Preparation method and application of clinoptilolite-modified water body cadmium adsorbent

An adsorbent, zeolite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of large specific surface area, easy oxidation failure, low adsorption efficiency, etc. Wide range of effects with enhanced adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

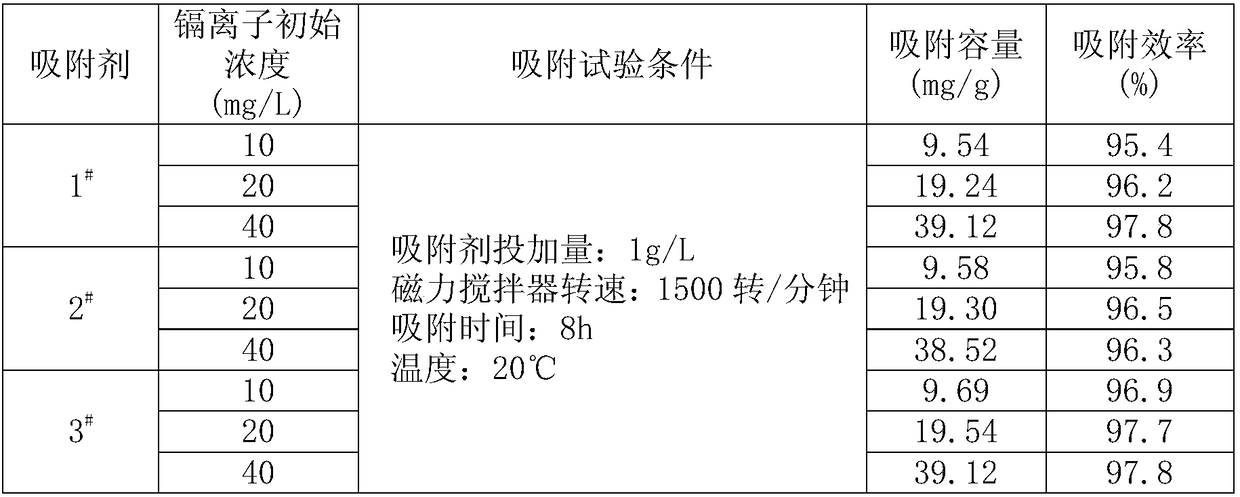

Examples

Embodiment 1

[0033] (1) The natural clinoptilolite is crushed, sieved and ground, and passed through a 1600-mesh sieve to obtain a fine powder zeolite with a particle size of 10-15 μm.

[0034] (2) Carry out high temperature and lanthanum chloride modification to fine powder zeolite, obtain modified fine powder particle size zeolite, specific process is as follows:

[0035] ①Treat the obtained fine powder size zeolite in a muffle furnace at 400°C for 4 hours to remove water molecules in the pores and channels of the fine powder size zeolite, increase the inner surface area and improve the adsorption capacity of the zeolite . Take out the modified fine powder particle size zeolite and put it into a desiccator to cool to room temperature.

[0036] 2. Take the modified fine powder particle size zeolite obtained in step 1 and place it in the NaOH solution of 1.5mol / L (the mass ratio of modified fine powder particle size zeolite to NaOH solution is 1:20), and the rotating speed of the mechanic...

Embodiment 2

[0047] (1) The natural clinoptilolite is crushed, sieved and ground, and passed through a 540-mesh sieve to obtain a fine powder particle size zeolite with a particle size of 10-30 μm.

[0048] (2) Perform high temperature and lanthanum chloride modification on the fine powder particle size zeolite to obtain the modified fine powder particle size zeolite. The specific process is as follows:

[0049] ①Treat the obtained fine powder particle size zeolite in a muffle furnace at 500°C for 3.5 hours to remove water molecules in the pores and channels of the fine powder particle size zeolite, increase the internal surface area and improve the fine powder particle size. Adsorption capacity of particle size zeolites. Take out the modified fine powder particle size zeolite and put it into a desiccator to cool to room temperature.

[0050] 2. Get the modified fine powder particle size zeolite that step 1. obtains and place in the NaOH solution of 2.0mol / L (modified fine powder particl...

Embodiment 3

[0060] (1) The natural clinoptilolite is crushed, sieved and ground, and passed through a 200-mesh sieve to obtain a fine powder particle size zeolite with a particle size of 10-74 μm.

[0061] (2) Carry out high temperature and lanthanum chloride modification to the fine powder particle size zeolite to obtain modified fine powder particle size zeolite, the specific process is as follows:

[0062] ①Treat the obtained fine powder particle size zeolite in a muffle furnace at 600°C for 3 hours to remove water molecules in the pores and channels of the fine powder particle size zeolite, increase the internal surface area and improve the particle size of the fine powder particle size. The adsorption capacity of diameter zeolites. Take out the modified fine powder particle size zeolite and put it into a desiccator to cool to room temperature.

[0063] 2. Get the modified fine powder particle size zeolite obtained in step 1 and place it in the NaOH solution of 2.5mol / L (modified fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com