Stone-plastic wood floor and processing technology thereof

A processing technology, wood flooring technology, applied in the direction of construction, building structure, floor, etc., can solve the problems of slippery and easy to fall on the ground, high processing costs, high cost, etc., to achieve convenient installation, soft and comfortable feet, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

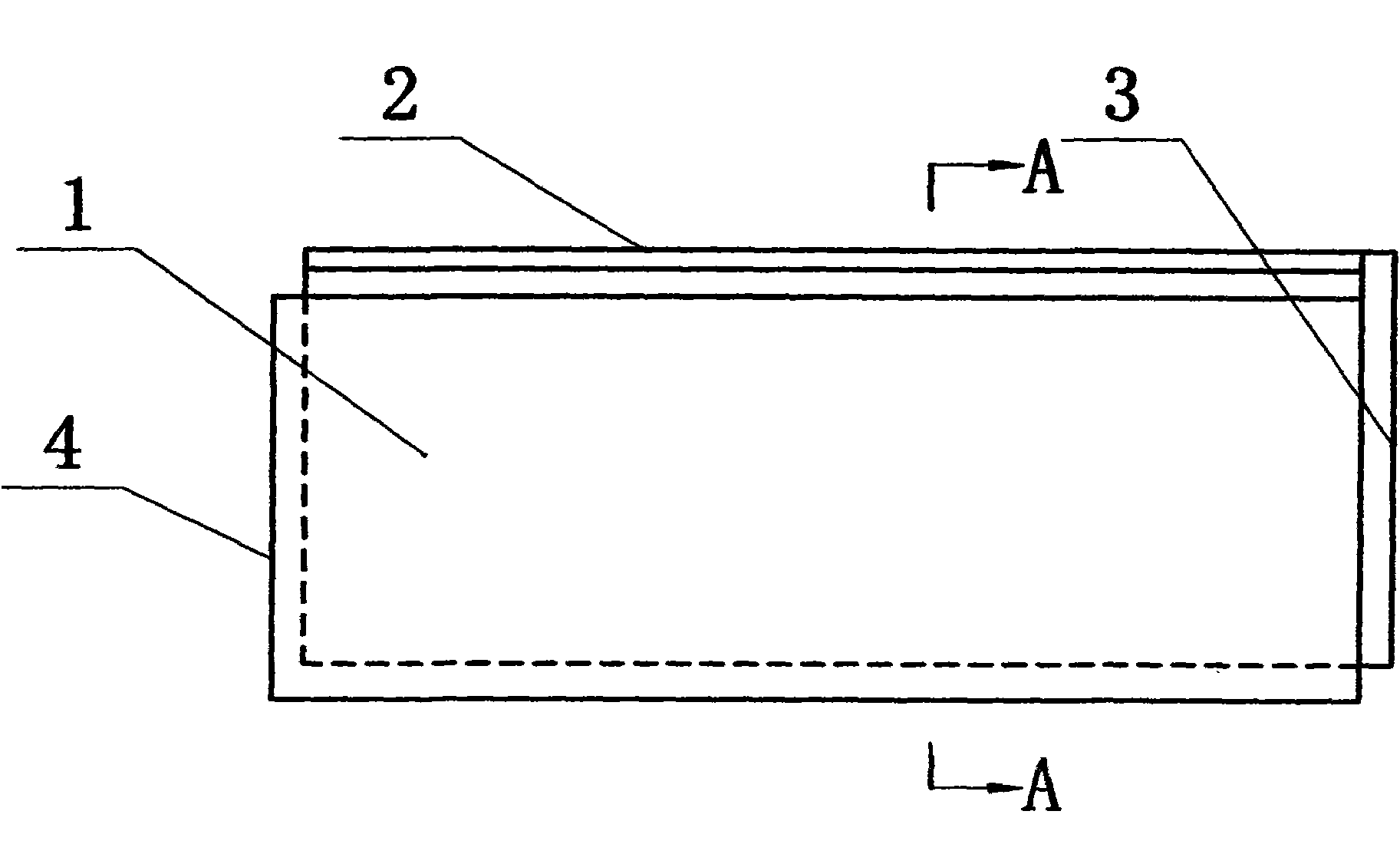

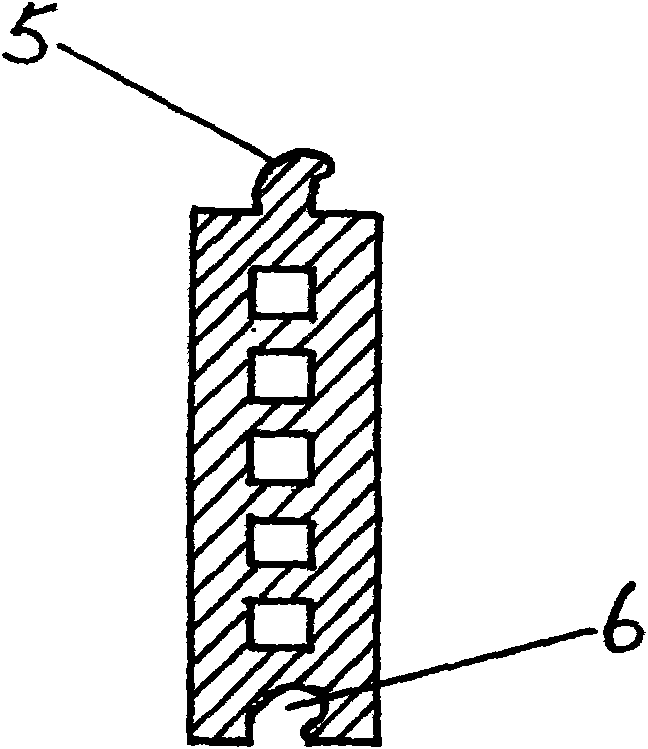

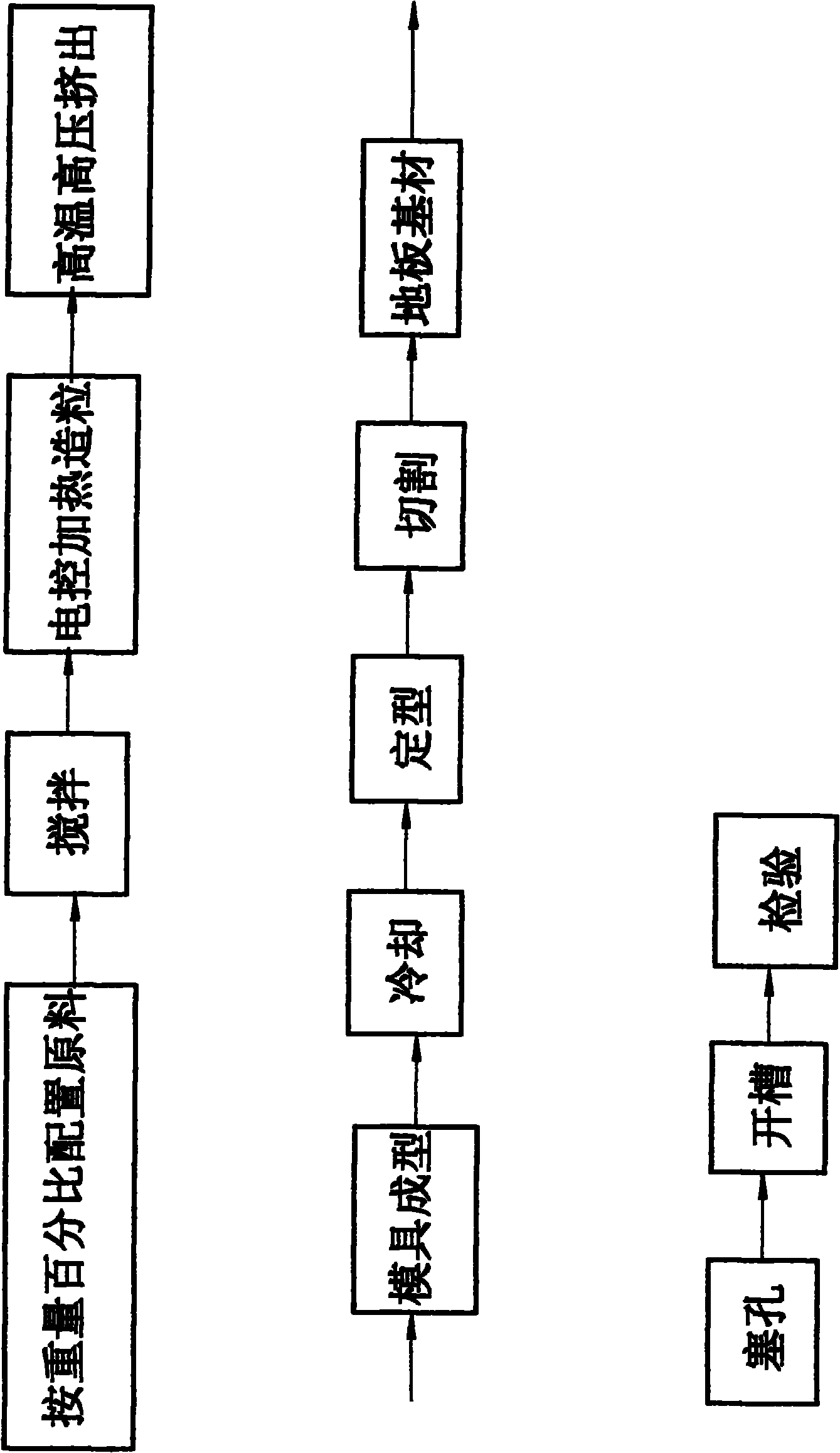

[0016] Embodiment, as a preferred mode, the floor is made up of the weight percentages of the following ingredients: natural calcium carbonate 30% fineness 500 mesh, recycled plastic powder 40% fineness about 40 mesh, wood fiber powder 27% fineness 80 mesh, ACR sticky 1% mixture, 2% composite stabilizer modifier, adhesive and modifier are all purchased in the market, and the raw materials of each component are taken in proportion and stirred for 30 minutes. The stirring temperature is about 130°C. Then granulate, the granulation time of every 50 kg of mixture is 40 minutes, the temperature of the granulator is about 190 ℃, and the particle size is 3-6mm. It is then extruded through an extruder, and the extrusion temperature is about 200°C. Then use a mold to shape it and then cool it to form a floor substrate. The floor substrate goes through plug hole-grooving-sanding-soil filling-dust removal-printing-UV environmental protection and wear-resistant paint coating-curtain cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com