Castor oil-based hydrophilic chain extender as well as preparation method and application thereof

A hydrophilic chain extender, castor oil-based technology, applied in the direction of sulfide preparation, organic chemistry, etc., to achieve the effect of fast reaction speed, large contact area and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

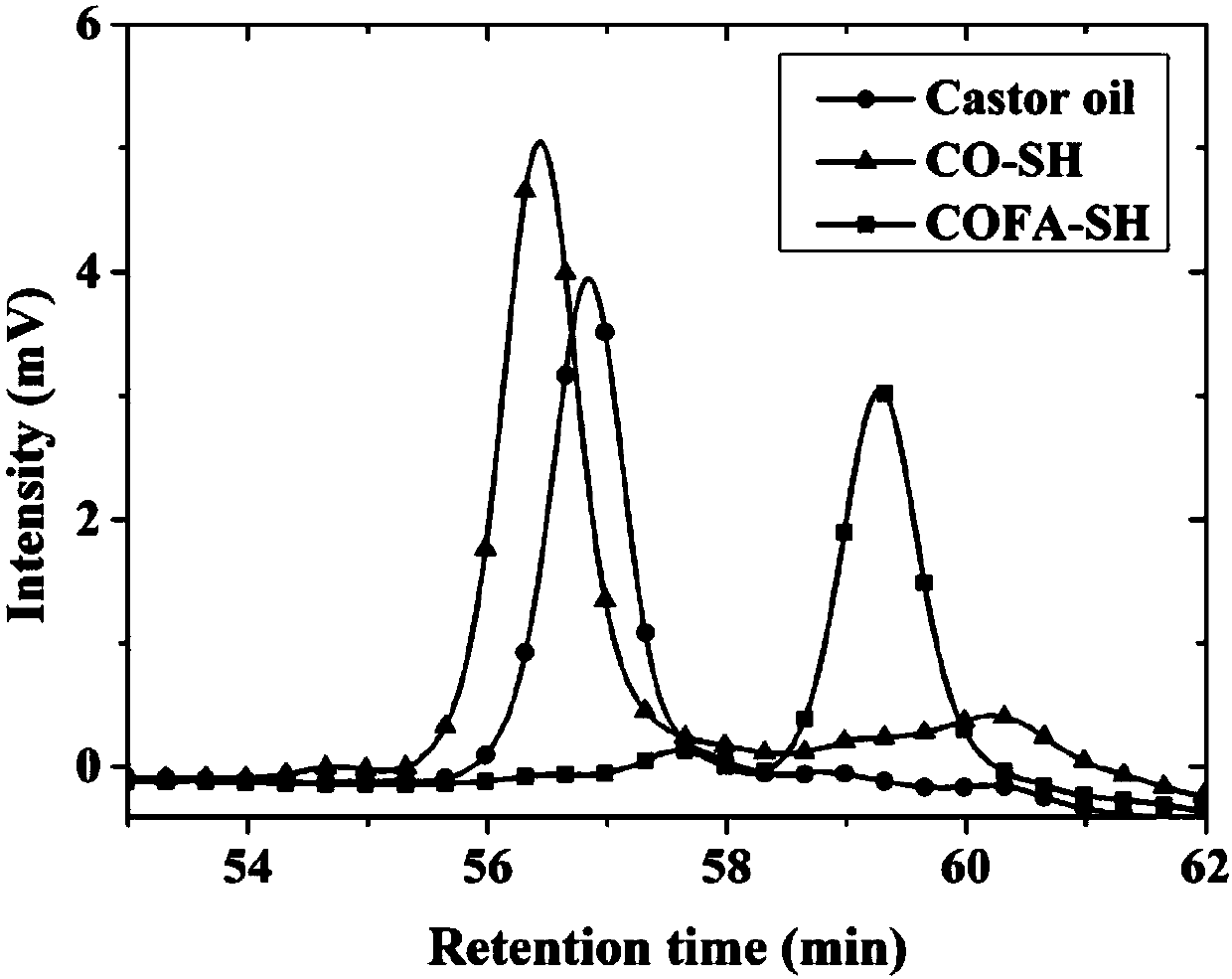

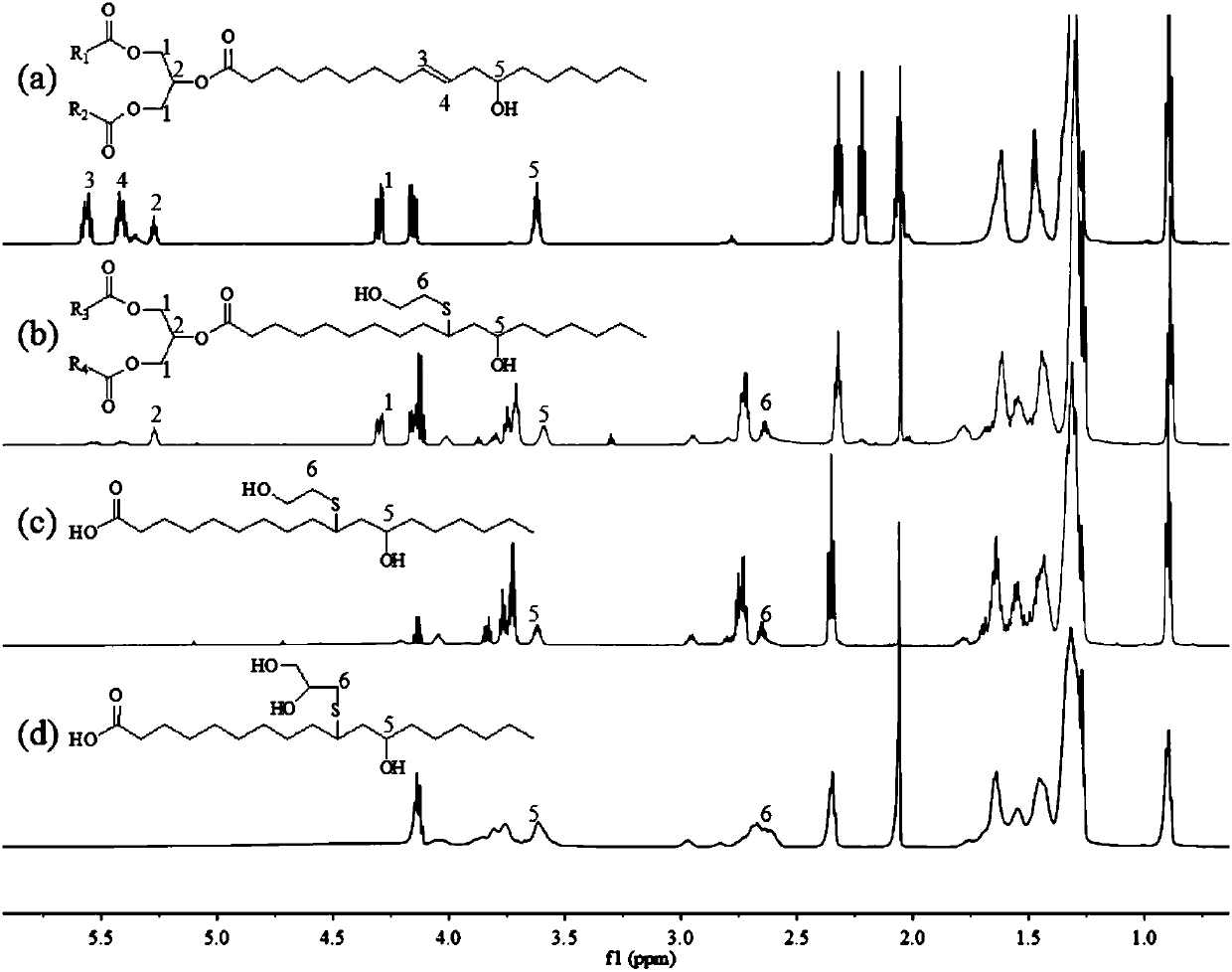

Embodiment 1

[0059] (1) Add metered photoinitiator 1173, castor oil and mercaptoethanol in the test tube in turn (the molar ratio of double bond to mercaptogroup is 1:4.5; the amount of photoinitiator is (oil quality+mercaptoethanol quality)×2%) , reacted under magnetic stirring and ultraviolet light for 4.5h. Using ethyl acetate as a solvent, wash the reaction product with brine for 5 times, discard the water phase, remove water with anhydrous magnesium sulfate, filter with suction, and rotary evaporate to obtain a light yellow viscous liquid castor oil-based polyol CO-SH, the first step The reaction is over.

[0060] (2) Put the intermediate product prepared in step (1) into an oven at 60°C and bake for 12 hours. Take an appropriate amount of the intermediate product CO-SH in a one-necked bottle, add an appropriate amount of NaOH (the molar ratio of ester group to NaOH is 1:2) under magnetic stirring at 80°C, react for 5 hours, and add HCl to adjust the reaction system to acidity. Usin...

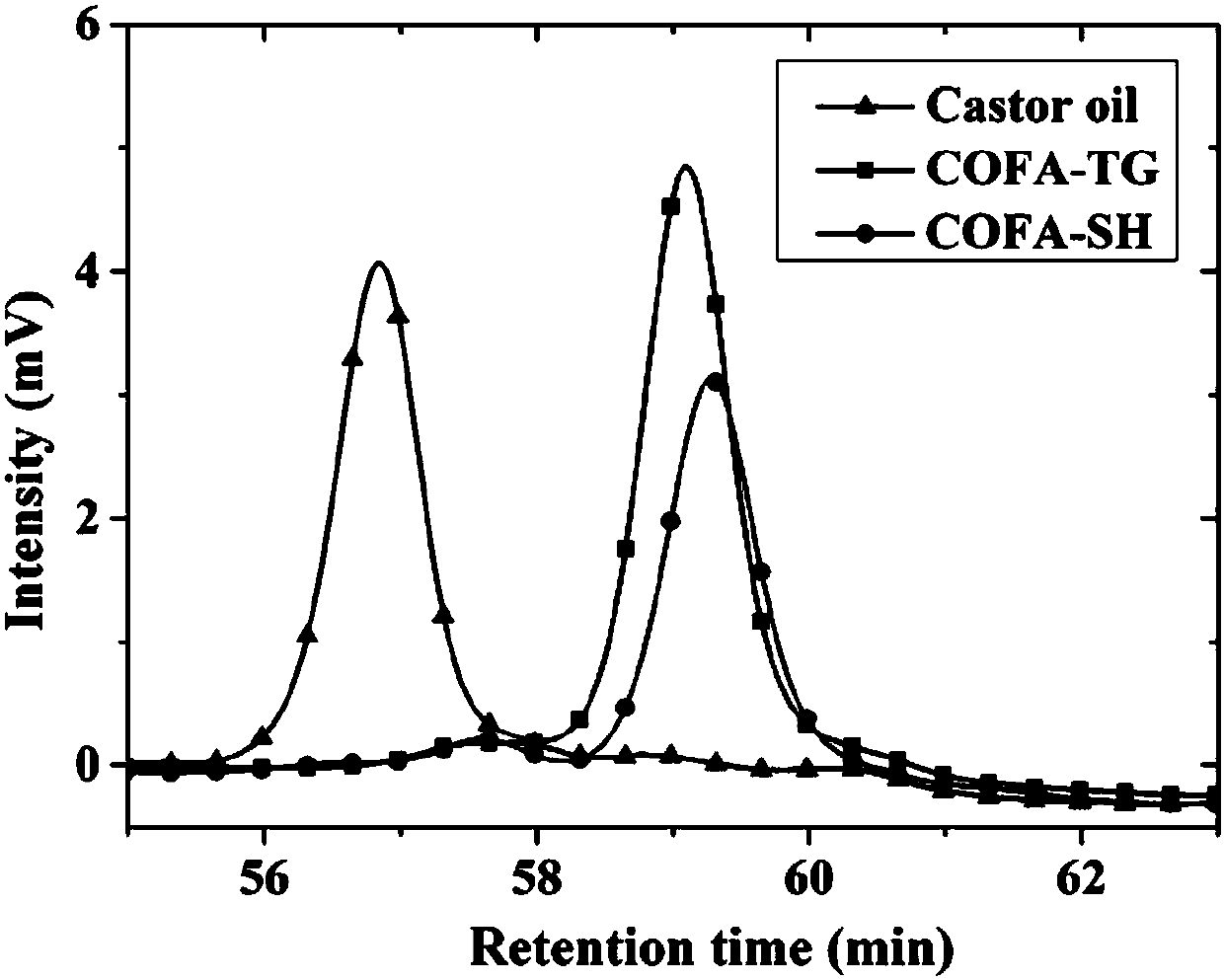

Embodiment 2

[0066] (1) Add metered photoinitiator 1173, castor oil and thioglycerol in sequence in the test tube (the molar ratio of double bond to mercapto group is 1:4.5; the amount of photoinitiator is (oil quality+thioglycerol quality)×2 %), reacted for 4.5h under magnetic stirring and ultraviolet light. Using ethyl acetate as a solvent, wash the reaction product with brine for 5 times, discard the water phase, remove water with anhydrous magnesium sulfate, filter with suction, and rotary evaporate to obtain a light yellow viscous liquid castor oil-based polyol CO-TG, the first step The reaction is over.

[0067] (2) Put the intermediate product prepared in step (1) into an oven at 60°C and bake for 12 hours. Take an appropriate amount of the intermediate product CO-TG in a one-necked bottle, add an appropriate amount of NaOH (the molar ratio of ester group to NaOH is 1:2) under magnetic stirring at 80°C, react for 5 hours, and add HCl to adjust the reaction system to acidity. Using...

Embodiment 3

[0071] (1) Add metered photoinitiator 1173, castor oil and mercaptoethanol in the test tube in turn (the molar ratio of double bond to mercaptogroup is 1:1.5; the amount of photoinitiator is (oil quality+mercaptoethanol quality)×2%) , Reacted under magnetic stirring and ultraviolet light for 5h. Use ethyl acetate as a solvent, wash the reaction product with brine three times, discard the water phase, remove water with anhydrous magnesium sulfate, filter with suction, and rotary evaporate to obtain a light yellow viscous liquid castor oil-based polyol CO-SH, the first step The reaction is over.

[0072] (2) Take an appropriate amount of the intermediate product CO-SH prepared in step (1) in a single-necked bottle, add an appropriate amount of NaOH (the molar ratio of ester group to NaOH is 1:1) under magnetic stirring at 60 ° C, react for 1 h, add HCl to dissolve The reaction system was adjusted to acidity. Using ethyl acetate as a solvent, wash the reaction product with brin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com