Patents

Literature

276 results about "Renewable materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rejuvenation of reclaimed asphalt

ActiveUS20140338565A1Low cloud and pour pointImprove thermal stabilityIn situ pavingsSolid waste managementCrack resistanceFatty acid

Asphalt compositions comprising reclaimed asphalt and a rejuvenating agent are disclosed. The reclaimed asphalt comprises aggregate and an aged binder. The rejuvenating agent, which has a cyclic content of at least 5 wt. %, comprises an ester or ester blend derived from an acid selected from aromatic acids, fatty acids, fatty acid monomers, fatty acid dimers, fatty acid trimers, rosin acids, rosin acid dimers, and mixtures thereof. The rejuvenating agent revitalizes the aged bitumen binder of reclaimed asphalt and restores its physical properties to those of the original performance-grade bitumen. Improvements include desirable softening, low-temperature cracking resistance, better fatigue cracking resistance, good elevated temperature performance, improved miscibility, and restored temperature sensitivity. The rejuvenating agents enable the use of higher levels of recovered asphalt, particularly RAP, in asphalt mixtures, reduce binder and aggregate costs, and help the road construction industry reduce its reliance on virgin, non-renewable materials.

Owner:KRATON CHEM LLC

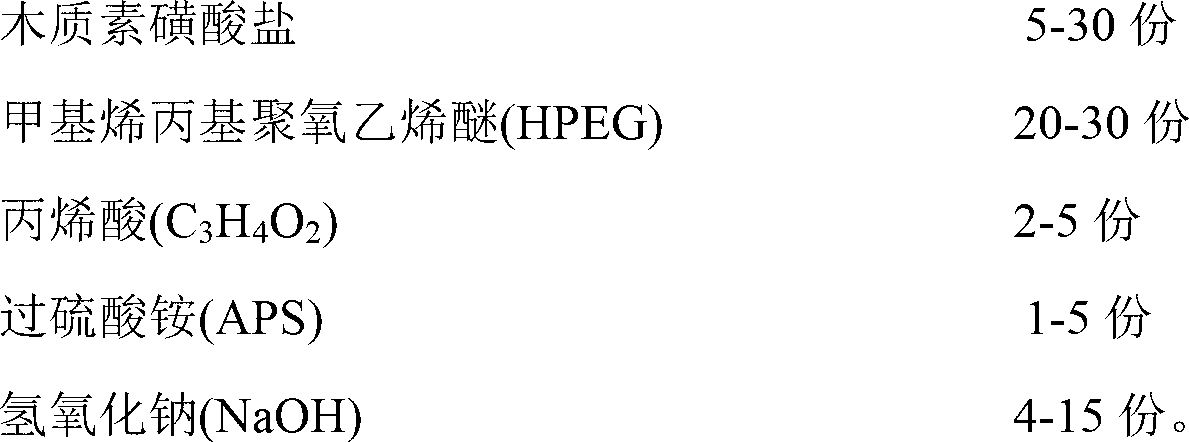

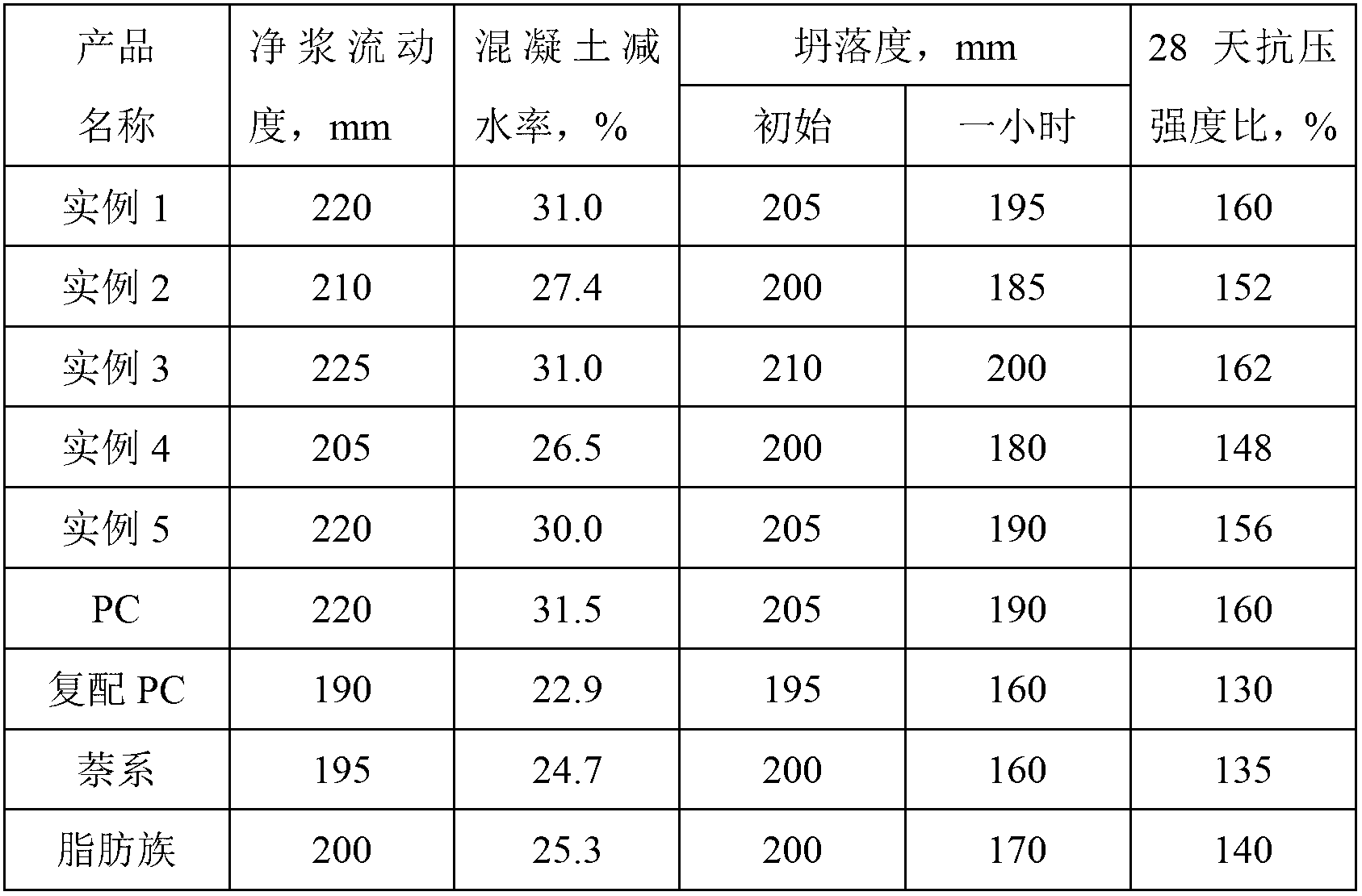

Lignosulfonate-polycarboxylic acid copolymerized composite high-performance water reducer and preparation method thereof

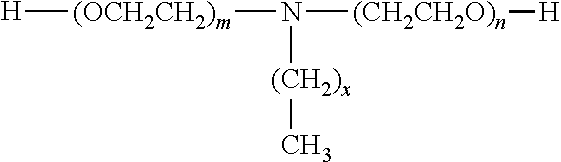

The invention discloses a lignosulfonate-polycarboxylic acid copolymerized composite high-performance water reducer and a preparation method thereof. The high-performance water reducer comprises the components in parts by weight: 5-30 parts of lignosulfonate, 20-30 parts of methyl allyl polyethenoxy ether, 2-5 parts of acrylic acid, 1-5 parts of ammonium persulfate, 4-15 parts of sodium hydroxide and water. The preparation method comprise the steps as follows: lignosulfonate, methyl allyl polyethenoxy ether and acrylic acid are directly synthesized under the action of ammonium persulfate, and the mixture is neutralized by sodium hydroxide to obtain the high-performance water reducer. As the high-performance water reducer is made from natural recycled materials, the high-performance water reducer is low in price, stable in performance, high in water-reducing rate, good in collapse prevention property, remarkable in improved effect, and is unlikely to bleed, separate and deposit after concrete is added, the quality problems of sand leakage, honeycomb-like phenomenon and leakage due to cracking in the middle and low-strength concretes are effectively avoided, and the safety performance is improved.

Owner:MAANSHAN CHINASEA NEW MATERIAL

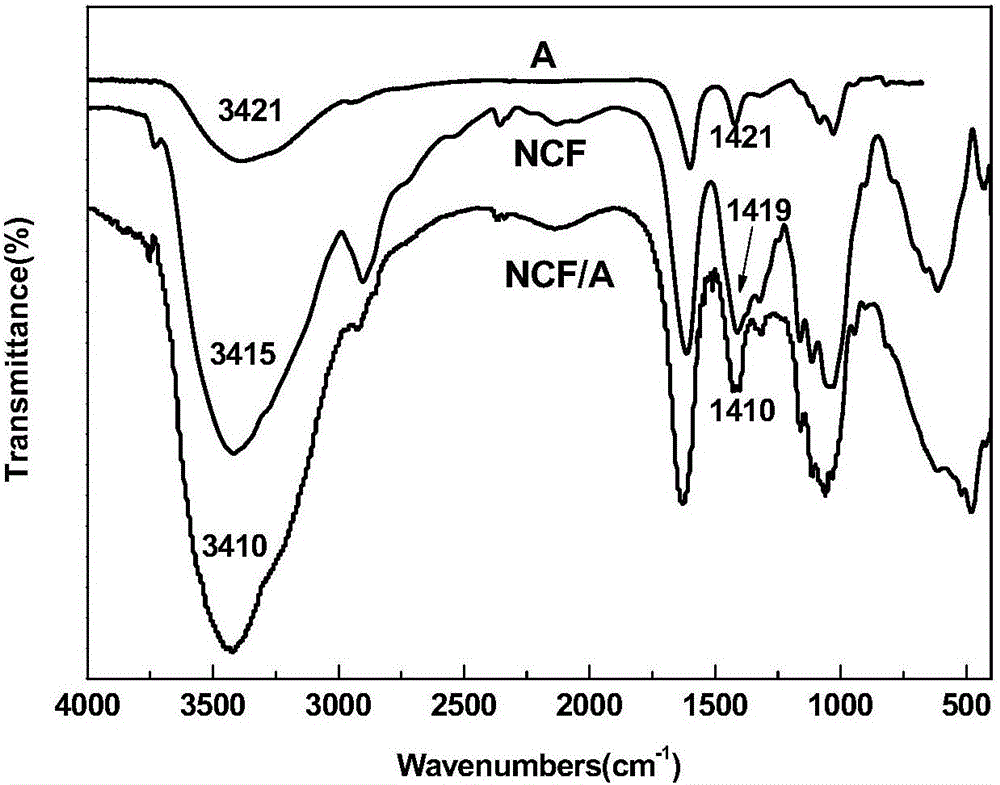

Globular cellulose chelate sorbent containing amidoxime group and carboxy and preparation method thereof

The invention discloses a spherical cellulose chelate sorbent with amidoxime group and carboxyl group and a preparation method thereof. The average pore size of the spherical cellulose chelate sorbent is 5-40nm, the specific surface area is 160-750m<2> / g, the skeletal density is 0.94-1.45g / ml, the apparent density is 0.35-0.78g / ml, the pore volume is 0.25-1.3ml / g, the water content is 45%-70%, the contents of the amidoxime group and the carboxyl group are respectively 10.6-15.0mmol / g and 0.30-0.80mmol / g. The preparation method comprises the steps of graft copolymerization, saponification and the formation of amidoxime. The spherical cellulose chelate sorbent with the amidoxime group and the carboxyl group of the invention has the advantages of high polarity and excellent special noble metal absorption selectivity, simple and easy preparation method and low manufacturing cost; and the cellulose is an abundant natural renewable material; therefore, the spherical cellulose chelate sorbent with the amidoxime group and the carboxyl group can produce practical economic benefit and environmental benefit on enrichment recovery of the noble metals, etc.

Owner:FUZHOU UNIV

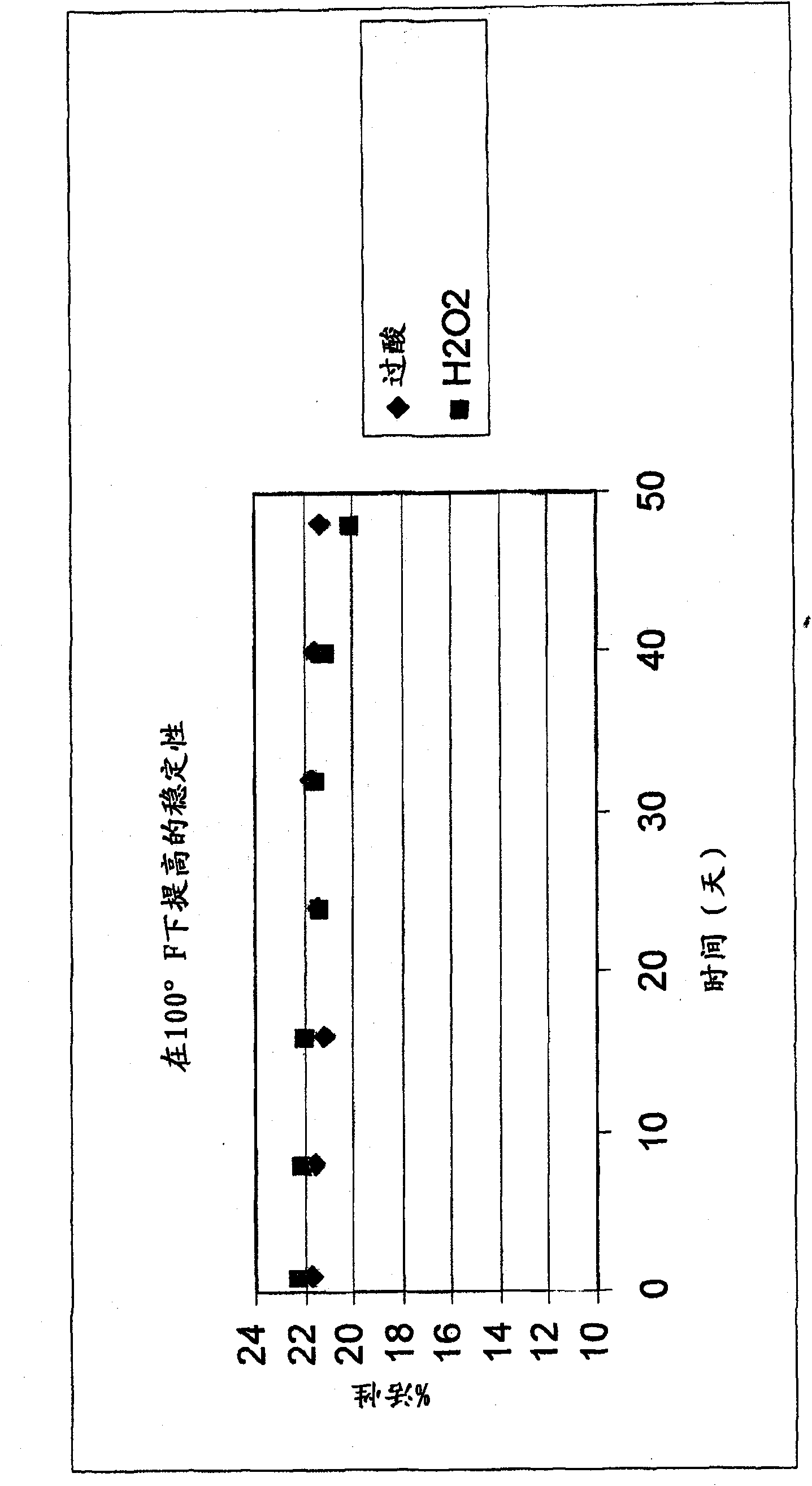

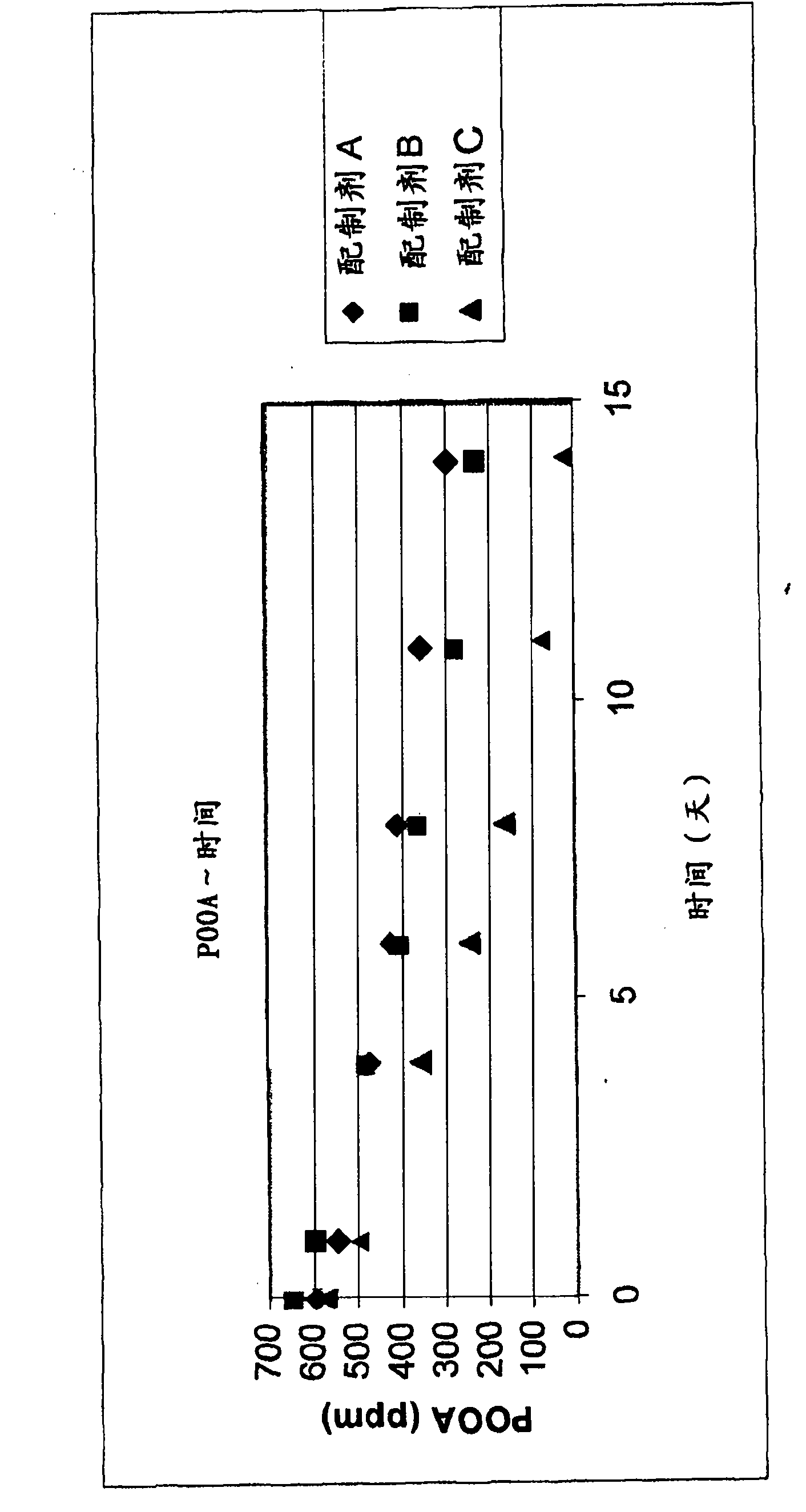

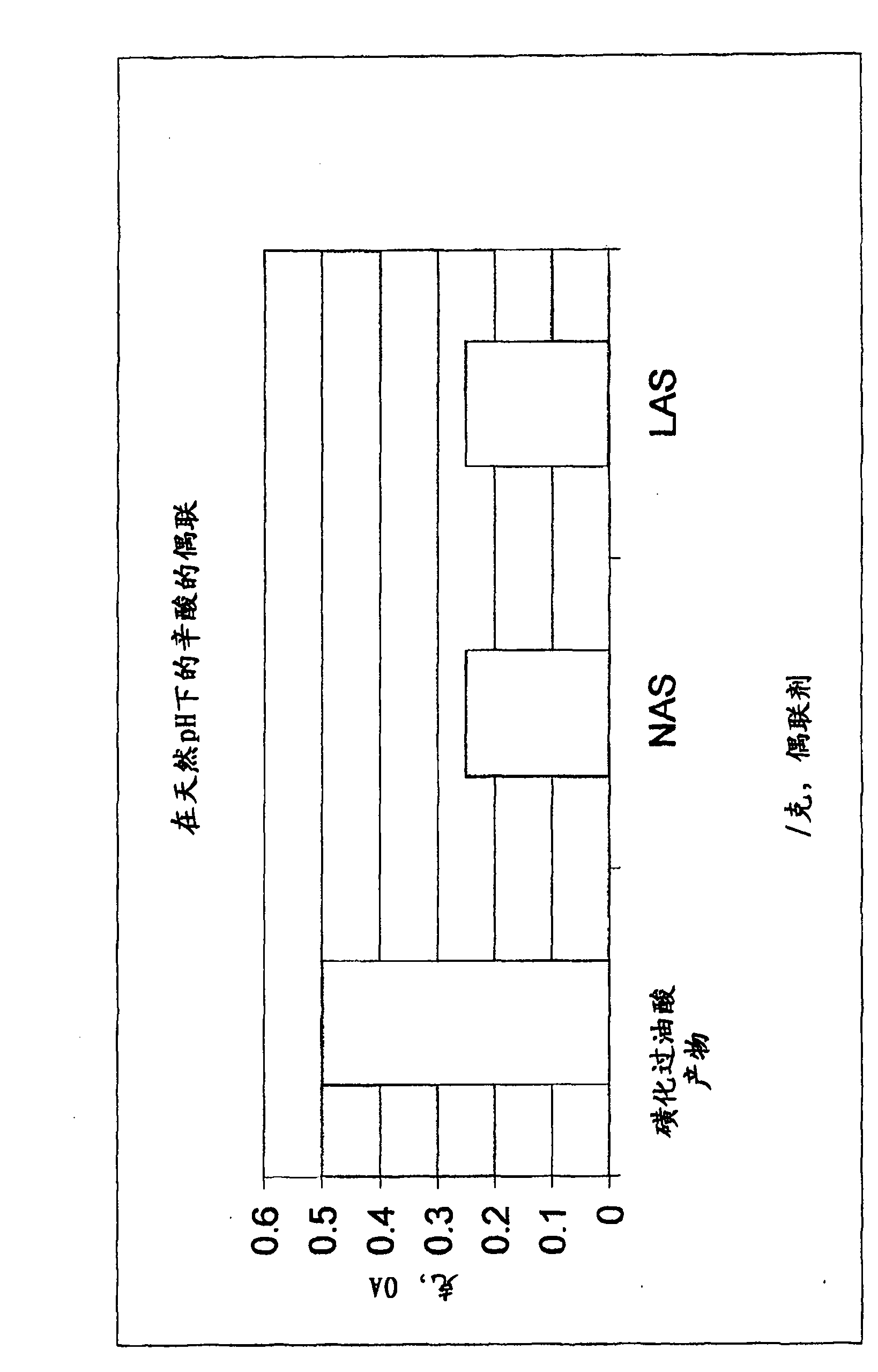

Sulfoperoxycarboxylic acids, their preparation and methods of use as bleaching and antimicrobial agents

The present invention relates to novel sulfoperoxycarboxylic acid compounds, and methods for making and using them. The sulfoperoxycarboxylic compounds of the invention are storage stable, water soluble and have low to no odor. Further, the compounds of the present invention can be formed from non-petroleum based renewable materials. The compounds of the present invention can be used as antimicrobials, and bleaching agents. The compounds of the present invention are also suitable for use as coupling agents.

Owner:ECOLAB USA INC

Vegetable oil-based adhesive, composite plywood and method for manufacturing composite plywood

ActiveCN102732200AEasy to prepareSimple manufacturing methodPolyureas/polyurethane adhesivesOil/fat/wax adhesivesVegetable oilHazardous substance

The invention discloses a vegetable oil-based adhesive, a composite plywood and a method for manufacturing the composite plywood from the vegetable oil-based adhesive. The vegetable oil-based adhesive comprises a vegetable oil-based resin, a reactive resin, a curing agent, a catalyst and additives and does not contain the formaldehyde. The composite plywood manufactured from the vegetable oil-based adhesive has high strength and good water resistance, does not contain benzene, toluene, xylene and other harmful substances and can not cause pollution to the environment. The waste petrochemical resin can be recycled, the resources can be saved, the economic cost can be saved, the use amount of the environmentally-friendly renewable materials can be increased, and the harm of the traditional composite plywood comprising the formaldehyde glue to the environment can be avoided. The composite plywood can be used as the furniture board and the floor and can be used for architectural decoration and internal decoration of motor vehicles.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

Plastic-wooden composite tray and preparation method thereof

The invention discloses a plastic-wooden composite tray which is prepared from the raw materials in parts by weight: 50-60 parts of high density polyethylene, 20-30 parts of copolymerization polypropylene, 30-40 parts of modified wood meal, 40-50 parts of plastic renewable material, 20-30 parts of active calcium, 1-2 parts of zinc stearate, 1-2 parts of calcium stearate, 2-3 parts of n-butyl methacrylate, 0.3-0.5 part of polyethylene wax, 0.4-0.6 part of triethoxyvinylsilane, 0.3-0.4 part of antioxidant 1010, 0.4-0.6 part of anti-aging agent MB, 8-10 parts of foaming modifier, 4-8 parts of ACM, 4-8 parts of MBS, 25-30 parts of oxidized polyethlene wax, 0.2-0.3 part of foaming agent, 4-8 parts of TPE (Thermoplastic Polyurethane Elastomer), 8-12 parts of chlorinated polyvinyl chloride, 5-8 parts of glass fiber and 3-4 parts of semi-reinforced carbon black. The plastic-wooden composite tray produced by using the preparation method has the advantages of excellent mechanical property, capability of being sawed, planed and nailed, good durability, high repeated usage rate, capability of being recycled, resistance to insect biting, acid and alkaline resistance, aging resistance, and low water absorption and low deformation rate.

Owner:芜湖太平洋塑胶有限公司

Methods for Producing Modified Aromatic Renewable Materials and Compositions Thereof

InactiveUS20080021155A1Low softening temperatureImprove responseLignin derivativesFriction liningRenewable materialsOrganic chemistry

Methods for producing modified renewable aromatic materials with lower softening temperatures and / or enhanced reactivity and compositions containing these modified aromatic products are provided.

Owner:GREENVALUE SA

Block copolymer derived from renewable materials and method for making such a block copolymer

ActiveUS20130022771A1Save energyDecrease in the amount of CO<subOrganic chemistryLayered productsPolymer scienceRenewable materials

Owner:ARKEMA FRANCE SA

BPA and polycarbonate made from renewable materials

Owner:SHPP GLOBAL TECH BV

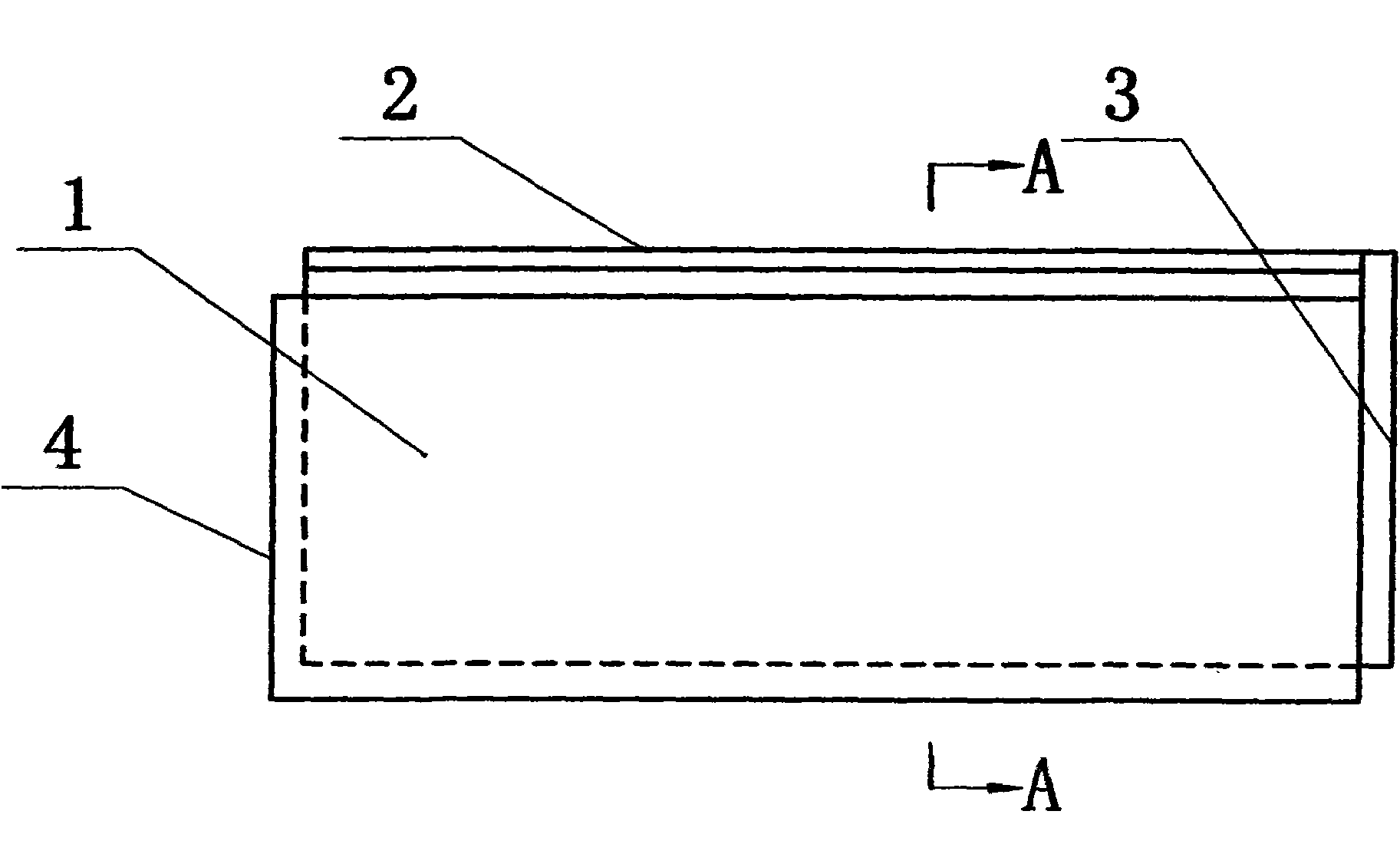

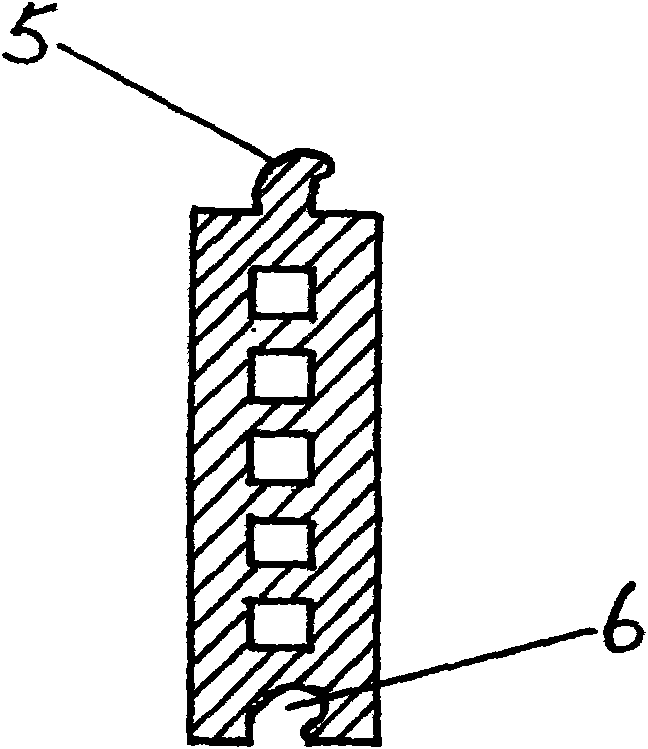

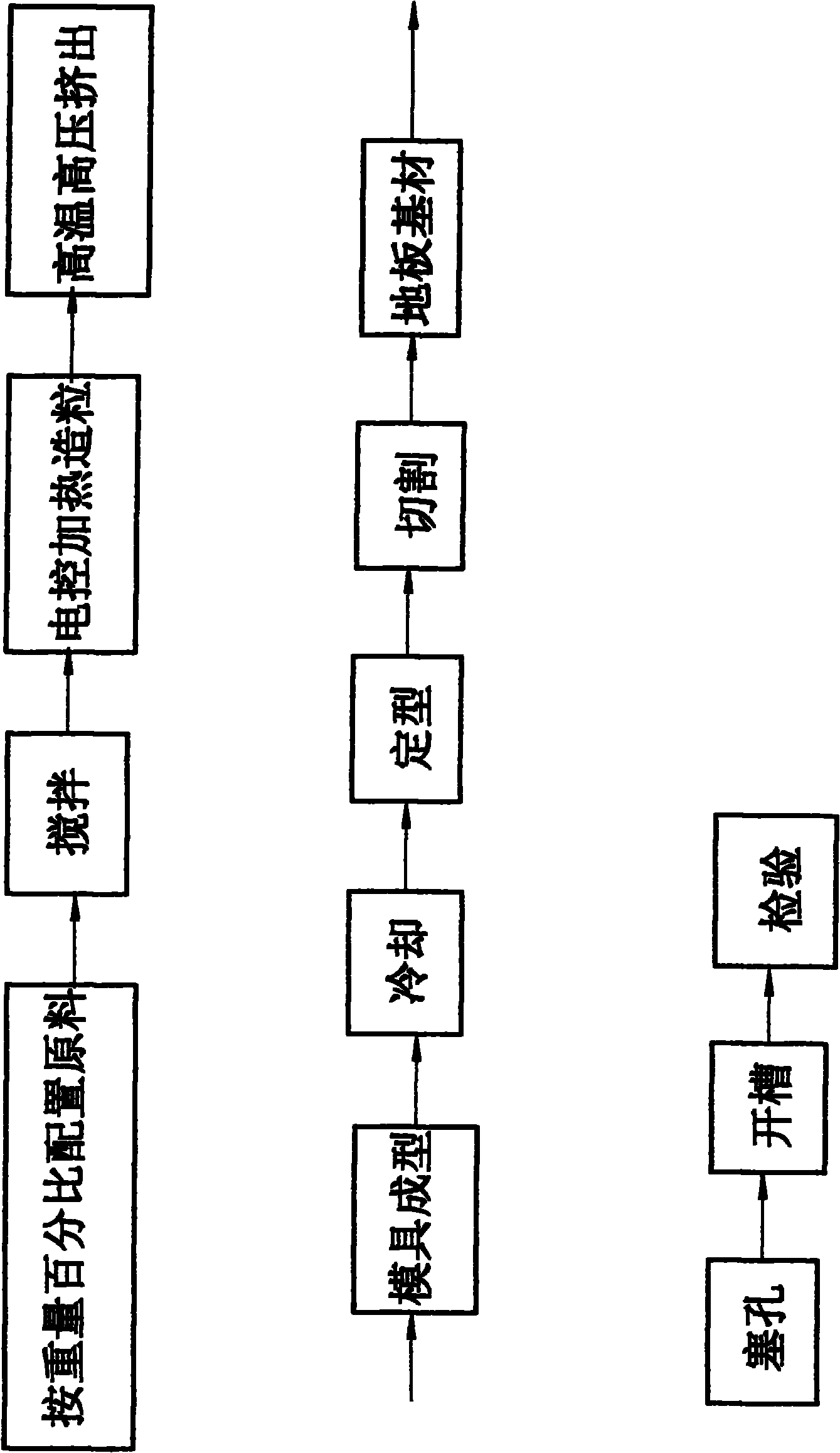

Stone-plastic wood floor and processing technology thereof

The invention relates to an indoor decorative material floor, in particular to a stone-plastic wood floor taking natural calcium carbonate stone powder, woody plant fiber powder and plastic renewable material as raw materials, and a processing technology of the stone-plastic wood floor. The stone-plastic wood floor comprises the following components by weight percent: 25%-35% of natural calcium carbonate with fineness of 500 meshes, 1% of acrylate polymer adhesive and 2% of compound stabilization modifying agent. The stone-plastic wood floor is characterized in that the floor also comprises 30-40wt% of regenerated plastic powder with the fineness of 40 meshes and 25-35wt% of woody fiber powder with the fineness of 80 meshes. The floor are processed by the processing technology to obtain pieces of floor sections with double-sided lock catch splicing structures; and the processing technology comprises a floor base material production technology and a surface treatment processing technology. The waste plastic regenerated material and woody fiber powder are fully utilized, thus wastes are turned into wealth; and the floor has the solidity of the stone product and the softness of the wood product, and the foot feeling is comfortable. The indoor decorative material floor has low cost, is convenient for installation, and time, labor and money are saved.

Owner:安徽温禾新材料科技股份有限公司

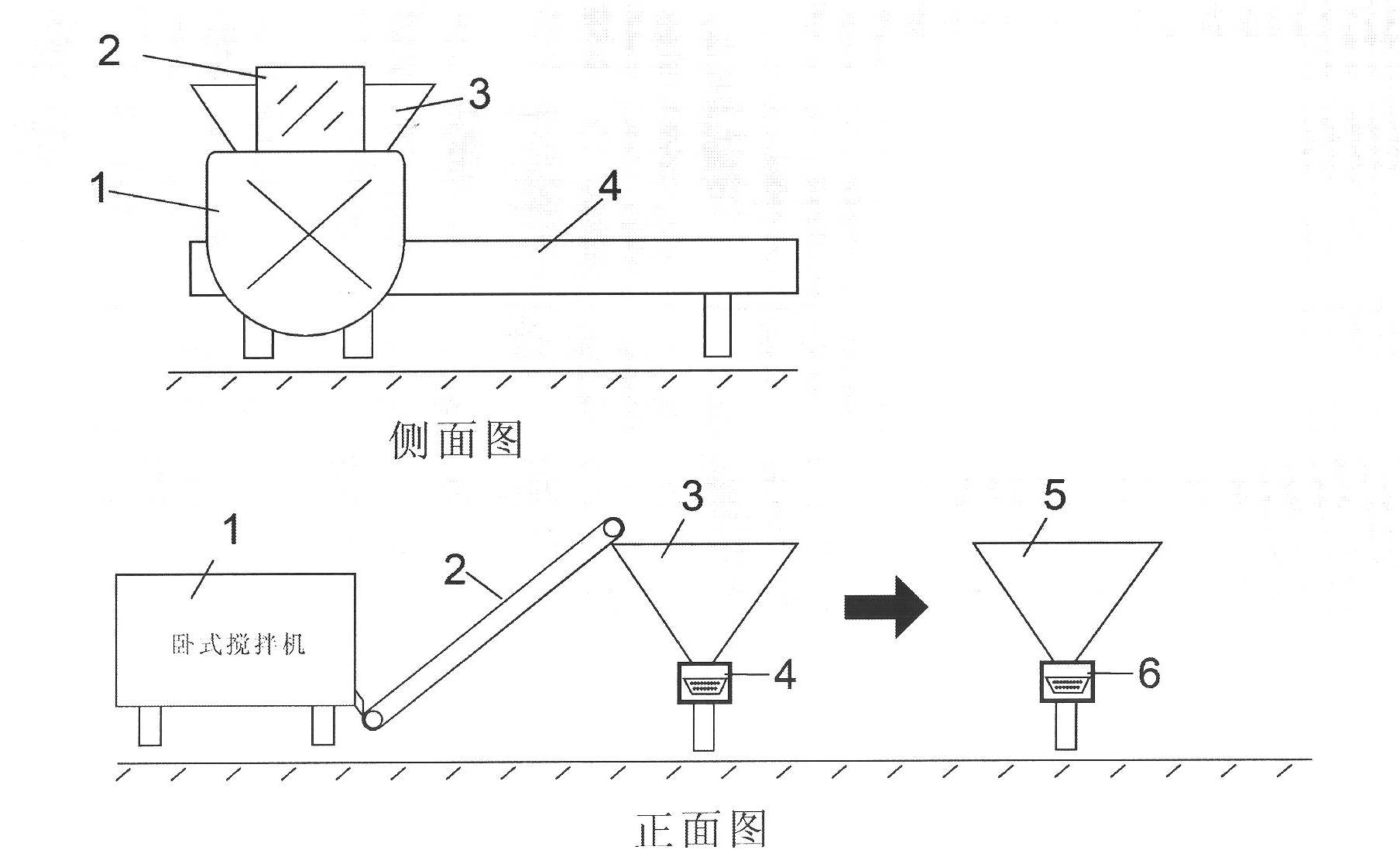

Bamboo fiber/polypropylene composite material and preparation method thereof

InactiveCN101880423AImprove processing fluidityImprove protectionPolypropylene compositesCompression molding

The invention discloses a bamboo fiber / polypropylene composite material and a preparation method thereof. The method comprises the following steps of: adding polypropylene, bamboo fibers, a compatilizer and a plasticizer into a kneading machine, an internal mixer or a double-screw extruder according to a certain ratio for mixing so as to prepare the bamboo fiber / polypropylene composite material; and preparing sheets, plates, tubes or sections of the bamboo fiber / polypropylene composite material through extrusion molding, calendaring and compression molding, and other post-procedures. The sheets, plates, tubes or sections can be used for manufacturing structural, decorative, packaging products and the like. Because the bamboo fibers come from bamboo which has the advantages of rich resources, short growth cycle and natural mold and bacteria resistance, the bamboo fiber / polypropylene composite material is a novel and renewable material.

Owner:EAST CHINA UNIV OF SCI & TECH

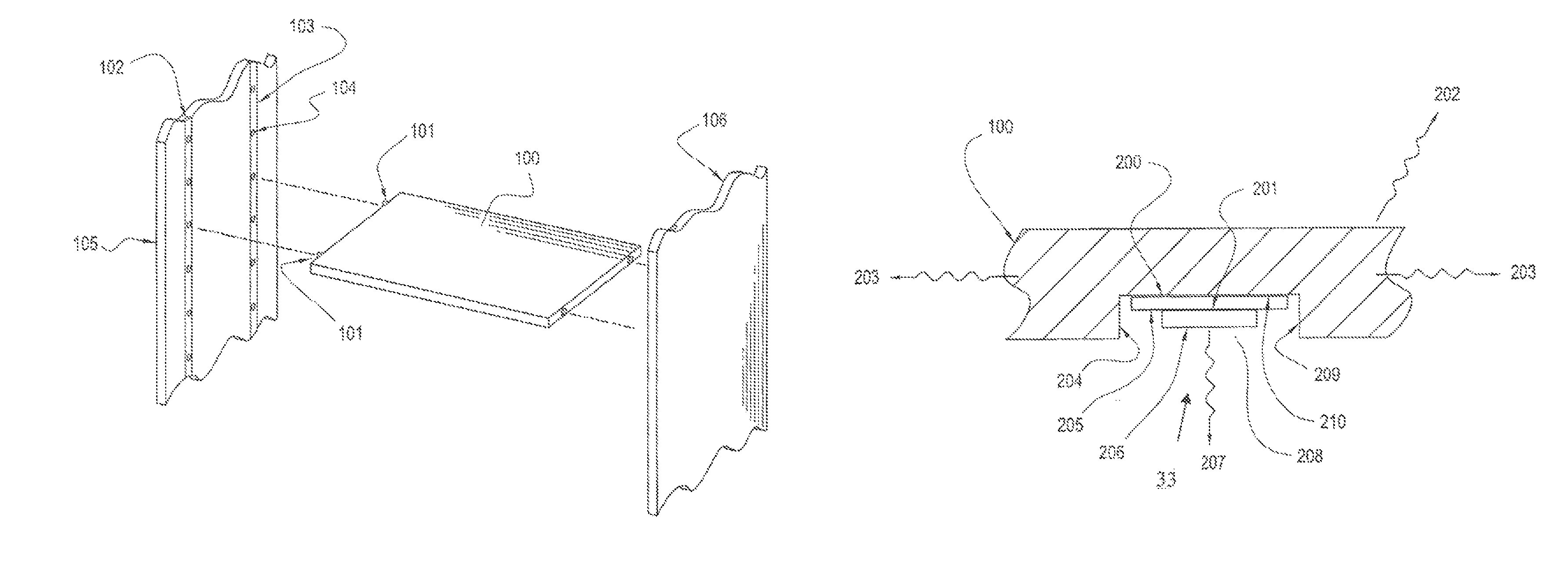

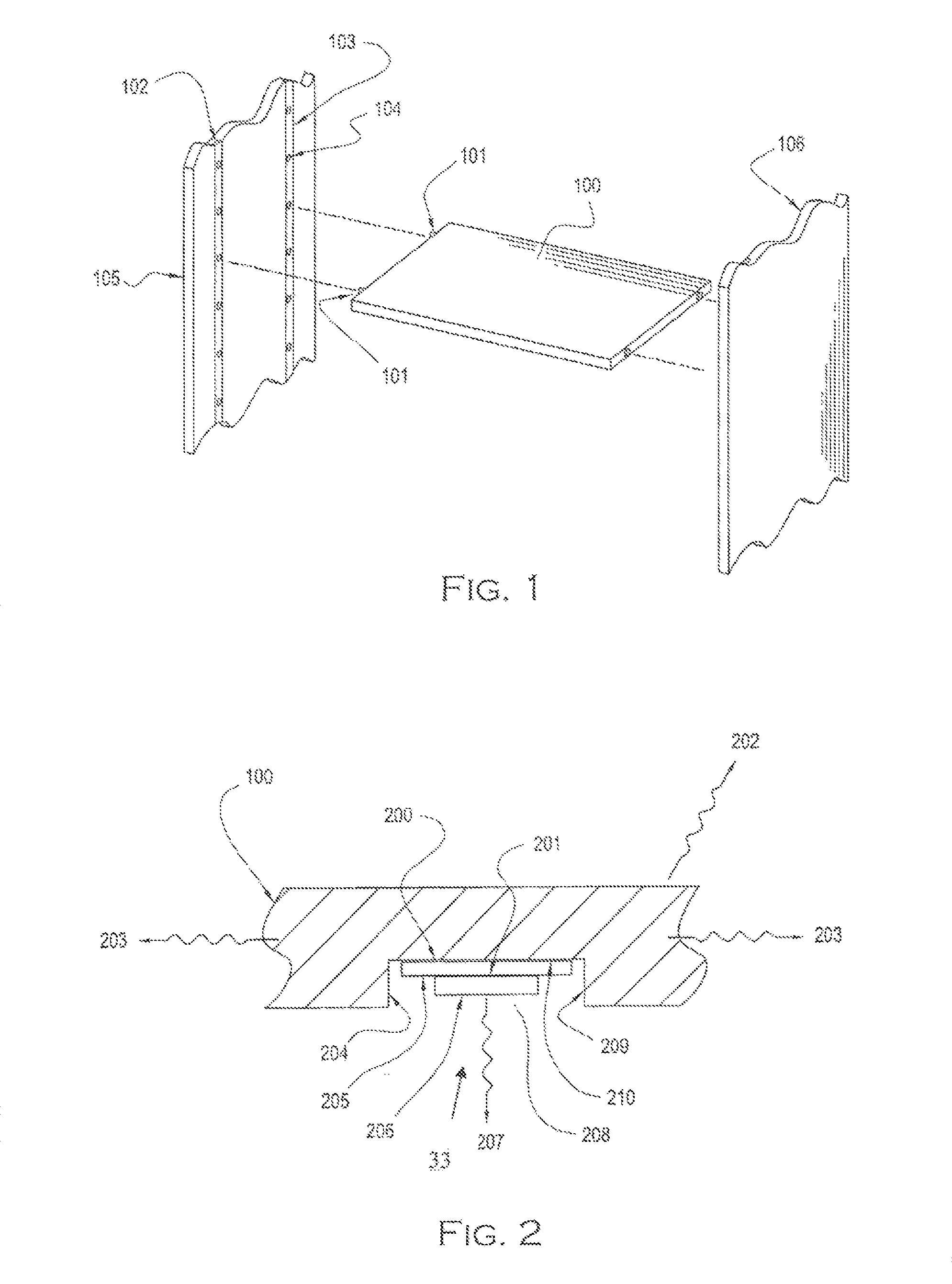

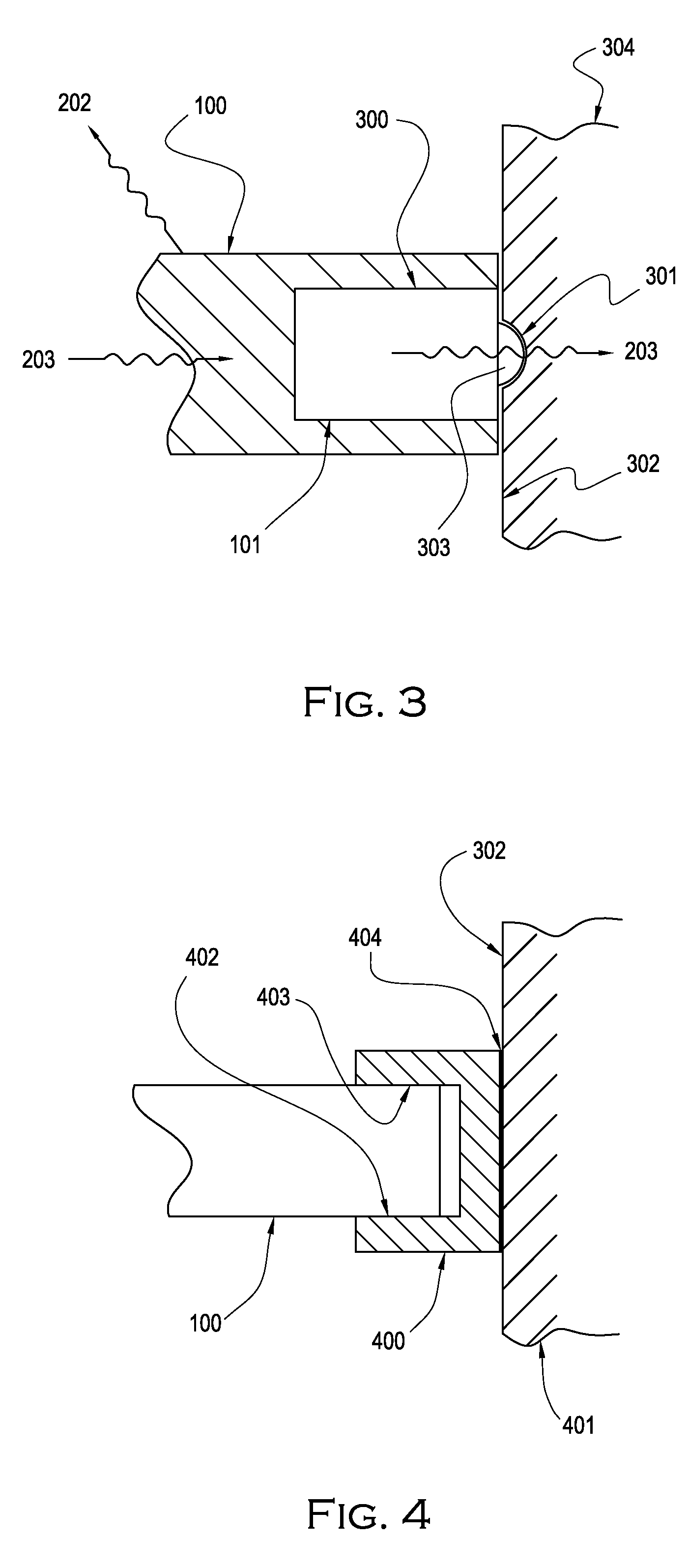

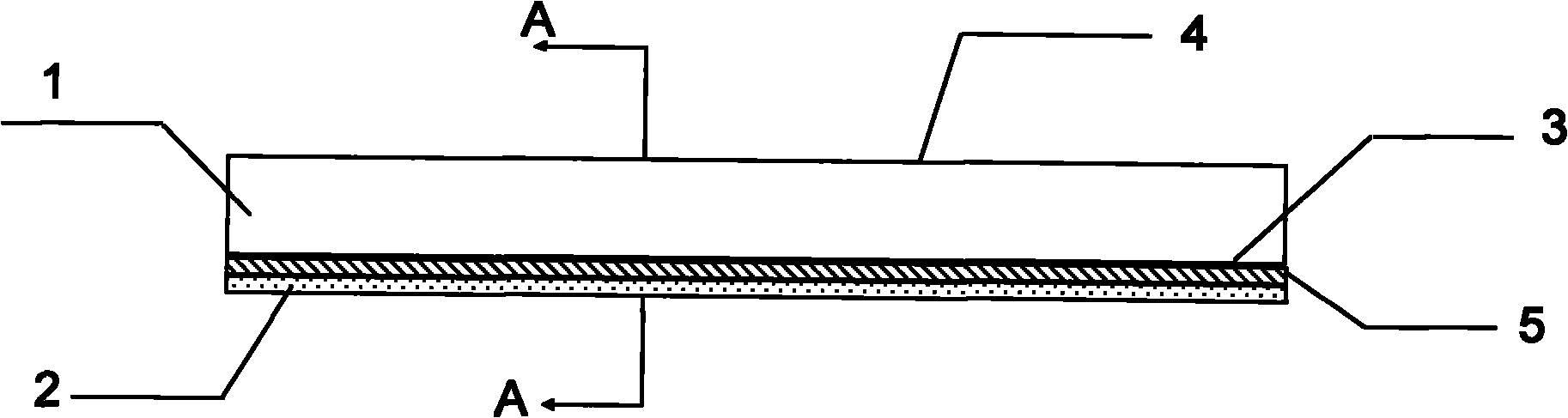

Sustainably constructed heat dissipating integrated lighting surface

ActiveUS7744252B2Reduce the burden onReduce carbon footprintMechanical apparatusPoint-like light sourceFiberGlass fiber

A lighted heat dissipating panel made of sustainable renewable materials such as recycled aluminum and soy-based urethane, for use in architectural or shelving applications. The panel may be flat, rectangular, curvilinear, or of varying cross section so as to include any three-dimensional shape as desired. Lightweight materials such as carbon fiber, fiberglass, resin, soy-based urethane, and similar materials are used in combination with thermally conductive structural materials, such as expanded aluminum honeycomb, preferably fabricated from recycled aluminum, to provide a stiff, lightweight, machinable, moldable, and thermally conductive panel for use with lighting elements. Lighting elements are housed within the panel, providing illumination as desired. Heat is transferred from the lighting elements through the panel to the supporting structure and radiated from the panel itself, providing cooling effect for the lighting elements, reducing the temperature in the immediate vicinity of the lighting elements and providing for longer lighting element life.

Owner:LIGHTING SCI GROUP

Cold-resistant and high temperature-resistant composite material and preparation method thereof

The invention relates to a cold-resistant and high temperature-resistant composite material and a preparation method thereof. The composite material is prepared from the following raw materials in part by weight: 20 to 30 parts of polyethylene, 5 to 10 parts of polyvinyl butyral, 10 to 15 parts of SBS, 10 to 20 parts of diatomite, 5 to 10 parts of vinlacetate copolymer (EVA), 10 to 15 parts of acrylonitrile (ABS), 20 to 25 parts of SMN resin, 5 to 10 parts of JC-G530C reinforcing agent, 0.3 to 0.5 part of lignocellulose and the balance of nano calcium carbonate, wherein the nano calcium carbonate accounts for 15 to 25 percent of the total weight of the materials. The composite material overcomes the defects of poor low-temperature stability of bituminous pavements in monsoon climate regions of medium latitudes in China and poor high-temperature rutting resistance of the bituminous pavements at the same time. In addition, most of the raw materials of the composite material are recyclable and renewable materials, so that the composite material is energy-saving and environmentally-friendly. The composite material is very flexible and convenient in use and has very high economic and social benefits.

Owner:深圳市天坤元环保科技有限公司

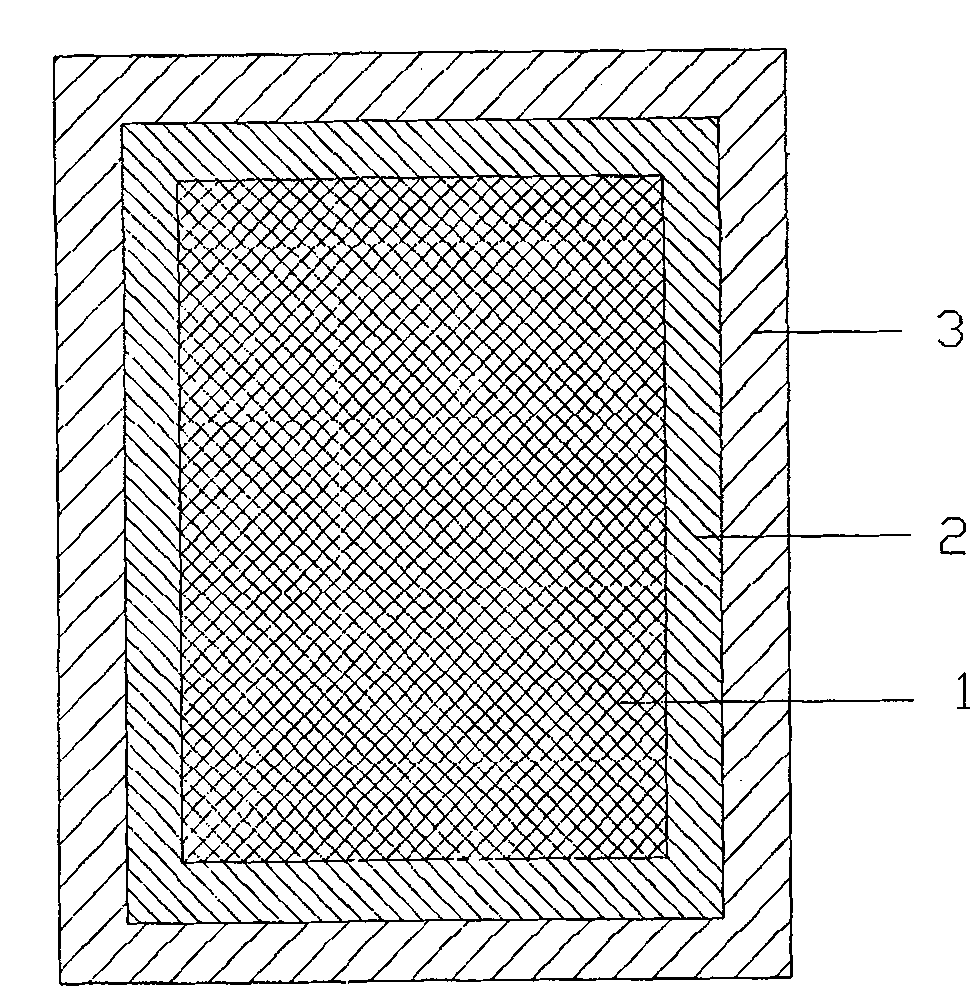

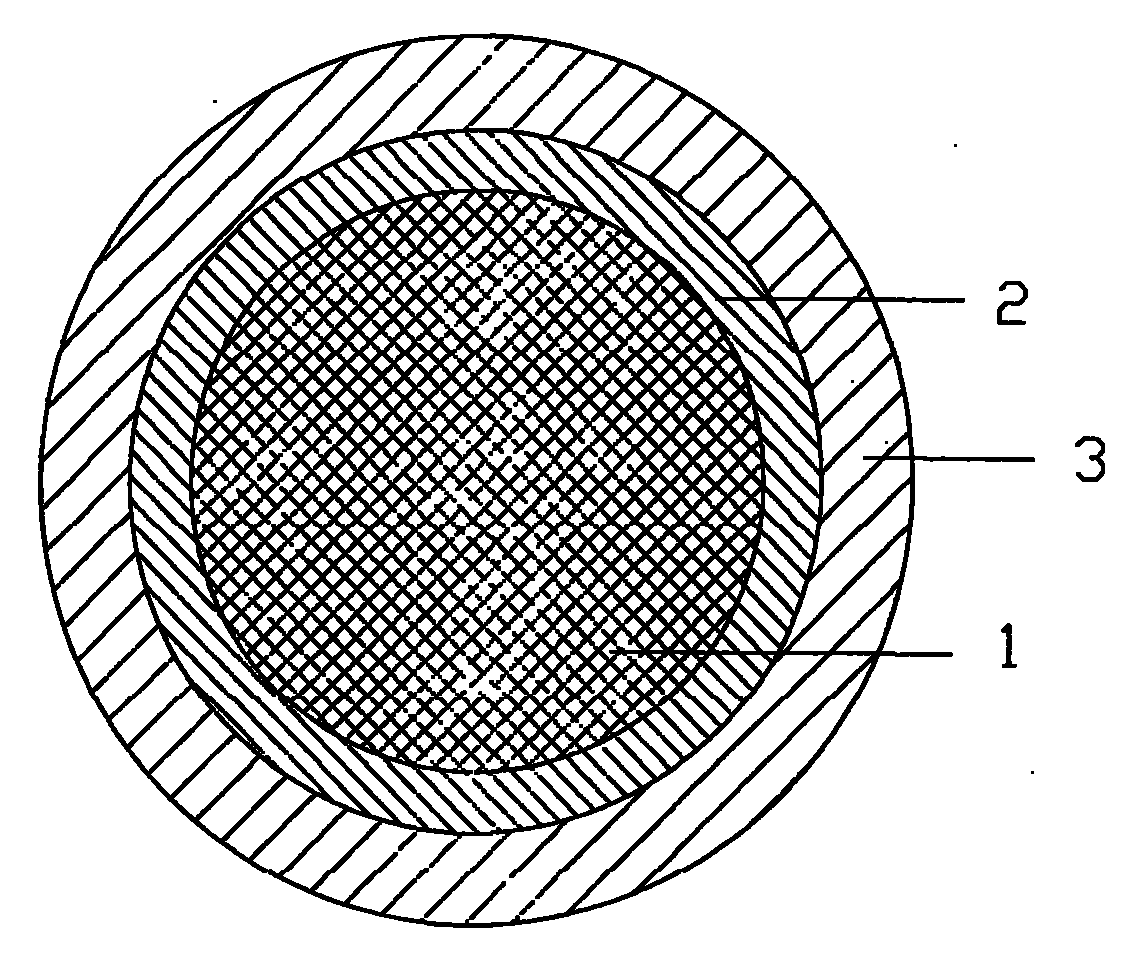

Compound tissue engineering scaffold containing PLGA (poly(lactic-co-glycolic acid) strengthening net, and preparation method and application thereof

The invention relates to a scaffold material for tissue engineering construction and a preparation method thereof, and particularly relates to a compound tissue engineering scaffold containing a PLGA (poly(lactic-co-glycolic acid) strengthening net, and a preparation method and application thereof. The compound tissue engineering scaffold containing a PLGA strengthening net comprises a porous scaffold having good biocompatibility and a PLGA strengthening net, wherein the PLGA strengthening net is formed by weaving PLGA fibers, and the PLGA strengthening net is tightly combined with the porous scaffold. The compound tissue engineering scaffold containing a PLGA strengthening net has mechanical property similar to that of the acellular dermal matrix, and is more beneficial to the maintenance of three-dimensional porous structures of the scaffold, thereby being more beneficial to the ingrowth of cells, blood vessels and tissues; and because of the good biocompatibility of collagen, chitosan and other naturally-derived macromolecules, the biological performance of the compound scaffold is maintained, thereby being beneficial to the adhesion, propagation and secretion of cells. Thus, the compound tissue engineering scaffold is a good renewable material applicable to the construction of tissues and organs of tissue engineering.

Owner:ZHEJIANG UNIV

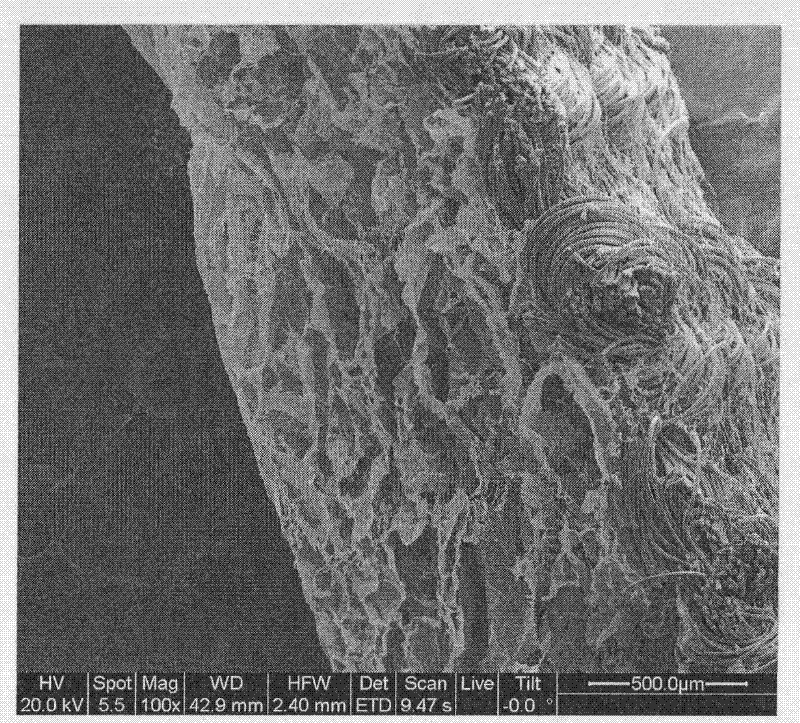

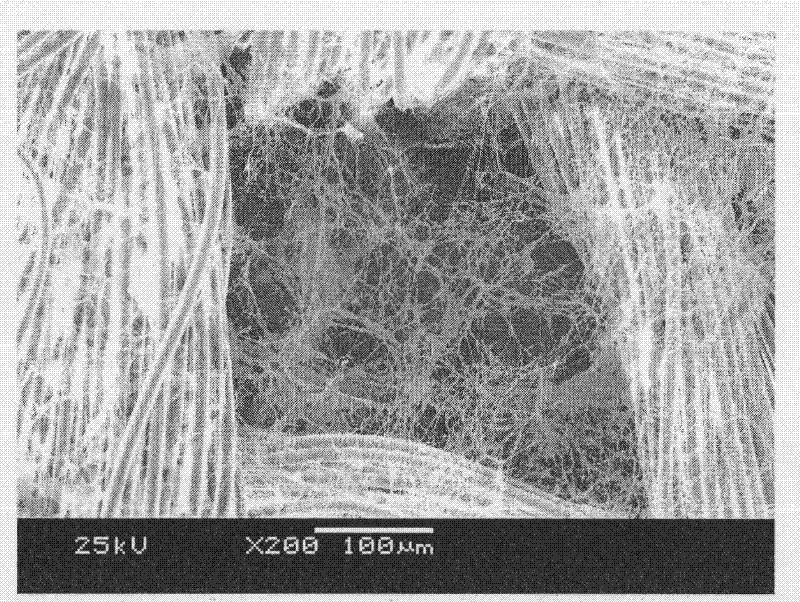

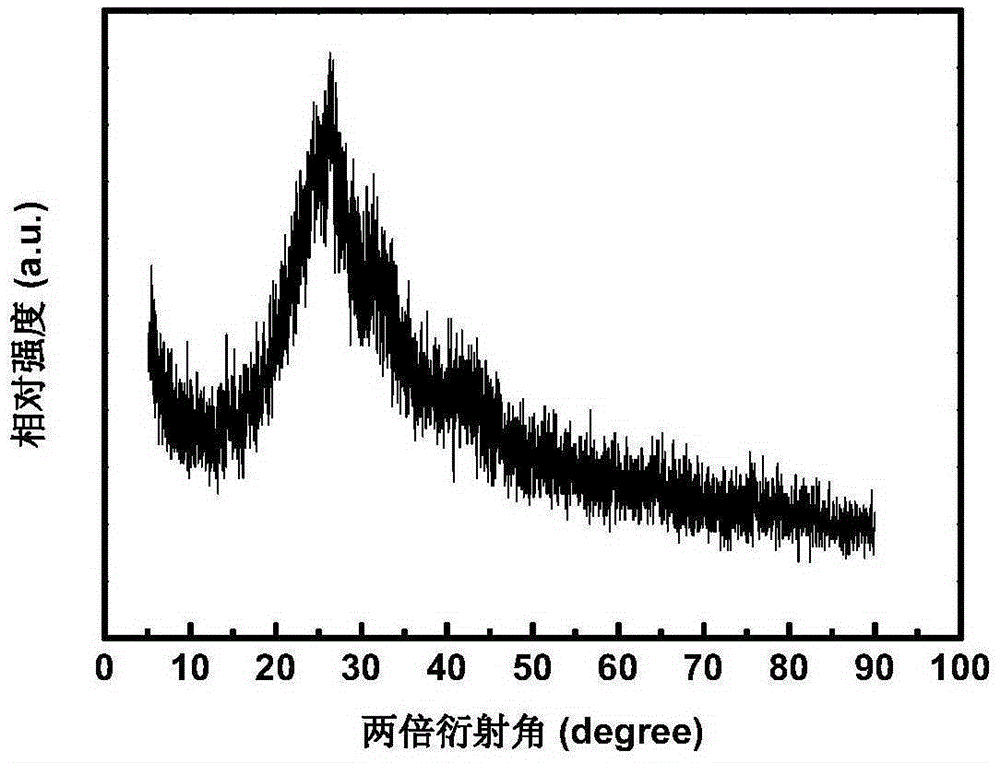

Preparation method of composite fiber of cellulose nanometer fibrils/alginate

ActiveCN106521706ALarge specific surface areaHigh crystallinityConjugated cellulose/protein artificial filamentsArtifical filament manufactureCelluloseFiber

The invention discloses a preparation method of composite fiber of cellulose nanometer fibrils / alginate. The method includes steps of evenly dispersing cellulose nanometer fibrils under ultrasound wave function, and preparing aqueous suspension; then evenly mixing with alginate solution and obtaining the mixed solution of cellulose / sodium alga acid as spinning raw liquid; spinning by wet method and obtaining the composite fiber of cellulose nanometer fibrils / alginate. The preparation method is simple and easy to operate, the technique is green and environmental-friendly; the prepared composite fiber of cellulose nanometer fibrils / alginate is an environment-friendly recycled material, and has the same excellent biocompatibility and biological degradability as the pure alginate fiber; the oriental controllability of cellulose nanometer fibrils is enhanced, and the cellulose nanometer fibrils and the base alginate are formed to be an interpenetrating polymer network structure, thereby effectively improving the intensity and flexibility of composite fiber and greatly improving the adaptation of alginate fiber in textile and garment and medical treatment health domain.

Owner:QINGDAO UNIV

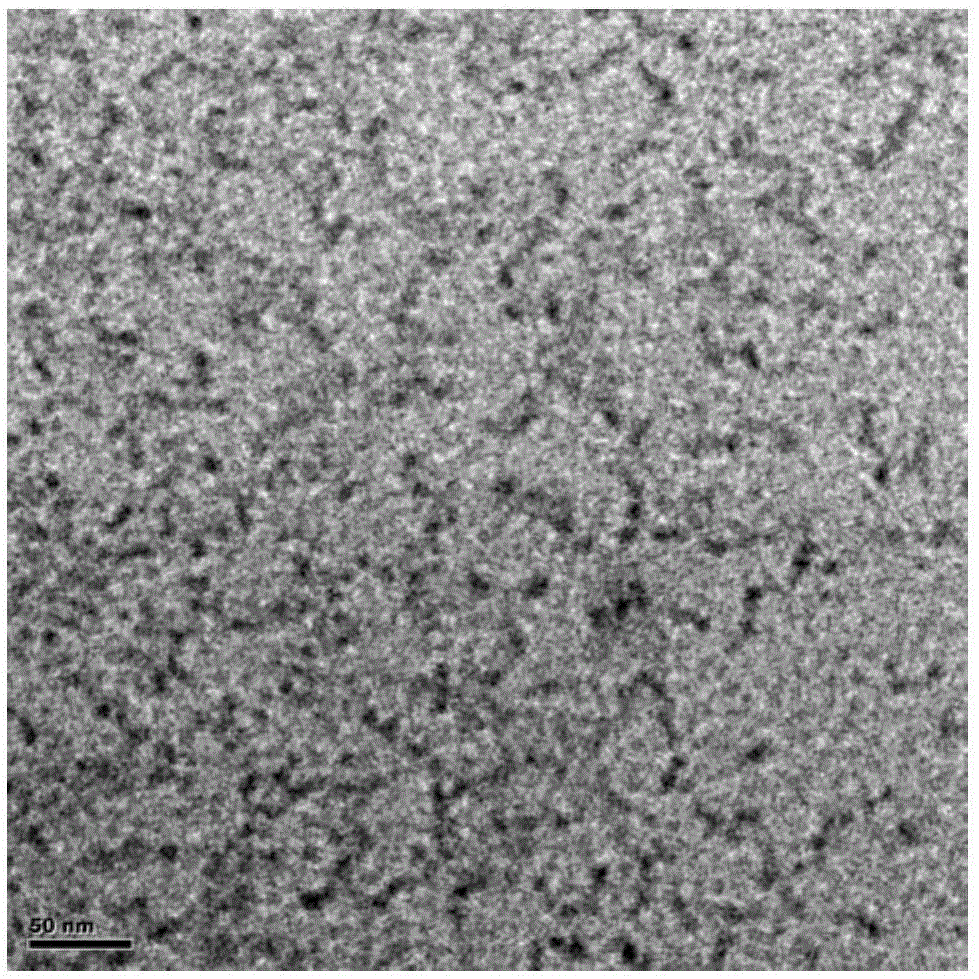

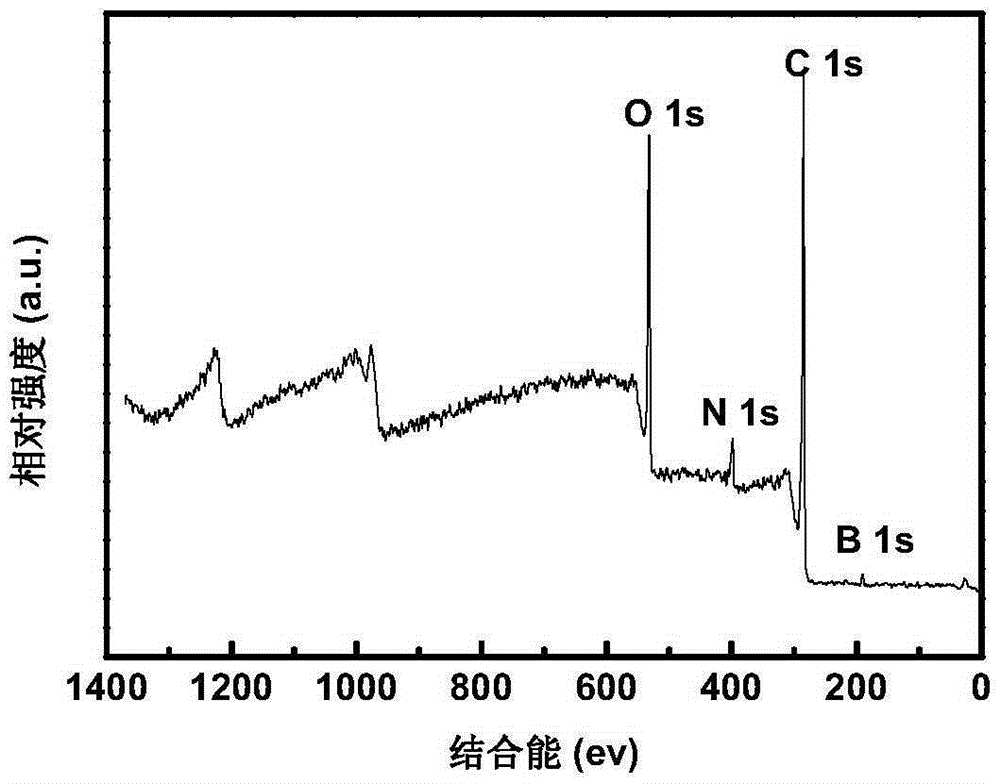

Preparation method of boron-nitrogen-co-doped carbon dots

InactiveCN105329876AEasy to batchEasy to produceMaterial nanotechnologyPhysical/chemical process catalystsMaterials scienceUltrapure water

The invention relates to a preparation method of boron-nitrogen-co-doped carbon dots. The method includes the steps of drying corn cobs without corn kernels, putting the corn cobs on a ceramic tray, sending the tray into a tubular furnace to be sintered under the protection of inertia gas, grinding the product into a grinding material, and baking the grinding material to obtain carbon powder; secondly, mixing, stirring and drying carbon powder, boric acid and ultrapure water, putting the product into a quartz tubular furnace with ammonia gas to be sintered, taking out powder to be acidized by mixed liquid of concentrated sulfuric acid and concentrated nitric acid, then stopping the reaction through ultrapure water, conducting repeated centrifuging and ultrasonic processing, and finally conducting vacuum freezing and drying to obtain the boron-nitrogen-co-doped carbon dots. The applied raw material is a sustainable recyclable material, namely, corn cobs, and has the advantages of being easily produced in batches on a large scale; the prepared boron-nitrogen-co-doped carbon dots are uniform in particle size; nitrogen can be prepared by decomposing water through sunlight without sacrificial agent.

Owner:DONGHUA UNIV

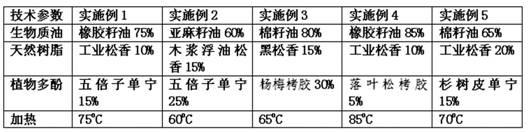

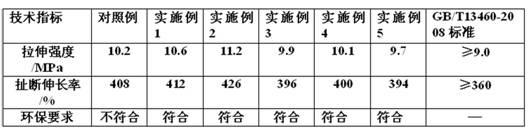

Environmentally-friendly biomass compound rubber regenerant and preparation method thereof

The invention provides an environmentally-friendly biomass compound rubber regenerant. The regenerant is prepared from the following raw materials in mass percentage: 60-85% of bio-oil, 10-20% of natural resin and 5-30% of plant polyphenol. The preparation method of the regenerant comprises the following steps: (1) heating the bio-oil to 60-85 DEG C; (2) respectively adding the natural resins andthe plant polyphenol to the bio-oil and evenly mixing; and (3) naturally cooling the evenly mixed product to room temperature to finally obtain the environmentally-friendly biomass compound rubber regenerant product. In the invention, the bio-oil, the natural resins and the plant polyphenol which are extracted from plants are taken as raw materials, and the raw materials are renewable materials, which realizes maximum resource utilization and reduces dependence on petrochemical resource so as to achieve the purpose of green production of reclaimed rubber. The regenerant has the advantages of good rubber regeneration effect, high product quality, low production cost and no pollution and nuisance during the production process. The environmentally-friendly reclaimed rubber produced by the regenerant can be widely applied to various rubber products and can replace rubber materials, thus saving rubber resources.

Owner:KUNMING PHOENIX RUBBERS

Method for blending corrugating base paper by utilizing secondary fiber after anaerobic digestion of paper mill sludge

ActiveCN103103866ASimple processEasy to operateSecondary cellulose fibresPaper-making machinesFiberResource utilization

The invention discloses a method for blending corrugating base paper by utilizing secondary fiber after anaerobic digestion of paper mill sludge, belonging to the fields of recyclable material and environmental protection. The method comprises the following steps of: by using the secondary fiber obtained after anaerobic digestion of paper mill sludge, waste paper pulp and softwood pulp as raw materials, separating and brooming the fiber through defibering and beating treatment, then dewatering, mixing, and then adding a reinforcing agent and a sizing agent to defiber; and adding paper pulp after defibering in a sheet machine so as to form uniform pages, and then pressing and drying to form corrugating base paper. The method is simple in process and high in operability, and the secondary fiber after anaerobic digestion of paper mill sludge is utilized for mixing with the waste paper pulp for papermaking, so that the energy of papermaking enterprises is saved, simultaneously efficient resource utilization of remaining secondary fiber after anaerobic digestion of paper mill sludge is realized, a new raw material source is created for papermaking factories, the cleaner production level of papermaking enterprises is improved, the resource utilization ratio of paper mill sludge is realized to the maximum, and the method has important engineering application value.

Owner:SOUTH CHINA AGRI UNIV

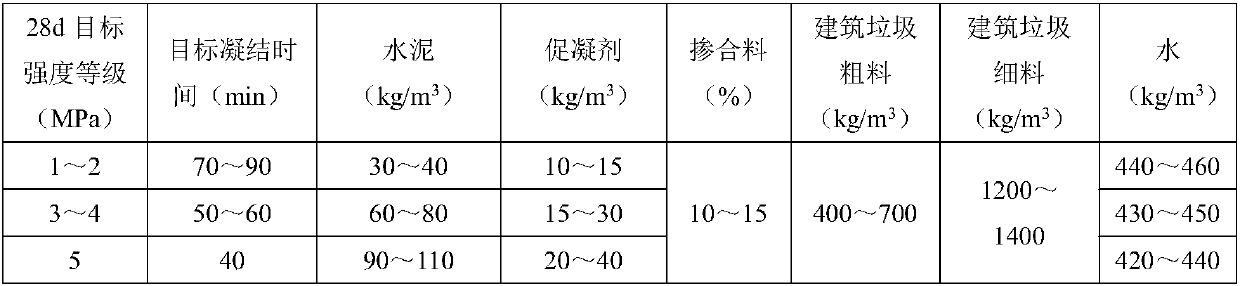

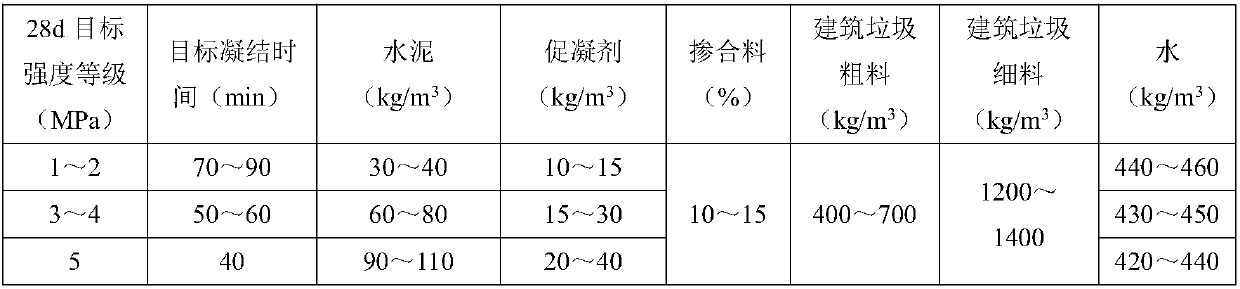

Road pipe trench quick backfill material produced with building wastes and construction technology thereof

The invention discloses a road pipe trench quick backfill material produced with building wastes and a construction technology thereof. The backfill material is prepared by mixing a building waste renewable coarse material, a building waste renewable fine material, cement, sprayed concrete coagulator shrinkage reducing agent, admixture and water. Building waste renewable products are classified and managed strictly in specification and quality, and are treated with other engineering technologies, so that the material fully utilizes building waste renewable aggregates of various specifications,and meets the technological requirements of pipe trench backfill and requirement of quick setting and hardening at the same time; the hardened material is adjusted in mechanical strength according toengineering need, 2h strength adjustment range is 0.2-1.0MPa, and 28d strength adjustment range is 1.0MPa-6.0MPa. The material utilizes building waste renewable materials generated in city construction to the maximum degree and is quick hardening, early strengthening low-strength concrete suitable for backfilling of city road pipe trenches and grooving.

Owner:BEIJING UNIV OF TECH

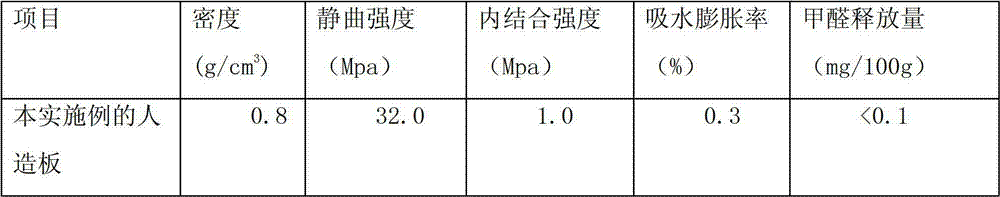

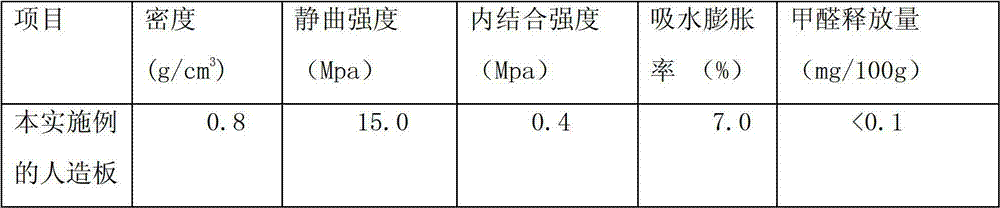

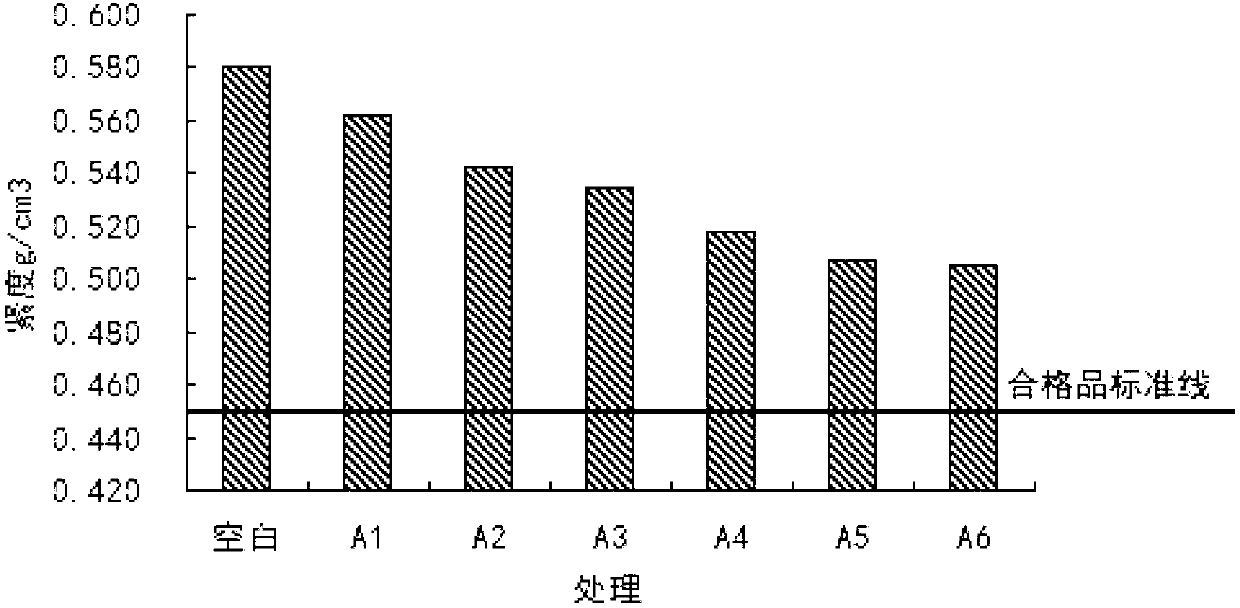

High-strength light plate material and manufacture method thereof

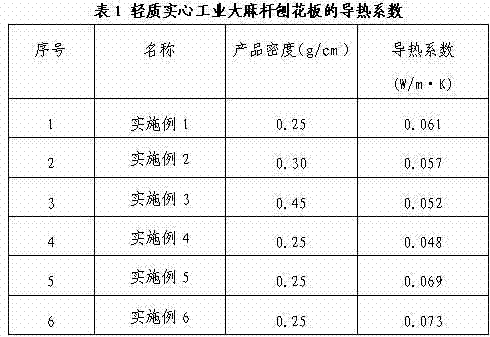

InactiveCN102218758AOvercoming the preparation of low density (0.25 ~ 0.45g/cm

<sup>3</sup>

) technical problems of lightweight materialsHigh mechanical strengthWood veneer joiningFlat articlesFiberPorosity

The invention discloses a high-strength light plate material and a manufacture method thereof. After industrial hemp stems are smashed into wood shavings or manufactured into fibers, 0.5-5% of adhesive is added, and then the high-strength light plate material is obtained after hot-pressing. In the technology, the light heat insulating material is prepared by using the characteristics of high strength, porosity and light weight of the industrial hemp stems. The product has the advantages of low manufacture cost, beautiful appearance, good heat insulating property, high mechanical intensity and good size stability, can be naturally degraded, is environmentally-friendly, is free from pollution and is convenient to realize industrial production. The high-strength light plate material can be used for replacing non-renewable materials, such as foamed plastics, perlite and the like. The high-strength light plate material can be widely used for the sandwich layer materials in fields such as wood structure buildings, partition walls, door planks and the like and can be used for light buffering materials, such as packaging cushion blocks and the like. The technology can change waste materials into things of value, provides a new path for applying industrial hemp stems, is favorable for popularizing the further development of the industrial hemp stem industry and has the advantages of good social benefit and economic benefit.

Owner:SOUTHWEST FORESTRY UNIVERSITY +1

Biodegradable and renewable film

A biodegradable and renewable film that may be employed in a wide variety of applications is provided. The film is formed from a thermoplastic composition that contains at least one starch and at least one plant protein. Even at a high renewable material content, the present inventors have discovered that films may be readily formed from plant proteins and starches by selectively controlling the individual amount of the starch and plant proteins, the nature of the starch and plant proteins, and other components used in the film. Balancing the amount of starches and plant proteins within a certain range, for instance, can reduce the likelihood of plant protein aggregation and enhance the ability of the composition to be melt processed. The composition also contains at least one plasticizer that improves the thermoplastic nature of the protein and starch components. The selection of the plasticizer may also help reduce the tendency of the plant protein to aggregate during melt processing. For example, a relatively acidic plasticizer (e.g., carboxylic acid) may be employed in certain embodiments to minimize the formation of disulfide bonds in a gluten protein, and thereby decrease its tendency to aggregate.

Owner:KIMBERLY-CLARK WORLDWIDE INC

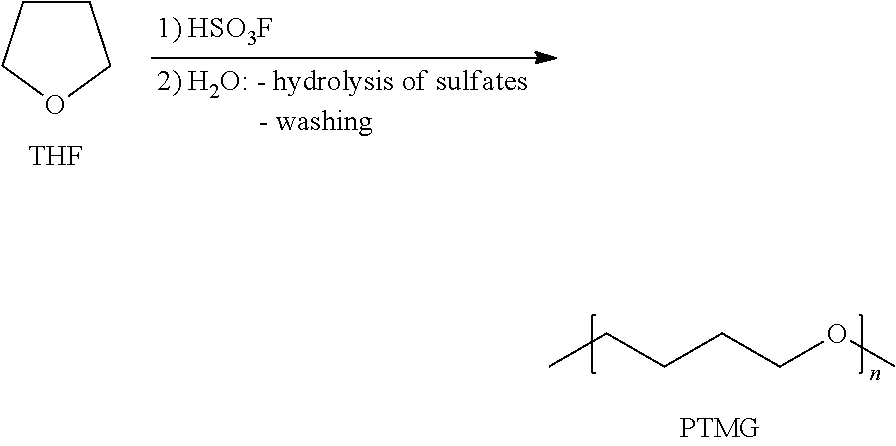

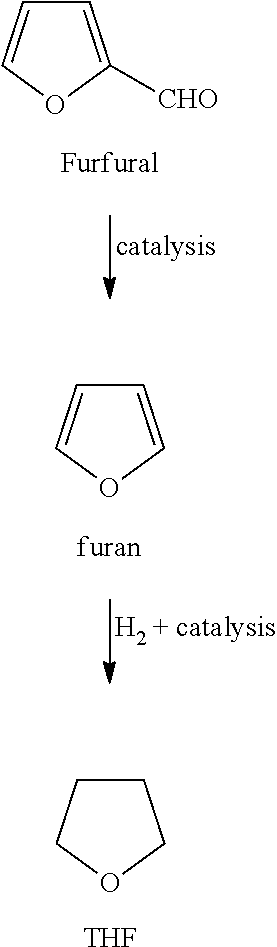

Block copolymer derived from renewable materials and method for making such block copolymer

ActiveUS20110183099A1Reduce and even completely eliminate consumptionEmission reductionSynthetic resin layered productsWoven fabricsPolymer scienceRenewable materials

The present invention relates to a block copolymer derived from at least one tetrahydrofuran monomer containing 14C. The present invention also relates to a method for preparing such a block copolymer.”

Owner:ARKEMA FRANCE SA

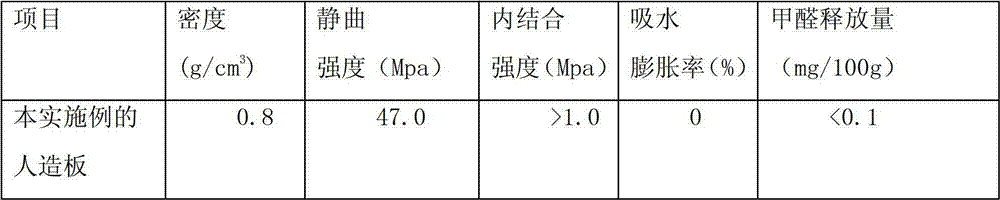

Bio-enzyme modified plant protein base timber adhesive and preparation method thereof

InactiveCN103709990AWidely plantedNot harmful to healthNon-macromolecular adhesive additivesProtein adhesivesHazardous substancePreservative

The invention discloses a bio-enzyme modified plant protein base timber adhesive and a preparation method thereof. The preparation method of the plant protein base adhesive is as below: conducting homogenization, pH adjusting, enzymolysis, pH readjusting and anti-corrosion treatment on the components of, by weight, 20-30 parts of biomass containing plant protein, 60-120 parts of water, 0.20-1.50 parts of biological enzyme, 0.3-0.8 part of acid, 0.2-2.0 parts of alkali and 0.24-1.10 parts of a preservative. The adhesive uses renewable material sources, contains no toxic or harmful substance, is green and environment-friendly, has water endurance bonding strength reaching the level of grade II adhesive (indoor), and can be used for manufacturing of various indoor man-made boards. The preparation method of the adhesive reduces the use of chemicals, and has the effects of energy saving and emission reduction; and the adhesive overcomes the problems of harm to the health of producers and users and environment pollution caused by chemicals in ordinary adhesive.

Owner:FUJIAN AGRI & FORESTRY UNIV

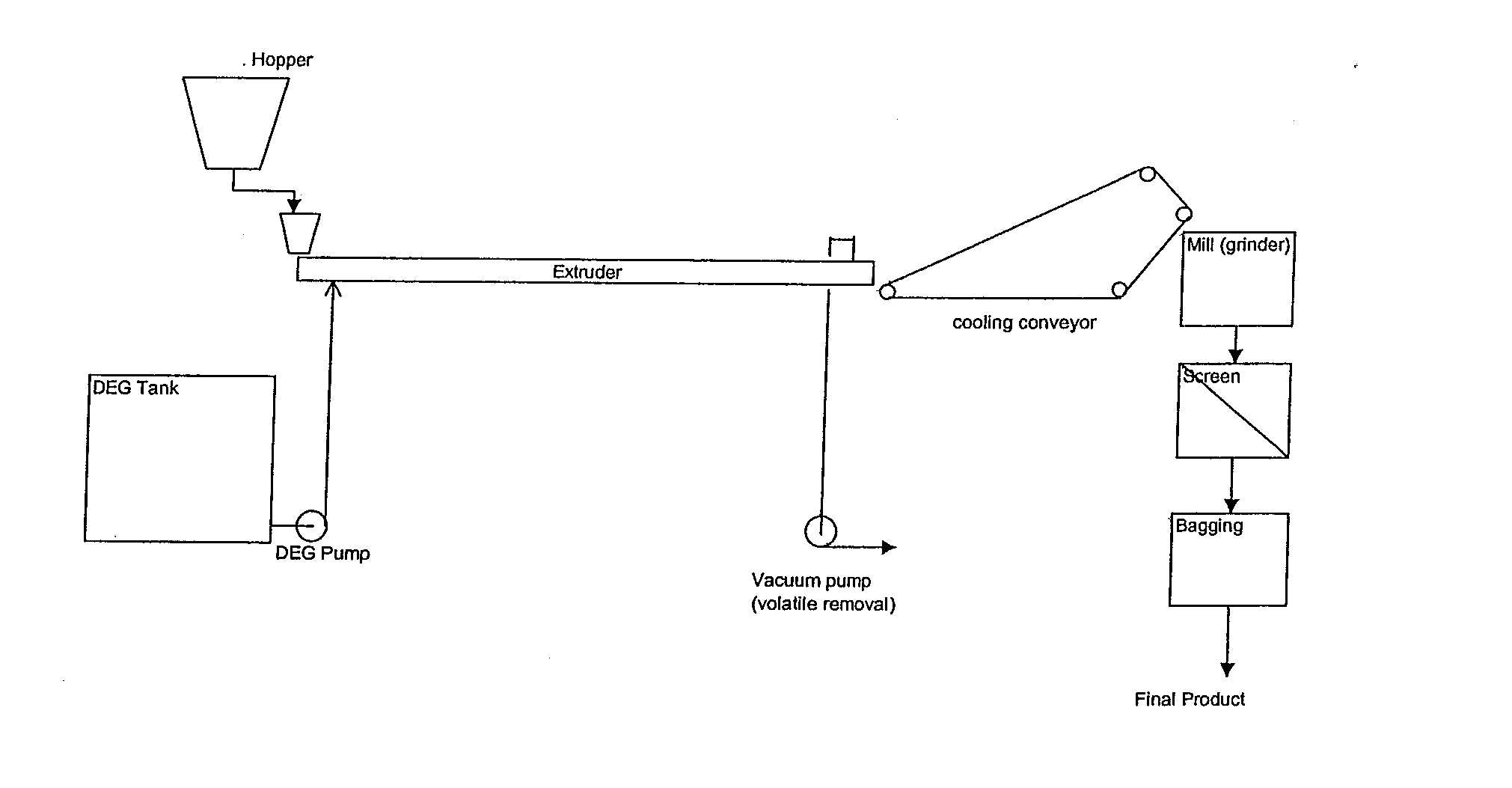

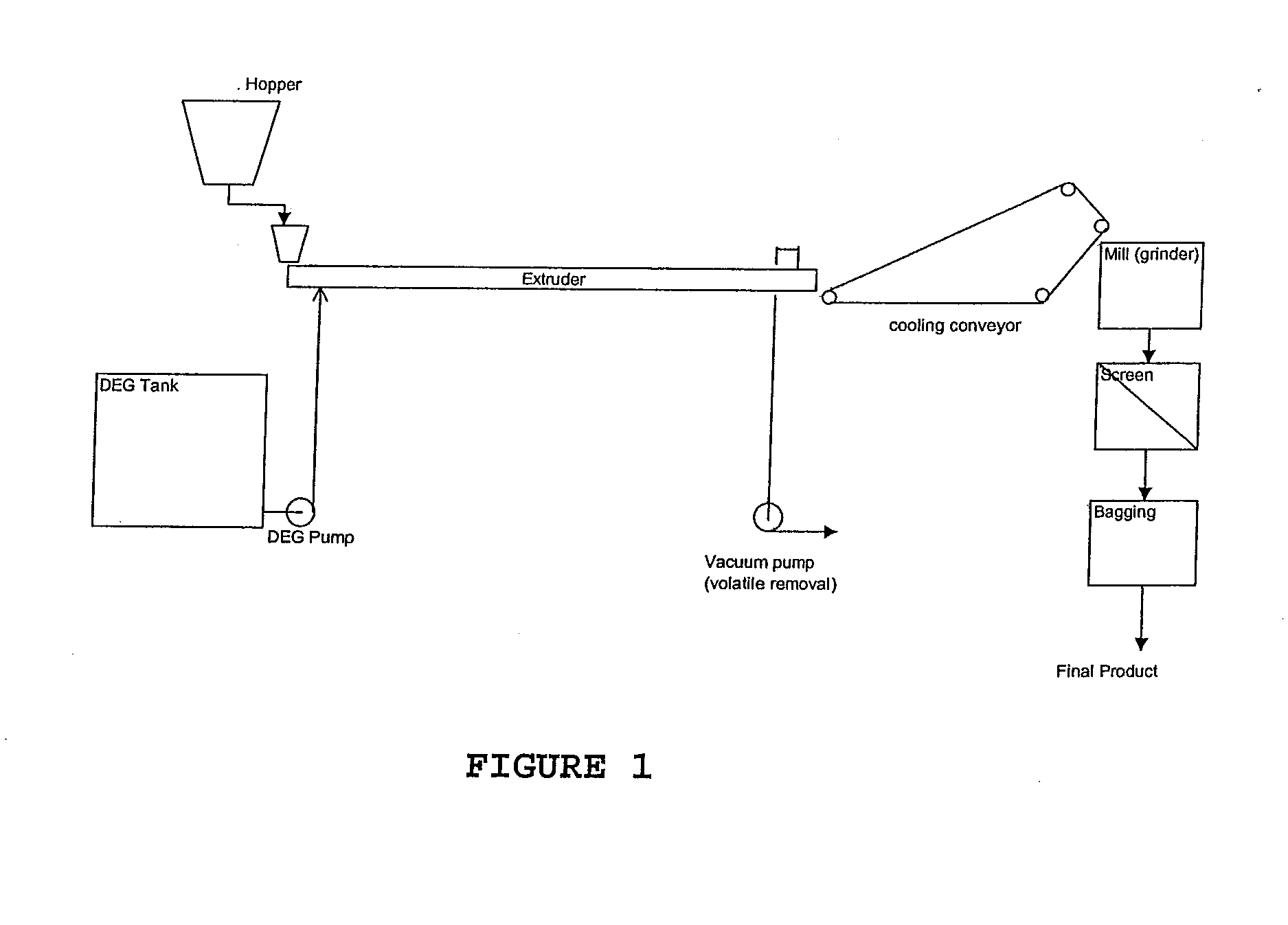

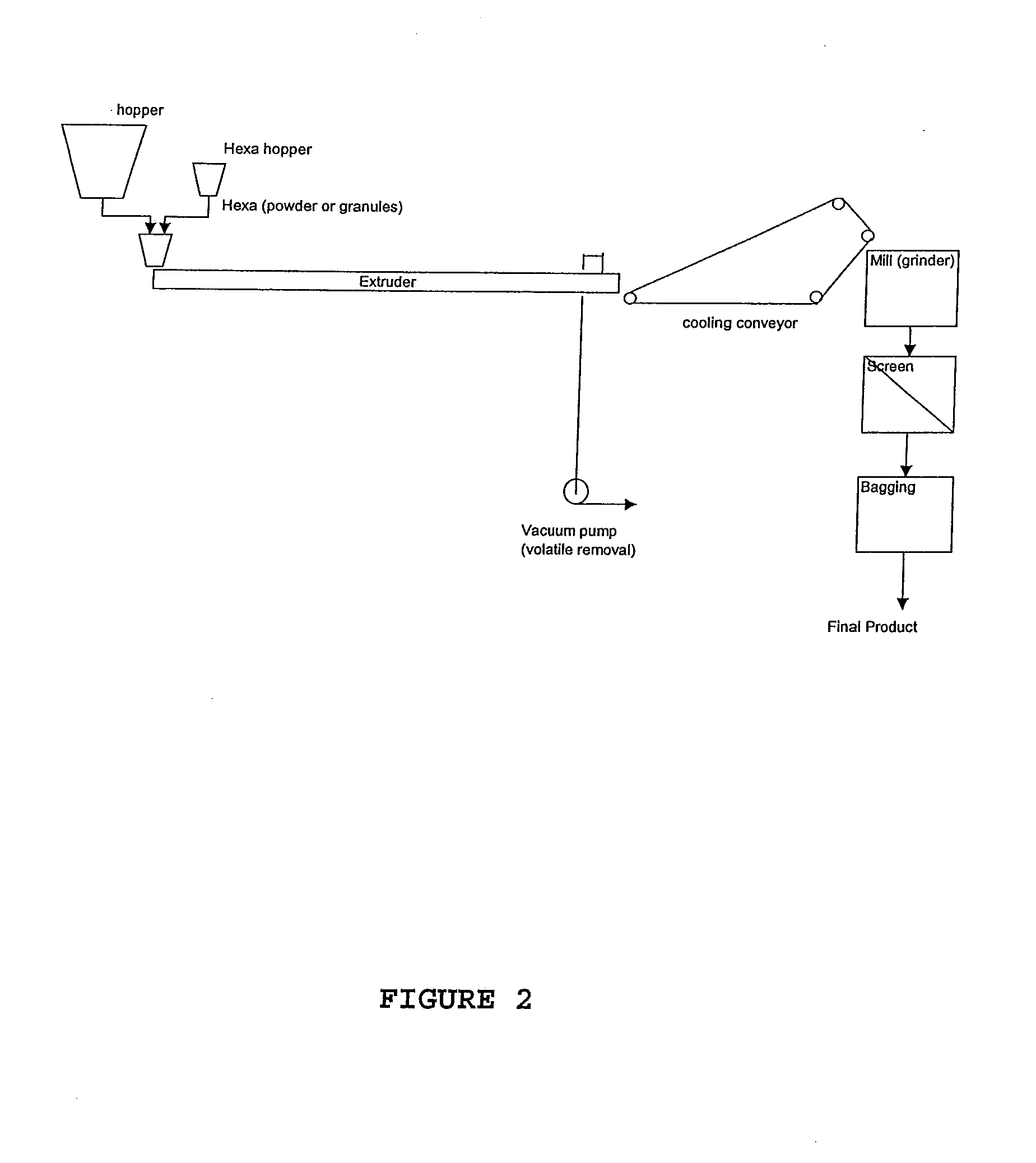

Biodegradable agricultural water retaining material and preparation method thereof

ActiveCN103145931ALarge specific surface areaImprove water absorptionAgriculture tools and machinesOrganic fertilisersAlcoholPolyol

The invention relates to a biodegradable agricultural water retaining material and a preparation method thereof. The biodegradable agricultural water retaining material comprises the following components in percentage by weight: 10-30 percent of biodegradable resin, 10-30 percent of a water-absorbing monomer, 0.1-1 percent of a radical initiator, 20-60 percent of a renewable material, 10-15 percent of polyhydric alcohol and 5-10 percent of water. The preparation method comprises the following steps: uniformly mixing various components in a mixer, extruding the materials in a twin-screw extruder, naturally foaming strips, performing air-cooling cooling, and finally granulating through a granulator, and crushing and screening to obtain porous water retaining particles. The biodegradable agricultural water retaining agent can be biodegraded, does not influence the components of soil, and is high in saline-alkaline resistance; and moreover, the preparation method is simple, vacuum is not required, the production efficiency is high, and the cost is low.

Owner:山东悦泰生物新材料有限公司

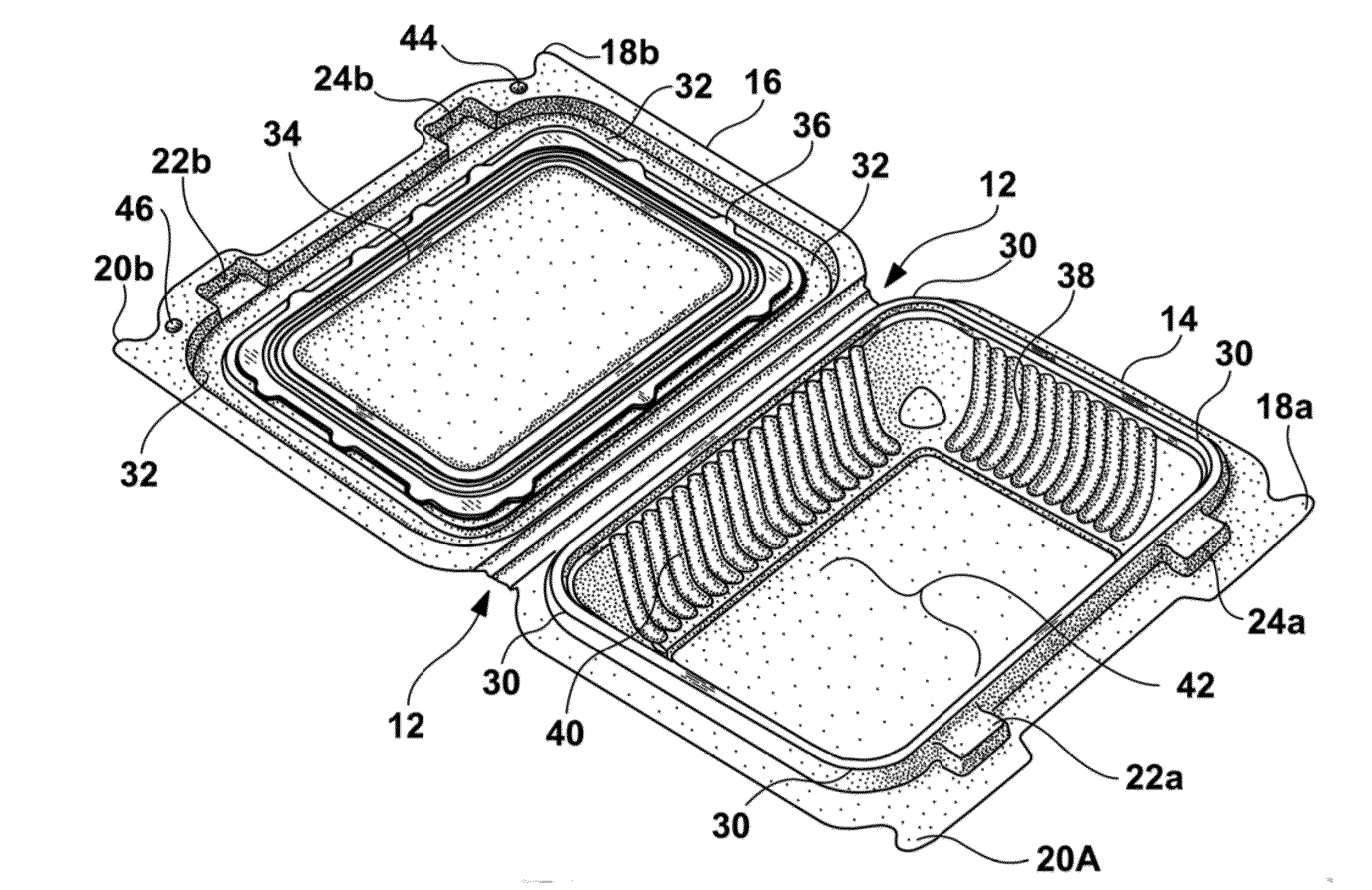

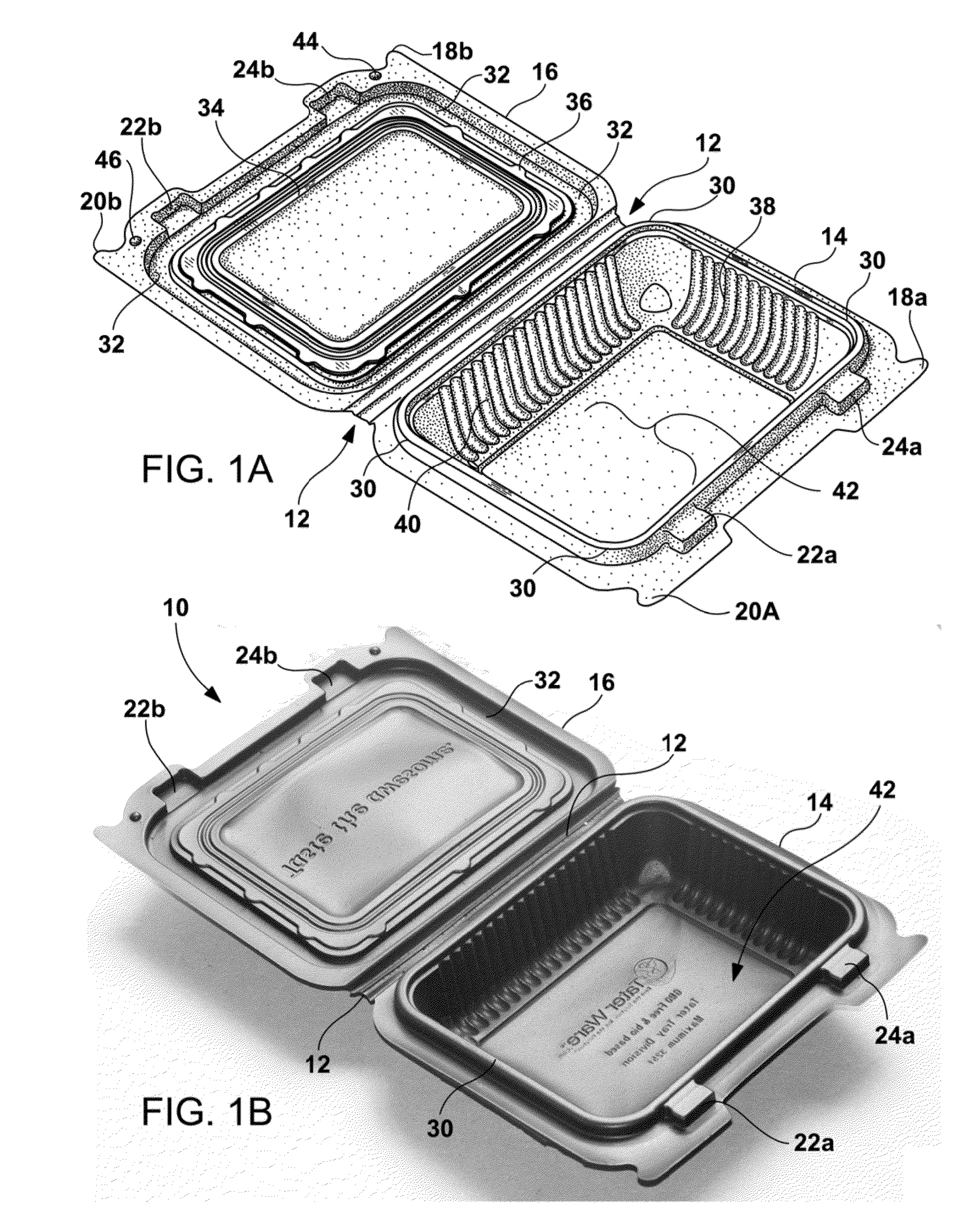

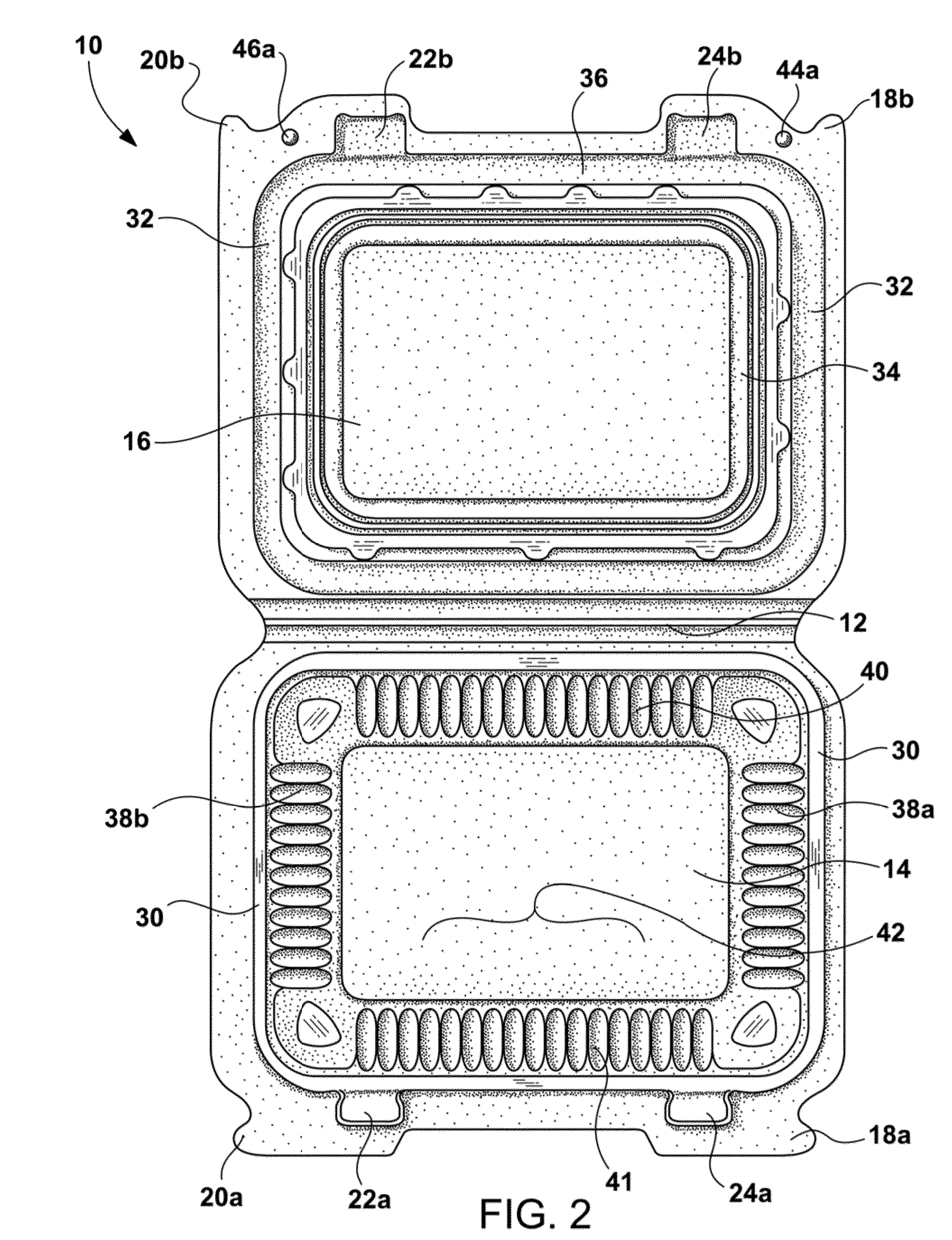

One-Piece Food Container having an Integral Hinge with Latching Mechanisms and a Full Perimeter Seal

InactiveUS20150069064A1Easy to separateResistant to bendingBio-packagingClimate change adaptationEngineeringSlurry

The present invention relates to a one-piece food container with an integral hinge and one or more latching mechanism, a full perimeter seal, and ribbed or ridged support structures. The food container is fabricated from hybrid bio-based and polymeric a material that has heat resistance capabilities. In particular, the present apparatus and method utilize a hybrid slurry of simple, abundant and renewable materials, such as food or plant starch and calcium carbonate (limestone), and a polymeric material, that uses high temperature and high pressure presses. An optional coating, such as wax, is applied to the surface of the food container. The present invention one-piece food container has a plurality of ridges that are incorporated into the container to provide rigidity and resisting folding or bending. Lastly, the one-piece food container with has enough rigidity and strength to be stackable for efficient storage for distribution to a user. The resulting one-piece food container is strong, light, heat-resistant, and attractive.

Owner:CHOICE FOODSERVICES

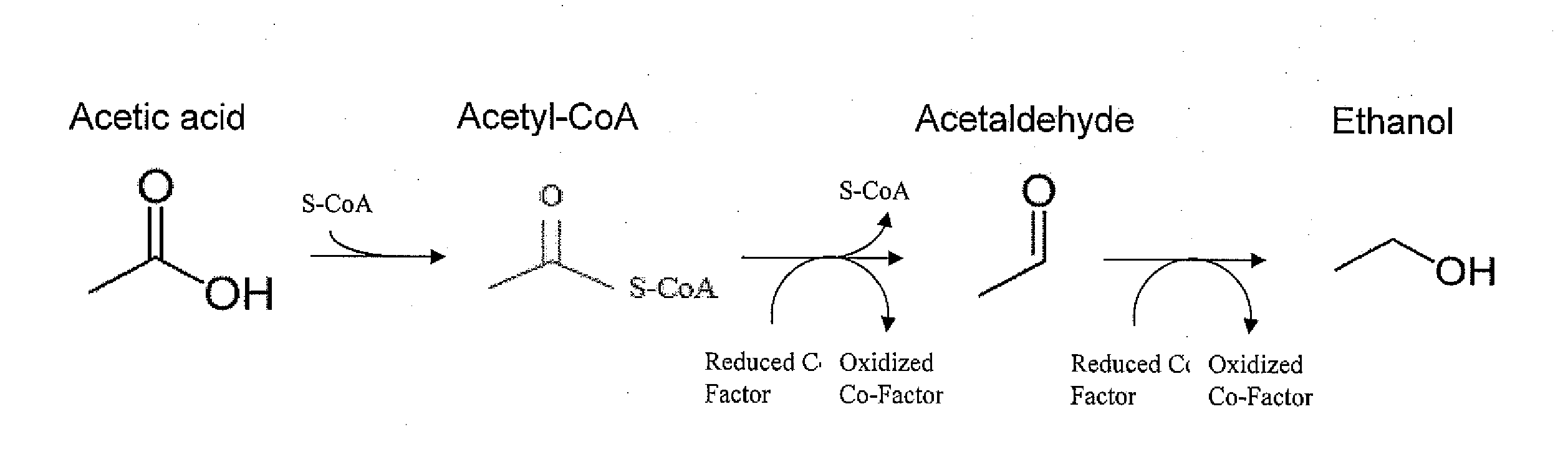

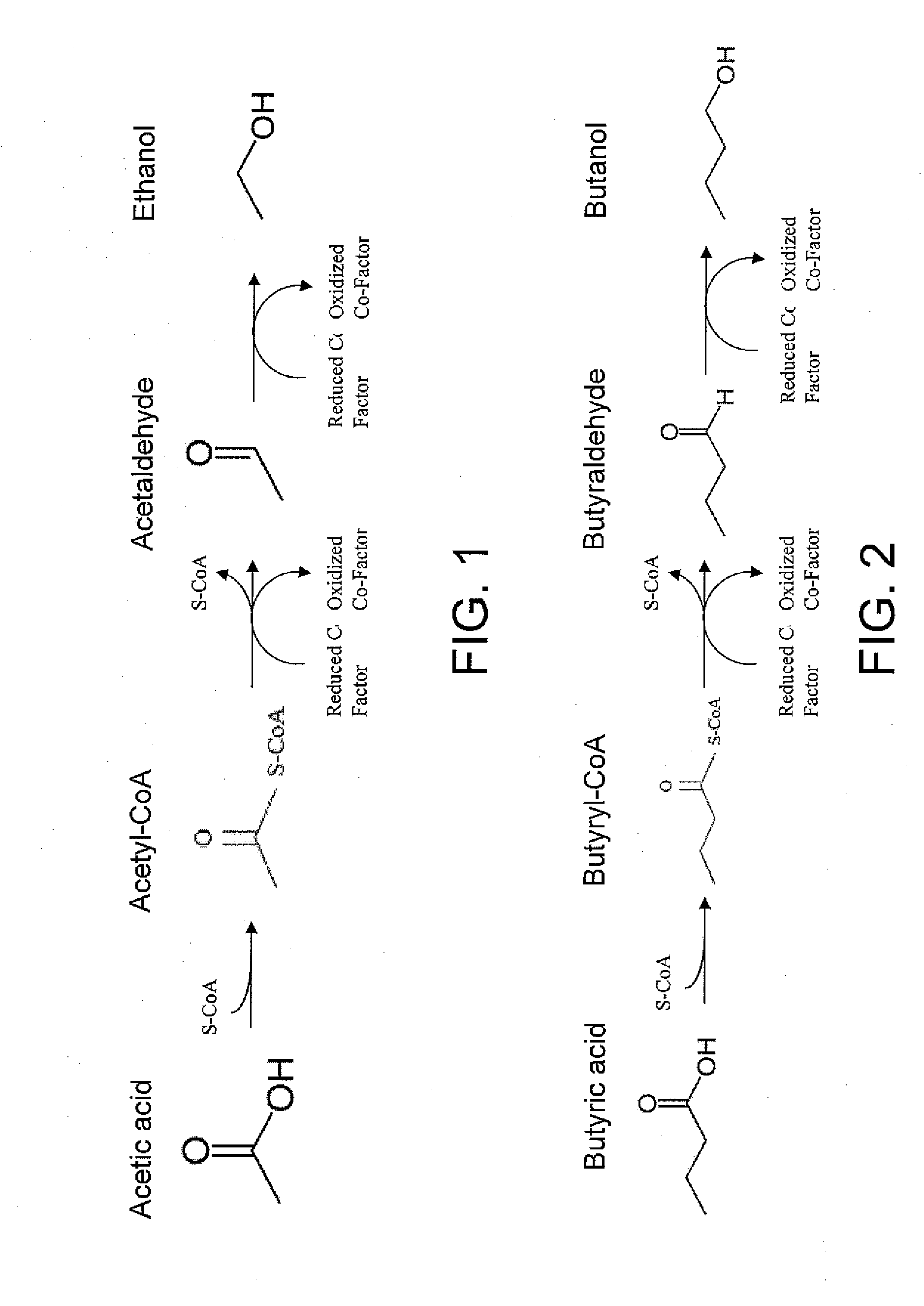

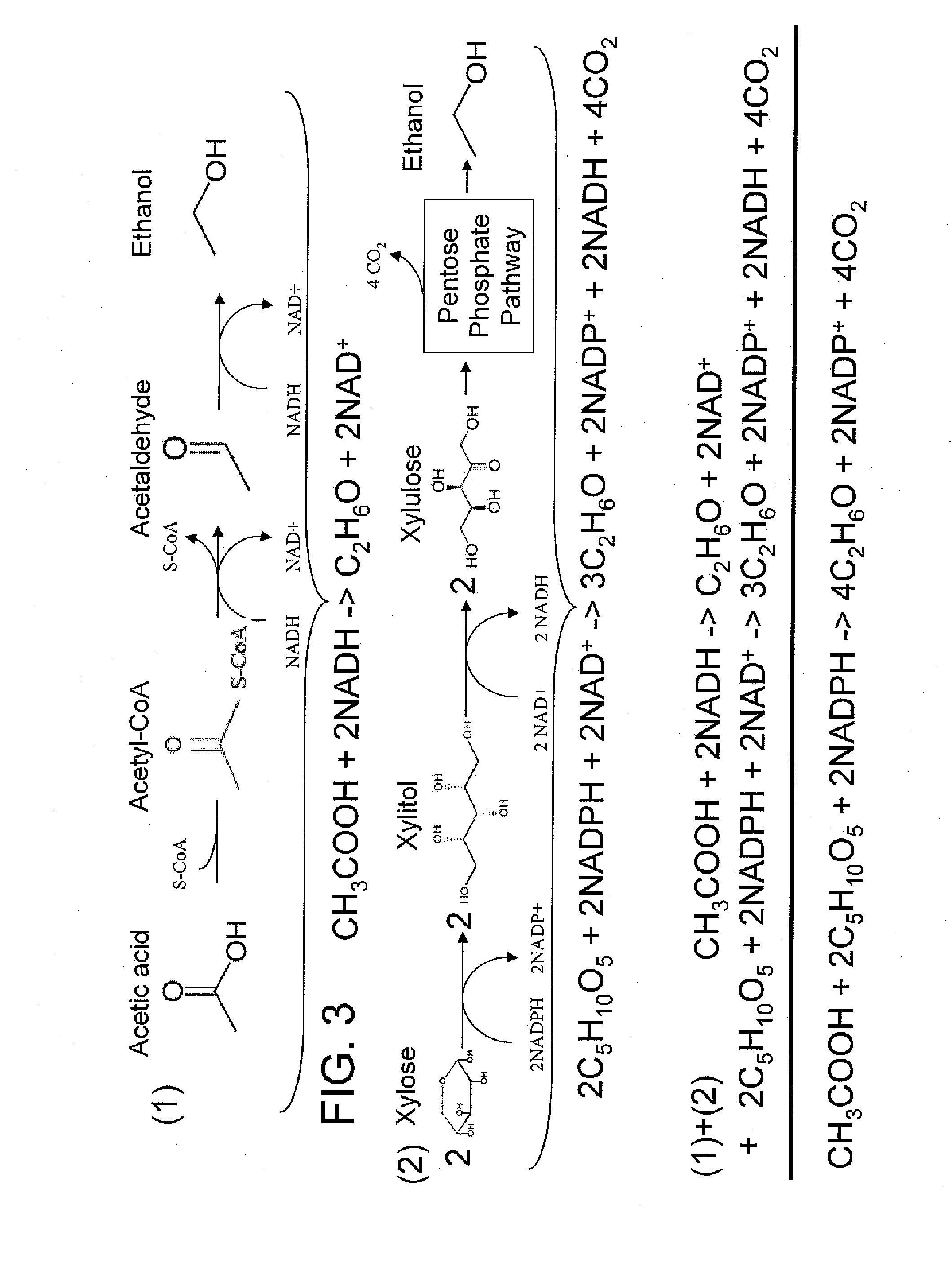

Methods and Apparatuses for Producing Renewable Materials From Inhibiting Compounds

InactiveUS20110137088A1Increase productionReduce wasteBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyRenewable materials

Renewable materials made from inhibiting compounds. A method includes the step of consuming a fermentation inhibiting compound with a biological organism, and the step of producing a renewable material with the biological organism from at least a portion of the fermentation inhibiting compound. The methods may include a net balance of cofactor production and consumption.

Owner:BP CORP NORTH AMERICA INC

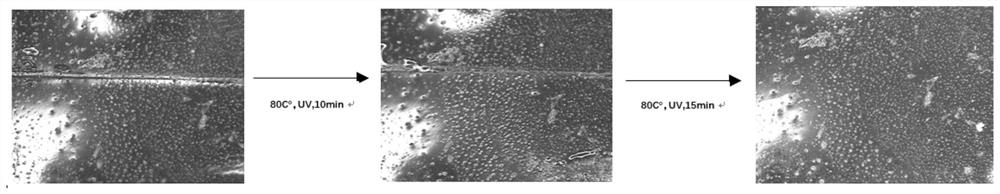

Bio-based polyurethane with photo-thermal dual-repairing function and preparation method thereof

The invention belongs to the technical field of preparation of degradable bio-based functional materials, and particularly relates to bio-based polyurethane with a photo-thermal dual-repairing function and a preparation method thereof. According to the invention, disulfide bond-containing small molecular alcohol or amine and cycloaddition monomer coumarin are introduced into a polyurethane system,and the disulfide bond-containing small molecular alcohol or amine and cycloaddition monomer coumarin are used as a bio-based chain extender or an end-capping reagent, such that self-repairing performance and mechanical properties of the polyurethane system are improved. Meanwhile, a carbon photothermal conversion agent is introduced into the system, so that the bio-based polyurethane can realizea self-repairing function under heating or human-friendly multi-band illumination. The invention belongs to a self-repairing intelligent bio-based material, and a renewable material taking bio-basedpolyurethane with a photo-thermal dual-repairing function as a bio-based source is prepared. The method is mainly suitable for packaging materials, coatings, elastomers and other industries, the preparation process is simple and environmentally friendly, and the repairing effect is obvious and efficient.

Owner:CHANGZHOU UNIV

Manufacture of ethylene/carboxylic acid vinyl ester copolymers from renewable materials, copolymers obtained and uses

InactiveUS20110287204A1Synthetic resin layered productsHydrocarbon from oxygen organic compoundsAlcoholCarboxylic acid

The present application relates to a process for the manufacture of copolymers of ethylene and of at least one vinyl ester, comprising the following steps: a) fermentation of renewable starting materials so as to produce at least one alcohol comprising ethanol; b) dehydration of the alcohol obtained so as to produce at least one alkene comprising ethylene and, optionally, purification of the alkene so as to obtain ethylene, c) copolymerization of the ethylene with at least one vinyl ester, d) isolation of the copolymer obtained. The application also relates to the copolymers of ethylene and of at least one vinyl ester in which the ethylene is at least partly obtained from renewable starting materials, and to uses thereof.

Owner:SK GLOBAL CHEM CO LTD

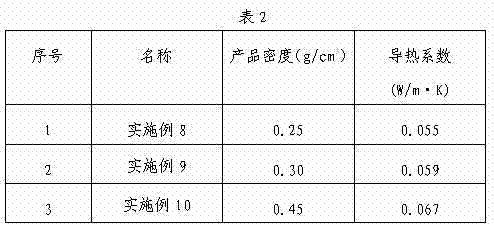

Method for strengthening wood beam

ActiveCN101956464AImprove bearing capacityRecover and increase strengthBuilding repairsGirdersRenewable materialsEnergy consumption

The invention relates to the field of construction engineering, in particular to construction strengthening and modification and discloses a method for strengthening a wood beam. The method for strengthening the wood beam comprises the following steps of: (1) performing surface evenness treatment on a stressed surface of the wood beam, scrubbing with acetone, and if a bottom face has a crack or recess, mending by adopting mending glue; (2) selecting bamboo chips which are treated by surface processing and are 3 to 7 millimeters thick, 10 to 25 millimeters wide and as long as the wood beam, and scrubbing with the acetone; and (3) coating base glue on the drawn face of the wood beam, adhering at least one layer of bamboo chips on the stressed surface of the wood beam by using structural glue and pressing to ensure that the bamboo chips, the structural glue and the wood beam are bonded compactly. The method can effectively avoid dismantling the original structure, guarantee the bearing capability and durability of the wood beam and meet the subsequent use requirements. The bamboo chip is a regenerative material and has high anti-drawing strength, so that the resource and energy consumption of the construction strengthening and modifying industry can be effectively reduced by using the bamboo chips to strengthen the wood beam.

Owner:上海建科预应力技术工程有限公司

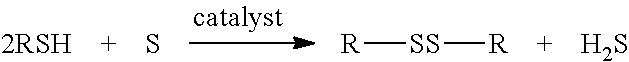

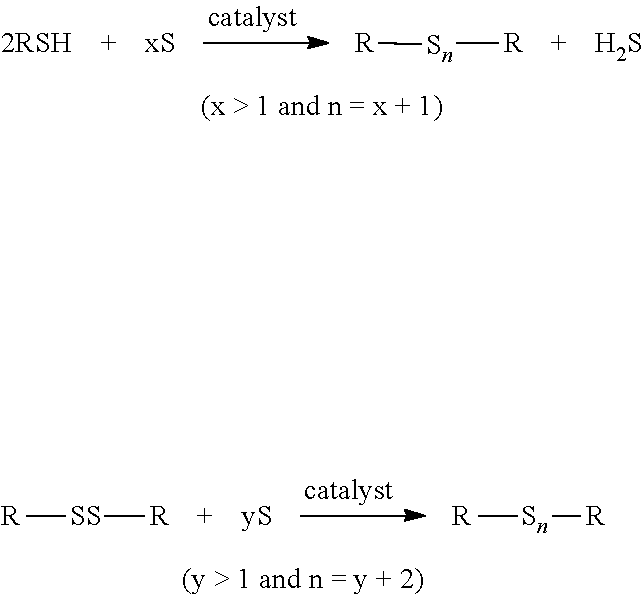

Dimethyl Disulphide Derived at least partially from Renewable Materials

ActiveUS20110172138A1Cosmetic preparationsOrganic compound preparationRenewable materialsDimethyl disulphide

Owner:ARKEMA FRANCE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com