Indoor evaluation method for nano-plugging agent for shale gas water-based drilling fluid

A technology of nano-blocking agent and water-based drilling fluid, which is applied in the preparation of test samples, analysis of suspensions and porous materials, and material analysis using wave/particle radiation. Effective evaluation of plugging performance, limiting the application of nano plugging agents, etc., to achieve the effect of sufficient theoretical basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] An indoor evaluation method of a nano-sealing agent for shale gas water-based drilling fluid, comprising the following steps.

[0045] (1) Preparation of "simulated core" for ultra-low permeability formation and permeability of nano-sealing agent.

[0046] a. Preparation of standard slurry for "simulated core".

[0047] Heat 1000mL of water to 60-70°C, add 10wt% bentonite and 5wt% sodium carbonate (based on bentonite) during the stirring process, then add 5wt% treatment agent SMC to the base slurry, stir evenly and continue to add to the slurry Add 5wt% SMP-1 to the body, then heat the base slurry to 60-70°C, add 100g of barite and stir evenly, then place it for 24h for later use.

[0048] b. Preparation of "simulated core".

[0049]After stirring the prepared standard slurry for 30 minutes, use the GGS42-2 high temperature and high pressure water loss meter to measure its 30-min filtration loss under the condition of 105 ° C / 3.5 MPa, record the initial water loss a...

experiment example

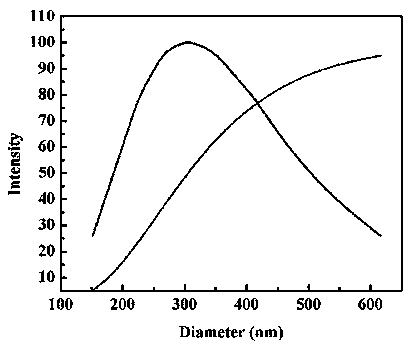

[0062] Using the above evaluation method, firstly through the preparation of standard slurry, the ultra-low permeability "simulated core" was successfully prepared, and its permeability reached 10 -4 mD, and the plugging performance of silica nano-sealing agents with different mass fractions (0.1, 0.2, 0.3, 0.4, 0.5wt%) was evaluated, and the average permeability of mud cake was calculated using the formula (1-1) After adding different concentrations of silica nano-sealing agent, the mud cake permeability K` is calculated according to the formula (1-2) to obtain the permeability reduction rate Kr of the silica nano-sealing agent. In addition, the laser particle size analyzer The particle size distribution of the silica nano plugging agent was analyzed, and at room temperature, the particle size distribution diagram of the silica nano plugging agent was obtained.

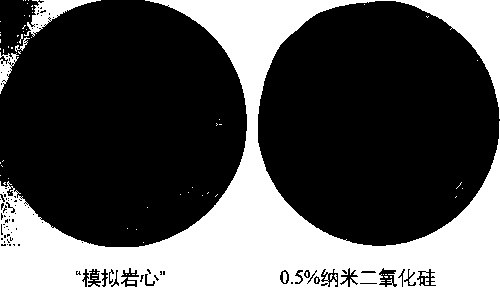

[0063] Environmental scanning electron microscopy (ESEM) was used to observe the microscopic morphology of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com