Ultrathin in-situ liquid sample room for transmission electron microscope and auxiliary installation device and installation method for ultrathin in-situ liquid sample room

An electron microscope, liquid sample technology, applied in circuits, discharge tubes, electrical components, etc., can solve problems such as difficulty in grasping the amount of resin, reduced sealing, and sample contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

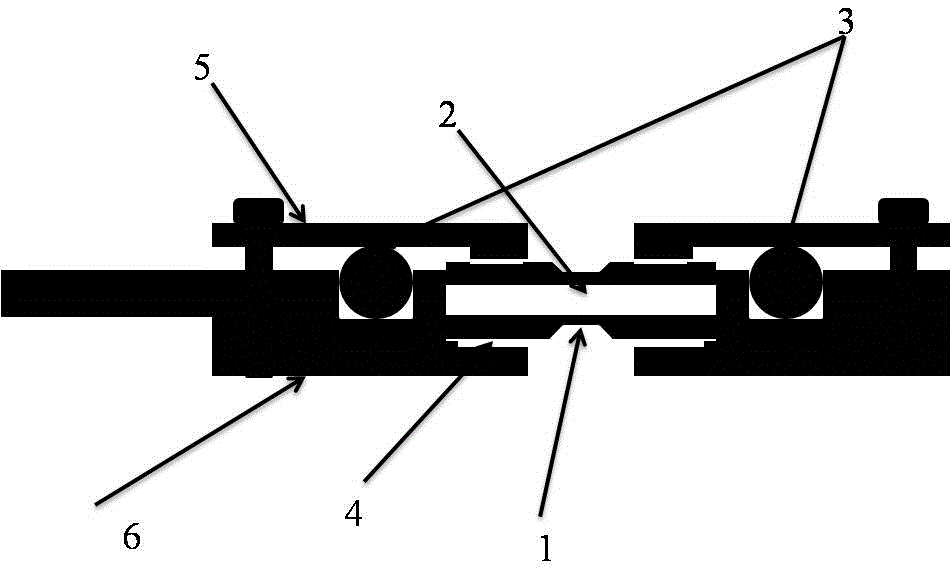

Method used

Image

Examples

Embodiment 1

[0038] Use 502 glue to glue the silicon nitride window substrate on the liquid chamber base and cover sheet, and add 0.5g / L of 10nm nano Ag solution ~1ul to the vicinity of the silicon nitride window of the in-situ liquid chamber, follow the above steps After the encapsulation in the single-ring sealed ultra-thin in-situ liquid sample chamber is completed, it is pre-evacuated for leak detection and placed under an optical microscope to observe the results as follows Figure 7 As shown, the silicon nitride window is intact and undamaged. And put the sample under the transmission electron microscope to obtain Picture 8 The photo of the nano Ag particles shown in the liquid.

Embodiment 2

[0040] Use 502 glue to glue the silicon nitride window substrate on the liquid chamber base and cover sheet respectively, and drop 0.5g / L of 10nm nano Ag solution ~1ul onto the silicon nitride window of the in-situ liquid box, follow the above steps After encapsulation in a single-ring sealed ultra-thin in-situ liquid sample chamber is completed, it is pre-evacuated for leak detection and placed under an optical microscope to obtain Figure 7 As shown, the silicon nitride window is intact and undamaged. And put the sample under the transmission electron microscope to select an appropriate area to observe the results as Picture 9 As shown, in addition to the nanoparticles, a large number of nanobubbles are also observed in the liquid.

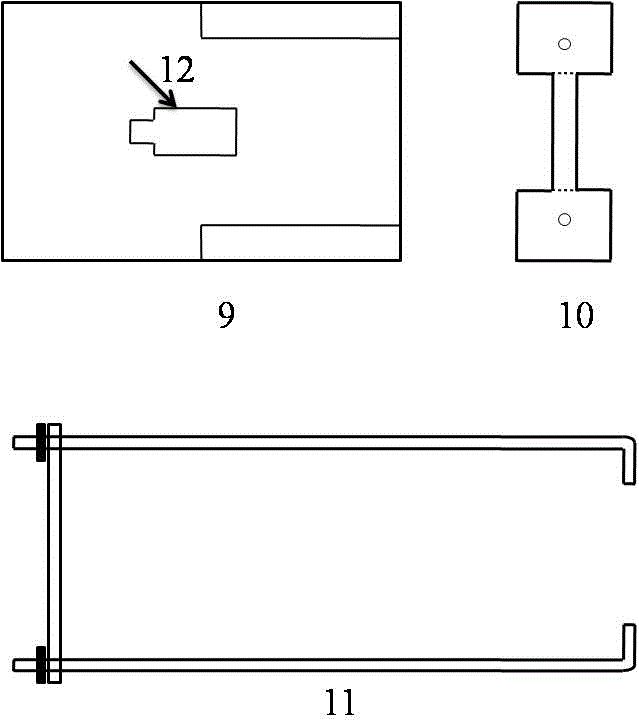

Embodiment 3

[0042] Design and process the liquid chamber with multiple rubber rings in accordance with the size of the auxiliary installation device, and use the auxiliary installation device to install, change the part where the sealant is applied to the seal ring, and add 0.5g / L 10nm nano Ag solution ~1ul dropwise to the original On the silicon nitride window of the liquid box, follow the above steps to encapsulate the in-situ liquid sample chamber. After pre-vacuum leak detection and observation and inspection under an optical microscope, install it on the TEM sample rod (such as Picture 10 Shown). And put the sample into the transmission electron microscope to observe, select the sample area to take a photo at the appropriate magnification, the result is as follows Picture 11 As shown, not only the presence of nanoparticles in the liquid is observed, but also a few particles on the photo are blurry, showing the dynamic information of the particles moving in the liquid in real time. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com