Patents

Literature

615 results about "Non-renewable resource" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A non-renewable resource (also called a finite resource) is a resource of economic value that cannot be readily replaced by natural means at a quick enough pace to keep up with consumption. An example is carbon-based fossil fuel. The original organic matter, with the aid of heat and pressure, becomes a fuel such as oil or gas. Earth minerals and metal ores, fossil fuels (coal, petroleum, natural gas) and groundwater in certain aquifers are all considered non-renewable resources, though individual elements are always conserved (except in nuclear reactions).

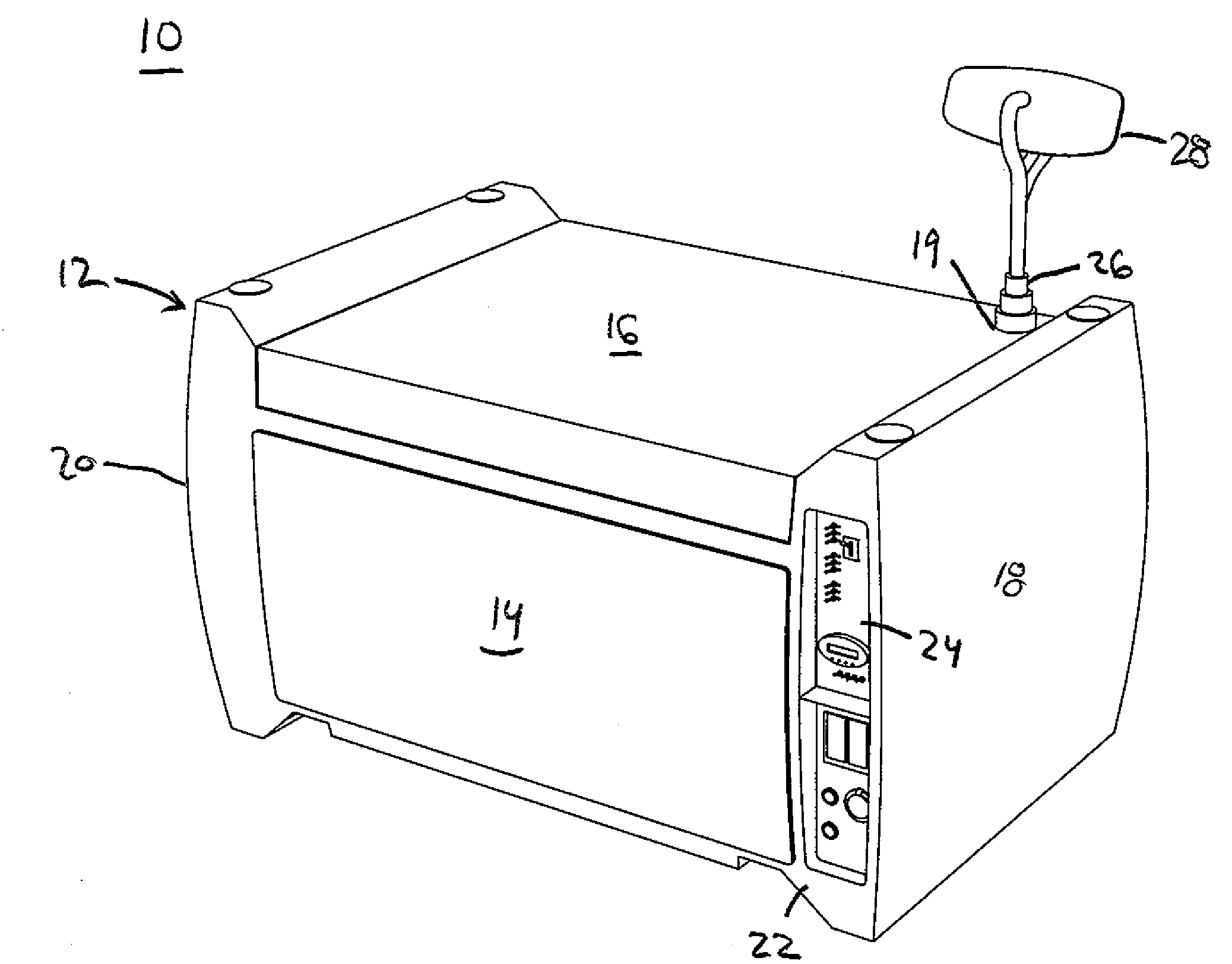

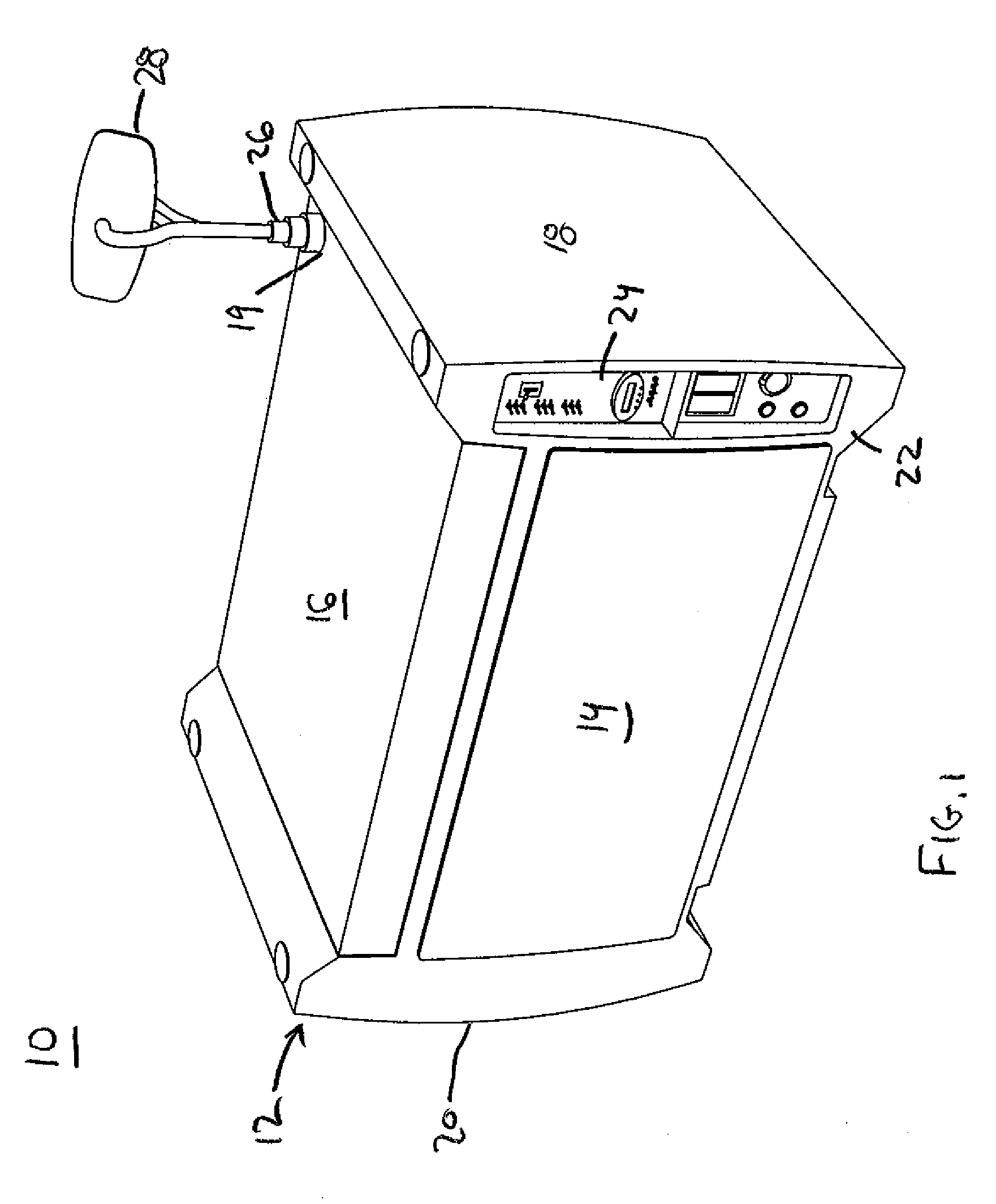

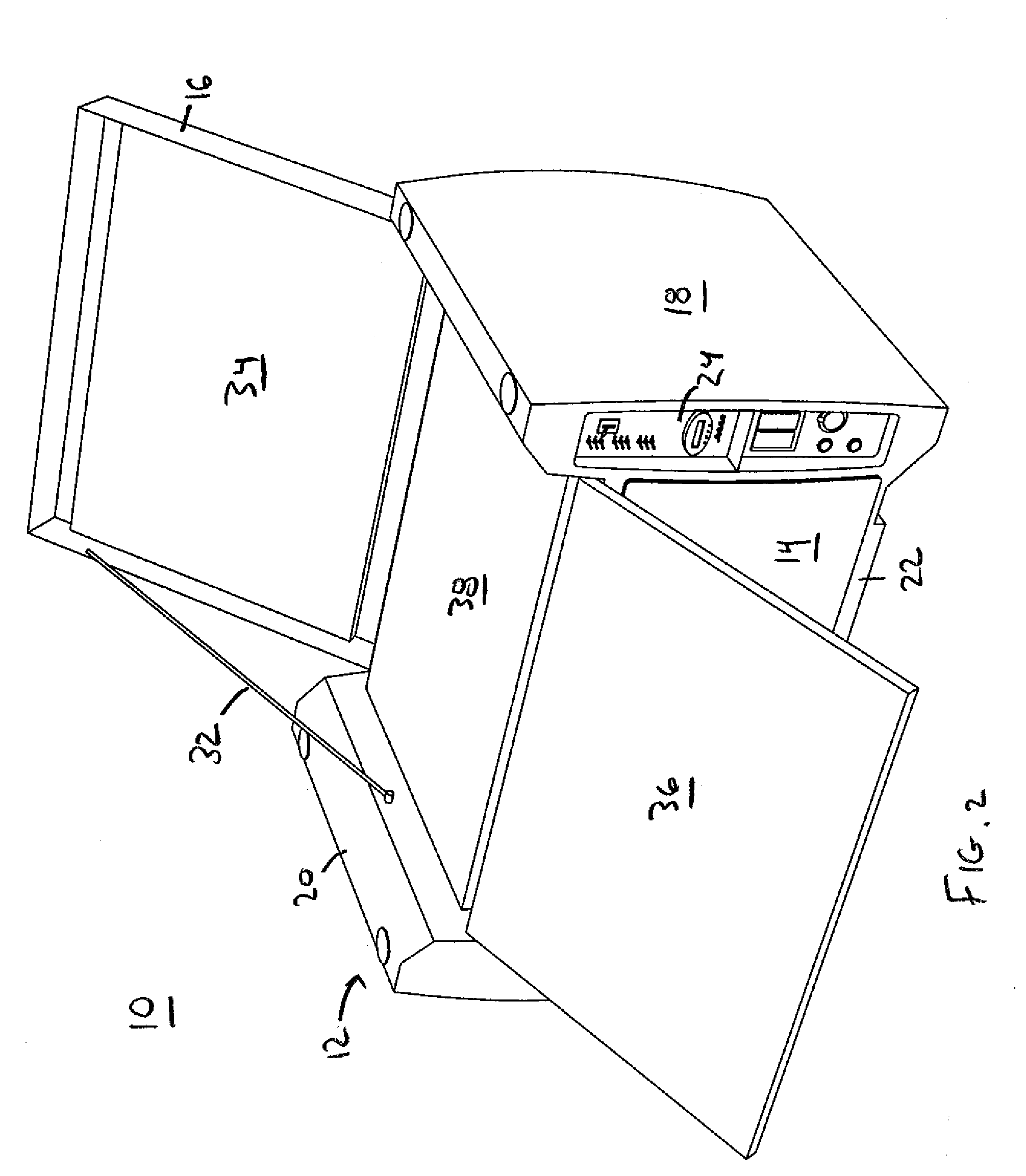

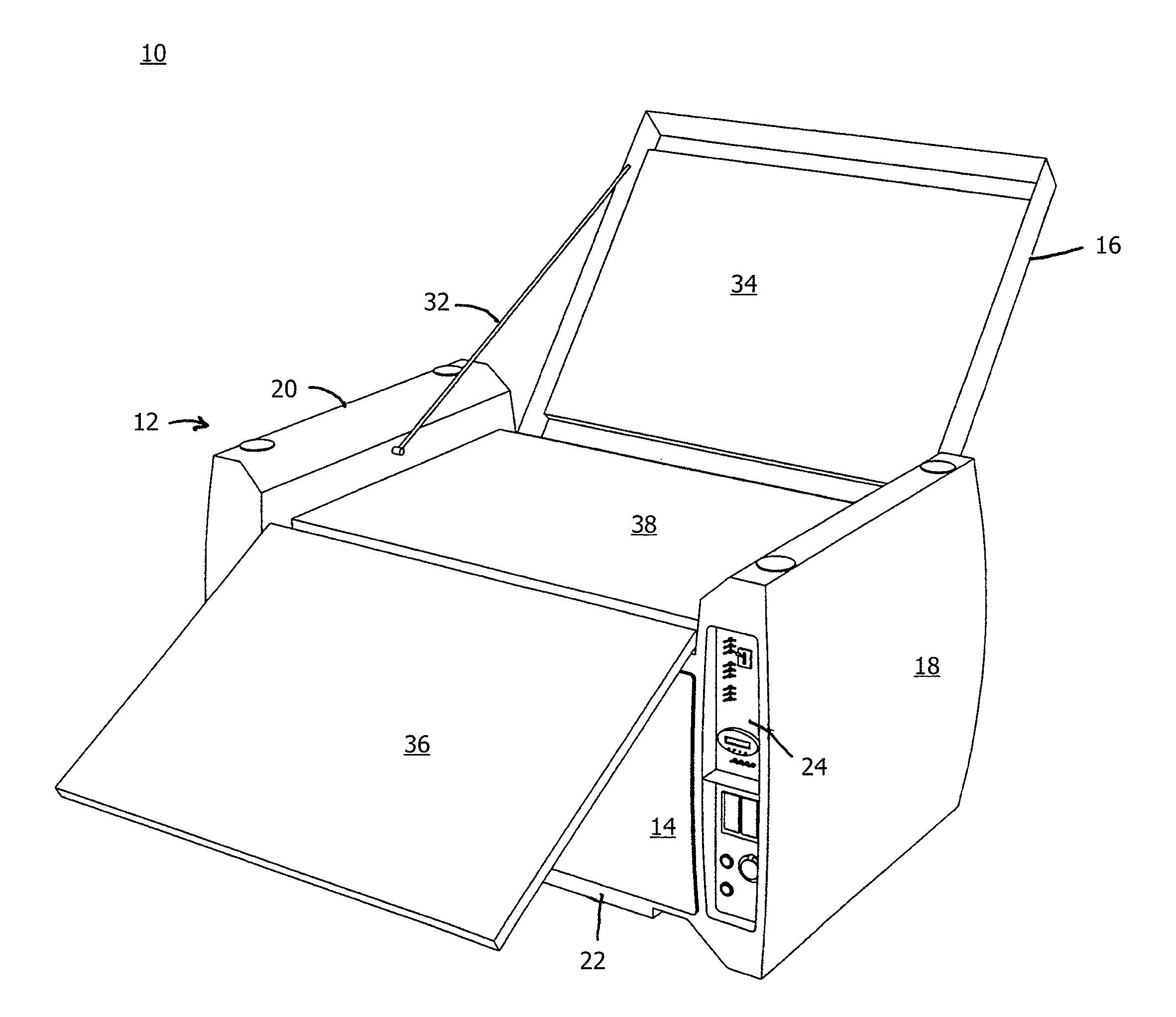

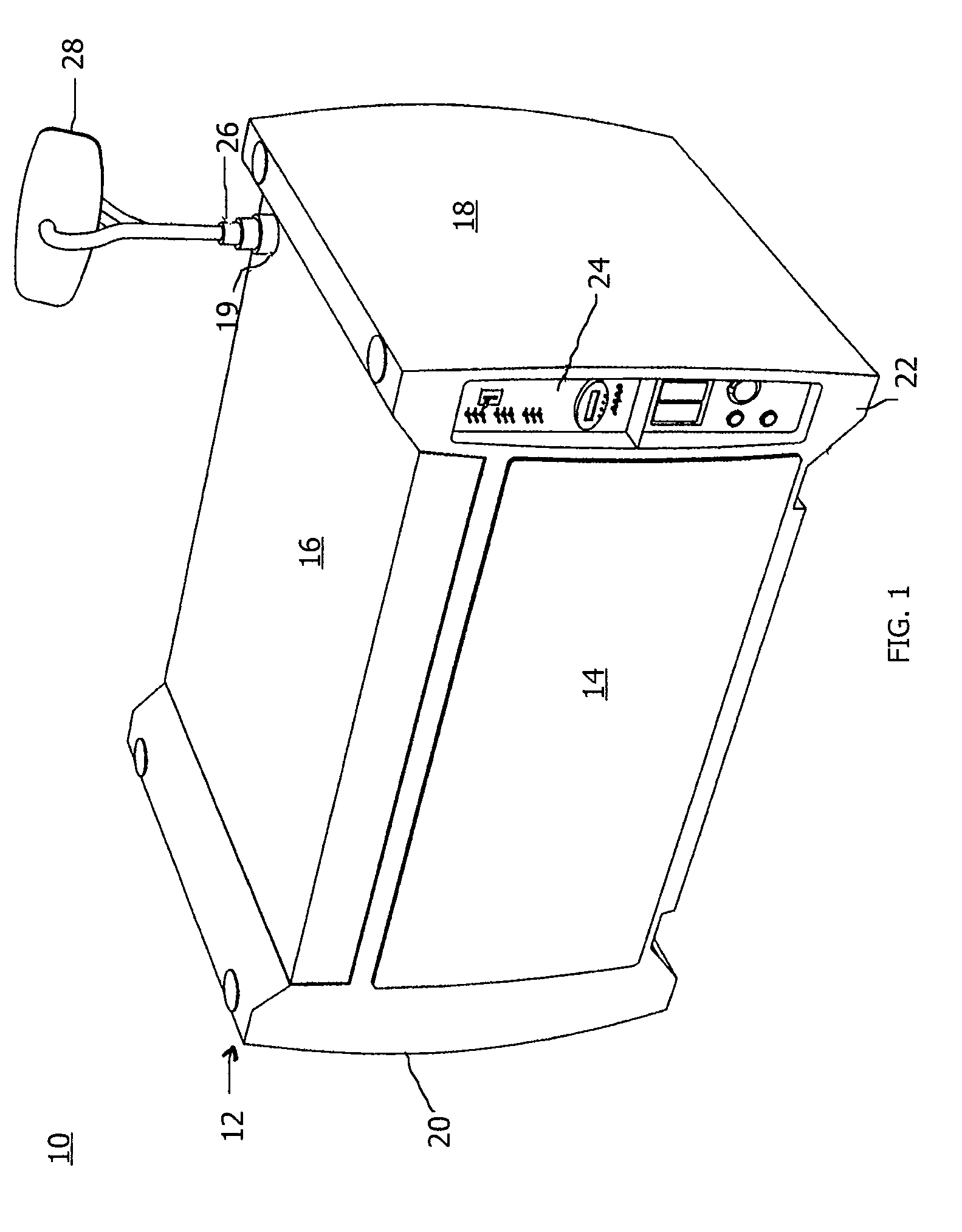

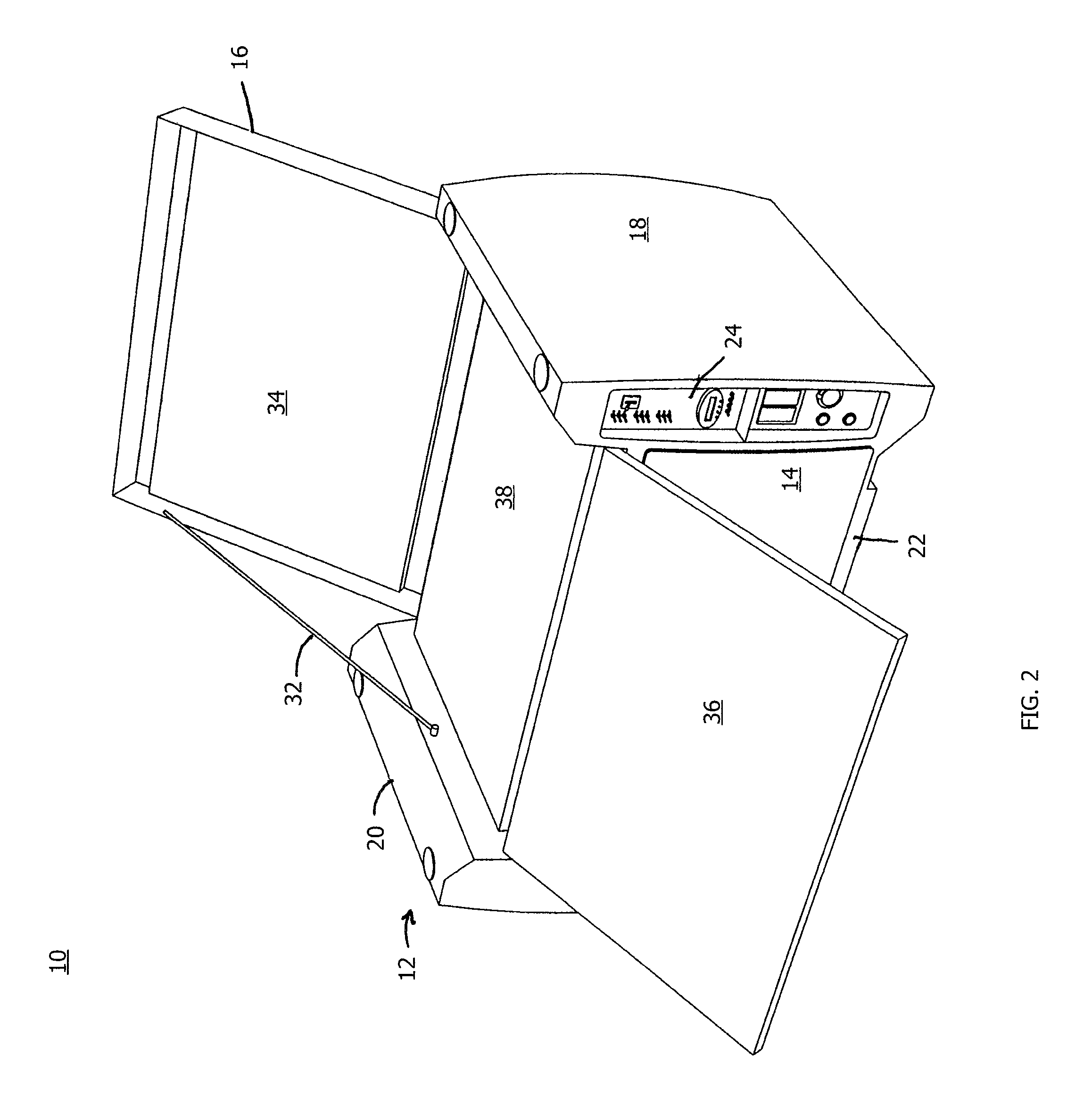

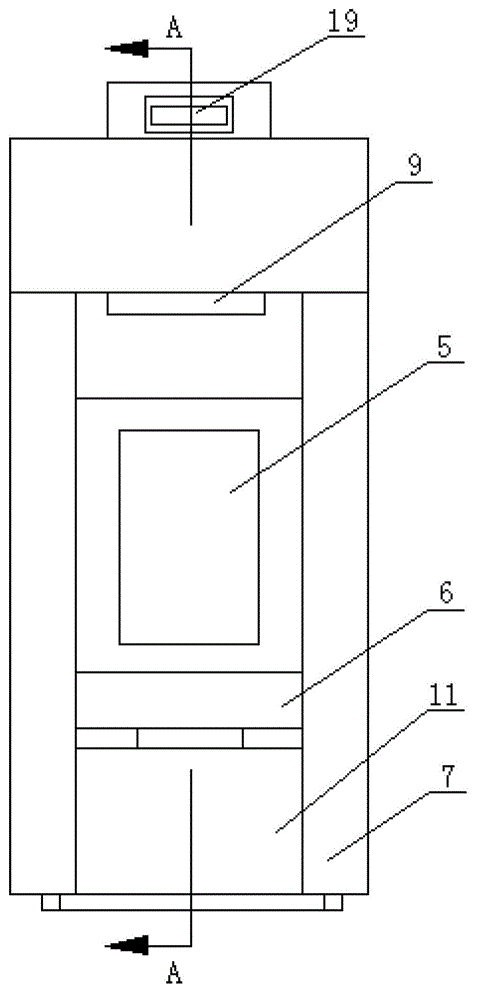

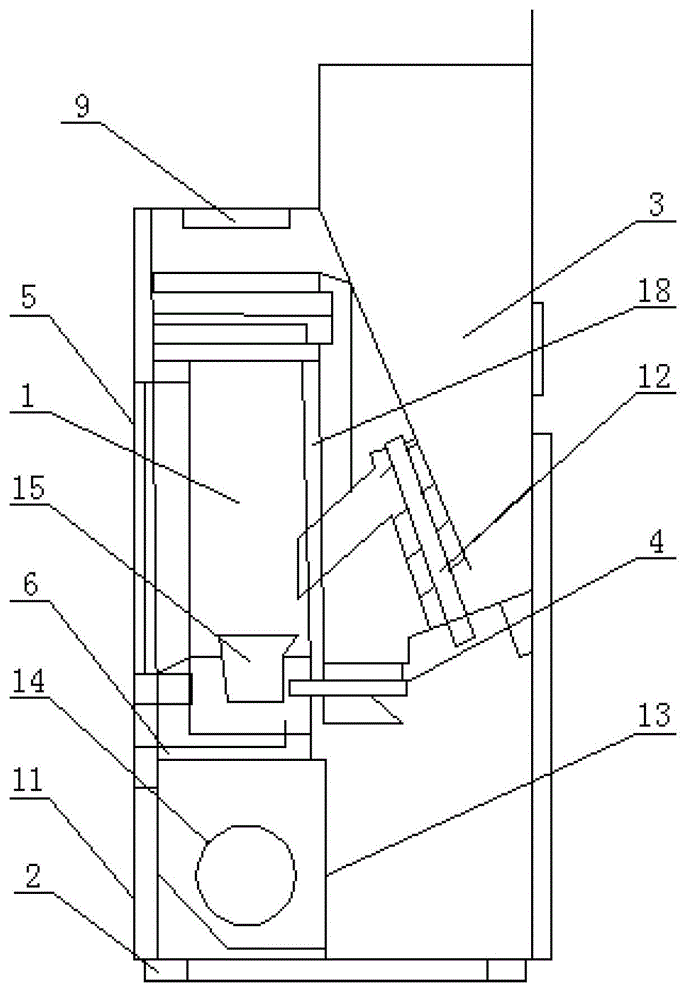

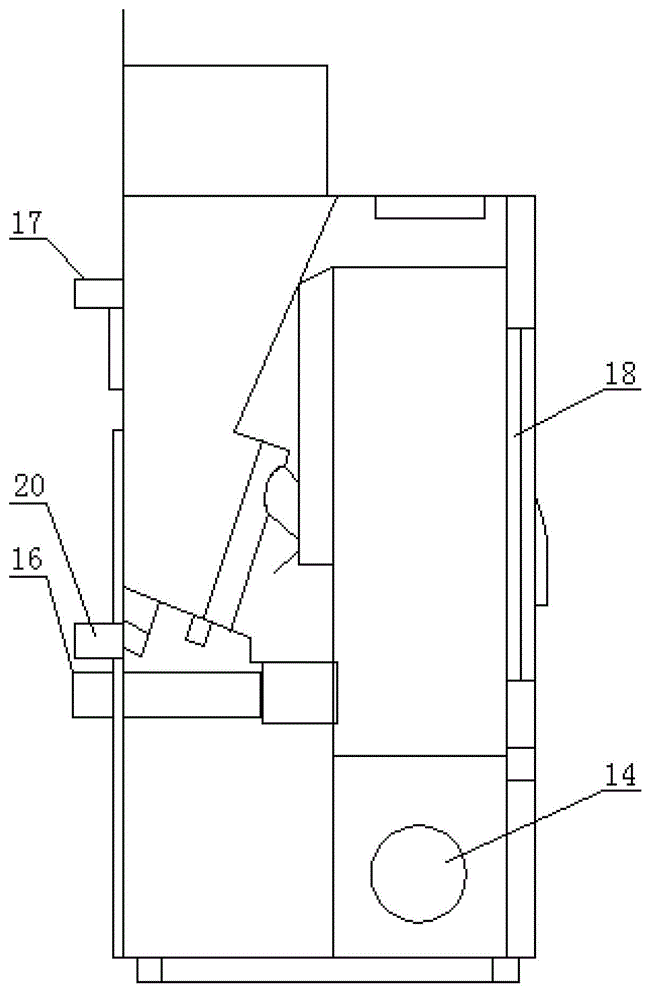

Deployable power supply system

InactiveUS20090039705A1Easy to operateEasy to scaleBatteries circuit arrangementsPV power plantsElectricityRemote system

A self-contained conveyable power unit for producing 12V / 24V, 110V AC, and 220V AC electricity at a desired location independent of external power sources integrates within one weather-resistant molded nonmetallic material based housing a power generating device of a selectable combination of a renewable energy type (e.g., solar), power management devices, power storage devices and management reporting devices. Additional optional power generating devices, renewable or of traditional fuel type, can be contained within or coupled to the housing. The system includes devices or an array of devices contained within the housing for the storage of electrical power. A device for power management is contained within the housing as is networking equipment of wireless or wired type for remote system observation and reporting. The system and housing are modular and configured to produce power using any combination of renewable and non-renewable energy resources. The conveyable power unit may provide easy access to different types of power outputs and inputs and be coupled with like appliances in a ‘daisy chain’ or network of power. Given its molded composite material construction and scaleable design, the appliance may be readily fabricated in a variety of sizes for varied applications. Further, the molded housing of composite material construction is designed for resistance to the elements, light weight and strength.

Owner:ZEROBASE ENERGY

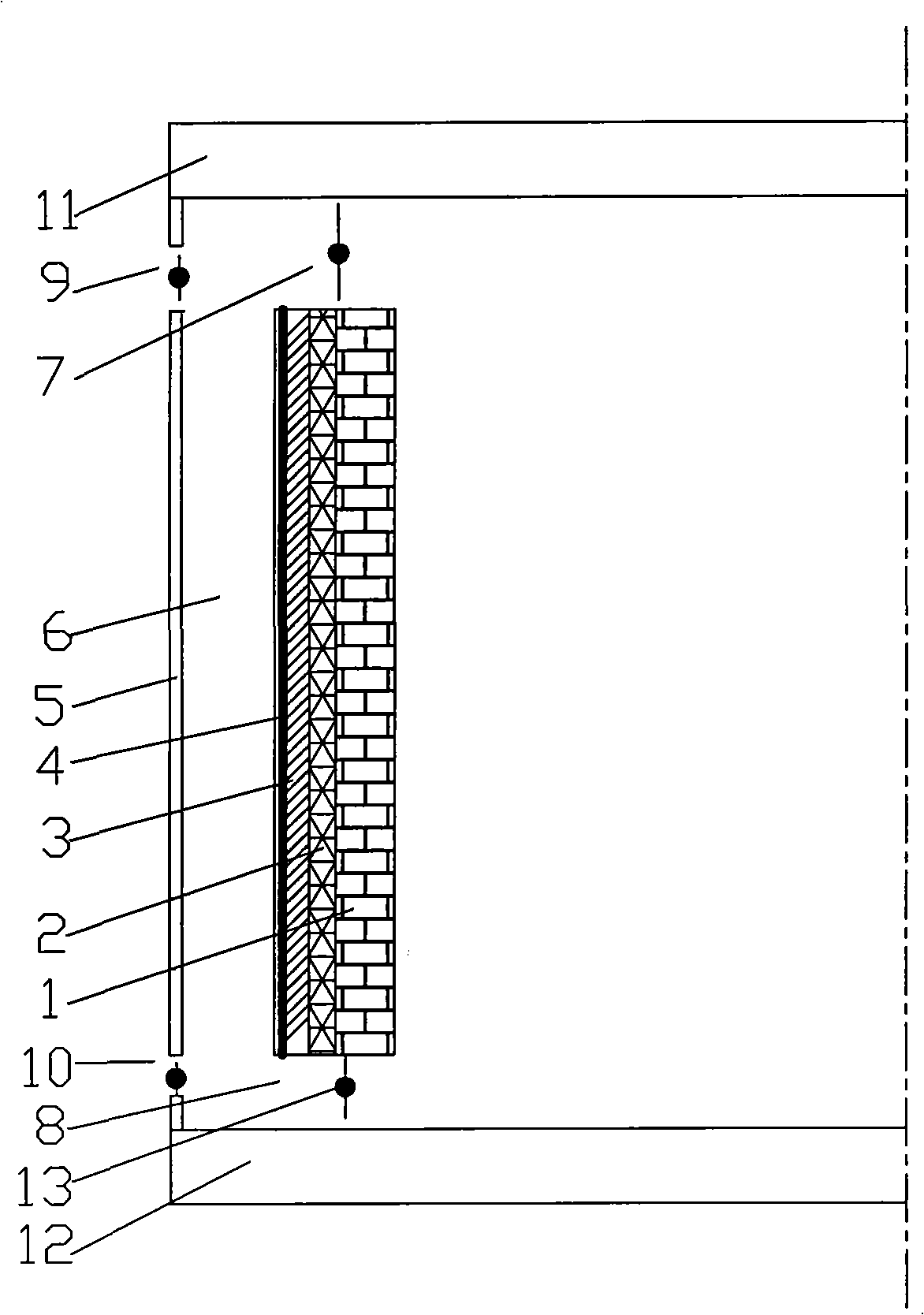

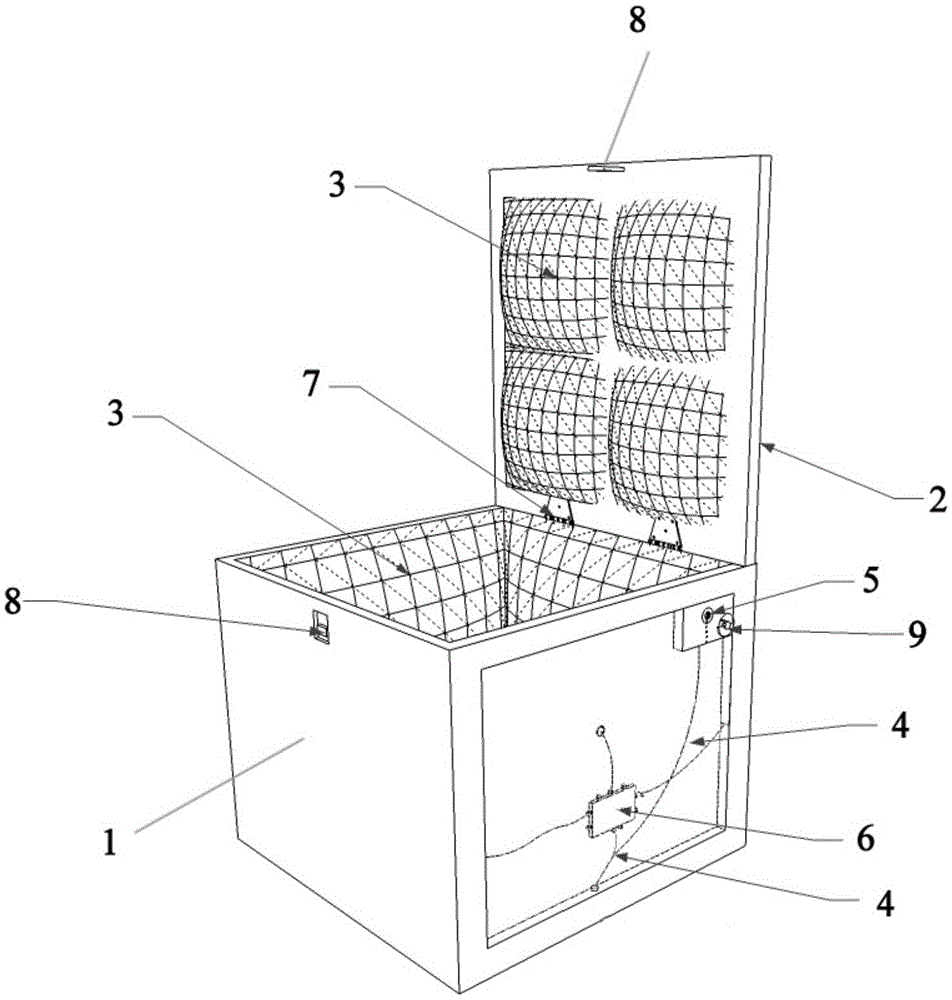

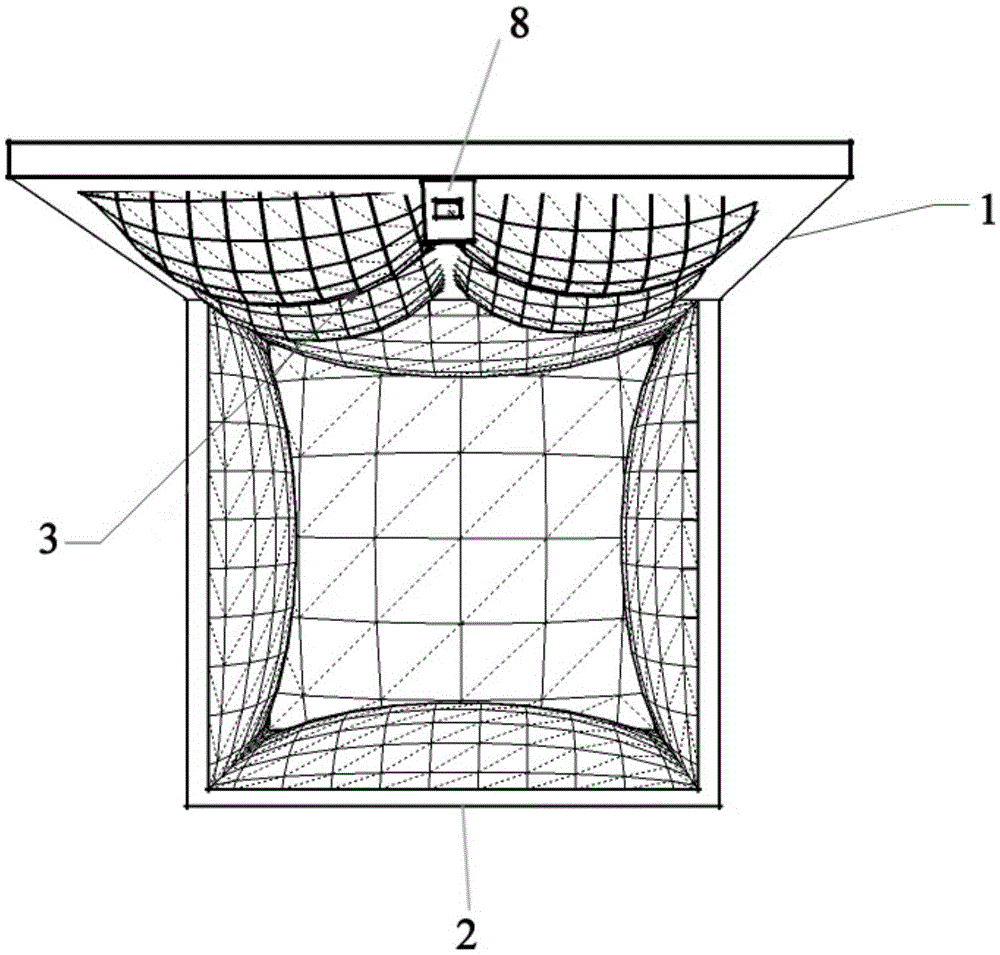

Solar energy storage ventilated heating system

InactiveCN101324352ANo lossNo pollution in the processCentral heating with accumulated heatSolar heat devicesInsulation layerSolar energy storage

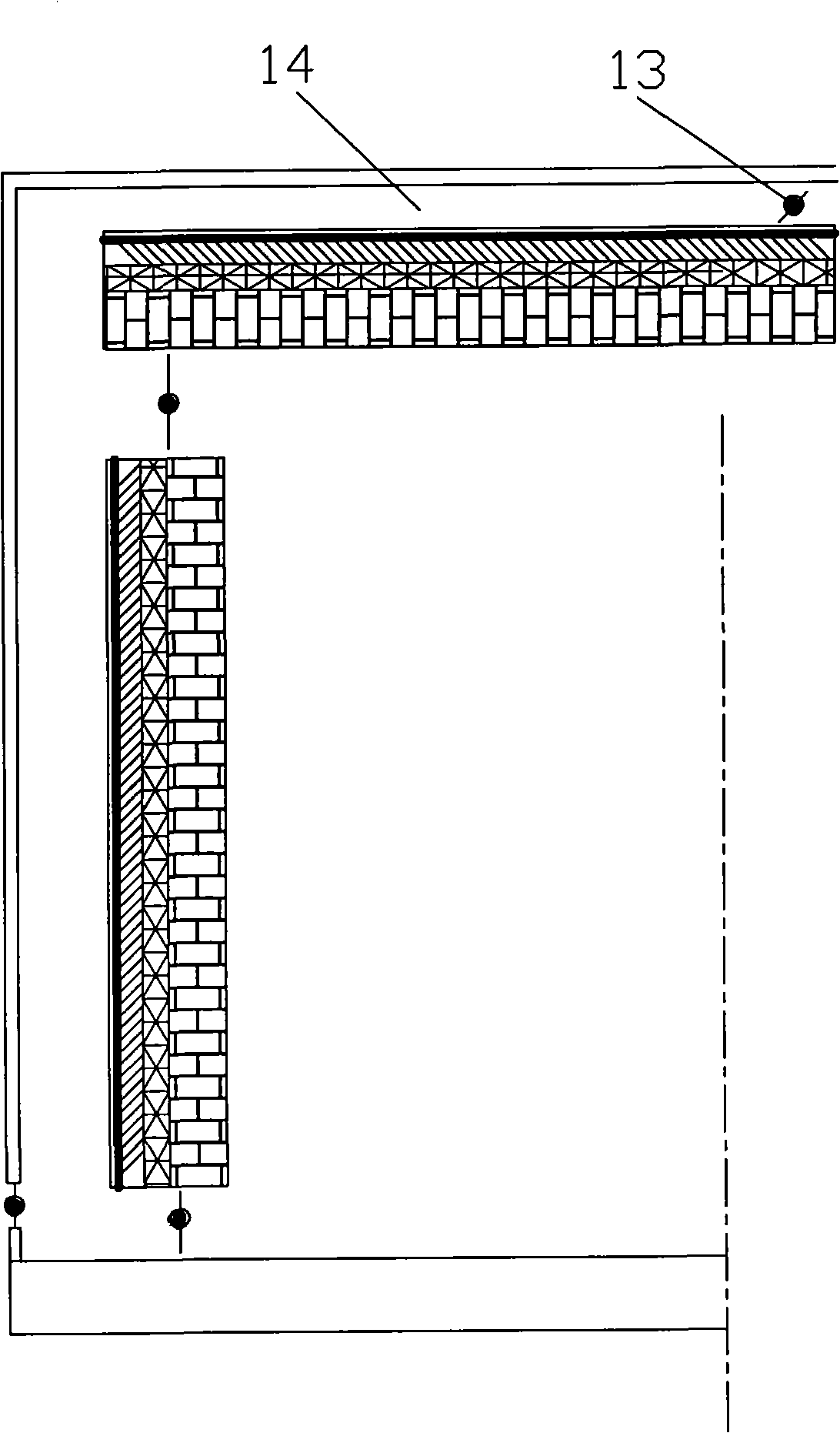

The invention discloses a solar energy storage, ventilation and heating system, which comprises a heat storage wall composed of a heat-insulation layer, a heat storage layer and an aluminum plate painted with black paint, a heat storage ventilation channel or a combination thereof, which are sequentially arranged on the outer side of the external wall of a building; a transparent cover plate arranged on the outer side of the heat storage wall or the heat storage ventilation channel; an air sandwich between the transparent cover plate and the heat storage wall; and an upper vent and a lower vent having valves and arranged on the transparent cover plate and the heat storage wall. The solar energy storage, ventilation and heating system can achieve intermittent ventilation and heating without consuming non-renewable energy by using the special heat absorption and release functions of a phase-change heat storage material and by controlling the valves of the vents. The system has the advantages of energy conservation, environmental protection, simple control and handsome structure, and can be widely used for common residential buildings and public buildings.

Owner:CHONGQING UNIV

Low-density ceramic proppant prepared from fly ash and preparation method thereof

InactiveCN102899015ALow densityQuality is not affectedFluid removalCeramic materials productionManganeseTurbidity

The invention discloses a low-density ceramic proppant prepared from fly ash and a preparation method thereof. The proppant comprises the following components, by weight: 60%-80% of bauxite, 10%-30% of fly ash and 5%-10% of manganese powder. The fly ash mainly comprises Al2O3 and SiO2, and the Al2O3 and SiO2 have higher content and purity than coal gangue, so that quality of the fly ash will not be influenced; and the fly ash has low density, and is suitable to be used as a raw material for preparation of low-density ceramic. Fly ash has wide distribution, and can be used to replace bauxite resource, which is becoming more and more limited, so as to save non-renewable resources. Compared with ceramic proppant prepared from coal gangue, the low-density ceramic proppant prepared from raw material of fly ash has substantially reduced fracture rate, bulk density and turbidity, improved product quality and reduced cost, so as to solve environmental pollution caused by fly ash emission.

Owner:YIXING TENGFEI OIL FRACTARING PROPPANT

High-efficiency solar photo-thermal tower-type electricity generation and seawater desalinization integral system

InactiveCN102345576AIncrease the concentration ratioSmall heat dissipation ratioSolar heating energyFrom solar energyCollection systemFresh water organism

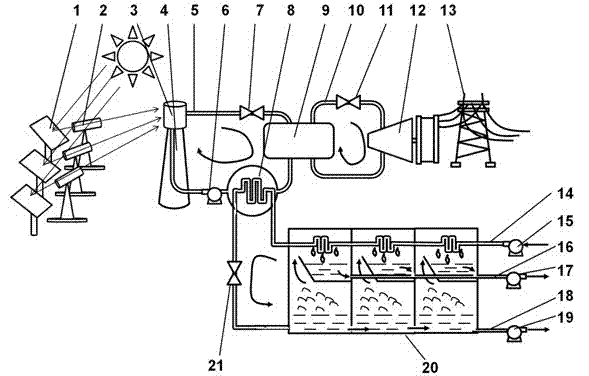

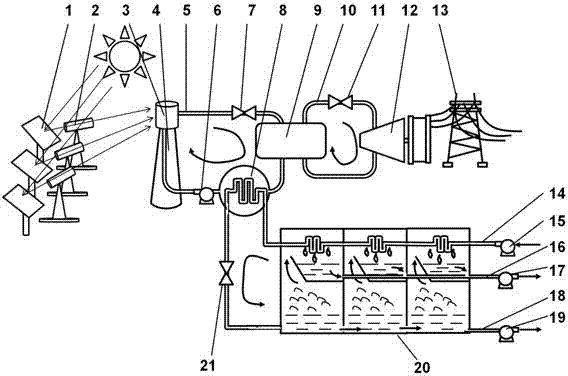

The invention discloses a high-efficiency solar photo-thermal tower-type electricity generation and seawater desalinization integral system, and in the prior art, a mass of non-renewable energy resources are consumed. The integral system provided by the invention comprises a solar thermal collection system, a heat transfer working substance circulating system, an electricity generating system and a seawater desalinization system, and particularly comprises a heliostat, a localizer, a heat absorber, a heat absorber support tower, a heat transfer working substance loop, a pump, a seawater heater, a steam generator, a steam loop, a turbine generator, a power grid, a cold seawater pipeline, a fresh water pipeline, a strong brine pipeline, multilevel flashing equipment and a flow valve, wherein the heat transfer working substance loop and the steam loop are enclosed, and the loop of the seawater desalinization system for generating freshwater is in an open type. The integral system provided by the invention has the advantages of high-efficiency and rapid heat collection function and stability in production of supplying heat, generating electricity and desalinizing seawater; and compared with conventional energy resources, the solar energy is renewable, environmentally-friendly, cost-free and common.

Owner:HANGZHOU DIANZI UNIV

Method for preparing dihydric alcohol from crop straw

InactiveCN103667365ANovel production processNovel processChemical recyclingFermentationCelluloseIon exchange

The invention discloses a method for preparing dihydric alcohol from crop straw. The method comprises steps of steeping raw material crop straw into diluted acid, pretreating for a short time at high temperature, then carrying out refining treatments such as cellulose hydrolyzing, decoloring and filtering, ion exchanging and high efficiently concentrating, so as to prepare straw sugar, in the presence of a special nickel alloy catalyst, continuously hydrocracking the straw sugar under high pressure so as to obtain a mixture of dihydric alcohol and polyhydric alcohols, rectifying the split product at reduced pressure and separating so as to obtain products such as ethylene glycol and propylene glycol. The method has the advantage of unique and novel and advance process; non-grain biomass resource is taken as the raw material, so that the grain risk is thoroughly avoided; the non-grain biomass resource can substitute for non-renewable resources such as petroleum or coal, so that the method has significance to development of circular economy.

Owner:郸城财鑫糖业有限责任公司

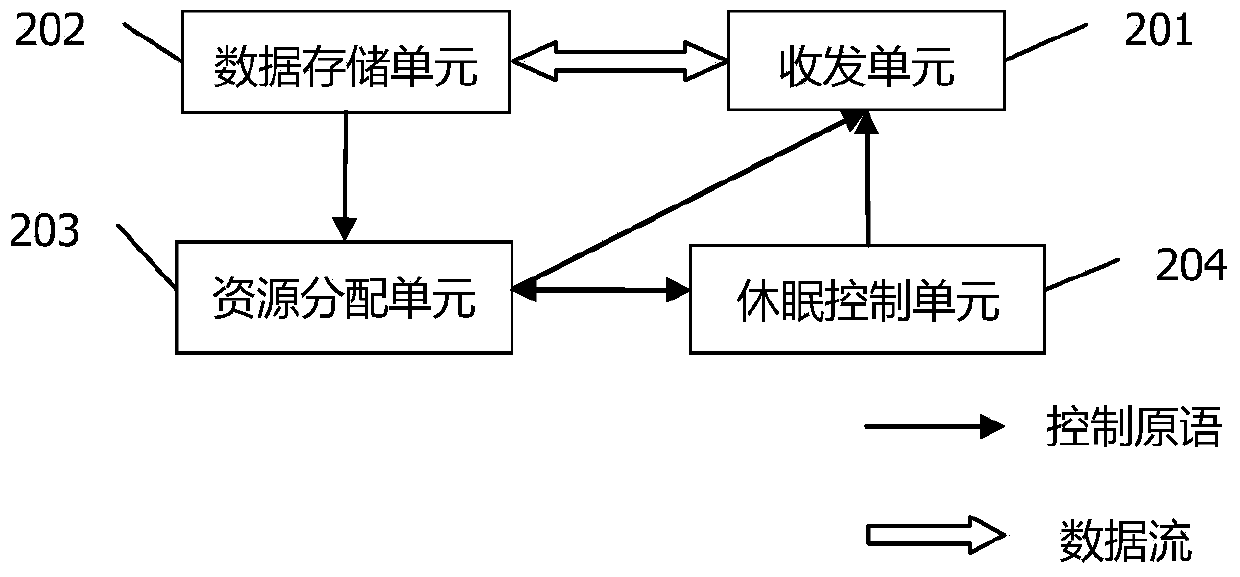

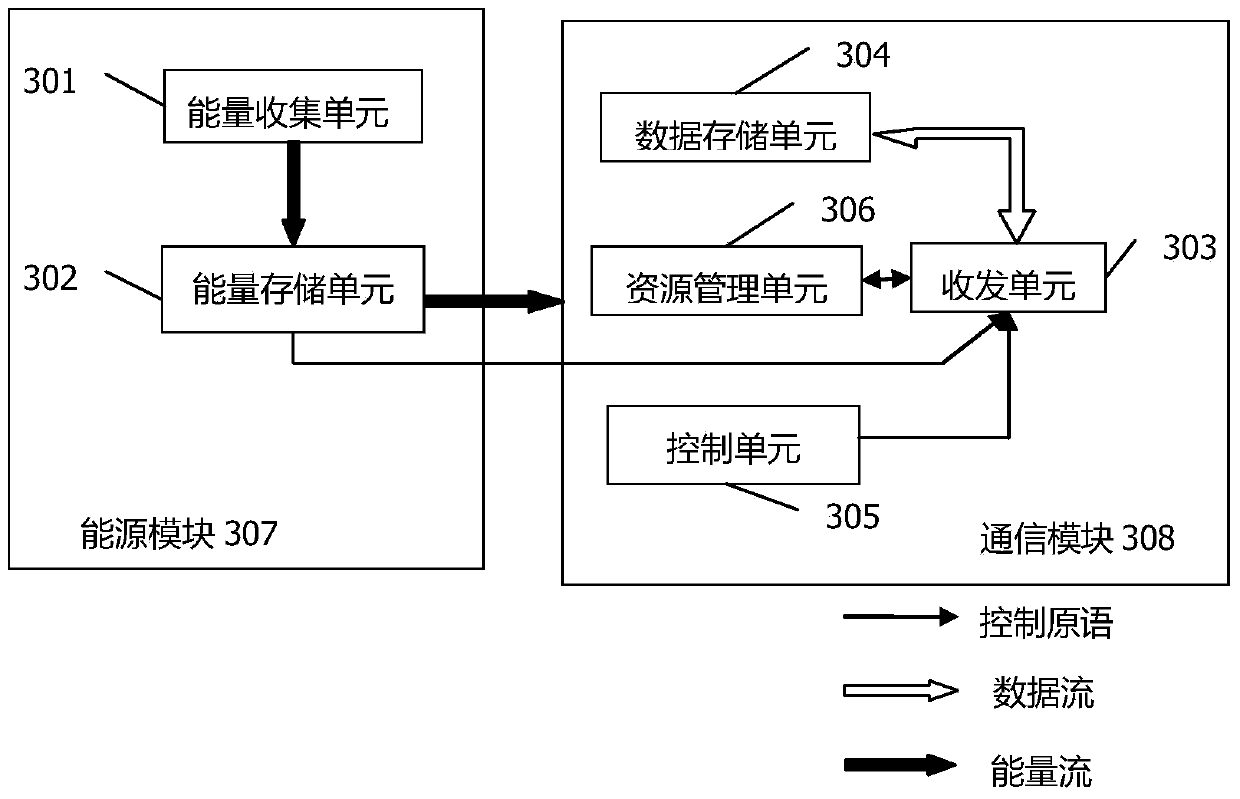

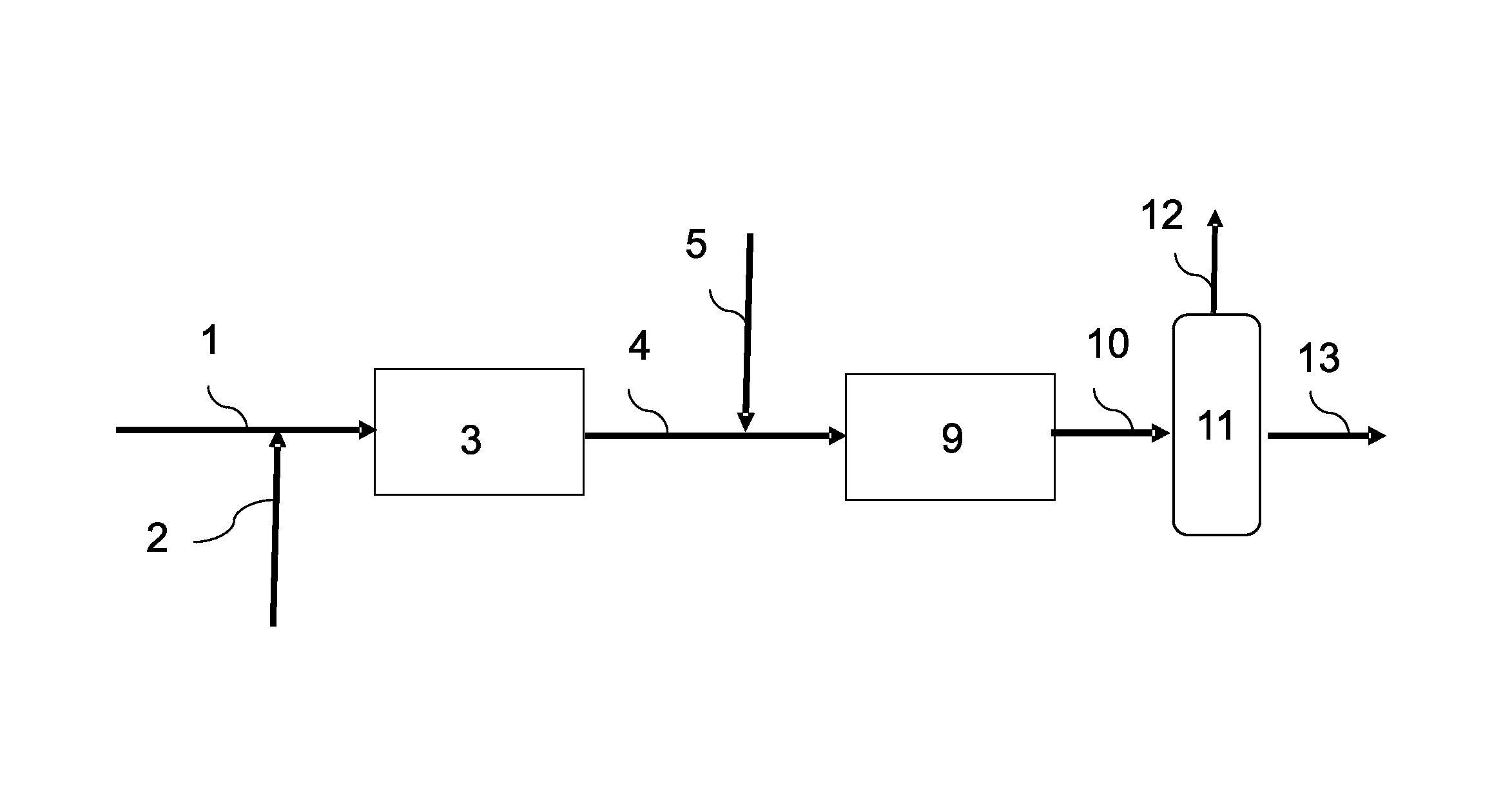

Relay communication system utilizing regenerable energy power supply and energy-saving mode

ActiveCN103596251AReduce consumptionExpand effective coverageEnergy efficient ICTPower managementEngineeringSupply energy

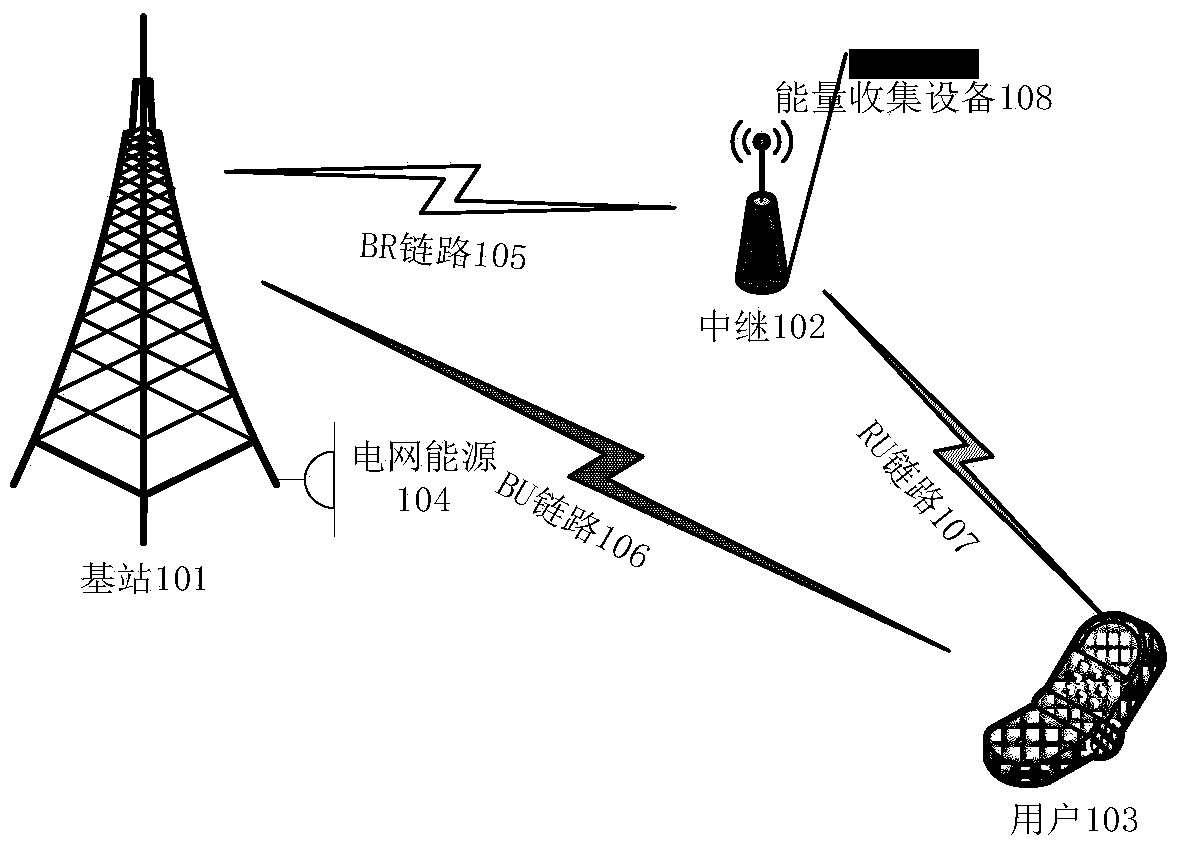

The invention discloses a relay communication system utilizing regenerable energy power supply and an energy-saving mode. The relay communication system is characterized in that traditional power grid energy supplies power for a base station, regenerable energy collected by an energy collecting device supplies power for a relay, and the relay processes received signals and forward the received signals; in a downlink link, the relay periodically sends channel state information and current energy storage to the base station, and the base station determines to select a direct connection transmission mode or a relay transmission mode according to load information, information fed back by the relay and the channel conditions and conducts corresponding downlink resource distribution; in an uplink link, the relay periodically sends the state information of channels from a user to the relay and the current energy storage to the base station, the base station combines the information, the load information and state information, of channels from the relay to the base station and from a user to the base station, obtained by self-estimation to choose a direct connection transmission mode or a relay transmission mode, and conducts corresponding uplink link source distribution. By the adoption of the method, communication quality can be ensured, and non-renewable energy consumption can be saved.

Owner:UNIV OF SCI & TECH OF CHINA

Deployable power supply system

InactiveUS7884502B2Catalyzes diffusion and adoptionEasy usabilityBatteries circuit arrangementsPV power plantsRemote systemMetallic materials

A self-contained conveyable power unit for producing 12V / 24V, 110V AC, and 220V AC electricity at a desired location independent of external power sources integrates within one weather-resistant molded nonmetallic material based housing a power generating device of a selectable combination of a renewable energy type (e.g., solar), power management devices, power storage devices and management reporting devices. Additional optional power generating devices, renewable or of traditional fuel type, can be contained within or coupled to the housing. The system includes devices or an array of devices contained within the housing for the storage of electrical power. A device for power management is contained within the housing as is networking equipment of wireless or wired type for remote system observation and reporting. The system and housing are modular and configured to produce power using any combination of renewable and non-renewable energy resources. The conveyable power unit may provide easy access to different types of power outputs and inputs and be coupled with like appliances in a ‘daisy chain’ or network of power. Given its molded composite material construction and scaleable design, the appliance may be readily fabricated in a variety of sizes for varied applications. Further, the molded housing of composite material construction is designed for resistance to the elements, light weight and strength.

Owner:ZEROBASE ENERGY

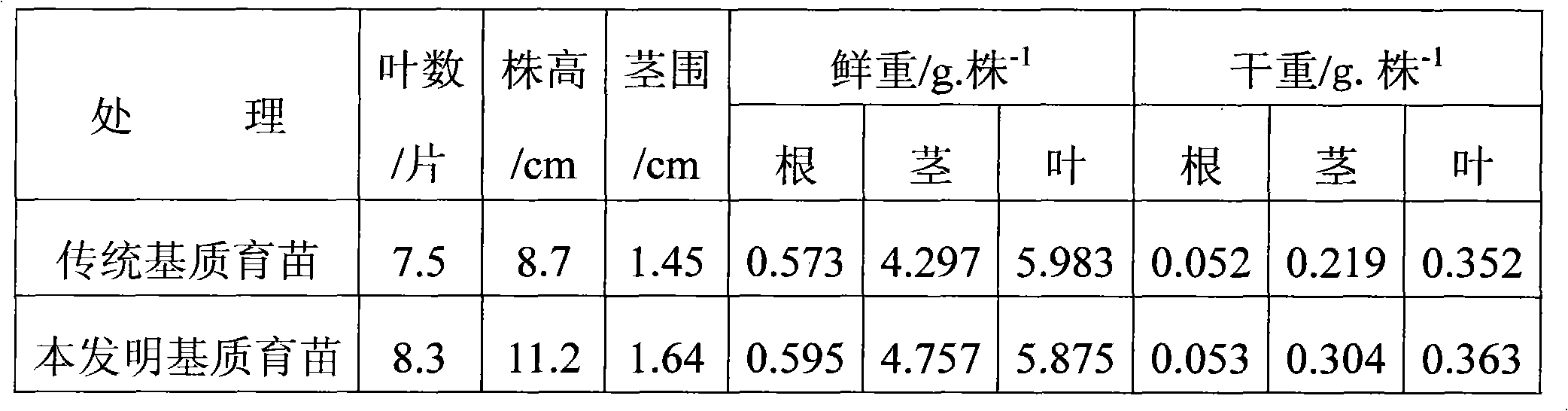

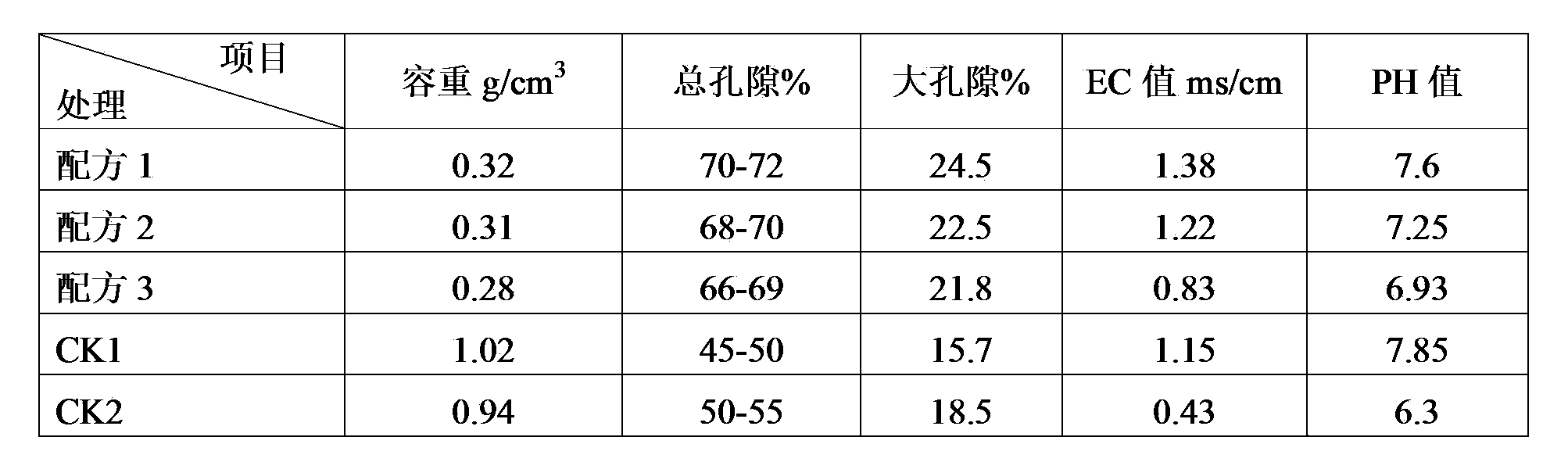

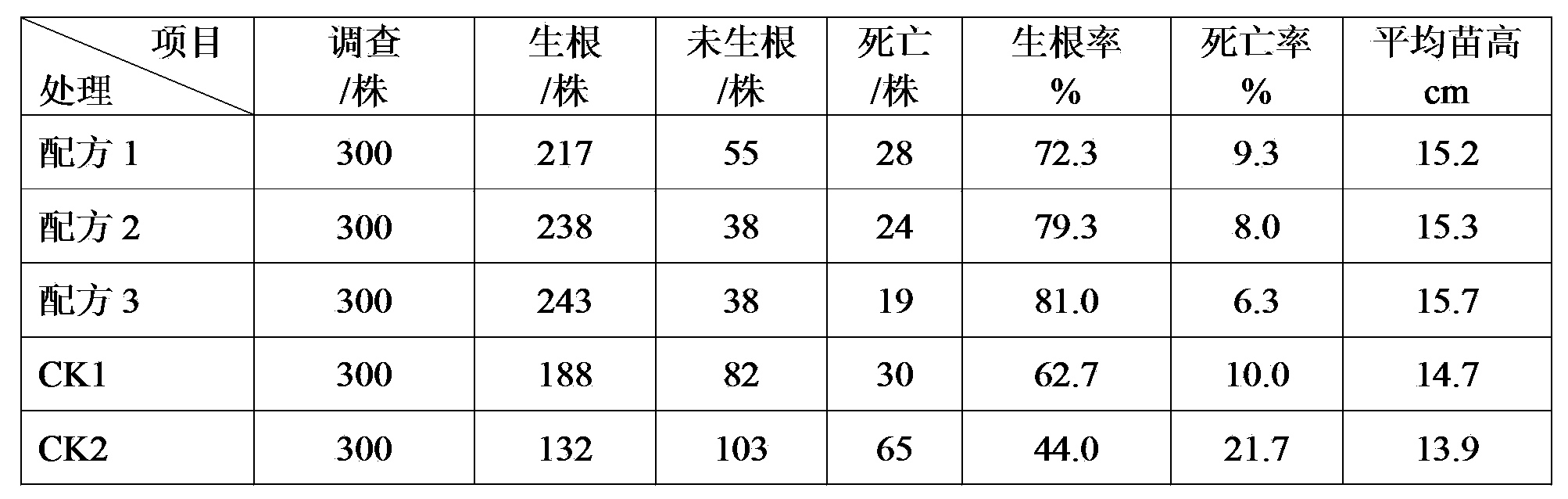

Soilless culture organic matrix used for tomato seedling raising and preparation method thereof

InactiveCN101697705AReduce overexploitationAchieve sustainable useAgriculture gas emission reductionCultivating equipmentsRenewable resourceNon-renewable resource

The invention discloses a soilless culture organic matrix and preparation method thereof; wherein the soilless culture organic matrix is formed by evenly mixing corn cob fragments, corn stalk fragments and mushroom residue after respective piling fermentation according to volume ratio of (1.5-2.5): (4-6): (1.5-4.5). The main raw materials of the soilless culture organic matrix provided by the invention adopts waste corn stalk, corn cob and mushroom residue in local agricultural production instead of matrix raw material grass carbon commonly used in the current seedling raising, thus not only greatly saving seedling raising cost but also reducing over-exploitation of non-renewable resources grass carbon, thereby maintaining ecological sustainable development; not only environmental pollution caused by burning is avoided, but also sustainable utilization of resources is realized.

Owner:NORTHWEST A & F UNIV

Transportation box

The embodiment of the invention discloses a transportation box which comprises a box body, a box cover, at least one gasbag and a gas charging and discharging connector, and further comprises a guide tube, a hinge, a lock catch, a manual gas exhaust valve and a pressure limiting valve, wherein the at least one gasbag is fixed to the inner side of the wall of the box body and / or the inner side of the box cover; the gas charging and discharging connector is arranged at the outer side of the wall of the box body and / or the outer side of the box cover; and the gasbags are connected to the gas charging and discharging connector. According to the scheme, during goods transportation, gas is charged by the gasbags to fix the goods; when the transportation box has collision or friction, the goods are prevented from being damaged; and the transportation box can be repeatedly used, so that use of non-renewable resources is reduced, and therefore, waste of the resources is greatly reduced.

Owner:陈明星

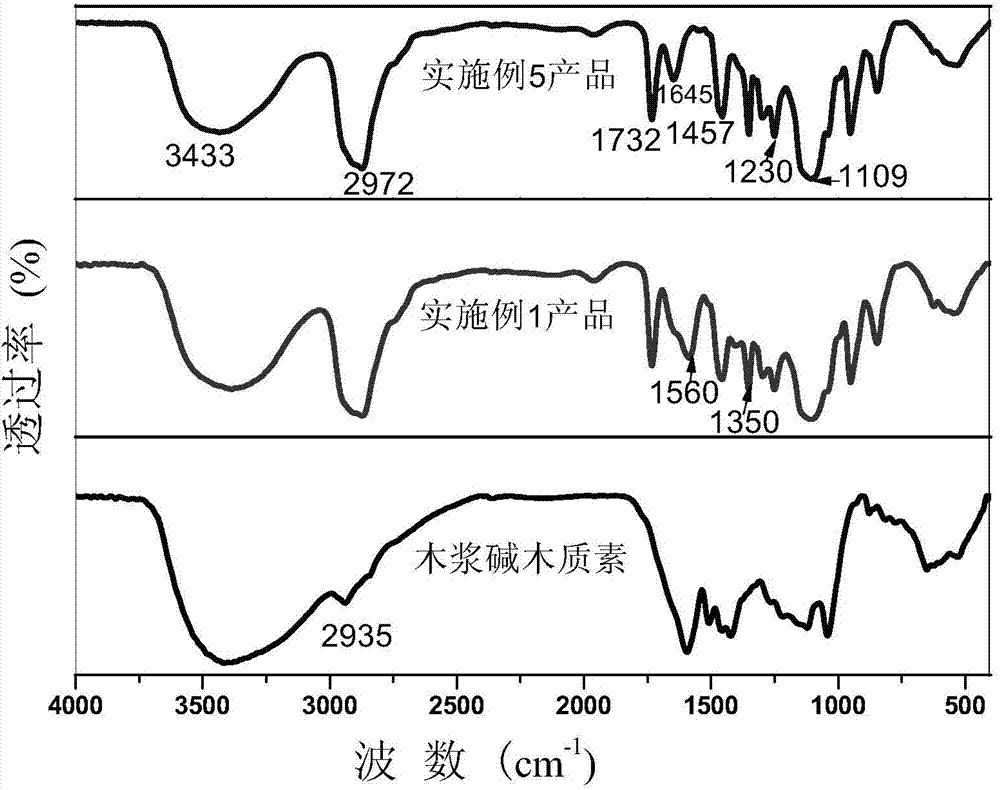

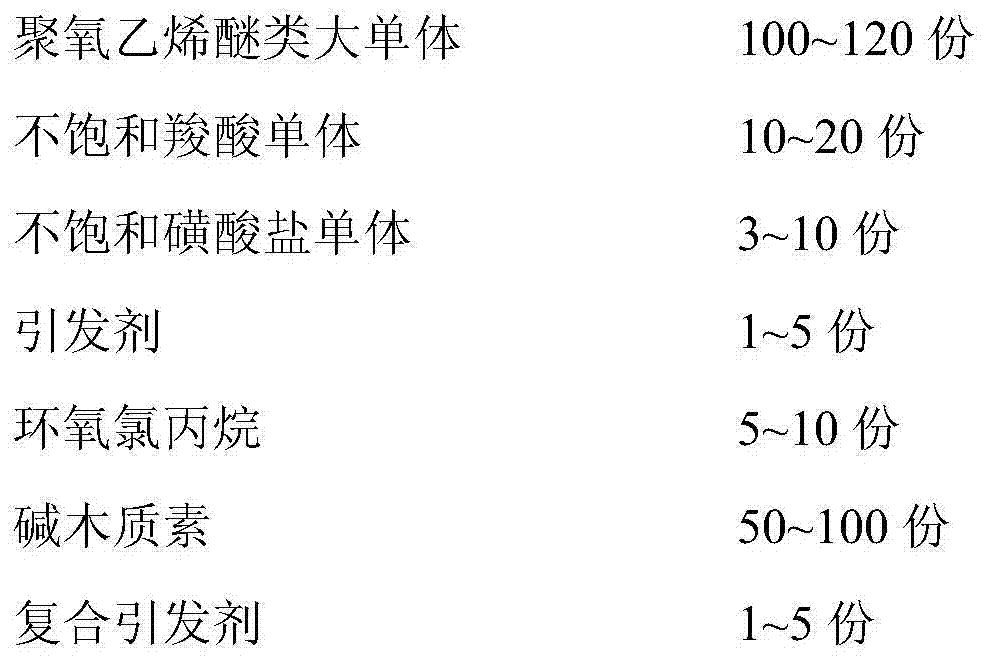

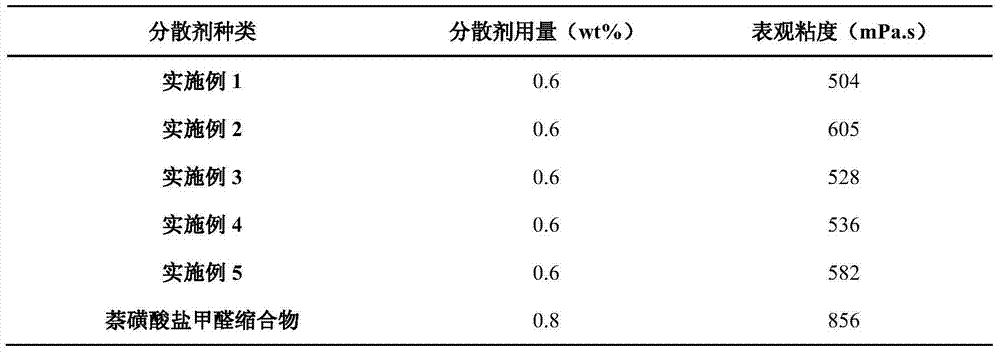

Preparation method of alkali lignin modified polycarboxylic acid-type coal water slurry dispersant

ActiveCN104327280AStay decentralizedReduce usageLiquid carbonaceous fuelsDispersion stabilityLiquid product

The invention relates to a preparation method of an alkali lignin modified polycarboxylic acid-type high-efficiency coal water slurry dispersant. The method comprises the steps: at the temperature of 50-80 DEG C, carrying out a copolymerization reaction of a polyoxyethylene ether macromonomer, an unsaturated carboxylic acid monomer, an unsaturated sulfonate monomer and an initiator for 2-3 h in an aqueous solution, adjusting the temperature to 30-50 DEG C, adding epoxy chloropropane, carrying out a reaction for 0.5-1 h, adding an alkaline regulator, adjusting the pH value to 10-12, adding an alkali lignin solution with the mass concentration of 20-50%, adjusting the reaction temperature to 60-80 DEG C, dropwise adding a composite initiator aqueous solution with the mass concentration of 2%, carrying out a reaction for 1-3 h, and thus obtaining a liquid product. The product has the dispersion viscosity reduction performance on coal water slurry superior to that of a naphthalenesulfonate formaldehyde condensation compound, and has good dispersion stability on coal slurry; and while original dispersive ability and other characteristics of the polycarboxylic acid-type dispersant are maintained, the production cost is reduced, and the usage amount of non-renewable resources and toxic materials is lowered.

Owner:SOUTH CHINA UNIV OF TECH

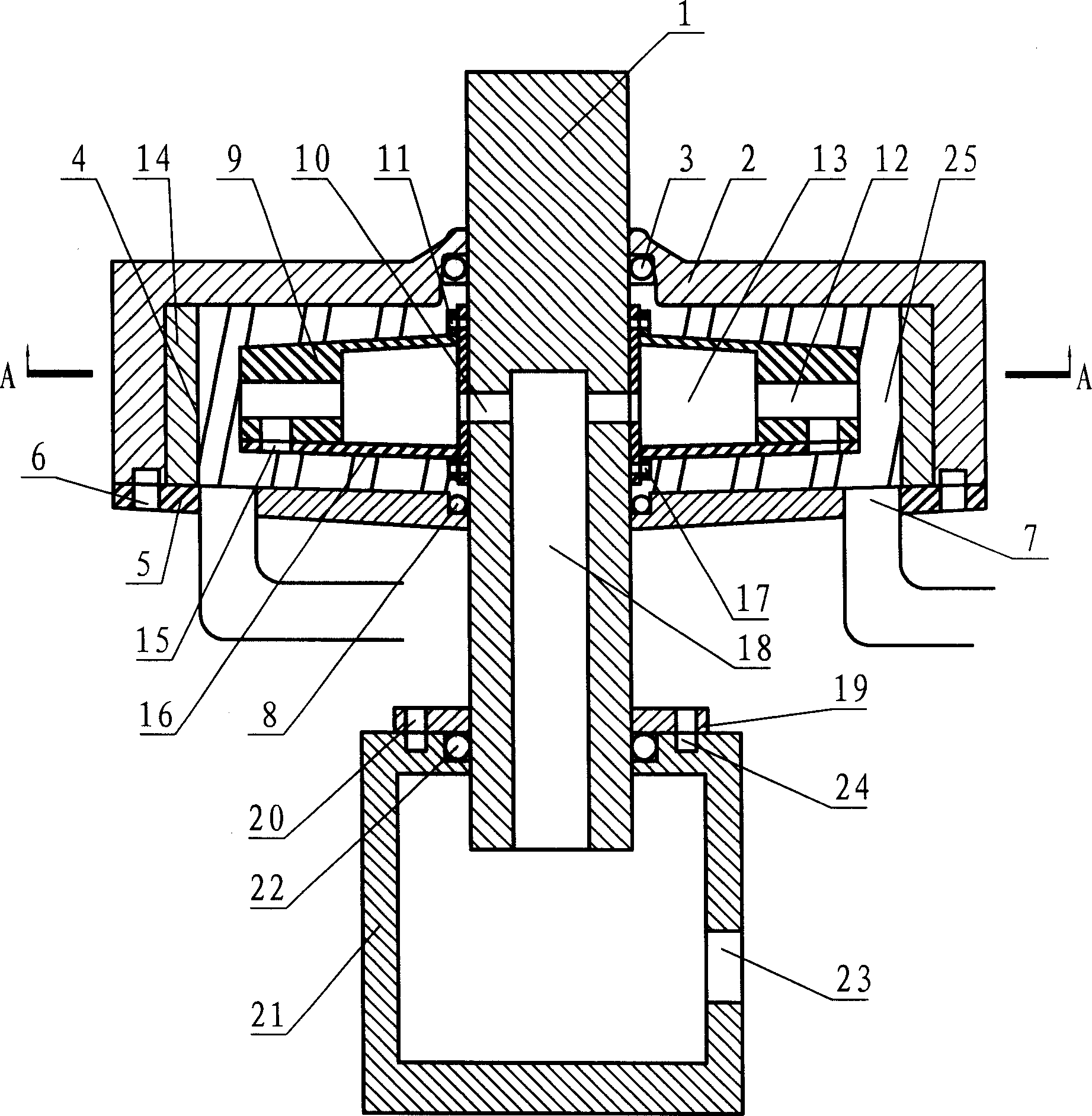

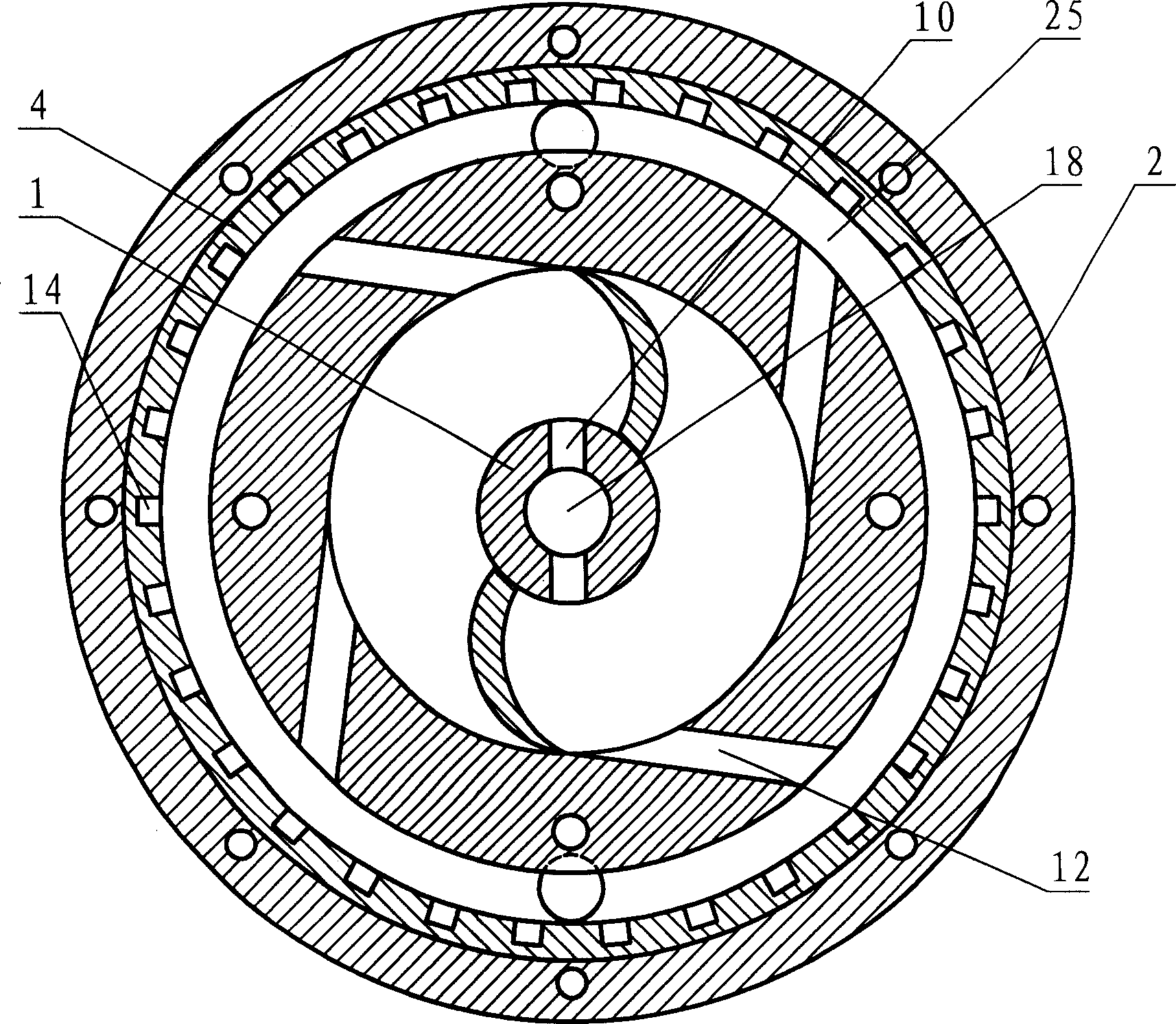

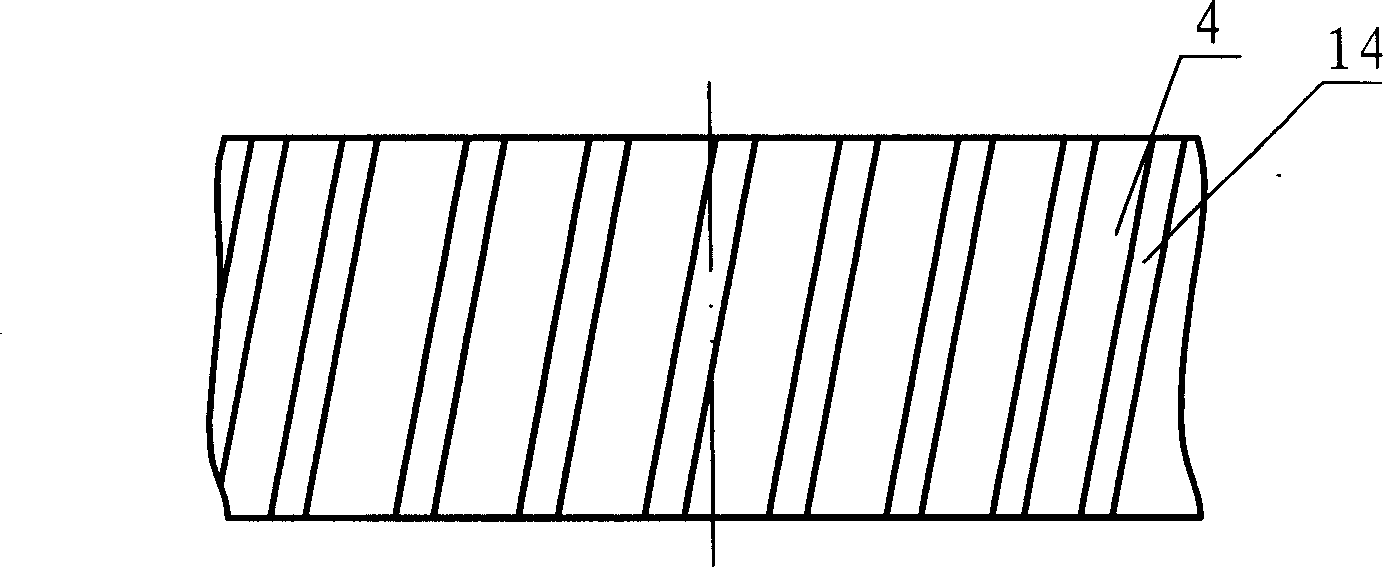

Rotaryshaft gas-supply rotor engine

InactiveCN1851263AReduce frictionReduce useless workMachines/enginesMechanical power devicesRotational axisEngineering

The invention relates to rotating shaft air feed rotary piston machine. It includes rotating shaft and air feed cabin. And the rotating shaft is set axial air induction channel and radial air induction hole. And it is set in stator air chamber by sealed bearing seat. The stator air chamber is set rotator air chamber. It is set intake hole connected to radial air induction hole. The stator air chamber is set air nozzle. The rotator is set exhaust hole. It has the advantages of energy saving, safe, long useful life, economic, and environment protecting.

Owner:李晓东

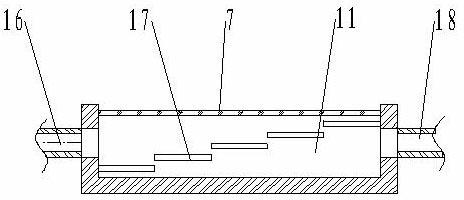

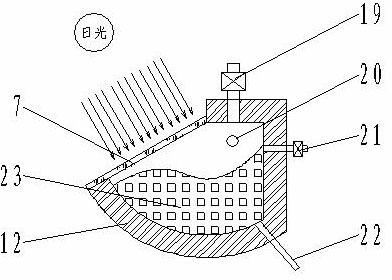

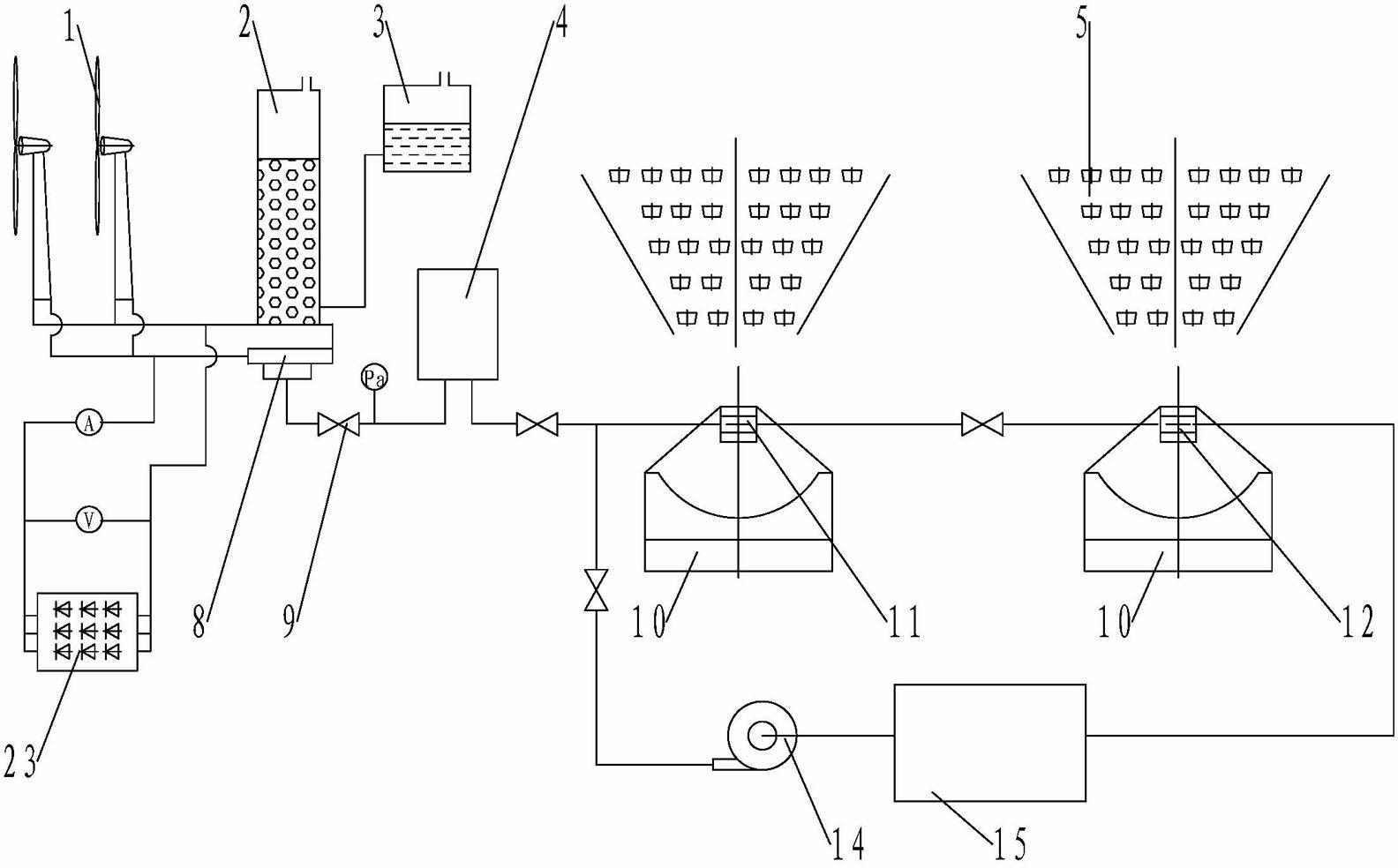

Method and device for solar reduction iron making

ActiveCN102424873AIncrease productivityAvoid emissionsProcess efficiency improvementGas emission reductionHeliostatHydrogen

The invention discloses a method and a device for solar reduction iron making. The device comprises a solar photovoltaic cell, a wind driven generator, an electrolyzer, a hydrogen heating chamber, a solar reduction furnace and gas treatment equipment. The hydrogen heating chamber and the reduction furnace are provided with a composite optical heating system consisting of a condenser, a heliostat and heat absorbing equipment. In the process of solar reduction iron making, hydrogen prepared by electrolyzing water is used as a reducing agent, the hydrogen is preheated and heat is provided for iron oxide reduction through a photo-thermal principle, the preheated hydrogen is introduced into the solar reduction furnace for reduction reaction so as to generate iron, the iron is smelted into molten iron, and the rest hydrogen is purified, and fed into a system for recycle through a circulating fan. Through the solar reduction iron making, non-renewable energy resources are saved, and the emission of greenhouse gases such as CO2 and the like is avoided. The electrolyzed hydrogen does not contain any harmful impurities, the temperature required by reduction in the reduction iron making process taking the hydrogen as the reducing agent is low, the reaction time is short, carbon dioxide is not generated, and the reduced iron has good quality.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

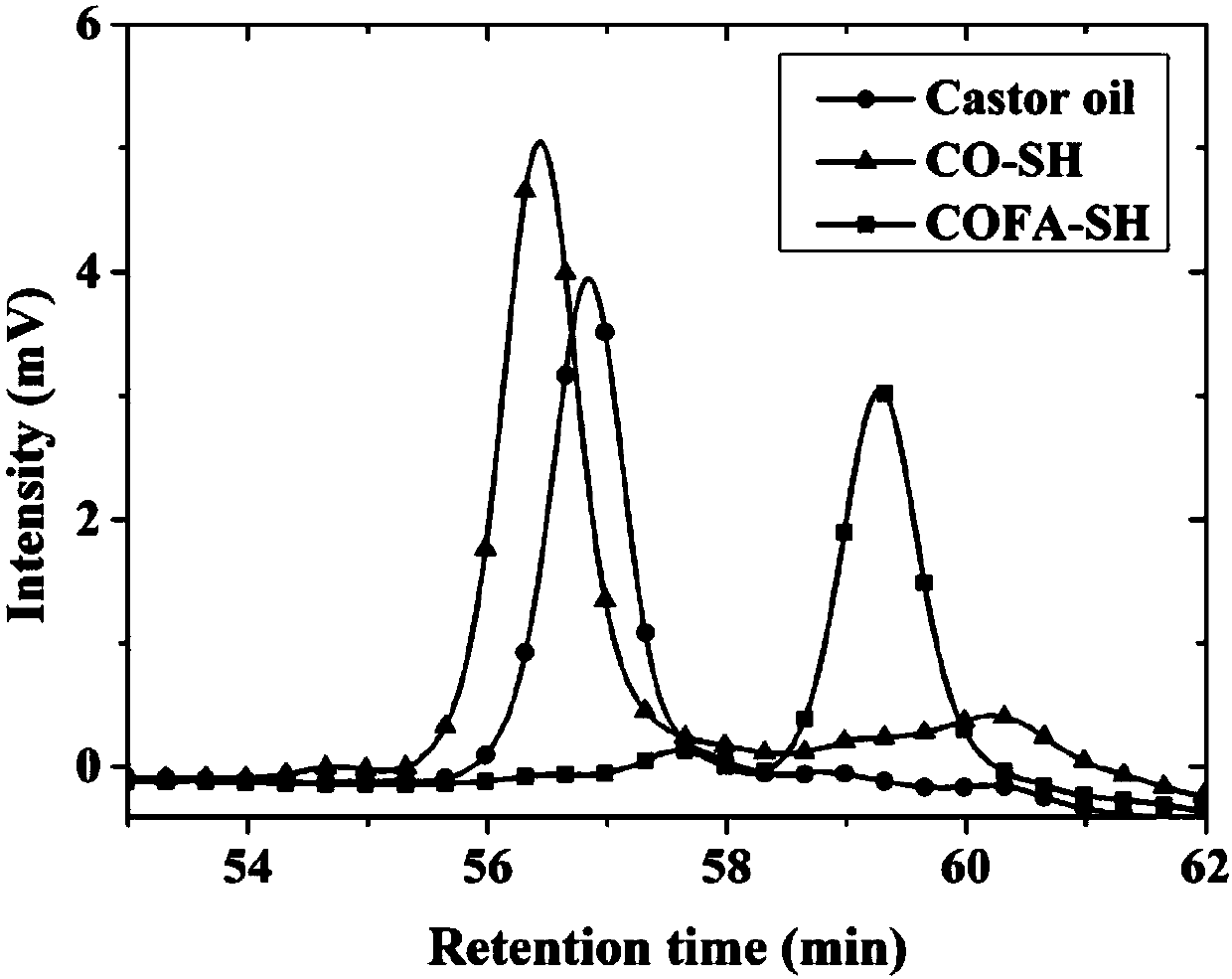

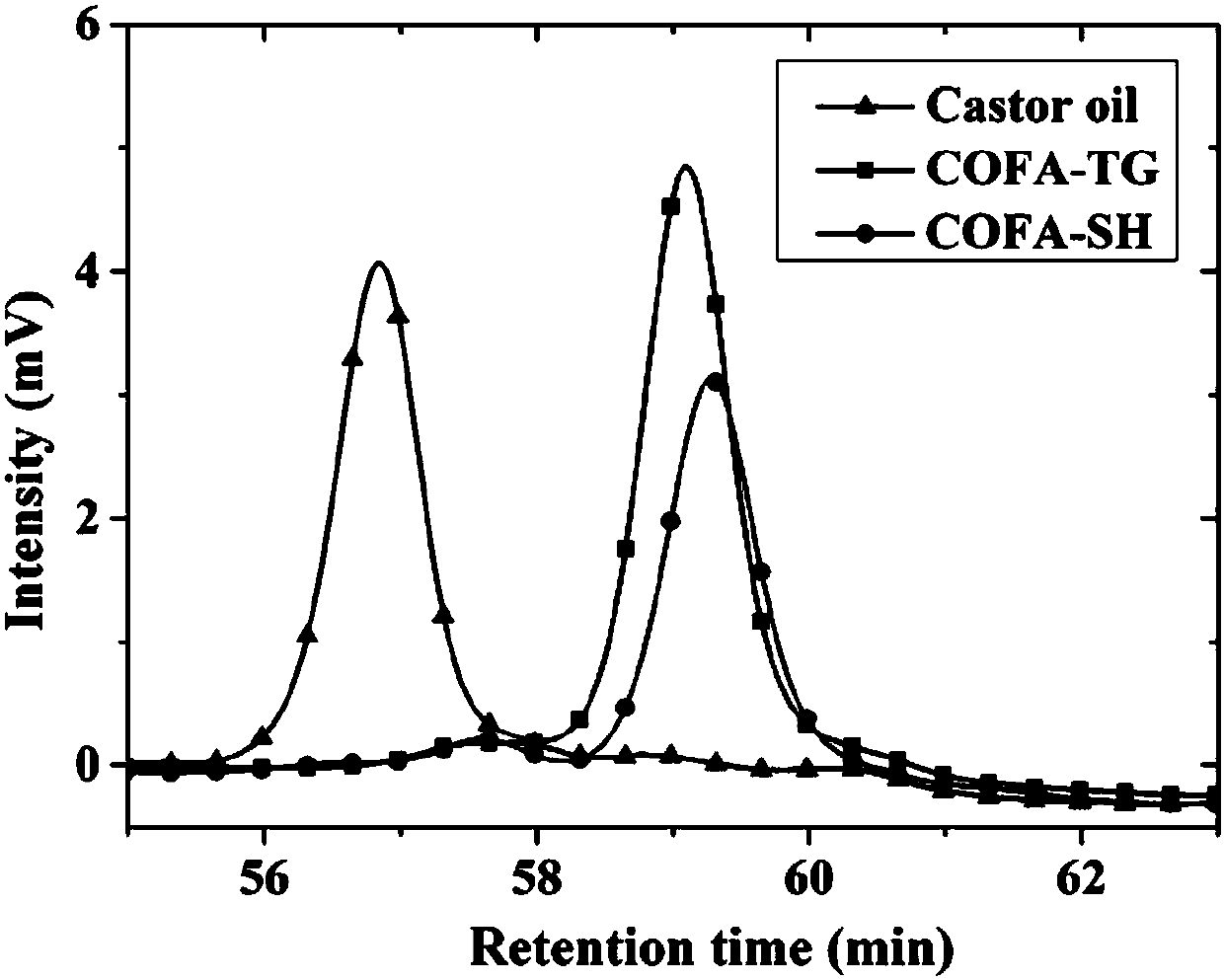

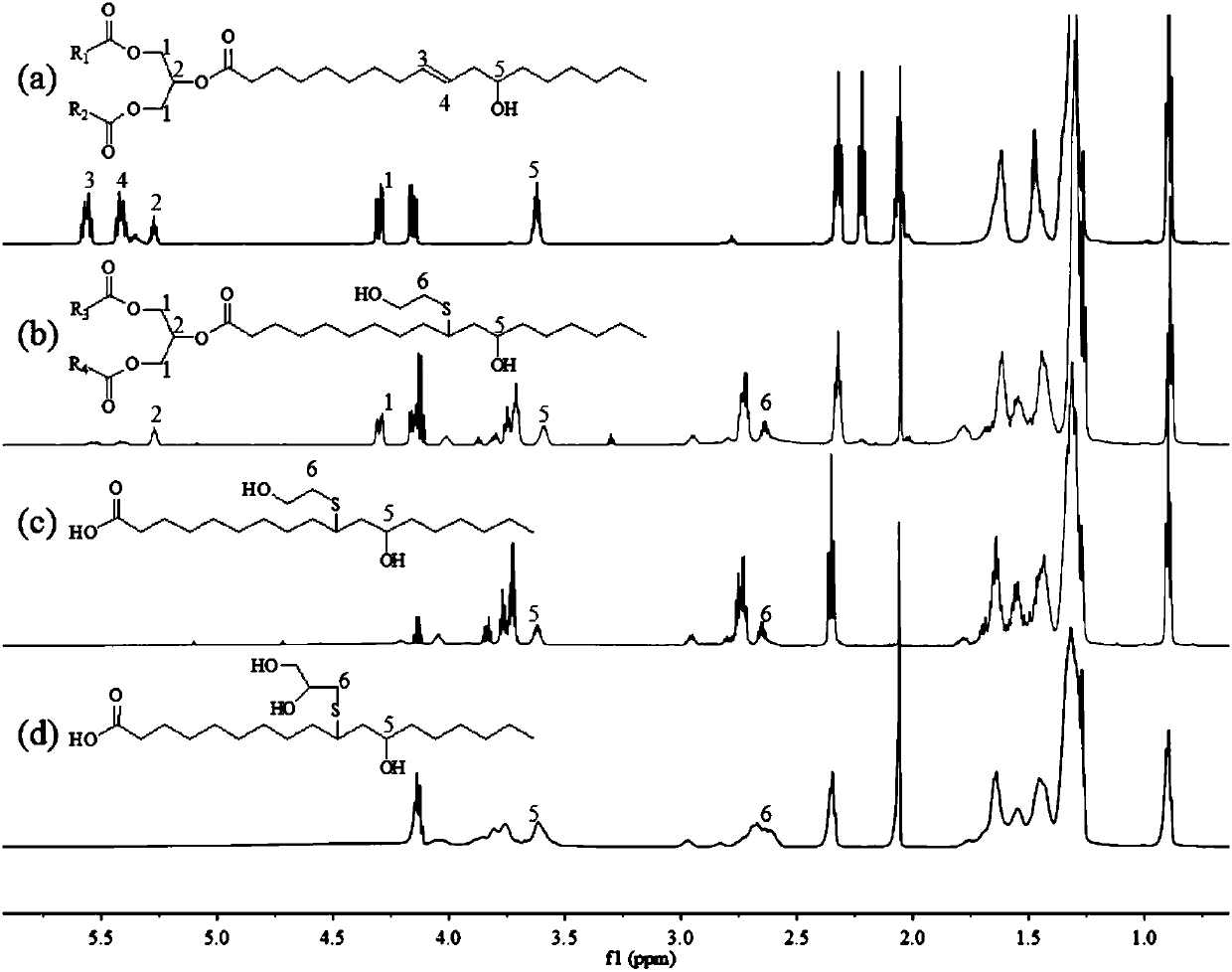

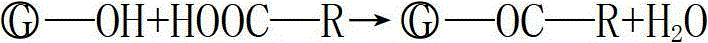

Castor oil-based hydrophilic chain extender as well as preparation method and application thereof

ActiveCN107556452AIncrease added valueReduce environmental problemsSulfide preparationEmulsionRenewable resource

The invention discloses a castor oil-based hydrophilic chain extender as well as a preparation method and application thereof. According to the castor oil-based hydrophilic chain extender, starting from castor oil, one of the renewable resources, a hydroxyl group is introduced by mercapto group-ene light click reaction to obtain an intermediate, and then a carboxyl group is generated through hydrolysis reaction of an ester group (or ricinoleic acid is generated through ester hydrolysis reaction of castor oil first, and then the hydroxyl group is introduced by mercapto group-ene light click reaction), the hydrophilic chain extender containing at least two hydroxyl groups and a carboxyl group is prepared, and the hydrophilic chain extender is applied to preparation of anionic aqueous polyurethane emulsion. According to the castor oil-based hydrophilic chain extender as well as the preparation method and the application thereof, the castor oil is applied to hydrophilic chain extender rawmaterials, has positive reference value for broadening application and increasing added value of natural fat products and also plays a positive role in reducing or replacing an environment problem caused by the use of petroleum non-renewable resources. The castor oil-based hydrophilic chain extender prepared by the invention is liquid at normal temperature, a contact area with other raw materialsduring a reaction is larger, the mixing is more uniform and the reaction speed is higher.

Owner:SOUTH CHINA AGRI UNIV

Method of producing propionic acid and propionate by microorganism fermentation

ActiveCN101748163AImprove securitySolve consumptionMicroorganism based processesCarboxylic acid salt preparationChemical synthesisPropanoic acid

The invention relates to a method of producing propionic acid and propionate by microorganism fermentation, which is characterized by using microorganism fermentation technology to produce propionic acid; with propionibacterium, charging the nitrogen into basic fermentation culture medium which takes glycerin as a carbon source for anaerobic fermentation culture; movably adding the aqueous solution of calcium hydroxide, or the alkaline solution or the saline solution of sodium hydroxide and calcium carbonate with the ongoing of fermentation, adjusting the fermentation liquor and maintaining the pH value between 6.5 to 7.5; movably adding the aqueous solution of glycerin after the fermentation preformed for a period of time; the fermentation is finished when the content of glycerin stops increasing and is more than 35g / L; and then filtering the fermentation liquor through a pressure filter, getting the filtered solution, charging the filtered solution into a spray tower for spray drying, and the dried powder is the propionate product. The invention has the effects: the method can substitute the existing chemical synthesis to produce propionic acid, remarkably improving the safety of the propionic acid product, and is a green food additive; moreover, the problem of consumption of non-renewable resources (such as oil) can be solved without a secondary processing, the negative impact generated by chemical synthesis can be prevented, and the process flow and the cost can be saved; and the invention particularly opens up an industrialization stage of the propionic acid production by fermentation and the simultaneous production of the propionate.

Owner:意葆(上海)生物科技有限公司

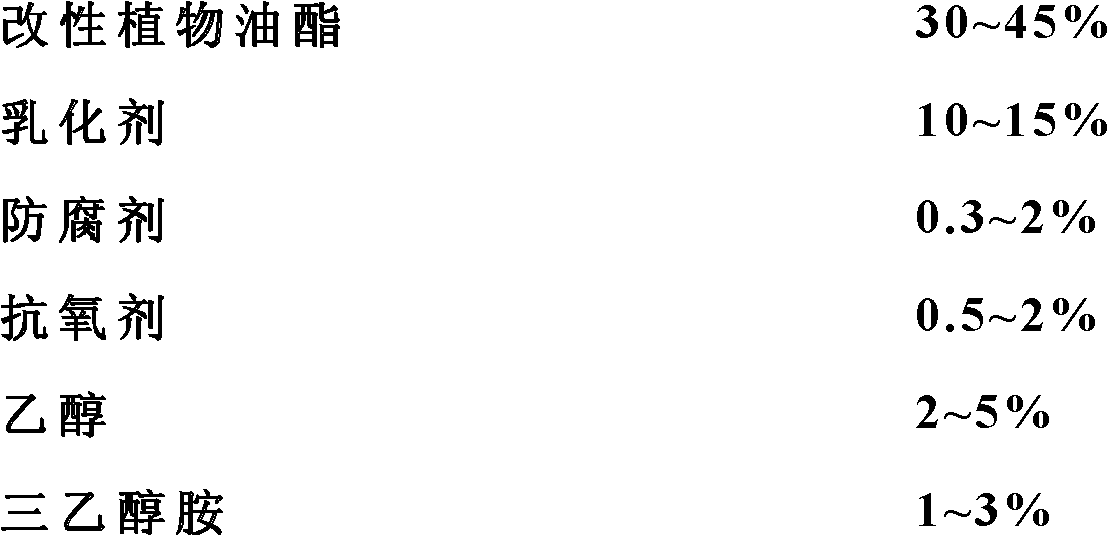

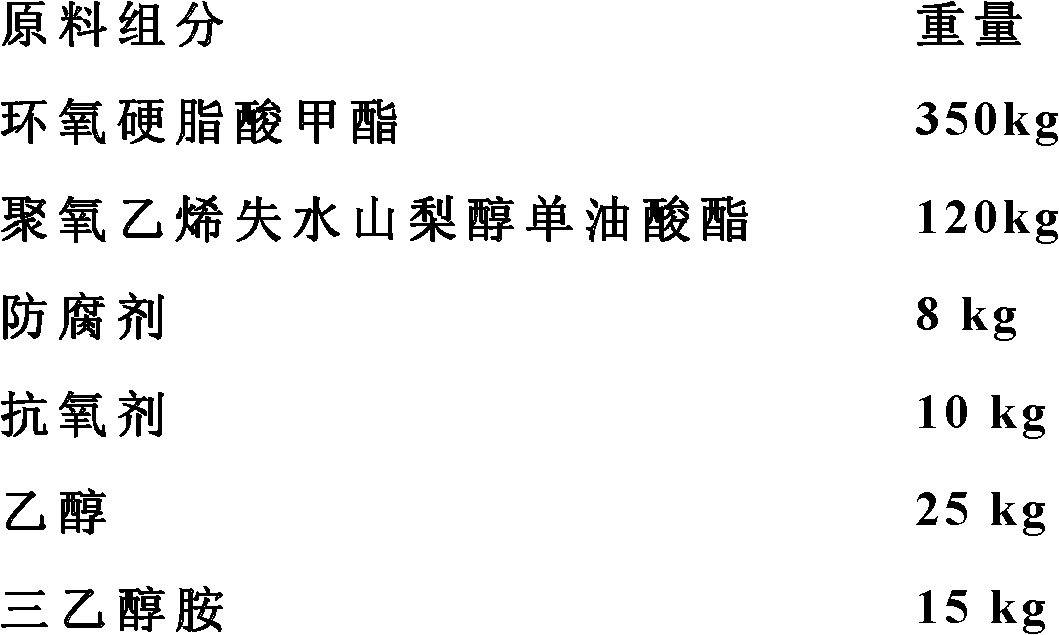

Environmentally-friendly casting mold-releasing agent and preparation method thereof

ActiveCN102205390AExcellent mold releaseReduce pollutionFoundry mouldsFoundry coresPreservativeCasting mold

The invention discloses an environmentally-friendly casting mold-releasing agent which comprises the following components by weight percent: 30-45% of modified plant grease, 8-40% of emulsifying agent, 0.3-2% of preservative, 0.5-2% of antioxidant, 2-5% of ethanol, 1-3% of triethanolamine, and the balance of deionized water. The casting mold-releasing agent has an excellent mold-releasing effect and is used for greatly reducing the environmental pollution and saving the usage of petroleum non-renewable resources.

Owner:SUZHOU XINGYE MATERIALS TECH

Novel floating seedling substrate special for tobacco and preparation method thereof

InactiveCN101828506AReduce usageSolve serious problems that seriously damage the wetland environmentCultivating equipmentsSoilless cultivationSocial benefitsOpen water

The invention discloses a novel floating seedling substrate special for tobacco and a preparation method thereof. The floating seedling substrate consists of the following raw materials in percentage by weight: 30 to 40 percent of decomposed tobacco straw, 25 to 35 percent of carbonized tobacco straw, 15 to 20 percent of decomposed rice straw and 10 to 15 percent of grass carbon. The preparation method comprises the following steps of: preparing various raw materials according to the mixture ratio of the novel floating seedling substrate special for the tobacco; leaching the carbonized tobacco straw by water with a pH value of between 5.5 and 6.5 for 5 to 10 minutes; drying the leached carbonized tobacco straw until no open water flows outwards; uniformly mixing and stirring the various raw materials; sterilizing the mixture at the high temperature of 250 DEG C for 10 to 15 minutes; and adjusting water content until the water content meet the requirement of a product so as to obtain the product of the invention. The grass carbon in a conventional seedling substrate mixture ratio is replaced by a large amount of tobacco straw, so the problem of ecological environmental damage due to the use of a large amount of non-renewable resources and the problem of soil ecological environmental damage due to natural decay of the large amount of tobacco straw are solved, the large amount of tobacco straw are recycled and waste materials are recycled. Therefore, the novel floating seedling substrate special for the tobacco has remarkable economic and social benefits.

Owner:HENAN AGRICULTURAL UNIVERSITY

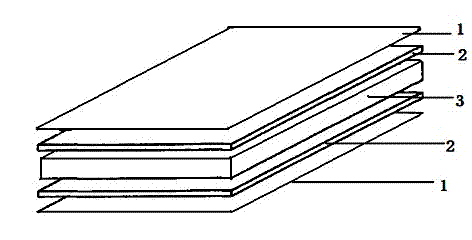

Preparation method of ecological plate

InactiveCN102198675AReduce usageConserve non-renewable resourcesSynthetic resin layered productsWood veneer joiningRenewable resourceNon-renewable resource

The invention discloses a preparation method of an ecological plate, which comprises the following steps of: step 1, preparing melamine impregnated cellophane paper, wherein glue content is increased by 15-20% in the preparation process in comparison with a traditional formula; step 2, attaching the melamine impregnated cellophane paper on special-shaped veneers; step 3, preparing an intermediate substrate; step 4, respectively adhering the veneers attached with the melamine impregnated cellophane paper to two surfaces of the intermediate substrates, and pressing and heating the two surfaces of the intermediate substrate to get the ecological plate. In the preparation method provided by the invention, a grainy paper for printing substitutes a natural wood material to serve as a decorative finish of the plate, so that usage amount of wood is greatly reduced, and non-renewable resource is saved; oil paint is substituted after the surface of the plate is impregnated by melamine, so that cost on processing is greatly saved, processing time is greatly shortened, and environmental performance of the preparation method is far better than that of the conventional production method; and the prepared ecological plate is excellent in surface abrasive resistance, scratch resistance, stain resistance and fire resistance, and is fashionable in design and color expression, so that the prepared ecological plate can meet the requirements of different consumers.

Owner:上海荷雨木业有限公司

Medium for seedling raising and cultivation and preparation method of medium

ActiveCN102838415AWide variety of sourcesNo pollution in the processFertilizer mixturesPlant growthPollution

The invention relates to a medium for seedling raising and cultivation and a preparation method of the medium, belonging to the technical field of agricultural production. In order to solve the problems that the existing cultivation medium uses non-renewable resources such as plant ash and vermiculite as raw materials, and environmental damages are caused because vermiculite and perlite cannot bedecomposed easily, the invention provides the medium for seedling raising and cultivation and the preparation method of the medium. The sources of raw materials are wide, the raw materials are degradable materials and pollution is not caused to the environment; and since chemical fertilizers are not used, the soil structure is not damaged. By using recycled aggregate, the problem of recycling building wastes is solved; and since kieselguhr and seaweed fertilizers take an effect of improving the soil and contain rich elements, the needs of growth of different plants can be met. By using the medium for seedling raising and cultivation provided by the invention, the survival rate of cultivated seedlings is high, the cultivated seedlings grow well and the situation that weeds grow is avoided.

Owner:山东天酵源生物科技有限公司

Automatic biofuel-combustion multipurpose furnace

InactiveCN102721169AFull and efficient combustionLow costStove/ranges for heating waterWater heatersAutomatic controlCombustion

An automatic biofuel-combustion multipurpose furnace comprises a furnace body, wherein the furnace body consists of a combustion furnace, a fuel bucket, a feeding device and an automatic control device, the fuel bucket is positioned above the combustion furnace which is obliquely provided with a feeding pipe and internally provided with a combustion pool, the lower port of the feeding pipe is positioned above the combustion pool, the feeding device is arranged between the upper port of the feeding pipe and the combustion bucket, the furnace body is provided with an automatic igniter, the front end of the automatic igniter is contacted with the combustion bucket, a water drum wall is arranged on the side wall of the combustion furnace, a water inlet and a water outlet corresponding to the water drum wall are arranged on the combustion furnace, a water boiling port is arranged at the upper end of the combustion furnace and provided with a water boiling tray, a slag collection box is arranged under the combustion furnace, the combustion furnace is provided with an air inlet under the automatic igniter, an air outlet is arranged at the lower part of the furnace body and provided with an exhaust fan. The automatic biofuel-combustion multipurpose furnace can save non-renewable resources by combusting biofuel, and has the advantages of environment friendliness and safety.

Owner:烟台市宜和环保设备有限公司

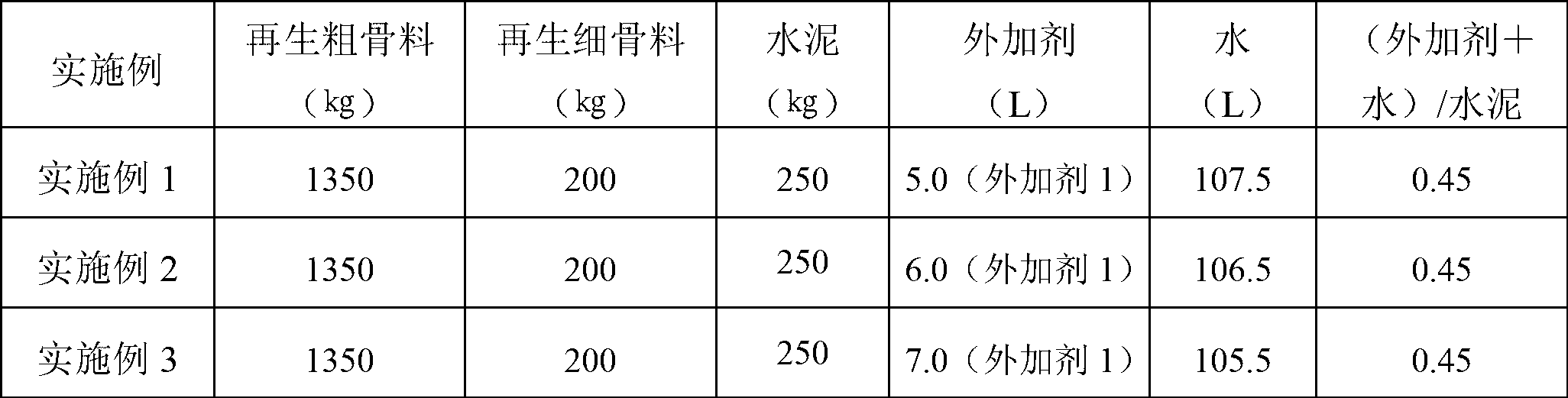

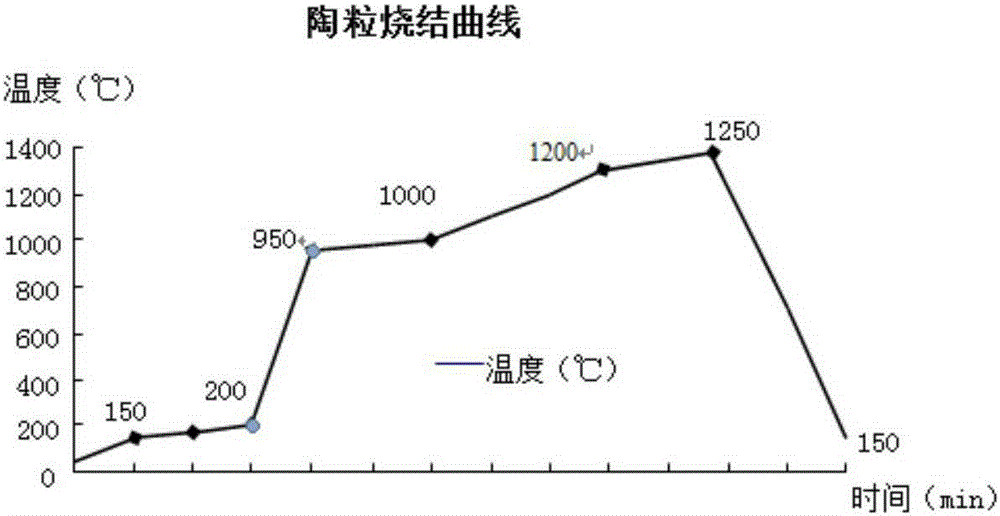

Recycled aggregate type permeable ecological concrete and preparation method thereof

InactiveCN102936120ARealize resource utilizationReduce usageResource utilizationCompressive strength

The invention discloses recycled aggregate type permeable ecological concrete and a preparation method thereof. The concrete comprises, by weight, 1350-1450 parts of recycled aggregate, 200-250 parts of recycled fine aggregate, 250-300 parts of cement, 110-130 parts of water and 5-7 parts of admixtures which are stirred and subjected to pouring forming. The formed ecological concrete is provided with pores in crunchy rice candy shapes and communicated continuously, the effective porosity is 12-15%, the compressive strength is 15-20MPa, and the permeation coefficient is 30-50mm / s. According to the concrete and the method, construction solid wastes are used for replacing natural gravels to prepare the recycled aggregate, not only the construction solid wastes are reused, but also utilization of non-renewable resources such as the natural gravels is reduced, the cost of the permeable ecological concrete is reduced, and resource utilization of the construction solid wastes is achieved.

Owner:JIANGSU UNIV

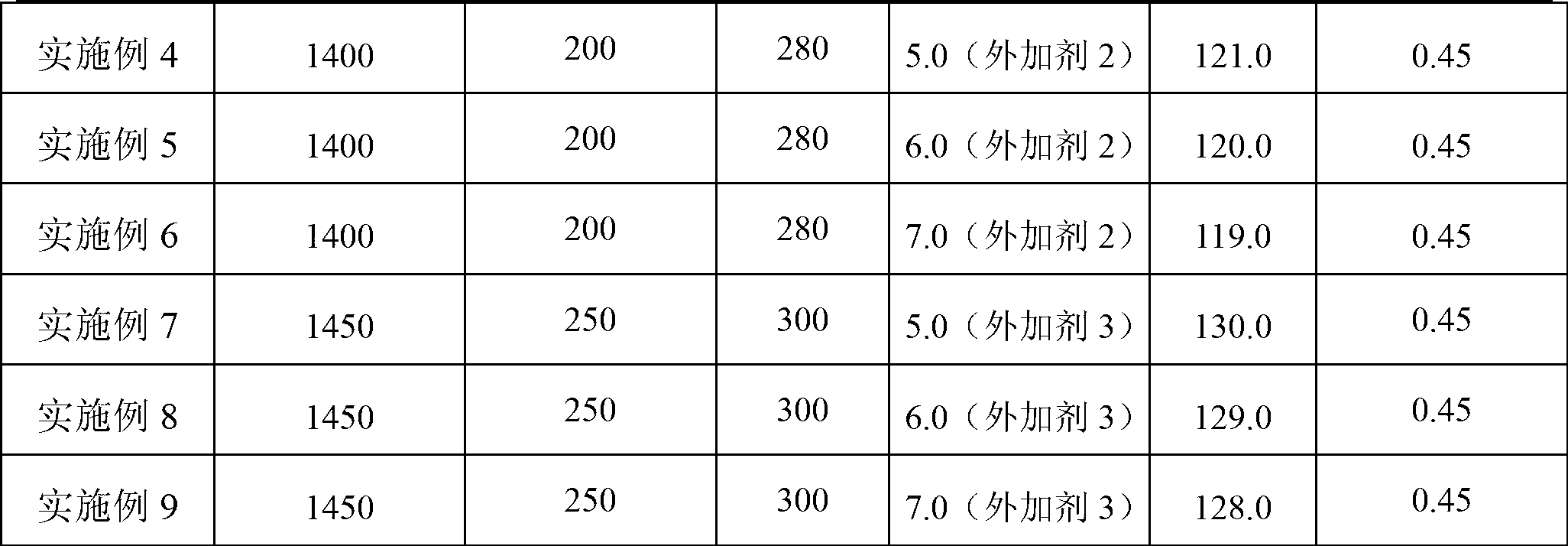

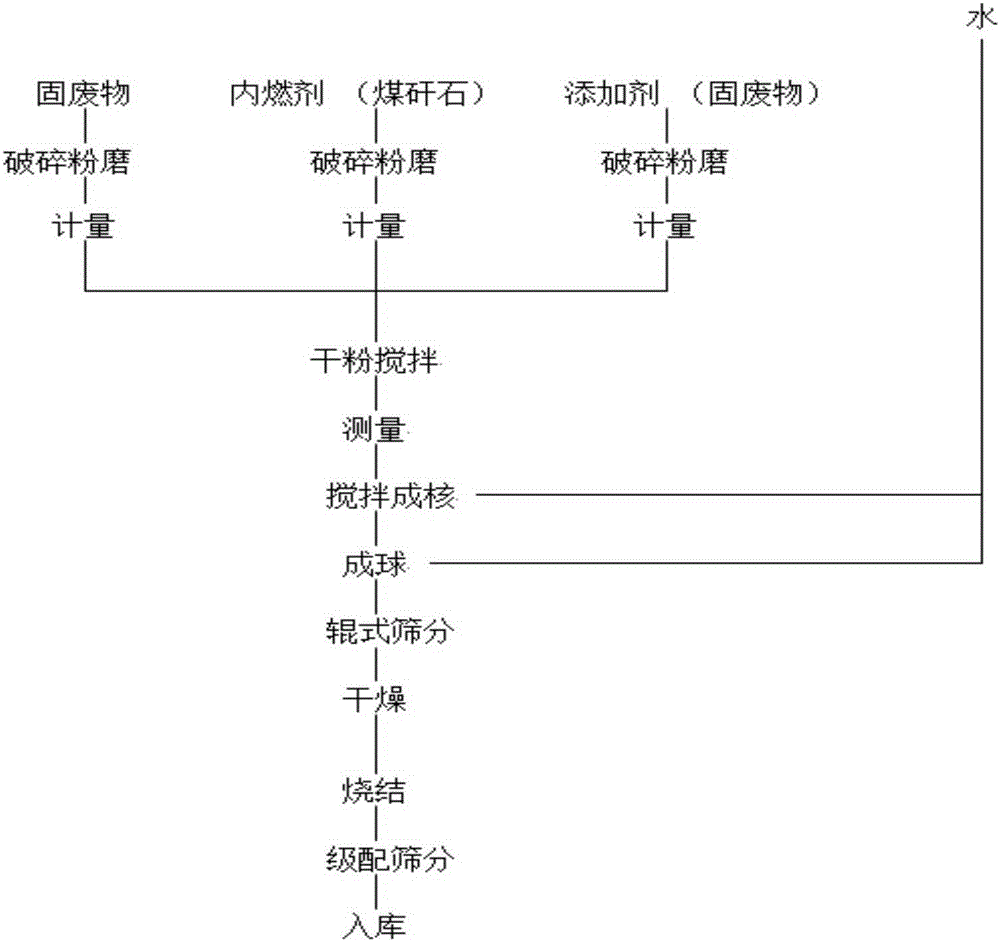

Technology utilizing waste solids to prepare ceramic particles used as soilless culture substrates

InactiveCN105174915ARestore ecologyEnsure chemical stabilityAgriculture gas emission reductionCultivating equipmentsSludgeRed mud

The invention relates to a technology utilizing waste solids to prepare ceramic particles used as the soilless culture substrates. The technology comprises the following steps: (1) grinding main raw materials and internal combustion agent into powder with a particle size of 60 to 80 [mu]m, and maintaining a dry state, wherein the main raw material is one or more of fly ash, city sludge, lake / river mud, industrial slag, electrolytic ash, tailings, and red mud, and the internal combustion agent is one or more of coal gangue, agricultural straw, and saw dust; (2) weighing 80 to 95 parts by weight of waste solid powder and 5 to 10 parts by weight of internal combustion agent powder, evenly mixing the powder, adding water into the evenly-mixed powder, keeping on stirring to form crystal nucleus accounting for 10 to 12% of the total weight, balling, performing roll-screening, and sintering to obtain the ceramic particles. Waste solids are taken as the raw material, then the components are scientifically and reasonably compounded, and finally inorganic substrate (ceramic particle) for soilless culture is produced by a sintering technology. The provided technology can save the energy and reduce the discharge, and is capable of replacing the conventional technical scheme using non-renewable resources to produce ceramic particles.

Owner:BAOTOU ZHENGTANG ENVIRONMENTAL PROTECTION IND

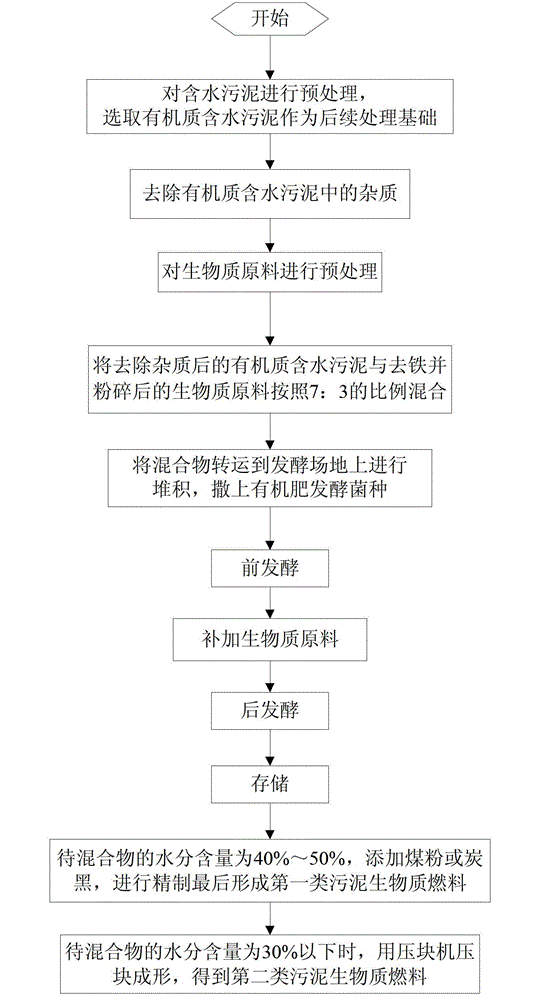

Manufacturing method of sludge biomass fuel

ActiveCN102942978ASolve the problem that cannot be directly returned to the fieldEnvironmentally friendly disposalBiofuelsSolid fuelsSludgeEmission standard

The invention relates to a manufacturing method of sludge biomass fuel. According to the method, organic materials containing water sludge and biomass raw materials are mixed and then subjected to fermentation and dehydration to manufacture the new sludge biomass fuel. The method for treating the sludge is economical, practical and high in treatment capacity, and by means of the method, the sludge biomass fuel can be manufactured. By means of the method, environment-friendly treatment of urban sludge is achieved, resource recycling is achieved, non-renewable resources are reasonably replenished, a novel energy material which is the sludge biomass fuel is developed, the sludge biomass fuel can replace natural coal, the calorific value of the sludge biomass fuel is 1500-5000 kilocalorie, the sludge biomass fuel is easy to burn, and the emission of the sludge biomass fuel is lower than emission standards of European Union. Ashes obtained by burning of the sludge biomass fuel are rich in elements of calcium, magnesium, phosphorus, potassium and sodium so that the ashes are superior warm readily available organic fertilizers, and the problem that the urban sludge can not be directly returned to fields is solved.

Owner:包晓东

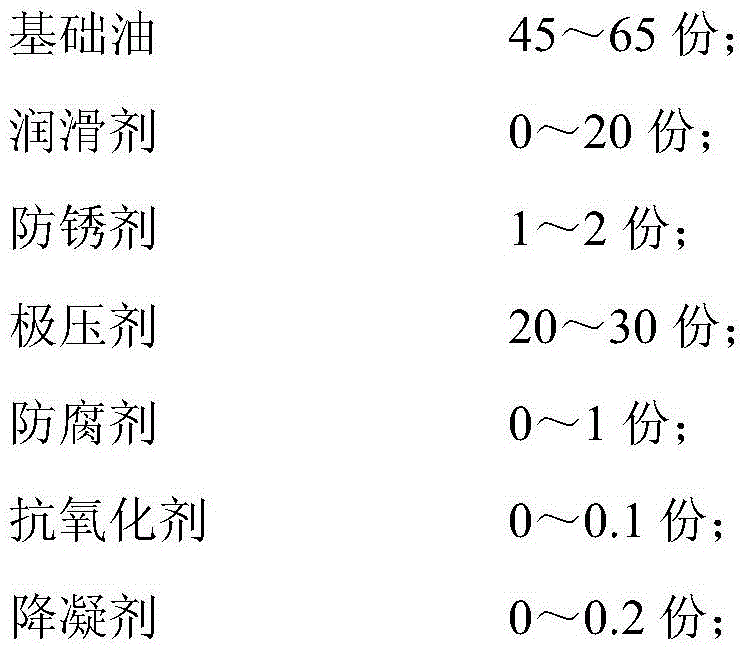

Environmentally-friendly cold heading oil with epoxidized vegetable oil as base oil, and preparation method thereof

ActiveCN105482873AHigh viscosity indexImprove the lubrication effectAdditivesBase-materialsVegetable oilRenewable resource

The invention discloses an environmentally-friendly cold heading oil with epoxidized vegetable oil as base oil, and a preparation method thereof. The environmentally-friendly cold heading oil is prepared through adding a lubricant, an antirust agent, an extreme pressure agent, an antiseptic, an antioxidant and pour-point depressant to the epoxidized vegetable oil used as the base oil. The epoxidized vegetable oil is used as the base oil to substitute traditional non-renewable mineral oil, so consumption of non-renewable resources is avoided, and pollution to environment is greatly reduced. The environmentally-friendly cold heading oil is suitable for various machining, such as carbon steel cold heading, molding processing hot headed nuts, high-strength bolt sleeves and hollow and semi-hollow rivets, and molding processing of rivets; and the preparation method is simple and has low requirements about devices.

Owner:NEUFTECH BIOTECH HEFEI

Ascendens mucronatum cutting medium and preparation method and application thereof

InactiveCN103449929ASolving nutritional problems at seedling stageAddress Nutritional IssuesHorticultureFertilizer mixturesEcological environmentPeat

The invention discloses an ascendens mucronatum cutting medium and a preparation method and application thereof. The ascendens mucronatum cutting medium comprises the following components in parts by mass:36-72 parts of organic fermentation materials, 2-6 parts of peat, 8-30 parts of vermiculite and 2-8 parts of perlite; the organic fermentation materials are obtained by mixing tea residues, rice husk and mushroom residues according to the dry matter mass ratio of (9-18):(1-5):(0.5-3) and then carrying out fermentation. The ascendens mucronatum cutting medium is rich in organic matters, humic acid and various nutrient substances, can realize the labor saving and cost saving during seedling culture, save the non-renewable resources, protect the ecological environment and realize the low-carbon circulation by substituting for the traditional cutting medium. According to the medium, a hole tray is adopted for cutting seedling culture, so that the slip cutting and rooting rate and the survival rate are remarkably increased, seedling are uniform and strong, root systems are prosperous and the integrated cost, namely labor cost and the like, of seedling culture and seedling lifting cost can be saved by 700-1000 yuan per mu compared with that of the conventional seedling culture production.

Owner:NANJING INST OF VEGETABLE SCI +1

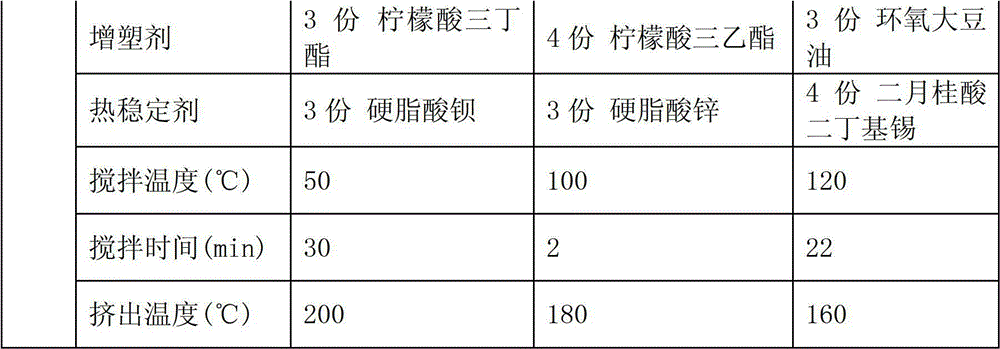

Biomass-plastic and preparation method thereof

The invention relates to biomass-plastic and a preparation method thereof. The biomass-plastic is prepared by reacting and mixing the following raw materials by a two-step method: 75 to 95 weight parts of natural high polymer material, 1 to 20 weight parts of reactive type aid, 1 to 10 weight parts of physical plasticizer, 1 to 10 weight parts of lubricant and 0.1 to 5 parts of antioxidant. The two-step method comprises the following steps of: 1, preparing the natural high polymer modified material; and 2, preparing mixture of the natural high polymer modified material and PVC. The obtained biomass-plastic is white or faint yellow solid; the melting point is 120 to 180 DEG C; the melt flowing speed is 5 to 20g / 10min; the tensile strength is 10 to 20MPa; the elongation at break is 300 to 1,000 percent; the bending strength is 10 to 25MPa; charpy notched impact strength is 5 to 25kJ / m<2>; and the biomass-plastic is excellent in forming processing property, can be prepared into various products by extrusion, injection molding, blow molding, suction molding, and hot pressing methods on common equipment for processing plastic. Compared with the conventional PVC plastic product, the biomass-plastic has the advantages that 50 to 85 percent of non-renewable resources can be saved, and the biomass-plastic has obvious environment-friendly significance.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

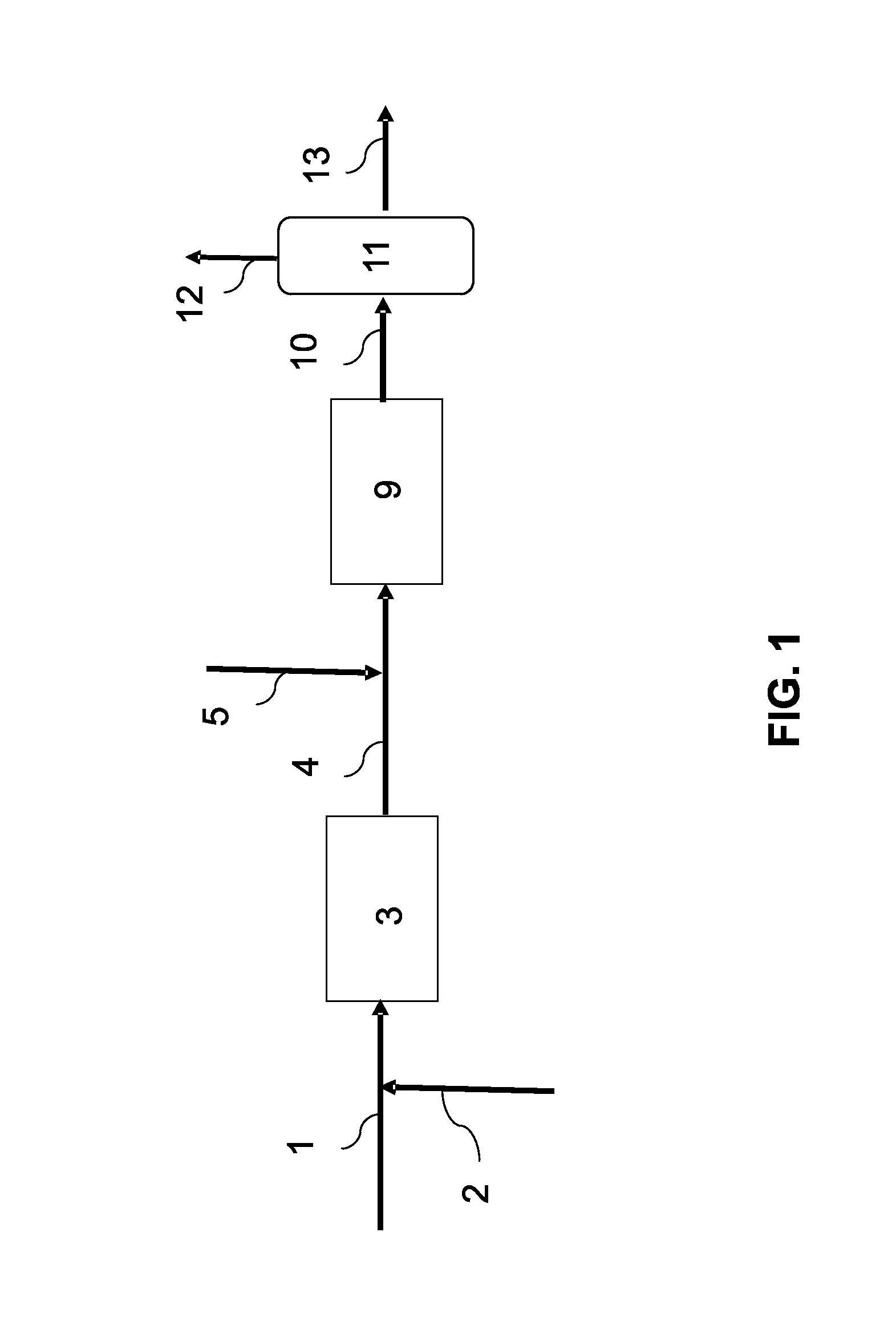

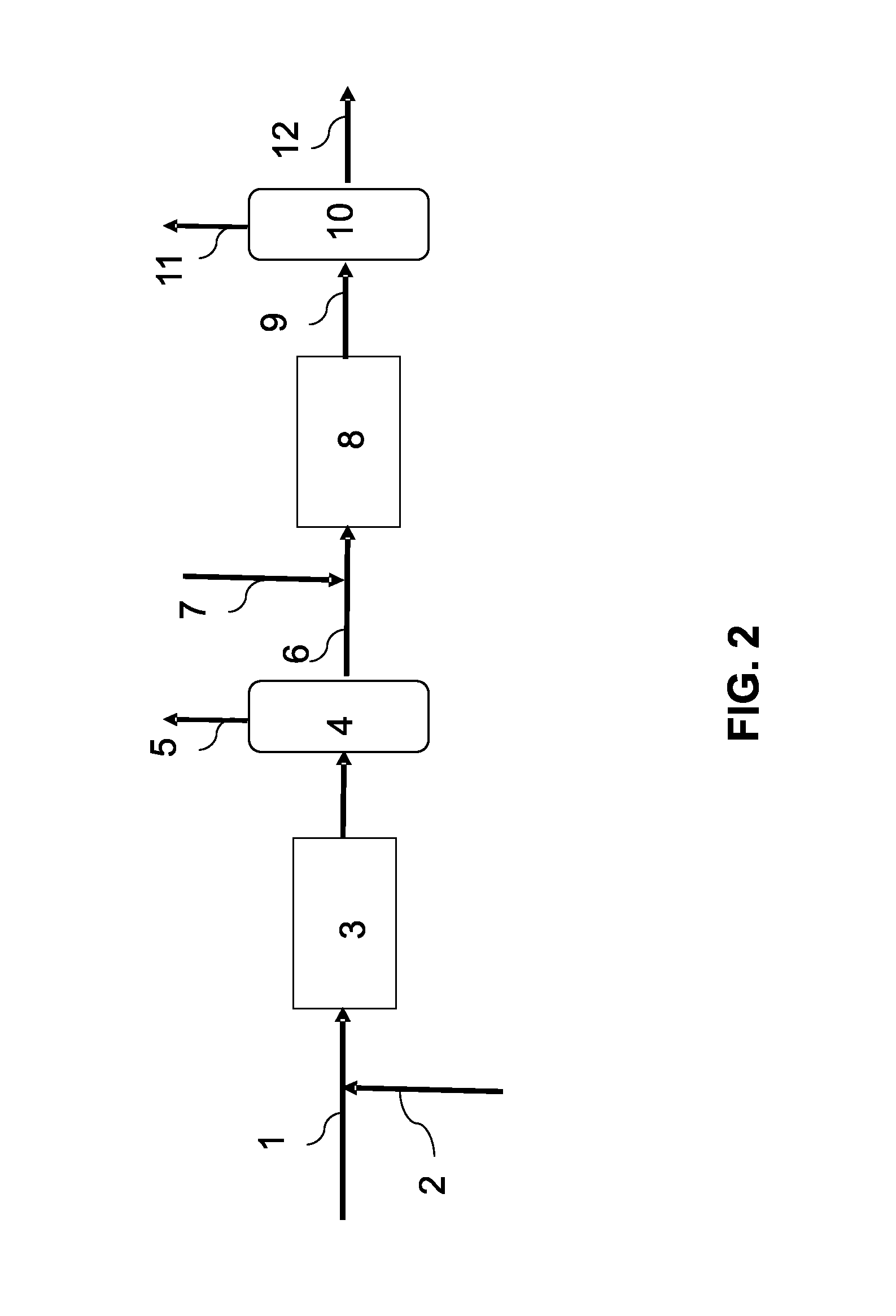

Process for conversion of feedstocks obtained from renewable sources based on marine fuels

The invention relates to a process for the production of diesel fuel bases comprising a sulfur content that is less than 100 ppm, starting from a feedstock that is obtained from a renewable source, comprising the following stages:a) A stage for bringing the feedstock into contact with a fixed-bed hydrotreatment catalyst for producing an effluent that comprises a gaseous fraction comprising hydrogen and a hydrocarbon-based liquid fraction,d) A stage for bringing into contact at least one portion of the hydrocarbon-based liquid fraction in the presence of a selective hydroisomerization catalyst in a fixed bed,e) A stage for separating the effluent that is obtained from stage d) into a gaseous fraction that comprises hydrogen and at least one diesel-fuel-based fraction.

Owner:INST FR DU PETROLE

Refractory insulation brick made by utilizing coal ash

InactiveCN101734932AMaterials are readily availableSave materialCeramic materials productionClaywaresBrickCoal

The invention relates to a refractory insulation brick, in particular to a refractory insulation brick made by utilizing coal ash. The refractory insulation brick is prepared by the following raw materials in parts by weight: 40 parts of microballon, 25 to 35 parts of high alumina, 15 to 25 parts of water, 20 parts of expanded perlite and 30 to 160 parts of waste bubble, wherein a binding agent is the high alumina, refractory clay, kaolin, mica, aluminate and organic or inorganic polymer. In the refractory insulation brick made by coal ash, the source of the adopted microballon is the microballon extracted from solid waste coal ash existing in all parts with the relative density larger than 1, and the materials are easy to obtain, are cheap, and can completely substitute non-renewable resources. The invention has low production cost, and the manufactured refractory insulation brick coincides with the relevant provisions of the national standards.

Owner:马健

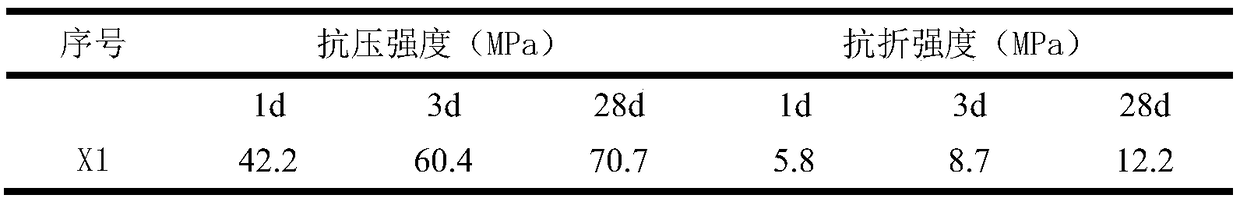

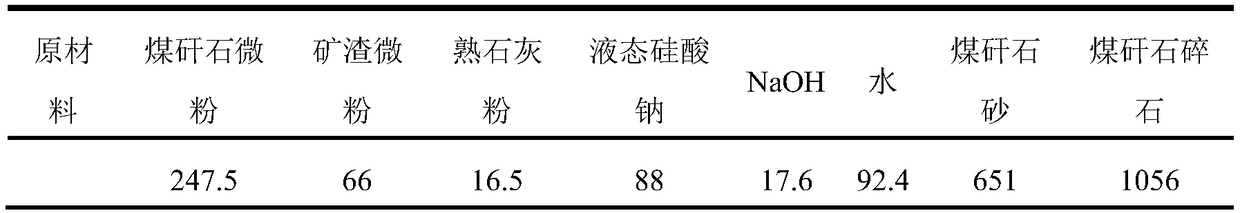

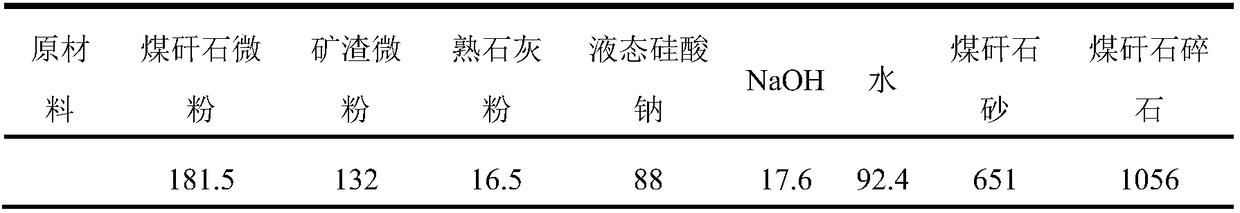

Method for preparing alkali-activated coal gangue concrete from coal gangue mainly

The invention discloses a method for preparing alkali-activated coal gangue concrete from coal gangue mainly and belongs to the method applied to preparation of alkali-activated coal gangue concrete.According to the method, coal gangue blocks are broken into coal gangue particles with different grain size range, the coal gangue particles are used as gel materials, fine aggregates and rough aggregates respectively for preparing the alkali-activated coal gangue, and thus, consumption of non-renewable resources such as cement, sand and pebbles is omitted. Besides, the alkali-activated coal gangue concrete is featured by early strength and high strength, and has functions of shortening maintenance time, accelerating construction progress and reducing construction cost, can substitute for cement concrete, can not only avoid the environmental pollution caused by accumulation of a great amount of industrial solid wastes, but weaken dependency on cement and reduce consumption of the non-renewable resources, and has a great significance for China, the country has the problems of energy deficiency and severe environmental pollution.

Owner:ANHUI UNIV OF SCI & TECH

High-performance ultra-lightweight foam ceramic prepared by taking shale as main raw material and method thereof

ActiveCN102603347APrevent extensionImprove flexural strengthCeramicwareRenewable resourceNon-renewable resource

The invention relates to high-performance ultra-lightweight foam ceramic prepared by taking shale as a main raw material and a method thereof. The high-performance ultra-lightweight foam ceramic comprises the following chemical components in percentage by weight: 50%-70% of SiO2, 10%-20% of Al2O3, 3%-8% of CaO plus MgO, 5%-10% of Fe2O3, 1.0%-6.0% of K2O plus Na2O and 1.0%-2.0% of ZrO2 plus SiC plus C, and the process flow comprises the following steps of preparing materials, performing fine crushing, granulating, loading into an assembled refractory castable kiln tool, striking off, placing into a kiln for firing, getting a product, cutting into the product in the required specification and the size, inspecting, packaging and putting into a warehouse. According to the high-performance ultra-lightweight foam ceramic disclosed by the invention, the defects that the expansion of cracks in the past can affect the product quality, the rupture strength and the compressive strength are not sufficient, the resistance to thermal shock damages is poor and the like, can be solved. According to the high-performance ultra-lightweight foam ceramic disclosed by the invention, compressive stress is generated in a main crack action region for preventing the expansion of the cracks, so that the toughening effect is shown; and by introducing dispersed zirconium oxide particles, the rupture strength and the compressive strength of a composite can be obviously improved, the resistance to the thermal shock damages of the material is also improved, and the optimization of non-renewable resources is further utilized.

Owner:浙江求健科技有限公司

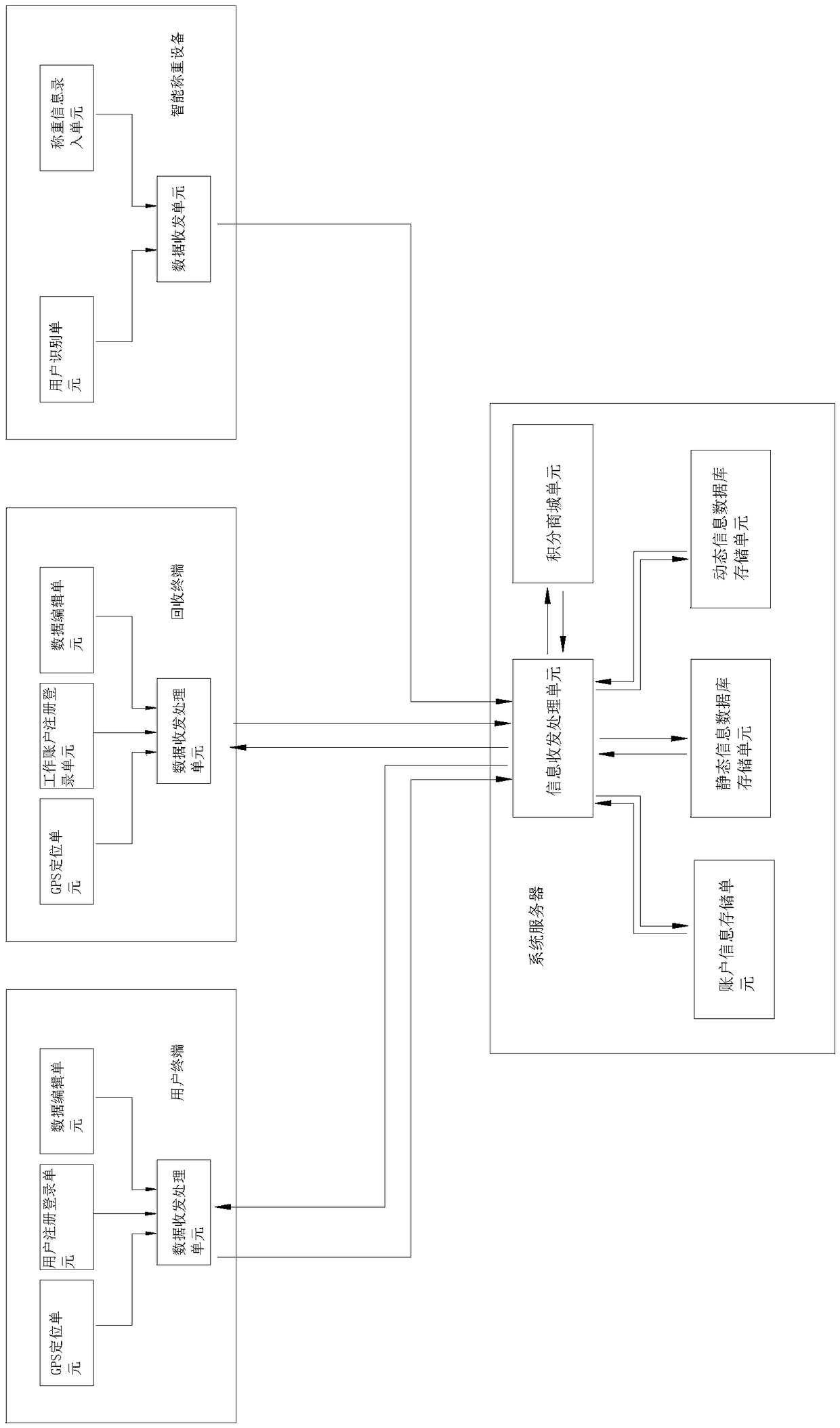

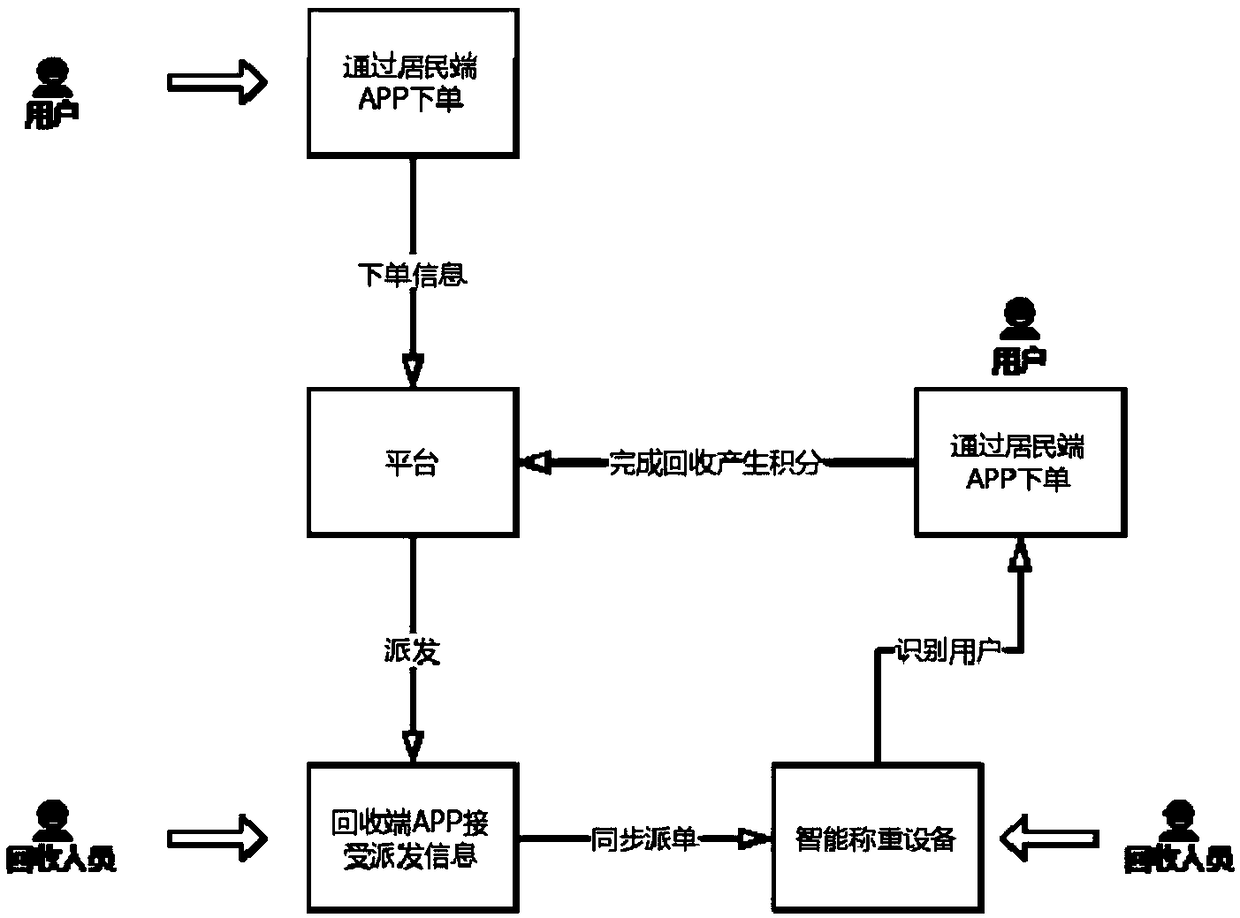

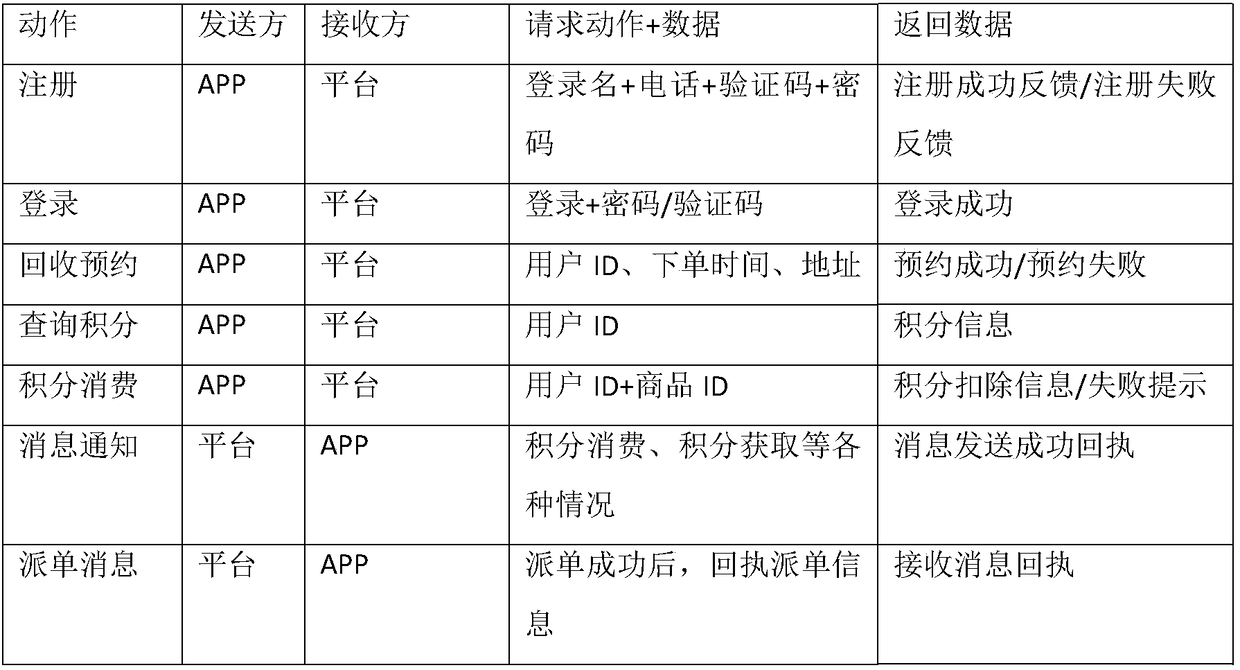

Integrated big data management system for urban renewable resources

The invention relates to the field of garbage classification, to an integrated big data management system for urban renewable resources. The system comprises a system platform, a user terminal, a recycling terminal and an intelligent weighing device. The user terminal sends order information edited by a data editing unit and an order address obtained by a GPS positioning unit to the system platform. The system platform screens appropriate recycling terminal information based on the order address and distributes the order information and the order address to the qualified recycling terminal; after the recycling terminal confirms the acceptance of the dispatched information, a staff member arrives at the order address by carrying the intelligent weighing device within the specified period; and after identifying user information, the intelligent weighing device obtains actual order information and sends the information to the system platform. On the basis of combination of the GIS geographic information technology, the mobile data communication technology and the GPS positioning technology, full-course dynamic management of garbage classification is realized according to the modern Internet mainstream software technology.

Owner:王远喆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com