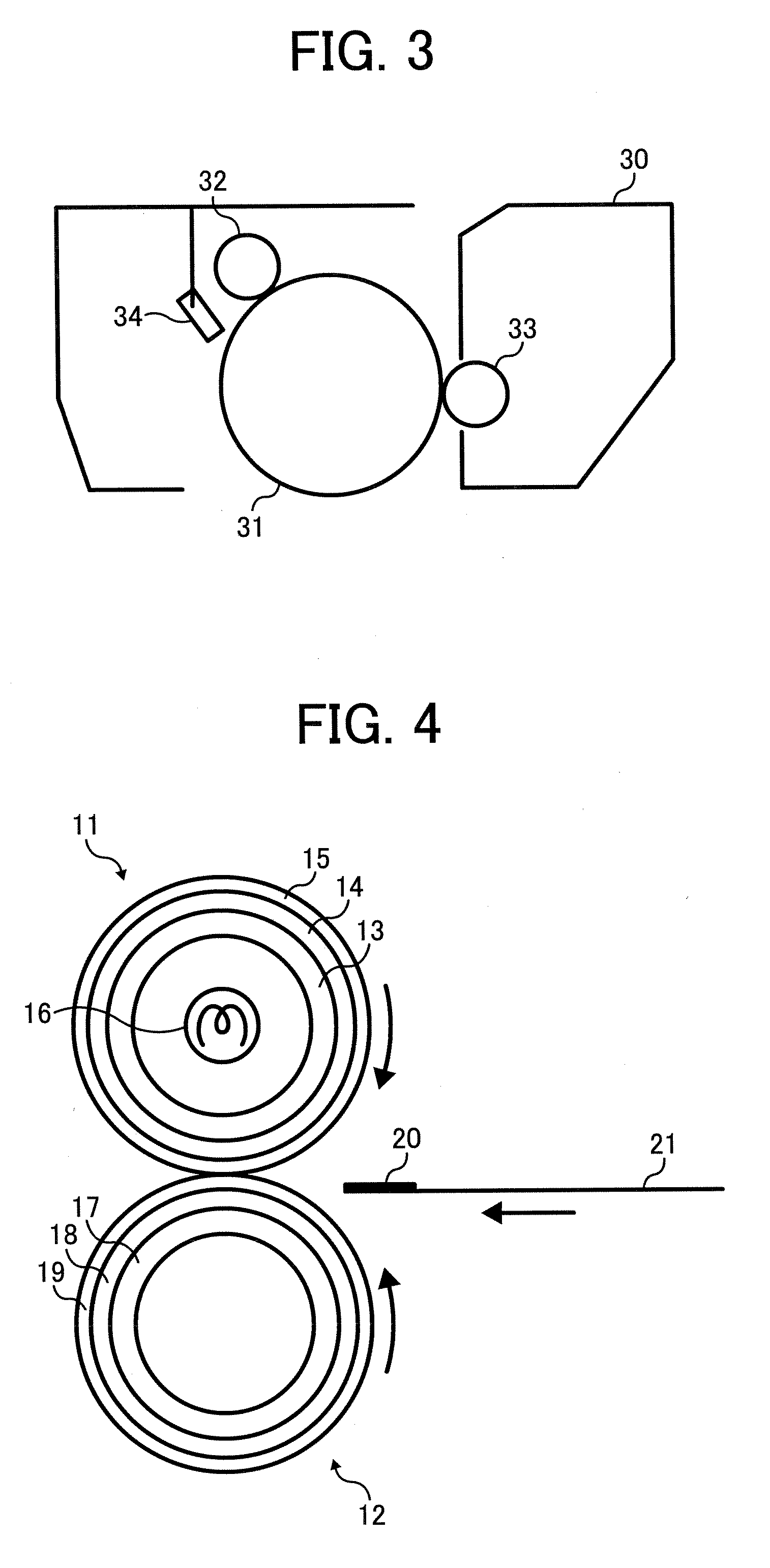

A toner is provided including a binder resin, a colorant, and a release agent, which has a volume average particle diameter (Dv) of from 3 to 9 μm, and wherein the binder resin and the release agent form a sea-island structure in which the island formed of the release agent is dispersed in the sea formed of the binder resin in a cross-sectional image of the toner obtained by a transmission electron microscope (TEM), and the following relationships are satisfied: IB>IA and IB>IC, wherein each of IA, IB, and IC represents an area ratio (%) of the island in an outermost region (A) of the cross-sectional image of the toner, an intermediate region (B) thereof located under the outermost region (A), and an innermost region (C) thereof located under the intermediate region (B); and a method of preparing the toner.

Owner:RICOH KK

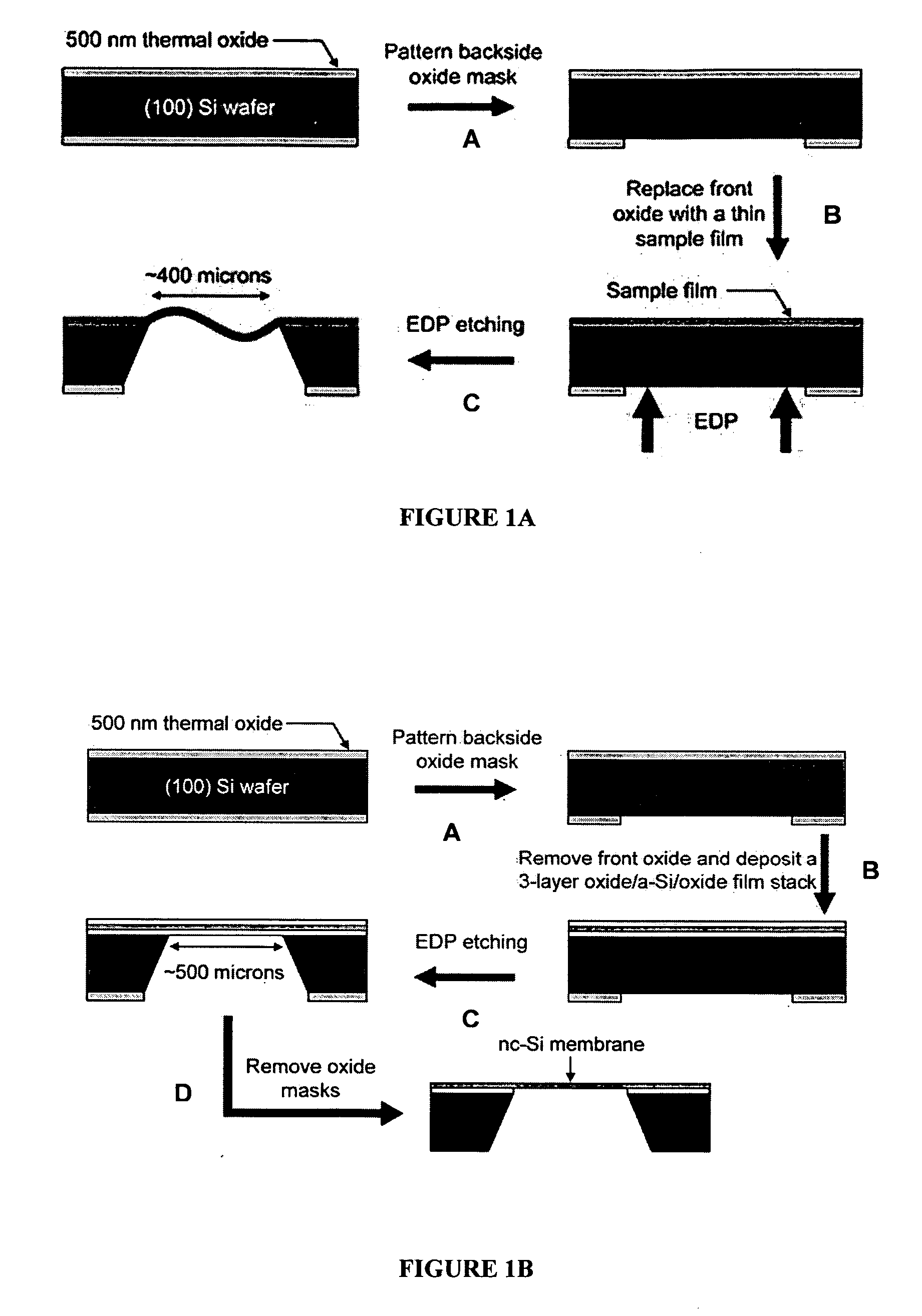

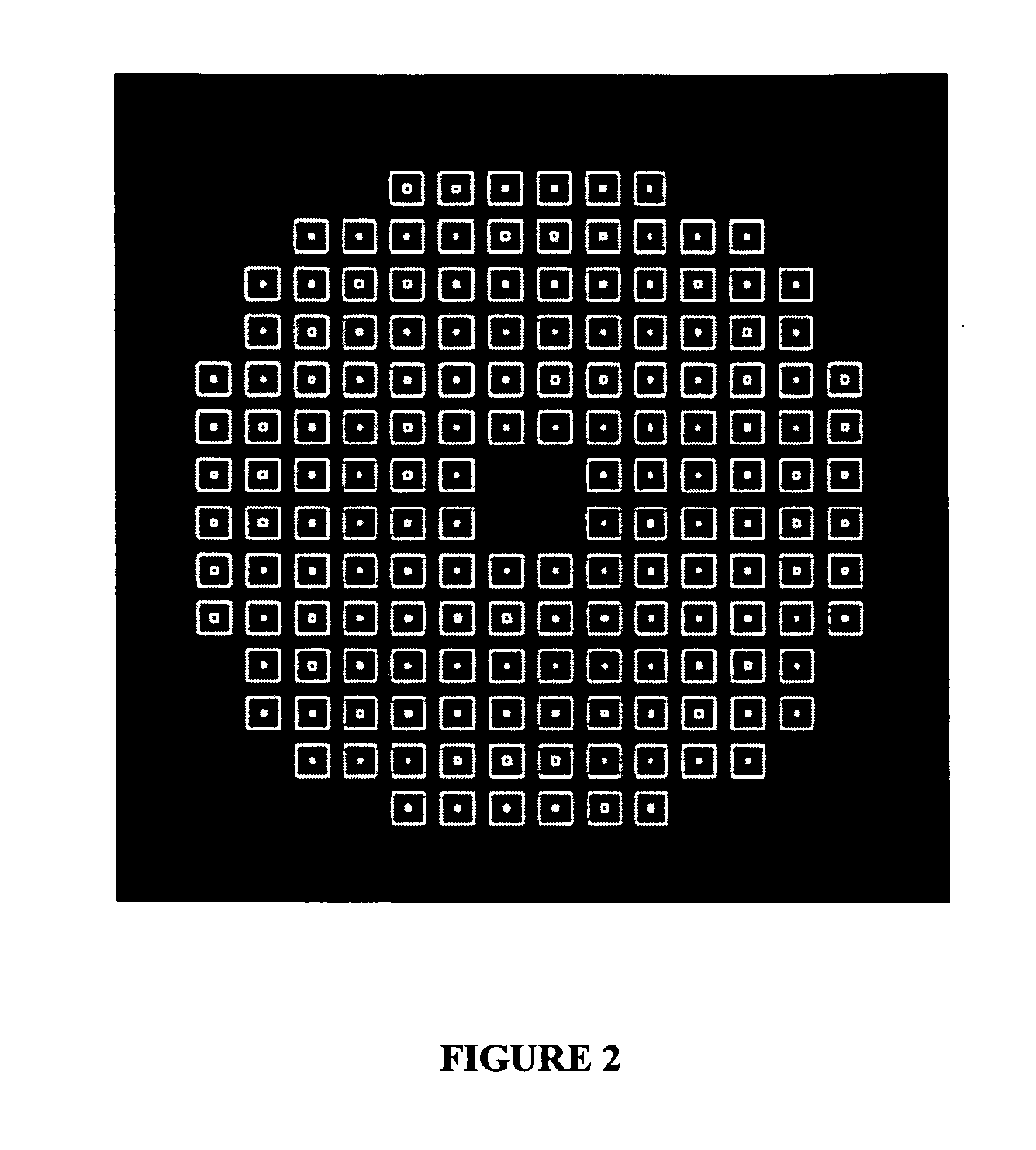

Ultrathin nanoscale membranes, methods of making, and uses thereof

ActiveUS20060243655A1Simple process requirementsAccessiblePaper/cardboard articlesFuel cell auxillariesFuel cellsElectron microscope

A nanoscale membrane exposed on opposite sides thereof and having an average thickness of less than about 100 nm, and a lateral length to thickness aspect ratio that is more than 10,000 to 1 is disclosed. Also disclosed are methods of making such membranes, and use thereof in a number of devices including fuel cells, sensor devices, electrospray devices, and supports for examining a sample under electron microscopy.

Owner:UNIVERSITY OF ROCHESTER

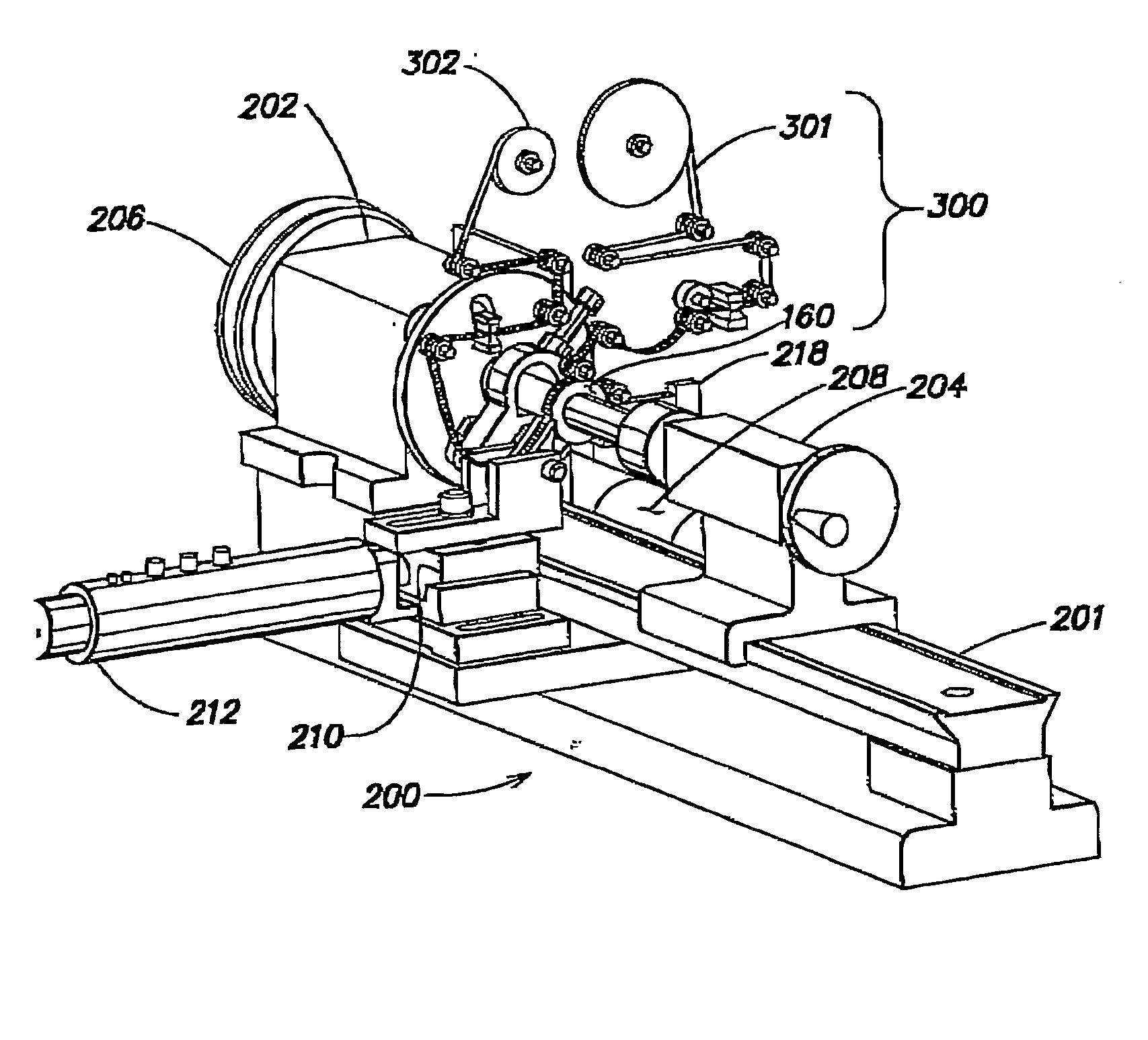

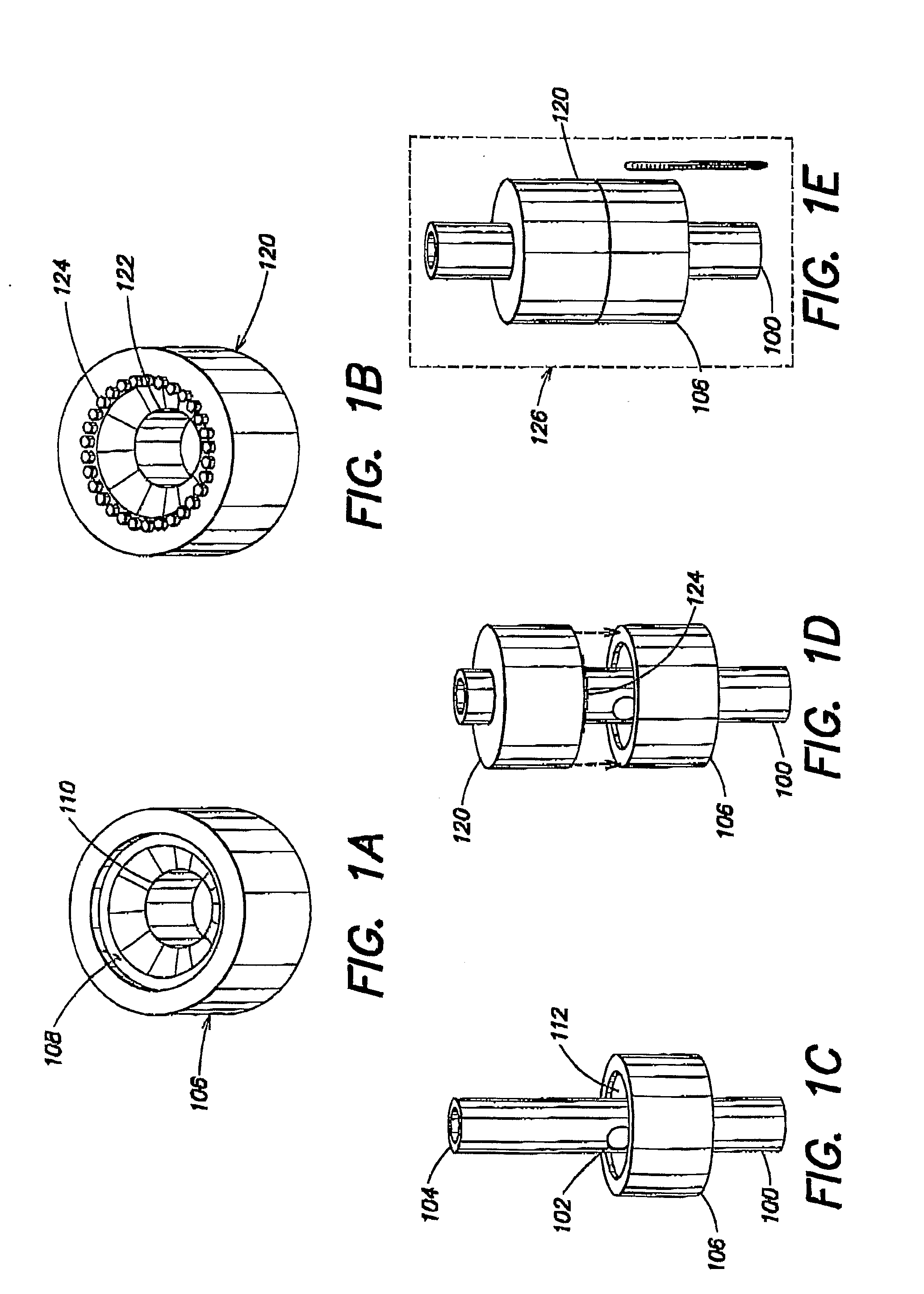

Methods and apparatus for providing and processing sliced thin tissue

InactiveUS20100093022A1Facilitate subsequent imagingPromote the fullTemperatue controlStatic/dynamic balance measurementSlice thicknessTissue sample

Methods and apparatus for providing and processing serial tissue sections. In one example, an “automatic tape collecting lathe ultramicrotome” (ATLUM) slices a block of tissue sample having various geometries into a continuous ribbon of thin tissue, or multiple thin tissue sections, and disposes the sliced thin tissue on an appropriate substrate to facilitate subsequent imaging of the sliced thin tissue. Closed-loop control of section thickness of the sliced thin tissue sections or ribbons is implemented to produce thinner sliced tissue sections or ribbons and tightly regulate thickness. Thin tissue sections or ribbons may be particularly processed / prepared to facilitate imaging with a scanning electron microscope (SEM). Collected thin tissue sections or ribbons may be used to create UltraThin Section Libraries (UTSLs) that allow for fully automated, time-efficient imaging in the SEM to facilitate expansive tissue studies.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

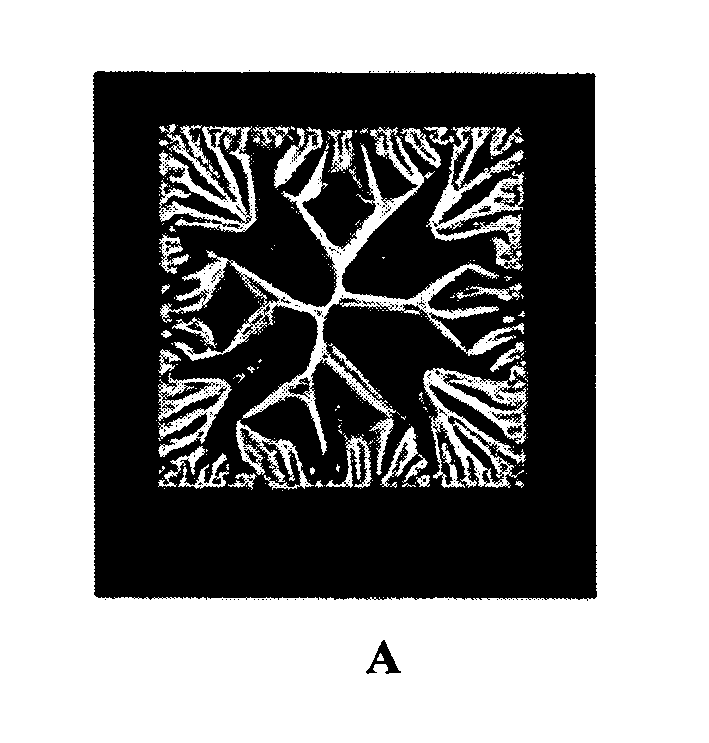

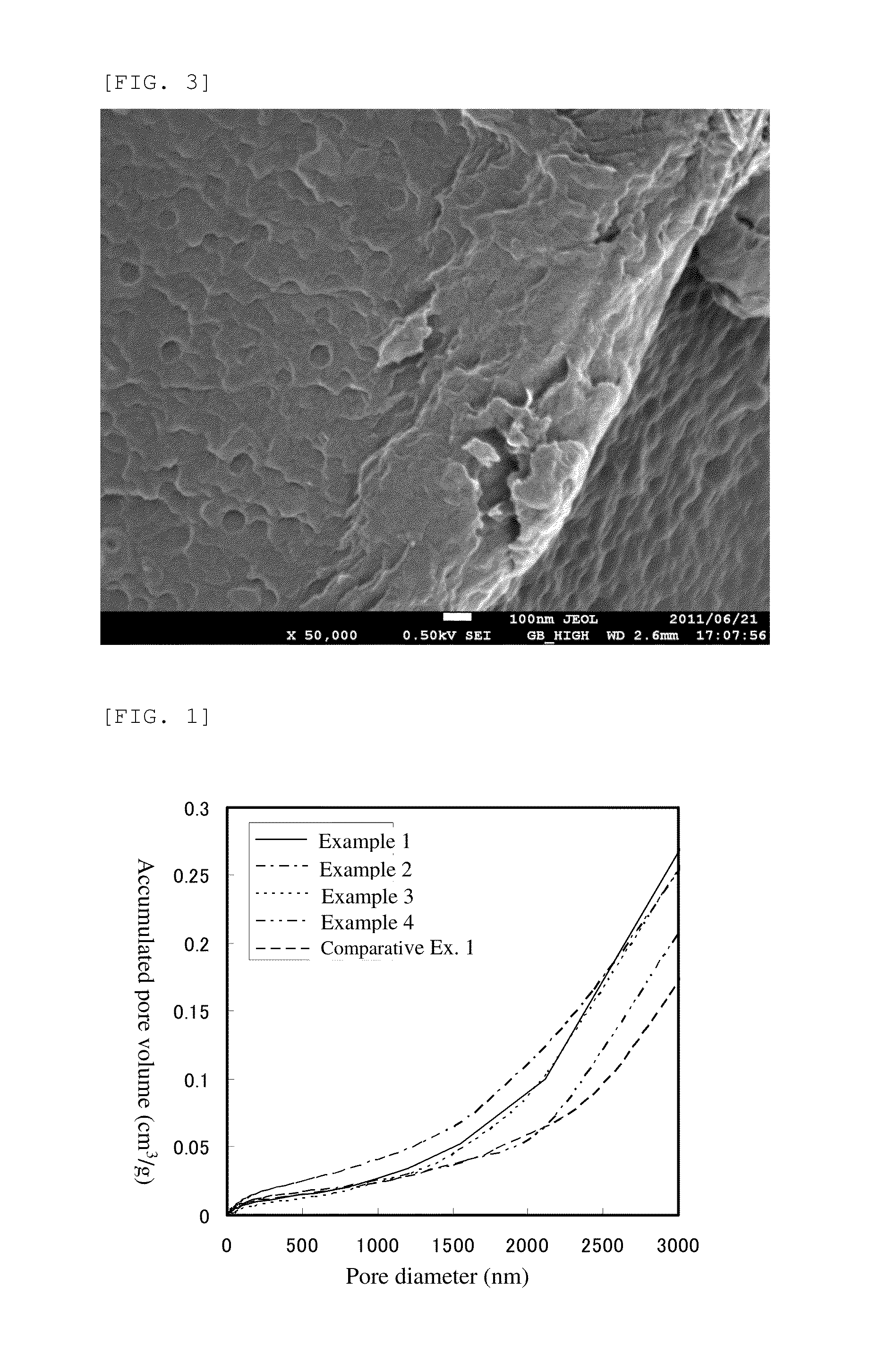

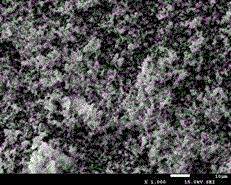

Composite graphite particle for nonaqueous-secondary-battery negative electrode, negative electrode for nonaqueous secondary battery, and nonaqueous secondary battery

InactiveUS20150194668A1Large capacityHigh charge-discharge efficiencyNegative electrodesNon-aqueous electrolyte accumulator electrodesScanning electron microscopeGraphite particle

An object of the invention is to provide composite graphite particles (C) for nonaqueous-secondary-battery negative electrode, wherein metallic particle (B) capable of alloying with Li are present in inner parts thereof in a large amount. The invention relates to a composite graphite particle (C) for nonaqueous-secondary-battery negative electrode, the composite graphite particle (C) comprising a graphite (A) and a metallic particle (B) capable of alloying with Li, wherein when a section of the composite graphite particle (C) is examined with a scanning electron microscope, a folded structure of the graphite (A) is observed and a presence ratio of the metallic particle (B) in the composite graphite particle (C), as calculated by a specific measuring method, is 0.2 or higher.

Owner:MITSUBISHI CHEM CORP

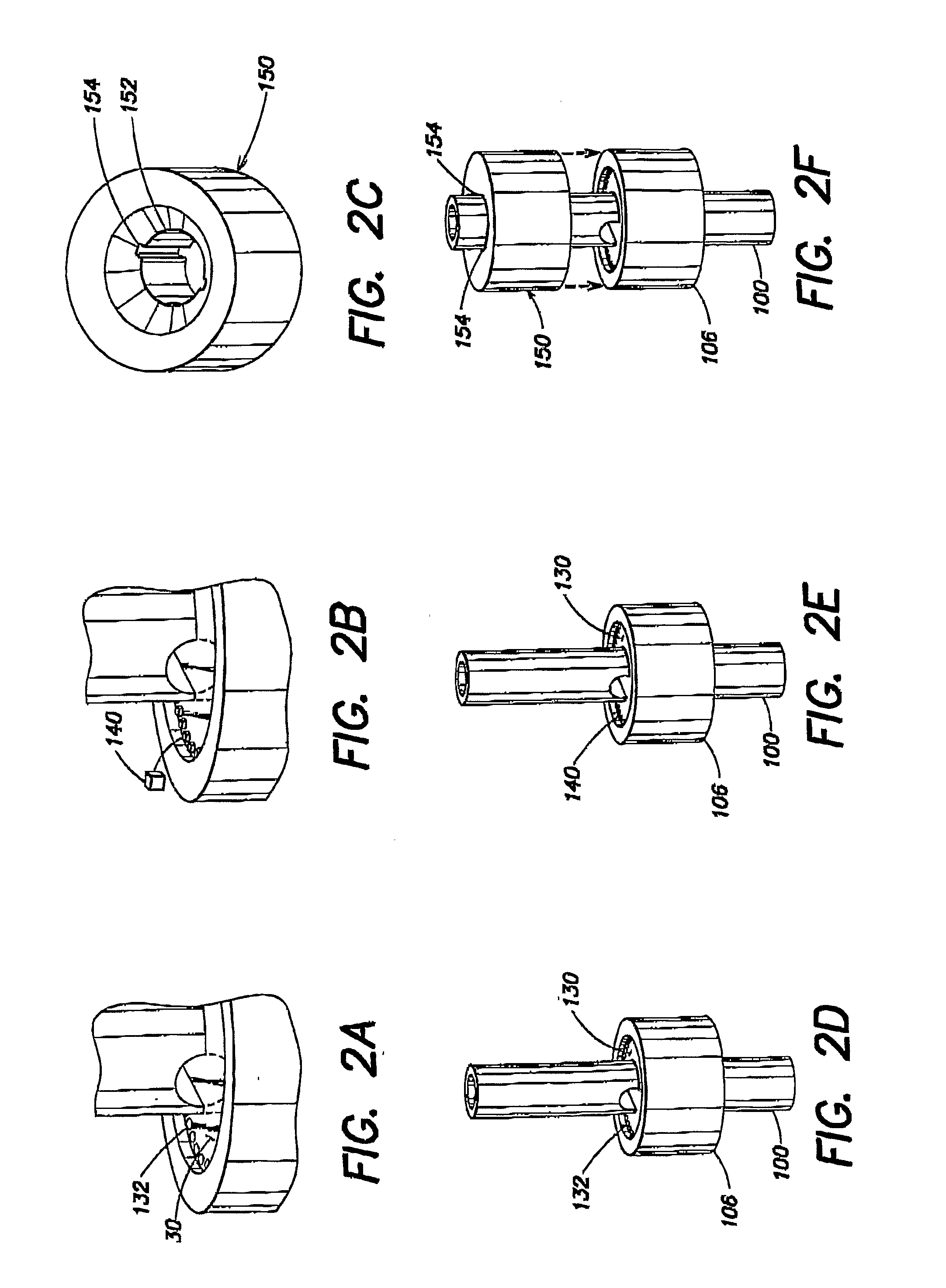

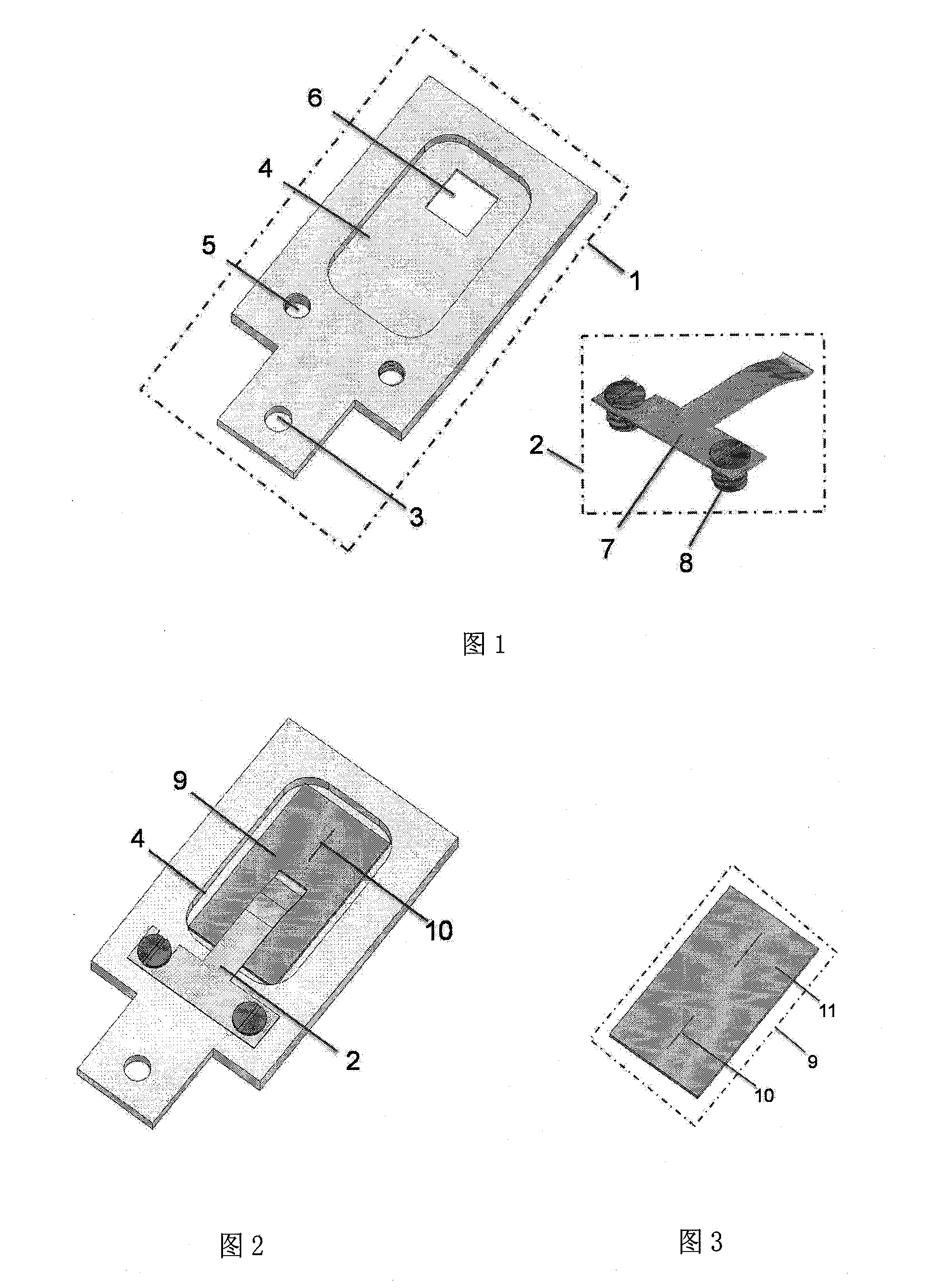

Specimen mount for microscopy

ActiveUS20110032611A1Material analysis using wave/particle radiationElectric discharge tubesElectron microscopeMicroscope

Devices, mounts, stages, interfaces and systems to be developed that allow for in situ manipulation, experimentation and analysis of specimens directly within an electron microscope.

Owner:PROTOCHIPS

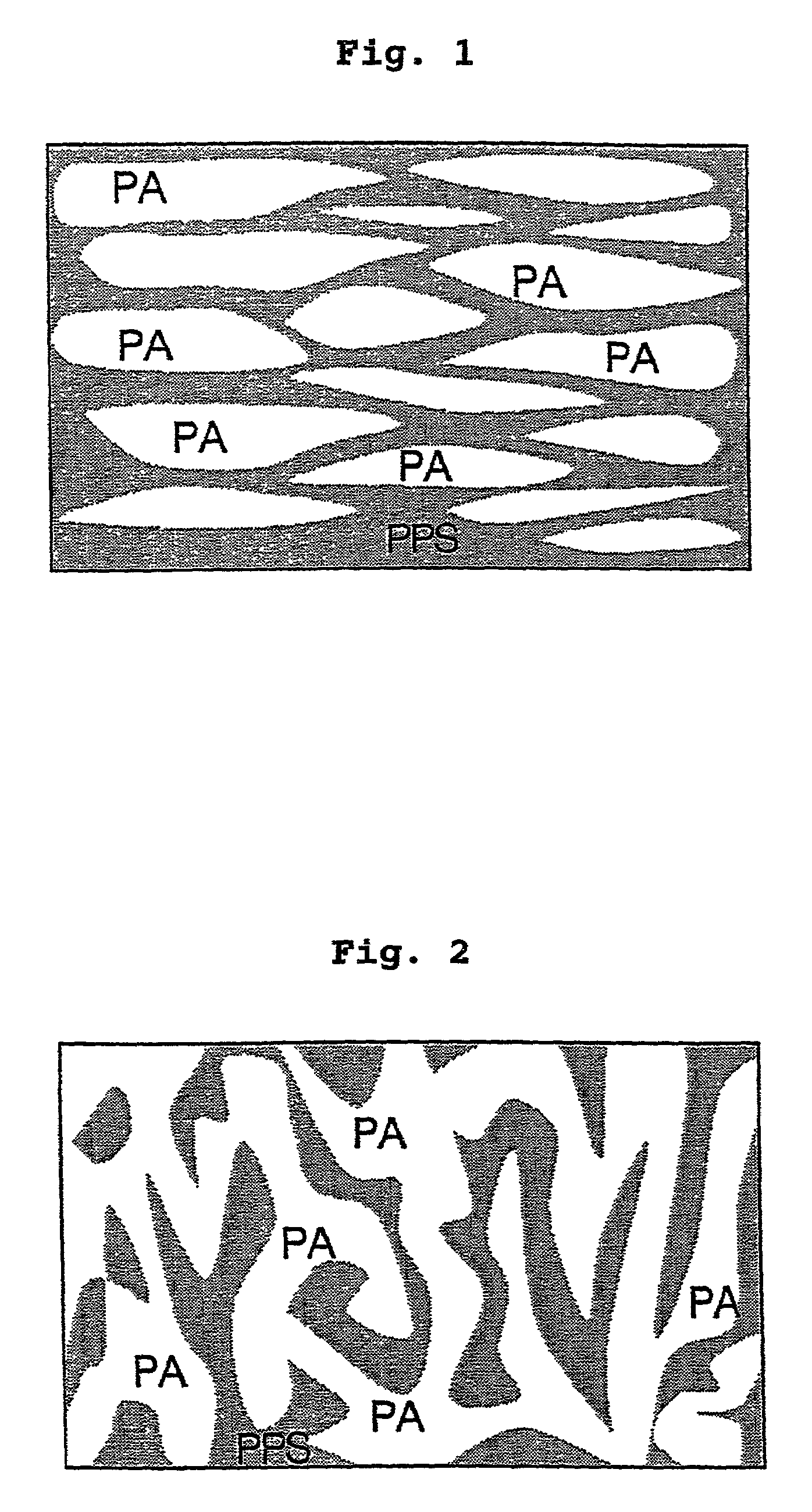

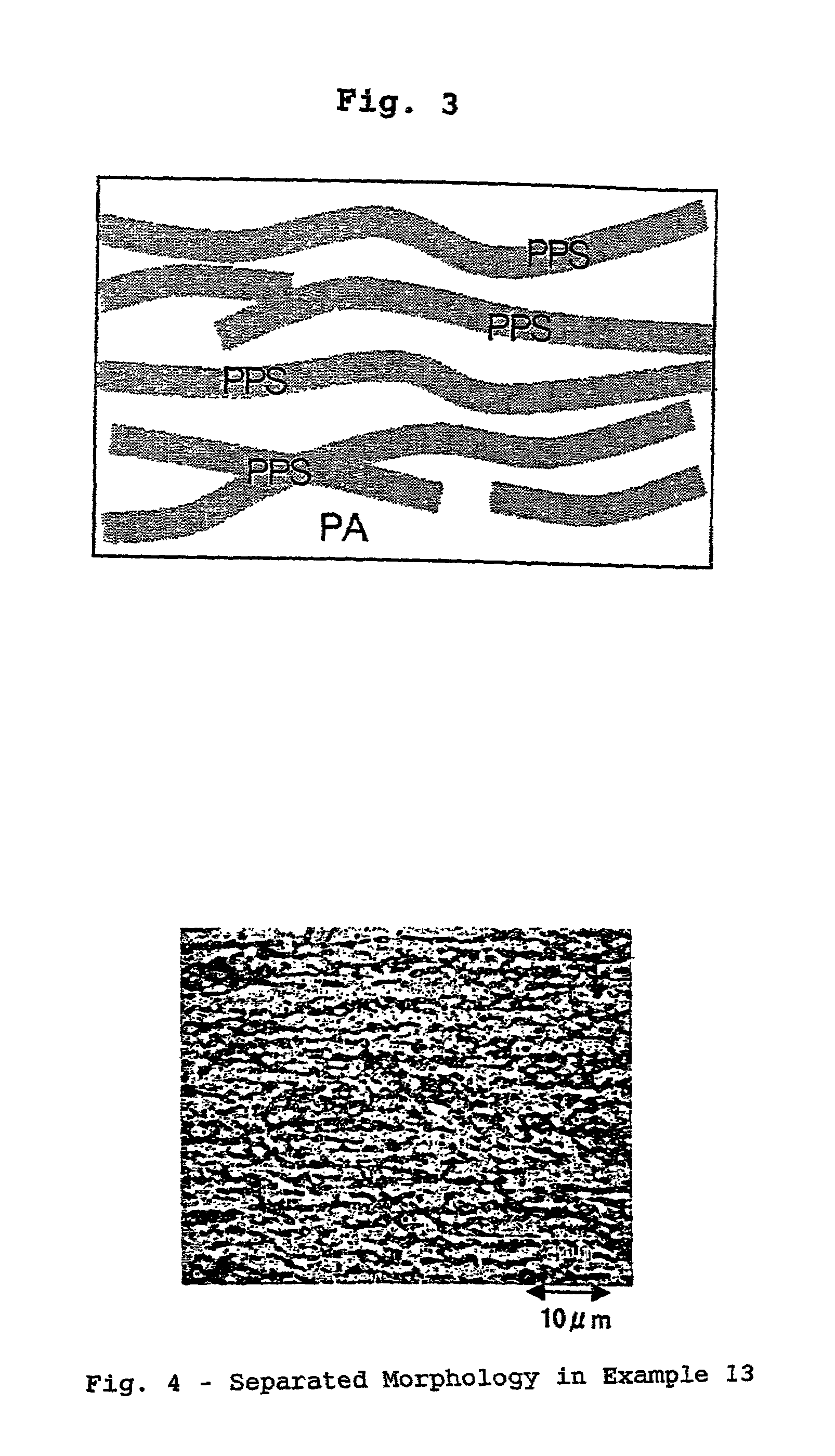

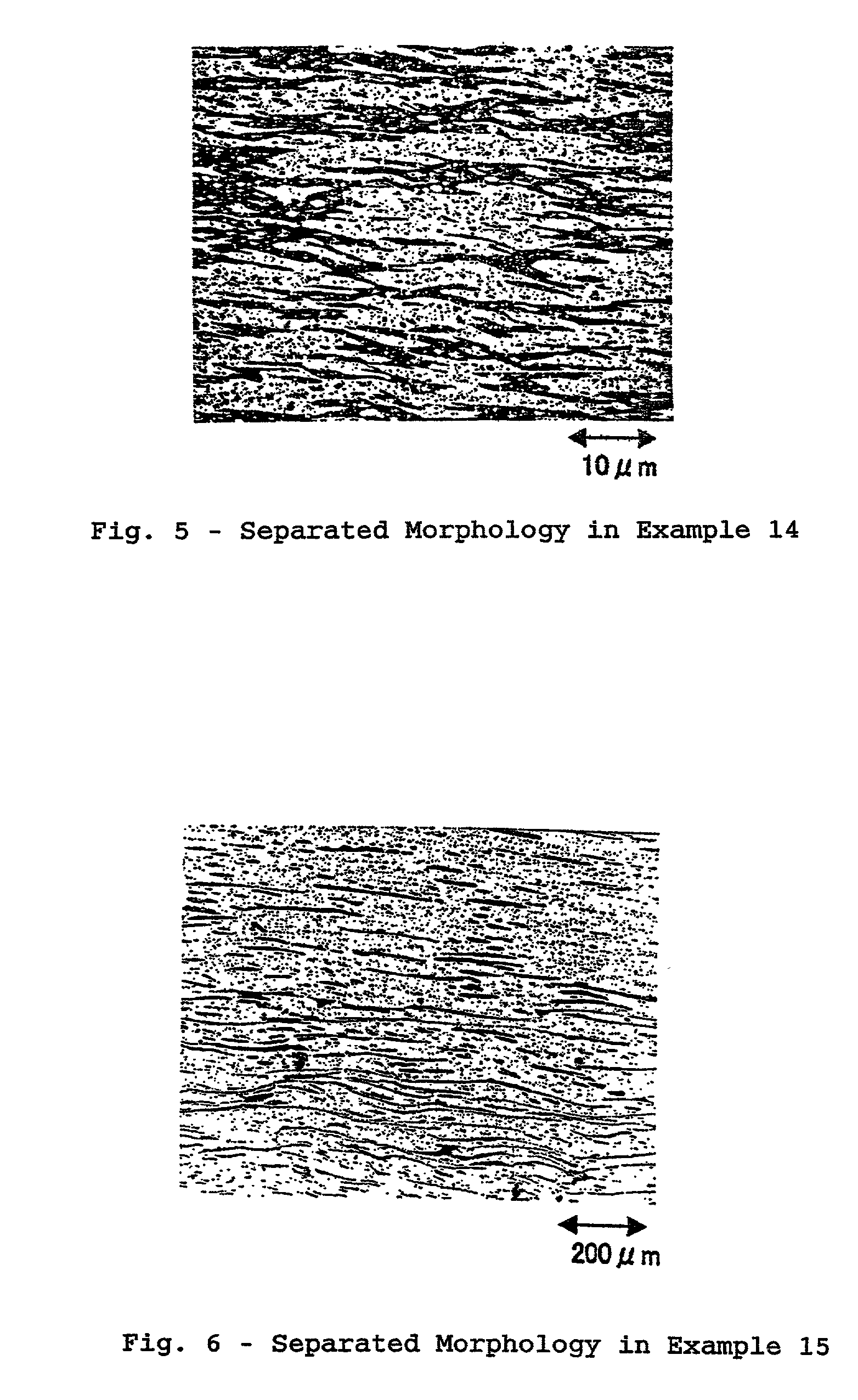

Resin structure and use thereof

InactiveUS7303822B1Satisfies requirementIncrease productivitySynthetic resin layered productsThin material handlingUltimate tensile strengthMachinability

Provided is a thermoplastic resin structure formed of a resin composition that comprises substantially (a) from 5 to 80% by volume of a polyamide resin and (b) from 20 to 95% by volume of a polyphenylene sulfide resin, which is characterized in that, in morphology therein seen through electronic microscopy, the polyphenylene sulfide resin (b) forms a matrix phase (continuous phase) and the polyamide resin (a) forms a disperse phase. The gives plastic containers, tubes and their Attached parts having good barrier properties, strength, durability and workability.

Owner:TORAY IND INC

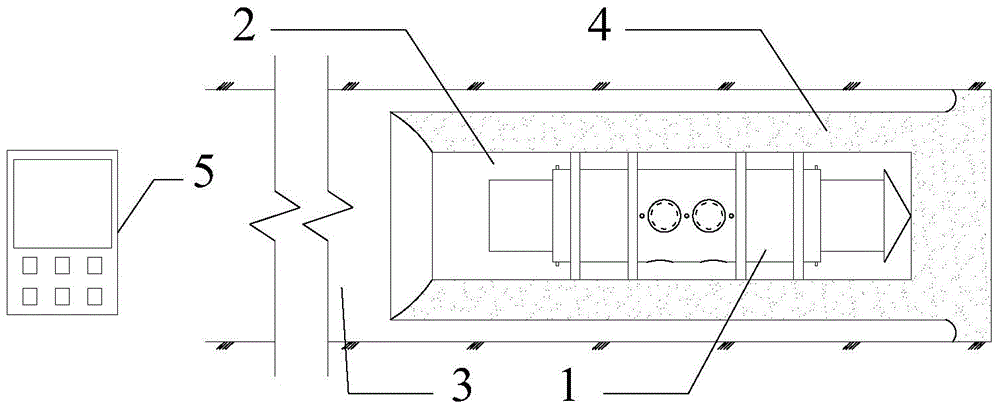

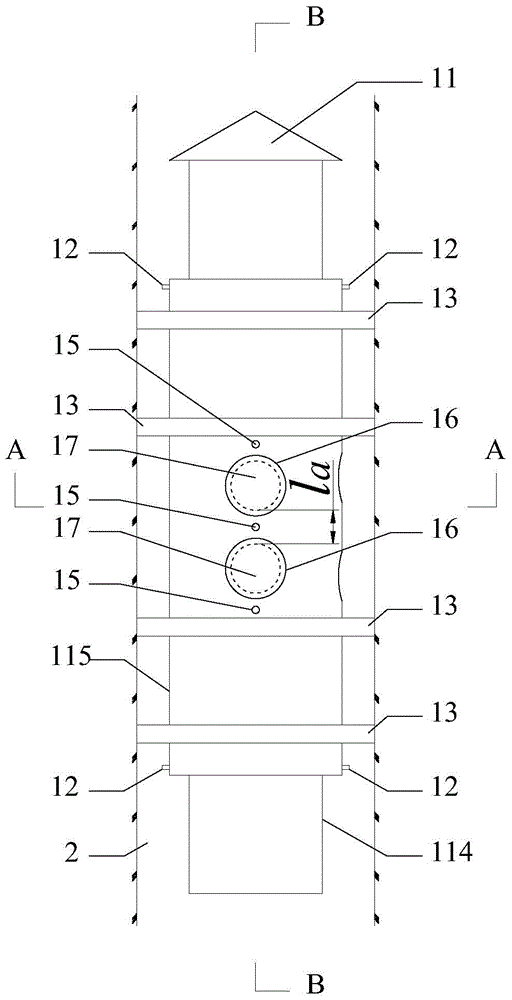

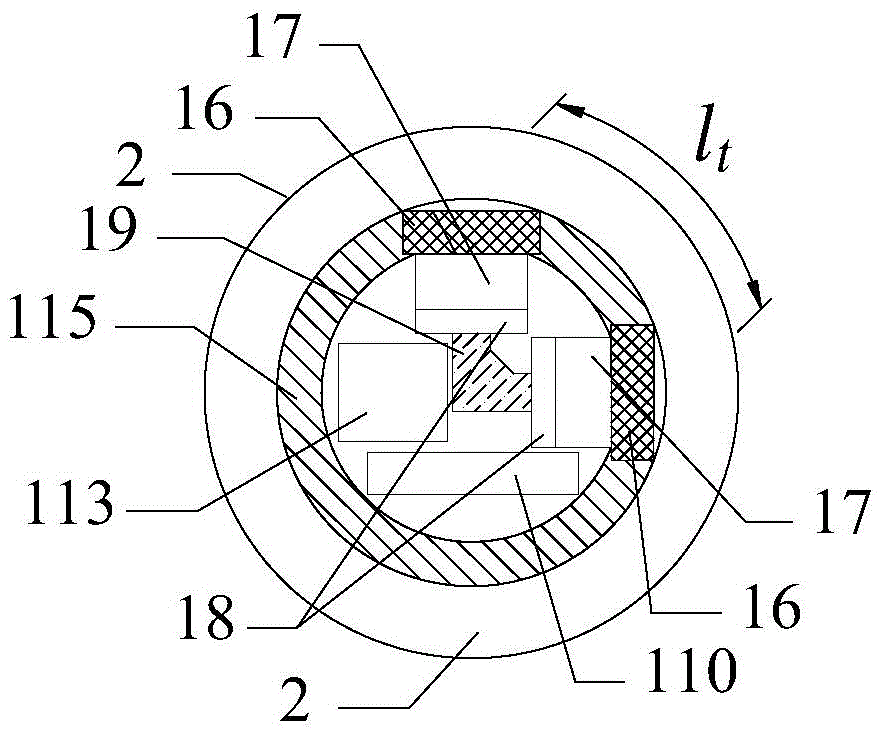

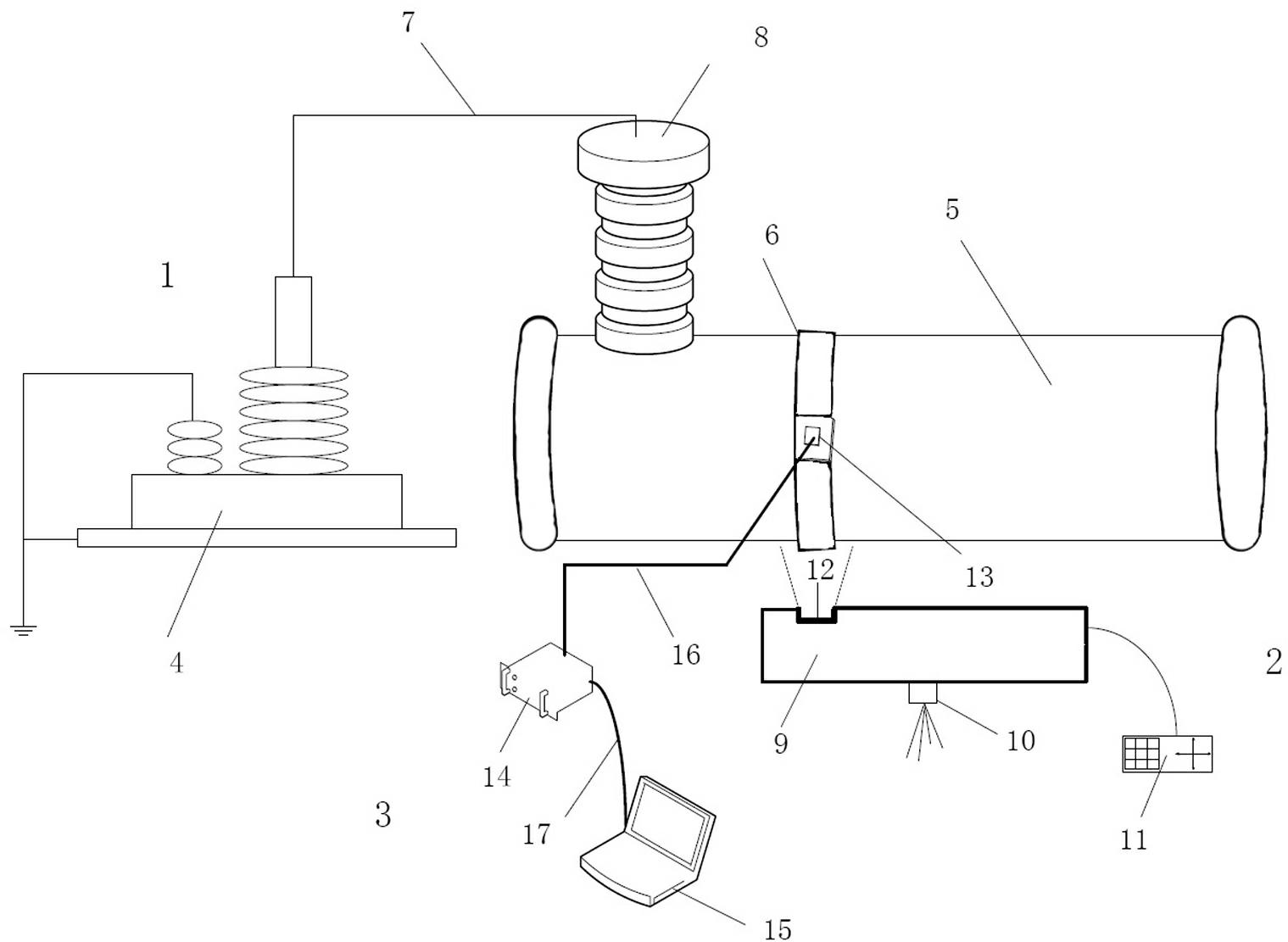

Non-contact ground stress testing device and method based on drilling microscopy digital photography

The invention relates to a non-contact ground stress testing device and method based on drilling microscopy digital photography and belongs to ground stress measuring device and method of geotechnical engineering. The device comprises an electronic microscopy camera, a signal processing and control module, a signal transmission module, a gyroscope, a signal collecting module, a portable power source and a device shell. The method includes: fixing the testing device in a device mounting hole, using the electronic microscopy camera to collect the hole wall digital images of the hole during a whole stress relieving process, selecting the representative images before and after the stress relieving, acquiring sub-pixel images through image interpolation, optimizing sub-pixel image analyzing areas and points, setting analyzing traces, calculating to obtain strain values, and calculating the ground stress values and the azimuth angles thereof by the hole partial wall surface stress relieving method theory. The non-contact ground stress testing device and method has the advantages that simple operation and high adaptability are achieved, testing precision can reach one micro strain, strain measuring mark points and analyzing traces are optimized, influence of temperature, rock viscosity and electromagnetic interference is avoided, a probe can be reused, and low cost is achieved.

Owner:CHINA UNIV OF MINING & TECH

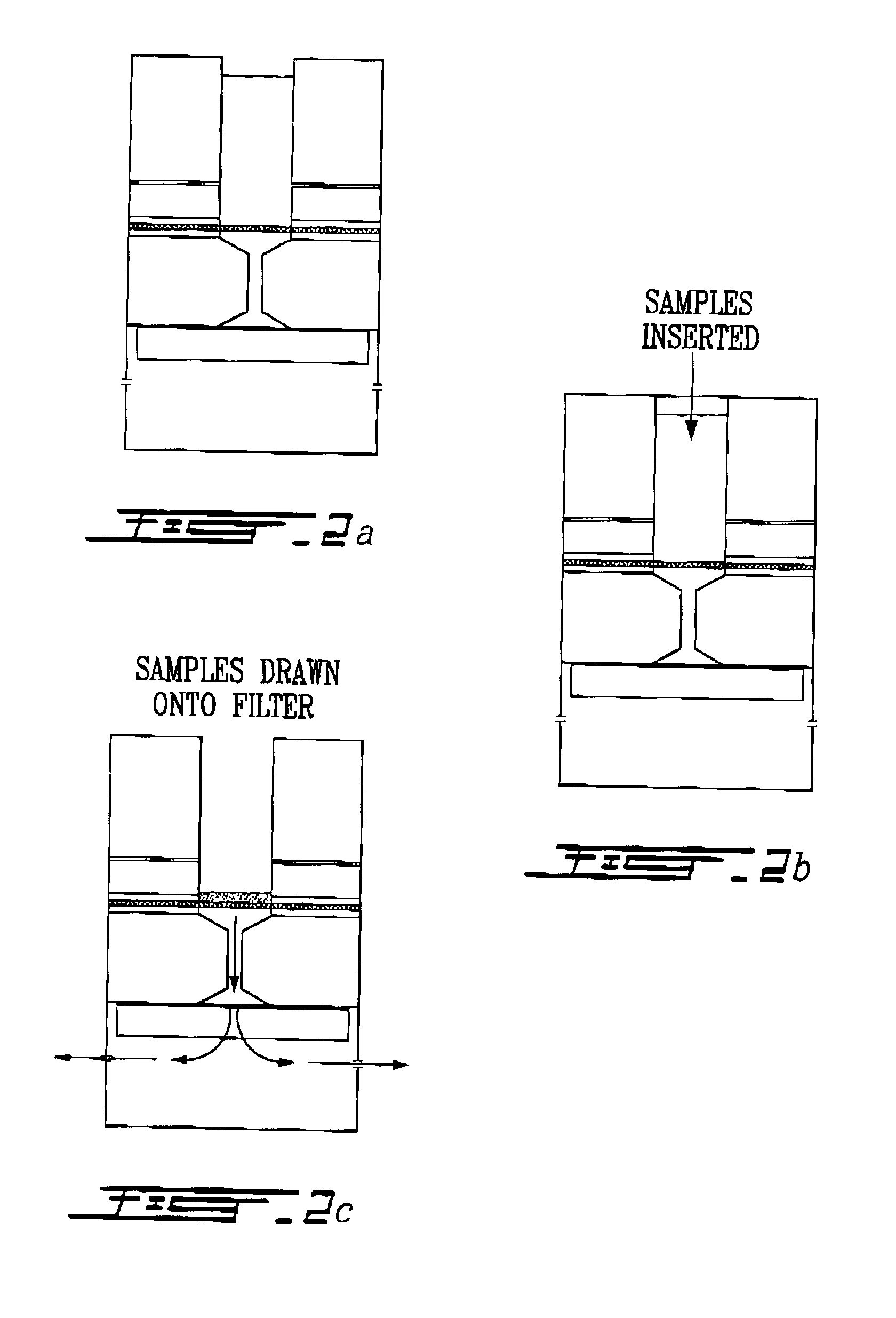

Electron microscopy cell fraction sample preparation robot

InactiveUS20060171850A1Reduce preparation timePreparing sample for investigationMaterial analysis by optical meansTemperature controlCell Fraction

A parallel processing, fluid handling apparatus for concurrent temperature controlled preparation of a plurality of cell fraction samples adapted to be used for electron microscopic viewing. The apparatus comprises generally a sample receiving member, a fluid handling means, and a separation means. The sample receiving member comprises a plurality of discrete apertures each adapted to receive a biological sample therein. The fluid handling means for inserting and removing fluid to and from the plurality of apertures substantially in parallel, permits the biological samples to be processed substantially in parallel by the insertion and removal of processing fluid. The separation means permits the parallel isolated separation of the post-processing samples. The post-processing samples are adapted to be polymerized in embedding solution and removed from the sample receiving member.

Owner:MCGILL UNIV

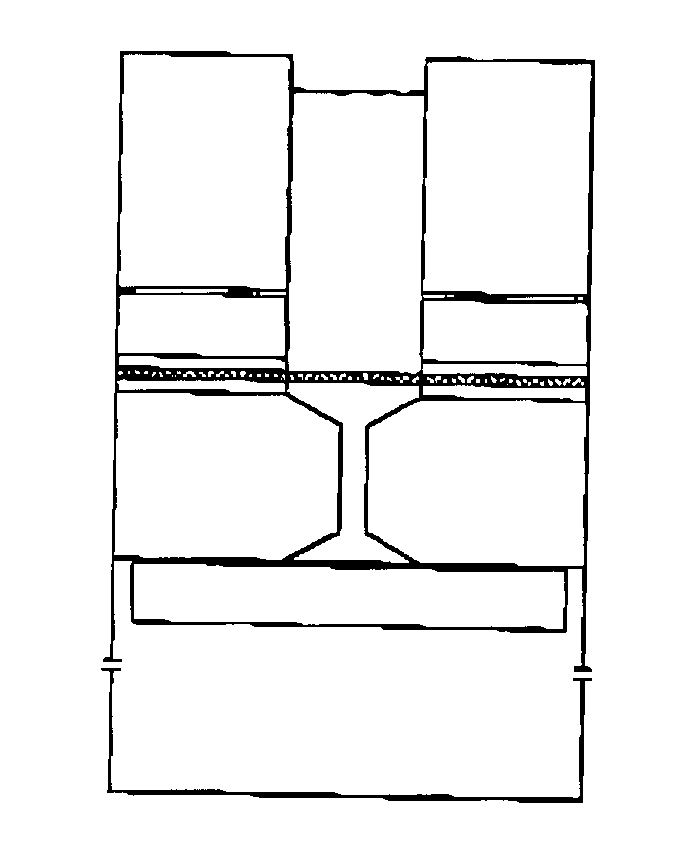

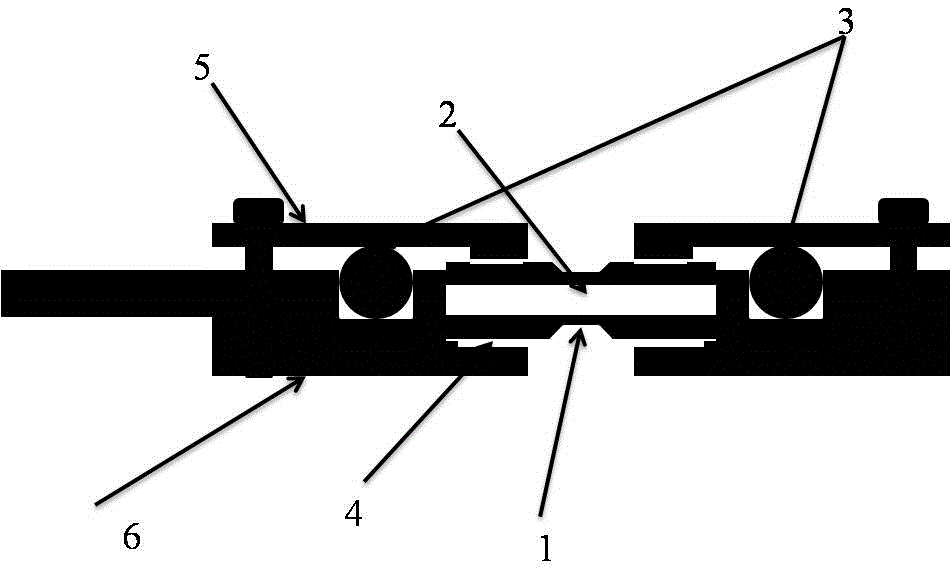

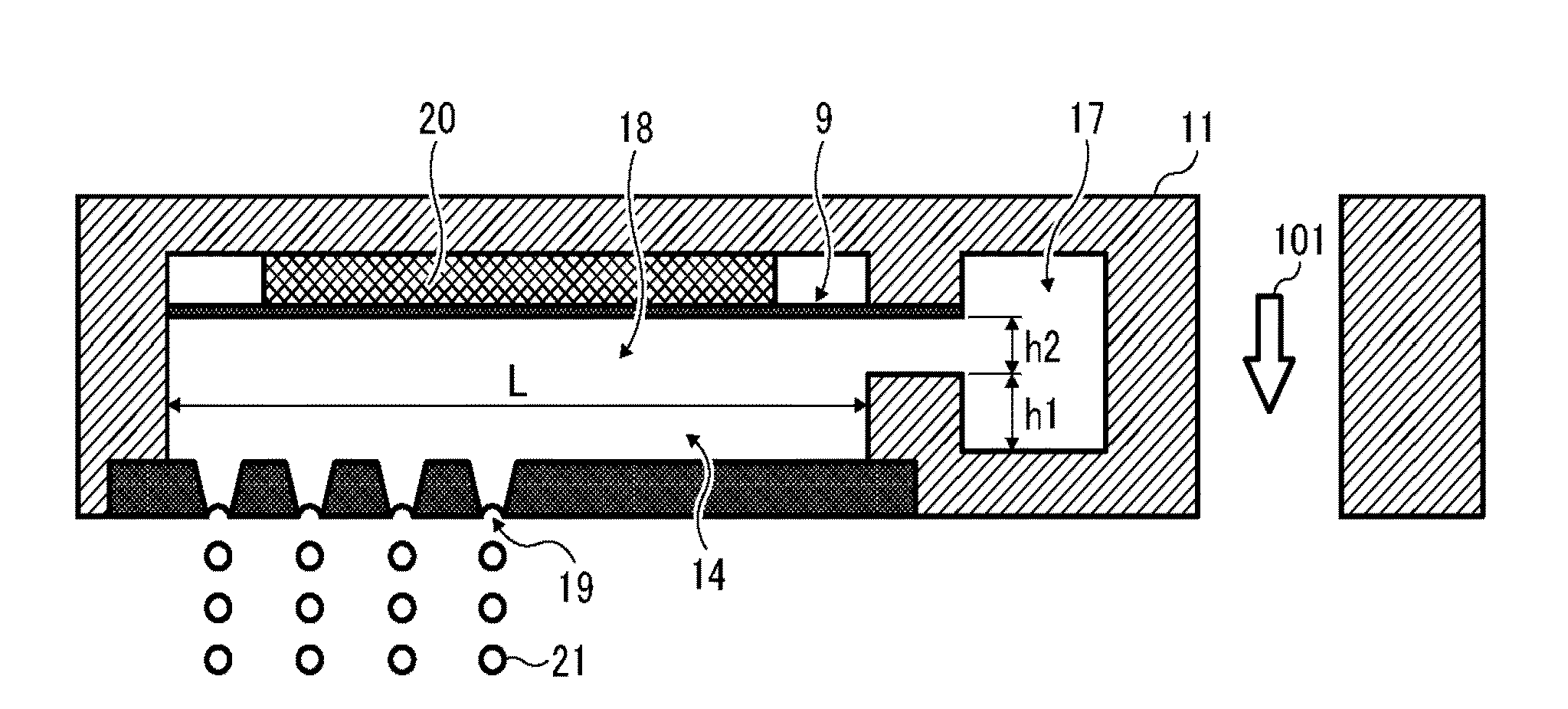

Ultrathin in-situ liquid sample room for transmission electron microscope and auxiliary installation device and installation method for ultrathin in-situ liquid sample room

ActiveCN105489462AReduce thicknessQuick installationElectric discharge tubesSmall samplePhysical chemistry

The invention aims at disclosing an ultrathin in-situ liquid sample room for a transmission electron microscope and an auxiliary installation device and installation method for the ultrathin in-situ liquid sample room. By design of a single rubber ring-sealed sample room and a synergistic effect of the auxiliary installation device, the thickness and the width of the in-situ liquid sample room are reduced; assembly is relatively safe and reliable; and relatively effective utilization of a small sample space in the transmission electron microscope and achievement of relatively multiple functions carried on the in-situ liquid sample room are facilitated.

Owner:南通励思仪电子科技有限公司

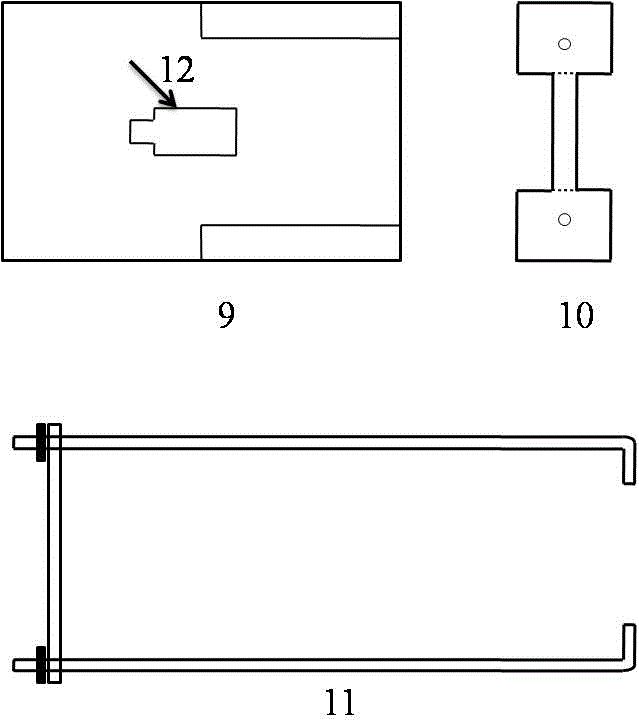

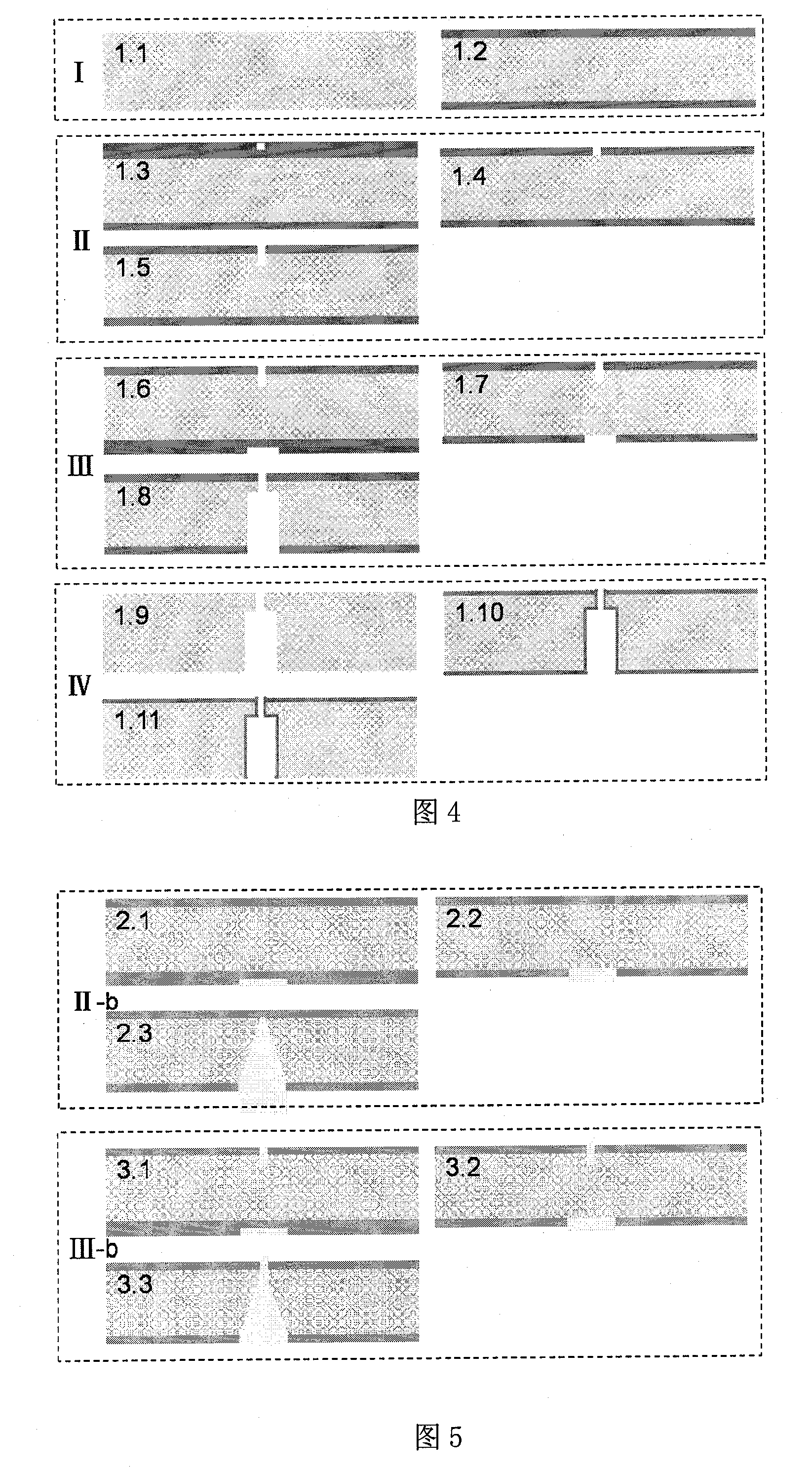

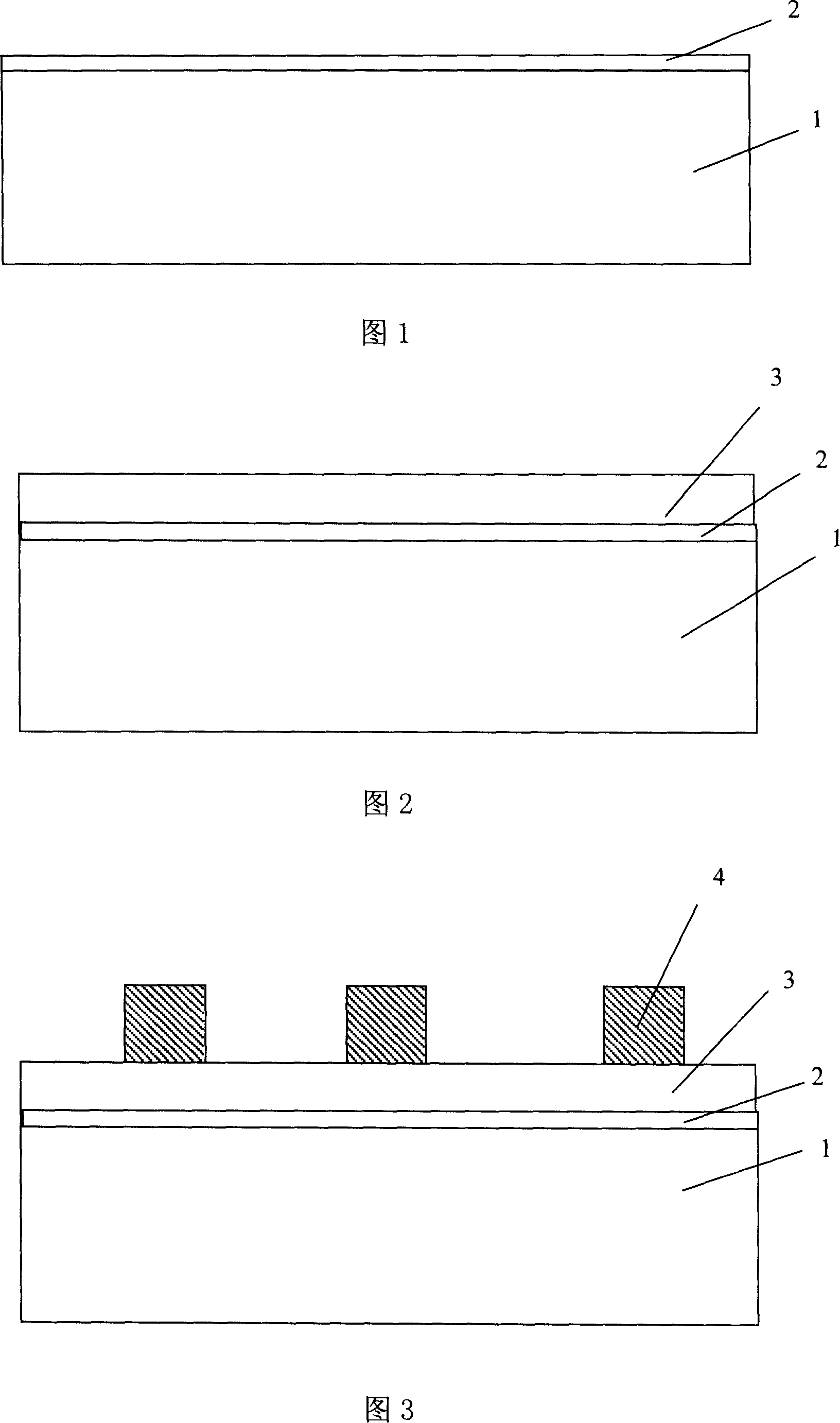

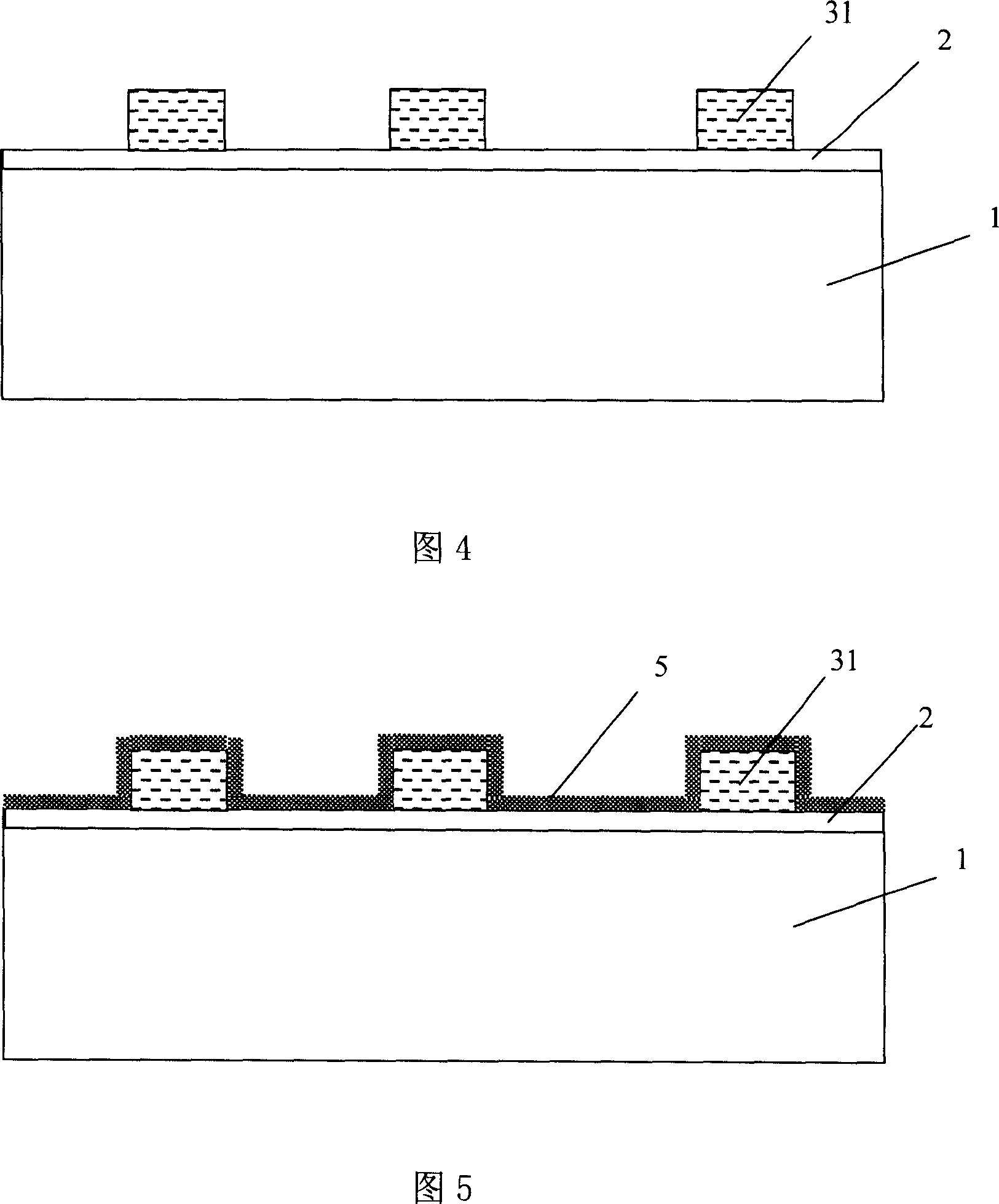

Adapter of transmission electron microscope example bench, its substrate and manufacturing method thereof

ActiveCN101221882AElectric discharge tubesSurface/boundary effectElectron microscopeMicroscopic scale

The invention provides a transmission electronic microscope sample stage connector utilized for property measurement, a substrate for complement use and a production method of the substrate. The invention has the advantages of producing a general TEM sample stage connector by precise mechanical processing and integral semi-conduct process flow, and combining the representing performance of the TEM on the micro structure of the materials and the measuring performance of the material property with the substrate as the carrier. After the substrate finishes the micro structure representation of the TEM, the substrate is taken out and put into any property measuring device which is compatible with the substrate for measuring the mechanics, electronics, optics, thermology, acoustics properties of the materials; meanwhile, a corner of the slit is taken as a mark, thereby guaranteeing the structure representation and the property measurement of the TEM are in the same micro area, which thus can really associate the material micro structure with the properties. In addition, the property measurement can be performed prior to the TEM structure representation.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Unsupported, electron transparent films and related methods

Owner:UNIV OF WASHINGTON

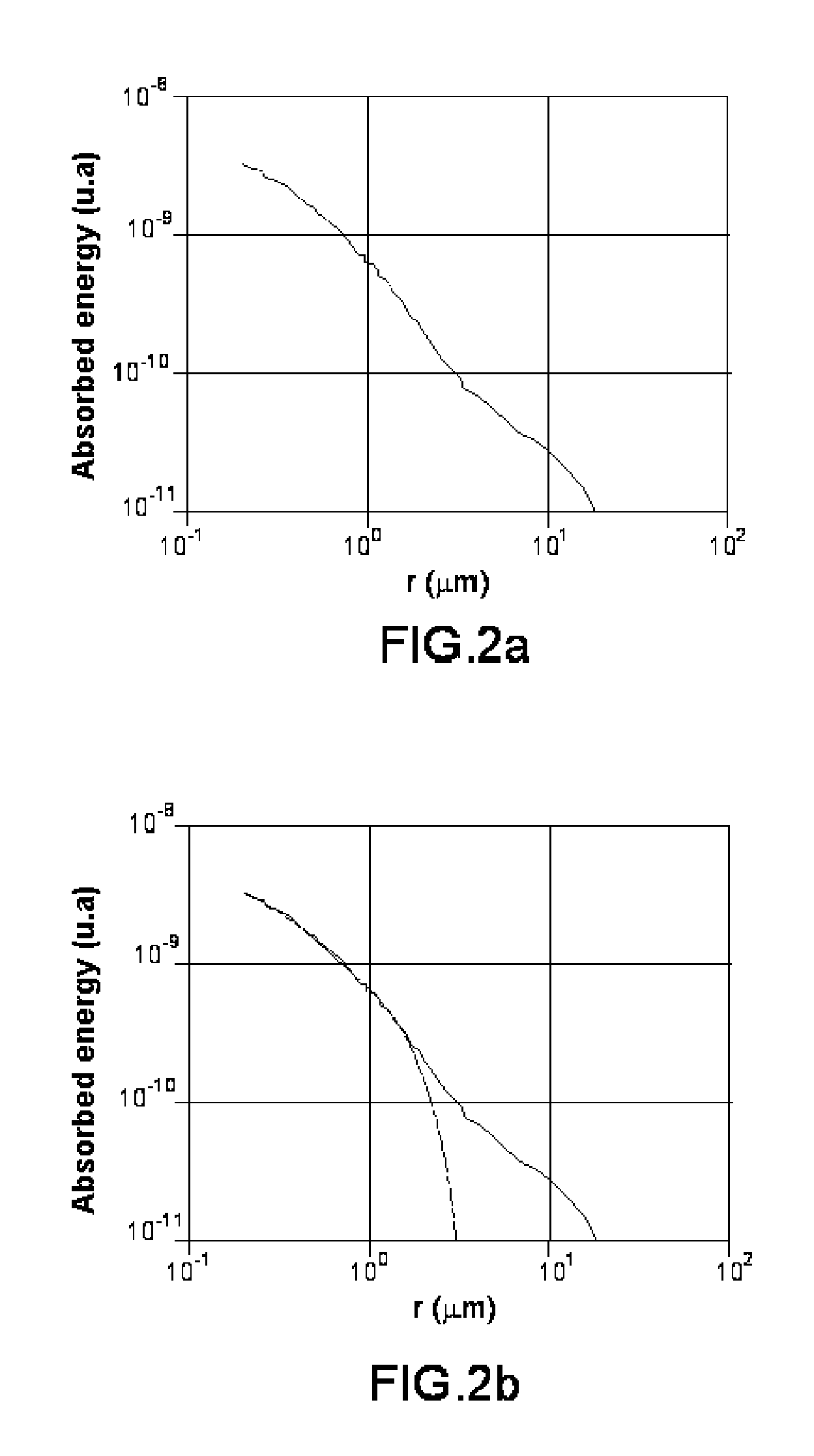

Method for correcting electronic proximity effects using off-center scattering functions

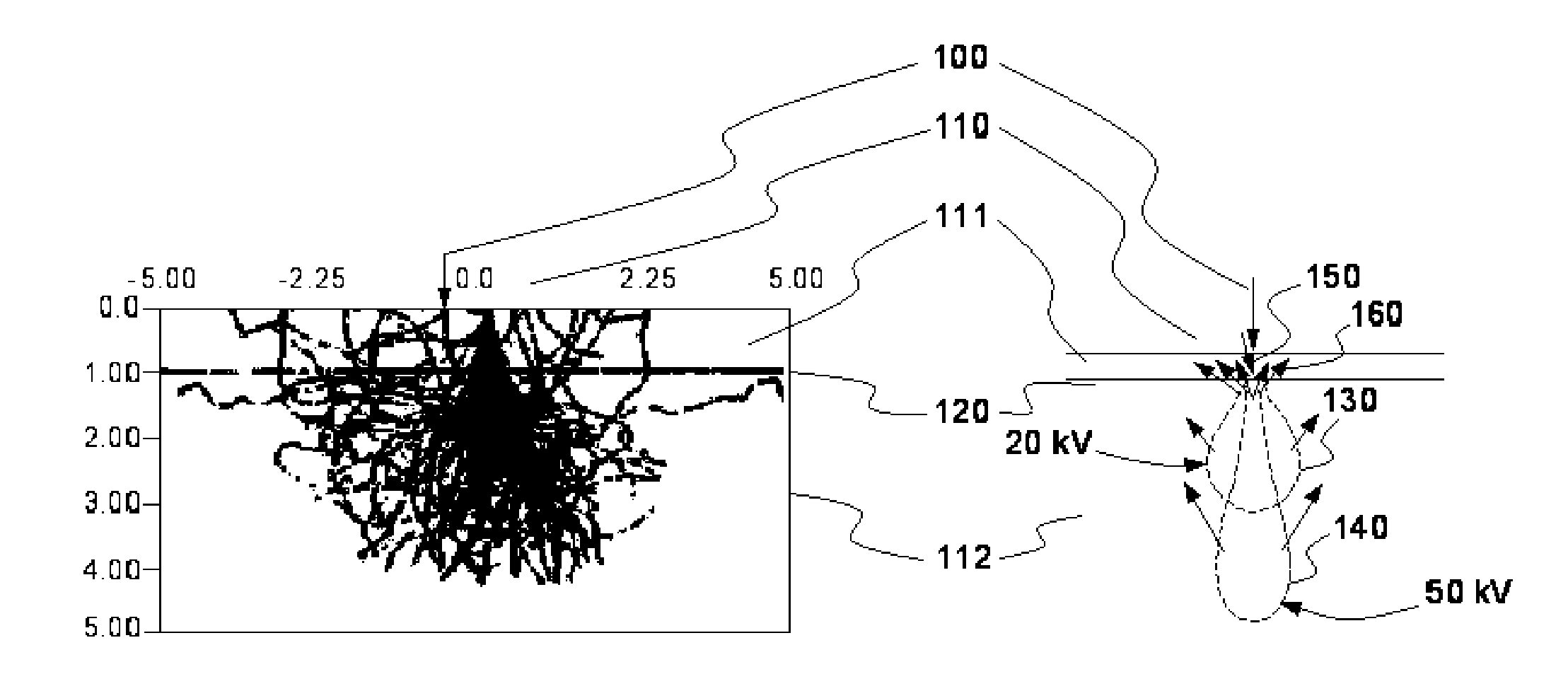

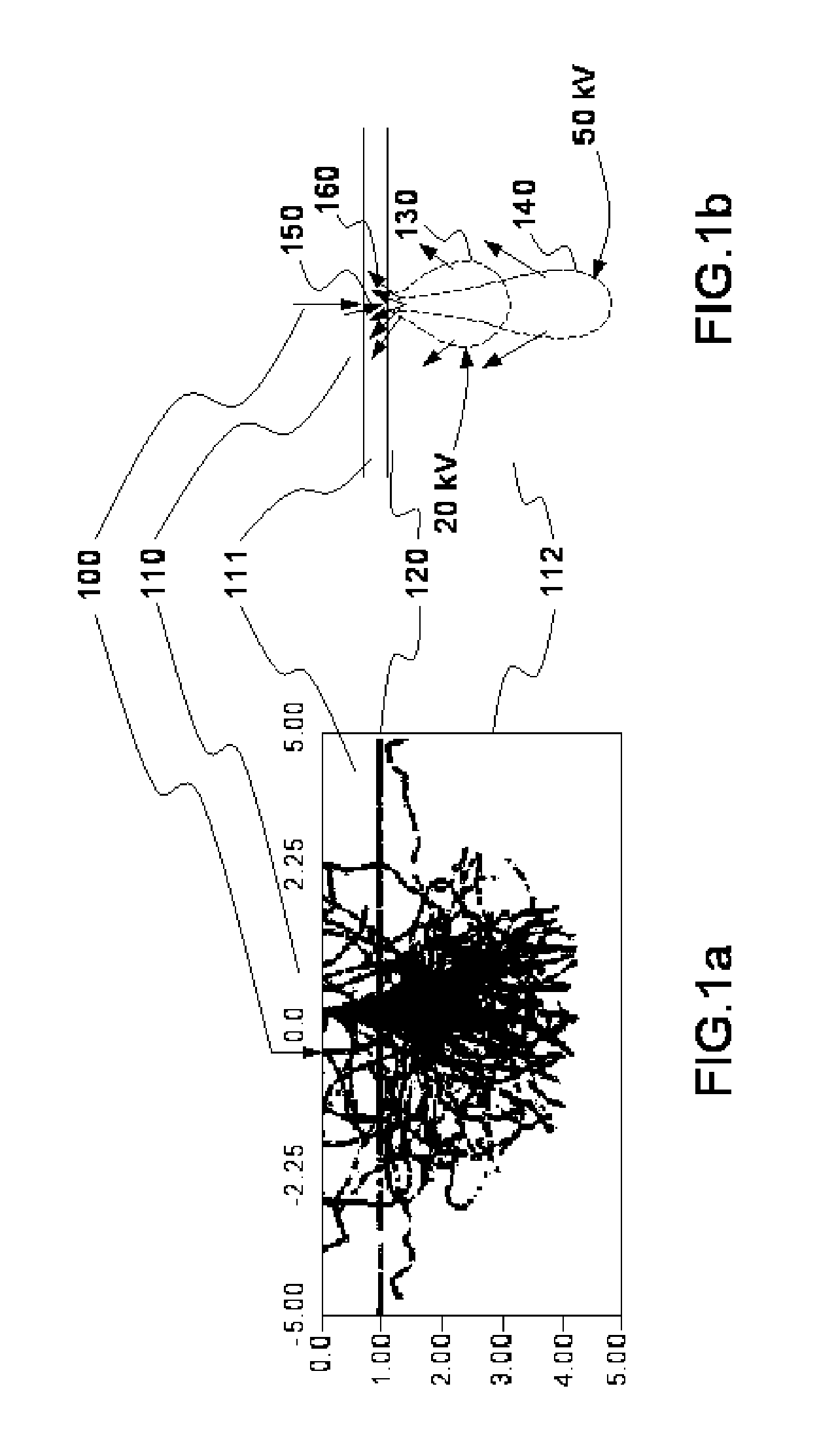

ActiveUS20130043389A1Improve errorMaterial analysis using wave/particle radiationCathode ray tubes/electron beam tubesLithographic artistScattering function

A method for projecting an electron beam, used notably in direct or indirect writing lithography and in electronic microscopy. Proximity effects created by the forward and backward scattering of the electrons of the beam in interaction with the target must be corrected. For this, the convolution of a point spread function with the geometry of the target is conventionally used. At least one of the components of the point spread function has its maximum value not located on the center of the beam. Preferably, the maximum value is instead located on the backward scattering peak. Advantageously, the point spread function uses gamma distribution laws.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

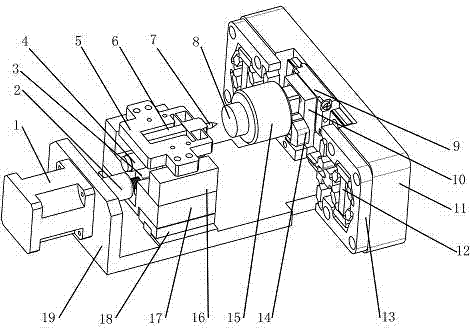

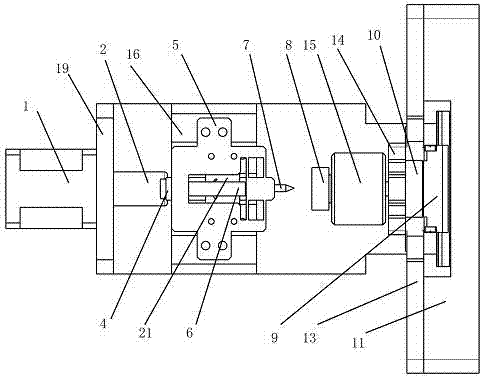

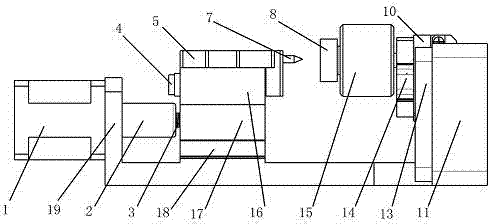

In-situ micro-nanometer mechanics testing and scoring machining integrated machine

InactiveCN102928306ARealize high-precision positioningImprove processing qualityNanotechnologyInvestigating material hardnessMicro nanoScientific instrument

The invention relates to an in-situ micro-nanometer mechanics testing and scoring machining integrated machine, belonging to a mechanical-electrical integration precision scientific instrument. A left side step motor drives a screw nut through a coupler; relative connecting pieces are driven by the screw nut, so that the rough feeding of a flexible hinge and a diamond pressing head can be realized; and a piezoelectric stack drives the flexible hinge to carry out precise feeding. A right side objective table and a precise force sensor are mounted on the flexible hinge, and is connected with a rotor through a screw; thin-sheet-shaped structures at the both sides of the rotor are in clearance fit with the output ends of the two flexible hinges; the rotor is connected with a guide rail sliding block; the two symmetrical flexible hinges and the guide rail are mounted on a tail base; and the tail base is mounted on the base. The in-situ micro-nanometer mechanics testing and scoring machining integrated machine has the advantages of small size and compact structure; and the in-situ micro-nanometer mechanics testing and scoring machining integrated machine can be mounted in a scanning electronic microscope for a micro-nanoindentation and scoring test. The in-situ micro-nanoindentation test of a material can be carried out at first; the scoring machining technique is optimized according to a test result; the scoring machining is realized according to an optimal technique parameter; and finally, the integrated testing and machining process can be finally realized.

Owner:JILIN UNIV

Universal liquid sample device and process for high resolution transmission electron microscope imaging and multimodal analyses of liquid sample materials

ActiveUS20170213692A1Enhance optical characteristic of imageImprove imaging resolutionElectric discharge tubesMaterial analysis by transmitting radiationElectron microscopeSample image

Liquid sample imaging devices and processes are disclosed for high resolution TEM imaging and multimodal analyses of liquid sample materials in situ under high vacuum that are compatible with standard type TEM chip membranes and TEM sample holders allowing TEM liquid sample imaging to be performed wherever a TEM instrument is accessible and at a substantially reduced cost compared to prior art systems and approaches.

Owner:BATTELLE MEMORIAL INST

Collecting electrode used in super capacitor and its surface treating method

InactiveCN101174509AEfficient removalEvenly distributedElectrode manufacturing processesElectrode carriers/collectorsChemical treatmentInternal resistance

The invention discloses a collector of super capacitor and the surface processing method, which is characterized in that a collector body film can be an aluminum film, a copper foil, a foam nickel film, a stainless steel film or punching nickel film; the purity of aluminum is over 99.9%; the thickness of the corrosion aluminum foil is 15 to 50 Mum; the roughness is 1.5 to 3.0 Mum; the collector body is spongy under 20000X electronic microscope; the average diameter of the corrosion hole is 0.05 to 0.2 Mum; 5 to 10 billion holes are arranged in the area of 1 cm2; the tensile strength is 1.0 to3.0 kg / cm. The invention has the advantages that chromic acid mixture is adopted for chemical treatment for the surface of the current collector; dust on the surface of aluminum foil of the current collector during storage and transportation can be removed; anti-septic oil and anti-sticking agent on the aluminum foil during machining process are also effectively removed; active functional groups are added, enabling even and consistent distribution of coated electrode material; the adhesion strength of the electrode film is improved; internal resistance of the electrode is reduced, the specificsurface area is increased; the collector is applicable to large scale production.

Owner:NINGBO FUDA ELECTRIC APPLIANCE

A method for making CDSEM calibration sample

InactiveCN101009236AExtend working lifeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingResistAggradation

A manufacturing method of measuring key size of scanning electronic microscope (CDSEM) calibration sample includes pre-cleanout of silicon underlay, forming underlay oxidizing layer, accumulating multi crystal silicon layer, forming photosensitive resist pattern, forming gate structure, forming a conducting layer. Gate structure sample gained restrains the aggradation of hydrocarbon induced by cumulation of surface charge for the abreaction effect of conducting layer, so the phenomenon of overloading of CD grown is eliminated to make service life of the calibration sample prolong apparently and guarantee the reliability of test of CDSEM.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

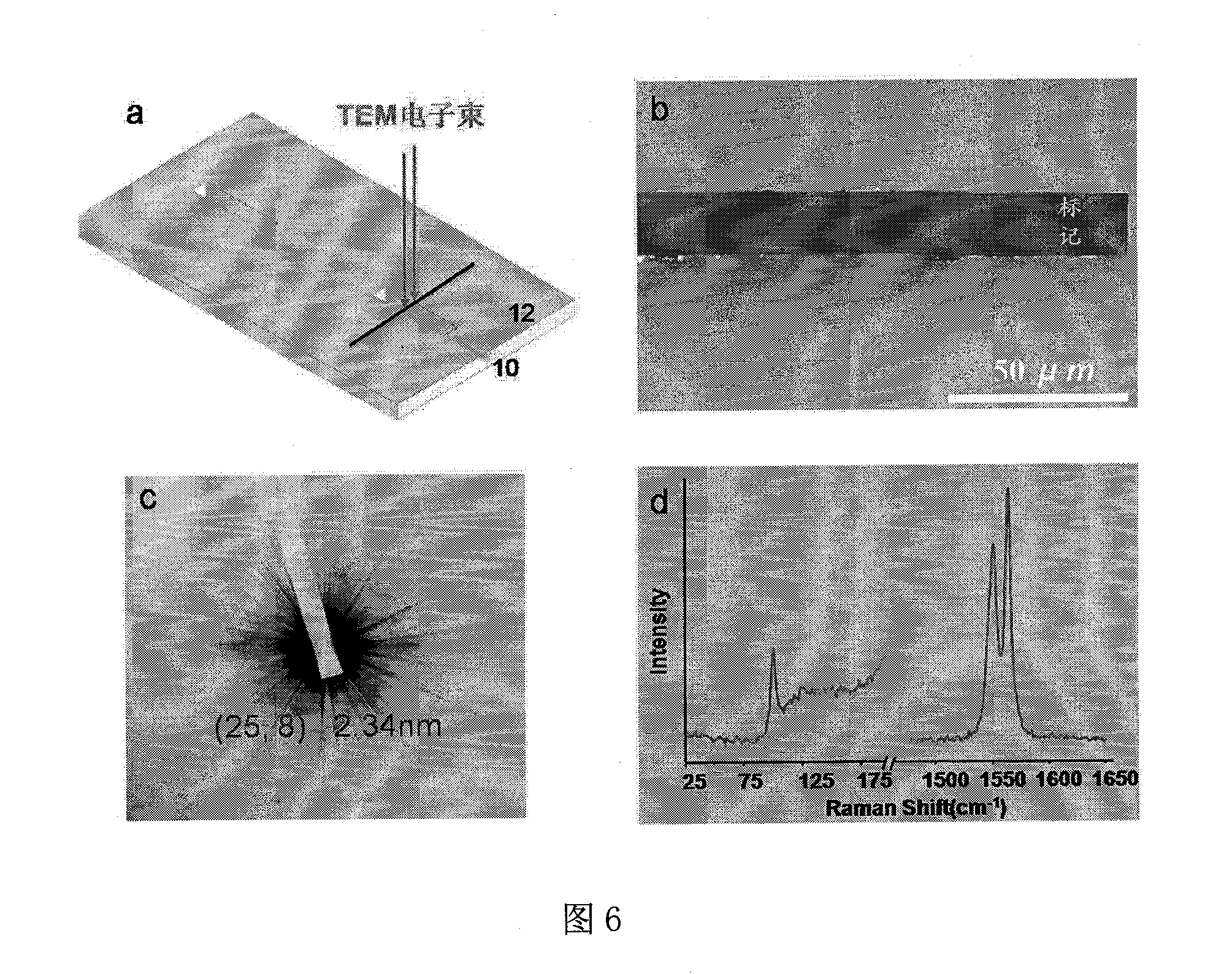

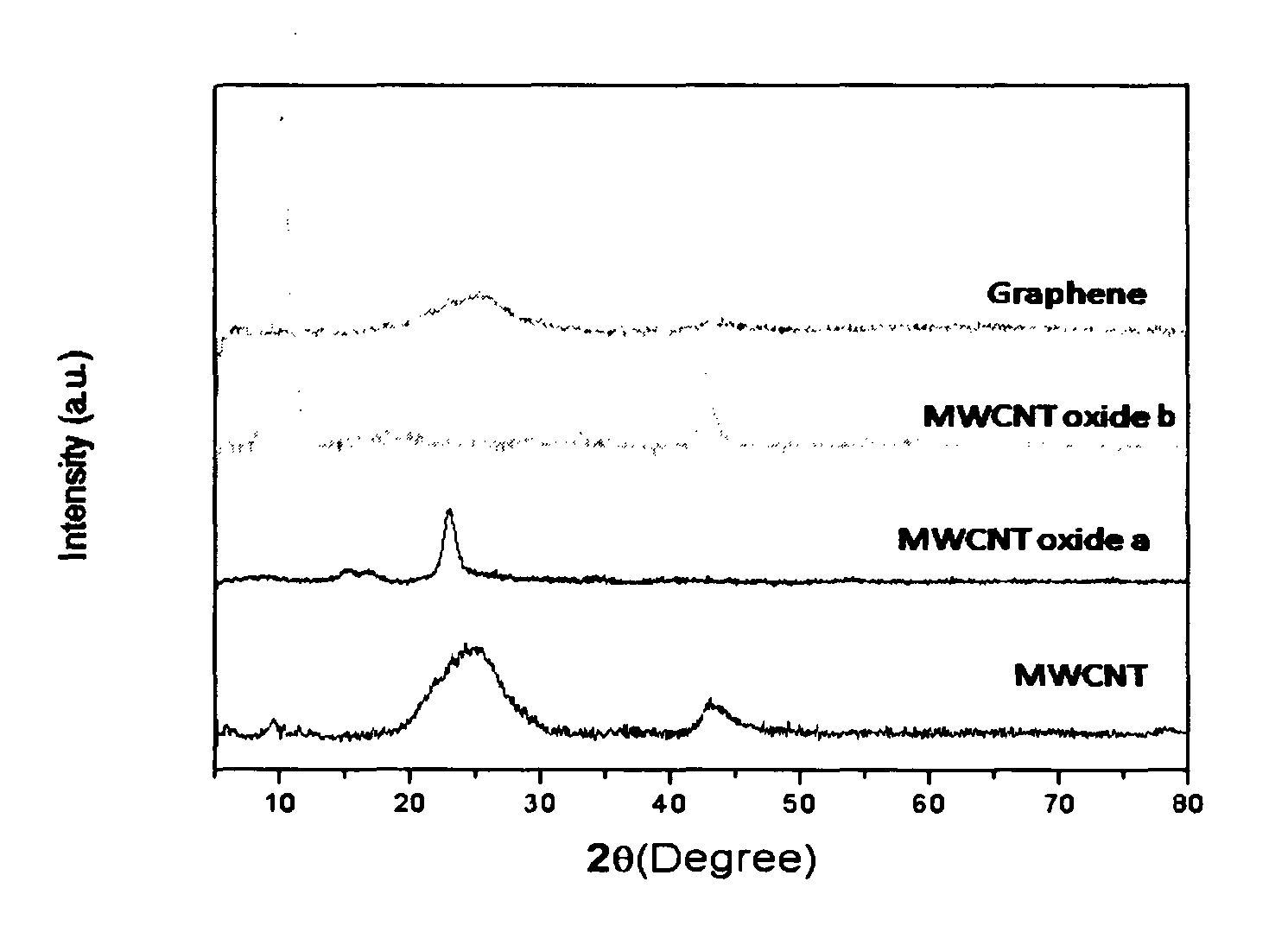

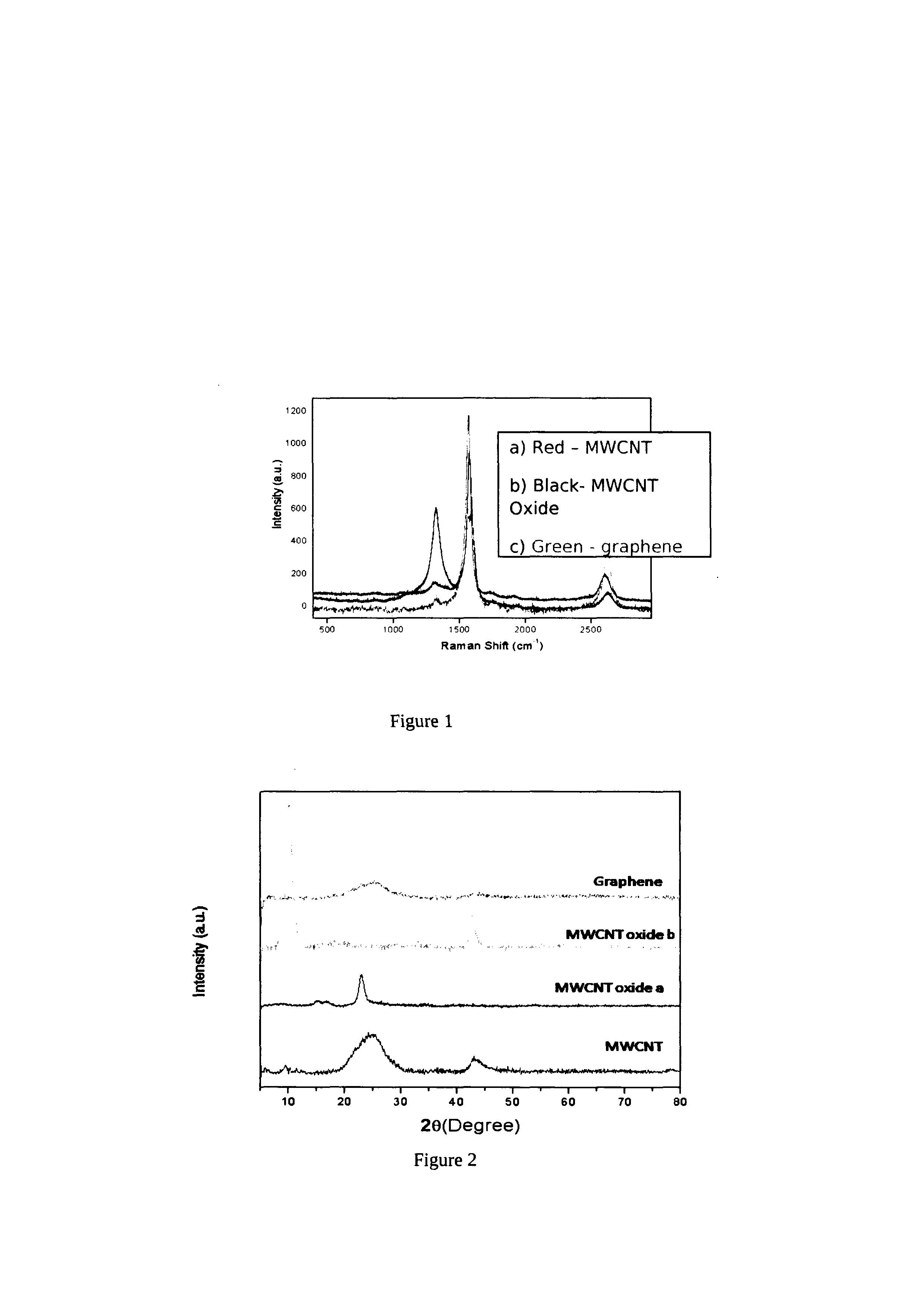

Electrochemical process for synthesis of graphene

InactiveUS20130175182A1Few defectUniform layer thicknessMaterial nanotechnologyElectrolysis componentsGraphene nanoribbonsCarbon nanotube

A process for the transformation of carbon nanotubes (CNTs) to nanoribbons composed of a few layers of graphene by a two-step electrochemical approach is disclosed in this invention. This consists of the oxidation of CNTs at controlled potential, followed by reduction to form graphene nanoribbons (GNRs) having smooth edges and fewer defects, as evidenced by multiple characterization techniques, including Raman spectroscopy, atomic force micro-scopy, and transmission electron microscopy. This type of ‘unzipping” of CNTs (single-walled, multi-walled) in the presence of an interfacial electric field provides unique advantages with respect to the orientation of CNTs, which might make possible the production of GNRs with controlled widths and fewer defects. The extent of oxidation was confirmed by various characterization techniques like XRD, XPS and Raman spectroscopy. In the second step of experiments, the CNT oxide were reduced for different periods such as 4, 8, 12 hours at fixed negative potentials of −0.5 V, so as to get layers of graphene ribbons as tabulated herein.

Owner:COUNCIL OF SCI & IND RES

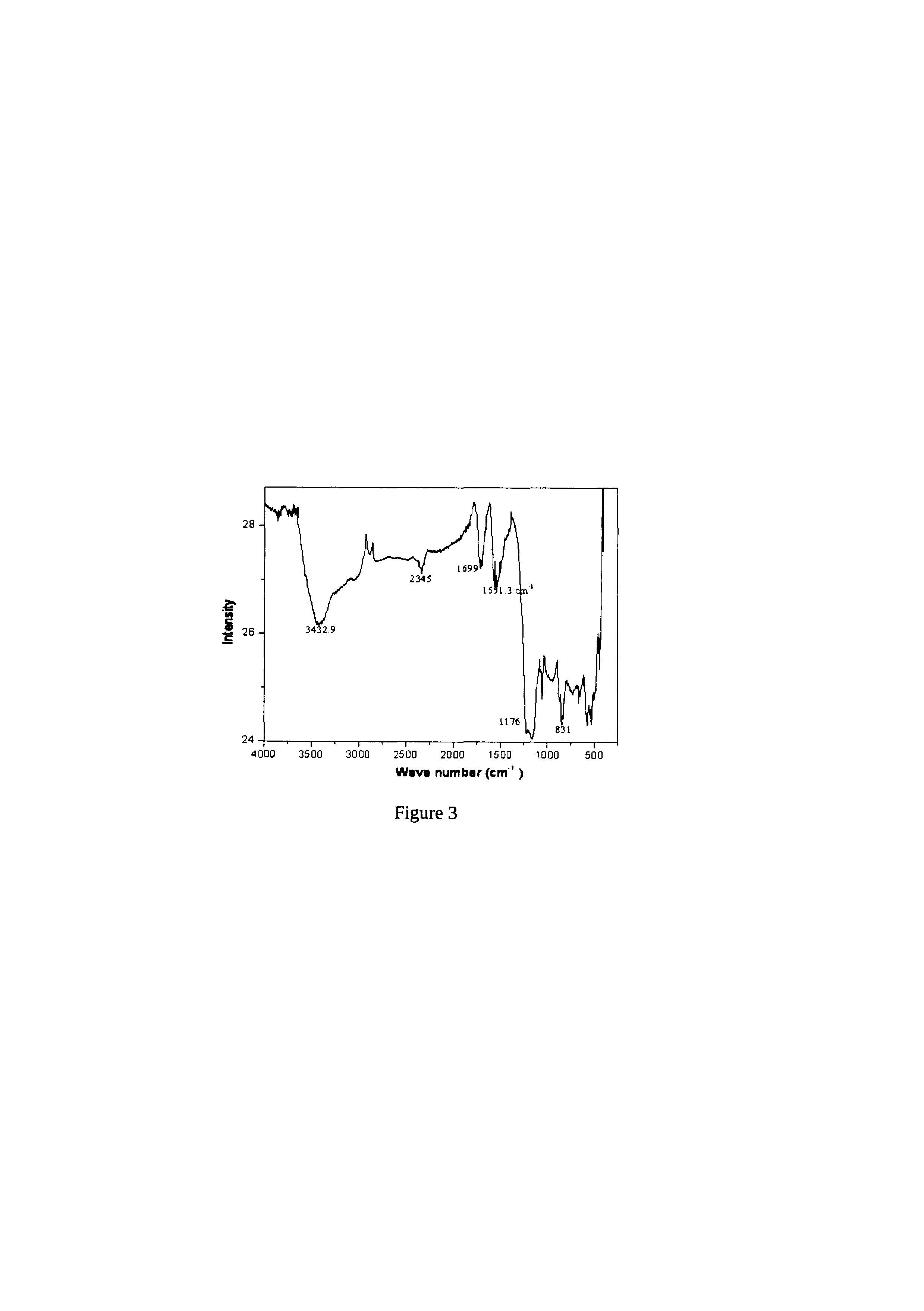

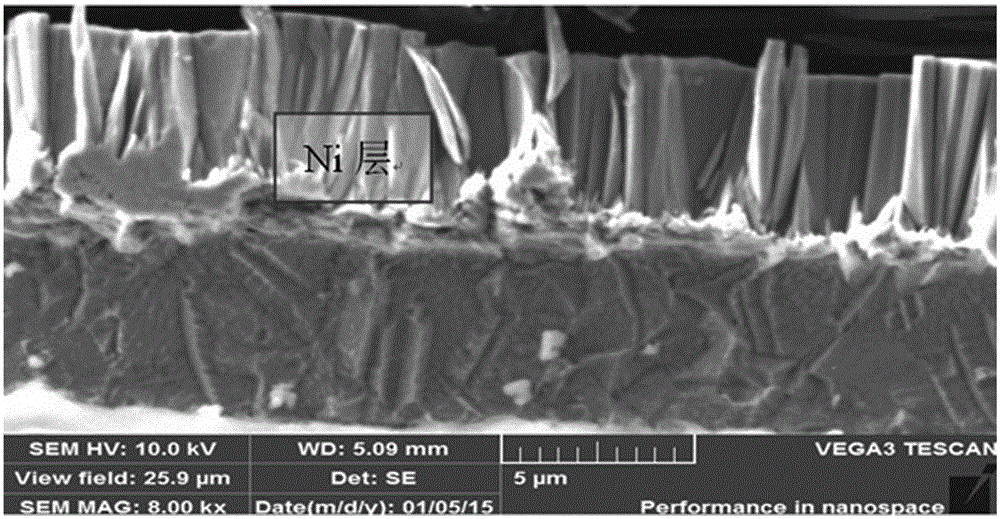

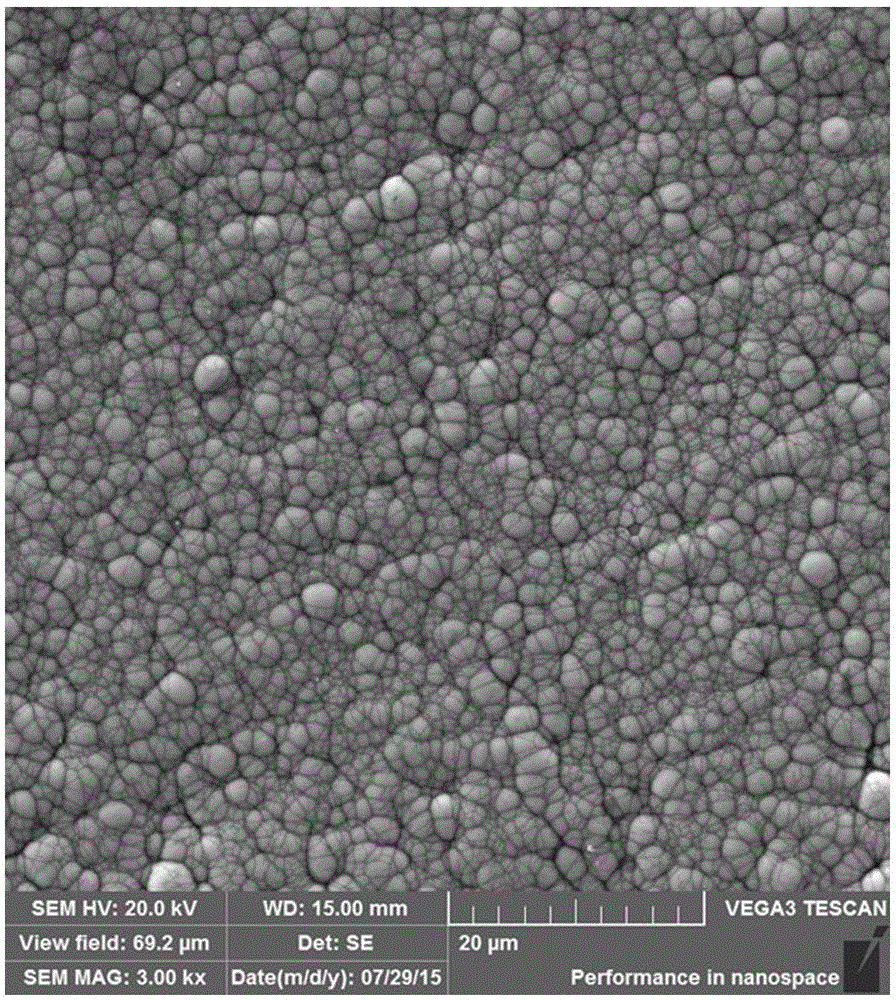

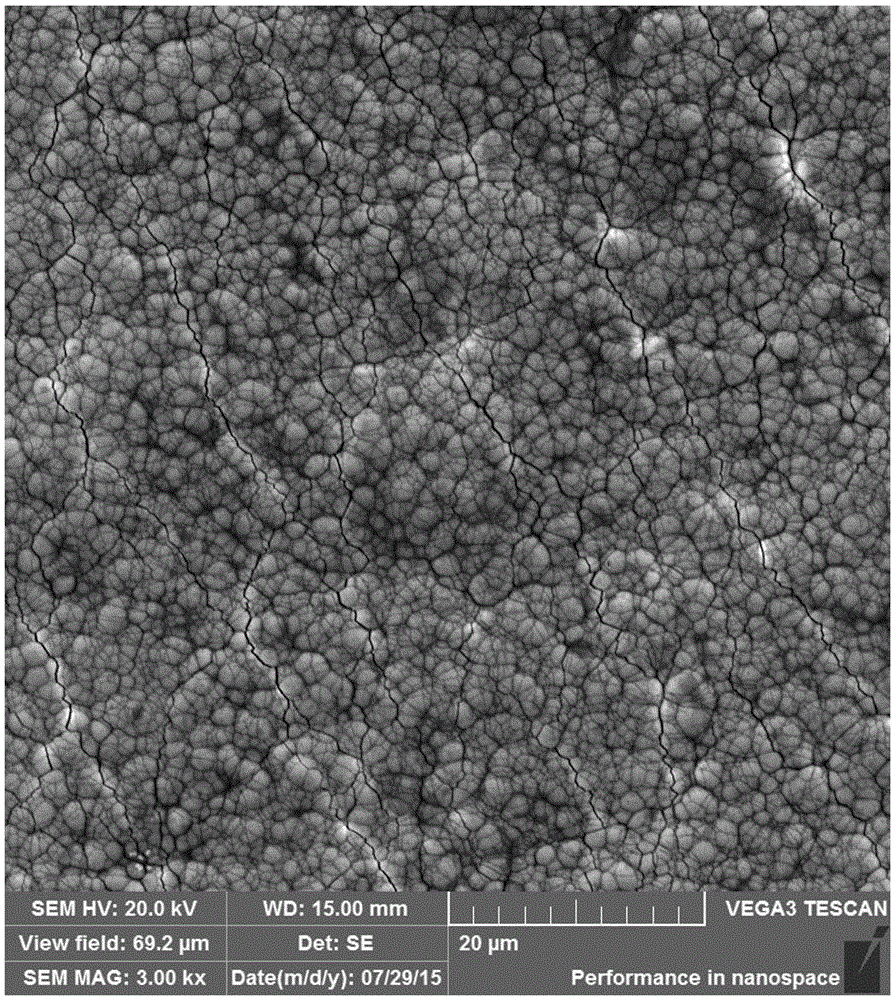

Chemical nickel plating solution for flexible printed circuit board and plating construction method thereof

ActiveCN105018904AImprove bending resistanceAccelerated corrosionLiquid/solution decomposition chemical coatingNickel saltChemical plating

The invention discloses a chemical nickel plating solution for a flexible printed circuit board and a plating construction method thereof. The chemical nickel plating solution for the flexible printed circuit board is characterized in that according to the formula of the nickel plating solution, each liter of the nickel plating solution comprises 20-30 grams of soluble nickel salt, 20-40 grams of a reducing agent, 20-50 grams of fatty carboxylic acid and / or a substituted derivative, 5-15 grams of a buffering agent and 0.5-10.0 grams of ethanediamine and / or a condensation compound thereof, and contains 0.01-10.0 ppm of a sulfocompound. A cylindrical nickel additive and an accelerator are added into the chemical nickel plating solution, the chemical nickel plating solution is plated on the surface of the FPC, a gold layer is deposited by a chemical gold plating solution in a follow-up procedure, after gold in the gold layer is removed by a gold removing agent, a nickel alloy layer is free of cracks under the observation of an electronic microscope, and a flexible nickel alloy layer is obtained. The nickel plating solution provided by the invention improves the flexibility and the corrosion resistance of the nickel alloy layer.

Owner:珠海斯美特电子材料有限公司

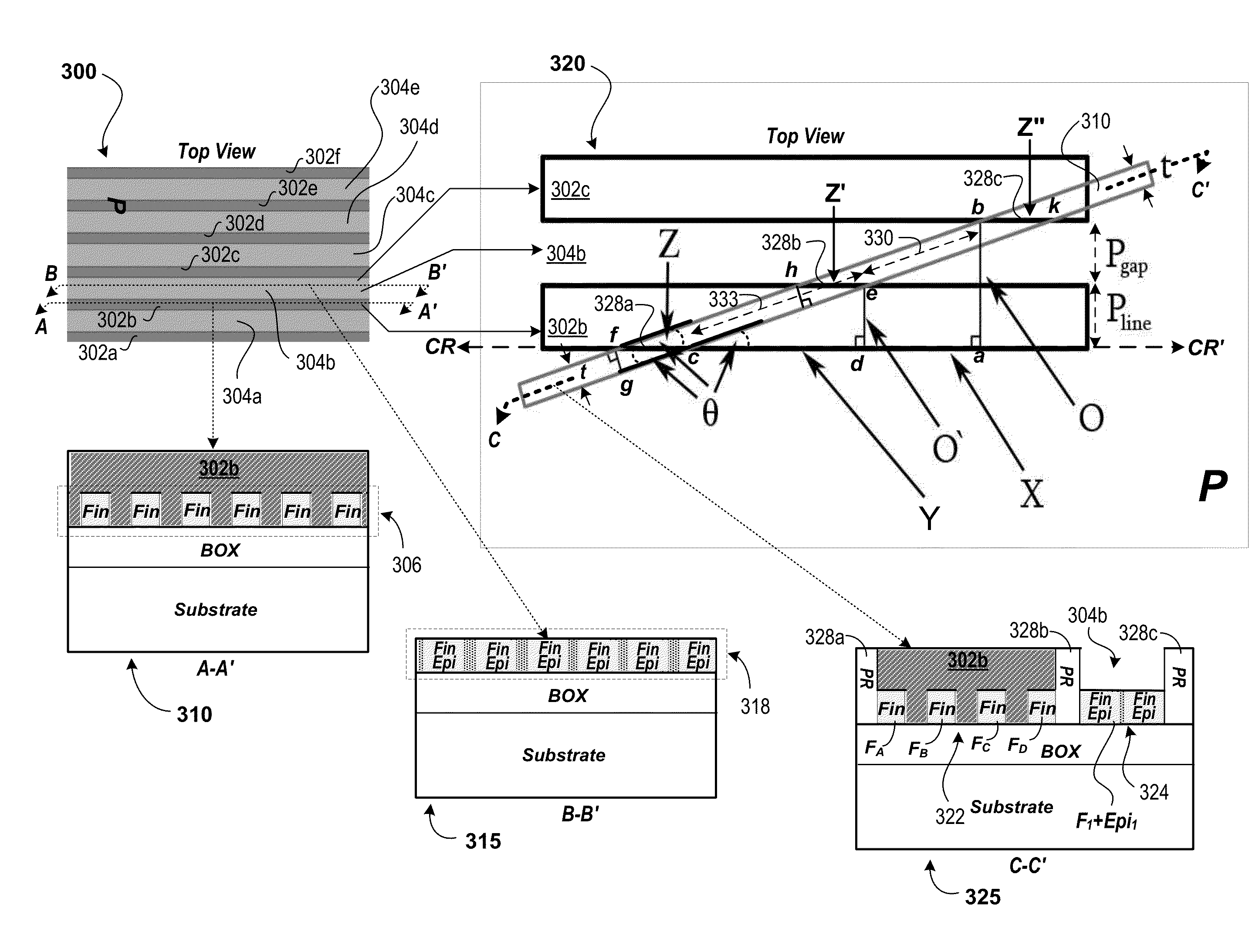

TCAD Emulation Calibration Method of SOI Field Effect Transistor

InactiveUS20130152033A1Accurate and effective pretestEffective guidanceSemiconductor/solid-state device testing/measurementComputer aided designOxide semiconductorComputer Aided Design

The present invention provides a Technology Computer Aided Design (TCAD) emulation calibration method of a Silicon On Insulator (SOI) field effect transistor, where process emulation Metal Oxide Semiconductor (MOS) device structures with different channel lengths Lgate are obtained by establishing a TCAD process emulation program; based on the process emulation MOS device structures, the process emulation MOS device structures are calibrated according to a Transmission Electron Microscope (TEM) test result, a secondary ion mass spectrometer (SIMS) test result, a Capacitor Voltage (CV) test result, a WAT test result, and a square resistance test result of an actual device, so as to complete TCAD emulation calibration of key electrical parameters of an SOI field effect transistor. Through the calibration method consistent with the present invention, in the same SOI process, TCAD emulation results of key parameters Vt and Idsat of MOSFETs of different sizes all meet a high-precision requirement that an error is less than 10%; moreover, accurate and effective pretest can be implement in the case of multiple splits, thereby providing effective guidance for research, development and optimization of a new process flow.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

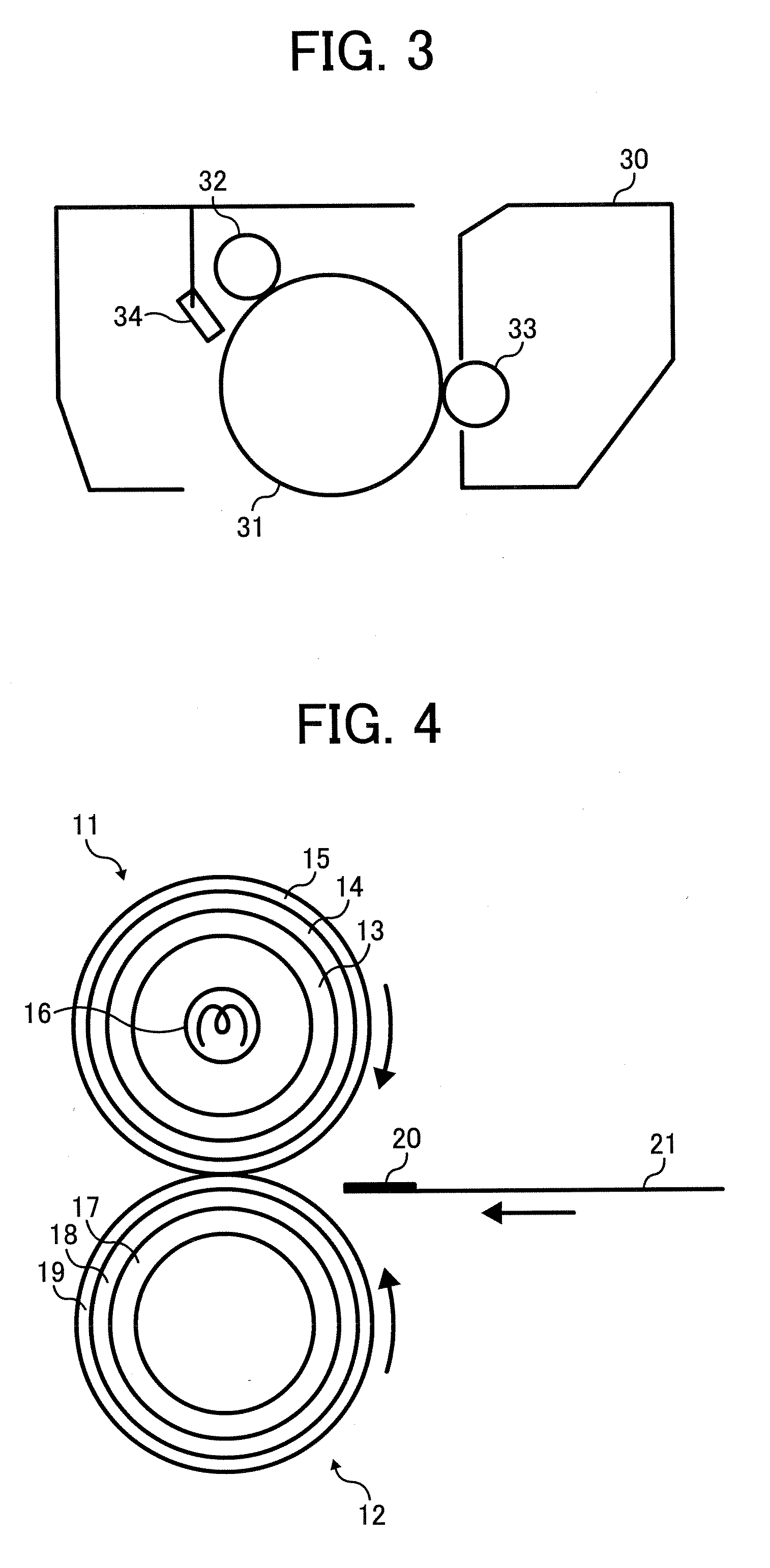

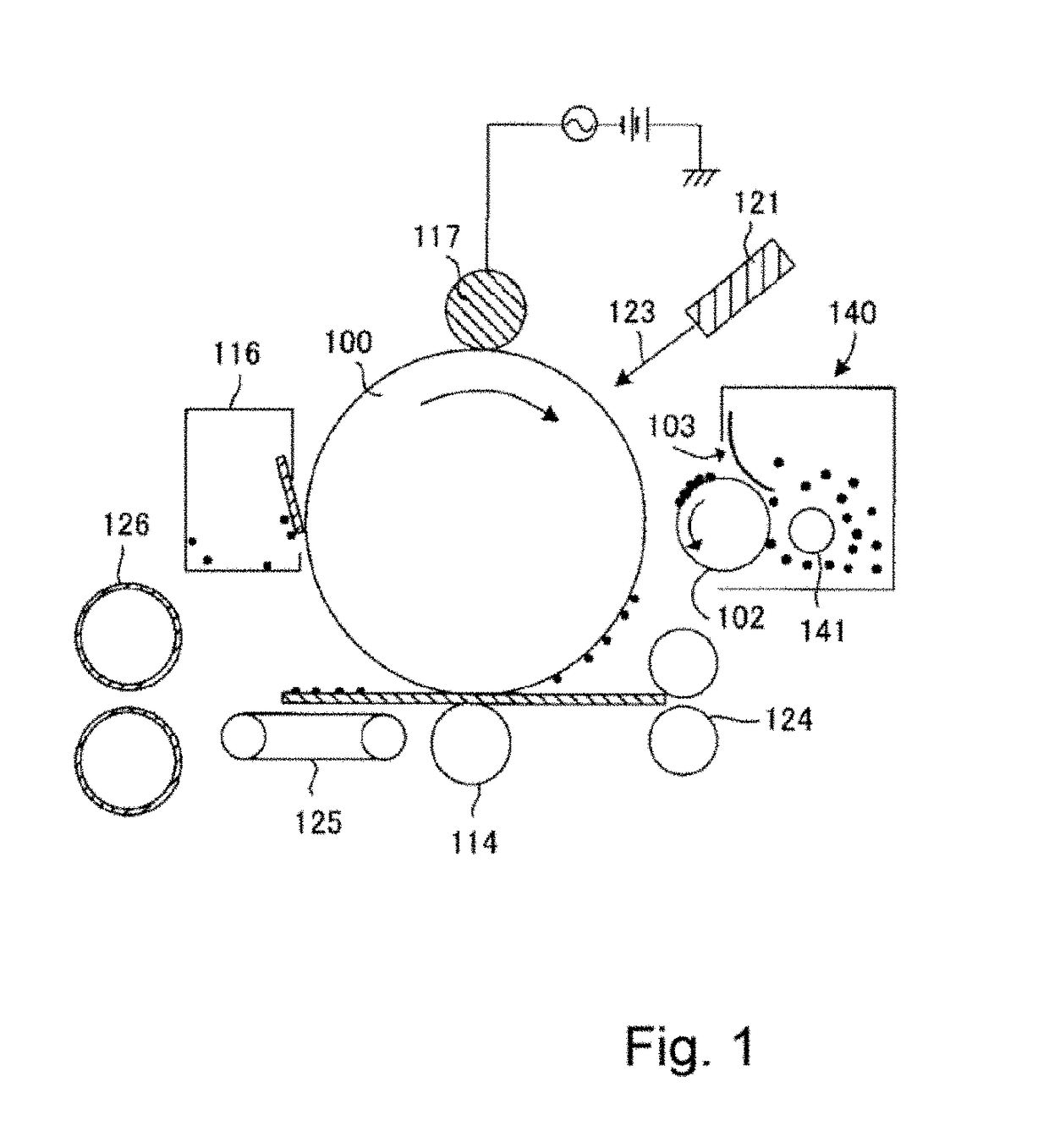

Toner, method of manufacturing toner, image forming method, and image forming apparatus

A toner including a binder resin and a release agent is provided. The binder resin includes an amorphous resin and a crystalline resin. In a cross-sectional image of the toner obtained by a transmission electron microscope, a longest length Lmax of the release agent is equal to or greater than 1.1 times a maximum Feret diameter Df of the toner, and the crystalline resin is dispersed in the amorphous resin forming domains having a maximum Feret diameter Cf of 0.20 μm or less.

Owner:RICOH KK

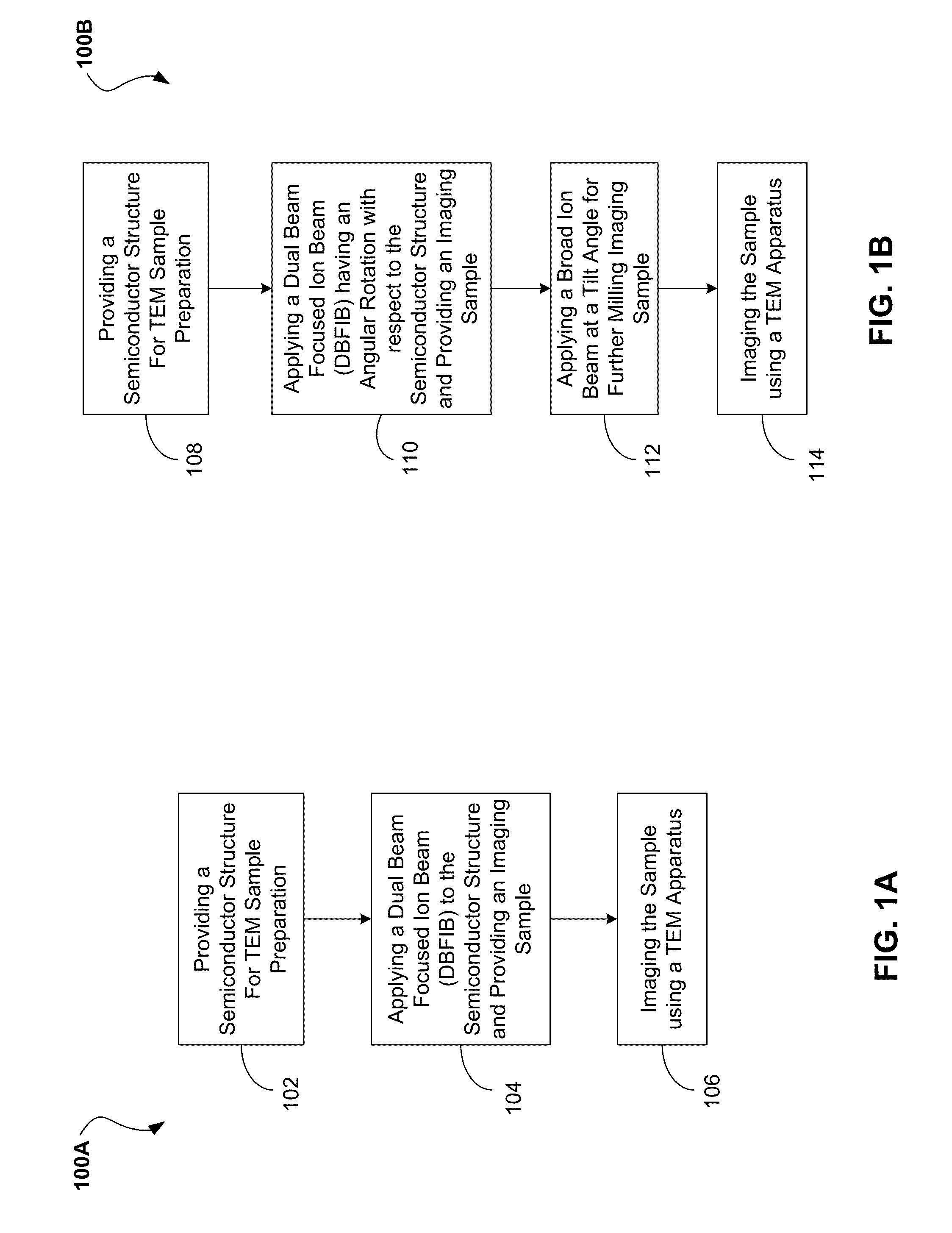

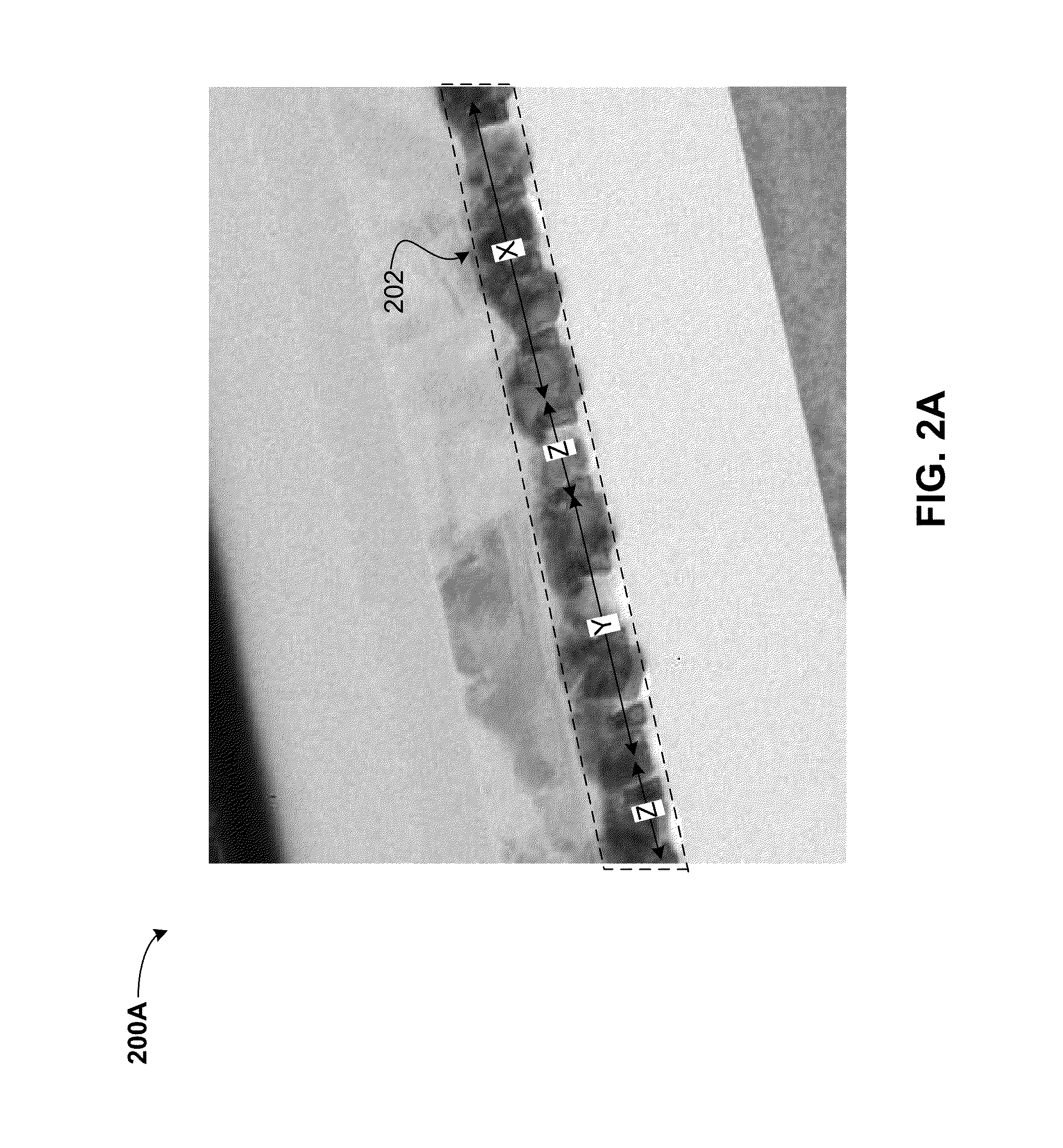

Transmission electron microscope sample fabrication

InactiveUS20140353497A1Enhanced TEM sample preparation processMaterial analysis using wave/particle radiationElectric discharge tubesConventional transmission electron microscopeSemiconductor structure

A method of preparing a transmission electron microscopy (TEM) sample from a semiconductor structure may include milling a region of the semiconductor structure with a focused ion beam and generating the transmission electron microscopy (TEM) sample. The focused ion beam providing the milling may include a rotation angle relative to the crystallographic axis of the semiconductor structure. A transmission electron microscopy image of a cross-sectional plane of the generated transmission electron microscopy (TEM) sample may be generated using a transmission electron microscope, whereby the transmission electron microscopy image of the cross-sectional plane includes an image projection-free region based on the rotation angle.

Owner:GLOBALFOUNDRIES INC

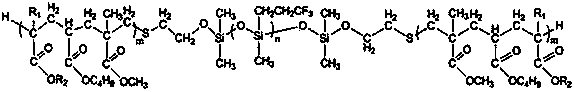

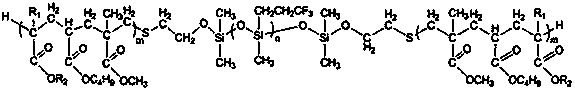

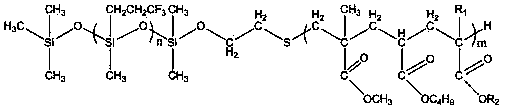

Fluorosiloxane-POSS acrylate block copolymers, blood-compatible coating thereof and preparation method of the fluorosiloxane-POSS acrylate block copolymers

ActiveCN103524752AImprove hydrophobicityNo deformationPharmaceutical containersMedical packagingPolymer sciencePolyvinyl chloride

The invention relates to fluorosiloxane-POSS acrylate block copolymers, a blood-compatible coating thereof and a preparation method of the fluorosiloxane-POSS acrylate block copolymers, and belongs to the fields of fluorosilicone copolymer preparation and biomedical polymers. The blood-compatible coating prepared from the fluorosiloxane-POSS acrylate block copolymers has good hydrophobicity, a static contact angle with water of more than 107 degrees, and an improved anticoagulation time compared with polyvinyl chloride surfaces. Adhesive platelet adhesion and aggregation states are observed under a scanning electron microscope. Compared to a bank PVC surface, surface adhesive platelets of the surface after being coated are obviously reduced above 85%, the surface adhesive platelets are distortionless largely, and blood compatibility is good. The preparation process of the blood-compatible coating is simple with easily available raw materials, is prone to industrialization and large-scale production, and has high practical value. The fluorosiloxane-POSS acrylate block copolymers are shown as the formula 1 and the formula 2. The formula 1 and the formula 2 are shown in the description.

Owner:UNIV OF JINAN

Cathode three-element alloy film and method for preparing film covered dipping diffusion cathode

ActiveCN101335166ASolve problems that are difficult to substantially improveIncreased emission current densityDischarge tube solid thermionic cathodesCold cathode manufactureRheniumManufacturing technology

The invention is a cathode ternary alloy film and a method for preparing coating-film dipped proliferation cathode, which relates to the technology of microwave electric-vacuum device manufacturing. The cathode ternary alloy film is a film of tungsten-rhenium-osmium ternary alloy. The method for preparing the coating-film dipped proliferation cathode comprises the following steps: A. before dipping an emitting material, a rhenium film is sputtered and deposited on the surface of cathode by adopting a surface sputtering method; an osmium-tungsten film is sputtered and deposited; next, the emitting material is dipped; by utilizing a high-temperature dipping process of the emitting material, the alloying of the cathode surface film is realized; B. after dipping the emitting material, the film of tungsten-rhenium-osmium ternary alloy is sputtered and deposited on the surface of the cathode by utilizing tungsten-rhenium-osmium ternary alloy target. The cathode prepared by the cathode ternary alloy film of the invention can enhance the density of current emitted by the cathode in a several-fold manner, and the emitting capacity of cathode is greatly improved; various specifications can be prepared in a comparatively easy way and batch production can be realized easily. The cathode of the invention can be applied to various electric-vacuum devices, and also can be used in to electronic tubes of TV and electronic microscopes.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

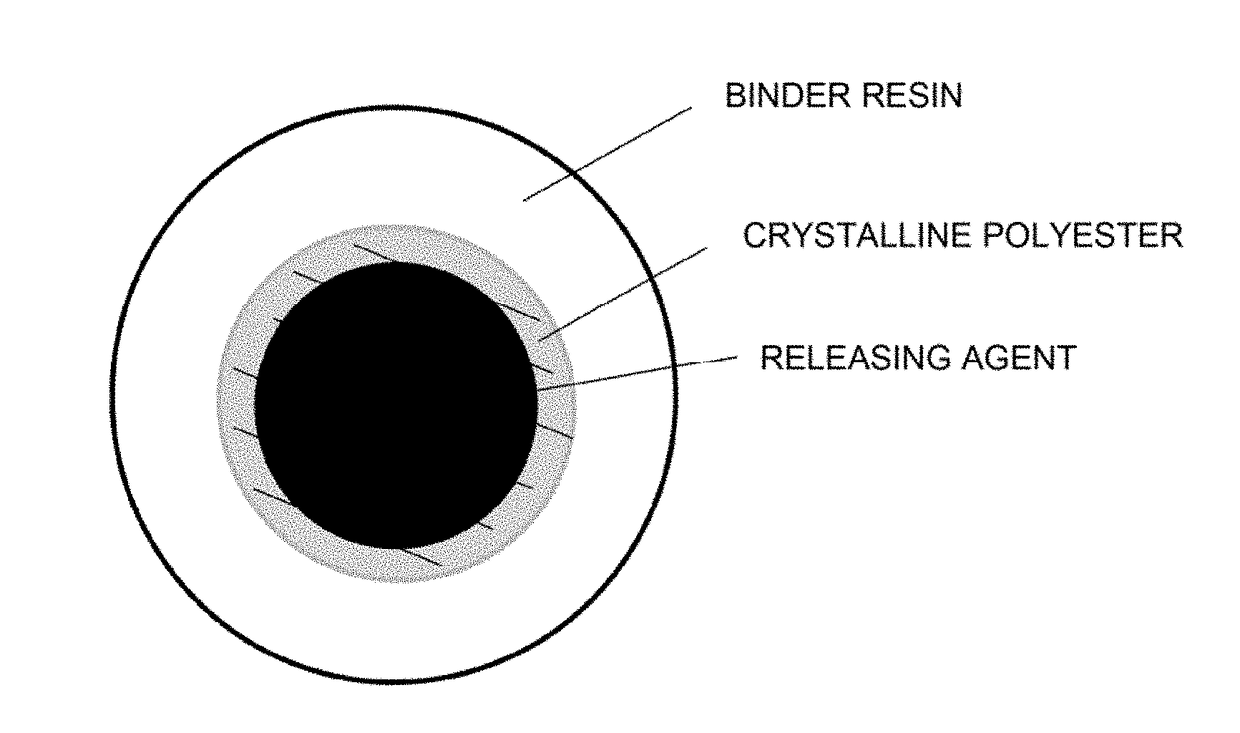

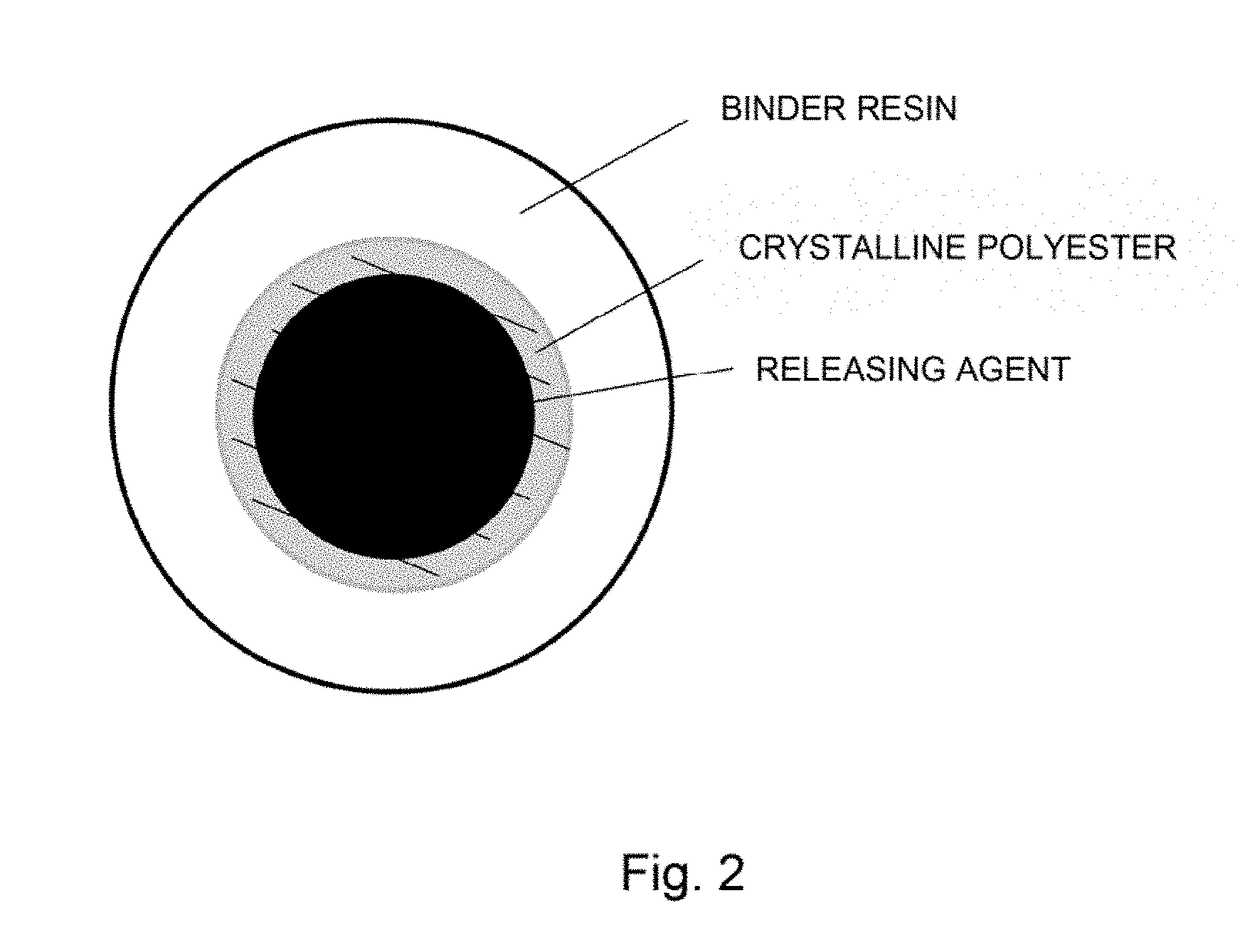

Toner

Provided is a toner including toner particles, each of which contains a binder resin, a colorant, a releasing agent and a crystalline polyester, wherein in an observation of a cross-section each of the toner particles by transmission electron microscopy, specific toner particles each of which has domains of the crystalline polyester and domains of the releasing agent, are present at a ratio of at least 70% by number of the toner particles in the toner, an arithmetic mean of maximum diameters of the domains of the releasing agent is within prescribed range, and the specific toner particles satisfy prescribed conditions.

Owner:CANON KK

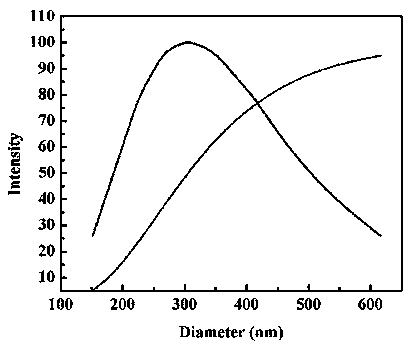

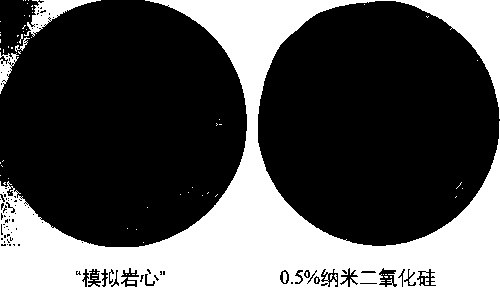

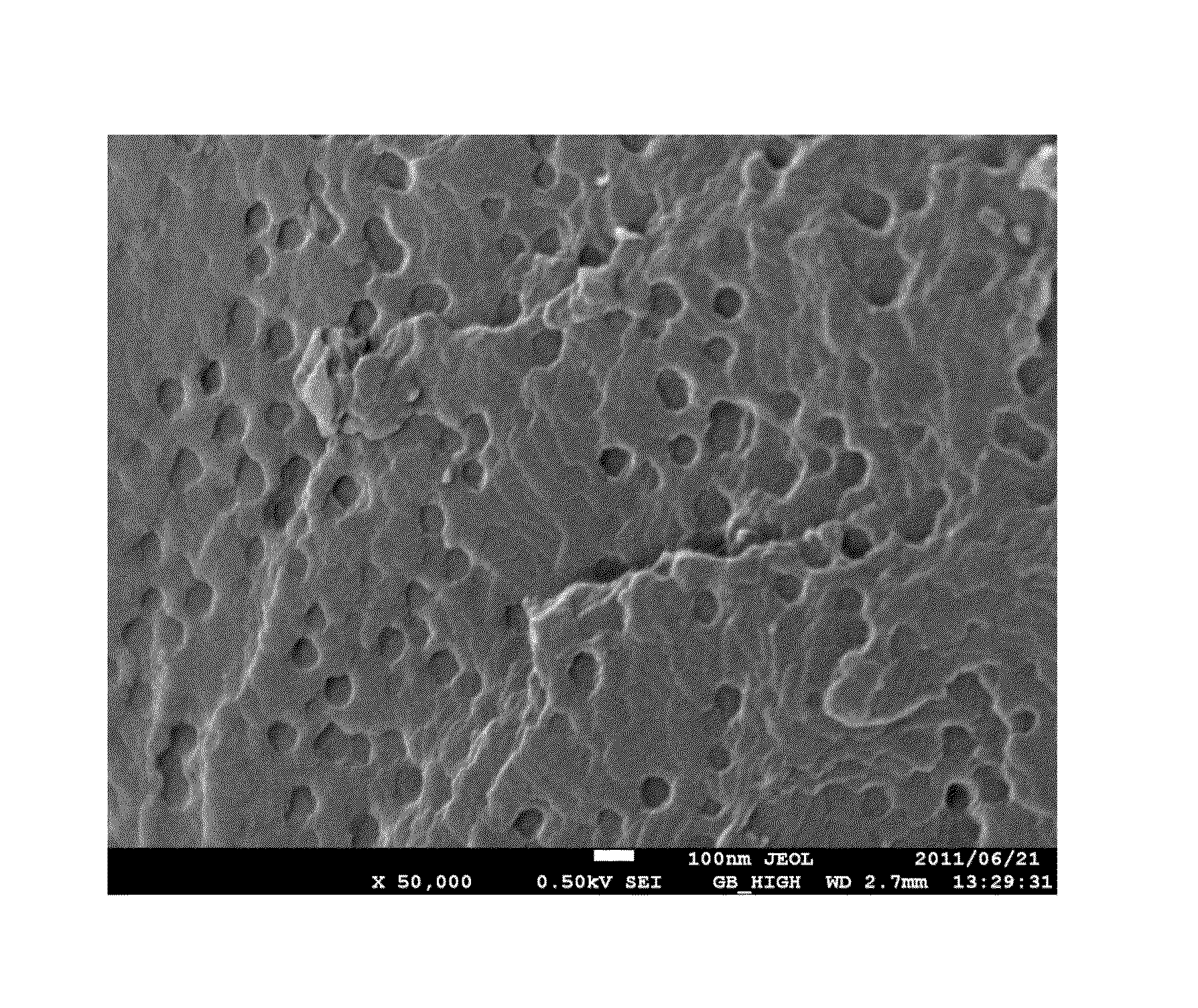

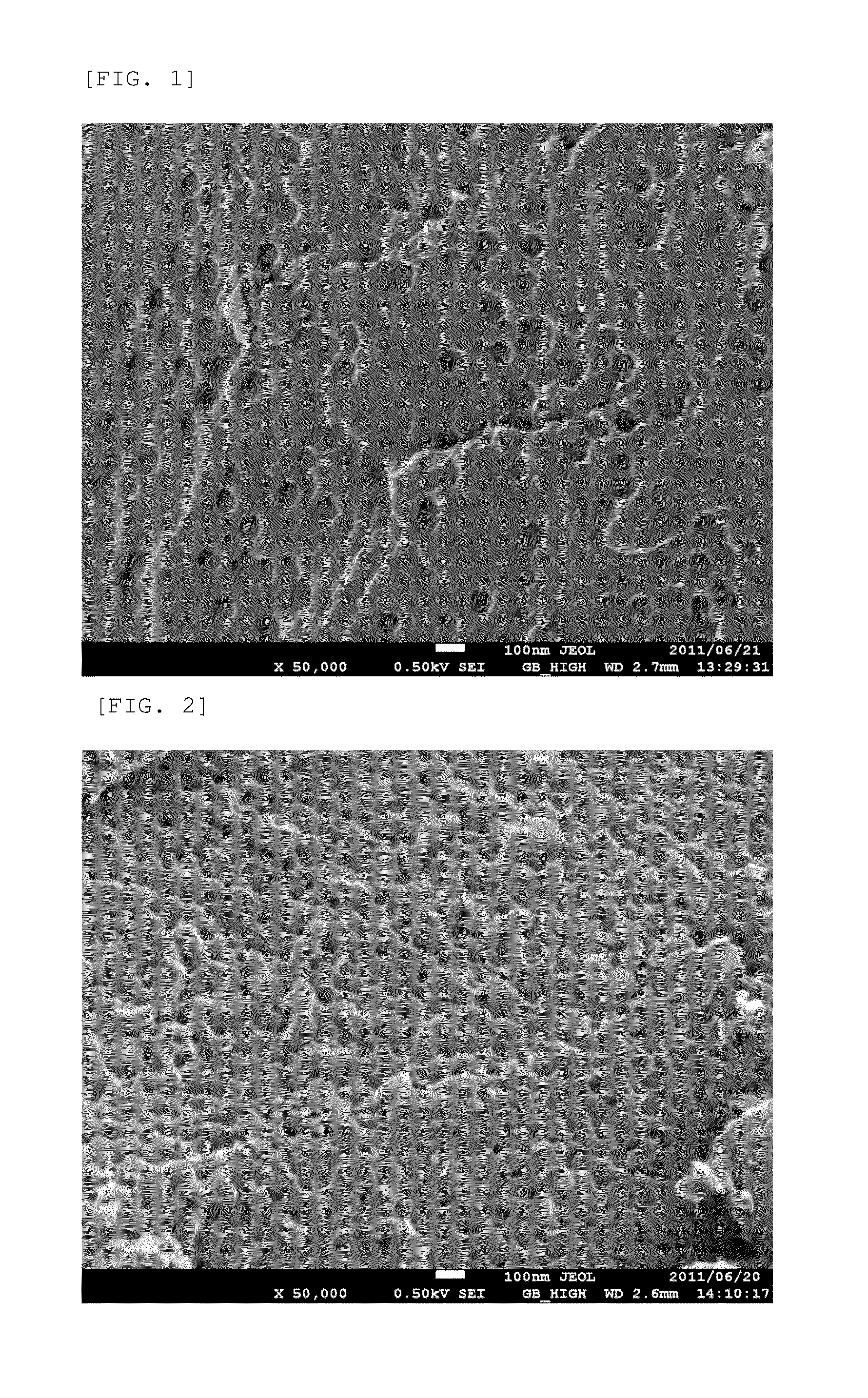

Indoor evaluation method for nano-plugging agent for shale gas water-based drilling fluid

InactiveCN109520897AEffectively reflect closureRealize application valueMaterial analysis using wave/particle radiationPreparing sample for investigationMicron scaleMicro nano

The invention discloses an indoor evaluation method for a nano-plugging agent for shale gas water-based drilling fluid. The indoor evaluation method comprises the following steps that (1) a ultra-lowpermeability stratum 'simulation core' is prepared, and the nano-plugging agent permeability reduction rate is determined; (2) particle size analysis is conducted on the nano-plugging agent; and (3) micro morphology is analyzed, specifically, firstly, the ultra-low permeability 'simulation core' (the permeability reaches 10<-4>mD) with nano and micron scale apertures is prepared successfully, thenthe permeability reduction rate of the 'simulation core' after the nano-plugging agent is added is obtained through determination of high temperature and high pressure filtration loss, the plugging performance of the nano-plugging agent is investigated, whether the size fraction magnitude of the nano-plugging agent is matched with the size of the micron and nano scale apertures or not is analyzedthrough a laser particle analyzer, finally, the micro morphology of a filter cake and filter liquor before and after the nano-plugging agent is added is observed through an environmental scanning electron microscope, the dispersion stability of the nano-plugging agent in a system is verified, and the plugging mechanism of the nano-plugging agent is further studied.

Owner:SOUTHWEST PETROLEUM UNIV

Graphite material, carbon material for battery electrode, and battery

ActiveUS20140335428A1Large capacityEasy dischargeGraphiteFinal product manufactureMicroscopic observationBattery electrode

A graphite material having pores which, when 200 rectangular regions of 6 μm×8 μm are randomly selected in a surface image of the graphite material observed by a scanning electron microscope, in the surface of the graphite material appearing in the regions, a pore appearing on the surface and having an aperture in a shape having a diameter of 15 nm to 200 nm, a circularity degree of 0.75 to 1.0 and a major axis / minor axis ratio of 1.0 to 1.5 is visible in two regions or more. Also disclosed is a carbon material for battery electrodes, a paste for electrodes, an electrode and a lithium ion secondary battery including the graphite material.

Owner:SHOWA DENKO KK

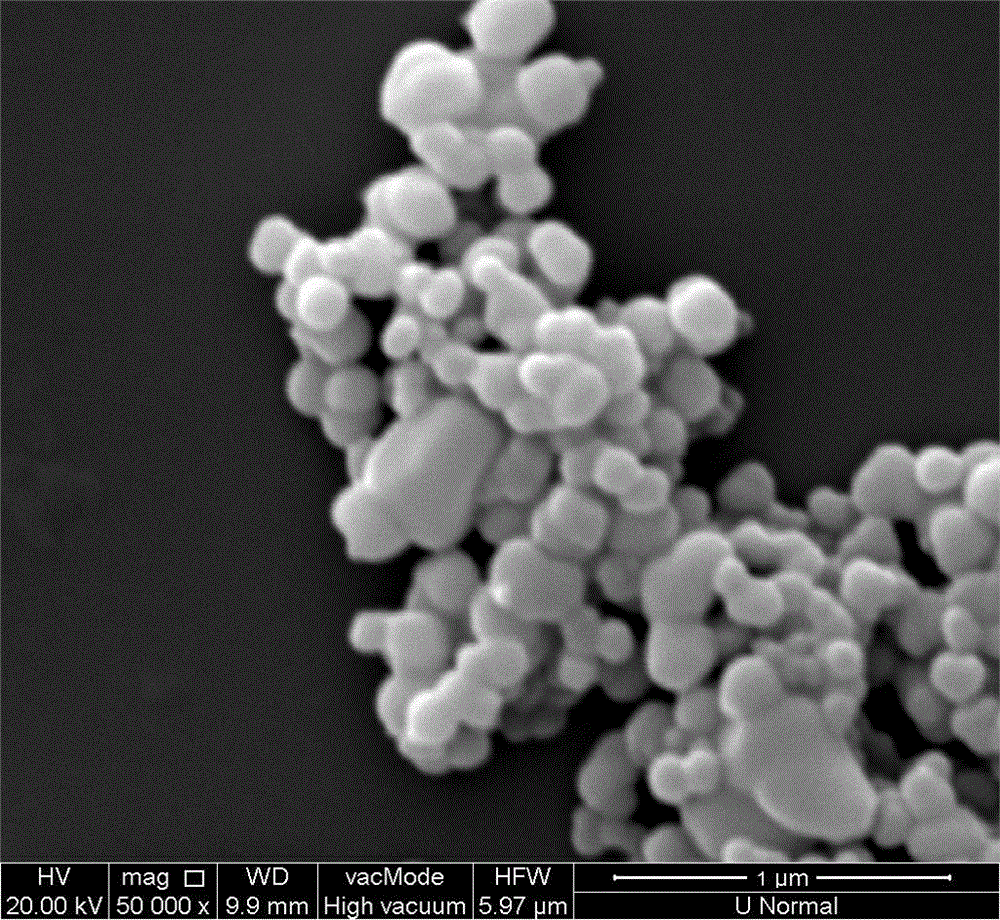

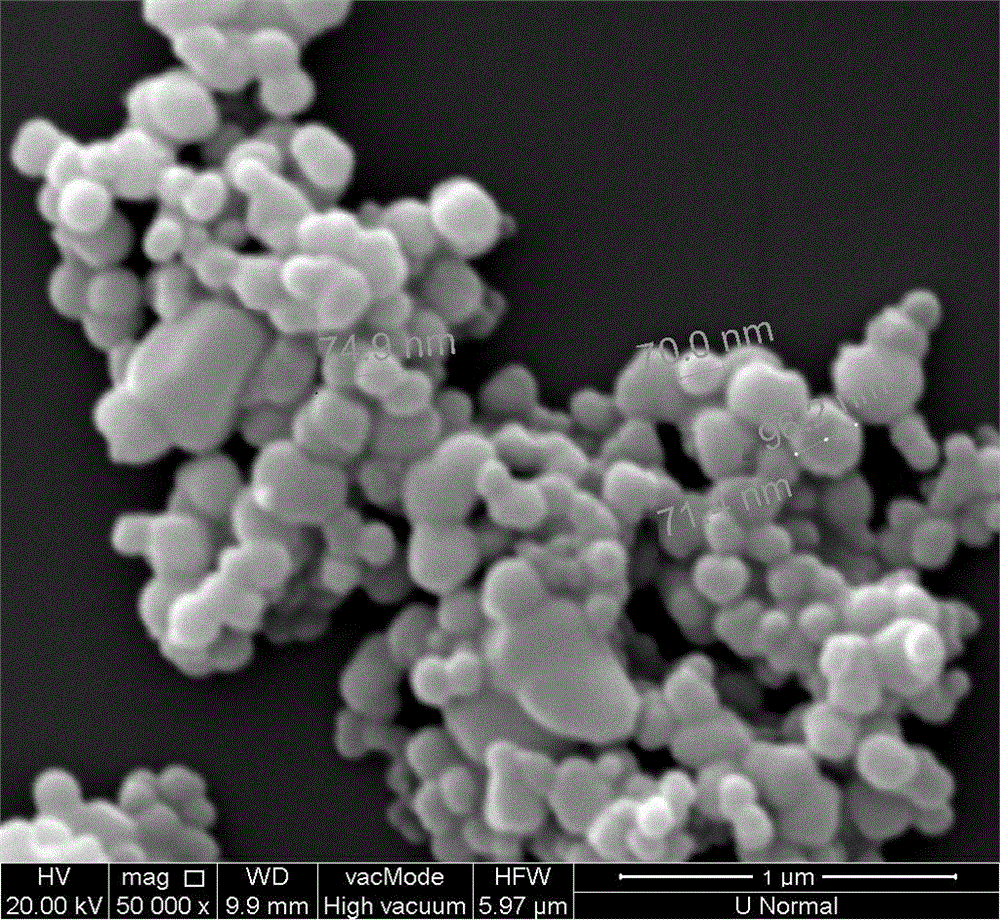

Preparation method for nanoscale rare earth oxide powder

ActiveCN105129834AIncrease dosageImprove washing efficiencyNanotechnologyRare earth metal compoundsRare earthGrain growth

The invention relates to the field of rare earth materials, in particular to a preparation method for nanoscale rare earth oxide powder. The preparation method comprises the steps that a precipitation method is adopted, rare earth material liquid of a nitric acid system or a hydrochloric acid system is taken as raw materials, a precipitant is added, and precipitating, filtering, drying and calcining are performed to obtain the rare earth oxide powder. The preparation method is characterized in that an inorganic dispersant is added before the precipitant is added, and a crystal grain growth inhibitor is added after the precipitant is added. According to the preparation method, the prepared nanoscale rare earth oxide powder is small and uniform in grain, easy to clarify and wash and low in production cost and can be produced on a scale on the basis of the precipitation method on the condition that special equipment is not added, it can be seen that the grain size of the powder is below 70 nanometers through electronic microscopy scanning, and production use is met.

Owner:SICHUAN PROVINCE LESHAN CITY RUIFENG METALLURGY CO LTD

Method and device for detecting power insulating material under irradiation of X rays

InactiveCN102508133ASimple structureEasy to implementTesting dielectric strengthDigital imagingX-ray

The invention discloses a method and a device for detecting a power insulating material under irradiation of X rays. The method comprises the following steps: 1), setting an insulating scratch defect; 2) measuring the insulating scratch defect by using an electronic microscope; 3), establishing a local discharge detection platform; 4), after local discharge detection stops, measuring the insulating scratch defect again, and comparing with a preceding measurement result; and 5), judging the change of the defect of a solid insulating material of power equipment according to a comparison result. The method and the device have the advantages as follows: by the method, the application range of an X-ray digital imaging detection technology in performing visual detection on the power equipment can be accurately determined; and the device is simple in structure, easy to implement and good in detection effect, and can acquire a visual defect and further determine the type of the defect.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST

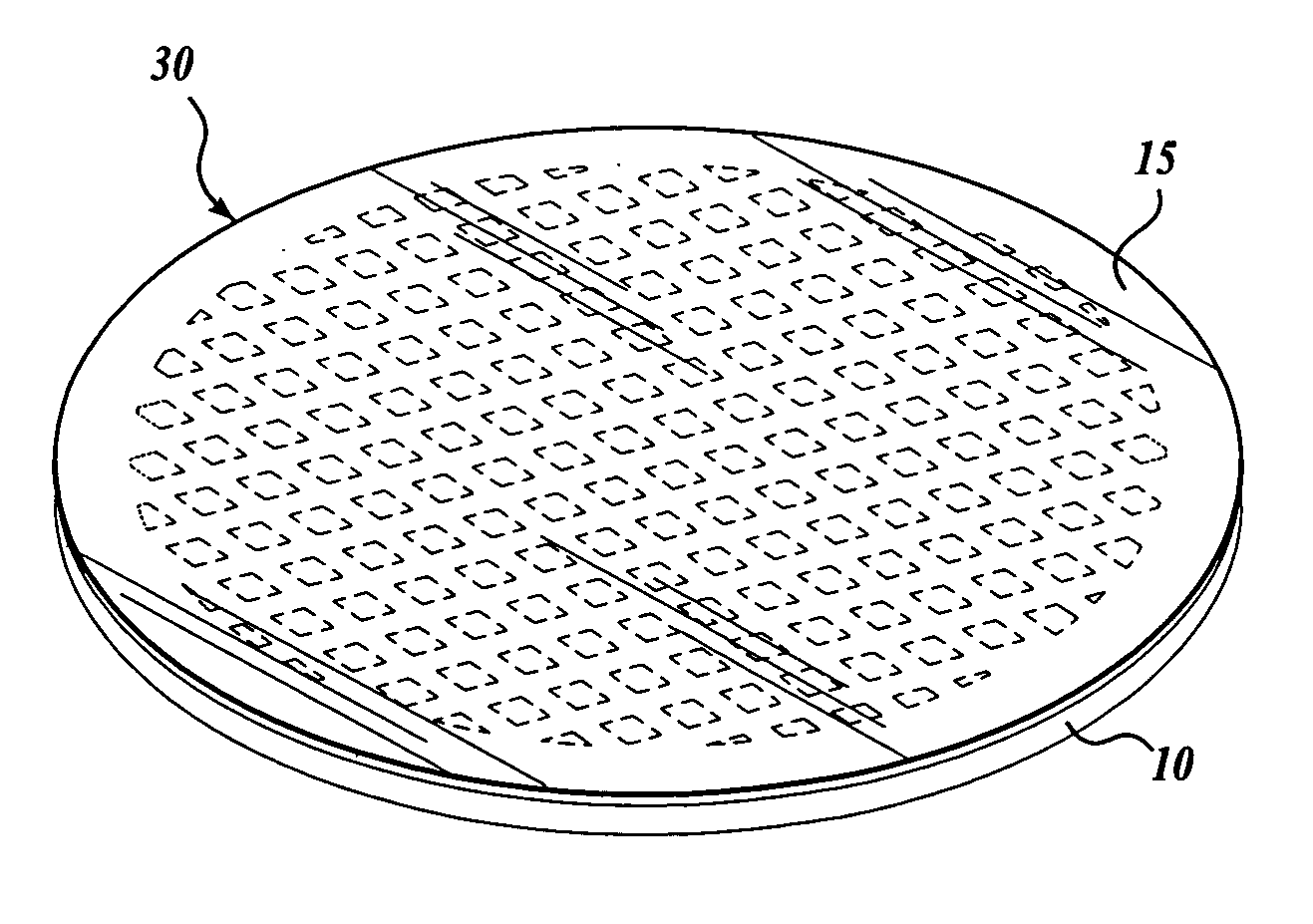

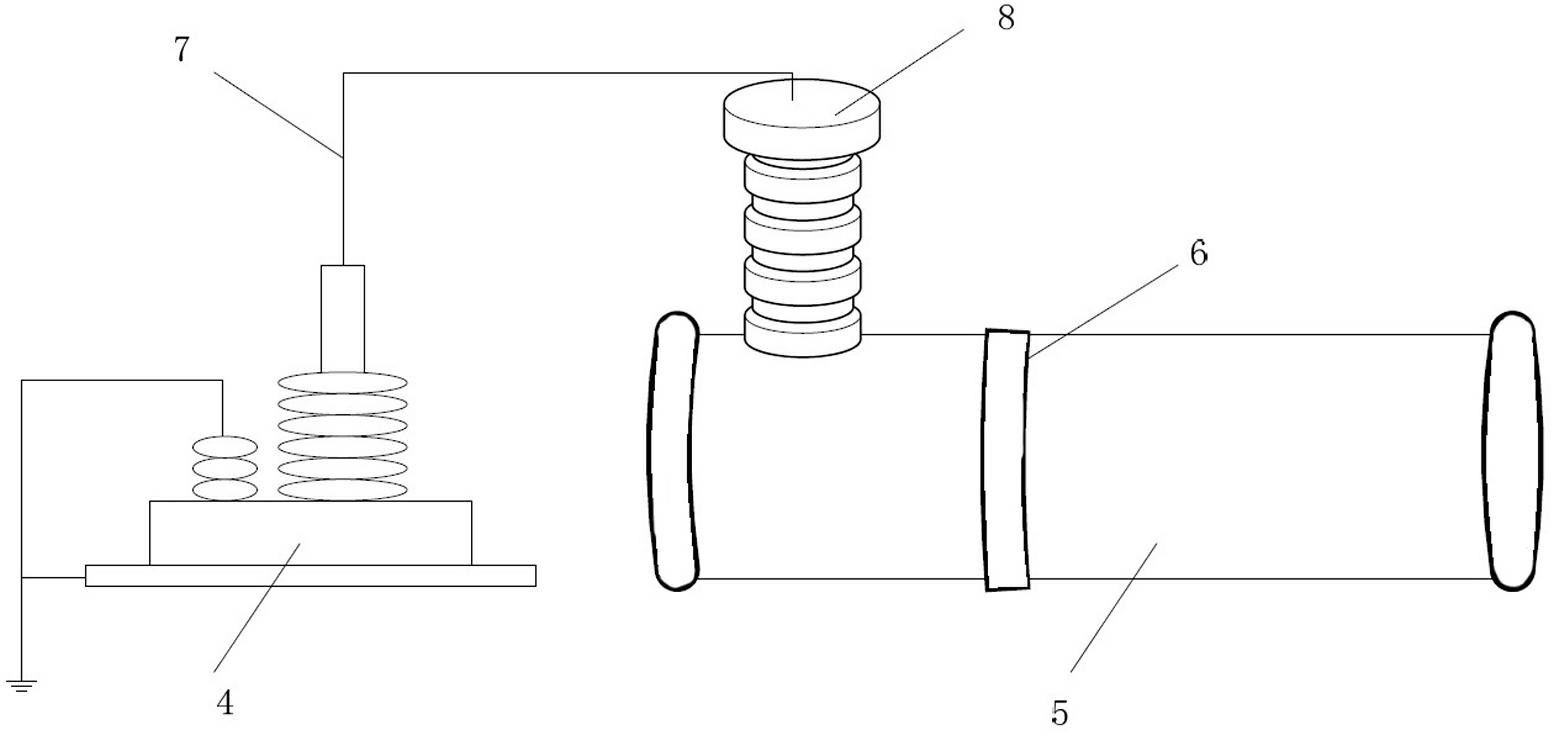

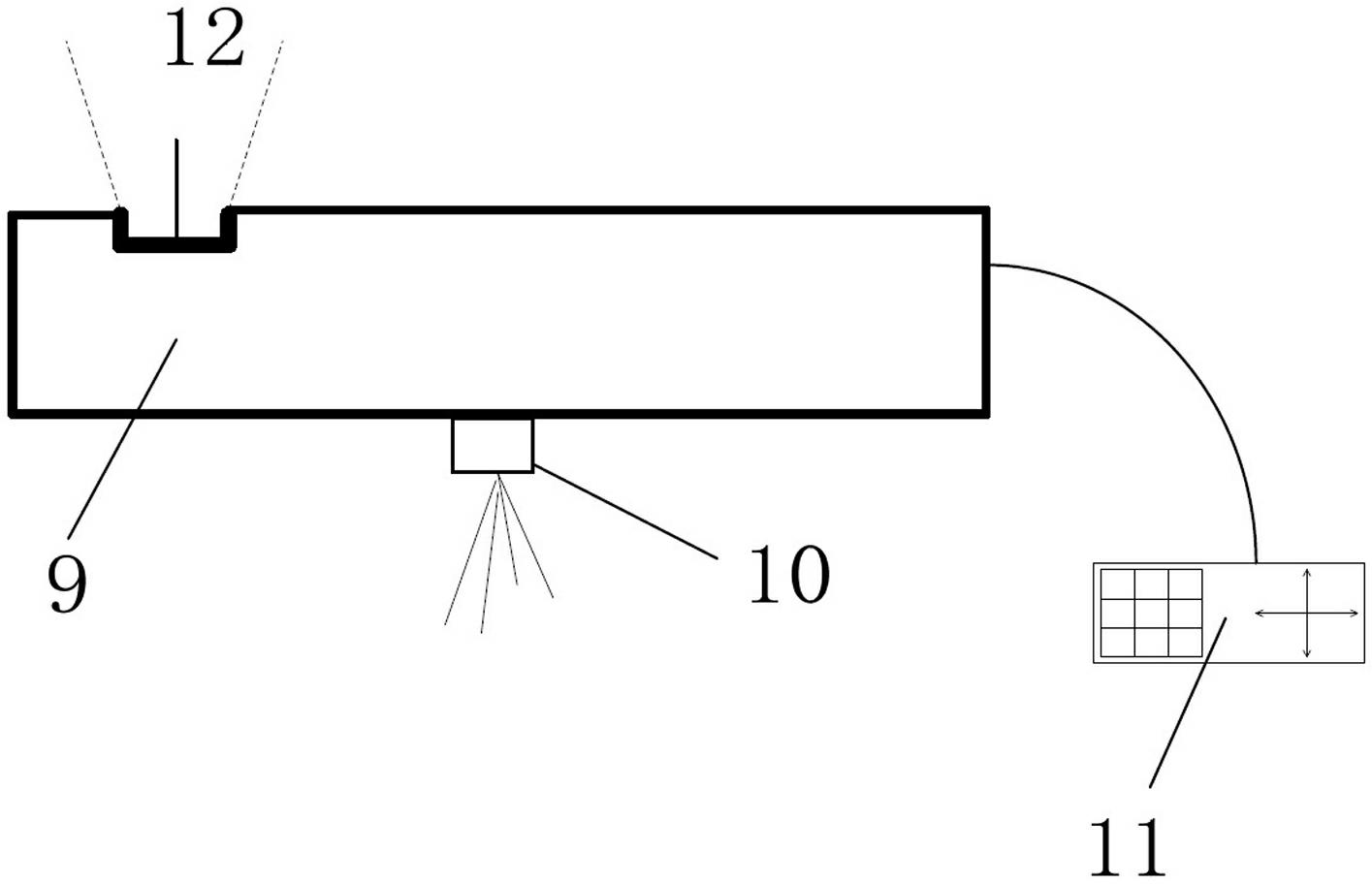

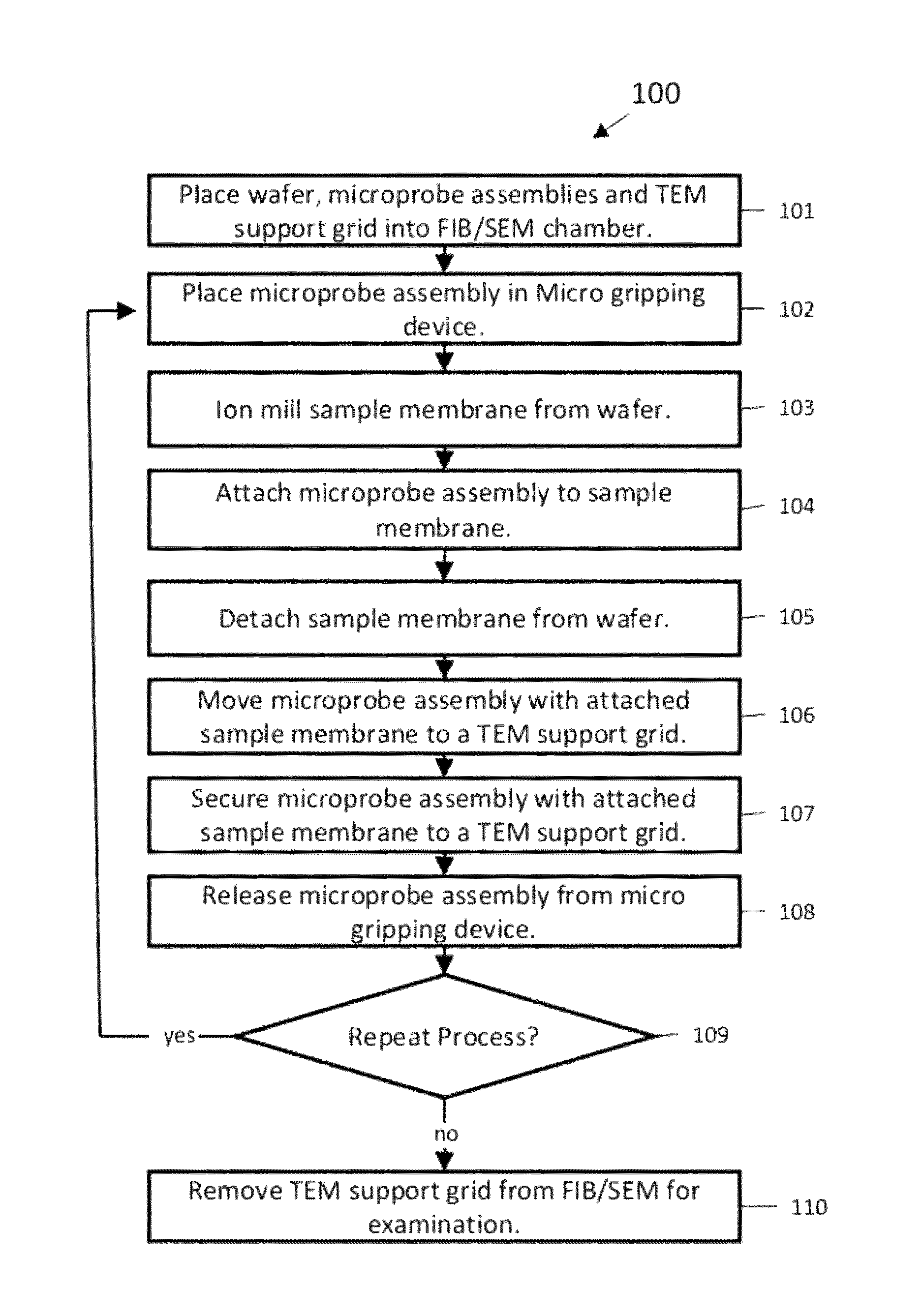

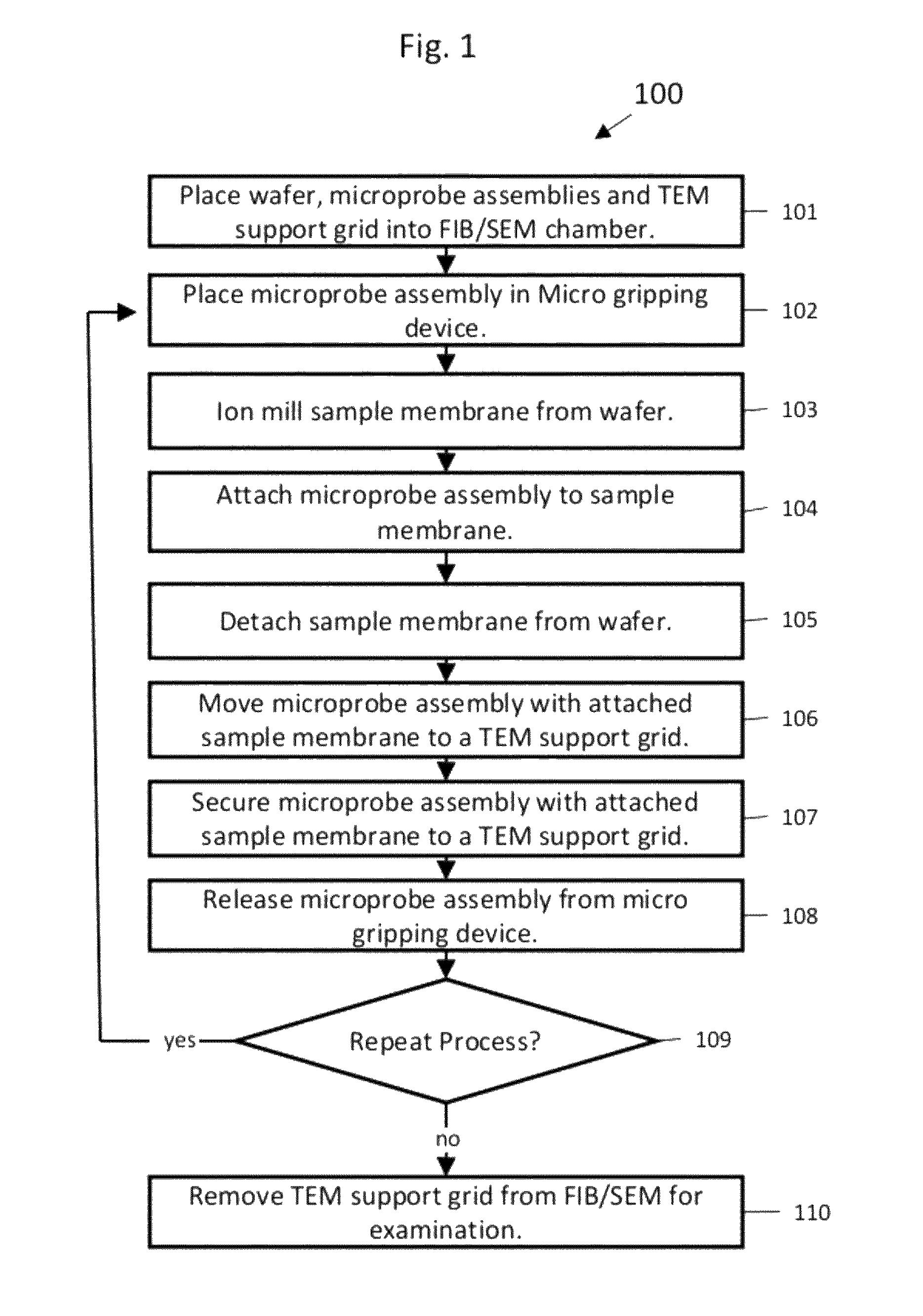

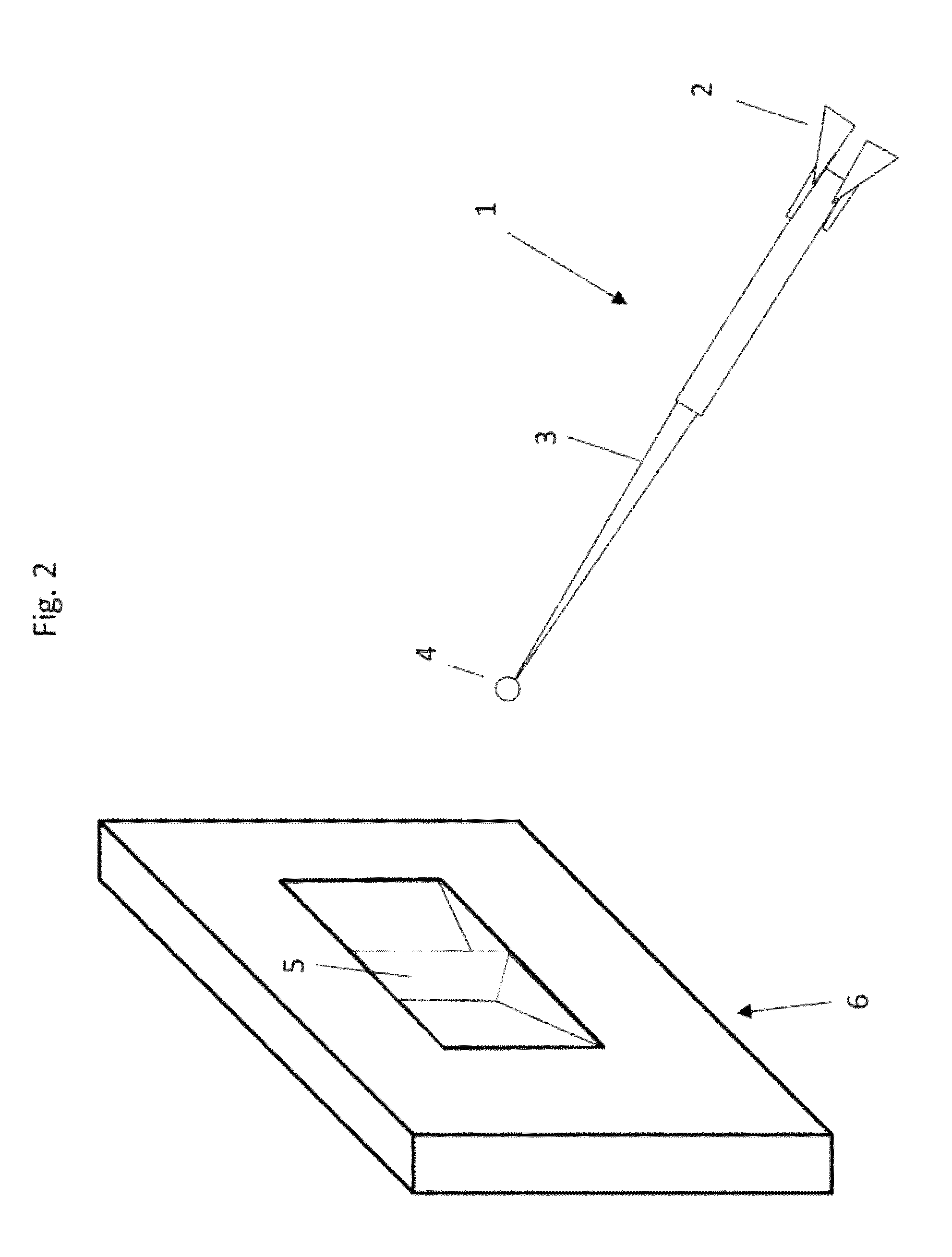

Method and apparatus for rapid preparation of multiple specimens for transmission electron microscopy

ActiveUS8258473B2Fast preparationImprove productivityMaterial analysis using wave/particle radiationSamplingProduction rateSputtering

A method and apparatus for in-situ lift-out rapid preparation of TEM samples. The invention uses adhesives and / or spring-loaded locking-clips in order to place multiple TEM-ready sample membranes on a single TEM support grid and eliminates the use of standard FIB-assisted metal deposition as a bonding scheme. Therefore, the invention circumvents the problem of sputtering from metal deposition steps and also increases overall productivity by allowing for multiple samples to be produced without opening the FIB / SEM vacuum chamber.

Owner:NANOTEM +1

Toner and method of preparing the toner

A toner is provided including a binder resin, a colorant, and a release agent, which has a volume average particle diameter (Dv) of from 3 to 9 μm, and wherein the binder resin and the release agent form a sea-island structure in which the island formed of the release agent is dispersed in the sea formed of the binder resin in a cross-sectional image of the toner obtained by a transmission electron microscope (TEM), and the following relationships are satisfied: IB>IA and IB>IC, wherein each of IA, IB, and IC represents an area ratio (%) of the island in an outermost region (A) of the cross-sectional image of the toner, an intermediate region (B) thereof located under the outermost region (A), and an innermost region (C) thereof located under the intermediate region (B); and a method of preparing the toner.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com