Preparation method of biomass adsorbent for treating wastewater containing metal ions

A biomass adsorbent and metal ion technology, which is applied in water pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of complex process, large investment and high processing cost, and achieves low cost and easy availability of materials. Inexpensive, the effect of increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

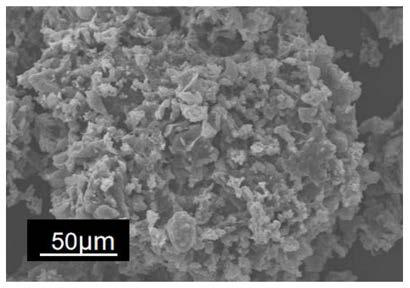

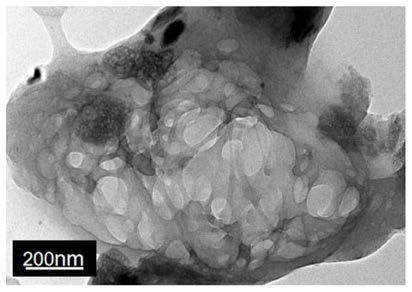

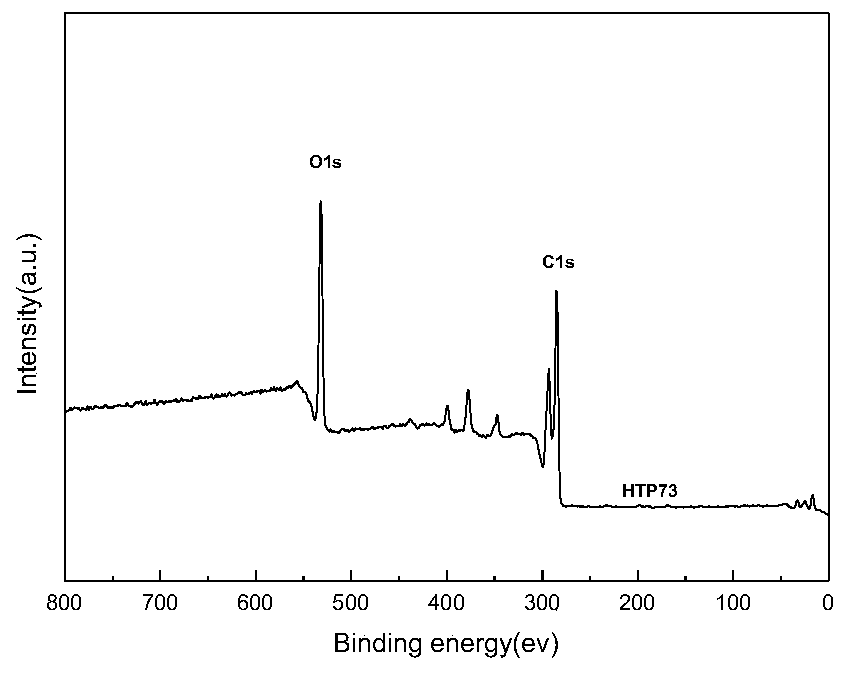

Image

Examples

Embodiment 1

[0037] A preparation method for a biomass adsorbent for treating wastewater containing metal ions, comprising the following steps:

[0038] (1) Wash the fresh walnut green peel with distilled water, then pulverize the washed walnut green peel with a pulverizer, and dry the crushed walnut green peel mud at 90°C for 2 hours, which is convenient for long-term storage and use;

[0039] (2) Mix the dry walnut green peel mud and ammonium oxalate according to the mass ratio of 7:3, fully pulverize and mix again, so that the ammonium oxalate and walnut peel are evenly mixed;

[0040](3) Under a nitrogen atmosphere, add the above-mentioned mixture of walnut green skin mud and ammonium oxalate into a pyrolysis reactor for pyrolysis and carbonization, and heat up to 530°C at a heating rate of 10°C / min, every time the temperature rises by 50°C and keeps for 10 minutes. , and keep warm for 6 hours to prepare the required biomass adsorbent for treating wastewater containing metal ions.

[...

Embodiment 2

[0049] A preparation method for a biomass adsorbent for treating wastewater containing metal ions, comprising the following steps:

[0050] (1) Wash the fresh walnut green peel with distilled water, then pulverize the washed walnut green peel with a pulverizer, and dry the crushed walnut green peel mud at 90°C for 2 hours, which is convenient for long-term storage and use;

[0051] (2) Mix the dry walnut green peel mud and ammonium oxalate according to the mass ratio of 7:3, fully pulverize and mix again, so that the ammonium oxalate and walnut peel are evenly mixed;

[0052] (3) Under a nitrogen atmosphere, add the above-mentioned walnut green skin mud and ammonium oxalate mixture into the pyrolysis reactor, and raise the temperature to 500° C. at a heating rate of 10° C. / min, and keep it warm for 10 minutes every 50° C., and keep it warm for 6 hours. , to prepare the required biomass adsorbent for treating wastewater containing metal ions.

Embodiment 3

[0054] A preparation method for a biomass adsorbent for treating wastewater containing metal ions, comprising the following steps:

[0055] (1) Wash the fresh walnut green peel with distilled water, then pulverize the washed walnut green peel with a pulverizer, and dry the crushed walnut green peel mud at 90°C for 2 hours, which is convenient for long-term storage and use;

[0056] (2) Mix the dry walnut green peel mud and ammonium oxalate according to the mass ratio of 7:3, fully pulverize and mix again, so that the ammonium oxalate and walnut peel are evenly mixed;

[0057] (3) Under a nitrogen atmosphere, add the above-mentioned walnut green skin mud and ammonium oxalate mixture into the pyrolysis reactor, and raise the temperature to 550°C at a heating rate of 10°C / min, and keep warm for 10 minutes every 50°C, and keep the temperature for 6h , to prepare the required biomass adsorbent for treating wastewater containing metal ions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com