Multi-functional mildew-proof pad

An anti-mildew mat and multi-functional technology, applied to carpets, insulation layers, etc., can solve problems such as inconvenient installation, high cost, and singleness, and achieve the effects of improving dimensional stability, improving quality of life, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

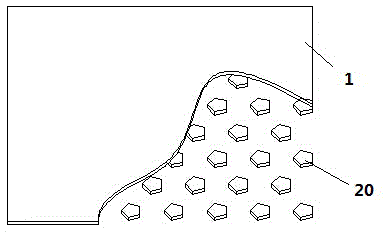

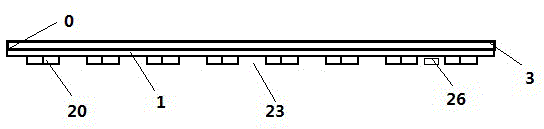

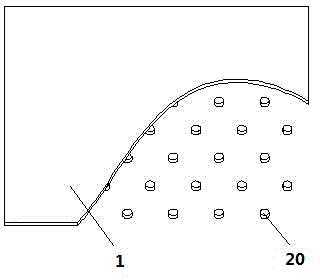

[0065] The multifunctional anti-mildew mat comprises a sound insulation layer 1 and a plurality of support units 20 positioned below the sound insulation layer 1; the gap formed between the support units 20 constitutes a channel 23; the width of the support unit 20 is 4mm; the height of the support unit 20 is 1.5mm ; The spacing between adjacent support units 20 is 4mm; the thickness of the sound insulation layer 1 is 1.5mm. The sound insulation layer 1 adopts a fully open-pore EPDM foam sponge layer, and the supporting layer adopts a half-open-pore PVC foam material layer.

[0066] When installing and using, take the following steps:

[0067] 1 Make sure the ground is flat and level, clean and dry;

[0068] 2 Turn the sound insulation layer 1 of the mat upwards, press it tightly to remove water vapor; lay the floor on the mat;

[0069] 3 Reserve a 1.5mm circulation gap between the floor 4 and the wall 5 or between the floor and the ground to provide air circulation.

[007...

Embodiment 2

[0083] The multifunctional anti-mildew mat comprises a sound insulation layer 1 and a plurality of support units 20 positioned below the sound insulation layer 1; the gap formed between the support units 20 constitutes a channel 23; the width of the support unit 20 is 10mm; the height of the support unit 20 is 10mm; The distance between adjacent supporting units 20 is 40mm; the thickness of the sound insulation layer 1 is 40mm. The sound insulation layer 1 adopts a closed-cell IXPE layer, and the supporting layer adopts a closed-cell polyethylene modified sound-proof material layer.

[0084] The preparation method of polyethylene modified sound insulation material comprises the following steps in sequence:

[0085] (1) Raw material preparation: 30 parts of polyethylene, 10 parts of zinc oxide powder, 8 parts of magnesium oxide, 10 parts of glass fiber, 0.8 parts of diisophenylpropylene peroxide crosslinking agent, 1 part of stearic acid active lubricant;

[0086] (2) Primary ...

Embodiment 3

[0094] The multifunctional anti-mildew mat comprises a sound insulation layer 1 and a plurality of support units 20 positioned below the sound insulation layer 1; the gap formed between the support units 20 constitutes a channel 23; the width of the support unit 20 is 1000mm; the height of the support unit 20 is 39mm; The distance between adjacent supporting units 20 is 500mm; the thickness of the sound insulation layer 1 is 30mm.

[0095] The sound insulation layer 1 adopts a closed-cell polyethylene modified sound insulation material layer, and the supporting layer adopts a semi-open EPDM foamed sponge layer.

[0096] The preparation method of polyethylene modified sound insulation material comprises the following steps in sequence:

[0097] (1) Raw material preparation: 75 parts of polyethylene, 40 parts of zinc oxide powder, 25 parts of magnesium oxide, 15 parts of glass fiber, 1.5 parts of diisophenylpropylene peroxide crosslinking agent, 2 parts of stearic acid active lubr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com