LiMnxFe1-xPO4 positive electrode active material and preparation method thereof

A cathode active material, mnxfe1-xpo4 2h2o technology, applied in the field of LiMnxFe1-xPO4 cathode active material and its preparation, can solve the problems of low temperature performance and high rate discharge efficiency, large particle size, etc. The effect of stable performance and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a LiMn x Fe 1-x PO 4 A method for preparing a positive electrode active material, the method comprising the steps of:

[0025] S1. Mix soluble ferric manganese salt solution, soluble ferric salt solution and soluble phosphate-containing substance solution to form a mixed solution, and add a pH regulator to adjust the pH value to 3-14, and the reaction generates Mn x Fe 1-x PO 4 2H 2 O precursor;

[0026] S2, under an inert atmosphere, the Mn prepared in step S1 x Fe 1-x PO 4 2H 2 The O precursor was mixed with Li source and water, dried, and then calcined under an inert atmosphere to obtain LiMn x Fe 1-x PO 4 ;

[0027] Among them, 0

[0028] Simultaneously the LiMn of the present invention x Fe 1-x PO 4 In the preparation method of the positive electrode active material, soluble ferric salt and soluble ferric manganese salt are used, the valence state of iron and manganese is consistent, and the ratio of iron and manganese c...

Embodiment 1

[0051] 1. Preparation of positive electrode active material:

[0052] Add 1L of 0.35mol / l concentration of ferric nitrate and 1L of 0.65mol / l concentration of manganese nitrate solution to 1L of 1mol / l concentration of sodium phosphate solution respectively, while using citric acid to control the pH of the reaction solution to 6.7 , stirred and reacted for 3 hours under circulating water at 40°C, filtered, washed and dried to obtain beige Mn 0.65 Fe 0.35 PO 4 2H 2 O material.

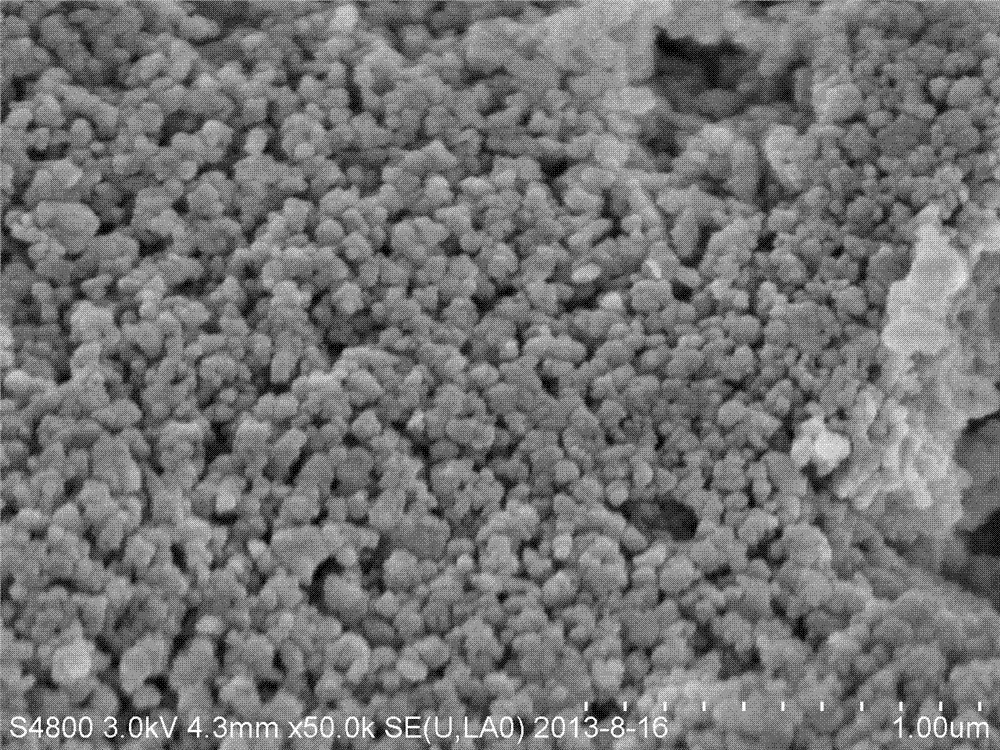

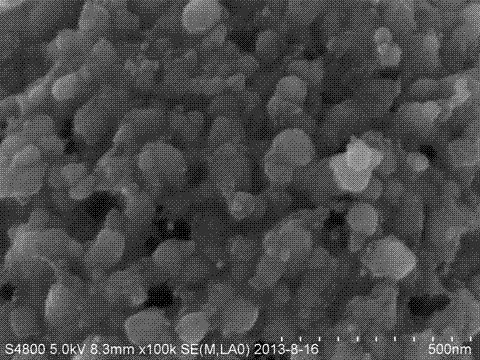

[0053] Adopt Hitachi S4800 type scanning electron microscope (SEM) to observe the morphology of the phosphate precursor of above-mentioned preparation, as figure 1 As shown, it was observed that the particle size of the phosphate precursor prepared above was uniform, the size was basically the same, and there was no agglomeration phenomenon.

[0054] 0.1mol of Mn 0.65 Fe 0.35 PO 4 2H 2 O powder, 0.1 mol lithium hydroxide, 2.355 g of glucose and 3.14 g of CNT (carbon nanotube) with a solid conte...

Embodiment 2

[0061] 1. Preparation of positive electrode active materials

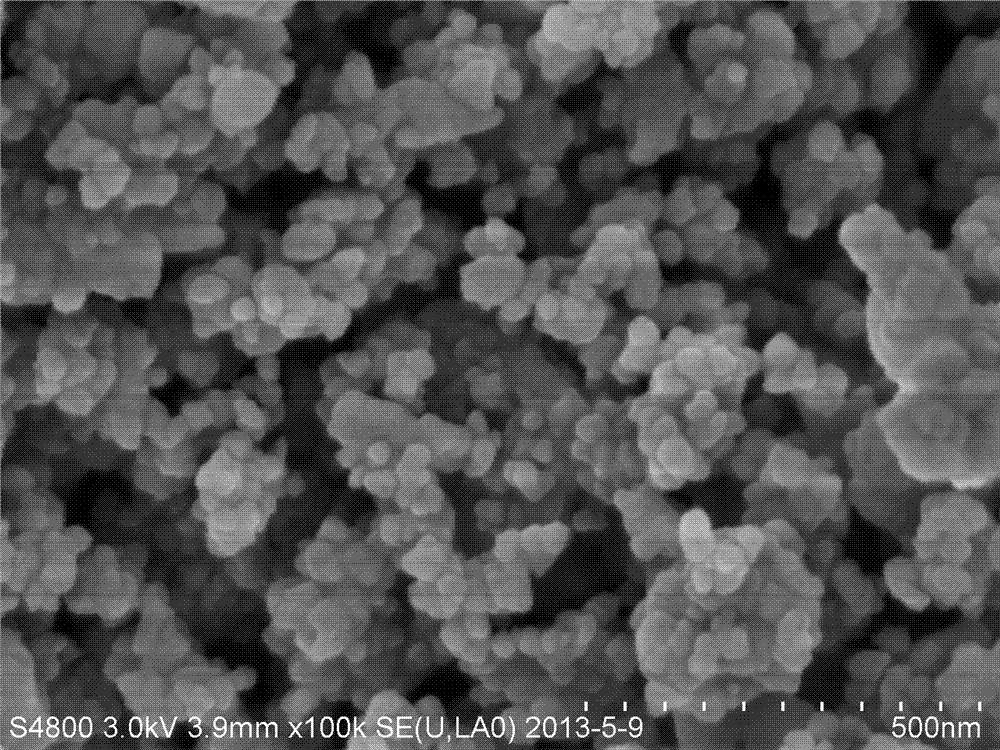

[0062] Add 1L of 0.4mol / l concentration of manganese chloride and 1L of 0.4mol / l concentration of ferric chloride solution to 1L of 0.8mol / l concentration of ammonium dihydrogen phosphate solution at the same time, and use ammonia water to control the concentration of the reaction solution. The pH is 7, stirred and reacted for 4 hours under the heat preservation of circulating water at 20°C, and when precipitation began to appear, it began to circulate sanding while stirring and reacting. After the reaction solution was left to age for 48 hours, it was filtered, washed and dried to obtain Nanoscale Mn 0. 5 Fe 0. 5 PO 4 2H 2 O material.

[0063] 0.5mol of Mn 0. 5 Fe 0. 5 PO 4 2H 2 O powder, 0.5mol lithium acetate, 7.85 grams of glucose and 15.7 grams of graphene with a solid content of 5% were added to 1.6L deionized water respectively, and the mixed solution was sand-milled in a sand mill for 4 hours, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com