Preparation method of ceramic additive by modified composite biomass base and application thereof

A ceramic additive and biomass technology, which is applied in the field of composite biomass-based modification to prepare ceramic additives, can solve the problems of single function of ceramic additives, complex preparation process, long reaction time, etc., to alleviate the crisis of non-renewable energy, and the process is simple Controllable and beneficial to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

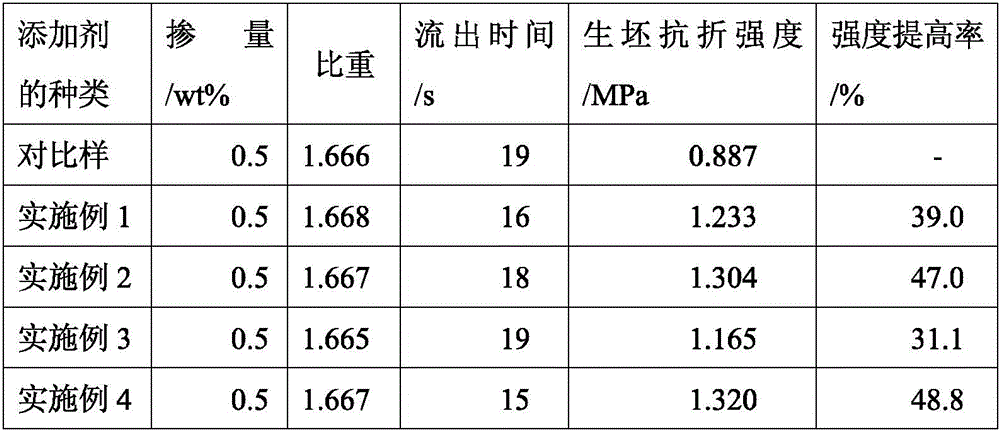

Examples

Embodiment 1

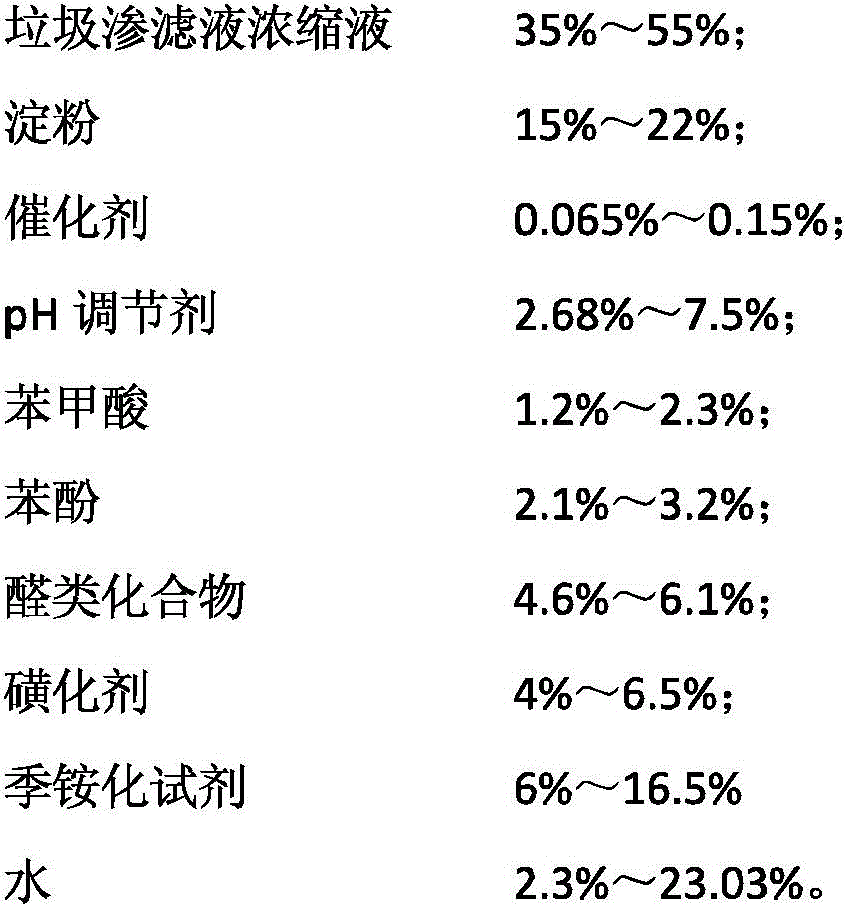

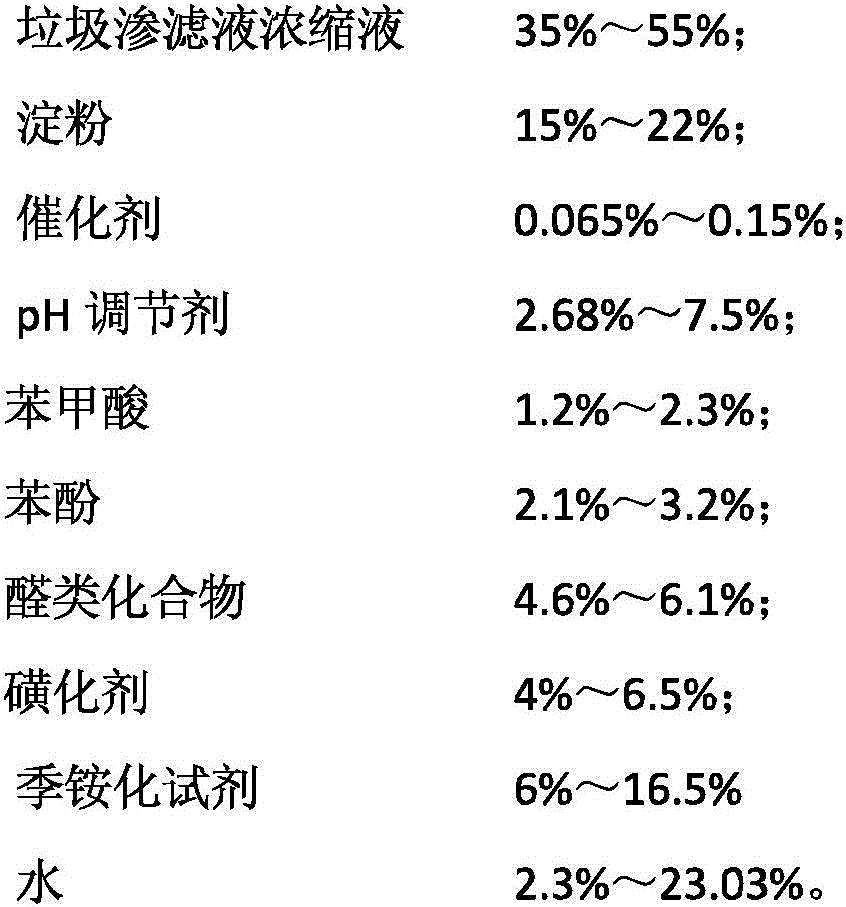

[0038] A method for preparing ceramic additives by modifying composite biomass, which includes the following steps:

[0039] (1) After mixing 350Kg of landfill leachate concentrate with a solid content of 20% and 150Kg of industrial corn starch homogeneously ultrasonically, add it to the reactor, and add 1.5Kg to ferric nitrate, copper nitrate and ferrous sulfate A catalyst prepared by mixing ammonium in a mass ratio of 8:1:1, and the temperature of the system is adjusted to 70°C, the pH value is adjusted to 10, and the reaction is continuously stirred for 4 hours;

[0040] (2) Add 12Kg of benzoic acid, 25Kg of phenol, 50Kg of aldehyde compound mixed with glutaraldehyde and paraformaldehyde in a mass ratio of 1:1 to the solution after the above reaction is completed, and 54.4Kg of ammonium sulfate and sulfonic acid. A sulfonating agent mixed with ammonium bisulfate in a mass ratio of 1:2 and 230.3Kg of water, and the temperature of the system is adjusted to 100°C, and reacted for 6...

Embodiment 2

[0043] A method for preparing ceramic additives by modifying composite biomass, which includes the following steps:

[0044] (1) After mixing 402Kg of landfill leachate concentrate with a solid content of 22% and 150Kg of industrial potato starch homogeneously ultrasonically, add it to the reactor and add 0.9Kg of nickel sulfate, ferric nitrate and ferrous sulfate The catalyst is mixed according to the mass ratio of 8:2:1, and the temperature of the system is adjusted to 80°C, the pH value is adjusted to 9, and the reaction is continuously stirred for 2h;

[0045] (2) Add 14Kg of benzoic acid, 30Kg of phenol, 49Kg of formaldehyde, glutaraldehyde, and paraformaldehyde to the solution after the above reaction is completed in a mass ratio of 1:1:1, 54.4Kg A sulfonating agent mixed with ammonium sulfite and ammonium bisulfite in a mass ratio of 3:2 and 134.7Kg of water, adjust the temperature of the system to 95°C, and react for 3.5h;

[0046] (3) Add 35Kg of a pH regulator mixed with s...

Embodiment 3

[0048] A method for preparing ceramic additives by modifying composite biomass, which includes the following steps:

[0049] (1) After mixing 409Kg of landfill leachate concentrate with a solid content of 18% and 200Kg of industrial corn starch and industrial potato starch at a mass ratio of 1:1, the mixture is homogeneously mixed by ultrasonic, and then added to the reaction Add 0.85Kg of a catalyst mixed with zinc nitrate, nickel sulfate, ferric nitrate and ferrous sulfate in a mass ratio of 8:1:1:1, and adjust the temperature of the system to 95°C and the pH to 9.5, carry out continuous stirring reaction for 6h;

[0050] (2) Add 16Kg of benzoic acid, 32Kg of phenol, 46Kg of formaldehyde and acetaldehyde in a mass ratio of 1:1 to the solution after the above reaction is completed, and 58Kg of ammonium sulfite and ammonium bisulfite. The sulfonating agent and 53.15Kg water are mixed in a mass ratio of 1:1, and the temperature of the system is adjusted to 85°C and reacted for 1.5h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com