Floor mounting bottom pad and its construction method

A construction method and flooring technology, applied in the direction of floors, buildings, building structures, etc., to achieve the effect of low cost, high compressive performance, and full toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The performance index of EVA sheet is shown in the table below.

[0021] characteristics

Embodiment 2

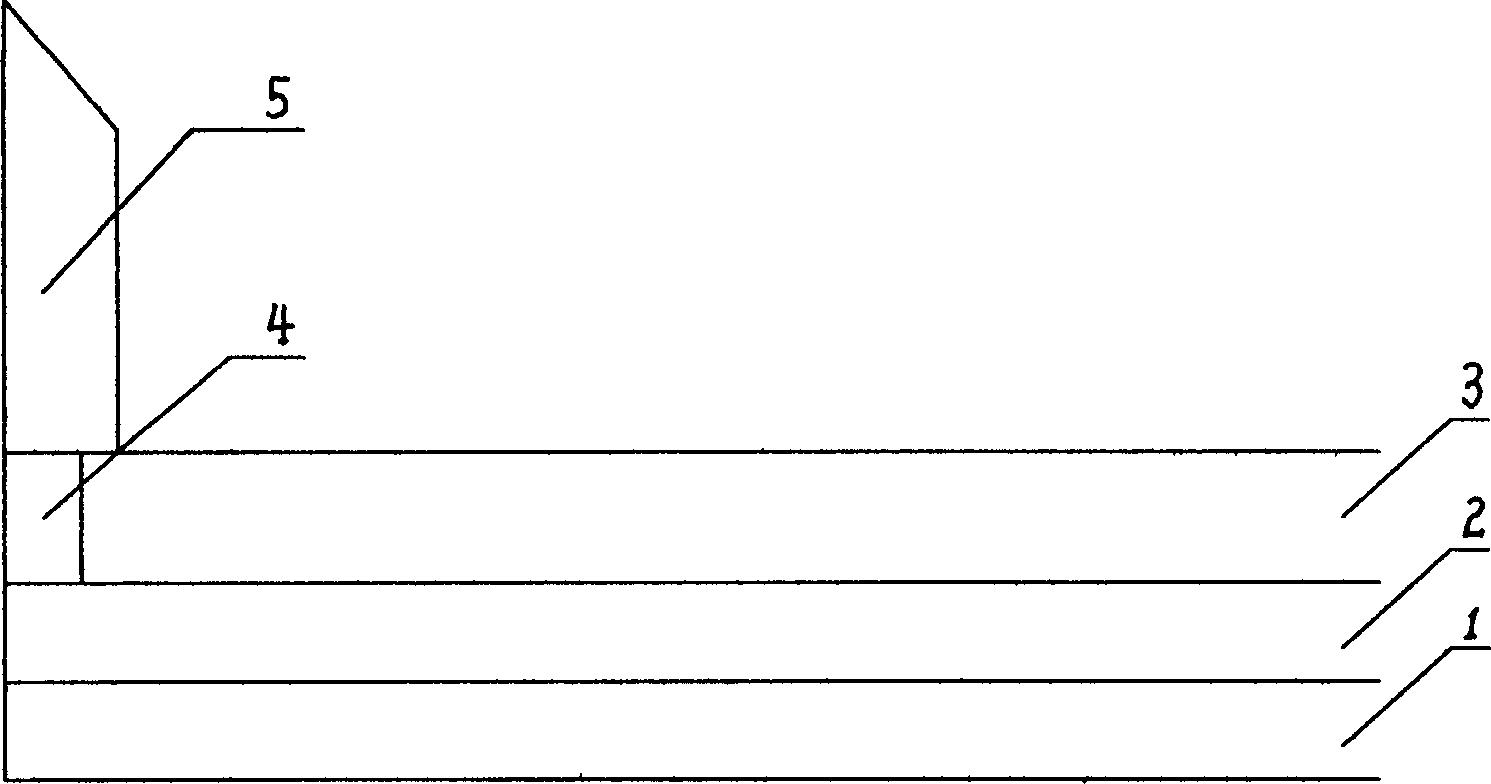

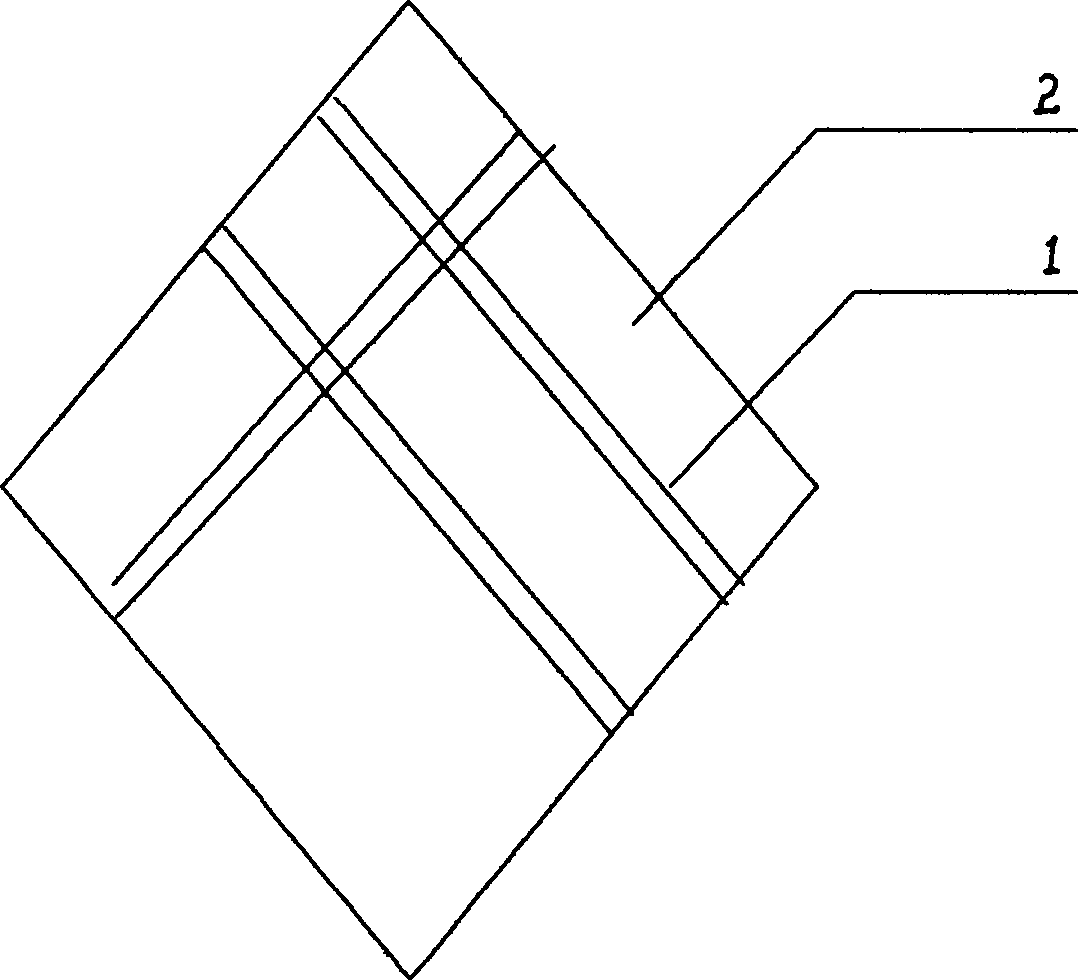

[0023] For the construction method of installing the floor with the EVA floor installation base pad, please refer to figure 1 , figure 2 . figure 1 Among them, 1 is the cement floor, 2 is the EVA floor pad, 3 is the wooden floor, 4 is the tightening strip, and 5 is the baseboard. figure 2 1 is tape, 2 is EVA floor mat. The wooden floor is solid wood floor, composite floor, solid wood composite floor, cork floor or bamboo floor, and the thickness of the EMA board is 2mm-30mm.

[0024] The construction method includes the following steps:

[0025] 1. Slightly level the ground and clean it.

[0026] 2. Lay the EVA floor installation bottom pad directly on the concrete floor.

[0027] 3. Reserve an expansion edge on the wall and start laying the floor.

[0028] 4. After the paving of the whole room is completed, use the EVA floor to install the bottom cushion and cut the edge material into small strips to make tightening strips and insert them into the expansion edge, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com