a limn x fe 1‑x po 4 Positive electrode active material and preparation method thereof

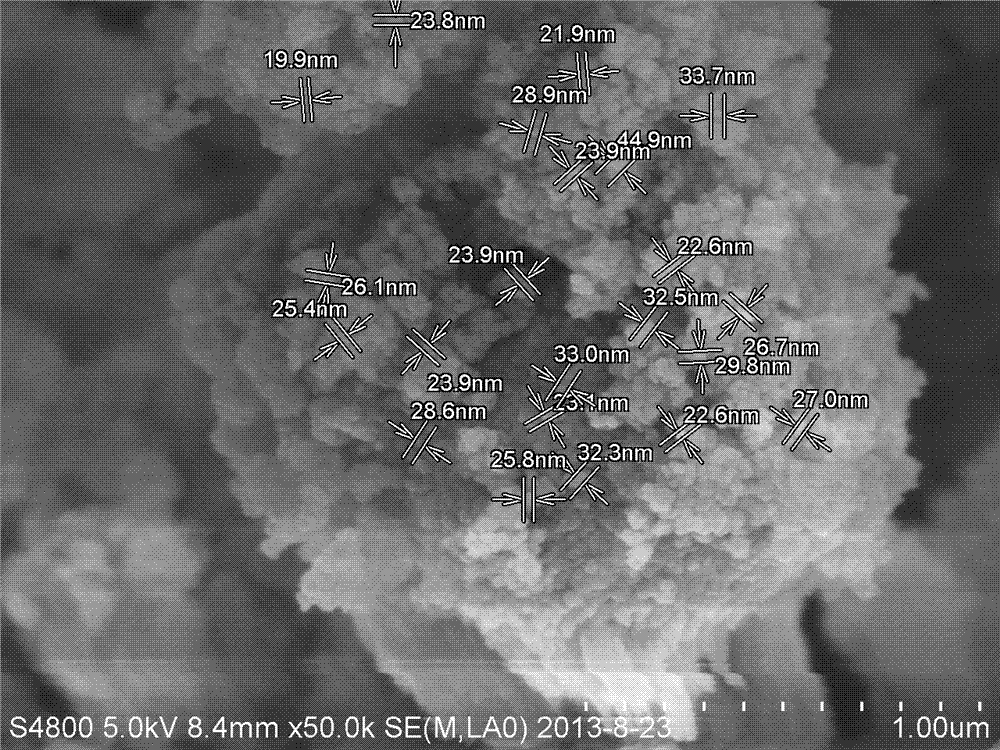

A cathode active material, mnxfe1-xco3 technology, applied in the field of LiMnxFe1-xPO4 cathode active material and its preparation, can solve the problems of large particle size, low temperature performance and low discharge efficiency at high rate, and achieve stable material performance and short time consumption , The effect of material particle uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a LiMn x Fe 1-x PO 4 A method for preparing a positive electrode active material, the method comprising the steps of:

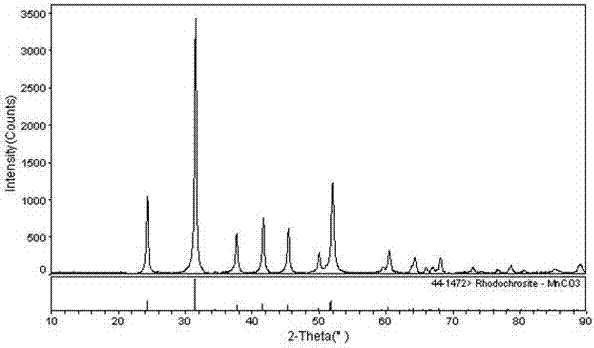

[0025] S1. Mix soluble divalent manganese salt and soluble ferrous salt to form a mixed solution; then under the protection of an inert gas, mix the mixed solution and carbonate to form a reaction solution for reaction, and control the pH of the reaction solution to 3-5, get Mn x Fe 1- x CO 3 Precursor;

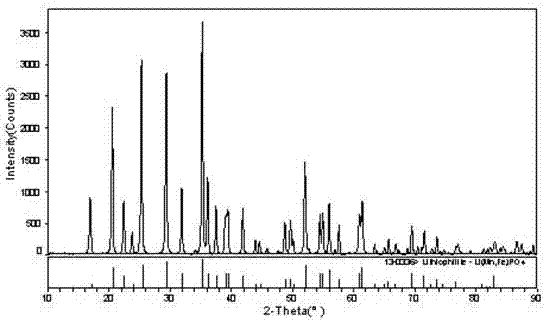

[0026] S2, under an inert atmosphere, the Mn prepared in step S1 x Fe 1-x CO 3 The precursor is mixed with lithium source, phosphorus source and water, dried, and then calcined to obtain LiMn x Fe 1-x PO 4 ;

[0027] Among them, 0

[0028] LiMn of the present invention x Fe 1-x PO 4 In the preparation method of the positive electrode active material, soluble divalent iron salt and soluble divalent manganese salt are used, the valence state of iron and manganese is consistent, and the ratio of iron and mangane...

Embodiment 1

[0049] 1. Preparation of positive electrode active material:

[0050] 97.3gFeSO 4 .7H 2 O was dissolved in deionized water by mechanical stirring to make 1L 0.35molL -1 FeSO 4 .7H 2 O solution, followed by 109.9g MnSO 4 .H 2 O dissolved in 0.35molL -1 FeSO 4 .7H 2 0.65molL in O solution -1 MnSO 4 .H 2 O solution, 158.12g NH 4 HCO 3 Dissolve in deionized water by mechanical stirring to make 1L 2molL -1 NH 4 HCO 3 solution, through a metering pump at 25mL min -1 rate while FeSO 4 .7H 2 O, MnSO 4 .H 2 The mixed solution formed by O and NH 4 HCO 3 The solution was poured into the emulsifier for reaction, and acetic acid was added to adjust the pH to 3, and the emulsification was carried out when the solution was just in contact with the reaction, and the reaction product obtained after emulsification for 1 hour was washed with a centrifuge, and the washed product was dried with nitrogen gas After obtaining nanoscale pure phase Mn 0.65 Fe 0.35 CO 3 .

[005...

Embodiment 2

[0059] 1. Preparation of positive electrode active material:

[0060] 98.955gMnCl 2 .4H 2 O was dissolved in deionized water by mechanical stirring to make 1L 0.5molL -1 FeCl 2 solution, followed by 63.375g FeCl 2 Dissolved in 0.5molL -1 MnCl 2 .4H 2 0.5molL in O solution -1 MnCl 2 .4H 2 O solution, and in this mixed solution, add 58g ascorbic acid, adjust pH to be 5. 202g NaCO 3 Dissolve in deionized water by mechanical stirring to make 1L 2molL -1 NaCO 3 solution, through a metering pump at 25mL min -1 Simultaneously flow into the emulsifier at the same rate to react, and emulsify when the solution is just in contact with the reaction, the reaction product obtained after emulsification for 1 hour is washed with a centrifuge, and the washed product is dried with nitrogen to obtain nano-scale pure phase Mn 0.5 Fe 0.5 CO 3 .

[0061] Weigh 115.30 g of 85% H 3 PO 4 , 24.42 gLiOH to make a 1mol / L solution, slowly drain the prepared phosphoric acid solution into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com