Patents

Literature

104results about How to "Widely planted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

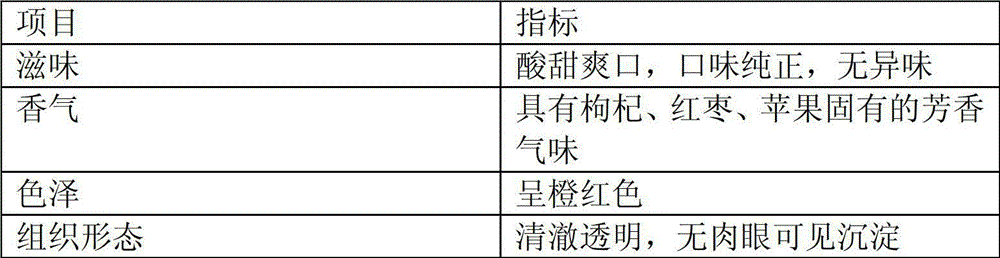

Medlar composite beverage and preparation method thereof

The invention relates to a medlar composite beverage which comprises 55% of medlar leach liquor, 8% of red date leach liquor and 12% of apple leach liquor. According to the invention, medlar with multiple health protection functions, red dates with rich vitamins and apples with special fruit flavor are complemented in nutrition and flavor so as to prepare the composite beverage which has unique flavor, and is sour and tasty, rich in nutrition and stable in property. According to the invention, boiling water is adopted for leaching, and effective ingredients in the raw materials can be utilized fully and effectively, so that on the one hand, the produced medlar composite beverage has functions of medical health protection and immune improvement of the medlar, on the other hand, the mouthfeel and the flavor of the beverage are enriched through the red dates and the apples, and the efficacies and nutritional values of the medlar beverage are improved, Meanwhile, the successful development of the medlar composite beverage provided by the invention not only provides a novel development direction for the research and development of the medlar beverage, but also opens a novel way for the development and utilization of medlar resources.

Owner:宁夏厚生记枸杞饮品股份有限公司

Tartary buckwheat tea and preparation technology thereof

InactiveCN102934710AExact health benefitsThe composition of the formula is reasonablePre-extraction tea treatmentBiotechnologyGreen teas

The invention discloses a tartary buckwheat tea and a preparation technology thereof. The tartary buckwheat tea is composed of 500 parts to 800 parts of tartary buckwheat cortex powder, 50 parts to 100 parts of tartary buckwheat extractives and 50 parts to 80 parts of green tea powder. The preparation technology of the tartary buckwheat tea includes steps of powder mixing, molding, drying and fragrance improving, the tartary buckwheat cortex powder, the tartary buckwheat extractives and the green tea powder are mixed uniformly until the color is uniform, and the mixture is stood for 20 minutes; uniformly mixed green tea is taken, 25% to 30% of water is added, the mixture is mixed uniformly by a pressurization molding machine and subjected to 30 meshes to be granulated; molded tartary buckwheat granules are placed in a plate and then in a hot air drying box, the granules are dried at a temperature ranging from 50 DEG C to 55 DEG C until the water content is less than 8%, then the dried granules are placed in a far infrared oven to be baked at a temperature ranging from 200 DEG C to 220 DEG C for 2 to 3 minutes and then cooled naturally; and the cooled tartary buckwheat tea is placed in a roller drying oven to be baked at a temperature ranging from 110 DEG C to 145 DEG C until the water content is no more than 5%.

Owner:太原市素有苦荞食品有限公司

Bio-enzyme modified plant protein base timber adhesive and preparation method thereof

InactiveCN103709990AWidely plantedNot harmful to healthNon-macromolecular adhesive additivesProtein adhesivesHazardous substancePreservative

The invention discloses a bio-enzyme modified plant protein base timber adhesive and a preparation method thereof. The preparation method of the plant protein base adhesive is as below: conducting homogenization, pH adjusting, enzymolysis, pH readjusting and anti-corrosion treatment on the components of, by weight, 20-30 parts of biomass containing plant protein, 60-120 parts of water, 0.20-1.50 parts of biological enzyme, 0.3-0.8 part of acid, 0.2-2.0 parts of alkali and 0.24-1.10 parts of a preservative. The adhesive uses renewable material sources, contains no toxic or harmful substance, is green and environment-friendly, has water endurance bonding strength reaching the level of grade II adhesive (indoor), and can be used for manufacturing of various indoor man-made boards. The preparation method of the adhesive reduces the use of chemicals, and has the effects of energy saving and emission reduction; and the adhesive overcomes the problems of harm to the health of producers and users and environment pollution caused by chemicals in ordinary adhesive.

Owner:FUJIAN AGRI & FORESTRY UNIV

Production method of pure silk quilt with jasmine flower fragrance

The invention provides a production method of a pure mulberry silk quilt with jasmine flower fragrance. The production method comprises the following steps: (1) putting matured silkworms on a spinning net; (2) stripping silk to obtain a crude soft piece; (3) degumming the crude soft piece; (4) cleaning with clean water and then dehydrating; (5) removing impurities, reshaping, and drying for later use; (6) picking and storing jasmine flowers; (7) taking the flowers and waiting for scenting; (8) parqueting and scenting by piling; (9) weighing the soft piece and pulling to be fluffy; (10) cutting the soft piece; (11) pulling the cut soft pieces open one by one, laying in a criss-cross manner, after laying is completed, checking and finishing, and removing impurities; (12) placing a silk-escape-preventing gauze above and below a finished soft bat respectively, so that silk escape is avoided; (13) covering the soft bat with a bat cover; and (14) quilting a seam between the bat cover and a silk floss bat and shaping. The mulberry silk quilt obtained by adopting the production method provided by the invention has no rib strip, no pupal fat and no chemical residue and is more natural and environment-friendly compared with the traditional silk quilt produced from silk floss; and the mulberry silk quilt has jasmine flower fragrance and also maintains the characteristics of the silk quilt of softness, breathability, closed fit and comfort.

Owner:GUANGXI GUIHUA SILK CO LTD

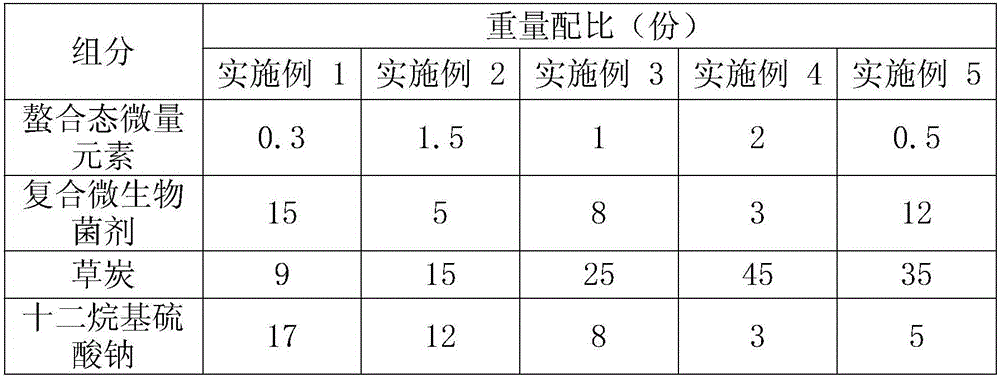

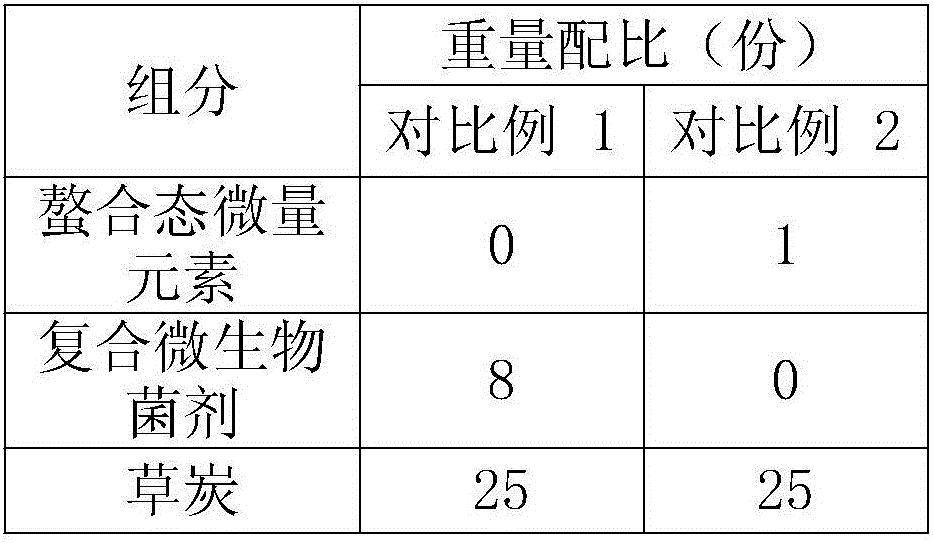

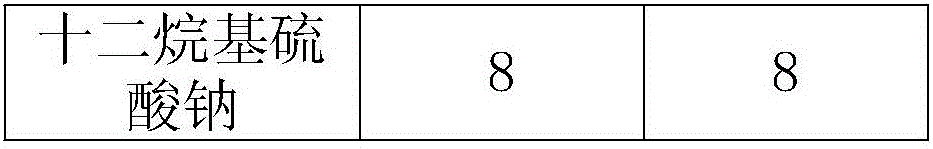

Cleating trace element containing microbial fertilizer and preparation method thereof

InactiveCN106810370AGuaranteed water solubilityIncrease profitBacteriaMicroorganism based processesOrganic farmingAzotobacter chroococcum

The invention relates to a cleating trace element containing microbial fertilizer and a preparation method thereof. The cleating trace element containing microbial fertilizer is prepared through the following raw materials in parts by weight: 0.3-2 parts of cleating trace element, 3-15 parts of compound microorganism bacterium agent, 9-45 parts of turf, and 3-17 parts of surfactant, wherein the cleating trace element includes zinc sulfate, ferrous sulfate, borax, copper sulfate, manganese sulfate and sodium molybdate; the compound microorganism bacterium agent comprises photosynthetic bacteria, azotobacter chroococcum, bacillus mucilaginosus and bacillus dephosphoria based on the volume ratio of 1: 2: 2: 2. With the adoption of the microbial fertilizer, the problems of low permeability, poor fertilizing and water preserving performance and high chemical fertilizer consumption caused by soil hardening in the prior art can be effectively solved; the absorption and utilization of crops to major elements such as nitrogen, phosphorus and potassium, and trace elements such as iron, manganese and copper can be obviously prompted. Therefore, the crop growing is improved; the crop quality is improved; the crop yield is increased; and as a result, the fertilizer is an ideal fertilizer for green agriculture and organic agriculture.

Owner:GUANGZHOU JUCHAN MODERN AGRI RES INST CO LTD

Corn beverage and processing method thereof

The invention relates to a maize beverage prepared from matured maize fruits as raw material, and processing method thereof, the maize beverage includes clean extract beverage, mixed extract maize beverage and cured extract maize beverage, wherein the clean extract maize beverage includes 50%-60% of clean maize extract, 20%-30% of mineralized distilled water and 10%-20% of baste fruit extract, the mixed extract maize beverage includes 92% of filtered maize extract, 4% of cane sugar and 4% of baste fruit extract, the cured extract maize beverage includes 93% of squeezed maize extract, 4% of cane sugar and 3% of baste fruit extract. The advantages of the invention includes the preservation of various nourishing components in matured maize.

Owner:赵明信

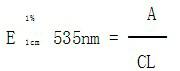

Preparation method of multi-tone beet red pigment

The invention relates to a preparation method of a multi-tone beet red pigment, and the preparation method is characterized in that fresh red beet is adopted as a raw materials to be continuously produced through the procedures of washing, slicing, extraction, filtering, column chromatography, color protection, concentration, color matching, ultrafiltration, microcapsulization, atomizing drying and mixed treatment, a beet red pigment product is obtained by utilizing a method combining a staging elution process of macroporous resin with a particular model number, pure water with particular electric conductivity and the mixed antioxidant, the color value of the beet red pigment product is more than or equal to 80, color tones include orange red (b: 14 to 8), pink (b: 8 to 5), true red (b: 5 to 0) and amaranth (b: 0 to 10). The beet red pigment has characteristics of light resistance, heat resistance, stability and the like. The beet red pigment is better than similar product standard both at home and abroad.

Owner:JIANGXI DANXIA BIOTECHNOLOGY CO LTD

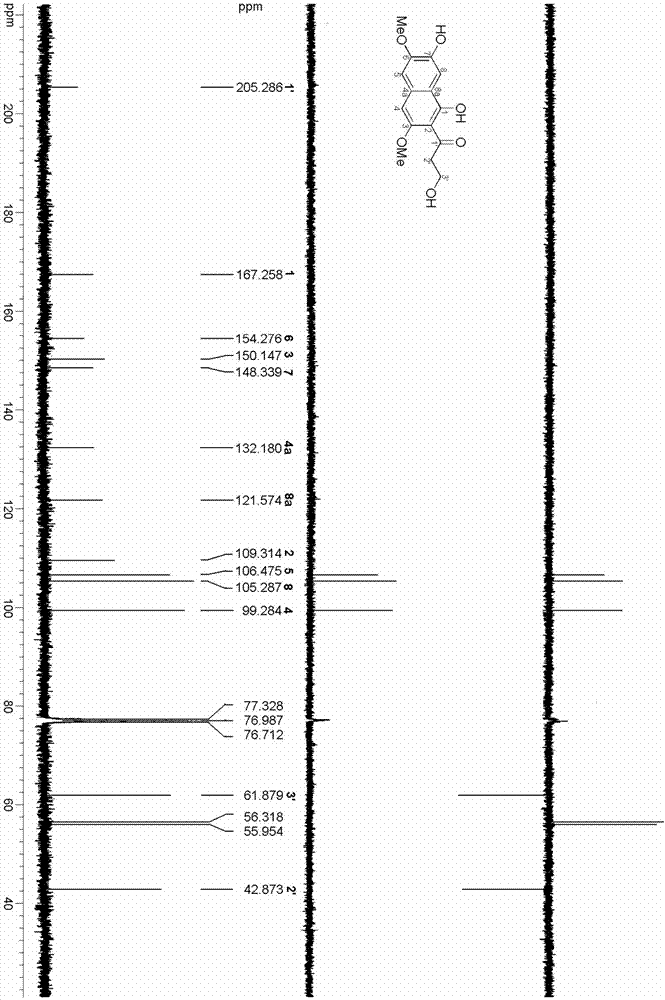

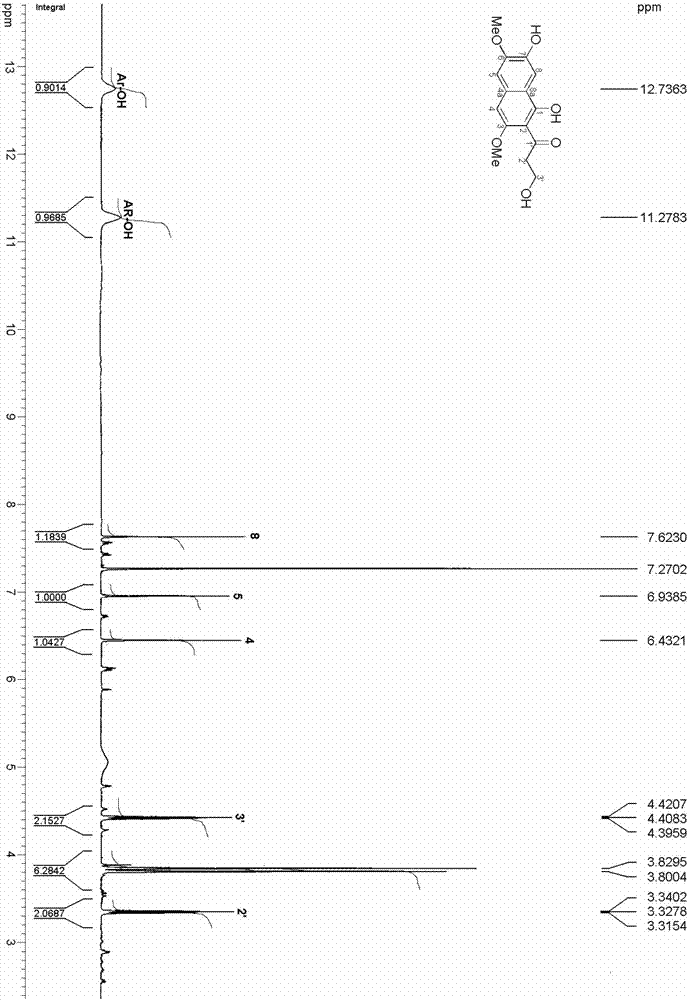

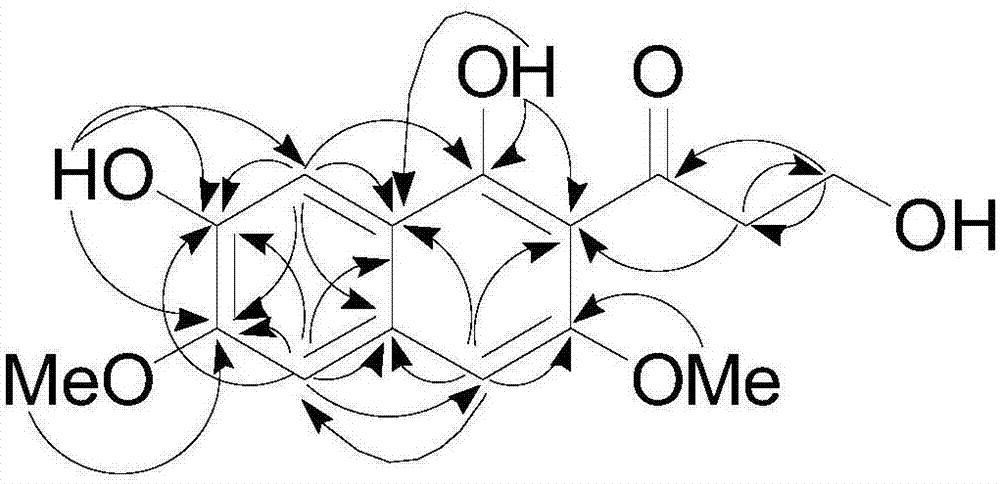

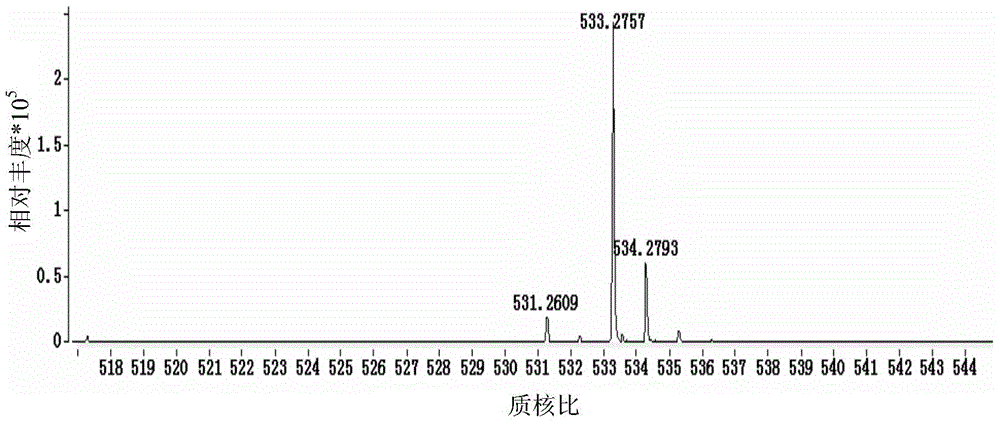

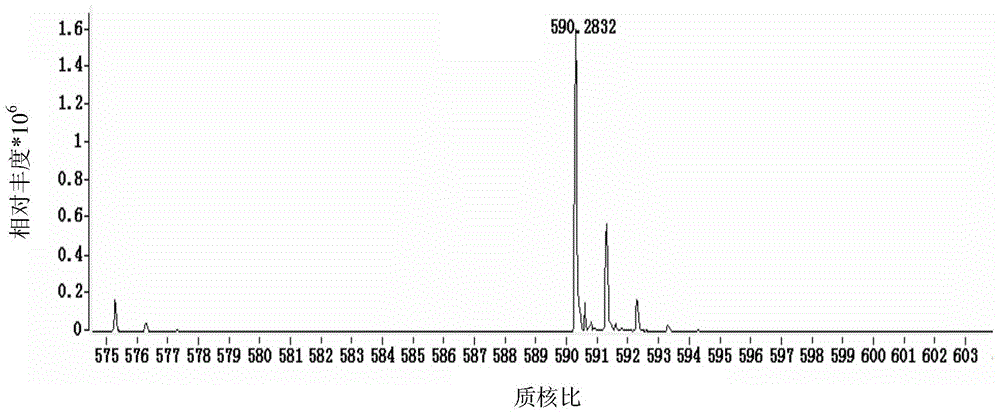

Multi-substituent-group naphthalene compound with antibacterial activity in aloe as well as preparation method and application of naphthalene compound

ActiveCN107501065AEdible with a long historyEasy to useTobacco treatmentCarbonyl compound separation/purificationChromatographic separationAntibacterial activity

The invention relates to a multi-substituent-group naphthalene compound with antibacterial activity in aloe as well as a preparation method and an application of the naphthalene compound and belongs to the chemical technical field of natural products. The structural formula of the compound is shown in formula (I) in the description. The compound is prepared from traditional edible and medicinal plant aloe as a raw material through extraction, silica gel column chromatography and high-pressure liquid-phase chromatographic separation and purification. Activity tests prove that the compound has a better antibacterial effect and can effectively inhibit growth of microorganisms in a feed liquid and prolong the expiration date of the tobacco feed liquid after being added to the tobacco feed liquid and has good application prospects.

Owner:CHINA TOBACCO YUNNAN IND

Tea leaf and sweet potato tip completely fermented formula black tea

ActiveCN103988945AWidely plantedSoup is red and thickPre-extraction tea treatmentAcute hyperglycaemiaSecondary hyperlipidemia

The invention discloses tea leaf and potato tip completely fermented formula black tea which is composed of tea leaves and sweet potato tips, wherein the tea leaves account for 3-8.5 parts by weight and the sweet potato tips account for 1.5-7 parts by weight, totaling 10 parts by weight. The formula black tea is sequentially prepared by processes of withering, twisting, fermenting and drying. The formula black tea disclosed by the invention avoids an industry prejudice that astringency of the black tea prepared by mixing the tea leaves and the potato tips is more intense, and the black tea prepared is completely free from astringency; the black tea prepared by the two formulas is intense and bright in liquor color, mellow and sweet in taste, and completely free from astringency of current black tea; after long-time consumption, the black tea is significant in effect of regulating hyperlipidemia, cholesterol and hyperglycemia, and the effect is apparently higher than an effect of only drinking the current black tea . The formula black tea disclosed by the invention is simple in preparation method, low in cost and easy in realizing mass production.

Owner:WUHAN MULAN LVDAO TEA IND

Glossy ganoderma fagopyrum tararicum tea and preparation technology thereof

The invention discloses a glossy ganoderma fagopyrum tararicum tea and a preparation technology thereof. The fagopyrum tararicum tea is formed by 500-850 parts of fagopyrum tararicum cortex powder, 150-500 parts of glossy ganoderma powder, 50-100 parts of folium mori powder, 20-70 parts of fagopyrum tararicum extracts, 2-10 parts of guar gum, 2-10 parts of xanthan gum and 2-10 parts of konjac glucomannan. The preparation technology includes steps of powder mixing, forming, drying and aroma raising, detailedly, first evenly mixing the fagopyrum tararicum cortex powder, the glossy ganoderma powder, the folium mori powder, the fagopyrum tararicum extracts, the guar gum, the xanthan gum and the konjac glucomannan until the color is uniform and standing for 20 minutes; then adding 25%-40% of water into the evenly mixed tea powder, blending evenly through a pressure forming machine, sieving the tea powder through a 30-mesh sieve, and granulating; filling a disk with formed fagopyrum tararicum tea particles, placing in a hot air drying oven, drying at 50-55DEG C until the water content is lower than 8%, then placing in a far infrared oven, baking at 200-220DEG C for 2-3 minutes, and cooling naturally; and finally, placing the cooled fagopyrum tararicum tea in a drum drying oven and baking until the water content is not higher than 5% at 110-145DEG C.

Owner:太原市素有苦荞食品有限公司

Method for preparing purple sweet potato pigment

The invention relates to a method for extracting purplish red pigment from natural purple sweet potatoes. The method is characterized by comprising the following steps of: taking fresh purple sweet potatoes as the raw material, carrying out continuous production of cleaning, cutting into shreds, extracting, filtering, carrying out column chromatography, protecting colour, heating, concentrating, freezing, carrying out concentration and ultra-filtration, microencapsulating, spraying, drying, processing in a mixed manner and the like, thereby obtaining purple sweet potato pigment as purplish red (black) powder. The purple sweet potato pigment is more than or equal to 100 in colour value, is high in yield, is light resistant, heat resistant and very steady, and is prior to similar product standard at home and abroad.

Owner:JIANGXI DANXIA BIOTECHNOLOGY CO LTD

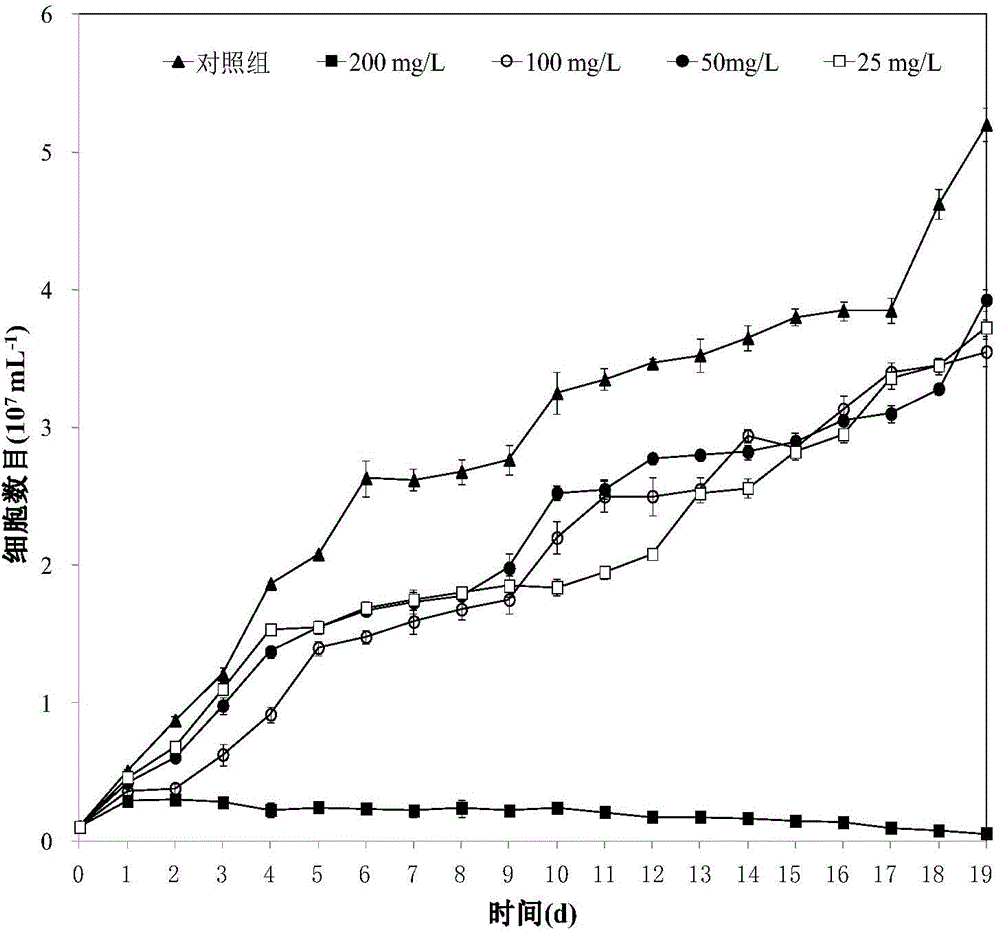

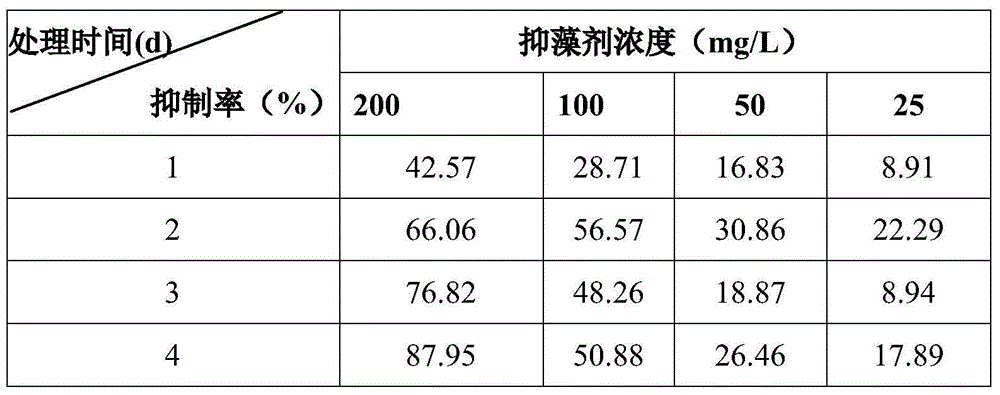

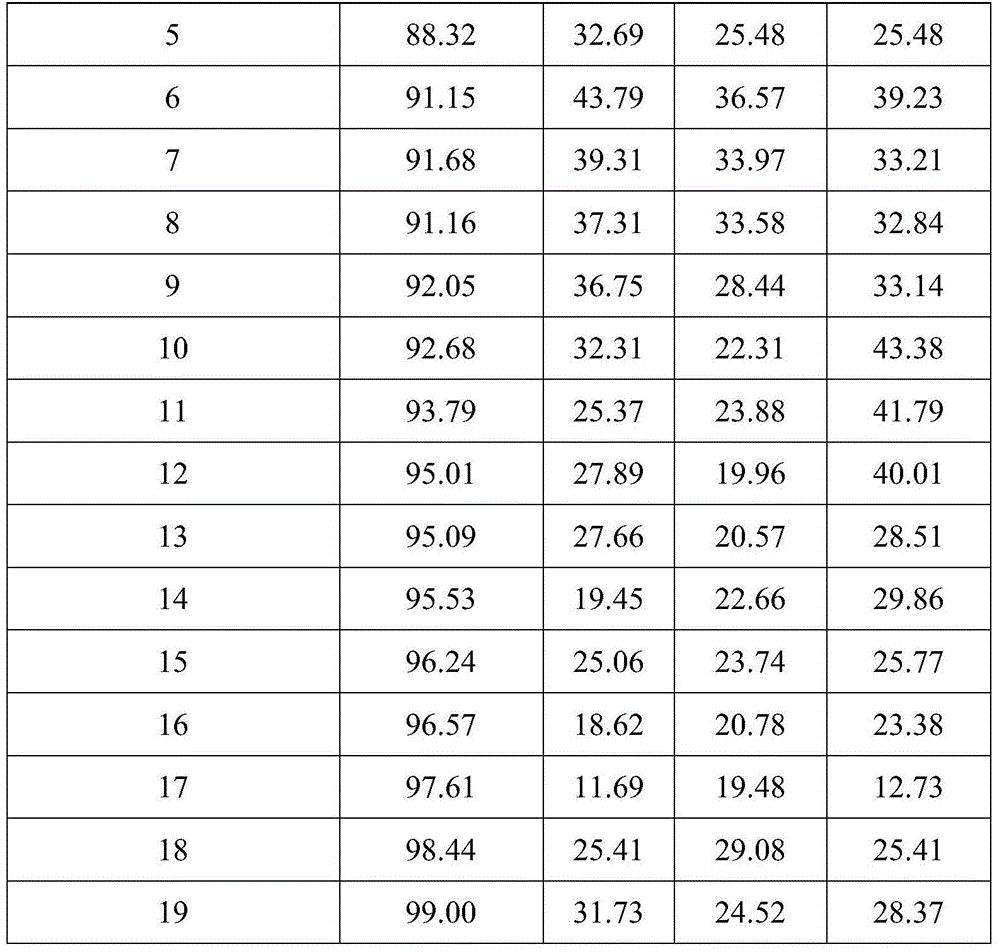

Ailanthus altissima bark algistat and preparation method and application thereof

InactiveCN104609521APromote growthEasy to prepareSpecific water treatment objectivesWater/sewage treatment using germicide/oligodynamic-processAilanthus altissimaEcological environment

The invention discloses an ailanthus altissima bark algistat and a preparation method and an application thereof, and belongs to the field of water boy pollution control. The algistat is an absolute ethyl alcohol crude extract of ailanthus altissima bark. Compared with the prior art, the defects that an existing chemical method causes secondary pollution and is high in cost, unlikely to be controlled, likely to damage the ecological environment and the like are overcome, and the limitation that the algistat is high in technical cost and complicated in operation is solved by utilizing water plant extraction. The algistat is extracted from the woody plant ailanthus altissima bark, and the preparation method is simple, convenient to use and high in operability and is suitable for large-scale popularization. The prepared algistat has high inhibition efficiency for microcystis aeruginosa, and can become effective on the second day; the inhibition ratio reaches more than 90%, and the water body can be effectively prevented from breaking out water bloom for a long period of time.

Owner:TAISHAN UNIV

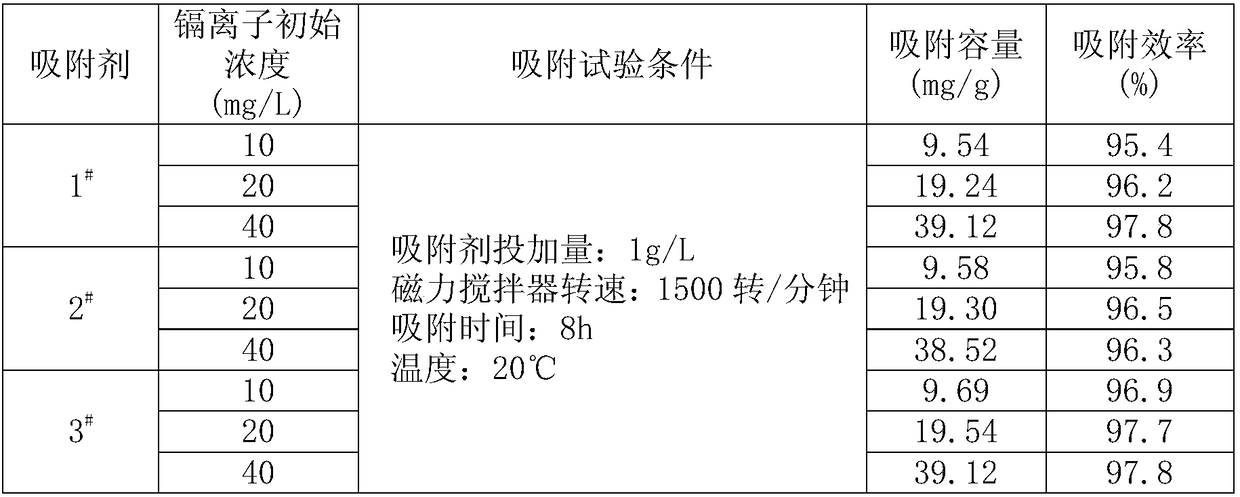

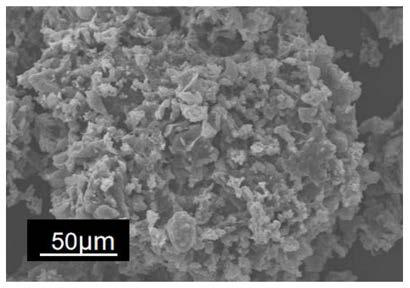

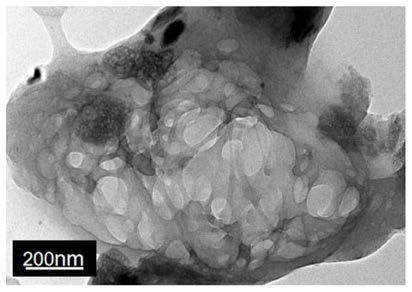

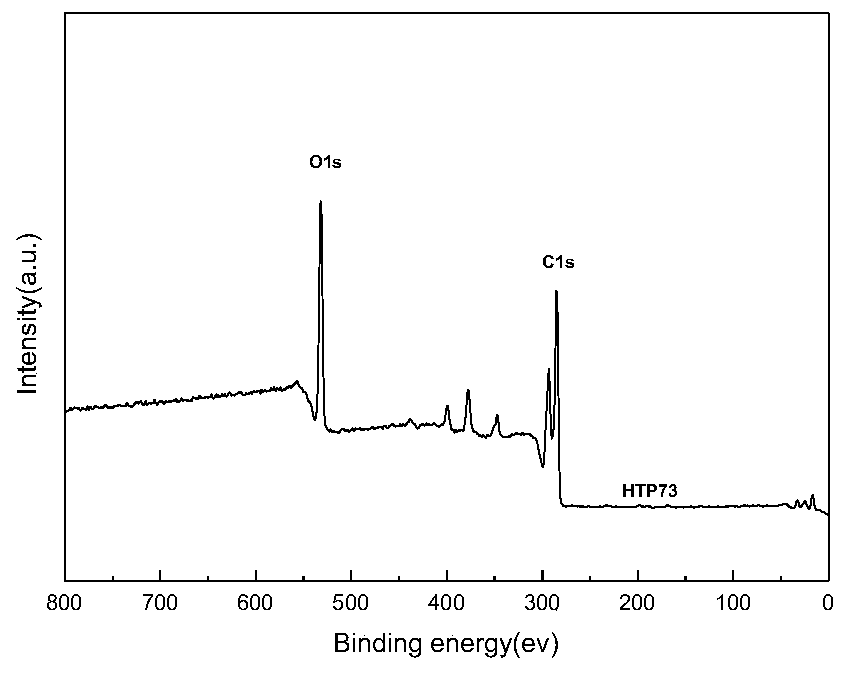

Preparation method and application of clinoptilolite-modified water body cadmium adsorbent

ActiveCN108905970AWidely plantedImprove growth abilityOther chemical processesWater contaminantsFiberSorbent

Provided are a preparation method and application of a zeolite-modified water body cadmium adsorbent. The preparation method comprises the following steps: (1) performing crushing, sieving and grinding on natural clinoptilolite so as to obtain zeolite of a fine powder particle size; (2) performing high temperature and lanthanum chloride modification on the zeolite of the fine powder particle sizeso as to obtain modified zeolite of the fine powder particle size; (3) adopting lignin as a raw material, and preparing nano carbon fiber-coated modified zeolite so as to obtain the zeolite-modified water body cadmium adsorbent. The zeolite-modified water body cadmium adsorbent prepared by using the method is suitable for a cadmium-contaminated natural water body, can be packed in a nylon mesh bagand move in the polluted natural water body, or is filled into an adsorption filler tower or pool, so that the purpose of cadmium removal from wastewater is achieved. The raw materials are cheap andeasily available, and the prepared adsorbent has a wide application range, a good adsorption effect and no secondary pollution, and is especially suitable for emergency treatment of a low-concentration suddenly cadmium-contaminated natural water body or treatment of cadmium-containing wastewater with the concentration of 10-40 mg / L; and the treatment efficiency can reach 95% or above.

Owner:SHANDONG JIANZHU UNIV

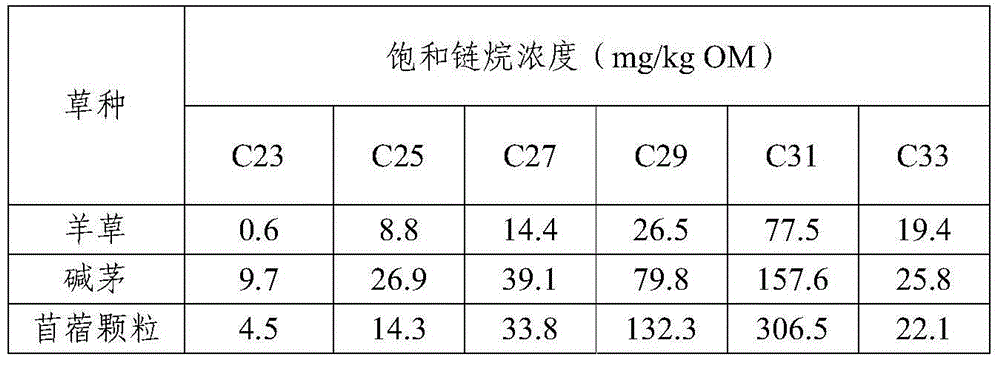

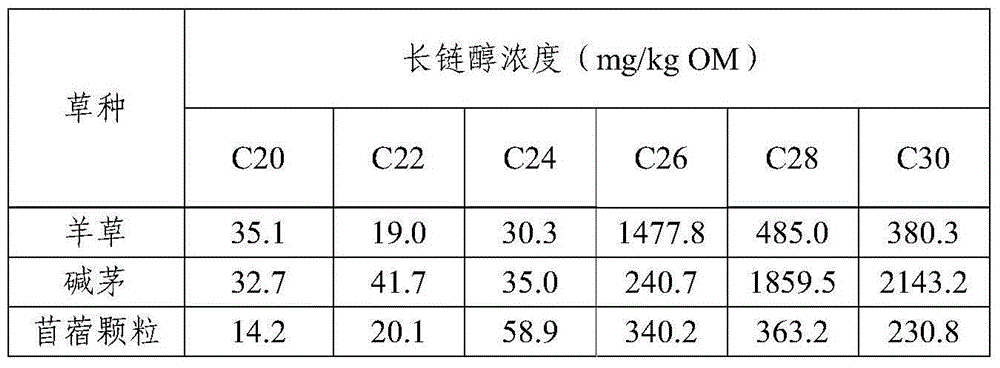

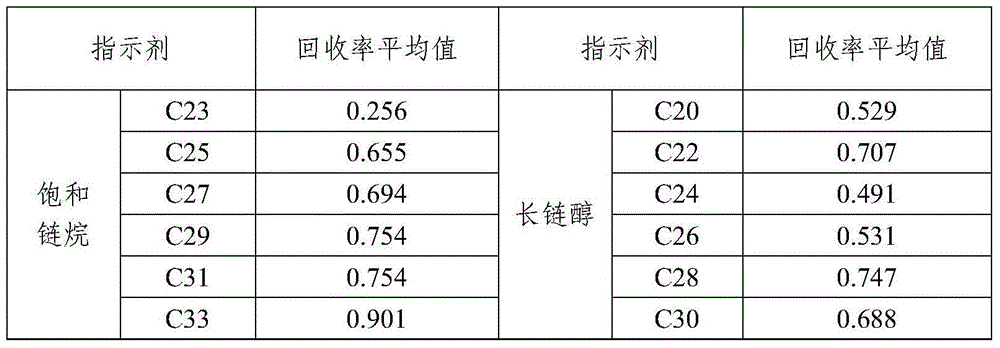

Livestock food intake estimating method

The invention relates to a livestock food intake estimating method. According to the method, within a feeding period of 4-7 days, alfalfa particles are used as supplementary feeding agents, saturate alkane and long-chain alcohol are used as endogeny indication agents, and the endogeny indication agent method is adopted for estimating food intake of grazed livestock. Alfalfa as a natural supplementary feeding agent is planted widely in China and obtained easily, and only needs to be manufactured into the alfalfa particles so as to be stored for a long term, the alfalfa is rare in the grassland, the process of feeding the alfalfa has little interference to the grazed livestock, and the situation that as the alfalfa is eaten, deviation of an estimation result is caused is avoided. The livestock food intake estimating method with the alfalfa as the supplementary feeding agent is easy to operate and high in accuracy and has a wide application prospect.

Owner:CHINA AGRI UNIV

Ethephon synergistic foliage fertilizer and compounding method thereof

The present invention provides a new functional foliage fertilizer for crops-ethephon synergistic foliage fertilizer and its preparation method. It is made up by using ethephon and xanthoxylum seed oil, according to a certain ratio. Said invention adopts the slage extraction technique and low-temp. chromatographic filtration and purification process to prepare xanthoxylum seed oil richly-containing linolenic acid and linolic acid by utilizing xanthoxylum seed. Said invented product can effectively improve form of crop plant, raise lodging resistance of crops and raise quality and yield of crops.

Owner:徐虎林

Method for breeding wheat resisting short-stalk powdery mildew

InactiveCN101595835AIncrease elasticityImprove cold resistancePlant genotype modificationAngiosperms/flowering plantsTriticeaeF1 generation

The invention mainly provides a method for breeding wheat resisting short-stalk powdery mildew, mainly comprising the following steps: carrying out the sexual hybridization with short stalk wheat as the maternal parent and Xi'an 8 wheat as the male parent to obtain an initial F generation; experimentally planting the cultured F generation under a severe environment, carrying out the purification, rejuvenation and sowing; carrying out the purification and rejuvenation again; using the remain seeds as the F1 generation; sowing the seeds of the F1 generation, and purifying and remaining the original strains of meeting the characteristics of the F1 generation through selective preference and rogueing; re-breeding till the strain being basically stable, separately planting seeds purified from various areas, and carrying out the mixed harvest; and planting the seeds of the mixed seeds of the mixed-harvest strain, and then purifying and rejuvenating again. The variety bred by the invention has good powdery-mildew resistance, is relatively light in the outbreak of banded sclerotial blight, and has better integral property; the variety is suitably and widely planted in the south areas of winter wheat in Yellow River and Huai River such as north Anhui Province, northwest Jiangshu Province, southwest Shandong Province, plain irrigation areas of Shanxi Province, North China plain, and the like.

Owner:河南亚星农业开发有限公司

Dogbane tartary buckwheat tea and preparation process thereof

InactiveCN102934717AExact health benefitsThe composition of the formula is reasonableTea substituesDrum dryingGuar gum

Disclosed are a dogbane tartary buckwheat tea and a preparation process thereof. The tartary buckwheat tea is composed of 500 to 900 parts of tartary buckwheat husk powders, 300 to 400 parts of dogbane powders, 50 to 100 parts of folium mori powders, 50 to 100 parts of chrysanthemum powders, 50 to 100 parts of tartary buckwheat extract, 2 to 10 parts of guar gum, 2 to 10 parts of xanthan gum and 2 to 10 parts of konjac glucomannan. The preparation process of the tartary buckwheat tea includes breading, forming, drying and fragrance enhancing. The preparation process specifically includes firstly uniformly mixing the tartary buckwheat husk powders, the dogbane powders, the folium mori powders, the chrysanthemum powders, the tartary buckwheat extract, the guar gum, the xanthan gum and the konjac glucomannan until the colour and luster are uniform, still standing for 20 minutes, then taking out uniformly stirred tea powders, adding 25% to 40% of water, uniformly mixing by a pressurization forming machine, screening through a sieve with 30 meshes, performing granulation, placing formed tartary buckwheat tea particles in a plate, placing the plate in a hot air drying oven, drying at the temperature of 50 DEG C to 55 DEG C until the moisture content is within 8%, then placing the plate in a far infrared toaster, baking at the temperature of 200 DEG C to 220 DEG C for 2 to 3 minutes, naturally cooling, finally placing cooled tartary buckwheat tea in a rotary drum drying oven, and baking at the temperature of 110 DEG C to 145 DEG C until the moisture content is not more than 5%.

Owner:太原市素有苦荞食品有限公司

Acanthopanax tartary buckwheat tea and preparation process thereof

InactiveCN102919456AExact health benefitsThe composition of the formula is reasonableTea substituesPolygonum fagopyrumDrum drying

Provided is acanthopanax tartary buckwheat tea and a preparation process thereof. The acanthopanax tartary buckwheat tea is formed by 500 to 850 parts of tartary buckwheat cortex powder, 200 to 400 parts of acanthopanax leaf powder, 50 to 100 parts of eucommia leaf powder, 25 to 50 parts of tartary buckwheat extractive, 2 to 10 parts of guar gum and 2 to 10 parts of xanthan gum. The preparation process of the tartary buckwheat tea comprises the steps of stirring powder, shaping, drying and enhancing incense. Firstly, the tartary buckwheat cortex powder, the acanthopanax leaf powder, the eucommia leaf powder, the tartary buckwheat extractive, the guar gum and the xanthan gum are evenly mixed until color is uniform to stand for 20 minutes. Then, 25% to 40% of water is added into evenly-mixed tea powder to be mixed evenly through a pressing forming machine, and the tea powder is sieved by 30 meshes to granulate. Formed tartary buckwheat tea particles are arranged in a disk to be in a hot air drying box to be dried at the temperature of 50 DEG C to 55 DEG C until the water content is within 8%, then the tea powder is positioned in an infrared oven to be baked for 2 to 3 minutes at the temperature of 200 DEG C to 220 DEG C, and the tea powder is cooled naturally. Finally, cooled tartary buckwheat tea is arranged in a drum drying box to be baked at the temperature of 110 DEG C to 145 DEG C until the water content is not higher than 5%.

Owner:太原市素有苦荞食品有限公司

Dry white wine and aroma-enhancing brewing method thereof

The invention discloses dry white wine and an aroma-enhancing brewing method thereof, and belongs to the technical field of wine processing. The key point of the technical scheme is the aroma-enhancing brewing method of the dry white wine. The method comprises the following steps: grape raw material treatment, semi-carbon dioxide impregnation, squeezing, clarification, fermentation, thermal stabilization treatment, cold stabilization treatment and cross flow. The method promotes the release of aroma substances in pericarp cells and further enhances the extraction of resveratrol in pericarp, and particularly improves the flower-and-fruit aroma intensity of neutral white grape varieties such as Chardonnay, so that the aroma expression of white wine is no longer limited by the attributes of grape varieties. The obtained dry white wine is rich in aroma, complex in flavor, complete in wine body, unique in style and strong in typicality, and health-care functions are further improved.

Owner:青岛华东葡萄酿酒有限公司

Blood flower milkweed milk extract rich in cardiac glycosides as well as preparation method and application of extract

InactiveCN104523792AGood antitumor activityLow toxicityOrganic active ingredientsAntineoplastic agentsOrganic layerCardiac glycoside

The invention belongs to the chemical field of natural medicine and discloses a blood flower milkweed milk extract rich in cardiac glycosides as well as a preparation method and an application of the extract. The preparation method of the extract comprises the following steps: (1) diluting the milk of the blood flower milkweed by use of water to obtain a diluent; adding an organic solvent to the diluent for extracting, and collecting the organic layer obtained after extraction; next, adding the organic solvent to the left water layer for extracting, collecting the organic layer again, and circularly extracting for 2-4 times, and then abandoning the water layer, and blending the organic the organic layers to obtain the cardiac glycoside extract of the blood flower milkweed milk; (2) performing reduced pressure concentration on the blood flower milkweed milk until a constant weight, thereby obtaining the blood flower milkweed milk extract rich in cardiac glycosides. The blood flower milkweed milk extract rich in cardiac glycosides has excellent anti-tumor activity and low toxicity to normal cells; the extract contains a plurality of types of cardiac glycosides rich in content. The preparation method of the blood flower milkweed milk extract rich in cardiac glycosides is simple, low in cost, high in extraction rate, and high in anti-tumor selectivity.

Owner:JINAN UNIVERSITY

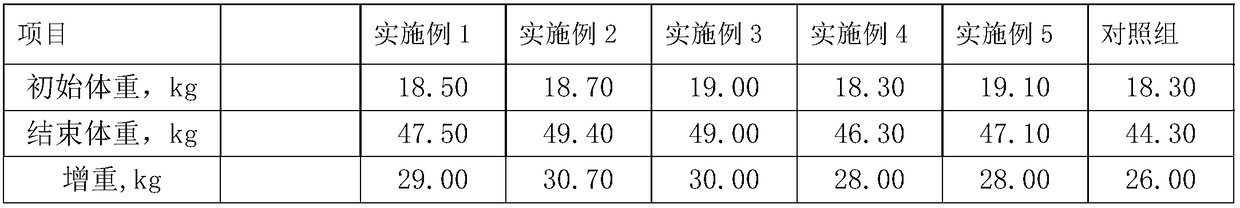

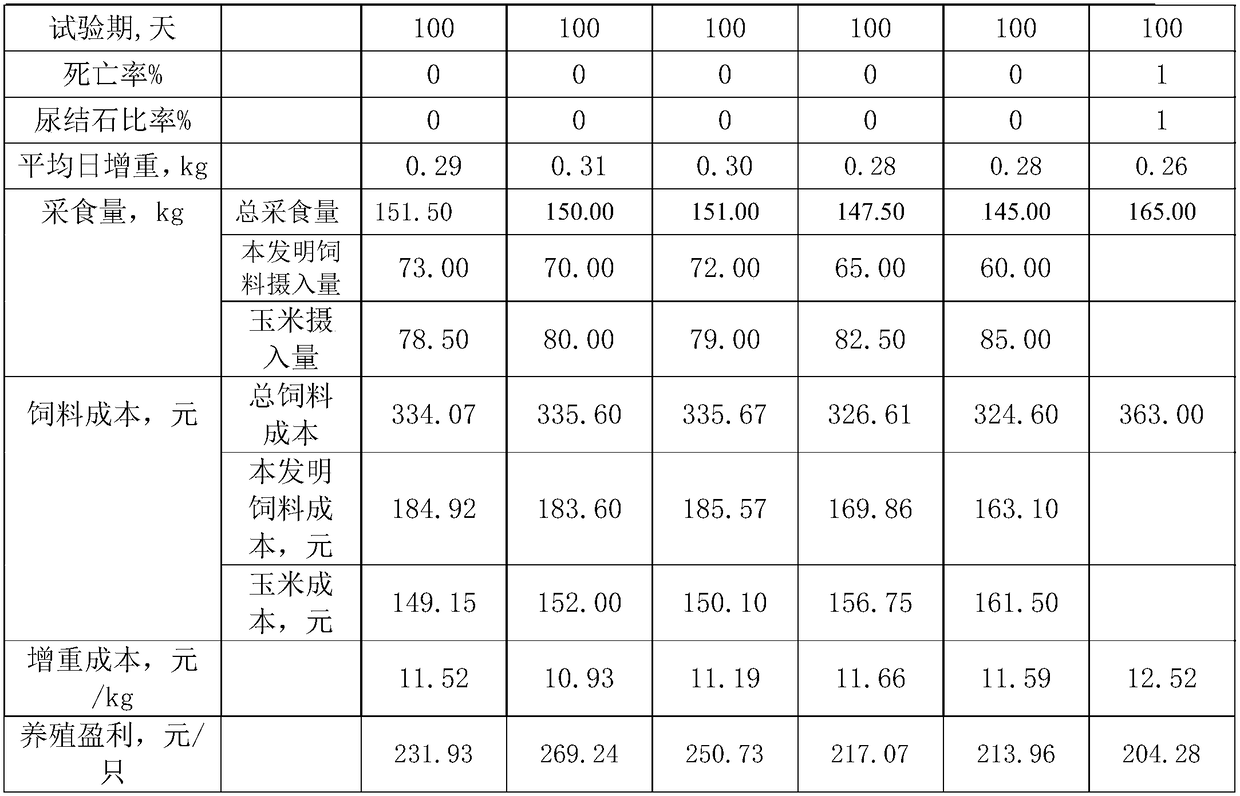

Energy-saving mixed ration capable of increasing daily gain of sheep and preparation method of energy-saving mixed ration

InactiveCN109480102AQuality assuranceExperienceFood processingAnimal feeding stuffGrape seedMethionine biosynthesis

The invention belongs to the technical field of a feed composition, and relates to an energy-saving mixed ration capable of increasing the daily gain of sheep, in particular to the preparation methodof the ration. The ration is prepared from the following raw materials in parts by weight of 40-45 parts of a coarse feed, 4 parts of soybean meal, 2-4 parts of cottonseed meal, 4-6 parts of sesame seed meal, 0-5 parts of grape seed meal, 22.7-39.7 parts of corn by-products, 5 parts of stone powder, 0.5 part of table salt, 1 part of rumen bypass fat powder, 0.1 part of rumen bypass methionine, 1 part of a composite premix feed for fattening of sheep, 0.1 part of a compound enzyme preparation and 0.1 part of probiotic factors. The ratio is used for meat sheep of 20-60kg, the weight increment can be increased, and the cost can be reduced.

Owner:BEIJING SANYUAN HEFENG ANIMAL HUSBANDRY

Preparation method of biomass adsorbent for treating wastewater containing metal ions

InactiveCN110075798AGood adsorption performanceImprove adsorption capacityOther chemical processesWater contaminantsChemical industryIon

The invention discloses a preparation method of a biomass adsorbent for treating wastewater containing metal ions, and belongs to the technical field of wastewater treatment. The method comprises thefollowing steps: cleaning walnut green husks with distilled water for several times to remove impurities on the surfaces of the walnut green husks, crushing the walnut green husks with a crusher, anddrying to constant weight for later use; mixing the walnut husks with ammonium oxalate in proportion, crushing again, and uniformly stirring; and finally, pyrolyzing and carbonizing under the nitrogenprotection condition. The obtained adsorbent has many gaps and a great many of oxygen-containing functional groups and nitrogen-containing functional groups, and has strong chemical adsorption capacity on the metal ions. The preparation method has the advantages of low running cost, simplicity in operation and stable running, a purpose of efficiently removing the metal ions is achieved, and advanced treatment and standard emission of the wastewater containing the metal ions in the chemical industry can be realized at low cost.

Owner:安徽工大化工科技有限公司

Aloe vera gel functional food

The invention discloses an aloe vera gel functional food which is prepared from the following raw materials according to weight percent: 25%-60% of one in puerarin powder, ginger powder, a green plum extract or a lily extract, and 40%-75% of aloe vera gel powder. The plants adopted by the aloe vera gel functional food are common in daily life, so that the aloe vera gel functional food is safe and reliable; the plants are recorded in related work, and have authentic health care functions; the plants can be widely planted, so that the raw materials are rich and easily available, and the production cost of an enterprise is reduced; the aloe vera gel functional food is prepared by the modern processing technology, and is small in package, light in weight, convenient to carry, simple in service and high in content of active ingredients, so that a safe and effective health care food is provided for busy modern people.

Owner:元谋县丰钰农业产业发展有限责任公司

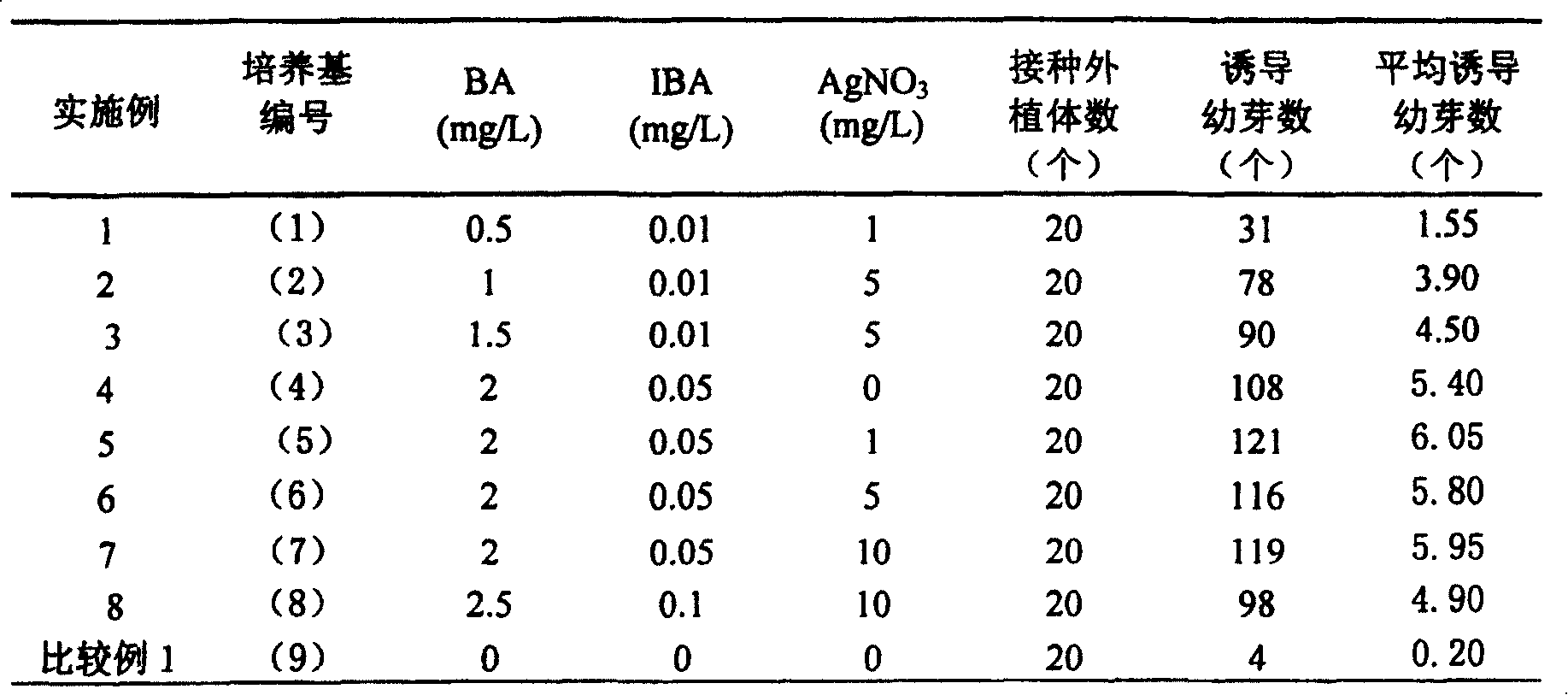

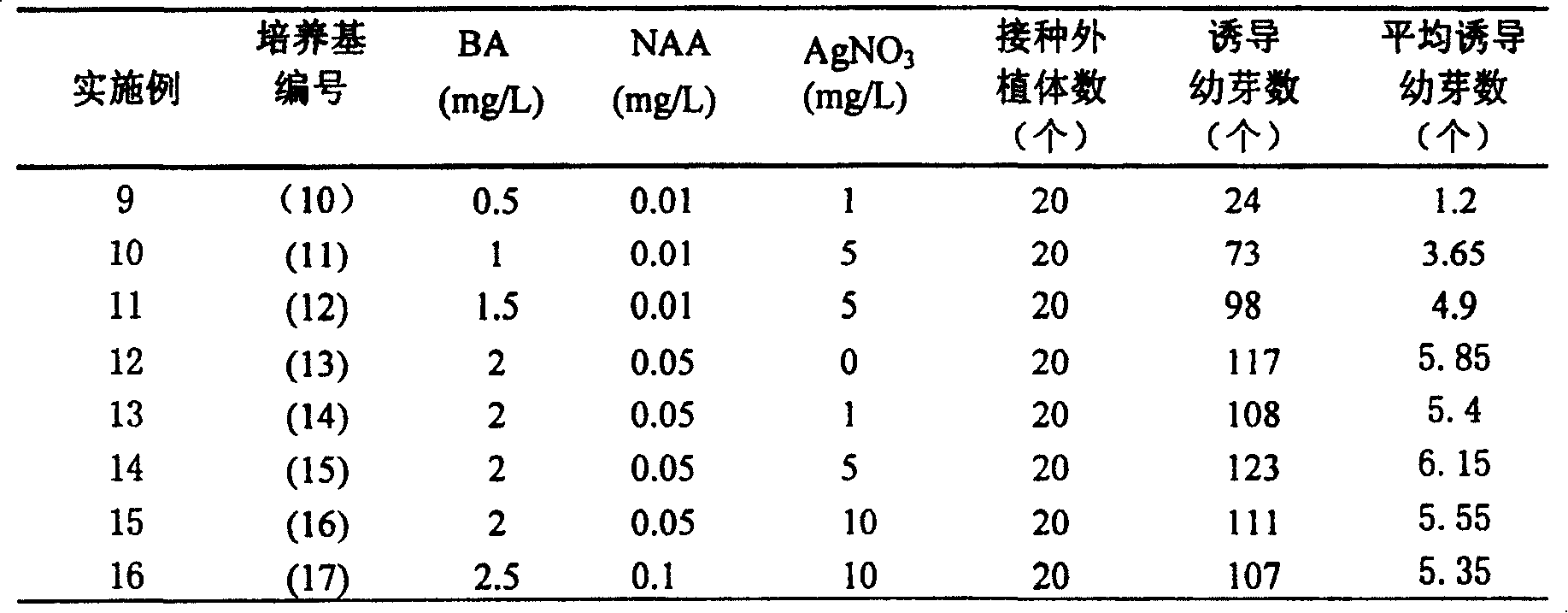

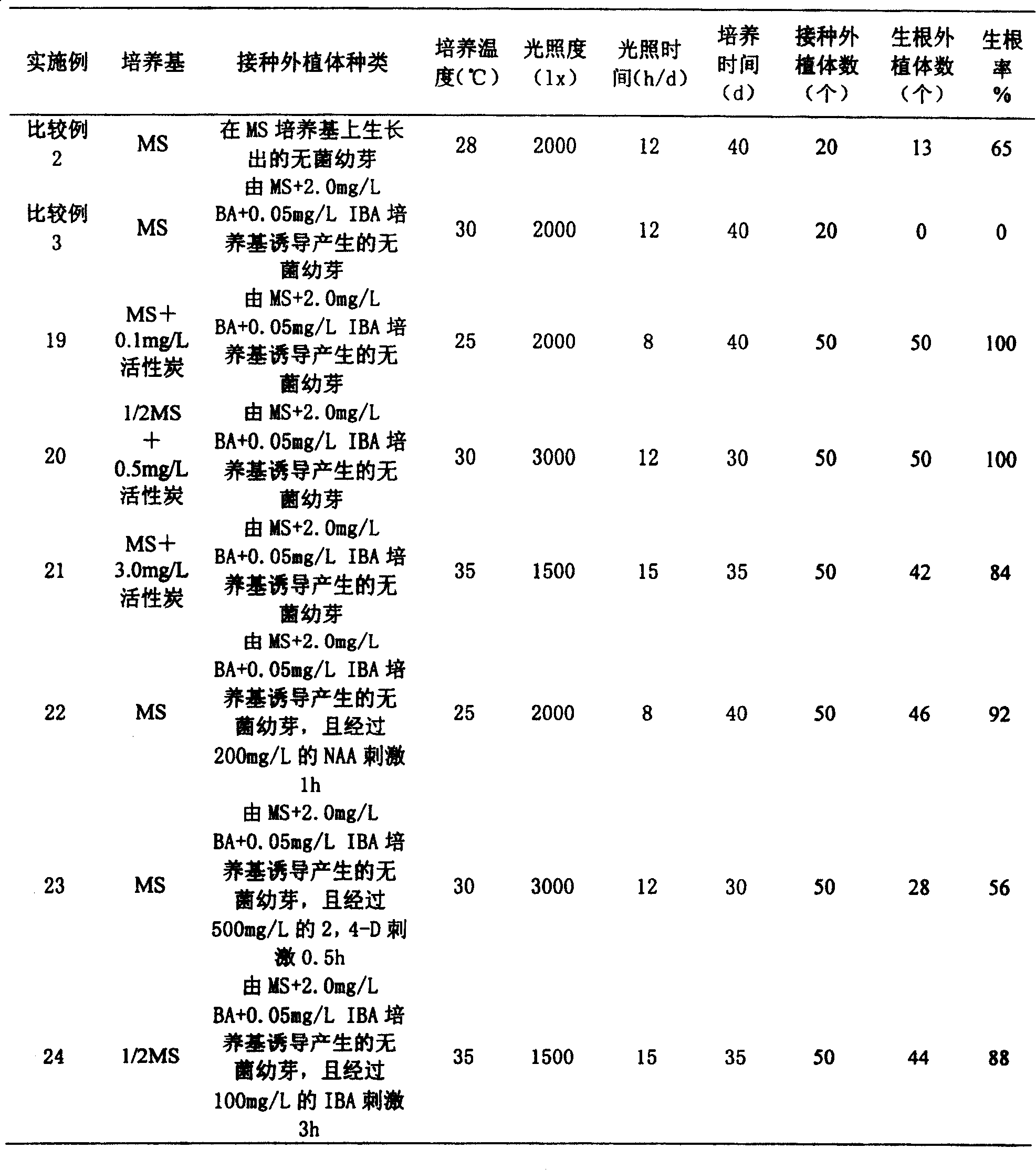

Fast teething and reproduction method for Mafeng tree

InactiveCN100407903CHigh average number of sproutsAvoid high reproductive variabilityPlant phenotype modificationPlant tissue cultureActivated carbonBud

Owner:SICHUAN UNIV

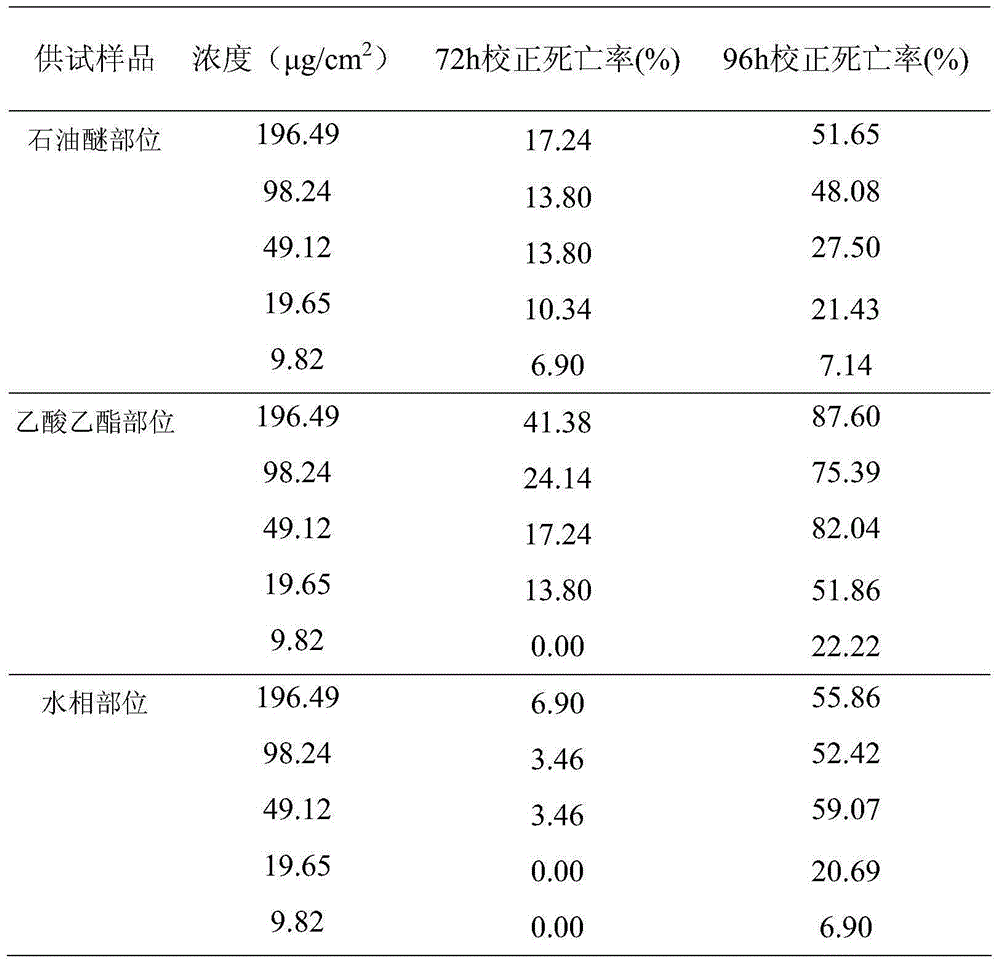

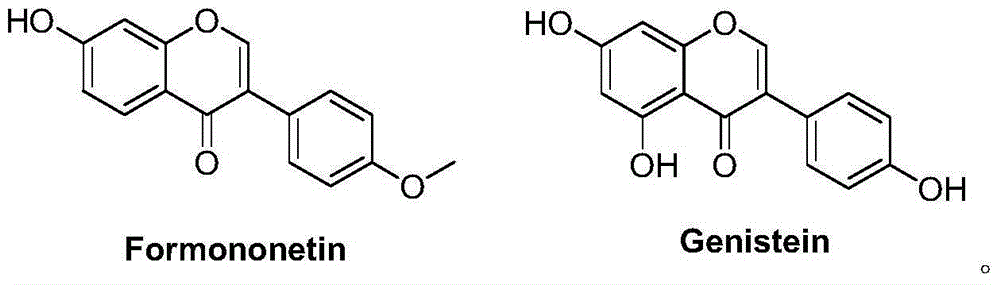

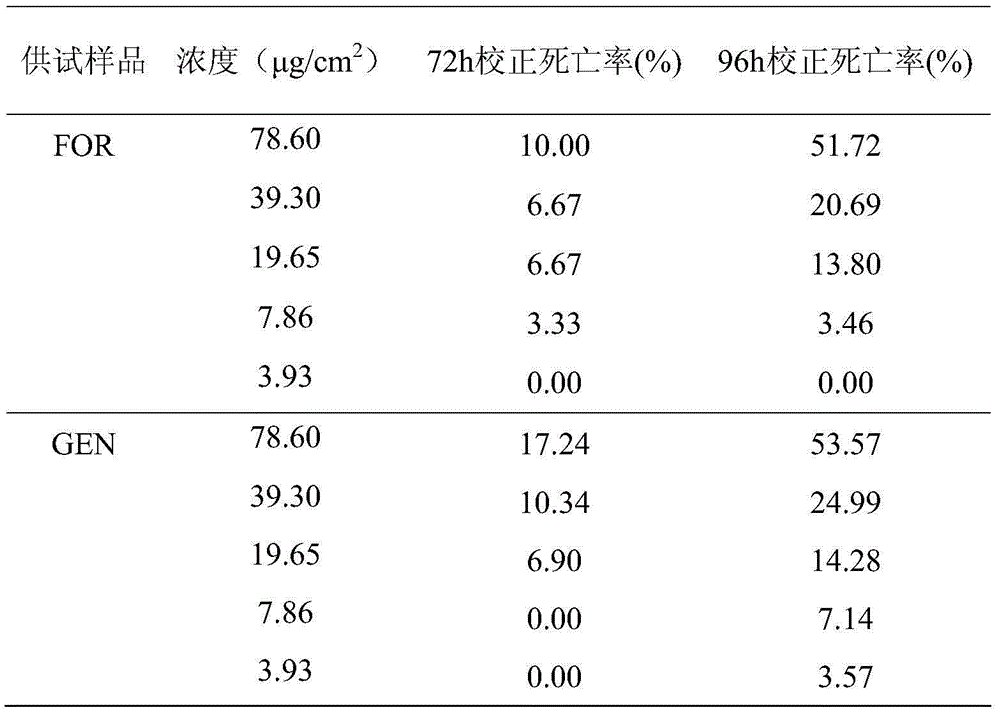

Preparation process of botanical insecticide capable of preventing and treating maize weevil

ActiveCN105076234AHigh contact activityWidely plantedBiocideAnimal repellantsAdditive ingredientRed Clover

The invention discloses a botanical insecticide capable of preventing and treating maize weevil. The main ingredient of the botanical insecticide capable of preventing and treating maize weevil is a trifolium pratense extract. A trifolium pratense botanical pesticide provided by the invention has obvious contact toxicity on stored grain insects, is beneficial to human health, is environment-friendly and is low in pesticide resistance generation possibility. In addition, the botanical insecticide is rich in plant resources and simple in preparation process and has favorable development and application prospects in the aspect of protecting the grain safety.

Owner:LANZHOU UNIVERSITY

Lilium brownii var.viridulum filial generation bulb expanding, developing and rooting method

ActiveCN106665364APromote rootingSatisfy industrializationHorticulture methodsPlant tissue cultureLilium columbianumSeedling

The invention provides a lilium brownii var.viridulum filial generation bulb expanding, developing and rooting method which comprises the following steps: 1, saving lilium brownii var.viridulum filial generation embryonic plants to make seedlings; 2, performing clumpy bud multiplication and quickly multiplying the seedling amount to make clump seedling; 3, performing bulblet induction and cultivating differentiated bulbs; 4, expanding and rooting bulblet, cultivating larger bulbs, rooting the larger bulbs and using the larger bulbs as a breeding original material for production to be directly transplanted into fields to be planted. By means of optimizing influence factors of quick expansion and rooting cultivation of hybrid lily bulbs, technical support is provided for large-scale production of lilium brownii var.viridulum filial generation test-tube plantlets; furthermore, technical assurance is provided for large-scale production of edible lilium brownii var.viridulum filial generation test-tube plantlets, and requirements of market for edible lily new hybrid varieties are met; thus, lilium brownii var.viridulum planting cost is reduced.

Owner:YICHUN UNIVERSITY

Method for improving germination percentage of paspalum natatum in warm temperate zones

InactiveCN102783341APromote germinationPromote growthSeed and root treatmentHorticultureWarm waterPotassium

The invention discloses a method for improving germination percentage of paspalum natatum in warm temperate zones, comprising the steps of: 1, pre-treating; 2, finishing; 3, sowing; and 4, managing after germinating. In the method disclosed by the invention, warm water is used to soak seeds for 4-5h, so that the wax coat is removed conveniently and safely, the feasibility is high, and the operation can be achieved in normal farms and pastures; concentrated sulfuric acid is dangerous when being used, the time is difficult to control, and the seeds are easy to carbonize carelessly, so that the result is failed; April and May are in blossoming spring in the warm temperate zones, and the climate is suitable, so the seeds are sowed in April and May, and the paspalum natatum germinates well; after the paspalum natatum germinates, the phosphatic fertilizer and fire ash mixed in the seeds provide sufficient phosphorus, potassium and nitrogen which are beneficial for growth of paspalum natatum seedlings; and therefore, the problem of low germination percentage is solved, the sufficient paspalum natatum seedlings are provided, can be widely planted and can be used for building lawns, growing pastures, fixing soil, protecting slope, and the like. The method provides a reliable guarantee for popularizing and planting the paspalum natatum in a large area.

Owner:NANYANG NORMAL UNIV

Hippophae rhamnoides and Fagopyrum tataricum wine and its brewage method

InactiveCN103173334AImprove antioxidant capacityGood workmanshipOrganic active ingredientsAntinoxious agentsSalvia miltiorrhizaGrape seed

The invention relates to a Hippophae rhamnoides and Fagopyrum tataricum wine and its brewage method. The Hippophae rhamnoides and Fagopyrum tataricum wine contains 40-60 parts of Fagopyrum tataricum, 15-20 parts of wheat bran, 10-20 parts of fresh distiller's grain, 10-15 parts of Luqu, 15-30 parts of Hippophae rhamnoides, 5-10 parts of ginseng leaf, 5-15 parts of Cornus officinalis, 5-15 parts of spina date seed, 5-15 parts of Ligustri Lucidi Fructus, 5-15 parts of gecko, 10-20 parts of luteolin, 5-15 parts of Salvia miltiorrhiza and 10-25 parts of grape seed. The Hippophae rhamnoides and Fagopyrum tataricum wine can clear free radicals in the body and improve the oxidation resistance, and has a certain protection effect on kidney damages.

Owner:太原市素有苦荞食品有限公司

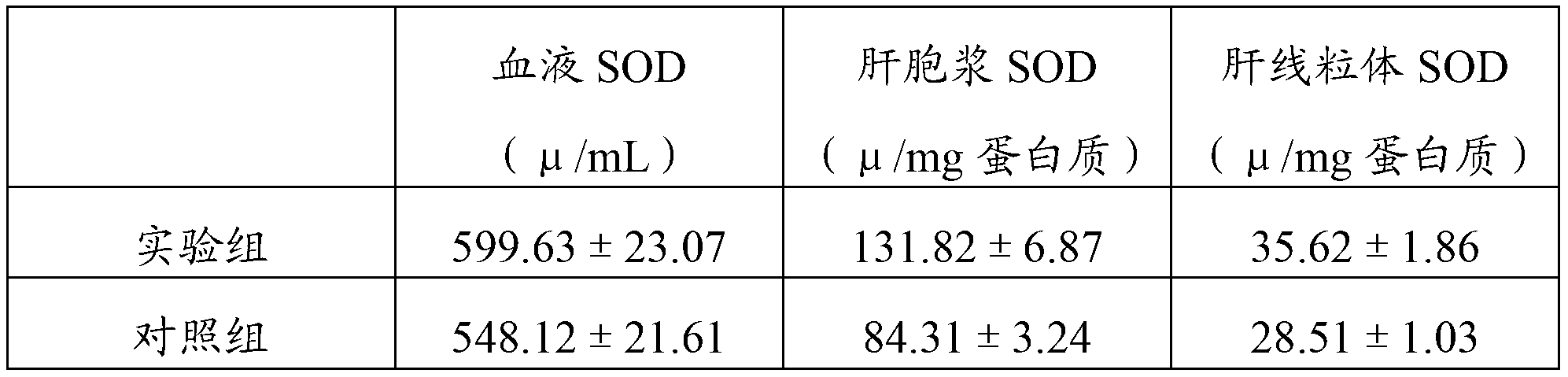

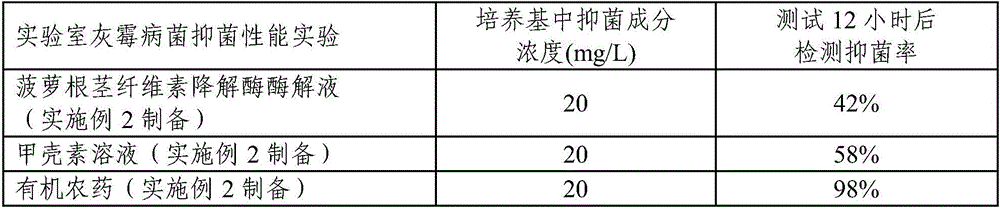

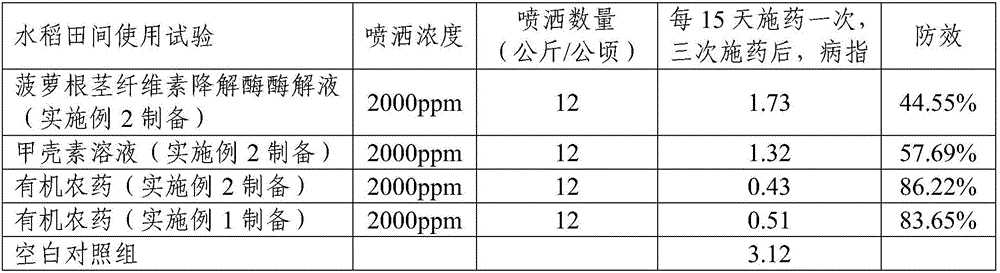

Non-toxic organic pesticide as well as preparation method and application thereof

InactiveCN106472598AHigh insecticidal activityEasy to useBiocideDead animal preservationNematode eggCuticle

The invention relates to a non-toxic organic pesticide as well as a preparation method and an application thereof. The pesticide takes bromeliad rhizome cellulose degradation enzyme enzymatic hydrolysate and chitin as main effective ingredients. The pesticide is wide in insecticidal spectrum, has a long lasting period and high insecticidal activity, particularly can effectively dissolve hard epidermis of insects, cytomembranes of bacteria and nematode eggs, and has a remarkable application effect.

Owner:北京山北绿色农业有限公司

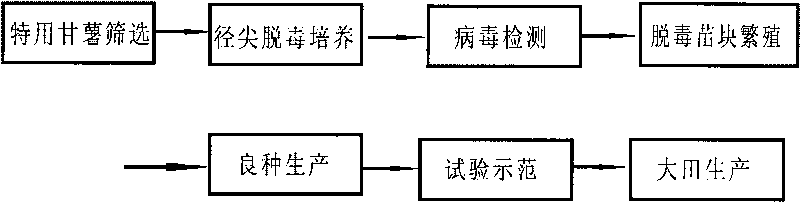

Method for raising seedlings of color virus-free sweet potatoes

InactiveCN101731143ADrought tolerantRidge resistantHorticulture methodsPlant tissue culturePharbitis nilShoot apex

The invention relates to a method for culturing and planting seedlings of color virus-free sweet potatoes. The method is characterized by utilizing the characteristic of low virus content or no virus content in stem tips of the sweet potatoes, cutting meristems of the stem tips of 0.2-0.4mm under an aseptic manipulation, forming test tube seedlings by culturing on a specific culture medium, and further detecting the virus-free seedlings by serology and indicator plant grafting. Meanwhile, the invention further provides the corresponding tissue rapid propagation technical regulations and a factorized production system according to different types, thereby accelerating the propagation of a large number of color style virus-free sweet potato seedlings. The method can propagate the potato species which has high nutritional value and bright color and is applicable to fresh-eating, baking or processing of the preserved sweet potatoes.

Owner:邱培标

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com