Synthetic method of mixed heavy metal trapping agent

A technology for a heavy metal scavenger and a synthesis method, which is applied in the direction of organic chemistry and the like, can solve the problems of inability to synthesize mixed thioaminocarboxylates, pollute the on-site environment, and uneven mixing, so as to avoid uneven mixing and achieve good stabilization effects. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

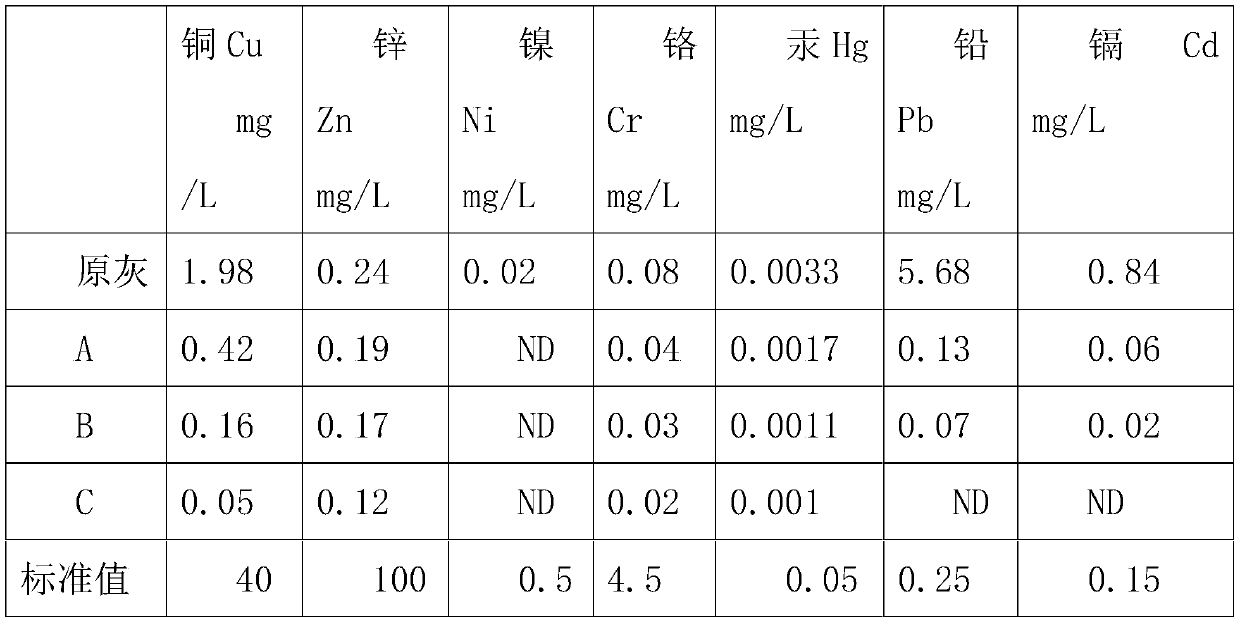

Examples

Embodiment 1

[0025] A kind of synthetic method of hybrid heavy metal scavenger comprises the following steps: comprising the following steps:

[0026] S1: Sampling: Take carbon disulfide, caustic alkali and organic mixed amine for use, the molar ratio of organic mixed amine, caustic alkali and carbon disulfide is 1:1:4, and the organic mixed amine is dimethylamine, diethylamine and ethylmethyl Diamine, organic mixed amine accounts for 30% of the total mass, the caustic is in powder form, which is convenient for reaction, and the caustic is sodium hydroxide;

[0027] S2: Synthesis: Mix carbon disulfide, caustic alkali and organic mixed amine by carbon disulfide excess solvent method, the temperature is 0°C, and the time is 2h;

[0028] S3: Carbon disulfide recovery: The excess carbon disulfide synthesized in step S2 is recovered by step-by-step distillation under normal pressure first and then under reduced pressure. The normal pressure distillation temperature is 70°C.

Embodiment 2

[0030] A kind of synthetic method of hybrid heavy metal scavenger comprises the following steps: comprising the following steps:

[0031] S1: Sampling: Take carbon disulfide, caustic alkali and organic mixed amine for use, the molar ratio of organic mixed amine, caustic alkali and carbon disulfide is 1:1:6, organic mixed amine is dimethylamine, diethylamine, ethylmethyl Diamine, diethylamine, propylethyldiamine and diethylamine, organic mixed amines account for 50% of the total mass, the caustic is flake, which is convenient for reaction, and the caustic is potassium hydroxide;

[0032] S2: Synthesis: Using carbon disulfide excess solvent method, carbon disulfide, caustic alkali and organic mixed amine are mixed and reacted at a temperature of 40°C for 6 hours;

[0033] S3: Recovery of carbon disulfide: The excess carbon disulfide synthesized in step S2 is recovered by step-by-step distillation under normal pressure first and then under reduced pressure. The normal pressure di...

Embodiment 3

[0035] A kind of synthetic method of hybrid heavy metal scavenger comprises the following steps: comprising the following steps:

[0036] S1: Sampling: Take carbon disulfide, caustic alkali and organic mixed amine for use, the molar ratio of organic mixed amine, caustic alkali and carbon disulfide is 1:1:5, and the organic mixed amine is diethylamine, ethylmethyldiamine, diethylamine, Ethylamine and propylethyldiamine, organic mixed amines account for 40% of the total mass, the caustic is granular, which is convenient for reaction, and the caustic is sodium hydroxide;

[0037] S2: Synthesis: Using carbon disulfide excess solvent method, carbon disulfide, caustic alkali and organic mixed amine are mixed and reacted at a temperature of 20°C for 4 hours;

[0038] S3: Carbon disulfide recovery: The excess carbon disulfide synthesized in step S2 is recovered by step-by-step distillation under normal pressure first and then under reduced pressure. The normal pressure distillation te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com