Fluorosiloxane-POSS acrylate block copolymers, blood-compatible coating thereof and preparation method of the fluorosiloxane-POSS acrylate block copolymers

A technology of block copolymers and blood compatibility, which is applied in the preparation of fluorosilicone copolymers and the field of biomedical polymers, can solve the problems of reducing platelet aggregation and activation, and achieves easy industrialization and large-scale production, and easy access to raw materials , the effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

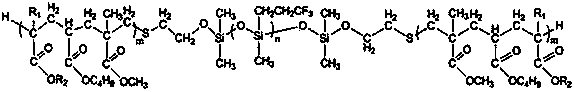

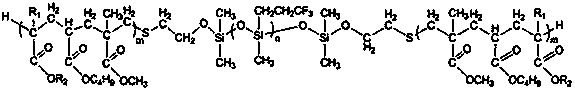

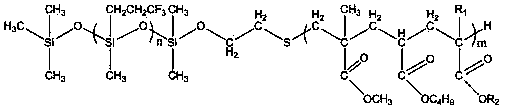

Image

Examples

Embodiment 1

[0031] (1) Preparation of hydroxyl-terminated POSS acrylate copolymer

[0032] Add 10 g methyl methacrylate, 5 g butyl acrylate, 0.9 g 4-acryloyloxybutyl-heptaisobutyl POSS, 0.075 g mercaptoethanol, 0.08 azobisisobutyronitrile and 16 g acetic acid to the reaction flask Butyl ester, after stirring and mixing evenly, raise the temperature to 60~110°C to react for 5 hours, cool down to room temperature, discharge, and dry to obtain the hydroxyl-terminated POSS acrylate copolymer with a number average molecular weight of 10,000.

[0033] (2) Preparation and properties of fluorosilicone-POSS acrylate block copolymer and its blood-compatible coating:

[0034] At room temperature 25°C, add 10g of hydroxyl-terminated POSS-acrylate copolymer prepared above, 10g of single-ended hydrogen polymethyltrifluoropropylsiloxane and 0.005g of Karstedt platinum catalyst into 180g of butyl acetate, and mix well , to generate a polymer solution with a mass concentration of 10%. The prepared polym...

Embodiment 2

[0036] (1) Preparation of hydroxyl-terminated POSS acrylate copolymer

[0037]Add 10g methyl methacrylate, 13g butyl acrylate, 3g 4-methacryloxybutyl-heptaisobutyl POSS, 0.75g mercaptoethanol, 0.12g azobisisobutyronitrile in the reaction flask and 40g of butyl acetate, stir and mix evenly, raise the temperature to 60-110°C for 5 hours, cool down to room temperature, discharge, and dry to obtain a hydroxyl-terminated POSS acrylate copolymer with a number average molecular weight of 1000.

[0038] (2) Preparation and performance of fluorosilicone-POSS acrylate block copolymer hemocompatible coating:

[0039] At room temperature at 25°C, add 20g of hydroxyl-terminated POSS-acrylate copolymer prepared above, 10g of double-terminated hydrogen polymethyltrifluoropropylsiloxane and 0.01g of Karstedt platinum catalyst to 135g of ethyl acetate and mix well , to generate a polymer solution with a mass concentration of 20%. The prepared polymer solution is coated on a dry and clean pol...

Embodiment 3

[0041] (1) Preparation of hydroxyl-terminated POSS acrylate copolymer

[0042] Add 10 g methyl methacrylate, 5 g butyl acrylate, 0.9 g 4-acryloxybutyl-heptaisobutyl POSS, 0.038 g mercaptoethanol, 0.07 azobisisobutyronitrile and 16 g acetic acid to the reaction flask Butyl ester, after stirring and mixing evenly, raised the temperature to 60°C to react for 8 hours, cooled to room temperature, discharged, and dried to obtain a hydroxyl-terminated POSS acrylate copolymer with a number average molecular weight of 20,000.

[0043] (2) Preparation and performance of fluorosilicone-POSS acrylate block copolymer hemocompatible coating:

[0044] At room temperature at 25°C, add 10g of hydroxyl-terminated POSS-acrylate copolymer prepared above, 20g of double-terminated hydrogen polymethyltrifluoropropylsiloxane and 0.01g of Karstedt platinum catalyst into 150g of ethyl acetate, and mix well , to generate a polymer solution with a mass concentration of 20%. The prepared polymer solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com