Plugging effect evaluating method by completely dipping rock debris

An evaluation method, cuttings technology, applied in the direction of measuring devices, suspension and porous material analysis, instruments, etc., to achieve the effect of improving work efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Select cuttings from the strata to be evaluated. This cuttings are mudstone cuttings in the Shahejie formation at a depth of 3,407 meters in Well Qingdong 32 (no need to crush them), and they are roughly divided into two parts. Put it into the cup of the high temperature and high pressure water loss instrument, and measure its weight as 38.65g and 39.11g respectively.

[0030] 2. Put the rock cuttings after weighing into the mud cups containing the original formula and the improved formula drilling fluid respectively, raise the temperature to 120°C, increase the pressure to 3.5Mpa, do not take the filtrate, keep the temperature and pressure and place it still for 2 Hour;

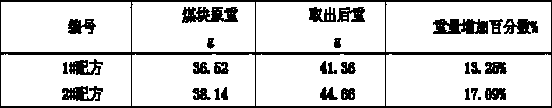

[0031] 3. Take out the cuttings, quickly wipe and absorb the surface attachments, measure its weight, and record it as W2, g; they are 46.42g and 44.35g respectively.

[0032] 4. Calculate the percentage of weight gain after absorbing liquid according to the formula I=(W2-W1) / W1×100%.

[0033] Pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com